2 minute read

torque hub—CT45 series; 1:110.07 5

TORQUE HUB – CT45 SERIES; 1:110.07

purpose

The torque hub provides the crawler tracks with high torque by reducing the speed of the hydraulic motor through gear reduction at a ratio of 1:110.07. For final speeds, torque ratings and drawbar pull see the “Drive Stats” heading under the “Belt Tailpiece System Statistics” section.

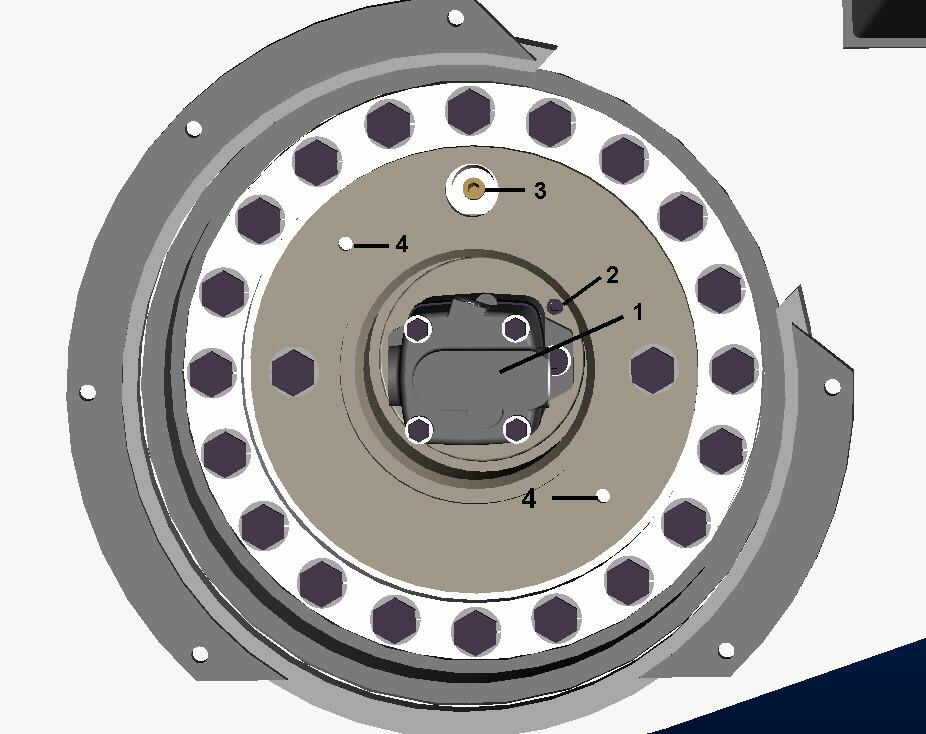

1---TRAM MOTOR 2---FILL LEVEL SITE PLUG 3---OIL LEVEL PLUG 4---MOTOR ADAPTOR PLATE PULLER HOLES

construction

The torque hub is a wheel hub drive type that is assembled with highstrength steel machined and cast parts. The gear reduction is achieved through a three-stage planetary gear sets. A center sun-gear can be disengaged for free wheeling (see the “Towing and Free Wheeling” section).

© DBT AUSTRALIA 2007

maintenance Visually inspect the torque hub for leaks or damage and replace or repair if necessary. For extended torque-hub life, change initial oil after the first 50 hours of operation with subsequent oil changes being made annually. The gearbox should be filled half-full of 90-weight gear lube with EP additive oil (4.7L Total). The lubricant used in the torque hub should be a petroleum based, non-detergent gear fluid containing antioxidation, antifoaming and extreme pressure additives. The lubricant should have a minimum viscosity index of 95 cst and maintain a minimum viscosity of 40 cst under normal operating temperature conditions. The following table lists the recommended viscosity for various ambient operating temperatures. These recommendations are based on a temperature rise of 10°C to 38°C at normal operating conditions.

Ambient Temperature -40°C to –20°C (1) ISO Index AGMA Lubricant #

VG100 3EP

-15°C to 4°C VG100 3EP

4°C to 40°C VG150 / VG220 4EP / 5EP

40°C to 65°C (2) VG320 6EP

Footnotes:

1. For operation in this ambient temperature range a synthetic oil or multi-grade oil is recommended with a pour point of 10°F lower than the minimum ambient temperature. 2. For operation in this ambient temperature range a synthetic oil recommended for proper lubricant life at elevated temperatures.

NOTICE The recommended oil temperature should be no higher than 70°C to 82°C for continuous operation, and no higher than 90°C for intermittent operation. It is also recommended to monthly check oil level by removing the site plug while the toque hub is in a level position.

operation

Self-operating