37 minute read

Thermal energy management

2.13 Thermal energy management

2_480_11

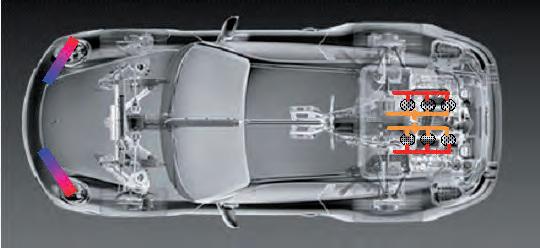

The new 911 Carrera (991) features a comprehensive thermal management system for the first time. The advantages achieved compared with the previous model are as significant as the possible operating states of the thermal management system are varied. Thermal management not only involves the engine, but also the transmission and heating.

Objective

Networking of all relevant heat sources in order to

• Reduce consumption by controlling the heat flows during all phases (up to 2%) • Reduce emission values • Reduce internal friction in the engine and transmission • Increase performance • Improve aerodynamics by doing away with air intakes in the underbody panelling, this also increases the top speed up to 189 mph (304 km/h) • Increase heating comfort • Enhance the OBD functions DME engine electronics 2

DME engine electronics 2

Fig. 2_482_11 Performance enhanced by reducing the coolant temperature to 185° F. (85° C.) during periods of increased operating load, or by actuating a map-controlled thermostat when Sport/Sport Plus mode is activated. Coolant temperature level, engine

Warm-up At operating temperature Cooling

221° F.

185° F.

Coolant temperature approx.

Time

2_481_11

Picture above: Comparison of coolant temperature level between Carrera 991 (S) and 997 (2)

The speed with which the operating temperature is reached is achieved by way of an innovative rotating piston valve that is actuated by the DME control unit according to a control map. The engine is at operating temperature when an engine coolant temperature of 221° F. (105° C.) is reached.

221° F.

185° F.

Coolant temperature approx. 991 (S) 997 (2)

Warm-up At operating temperature Consumption

Performance Cooling

Time

2_482_11

Operating modes

The operating modes of the thermal management system can be categorized as follows for the 991:

1. Operating mode: Warm-up

a) Measures aimed at reducing fuel consumption • Specific channelling of available heat flows to operating fluids and components that are relevant to consumption • Reduces heat losses to a minimum, accelerates warm-up

b) Increased heating comfort Specific channelling of the available heat flows into the passenger cell

2. Operating mode: At operating temperature

• Reduces consumption by increasing the coolant temperature (221° F./ 105° C.)

3. Operating mode: Cooling

• Optimizes performance by reducing the coolant temperature (185° F./85° C.) • Reduces the cooling of operating fluids and components relevant to consumption after the engine is switched off until it is started again

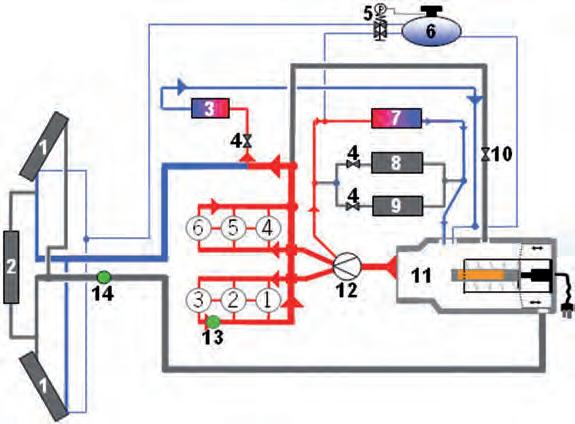

Overview of the engine cooling system from the front

11

1

2

5 9

8

7 10

3 4

6

2_483_11

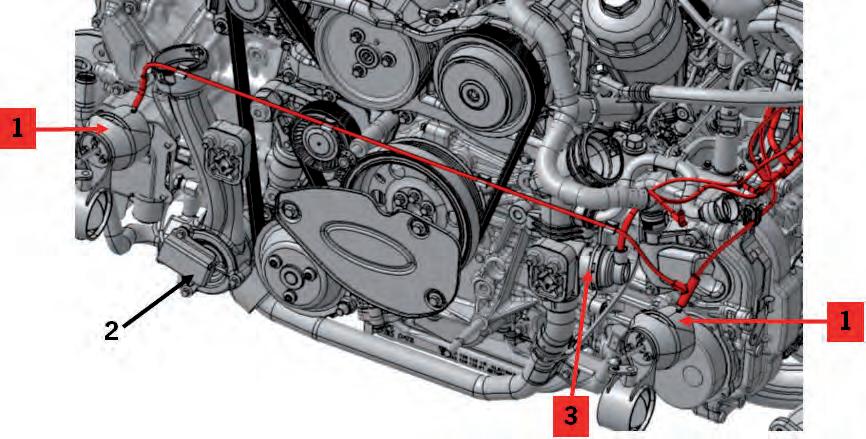

Shut-off valves

The coolant throughput to different components is controlled in the cooling system of the 991 (S) by way of the map-controlled thermostats (3) on the one hand and electropneumatically actuated valves (7) on the other.

Electropneumatic switching valves

The thermal management system features electropneumatic shut-off valves for the following components: • Engine coolant shut-off valve (7) • Heat exchanger • Gear oil heat exchanger • ATF heat exchanger (Porsche Doppelkupplung [PDK] only) DME engine electronics 2

Note: The coolant temperature gauge in the instrument cluster shows 194° F. (90° C) at normal operating temperatures 185° F. 221° F. (85° C. - 105° C.).

