HD HD

Commodities: Rock, pellets, concentrate

Discharge rate: Up to 25,000 tonnes/h

• 15–35 % lower logistic cost

• 57 % lower CO2 emissions

• Less noise and dust

• Optimised for complete unloading

Commodities: Rock, pellets, concentrate

Discharge rate: Up to 25,000 tonnes/h

• 15–35 % lower logistic cost

• 57 % lower CO2 emissions

• Less noise and dust

• Optimised for complete unloading

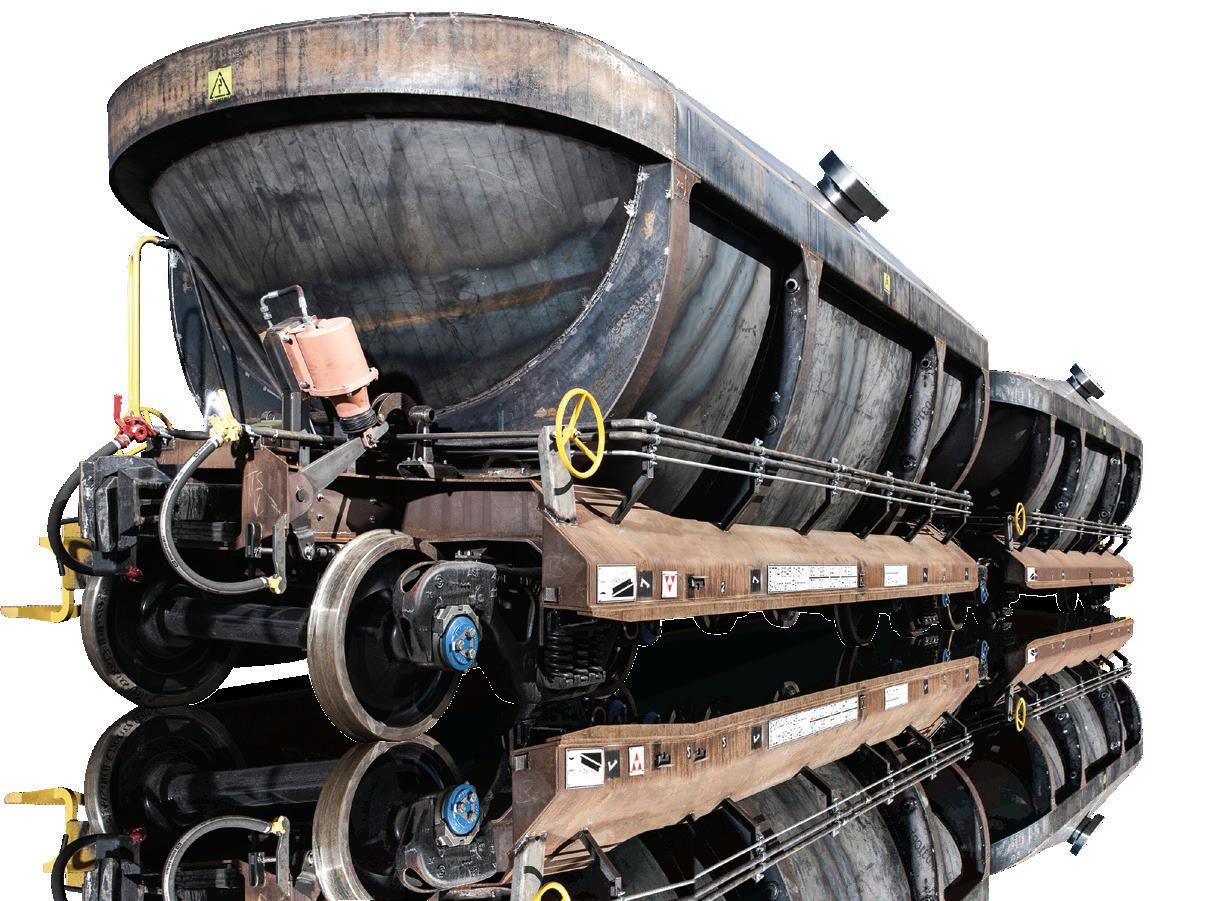

Kiruna Wagon’s Helix Dumper is the wagon of choice for high density dry bulk that doesn’t need to be covered.

