1 minute read

Every 3 months ........................................................ 5

BI632977

electric motor

reducer Every 3 months

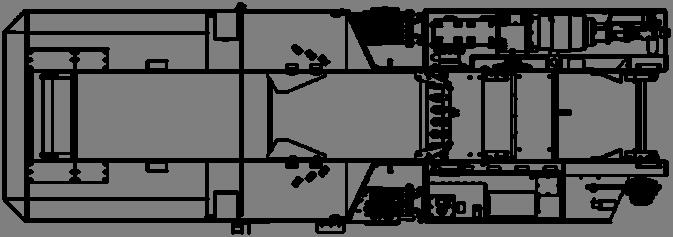

Lubricate the feeder breaker’s electric motor through the two (2) grease fittings located on the central lubrication panel (Fig. 40) located on the right side of the discharge section. Pump only one or two pumps of grease into each fitting.

NOTICE! Incorrect grease or over greasing may cause serious damage to the electric motor.

Lubricate the reducer through the two (2) grease fittings located on the central lubrication panel (Fig. 40) located on the right side of the discharge section. Pump only one or two pumps of grease into each fitting.

Fig. 40: Electric motor and reducer lubrication

Reducer central lubrication panel Electric motor central lubrication panel

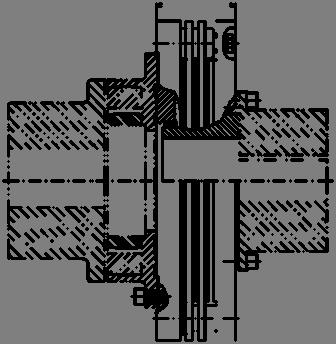

torque limiter Check torque limiter clutch disk wear as shown. Clutch disk must be changed when 3.46” is measured as shown in Fig. 41.

Fig. 41: Torque limiter clutch wear

3.55” New thickness 3.46” Worn thickness