1 Connection for heat exchanger and expansion tank 2 Coolant return line for coolant radiator 3 Map-controlled thermostat 4 Mechanical coolant pump 5 Coolant return line forcylinder banks 1 and 2 6 Coolant supply line for cylinder banks 1 and 2 7 Coolant shut-off valve (electropneumatically actuated) 8 Coolant supply line for coolant radiator 9 Coolant return line for engine oil heat exchanger 10 Coolant supply line for engine oil heat exchanger 11 Engine vent line

Electropneumatic disc valve

DME engine electronics 2

* 991 S only ** Only with the sports exhaust system (optional) *** Only with the Porsche Doppelkupplung (PDK) (optional)

See blue arrow

2_487_11

Direction of travel

1 Solenoid valve for shut-off valve for heat exchanger 2 Shut-off valve for heat exchanger (pneumatic) 3 Unfiltered air connection, solenoid valve for exhaust flaps (exhaust flaps only with sports exhaust system, optional) 4 Solenoid valve for engine coolant shutoff valve 5 Solenoid valve for tuning flap switching valve (991 S only) 6 Switching valve for tuning flap (pneumatic, 991 S only) 7 Vacuum connecting line for transmission Vacuum system

The 991 has a maximum of eight electropneumatic valves in total, four of which belong to the thermal management system. Further electropneumatic valves are used to switch • the tuning flap (991 S only), • the air cleaner flap, • the sound symposer and • the sports exhaust system flap (optional).

Overview of the vacuum system

Air cleaner housing

Mechanical vacuum pump Unfiltered air hose

Vacuum hose

Valve for air cleaner box flap

Valve for tuning flap*

Valve for sound symposer

Valve for exhaust flaps**

Engine coolant shut-off valve Shut-off valve for heat exchanger Shut-off valve for gear wheel heat exchanger

Shut-off valve for ATF heat exchanger***

2_485_11

Vacuum Unfiltered air Control line

2_486_11

Vacuum lines, installation position on air cleaner box/cylinder bank 2

2_489_11

The solenoid valves for the sound symposer switching valve and for the air cleaner flap are installed on the right behind the air cleaner box.

Diagnosing faults in the vacuum system

2_490_11

Diagnosing faults in the vacuum system

The electric solenoid valves in the vacuum system are fully diagnosable (short circuit/open circuit); electrical faults result in an entry in the DME control unit and, if applicable, in the PDK control unit. DME engine electronics

See blue arrow

1 Solenoid valve for sound symposer switching valve 2 Solenoid valve for air cleaner flap switching valve 3 Solenoid valve for heat exchanger shut-off valve

Vacuum Unfiltered air Control line

1 Switching valve for exhaust flaps (pneumatic, sports exhaust system [optional] only) 2 Map-controlled thermostat 3 Switching valve for engine coolant shut-off valve

DME engine electronics 2

It is important to proceed as per the specifications of the Workshop Manual/Guided Fault Finding when troubleshooting the vacuum system.

2_500_11 Leaks in the vacuum system are detected through the malfunctioning of pneumatic switching valves and the associated effects. The DME control unit cannot, however, output an unequivocal fault message in the event of leaks in the vacuum system because there are too many different vacuum components connected. For example, a leak in the pneumatic switching valve for the tuning flap could generate a fault message about the cooling system.

Background knowledge on electropneumatically controlled valves

The pneumatic valves are switched in steps, in other words they are either fully closed or fully open. They can, in principle, also be operated continuously, but the compression properties of air mean that this cannot be done with any precision.

Background knowledge on electronically controlled actuators

Consequently, electrical actuators are currently used for precise, continuous control of valves; these have the following disadvantages compared with pneumatic valves: • Higher production costs • Higher weight • More complicated activation A further advantage of the electrically actuated valves is their better diagnostic capabilities. Feedback devices (potentiometers) are attached to the drive links and communicate the position detected by the actuator directly to the control unit, which also makes for easy and precise control of the relevant component.

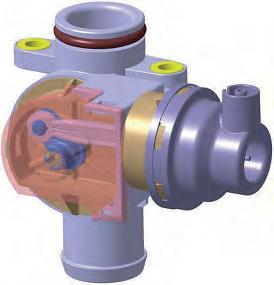

Engine coolant shut-off valve

The engine coolant shut-off valve (electropneumatically actuated) is designed as a rotating piston valve and is used, among other things, to reach the engine operating temperature faster during the warm-up phase. The coolant throughput is increased as required by closing the electropneumatically actuated coolant shut-off valve via the DME control unit.

Closing the engine coolant shut-off valve (vacuum present) largely prevents the coolant circulating in the engine, even though the impeller of the mechanically driven coolant pump is turning. This applies as long as the map-controlled thermostat is closed.

The coolant in the engine means that the combustion engine reaches its operating temperature much faster than in systems without thermal management, however the coolant pressure also increases along with the engine speed. If the engine coolant shut-off valve is closed when the thermostat is open, the coolant throughput in the coolant radiators increases. The engine coolant shut-off valve must be open above 3,000 rpm as high pressures would otherwise build up in the cooling system, possibly resulting in leaks and damage to the cooling system.

