Journal of Nutr ient Management

6

Where nutrient management and application meet

12 Guiding farms to more sustainable pathways

16 Making manure shine

Published by W.D. Hoard & Sons Co. August | 2023

FREE GREEN BEDDING TURNING LIQUID GOLD INTO ENRICHED BEDDING WWW.FAN-SEPARATOR.DE MAGNUM CSPH Submersible motor pump gear MSXH Submersible motor mixer SEPARATOR PSS For solid-liquid separation East: Midwest: West: Western Canada: Sales Director: Parts/Operations: Jim Dewitt Trey Poteat Jeff Moeggenberg Rex Harwood Ray Francis Rob Hultgren 1-630-750-3482 1-219-561-3837 1-630-334-1913 1-219-229-8125 1-219-229-2066 1-800-922-8375 j.dewitt@bauer-at.com t.poteat@bauer-at.com j.moeggenberg@bauer-at.com r.harwood@bauer-at.com r.francis@bauer-at.com r.hultgren@bauer-at.com BAUER North America Inc. 107 Eastwood Road, Michigan City, IN 46360, 1-800-922-8375 bnasales@bauer-at.com Call the FAN boys. FAN produces bedding material with a dry matter content of a least 38% in solids FAN PRESS SCREW SEPARATORS - Saves Money * Easy to Maintain * Low Energy Consumption. High – Quality Bedding Made From Manure

Making manure shine

Journal of Nutrient Management

Managing Editor

Abby Bauer

Art Director

Todd Garrett

Editorial Coordinator

Jennifer Yurs

Director of Marketing

John Mansavage

Advertising Sales

Beth Gierke bgierke@nutrientmgmt.com

Advertising Coordinator

Patti Kressin pkressin@hoards.com

Online Media Manager

Patti Hurtgen phurtgen@hoards.com

Digital Marketing Manager

Sam Rasmussen samr@hoards.com

Publisher

W.D. Hoard & Sons Co.

Brian V. Knox, President

CONTACT INFORMATION

Editorial Office PO Box 801 28 Milwaukee Ave. West Fort Atkinson, WI 53538

Website: www.jofnm.com

Email: info@jofnm.com

Phone: 920-563-5551

Journal of Nutrient Management (ISSN# 26902516) is published four times annually in February, May, August, and November by W.D. Hoard & Sons Company, 28 Milwaukee Ave. West, Fort Atkinson, Wisconsin 53538 Tel: (920) 563-5551. Email: info@ jofnm.com Website: www.jofnm.com. Postmaster: Send address corrections to: Journal of Nutrient Management, PO Box 801, Fort Atkinson, Wisconsin 53538-0801. Tel: (920) 563-5551. Email: info@jofnm. com. Subscription Rates: Free and controlled circulation to qualified subscribers. For Subscriber

Services contact: Journal of Nutrient Management, PO Box 801, Fort Atkinson, Wisconsin 53538, call (920) 563-5551, Email: info@jofnm.com.

Copyright © 2023 W.D. Hoard & Sons Company. ALL RIGHTS RESERVED. Content may not be reproduced or used for any commercial activity without express written consent from W. D. Hoard & Sons Company

jofnm.com August 2023 | Journal of Nutrient Management | 3

CONTENTS Find us online at: www.jofnm.com twitter.com/JournalofNM facebook.com/JournalofNM ON THE COVER New technology and equipment help widen the

application window and reduce field compaction. For instance, a field demonstration on a Midwest farm showed how this self-propelled liquid manure spreader with up to 118 feet of dribble bar can be used on a growing crop to gently apply manure on the ground’s surface. Photo by Abby Bauer, Managing Editor. First Thoughts 4 Policy Watch 5 In the Field 10 Manure Minute 15, 21 Fresh Paint 19 Places to Be 24 Nutrient Insights 26 DEPARTMENTS Volume 4 | No. 3

16 4| Opportunity awaits 6| Where nutrient management and application meet 8| Concentrating the contents of manure 10| Corn harvest leaves fields vulnerable 12| Guiding farms to more sustainable pathways 20| Why these farms chose digesters 22| Industry efforts drive sustainability 26| Nutrient management is the driver

manure

Abby Bauer Managing Editor

If you live in an area where livestock outnumber people, manure being used as a fertilizer source is simply common practice. Collected manure needs to go somewhere, and the available nutrients can be put to good use in soil where crops are grown. Manure flows through draglines or travels by tankers to fields nearby.

