1 minute read

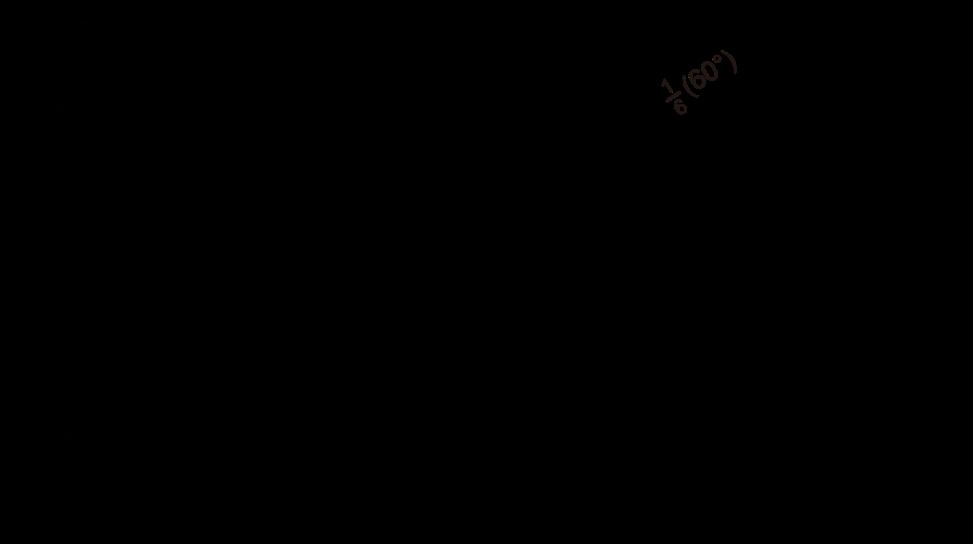

f) Apply manual torque on through bolt set

f) Apply manual torque on through bolt set

For CB80 and above, manual torque can also be applied if power torque wrench out of order.

1st step

Make Initial Setting of top nuts with 50 kg.m (490 N.m) torque wrench and impact socket. Mark an apex of top nut and also mark back head surface where each apex of top nut indicates.

2nd, 3rd, 4th step

Turn top nut with hammer and impact socket until the marked apex turns by number of turns specified on the 2nd, 3rd, 4th step respectively. See Manual Torque table.

Marking point

C

Back head

A

NOTE! Hammer size CB80 10 lb (4.54 kg) CB140 12 lb (5.44 kg) CB210 16 lb (7.26 kg) CB380 20 lb (9.07 kg)

B D

Top nut

Through bolt NOTE! Apply each step torque in “A B C D” sequence.

Manual torque applying

Manual torque

Model Torque value (kg.m/N.m/ft.lb)

1st step 2nd step

Torque value Turn Torque value Turn (from previous step) CB20 30/294/217 15/147/108 – 30/294/217 –CB40 45/441/326 20/196/145 – 45/441/326 –CB60 50/490/362 20/196/145 – 50/490/362 –CB80 50/490/362 50/490/362 – 95/931/687 2.5/6 CB140 160/1,568/1258 50/490/362 – 90/882/651 1/6 CB210 270/2,646/1,953 (310/3,038/2,242) 50/490/362 – 90/882/651 0.5/6 CB380 390/3,822/2,821 (450/4,410/3,255) 50/490/362 – 150/1,470/1085 1/6