The engine coolant shut-off valve is closed as a function of: • Setpoint engine coolant temperature • Engine coolant temperature • Coolant temperature at the radiator outlet • Gear oil and ATF temperature (Porsche Doppelkupplung [PDK] only) • Heating request to the air conditioning system • Engine power • Engine speed • Ambient air temperature

The engine coolant shut-off valve is kept closed in the following operating modes by the DME control unit: • Heating phase (not USA) • Maximum cooling • Heating engine boost mode

Diagnosis

Component Condition

Engine coolant shut-off valve

Stuck open • No electrical connection • No pneumatic connection • Valve sticking

Stuck close • Short circuit to ground • Activation lines • interchanged • Valve sticking Consequence

• Extended heating phase • Increased fuel consumption • Restricted cooling • performance

• Overheating in the cylinder • head • Pressure in the cooling • system too high (leaks in the • cooling system)

The evaluation electronics can detect mechanical faults in the map-controlled thermostat and engine coolant shut-off valve by evaluating the temperature signals, but cannot identify which of the specified components is defective. A thermostat or engine coolant shut-off valve that is stuck closed will result in an entry in the fault memory after a diagnostic routine. DME engine electronics 2

DME engine electronics 2

2_503_11 Thermal management for heat exchanger

Coolant flows through it during: • Heating requests • Maximum engine cooling requests

Shut-off valve for heat exchanger

2_502_11

The shut-off valve for the heat exchanger is opened via the air conditioner control unit when the driver requests heat. The engine coolant shut-off valve, which is closed when the engine is not yet at operating temperature, ensures that sufficient hot coolant is available even after a very short time in order to heat the passenger compartment.

When the passenger compartment no longer needs to be heated, the shut-off valve for the heat exchanger is closed again so that the combustion engine can reach its operating temperature faster.

The shut-off valve for the heat exchanger is also automatically opened when a request for maximum engine cooling is sent via a CAN message from the DME control unit to the air conditioner control unit in order to further reduce the coolant temperature in the engine and in this way prevent damage to the engine and transmission.

Closing the engine coolant shut-off valve below 1,800 rpm increases the flow of coolant in the heat exchanger, but also increases the heating output considerably (heating boost mode).

Diagnosis

Component Condition

Shut-off valve for heat exchanger

Stuck open • No electrical connection • No pneumatic connection • Valve sticking

Stuck closed • Short circuit to ground • Activation lines • interchanged • Valve sticking Consequence

• Extended heating phase • Increased fuel consumption

• No heating of the passenger

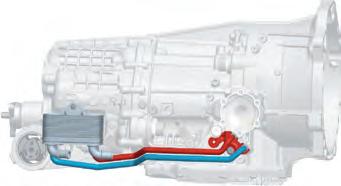

Thermal management for gear wheel set (Porsche Doppelkupplung [PDK]and manual transmission)

Gear oil heating

A temperature sensor (see photo on the next page) is installed close to the gear oil heat exchanger (which is attached to the transmission housing) that continuously detects the gear oil temperature and communicates this information to the DME control unit. To heat up the gear oil faster, the shut-off valve for the gear oil heat exchanger(1) is opened during the engine warm-up phase as soon as the coolant has reached a temperature of 158° F. (70° C.) and is therefore hotter than the gear oil. The coolant then flowing into the gear oil heat exchanger(2)boosts heating of the gear oil to the setpoint temperature of 194° F. (90° C.). The friction in the gear wheel set is reduced faster (the viscosity characteristics of the oil improve when the oil temperature increases), shifting comfort is increased and fuel consumption is reduced.

The shut-off valve is closed (vacuum present) as soon as the setpoint gear oil temperature of 194° F. (90° C.) is reached. This prevents excessive heating of the gear oil.

The specified temperatures are for guidance only and may vary depending on the operating condition and variant.

Gear wheel cooling

The disc valve is opened again if the gear oil temperature increases beyond the setpoint temperature and beyond the temperature of the coolant; the purpose of this is to cool the gear oil (component protection). DME engine electronics 2

1

2

1 Pneumatically actuated shut-off valve for gear oil heat exchanger 2 Gear oil heat exchanger

DME engine electronics 2

1 Gear oil pump (installation position) 2 Gear oil heat exchanger 3 Gear oil temperature sensor (NTC)

Gear oil pump

The cooling oil is supplied to the gear wheel set via a Wankel pump (1) installed directly at the heat exchanger (see Fig. 2_506_11, 2) and driven by a pinion shaft. This way that the supply of cooling oil to the gear wheel set is speed-dependent.

1

2

2_507_11 3

Diagnosis

Component Fault

Shut-off valve for gear oil heat exchanger

Stuck open • No electrical connection • No pneumatic connection • Valve sticking

Stuck closed • Short circuit to ground • Activation lines • interchanged • Valve sticking Direction of travel

2_506_11

Consequence

• Extended heating phase • Increased fuel consumption • Increased wear on the • transmission possible • during normal driving at 2221° F. (105 °C.)

• Overheating of the transmission possible (at high engine speeds and loads, high ambient temperatures)

The Porsche Doppelkupplung (PDK) in the 991 features an additional ATF heat exchanger (1 on the following page) that is integrated in the thermal management system for the entire vehicle by way of sensors. The ATF temperature sensor (on the right in the picture) is necessary for this. The DME control unit receives its values via the PDK control unit. The ATF heat exchanger (1 on the following page) is mounted on the PDK housing. Its purpose is to heat the ATF faster (and cool it if necessary) or to cool the oil-cooled and oil-lubricated double-clutch transmission.

