1 minute read

GREASING THE HYDRAULIC BREAKER

GREASING THE HYDRAULIC BREAKER (optional) Greasing intervals Correct greasing

1. The tool shank must be well lubricated before installing. 2. Press the grease gun between 5 to 10 times, at regular intervals, to grease the tool bushing and the tool. 3. Adapt the intervals and the quantity of grease to the wear rate of the tool and to working conditions. This can be anything between every two hours and once a day, depending on the type of material (rock/concrete) being broken. Insufficient greasing or improper grease may cause : • Abnormal wear of tool bushing and tool

• Tool breakage While greasing, the hydraulic breaker must be standing upright resting on the tool to ensure that the grease will penetrate downwards between the tool and the bushing. Do not fill the space between the piston and the tool with grease. A lower piston seal failure can result and the hydraulic breaker will eventually leak oil.

Grease points

Use the following grease: -EP NLGI grade 2 (for temperate and hot climates) -20°C to +60°C -EP NLGI grade 0 (for cold climates) 40°C to +20°C

Every 2 hours

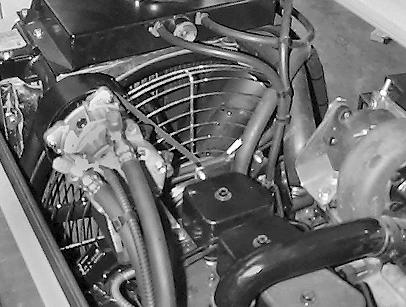

CP99C004 Tool shank....................................(1) Tool bushing.................................(1) NOTE: The figures given in brackets show the number of grease points.

This page is intentionally left blank