The scene is much different in other parts of the country. In places where corn and wheat fields span as far as the eye can see, manure is often not easily accessible. In fact, according to numbers from the United States Department of Agriculture (USDA), just under 8% of the 240.9 million acres planted to the seven major field crops of corn, soybeans, wheat, cotton, barley, oats, and peanuts received manure as a nutrient source in 2020.

That number seems small, considering the millions of farm animals that live across the country. Yet, maybe it is not that surprising given that one of manure’s biggest hurdles for use is transportation.

In a USDA report released earlier this year, titled “Increasing the value of animal manure for farmers,” the authors noted that manure has a low nutrient value-to-mass ratio. This is partly due to water content, which can be up to 90% of the manure’s weight in some cases. The sheer volume makes transportation and application costly.

Also, while manure supplies nitrogen, phosphorus, and potassium, it does not come with a guaranteed analysis, and the nitrogen-to-phosphorus ratio is lower than what is required by crops. So, while manure can be a wonderful complement, it is not always a perfect substitute for commercial fertilizer.

Because animal production and manure management differ by region, the amount and type of manure used to fertilize certain crops varies. A breakdown of what type of manure is applied to each of the major crops can be found on page 15.

Corn acres are most likely to receive manure, in part because more acres are planted to corn than any other field crop. Of the acres that receive manure, 78% are planted to corn. More details about this are available on page 21.

Of the 3,109 counties in the contiguous United States, an estimated 390 counties generate more manure-supplied phosphorus than crop production can use, and about 100 counties generate excess nitrogen. The uneven distribution of manure does not make it a hot commodity, though. The authors of the report explained that, if manure-supplied nutrients exceed crop needs, the growers will not demand the extra nutrients, actually lowering the overall value of manure.

To capture more from manure, the report highlighted several opportunities for farms to enhance the fertilizer value or lower its cost of use. This included subsurface application to conserve nitrogen, ration formulation that affects the characteristics of manure excreted, manure additives that can enhance the end-products’ fertilizer value, and composting to remove water and condense the final product. The authors also pointed to liquid-solid separation as a practice that provides several benefits for the high moisture content manure that comes from dairy and hog farms. Other technologies that remove liquid from manure to make it easier to transport are also intriguing options.

Beyond fertilizer, the report also gave a nod to the nonfertilizer uses, including energy production. The feasibility of these potential income streams, however, often depends on the incentives and financial support provided by governmental or private industry sources.

The bottom line is that there are more acres that could utilize the benefits of manure, if we can find ways to move these nutrients farther. If you would like to view the whole report, it can be found at this link: bit.ly/valueofmanure. It is an interesting read and highlights the challenges of manure — and the opportunities that await.

Until next time, Abby

Let us know your thoughts. Write Managing Editor Abby Bauer, 28 Milwaukee Ave. West, P.O. Box 801, Fort Atkinson, WI 53538; call: 920-563-5551; or email: abauer@jofnm.com. FIRST THOUGHTS Opportunity

4 | Journal of Nutrient Management | August 2023 jofnm.com

awaits

WISCONSIN

The state of Wisconsin’s Senate and Assembly showed their support of agriculture by passing Senate Bill 247, which was signed into law as Wisconsin Act 13 less than a week later by Governor Tony Evers. The Agricultural Roads Improvement Program, created under the existing Local Roads Improvement Program, will reimburse local governments for repairs to roads, bridges, and culverts used by farms that are not likely to receive other state aid. The priority for the $150 million in funding will go to projects that serve the largest number of farms or eliminate weight restrictions that can prevent farm equipment from traveling certain routes.

UNITED STATES

A Farm Service Agency exemption for concentrated animal feeding operations (CAFOs) under 1,000 animal units has been vacated by a federal court. In 2016, the agency adopted a rule that exempted CAFOs with fewer than 2,500 pigs, 1,000 head of beef cattle, 700 dairy cows, 125,000 chickens, or 55,000 turkeys from environmental review. A judge ruled that the exemption violated the National Environmental Policy Act. Now, those farms that receive USDA loans will be required to have an environmental assessment.

