1 minute read

TOWING THE MACHINE

WARNING: Towing is a delicate operation. There is always a certain amount of risk for the operator. The manufacturer’s guarantee does not apply to accidents or problems which occur while towing.

WARNING: Never use the towing eye to tow another vehicle.

WARNING: The machine must be towed very slowly, for a short distance and only if absolutely necessary.

WARNING: A towing bar must be used for all towing operations.

IMPORTANT: Before towing, you must install the stabilizer (if fitted) and dozer blade (if fitted) lock pins. See “Road travel” in the “Job Site and Road Operation” Section. For all towing operations, the front and rear axle universal joints must be uncoupled.

STEP 1 STEP 4

Place blocks under the machine wheels.

Removal of universal joints

Tools required

-One 19 mm wrench for hexagonal head screws -One towing bar

STEP 2

Mark both parts before uncoupling them. NOTE: Marking the parts will facilitate their reassembly.

STEP 3

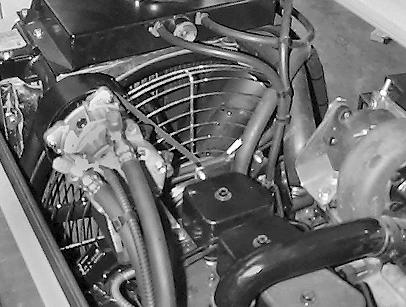

Support the front axle universal joint using a sling attached to the undercarriage.

PH07813 Remove the four screws from the front axle universal joint.

STEP 5

Repeat Steps 2 through 4 for the rear axle universal joint.

Towing

STEP 6 STEP 7

PH07408 PG02702 Install the rotary beacon and switch on the rotary beacon from the instrument panel (specific to certain countries).

STEP 8

Remove the wheel blocks.

STEP 9

PG03411 Attach a towing bar of suitable capacity to the stabilizer beam or to the dozer blade (depending on machine version).

Switch on the hazard light.

CD96H009

Directional towing limits

10°

10°

25°

25°

Installing the universal joints

Tools required

-One 19 mm wrench for hexagonal head screws

STEP 10

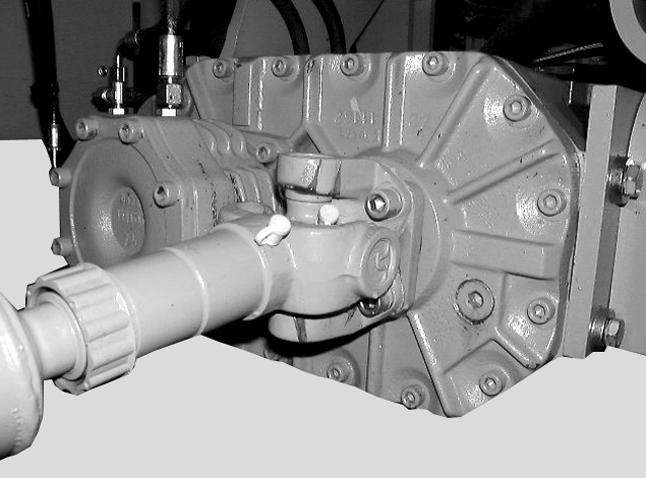

Remove the sling from the rear axle universal joint and align the two marks on the previously marked parts.

STEP 11

PDH0092 CD99G036 Install the four screws on the rear axle universal joint. Torque setting: 100 Nm.

STEP 12

Repeat Steps 10 and 11 for the front axle universal joint.