2

3

2_508_11

ATF heating

To heat up the ATF faster, the shut-off valve for the ATF heat exchanger (3) is opened during the engine warm-up phase as soon as the coolant has reached a temperature of 158° F. (70° C.) and is therefore hotter than the ATF. The coolant then flowing into the ATF heat exchanger (1) boosts the heating of the ATF to the setpoint temperature of 185° F. (85° C.). The friction losses of the moving parts in the hydraulic area of the transmission are reduced (the viscosity characteristics of the oil improve when the oil temperature increases), shifting comfort is increased and fuel consumption is reduced.

If the setpoint ATF temperature of 185° F. (85° C.) is reached, the DME control unit actuates the solenoid valve for the ATF heat exchanger (2) and the solenoid valve directs vacuum to the pneumatic shut-off valve (3). The shut-off valve closes and prevents any more coolant flowing into the heat exchanger. This prevents excessive heating of the ATF.

The specified temperatures are for guidance only and may vary depending on the operating condition.

ATF cooling

Operation of the double-clutch transmission results in greater heating of the ATF than of the gear oil. The disc valve is opened again if the ATF temperature increases beyond the setpoint temperature and the engine coolant temperature is below the temperature of the gear oil. The coolant circulating in the ATF heat exchanger cools the gear oil (component protection). DME engine electronics 2

1 ATF heat exchanger 2 Solenoid valve for ATF heat exchanger 3 Pneumatic shut-off valve for ATF heat exchanger

1

Installation position

DME engine electronics 2

2_510_11

Thermostat (997 II) +

Heating element

2_511_11

Map-controlled thermostat (991)

Component protection for the Porsche Doppelkupplung (PDK)

A message appears in the instrument cluster (first white, then red transmission temperature warning) as a safety measure if the transmission overheats. The DME control unit additionally reduces the torque until the ATF temperature reaches a non-critical value again. The warning message then disappears.

Diagnosis

Component Condition Consequence

Shut-off valve for ATF heat exchanger

Stuck open • No electrical connection • No pneumatic connection • Valve sticking

Stuck closed • Short circuit to ground • Activation lines • interchanged • Valve sticking • Extended heating phase • Increased fuel consumption • Close to the critical clutch temperature

• Overheating of the transmission/clutch possible (lots of gear changes, racing starts, high ambient temperatures are critical)

Map-controlled thermostat

The map-controlled thermostat is an insertion map-controlled thermostat with a heating element. The map-controlled thermostat can be energised via the DME control unit. The flow of current through the heating element (electric resistor) causes it to heat up, which in turn influences the expansion element in the thermostat and enables it to be opened. Actuation by the DME control unit is performed by means of pulse width modulation, which means that the coolant temperature level can be continuously controlled.

The usual coolant temperature when the engine of the 991 (S) is at operating temperature is 221° F. (105° C); it is reduced to 185° F. (85° C.) during sporty driving and in Sport/Sport Plus mode by opening (energising) the thermostat. This supports a performance-oriented driving style.

The DME control unit can also have the thermostat closed by switching off the heating current. The coolant temperature must be less than 216° F. (102° C.) for this to be possible. The map-controlled thermostat starts to open at 216° F. (102° C.) +/- 36° F. (2° C.) when de-energized and is fully open at 239° F. (115° C.).

The coolant temperature is measured by the engine coolant temperature sensor and the radiator outlet coolant temperature sensor and transmitted to the DME control unit.

The DME control unit energizes the heating element (resistor) in the map-controlled thermostat: • In the lower and medium load range in order to limit the coolant temperature in the engine to 221° F. (105 C.). • With an increased load requirement as well as during operation in Sport and Sport Plus mode in order to reduce the engine coolant temperature to 185° F. (85° C.). The cooler cylinder walls result in higher density of the oxygen content in the combustion chamber. The improved charging enhances the performance of the combustion engine. • If necessary to prevent critical gear wheel oil and ATF (Porsche Doppelkupplung [PDK] only) temperatures. The heat exchanger can also be activated for this purpose.

Diagnosis

The map-controlled thermostat is diagnosable for legal reasons. Electrical faults and detection of a thermostat that is stuck open result in an entry in the fault memory, the OBD indicator light comes on and the warning message “Cooling system error” appears in the instrument cluster.

A thermostat or an engine coolant shut-off valve that is stuck closed is also indicated in the instrument cluster by way of the warning message “Cooling system error”, but the OBD indicator light does not come on. The evaluation electronics cannot yet correctly identify whether the map-controlled thermostat or the coolant shut-off valve is defective. As of MY 12/13 it will be possible to correctly identify which of the specified components is defective with the help of PIWIS Tester II using the “Short test” function.

2_512_11 DME engine electronics 2

DME engine electronics 2

2_514_11 Component Fault

Map-controlled thermostat

Stuck open

Stuck closed Consequence

• Extended heating phase • Increased fuel consumption

• Overheating of the cooling system

The following parameters are used for diagnosis: • Setpoint engine coolant temperature • Engine coolant temperature • Coolant temperature at the radiator outlet • Engine speed • Mass air flow • Deceleration phases • Vehicle speed • Ambient temperature

Engine coolant temperature sensor

The engine coolant temperature sensor (NTC) is installed in cylinder bank 1 near the third cylinder and is designed as a temperature-dependent resistor.