TEXAS

The cause of a massive barn fire on a dairy in Texas was determined to be an engine fire in a vacuum truck being used to clean manure from the barn’s alleyways. On April 10, a fire and explosion at Southfork Dairy in the Texas Panhandle injured one person and killed approximately 18,000 head of dairy cattle. One employee attempted to put out the fire initially using fire extinguishers, but the fire spread rapidly in the cross-ventilated barn. The incident was determined to be accidental according to state investigators.

THE INNOVATIVE BIOSELECT FOR EFFICIENT MANURE SEPARATION.

MARYLAND

A well-established program that helped farmers in Maryland comply with nutrient application and reporting will be discontinued, according to a recent Maryland Department of Agriculture (MDA) announcement. For more than three decades, many farmers in the state relied on University of Maryland Extension county advisers to develop their nutrient management plans at no cost. However, as of August 31, the MDA will no longer fund the nutrient management program through the University of Maryland’s College of Agriculture and Natural Resources. The MDA said the shift in the program will “focus on a new approach to education, training, and farmer empowerment.” Farmers will now need to hire paid consultants or become trained and certified to write their own plans.

FEATURES:

+ Low Life-Cycle Costs

+ Turnkey from a Single Source: Separator Pump(s) Control Unit Stationary or Mobile Skids

+ Large Capacities

+ Patented Profile Auger with Counter Bearing for No Auger Screen Contact

+ Continuously Variable Dry Matter Content

844-647-7867 | www.boerger.com

POLICY WATCH jofnm.com August 2023 | Journal of Nutrient Management | 5

Where nutrient management and application meet

by Scott Fleming

by Scott Fleming

Farming can take on many forms. In the early days, full tillage and “plowing it black” was the law of the land. Then came the early conservation tillage tools. These were designed to leave more residue on the surface and slow wind and water erosion. A further desire to cut back on tillage led growers to reduced tillage options such as vertical till or strip till. The ultimate reduced tillage

can be found with no-till farming. Today, all of these tillage options can be found on farms from coast to coast. While every grower has his or her reasons for choosing a particular tillage program, how do these styles of farming fit into the world of nutrient management?

N and P — same to me

Phosphorus is unlike nitrogen. It doesn’t start its life at the top of the soil

profile and leach down and out of reach of plant roots. Phosphorus is actually quite the opposite.

Phosphorus anions form bonds with calcium, aluminum, and iron and take on a positive charge. This positive charge forms a strong bond to soil particles that nearly eliminates phosphorus leaching. Phosphorus generally leaves the field still attached to these tiny soil particles, most of which are undetectable to the human

6 | Journal of Nutrient Management | August 2023 jofnm.com

Weaving together nutrient planning and application strategies can be a daunting but worthwhile exercise.

Applying manure to a rye cover crop is one way to help keep nutrients in the field where they belong and are best utilized.

eye. If manure is present in the system, especially surface applied manure, the manure itself may leave the field and contribute to even greater phosphorus losses.

How can we overcome the issue of soil loss and phosphorus loss at the same time? That’s when the soil loss and manure application interface gets more difficult! Effective incorporation serves two very valuable purposes when it comes to nutrient management. The first should be quite apparent at this point. Putting manure below the soil surface makes it far less susceptible to field runoff loss.

The second item may be less clear. When manure is injected into the soil or incorporated promptly, you will make more efficient use of manure nitrogen. This is because manure that is buried in the soil is less susceptible to atmospheric loss through volatilization. Both of these benefits point toward injection or, at the very least, incorporating manure as soon as it’s applied.

But effective incorporation also means soil disturbance. Soil disturbance means greater risk of soil loss. Industry-wide, it seems that two management concepts are coming to the forefront to help growers avoid this higher soil loss.

The first is low disturbance application bars. These bars do everything their name implies — injecting the manure into the soil with as little soil disturbance as possible. They range from cutting small slits in the ground and knifing in manure to row units that function similar to a strip till bar.

The second practice is one that is gaining major traction throughout all of agriculture: cover crops. Cover crops can be planted before or after manure application. Armoring the soil through the use of cover crops protects against the effects of rainfall and will help keep nutrients in the field right where they belong. A cover crop may also help trap applied nutrients from leaching loss over the winter while capturing and upcycling underutilized nutrients from the previous growing season.

In my travels as a nutrient management planner and professional soil sampler, I have seen several combinations of cover crops and manure. A very common method seems to be harvesting corn silage followed by immediate chisel

plowing. About a bushel of oats or rye is then no-till planted into the worked ground. This is followed by manure application with a low disturbance bar a month or two later, once the cover is up and growing well. I have also seen similar variations that broadcast the cover crop seed rather than drilling it in. This seems to have a weaker establishment, but it does help save a trip.

