1 minute read

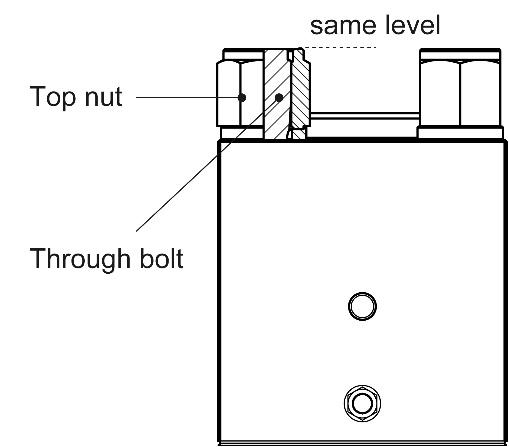

e) Through bolt set assembly

e) Through bolt set assembly

Put bottom nuts into the holes on the front head. Put washers on the holes on the back head. Insert through bolts into the holes of back head. Put top nuts on the through bolts. Then tighten the nuts with specified torque by power torque wrench. See section Torque value on page 65.

NOTE! When setting through bolt and top nut before you apply initial torque, ensure through bolt top surface and top nut surface are aligned as show below. NOTE! Apply torque step by step. Initial torque, intermediate torque, then final torque according to the instruction of Torque Value on page 65. NOTE! Initial setting shall be made by 15 or 20 kg.m for CB20, CB40, CB60 and 50 kg.m for CB80, CB140, CB210 and CB380.

NOTE! Apply each step torque in “A B C D” order as shown above.

CB20 to CB380