2_513_11

The sensor signal is used for: • DME control (ignition/injection system) • Actuating the engine coolant shut-off valve • Actuating the map-controlled thermostat • Actuating the engine compartment purge fan • Checking the oil temperature sensor/oil temperature • Air conditioning control • Diagnosing the engine coolant shut-off valve • Cross-check diagnosis

Diagnosing the engine coolant temperature sensor (cross-check diagnosis)

The purpose of cross-check diagnosis is to check that temperature sensors are working correctly. The control unit compares the temperature values of different sensors and checks them for plausibility. The following temperatures are compared when checking the engine coolant temperature sensor: • Engine coolant temperature • Engine oil temperature • Intake air temperature • Ambient temperature

Step 1 When an engine is started after the ignition has been off for more than 8 hours, the specified temperature values are compared. The temperature values must not deviate by more than a certain value (depending on when the ignition was switched off). A suspected fault is set if the deviation is too great, but this must be confirmed in Step 2.

Step 2 The check is repeated if a journey during which the vehicle travels at more than 16 mph (25 km/h) for a total of 45 seconds takes place within 6 minutes of the engine starting. The relevant fault is written to the fault memory if the temperature of the suspected sensor continues to deviate by too much (difference > 77° F. (25° C.). The suspected fault is dismissed and no fault is entered in the fault memory if the deviation in temperature of the suspected sensor is no longer as great. The suspected fault is dismissed and no fault is stored in the fault memory if the vehicle is not driven within 6 minutes of starting the engine. DME engine electronics 2

DME engine electronics 2

2_515_11

Unapproved wheel retrofits (wheel diameter too large) can result in a reduced air-flow rate at the coolant radiators.

The following fault causes can be detected with the help of the engine coolant temperature sensor: • Engine coolant temperature sensor faulty • Thermostat/thermostat housing seal/thermostat housing faulty • Air in the cooling system • Oil temperature sensor faulty • Fault in DME

Radiator outlet coolant temperature sensor

The radiator outlet coolant temperature sensor is located on the coolant pipe at the radiator outlet towards the engine on the vehicle underbody. The temperature information is transmitted to the DME control unit. The DME control unit uses the plausible signal to control the thermal management system.

The sensor signal is used for: • Actuating the coolant radiator fan – as a function of the coolant temperature – as a function of the setpoint engine coolant temperature • Testing the function of the map-controlled thermostat/engine coolant shut-off valve • Diagnosis

Diagnosis

The DME control unit compares the following values when checking the radiator outlet coolant temperature sensor: • Engine coolant temperature • Intake air temperature sensor The radiator outlet coolant temperature sensor can detect the following faults: • Radiator outlet coolant temperature sensor faulty • Engine coolant temperature sensor faulty • Engine coolant shut-off valve jammed • Radiator air intake covered with debris • Intake air temperature sensor faulty

Operating modes

The thermal management system is influenced by a number of different operating conditions. For that reason, only the most significant conditions are described here. We will start with a few generally valid statements regarding the cooling system in the 991: • The coolant cooling system for the engine is designed in two parts. The two parts are kept separate by the closed engine coolant shut-off valve. • Coolant is continuously passed through the engine oil heat exchanger while the engine is running. • As well as its primary task of cooling the engine, the cooling system is also used to heat/cool transmission oils. An ATF heat exchanger (Porsche Doppelkupplung [PDK] only) and gear oil heat exchanger are integrated for this purpose. • Only vehicles intended for extremely hot countries have an additional center radiator. (Not for USA) • All solenoid valves are open when de-energized, i.e. all pneumatic valves are pressurized and therefore open.

First operating condition: Engine cold/off

2_516_11

Second operating condition: Heating boost mode

• Ambient temperature < 32° F. (0° C.) • Coolant temperature < 203° F. (95° C.) • Heating request present • n < 2,000 rpm • Coolant pressure < 14.5 psi (1 bar) DME engine electronics 2

USA) 3 Heat exchanger 4 Disc valve, vacuum-controlled 5 Comfort valve 6 Coolant expansion tank 7 Engine oil heat exchanger 8 ATF heat exchanger (Porsche Doppelkupplung [PDK] only) 9 Gear oil heat exchanger 10Engine coolant shut-off valve 11Map-controlled thermostat 12Coolant pump (mechanical) 13Engine coolant temperature sensor 14Coolant temperature sensor, radiator outlet

DME engine electronics 2

The procedure for filling and bleeding the cooling system must be followed as outlined in the Workshop Manual to prevent damage to the engine and transmission.

2_517_11

The heating boost mode function enables faster heating of the passenger compartment. The heating boost mode function also has the task of preventing the passenger compartment from cooling down, even with low load requirements and very low outside temperatures.

In addition to the thermostat, the engine coolant shut-off valve (10) also stays closed up to an engine speed between 1,600 and 2,000 rpm when the ambient temperature < 32° F. (0° C.), coolant temperature < 203° F. (95° C.) and a maximum heating request is present. The closed engine coolant shut-off valve increases the coolant throughput in the heat exchanger (3) by approx. 60% compared with operation with the engine coolant shut-off valve open. The engine coolant shut-off valve is opened once the coolant temperature rises above 203° F. (95° C.).