Timing is everything

Another practice that can fit into both manure and nonmanured systems is split application of nutrients. These are particularly important when it comes to nitrogen, as it has a propensity for loss through the bottom of the system. Through strategically timing manure applications closer to crop uptake, growers can reduce the possibility of nitrogen loss due to leaching.

All soils are different and some soils can hold more nutrients than others. Each state has a list of soil types with a high probability of nitrate leaching. Most nutrient management plan rules contain a maximum application rate for manure or fertilizer applications to these soils. Maximum fall application rates may be based on total volume or nutrient content. Some fall applications, especially commercial fertilizer, may be prohibited completely. The actual rules will vary by state.

Additional manure may be applied to these fields if the applications are split up between spring and fall seasons. A common example involves spreading a half rate of injected dairy manure in the fall, then following that up with an additional half rate of manure in the spring. This will allow for a full rate of nitrogen to be applied to a sensitive field in an environmentally sound manner.

With high input prices, more and more growers are looking to spread manure on more acres. A base rate of manure can be laid down on nonlegume ground followed by a supplemental preplant and/or sidedress application of commercial fertilizer to meet total crop nutrient demand. The split application system can be taken a step further by incorporating pre-sidedress nitrate testing (PSNT) or nitrogen models into the equation. Both of these options will help evaluate the quantity of nitrogen still available

from the manure and help fine-tune additional applications.

It’s a precision decision

Technology is advancing rapidly when it comes to optimizing nutrient applications. More and more growers are pulling precision grid PSNT samples. Farmers are still incorporating nitrogen models to estimate follow-up application rates. Improved technology is booming in the sidedress application field.

On the manure application side, flow meters and near infrared reflectance spectroscopy (NIRS) are becoming more prevalent on field equipment. By combining flow meter and/or NIRS data, the exact inputs applied to each area of a field can be entered into data management software. A nitrogen recommendation can then be generated that incorporates all of the small variabilities of large-scale manure application into the recommendation.

Taking things up another level, there are hosts of remote imaging tools available to aid in estimating crop nutrient demand. These can be satellite based, airplane or drone based, or even mounted right to a sidedress application rig. There are many variations, but the general principle remains the same: capture an image of the growing crop, evaluate the need for additional nitrogen, and vary the nitrogen application rate based on the imagery.

Weaving together manure application and nutrient management can be a troublesome task at times. Balancing the risk of phosphorus loss and soil loss while still managing nitrogen leaching and volatilization can seem daunting. However, keeping an open mind, considering the farm management style, utilizing resources and tools available, and turning an eye to the future can help quell some of these challenges to optimize a nutrient strategy.

Growers shouldn’t be afraid to give new technology or even different management styles a try on a few acres. It could turn into the future strategy for the farm.

jofnm.com August 2023 | Journal of Nutrient Management | 7

The author is a nutrient management specialist and sampling director at Rock River Laboratory in Watertown, Wis.

Concentrating the contents of manure

Slow release fertilizer created from swine manure enables sustainable nutrient management for farmers.

by

Iowa is the top pork producing state, generating almost one-third of the nation’s pork supply worth about $40.8 billion in 2020. Each of those 24 million pigs produce about 1.2 gallons of manure every day.

This abundant manure resource can be used as an inexpensive crop fertilizer, with high nitrogen (N), phosphorus (P), and potassium (K) values. Currently, 30% to 40% of nitrogen and phosphorus needed by crops are supplied by manure, and 75% and 60% of Iowa’s available nitrogen and phosphorus, respectively, come from swine manure.

The loss of nutrients

Application of fertilizers beyond what is required by crops is commonly practiced to maximize crop yield. However, overapplication results in excess nutrients ending up in water bodies where it causes algal blooms and degrades water quality. Manure can be especially problematic in this respect.

Although valued as an organic fertilizer, manure is a dilute source of nutrients, making it impractical to transport far from animal barns or feedlots. As a result, overapplication close to the source of the manure is common. Additionally, when farmers apply manure to meet recommended nitrogen or phosphorus rates for a crop, other nutrients can be over applied.

Nitrogen loss from field-applied manure usually occurs as ammonia volatilized into the atmosphere or nitrate leached into the groundwater. On the

other hand, phosphorus loss occurs when this nutrient is added beyond the soil’s phosphorus-holding capacity.

