4 minute read

Dynamic engine mountings

4.5 Dynamic engine mountings

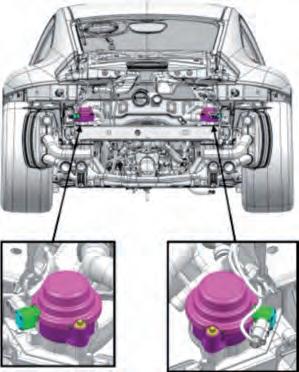

To further improve the driving dynamics as well as driving and vibration comfort, the Sport Chrono package on the new 911 Carrera models now also comes with dynamic engine mountings (Porsche Active Drivetrain Mount, PADM) as were previously only used on the 911 Turbo and 911 GT3 models.

These adjust their rigidity and damping depending on the driving situation. They significantly minimize the transmission of vibrations in the entire drivetrain and in particular from the engine to the body.

The delayed power impulse produced by the mass moment of inertia of the engine when steering into a corner or during a quick series of alternating bends, for example, is significantly reduced and any pushing from the rear minimized. Inspired by racing cars, in which the drive unit is bolted rigidly to the body, this leads to more stable and precise handling. The disadvantages are noticeable engine vibrations and reduced day-to-day usability for a comfort-orientated driving style. This vibration is filtered by way of softer mounts. Chassis 4

1_20_11

Chassis 4

*The control unit is housed behind the rear seat assembly. It is programmed as PASM and PADM, as PASM only or as PADM only depending on the equipment version.

1_21_11 The dynamic engine mountings combine both of these advantages and at the same time reduce vertical engine vibration during acceleration at full throttle. The result is more uniform and higher drive power at the rear axle with higher traction and better acceleration. The system is automatically controlled by the PASM control unit or a separate control unit* with a highly dynamic control loop and response times of just a few milliseconds when switching between soft and hard engine mountings.

A large amount of information is processed, including the steering angle, lateral, longitudinal and vertical acceleration as well as the fluid pressure in the respective engine mounting. The control strategy of the dynamic engine mountings is also influenced by the sport functions pre-setting. Depending on whether the SPORT or SPORT PLUSbutton is activated, the pre-set damping of the engine mountings is decreased or increased as required for sporty driving. In the sportiest setting SPORT PLUS, for example, a control strategy suitable for race circuits with greater rigidity of the engine mountings is pre-selected.

Function

The dynamic engine mountings comprise an electric coil and two chambers filled with magnetizable (magnetorheological) fluid. The upper chamber is coupled to the body, while the lower chamber is connected to the drive unit. The chambers are connected to each other by means of an annular gap. The electric coil is located directly next to this annular gap. Relative motion between the engine and the body forces the fluid through the annular gap. An electromagnetic field is generated in this annular gap by means of a defined electric current through the coil. This modifies the viscosity of the magnetorheological fluid and the engine mountings are made softer or harder. When there is no current flowing through the coil, the fluid has a relatively low viscosity and the flow resistance is low. The mountings have low rigidity and damping and are therefore soft. When a defined current is applied to the coil, the iron particles in powder form in the fluid are magnetized and join together to create chains. The fluid becomes viscous and the flow resistance high. The mountings are then characterized by high rigidity and damping and are therefore hard.

The system is controlled by a separate control unit with a highly dynamic control loop and response times of just a few milliseconds when switching between soft and hard engine mountings. A large amount of information is processed, including the steering angle, lateral, longitudinal and vertical acceleration as well as the fluid pressure in the respective engine mounting. To ensure excellent driving dynamics and functionality, vehicles with dynamic unit mountings feature separate and independent control of the right and left engine mountings. The control strategy of the dynamic engine mountings is also influenced by the PSM vehicle stability system pre-setting and other driving conditions described later on.

Overview

The inputs and outputs of the control units as well as the corresponding signals are shown below. Chassis 4

Chassis CAN

Lateral acceleration Longitudinal acceleration Vehicle speed Wheel speed, FR/FL/RR/RL Engine torque Sport button Clutch switch PDK shifting Steering angle Steering angle change time Engine speed Accelerator-pedal position Driver request torque Transmission status

Body acceleration sensor, front right PADM control unit Gateway

Error message on instrument cluster

Left mounting Control current Sensor signal

Right mounting Control current Sensor signal

Legend:

Chassis CAN Display CAN PWM signal Analog signal