Coasting mode (Porsche Doppelkupplung [PDK] only) is an exception. Heating boost mode remains active during coasting when outside temperatures are below 32° F. (0° C.) and a maximum heating request is present.

The map-controlled thermostat (11) is closed so that the coolant volume to be heated can reach its temperature faster.

Comfort valve closed No coolant flows into the expansion tank (6)because the comfort valve (5) only opens the return lines from the two coolant radiators and engine to the expansion tank when the coolant pressure exceeds approx. 14.5 psi (1 bar). The closed comfort valve (5) ensures that there is less coolant to be heated at pressures below 14.5 psi (1 bar), which means that the coolant temperature can increase faster.

Any air bubbles in the cooling system cannot be automatically bled because the comfort valve does not open. During a pressure increase with air inclusions in the cooling system, the trapped air is compressed but the comfort valve remains closed. This can result in overheating damage to the engine and transmission.

Third operating condition: Cold start/warm-up

• Ambient temperature 59° F. - 95° F. (15° C. - 35 °C.) • Coolant temperature < 122° F. (50° C.) • Heating request • n <= 3,000 rpm • Coolant pressure > 14.5 psi (1 bar)

2_518_11

Coolant throughput only takes place between the engine, engine oil heat exchanger (7) and, in the event of a heating request, the heat exchanger (3) so that the temperature losses of the coolant are very low and the coolant heats up very quickly in the engine. The disc valve (4)of the heat exchanger (3) is opened in the event of a heating request so that coolant can flow into the heat exchanger.

Engine coolant shut-off valve control When the starting temperature (ambient temperature) is between 59° F. - 95° F. (15° C. - 35 °C.), the engine coolant shut-off valve (10)remains closed until the coolant in the engine has reached a temperature of 122° F. (50° C.) in order to heat the engine faster. The engine coolant shut-off valve (10) remains open if the ambient temperature exceeds 95° F. (35° C.). DME engine electronics 2

USA) 3 Heat exchanger 4 Disc valve, vacuum-controlled 5 Comfort valve 6 Coolant expansion tank 7 Engine oil heat exchanger 8 ATF heat exchanger (Porsche Doppelkupplung [PDK] only) 9 Gear oil heat exchanger 10Engine coolant shut-off valve 11Map-controlled thermostat 12Coolant pump (mechanical) 13Engine coolant temperature sensor 14Coolant temperature sensor, radiator outlet

DME engine electronics 2

The engine coolant shut-off valve opens when an engine speed of 3,000 rpm is exceeded in order to prevent excessively high pressures in the cooling system. The map-controlled thermostat (11) is always closed during the heating phase.

Comfort valve open The slight increase in the coolant temperature causes the coolant pressure to exceed 1 bar and the spring-loaded comfort valve (5)to open. The return lines to the expansion tank are now opened and approx. 1.3 gal. (5 liters) of additional coolant are introduced into the cooling system.

Fourth operating condition: Warm-up

• Ambient temperature >= 32° F. (0° C.) • Coolant temperature > 122° F. (50° C.) • Heating request

2_519_11

The engine coolant shut-off valve (10) remains open even at engine speeds below 3,000 rpm, regardless of whether or not a heating request is present, because the ambient temperature is high enough to heat the passenger compartment with the available coolant throughput and the available coolant temperatures.

The coolant in the small cooling system continues to heat up very quickly due to the still-closed thermostat (11) and the closed shut-off valves for gear oil cooling(9) and ATF cooling (8, Porsche Doppelkupplung [PDK] only). The shut-off valves for the gear oil heat exchanger and ATF heat exchanger can open from a minimum coolant temperature of 113 - 194° F. (45 - 90° C.), depending on the variant and operating condition.

Fifth operating condition: Transmission heating

• Coolant temperature > 113° F. (45° C.) < 194° F. (90° C.) • Gear wheel oil temperature < 194° F. (90° C.) • ATF temperature < 185° F. (85° C.) (Porsche Doppelkupplung [PDK] only)

2_520_11

The shut-off valves for the gear oil heat exchanger (9) and ATF heat exchanger (8, Porsche Doppelkupplung [PDK] only) are opened within a coolant temperature range between 113° F. (45° C.) and 194° F. (90° C.). When the shut-off valves open depends on the operating condition/variant. The coolant boosts the heating of the gear oil and ATF (Porsche Doppelkupplung [PDK] only) in this condition.

The shut-off valve for the gear oil heat exchanger (4) is closed once the setpoint gear oil of 194° F. (90° C.) is reached in order to prevent overheating of the gear oil. The shut-off valve for the gear oil heat exchanger (4) is opened again if the gear oil temperature falls below 158° F. (70° C.) in order to heat the gear oil again. This can occur especially during trips at very low ambient temperatures.

Porsche Doppelkupplung (PDK) only: The shut-off valve for the ATF heat exchanger is closed once the setpoint gear oil of 185° F. (85° C.) is reached in order to prevent overheating of the ATF. The shut-off valve for the ATF heat exchanger is opened again if the ATF temperature falls below 158° F. (70° C.) so that the coolant can heat the oil again.