Easier to transport

Recent research at Iowa State University investigated the various ways for separating and concentrating nitrogen and phosphorus from swine manure using biochar and zeolite. These concentrated forms of nutrients can be transported long distances more economically than can manure, thus helping alleviate problems in overapplication of manure.

Iowa State University has produced an engineered biochar by pretreating corn stover with iron sulfate before pyrolyzing it at high temperatures under slightly oxidizing conditions. Biochar

produced in this manner can adsorb phosphorus from sources such as agricultural effluents, industrial and municipal wastewater, and livestock manure. The acidic nature of this engineered biochar slightly reduces the system pH, which helps further stabilize nitrogen as ammonium ion. The mineral zeolite is blended with the biochar to enhance adsorption of ammonium beyond what the biochar can adsorb.

Manure is a complex mixture of colloidal organic compounds and several inorganic nutrients. The charged colloidal particles compete for sorption sites on the biochar, reducing phosphorus sorption capacity of the biochar. This problem can be largely overcome by increasing the loading of biochar. The combination of engineered biochar

8 | Journal of Nutrient Management | August 2023 jofnm.com

Santanu Bakshi, Chumki Banik, Daniel Andersen, and Robert C. Brown

and zeolite was found to slowly release the phosphorus to the soil, thus serving as a slow-release phosphorus fertilizer. Nitrogen was similarly adsorbed by the combination of engineered biochar and zeolite.

manure is the soil quality improvement over time, which is not feasible with inorganic fertilizer use.

The cost of this slow release fertilizer is higher than synthetic fertilizers. However, the combined benefits of nutrient recovery and protecting water quality

will make this slow-release fertilizer increasingly attractive. ■

Although not expected from simple adsorption-desorption theories, ammo nium was also slowly released to the soil. The low recovery was suspected to have happened for two reasons. First, the ammonium release was more related to the pH of the mixture, which progressed with the manure load. Second, the immobilization of ammonium nitrogen by biochar and trapping of ammonium in biochar pores are other possible theories suspected of the low release of the ammonium nitrogen from the biochar-treated manure materials. The formation of mineral struvite and strengite was recorded for nitrogen and phosphorus recovery, which elevated in the presence of biochar. Different phases of iron minerals in the engineered biochar participated in phosphorus sorption. Whereas acidic nature of biochar reduced the ammonium loss from the recovered material, the use of zeolite increased the recovery of the nitrogen through specific adsorption to a great extent.

Weigh the benefits

Nutrient loss is a common problem for both inorganic and organic fertilizers. Thus, concentrating the manure nutrients can benefit the environment as the inorganic fertilizer price is progressing with our daily crop needs in the current fertilizer market. The additional benefit of using nutrients recovered from

jofnm.com August 2023 | Journal of Nutrient Management | 9

Authors Chumki Banik and Santanu Bakshi show how biochar can be used to extract nu trients from manure.

Gannon, Iowa State University.

(920) 948-9661 | www.pippingconcrete.com dennis@pippingconcrete.com 37+ years in business | U.S. Navy Seabee Veteran AGRICULTURAL CONCRETE THE NATION’S LEADER IN AGRICULTURAL CONCRETE OUR TANKS ARE NRCS PRE-APPROVED! THE TANK BUILDER

The authors are all with Iowa State University. Bakshi and Banik are research scientists, Anderson is an associate professor, and Brown is a professor.

CORN HARVEST LEAVES FIELDS VULNERABLE

Fields left bare after harvest can lead to soil loss and water quality issues; corn silage fields are especially problematic.

by Amber Radatz

Corn silage is one of the main forages harvested for cattle feeding in the United States. Seven states made up over half of the 6.86 million acres harvested in 2022. Wisconsin leads the nation in corn silage production.

While there are benefits to corn silage from a nutrition standpoint as well as ease of harvest, harvested corn silage fields can be an area of environmental vulnerability. The areas of opportunity for water quality improvement in these fields relate to management changes that prevent long periods of exposed soil.

Differences between crops

In Wisconsin, runoff happens annually, no matter the crop type, because of long periods of frozen soil, spring rain and snowmelt, and typically over 35 inches of precipitation per year. While runoff is often controlled by weather, especially while the soil is frozen, the amount of soil and nutrient loss contained in the runoff varies by crop type and can be controlled by management. Typically, annual runoff from Wisconsin cropping systems is less than 5 inches. This does vary slightly by crop type and depending on the weather in any given year.

