BI623043

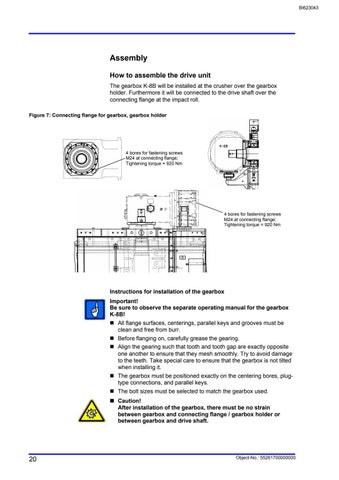

Assembly How to assemble the drive unit The gearbox K-8B will be installed at the crusher over the gearbox holder. Furthermore it will be connected to the drive shaft over the connecting flange at the impact roll. Figure 7: Connecting flange for gearbox, gearbox holder

4 bores for fastening screws M24 at connecting flange; Tightening torque = 920 Nm

4 bores for fastening screws M24 at connecting flange; Tightening torque = 920 Nm

Instructions for installation of the gearbox Important! Be sure to observe the separate operating manual for the gearbox K-8B! All flange surfaces, centerings, parallel keys and grooves must be clean and free from burr. Before flanging on, carefully grease the gearing. Align the gearing such that tooth and tooth gap are exactly opposite one another to ensure that they mesh smoothly. Try to avoid damage to the teeth. Take special care to ensure that the gearbox is not tilted when installing it. The gearbox must be positioned exactly on the centering bores, plugtype connections, and parallel keys. The bolt sizes must be selected to match the gearbox used. Caution! After installation of the gearbox, there must be no strain between gearbox and connecting flange / gearbox holder or between gearbox and drive shaft.

20

Object-No.: 55281700000000