The specified temperature values for closing the shut-off valves of the transmission heat exchangers vary depending on the operating condition/variant. DME engine electronics 2

USA) 3 Heat exchanger 4 Disc valve, vacuum-controlled 5 Comfort valve 6 Coolant expansion tank 7 Engine oil heat exchanger 8 ATF heat exchanger (Porsche Doppelkupplung [PDK] only) 9 Gear oil heat exchanger 10Engine coolant shut-off valve 11Map-controlled thermostat 12Coolant pump (mechanical) 13Engine coolant temperature sensor 14Coolant temperature sensor, radiator outlet

DME engine electronics 2

Sixth operating condition: At operating temperature

• Driving program: Normal (moderate driving) • Coolant temperature = 221° F. (105°C)

2_521_11

The map-controlled thermostat (11) automatically begins to open at approx. 216° F. (102° C), providing a small gap for the coolant. From now on, the coolant is cooled by the coolant radiators (1, 2) in the front end. The setpoint coolant temperature in the engine is 221° F. (105°C) with a moderate driving style and Sport/Sport Plus mode deactivated.

Shut-off valve for gear oil heat exchanger and ATF heat exchanger (Porsche Doppelkupplung [PDK] only) The shut-off valves for the gear oil and ATF heat exchangers are only opened in this operating condition if the gear oil temperature and/or the ATF temperature are too low (e.g. in cold countries), or their temperatures are higher than that of the engine coolant, resulting in cooling of the heat exchangers at the transmission (8, 9).

Seventh operating condition: At operating temperature

• Driving program: Sport/Sport Plus, or: performance-oriented driving in the Normal program • Coolant temperature approx. 185° F. (85° C.)

2_522_11

The coolant temperature is reduced to 185° F. (85° C.)in Sport/Sport Plus mode and with a sporty driving style in Normal mode in order to improve the performance values through improved charging.

Map-controlled thermostat The temperature reduction is achieved by heating and therefore opening the map-controlled thermostat (11). The map-controlled thermostat is completely open at an expansion element temperature of 239° F. (115 °C) (does not have to correspond to the coolant temperature).

Transmission cooling The shut-off valves for the gear oil heat exchanger (9) and ATF heat exchanger (8) are additionally opened if necessary in order to reduce the operating fluid temperatures in the transmission and in this way prevent overheating of the transmission parts. DME engine electronics 2

USA) 3 Heat exchanger 4 Disc valve, vacuum-controlled 5 Comfort valve 6 Coolant expansion tank 7 Engine oil heat exchanger 8 ATF heat exchanger (Porsche Doppelkupplung [PDK]only) 9 Gear oil heat exchanger 10Engine coolant shut-off valve 11Map-controlled thermostat 12Coolant pump (mechanical) 13Engine coolant temperature sensor 14Coolant temperature sensor, radiator outlet

DME engine electronics 2

Eighth operating condition: Maximum cooling • Coolant temperature > 221° F.(105° C.)

2_523_11

If the setpoint coolant temperature at the engine and coolant outlet (depending on the operating condition) is exceeded despite the thermostat (11) being open, the engine coolant shut-off valve (10) is closed in order to increase the coolant throughput in the coolant radiators. The DME control unit opens the shut-off valve for the heat exchanger (4) via a command to the air conditioner control unit even if no heating request is present. The additional coolant and the heat emitted by the heat exchanger boost the engine cooling, and if necessary the cooling of the transmission. The coolant pressure is reduced at the same time by opening the shut-off valve for the heat exchanger. The cooling performance of the air conditioner increases in this operating condition because the passenger compartment has to be additionally cooled in order to keep the temperature in the passenger compartment constant. The DME control unit has the two electric fan motors running at maximum speed due to the high coolant temperatures at the coolant outlet.

Porsche Doppelkupplung (PDK) excess temperature The PDK control unit can request a torque reduction from the DME control unit if transmission temperatures are too high in order to prevent the transmission from overheating. The torque reduction ceases once the transmission temperature is no longer critical.

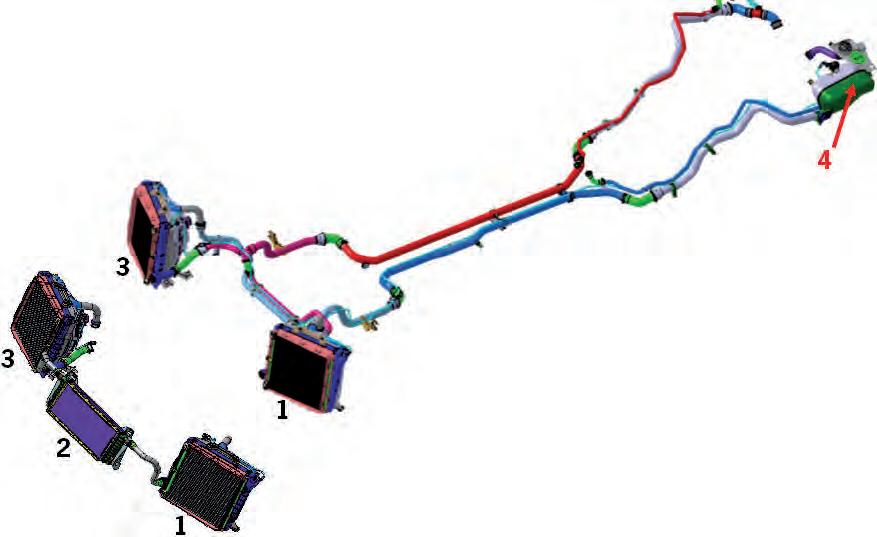

Coolant radiators

2_524_11

Electric fans for coolant radiators

The coolant radiators with electric fans (1, 3) are installed on both sides in the front end of the vehicle. The variants intended for extremely hot countries are equipped with a third, center additional radiator (2) (Not for USA) without an electric fan.