Discovery Farms data show that there is more risk for soil loss during corn silage years. This is based on the amount of soil disturbance or tillage and the amount of time that the soil is bare (or bare and disturbed) in the fall, winter, spring, and early summer.

Overall, most soil losses occur during May and June, and in years following corn silage, the soil is largely bare from September until the following June.

Discovery Farms data reveal that average monthly soil loss following corn silage is three to five times higher on tilled fields compared to no-till fields. Corn silage has the highest risk for soil loss compared to alfalfa, corn for grain, soybean, and pasture (Figure 1).

On corn silage acres, no-till management will reduce soil losses. In addition, corn silage fields are one of the easiest places to establish a cover crop, since

there is still plenty of growing season left after harvest. Farmers are even seeing success with planting the following year’s crop directly into the green cover crop. This amount of soil protection during May and June — when the risk for soil loss is the highest — will help keep soil in place.

Noticeable nutrient losses

When soil leaves the field, we aren’t just losing productivity and moving sediment somewhere downstream; phosphorus also goes with it. From Discovery Farms research, phosphorus losses are

10 | Journal of Nutrient Management | August 2023 jofnm.com IN THE FIELD

3,000 2,000 1,000 0 Soil loss (lb./ac)

Figure 1. Annual soil loss values by crop

Alfalfa/ grass CornCorn silage New seeding Soybean

Figure 1: Box plots representing annual soil loss values from Discovery Farms sites separated by crop type. Bottom line is 25% of values, middle line is median, and upper line is 75% of values.

higher from corn silage fields as well. Most of the loss is particulate phosphorus (Figure 2), which means it is bound to soil. Data indicate that lessening soil loss through reduced tillage and greater soil cover is the first step to cutting phosphorus loss, and thus improving a farm’s water quality impact.

Establishing a cover crop after corn silage harvest has manure application and nutrient uptake benefits in addition to soil conservation benefits. In a study done by Matt Ruark and Monica Schauer with the University of Wisconsin-Madison Department of Soil Science, they looked at the biomass and nitrogen uptake of a rye cover crop following corn silage.

In terms of biomass, 60 pounds per acre was the best rye seeding rate to optimize ground cover and nitrogen uptake benefits. This seeding rate resulted in 72% ground cover in the spring, which was similar to ground cover at higher seeding rates. At this seeding rate, the nitrogen uptake from the rye cover crop was 43 pounds per acre. Higher seeding rates did not yield better environmental benefits, but it would be an extra cost to the farmer.

Capture the manure nutrients

In this study, liquid manure was surface applied at 10,000 gallons per acre just before the rye was planted. In the absence of a cover crop, the nitrogen and phosphorus from manure would have no living roots to utilize the nutrients for six to seven months. This allows nutrients to leave the field via runoff and leaching, especially when there is very little residue left on the field after corn silage harvest.

In terms of impact to the following corn crop harvested for grain, the economic optimum nitrogen rate was slightly higher in the cover-cropped areas when soil nitrate values in non-cover-

cropped areas were similar from fall to spring. However, in the other year of the trial, soil nitrate values in noncover-cropped areas fell from fall to spring due to nitrate leaching. This resulted in similar optimum nitrogen rates, and no significant impact to yield, whether the area had a cover crop or not. If manure or fertilizer needs to be applied in the fall, it is best to have a living plant in the soil to capture some of those nutrients.

Corn silage fields are an opportunity to make positive water quality impacts. First, prioritize no tillage or low soil disturbance after corn silage harvest to cut back soil loss through surface runoff. Next, plant a cover crop immediately after harvest to protect the soil from erosion and to capture nutrients so that they will be available for future crops and, most importantly, not lost to surface or groundwater resources. As you continue to evaluate your farm’s future, consider ways to reduce the vulnerability of your current system to soil and nutrient loss.