The Helix Dumper unloads materials at rates up to 25,000 tonnes per hour. Currently, there is no technology that can match its productivity.

Unloading is powered by the locomotive’s forward motion and the robust and uncomplicated unloader requires no additional power supply. The wagons, as well as the unloader, are designed by Kiruna Wagon, making it possible to optimise the unloading process.

The body is rotated 148° and the run-off angle for the critical bottom material is over 100°.

The Helix Dumper specialises in handling and unloading bulk goods that are both heavy and fine-grained, at high unloading speeds. In comparison, bottom tipping systems work at a fast pace but do not handle sticky materials, and rotary car dumpers are slow and expensive compared to the Helix Dumper with its rolling unloading solution.

The Helix Dumper unloader is a robust and low-cost solution that requires minimal maintenance. When the Helix Dumper enters the unloading area, a wheel at the top of the wagon is in contact with the spiral-shaped rigid guide that constitutes the unloader. As the wheel travels along the path of the guide, the chassis remains on the rails while the body of the wagon is rotated 148 degrees to dump its load.

The unloading process is powered by the locomotive’s forward motion –the Helix Dumper unloader has no moving or motorised parts and requires no additional power supply.

The Helix Dumper unloader is delivered with principle drawings and a maintenance program. Kiruna Wagon will perform the installation, supervise the start-up process and train the operators.

A shallow pit requires a lower investment and less energy for material reclaim and handling.

The greatest potential to increase the logistic performance is by optimising the unloading process.

The Helix Dumper system has low complexity and high unloading capacity. In our study, we compared our system with the dominating RCD, Rotary Car Dumper, by evaluating a set of key performance indicators, selected to reflect the overall performance.

The total logistic costs of the Helix Dumper solution are 15–35 percent lower for annual volumes of 10 million tonnes and more. In addition, the system is also sustainable from a quality perspective, and results in a CO2 reduction of almost 60 percent per transported unit of commodity. Due to the low cost of the unloader, the logistic cost is almost unaffected by annual transport volumes which also makes the Helix Dumper system suitable for transportation of lower annual volumes.

The quantitative qualities were evaluated with a calculation model for a case with 200 km from pit to port.

The Helix Dumper reduces your unloading times and maximises the utilisation of the wagon through the efficient unloading process.

At Kiruna Wagon, we consider average annual wagon speed (AAWS) as one of the most important key performance indicators. In the authentic case of Kaunis Iron’s ore transports from northern Sweden to the Port of Narvik in northern Norway, the Helix Dumper system is designed to operate at 26.1 km/h AAWS.

The AAWS of our Bottom Dumper wagons for LKAB is 17.5 km/h, while our Bottom Dumper wagons for Rana Gruber operate with an AAWS of 25.7 km/h. On our website, you can download our AAWS Calculator and compare with the numbers of your own fleet.

Kiruna Wagon delivers both wagons and unloaders that increase production and scalability for our customers.

When you buy a system from Kiruna Wagon, you acquire a solution for both transport and unloading of materials.

We consider the whole logistics chain and design systems for efficient transport at the right total CAPEX and OPEX. We are one of very few companies to deliver both the wagons and the unloader.

If the future brings increases in production, the Helix Dumper system can easily be scaled up with one or more additional unloaders.

Thanks to its limited construction depth and lack of electric motors, the Helix Dumper unloader requires a smaller initial investment than, for example, rotary car dumpers.

Wagon Specifications

Station Specifications

All wagon types from Kiruna Wagon can be customised to fit your logistic preconditions. Such as axle load, length, volume, loading profile, AAR, TSI, etc.