The functions of the electric fans are to • respond to cooling requests from the DME control (reduce engine coolant temperature, reduce air conditioner refrigerant temperature), • provide maximum cooling (emergency operation, n = 2,400 rpm) if there is no DME information available, • switch themselves off if there is a risk of damage from overheating. The fan motors are phase-controlled synchronous motors that are continuously actuated via separate control units (drivers). The fan motors are most efficient at n = 1,800 rpm. The drivers required for operation of the fan motors receive their commands from the DME control unit by means of PWM signals and form one unit with the fan motor.

The 12V power supply for the fan motor is provided via a common line that also supplies the control unit mounted on it with current.

Diagnosis

Both the control units of the radiator fans and the DME control unit can detect faults in the fans and insufficient cooling performance (radiator covered/dirty/air inclusions in the cooling system) and store them in the fault memory of the DME control unit. DME engine electronics 2

1 Left coolant radiator with electric fan 2 Center coolant radiator (extremely hot countries only) (Not for

USA) 3 Right coolant radiator with electric fan 4 Coolant expansion tank

DME engine electronics 2

The fan motors must not be tested by applying an external power supply, as this can damage the motors.

DME inputs

•Engine power •Engine torque •Engine speed •Engine coolant temperature •Coolant temperature, radiator outlet •Oil temperature

CAN inputs

•Heating request via air conditioning control unit •Request for ATF cooling via transmission control unit (Porsche Doppelkupplung [PDK] only) •Ambient temperature via air conditioning control unit •Sport/Sport Plus mode via air conditioning control unit Electrical faults The radiator control unit detects electrical faults. If a short circuit/open circuit occurs, a fault entry is made in the DME control unit and the fans are no longer actuated.

The fan motors are operated in emergency mode (maximum speed) if the drive CAN bus is faulty or a fan control unit is not receiving any signal from the DME control unit.

Measuring the current consumption not only provides a way of detecting short circuits, but also stiff/mechanically blocked fan motors.

Overheating/mechanical faults The radiator fan control units have an integrated temperature sensor. The fan control unit can detect overheating of a fan motor by means of the signal from the temperature sensor and switch off the fan (temporarily) (component protection).

The fan control unit can initiate measures (e.g. radiator fan motor working loose, operating the radiator fan at reduced speed) in the event of mechanical faults.

Inputs and outputs for thermal management control

DME control unit

Outputs

•Map-controlled thermostat •Engine coolant shut-off valve •Shut-off valve for heat exchanger •Shut-off valve for gear oil heat exchanger •Shut-off valve for ATF heat exchanger (Porsche Doppelkupplung [PDK] only) •Coolant radiator fan motors

Engine compartment purge fan

The engine compartment purge fan consists of two electrically actuated fans. The fan motors can be operated at two speed settings (low and high) and are switched using two relays.

The engine compartment fan motors do not have their own control unit. There is one relay for each of the two settings (low/high). The fan motors are actuated on the instruction of the DME control unit. Actuation takes place as a function of the engine compartment temperature, which is detected by a separate engine compartment temperature sensor. The engine compartment temperature sensor is connected to the DME control unit. Another variable is the engine coolant temperature.

2_526_11

Operating condition: Engine off, ignition on

The engine compartment purge fan runs at setting 2 when the engine compartment temperature is > 162° F. (72° C.). It switches off again under these conditions when the engine temperature is < 154° F. (68° C.).

Operating condition: Engine on

When the engine is running, fan setting 1 is switched on when the engine compartment temperature is > 75° F. (24° C.) and switched off again when the engine temperature is < 59° F. (15° C.).

Fan setting 2 is switched on when the engine compartment temperature is > 149° F. (65° C.) or the engine coolant temperature is > 226° F. (108° C.). When the engine is running, fan setting 2 is switched off again when the engine compartment temperature is < 145° F. (63° C.) or the engine coolant temperature is < 221° F. (105° C.).

Fan setting 2 is activated in the event of heavy acceleration from standstill. Activation depends on the speed with which the accelerator pedal is depressed and the accelerator pedal travel (depress fully). The same applies to the launch control start on vehicles with Porsche Doppelkupplung (PDK). DME engine electronics 2

DME engine electronics 2

Operating condition: Engine switched off

If the engine has been switched off, the fans can run for up to 25 minutes in order to purge the engine compartment.

Setting 2 runs at an engine temperature > 180° F. (82° C.) until the temperature in the engine compartment has fallen to < 158° f. (70° C.). The fan motors run at fan setting 1 until the engine temperature is < 113° F. (45° C.) in order to reduce the temperature further.

Operating condition: Interruption of fan operation

Fan operation is interrupted if any of the following situations occur: • Engine compartment lid open • Cabriolet only: convertible top open • Battery voltage < 10 volts

Diagnosis

The engine compartment purge fan can be diagnosed using the DME control unit. Drive-link diagnosis is possible using PIWIS Tester II. Detected faults are stored in the DME control unit.