The author serves as the agriculture water quality program manager for the University of Wisconsin-Madison Division of Extension. She would like to thank Lindsey Hartfiel and Monica Schauer for providing this information in their presentations at the Dairy Innovation Hub Symposium.

jofnm.com August 2023 | Journal of Nutrient Management | 11

1.25 1.00 0.75 0.50 0.25 0.00 P loss (lb./ac)

Figure 2. Annual phosphorus loss by crop

Alfalfa/ grass CornCorn silage New seeding Soybean

Type DP PP

Figure 2: Median annual phosphorus loss from Discovery Farms sites separated by crop type. P=Phosphorus, DP=Dissolved reactive phosphorus, PP=Particulate phosphorus

Guiding farms to more sustainable pathways

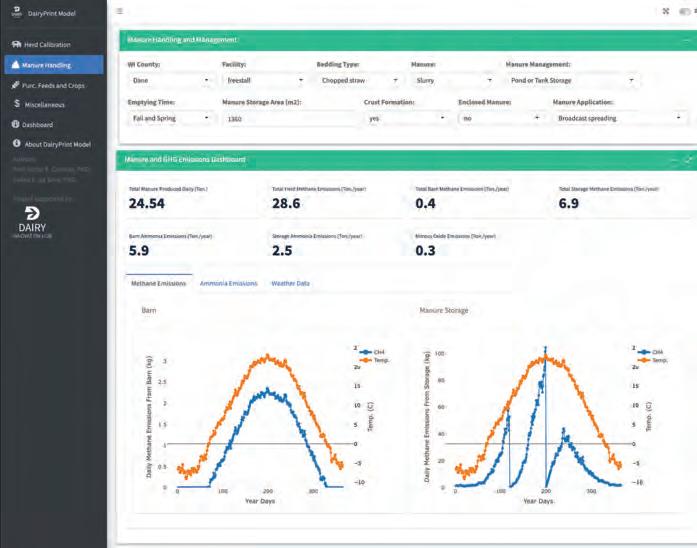

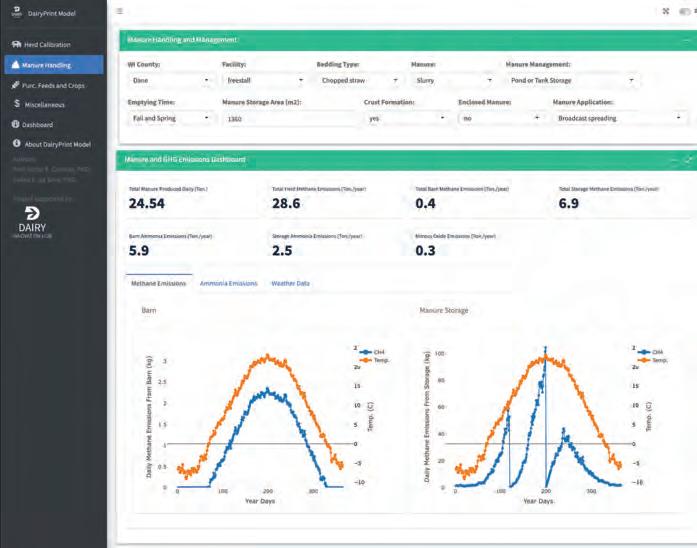

The DairyPrint Model is a simple way to assess economic and environmental trade-offs for nutrient management decisions.

by Tadeu da Silva and Victor Cabrera

Dairy farmers are under pressure due to the environmental impacts of greenhouse gasses (GHG), such as methane, nitrous oxide, and carbon dioxide emissions, which have been pointed out as contributors to global warming and climate changes. Furthermore, dairy farms can be sources of polluting elements such as phosphorus and nitrogen, potentially contaminating soils and groundwater when nutrients are not properly handled in those systems.

However, monitoring both GHG emissions and nutrient balance on dairy farms is a difficult and prohibitively expensive task. The most viable alternative for estimating GHG emissions and performing nutrient balance calculations for dairy farms has been the use of mathematical models.

Mathematical models constitute an important tool for the decision maker in the sense of offering diagnosis and guidance for designing strategies to mitigate GHG emissions or nutrient excretion. Fortunately, there are already several reliable model options that can be used with this purpose. The options out there vary in the types of approaches and levels of complexity, ranging from simple emissions factors to the use of process-based modeling, contemplating small details inherent to each step of the processes that occur inside a dairy farm.

Nevertheless, most of these models fail to reach end users and decision-mak-

ers because they require a significant amount of inputs to be populated and experience or training before they can be used. In this context, the DairyPrint Model takes its place as a high-level, simple, minimalistic, user-friendly, still

powerful, and scientifically sound wholefarm decision support model to assess economic and environmental trade-offs of dairy farming for strategic nutrient management decisions.

The DairyPrint Model is minimalistic

12 | Journal of Nutrient Management | August 2023 jofnm.com

Figure 1. Screenshot of the manure handling selected options and estimates of greenhouse gasses emissions performed by the DairyPrint Model.

regarding the inputs required, avoiding complex data-retrieving and focusing on the most relevant input variables. Moreover, it has a very user-friendly and intuitive graphical interface, allowing the user to set up their baseline scenario and easily interact with the tool to respond to “what-if” questions. For each simulated scenario, the user is able to explore the model interface, analyzing the main outcomes in detail through interactive dashboards and simple reports (Figure 1).

The model and its bases

The DairyPrint Model is being developed in a modular fashion, comprising the herd, manure handling, crop and feeds (homegrown and purchased), and economic modules. The herd module is the main driver and input provider for the other modules.

In the herd module, based on user inputs such as total number of cows,

calving interval, replacement rate, and age at first calving, the model runs the simulations performing herd dynamics in monthly steps, estimating the herd demographics throughout the year. In addition to the herd demographics, milk yield curves and milk composition, body weight, dry matter intake, water intake, and feed efficiency are estimated. These outcome variables, along with diet inputs, are used to estimate the total mass of excreted manure, urine, feces, nitrogen (N), phosphorus (P), and potassium (K), in addition to enteric methane and nitrous oxide emissions. The equations used in the model come from well-known literature sources (such as NRC 2001, IFSM, IPCC, and others) and were selected based on simplicity but keeping relevance.

From the herd module, there is a distribution of the produced outputs into other modules, in addition to the specific user inputs for each additional

module. The economic module receives the dry matter intake (DMI) and milk yield from the herd module so that, in addition to inputs such as the cost of diets, total income, and income over feed cost (IOFC) are calculated.

The barn module receives all the manure produced and from it, along with information from weather data and type of facility, methane and ammonia emissions are estimated. The manure is transferred to the manure module, where it is handled and processed according to the practices adopted by the farm. The way manure is handled affects the amount and type of GHG emitted in this process.

Then, the processed material is distributed to the crop fields in the crop module. In the crop module, all GHG emissions are accounted for due to the application of manure, chemical fertilizers, and limestone. Additionally, emissions from feeds that are purchased on

jofnm.com August 2023 | Journal of Nutrient Management | 13

800.628.6196 OXBO.COM CAPACITY THAT KEEPS APPLYING Liquid or Dry, Oxbo has the SOLUTION OXBO.COM

the farm are accounted for in terms of carbon dioxide equivalents (CO2e).

After accounting for all the processes that emit GHG, normalization for the calculation of CO2e is carried out using 100-year global warming potentials of 28 for biogenic methane and 264 for nitrous oxide. Based on the total sum of CO2e, and dividing the same by the total amount of milk produced in the year corrected for fat (4%) and protein (3.3%), an approximation of the carbon footprint of the farm is estimated. In addition to GHG emissions and carbon footprint, nutrient balances (N, P, and K) are also estimated.

Evaluating emissions

To demonstrate some scenarios, we first set up an average herd in the DairyPrint Model. For this, we considered a Wisconsin dairy farm located in Dane County with 150 Holstein cows housed in a freestall barn. Average weight at maturity of 1,500 pounds, with a calving interval of 15 months, culling rate of 35%, age at first calving of 24 months, average milk production per cow of 88 pounds per day, and cows

milked three times a day. From this initial configuration of the herd, we designed three scenarios:

Scenario 1: Baseline Chopped straw as the bedding type, slurry manure, crust formation, no biodigester, and manure lagoon emptied in the fall.

Scenario 2: Manure pond emptied twice a year — Chopped straw as the bedding type, crust formation, slurry manure, no biodigester, and manure lagoon emptied in fall and spring.

Scenario 3: Biodigester — chopped straw as bedding type, slurry manure, with biodigester (30% of efficiency), pond emptied in fall and spring.

As seen in Figure 2, we analyzed the scenarios from two different perspectives: in relation to the absolute total methane emission and with respect to the emission profile, represented by the proportions.

In terms of absolute methane emissions, we can see that both the manure lagoon emptied twice a year and biodigester scenarios were able to reduce emissions by 32% and 37%, respectively, compared to the baseline. The twiceyearly emptying of the manure storage significantly reduces the amount of

volatile solids available in the lagoon, making emissions low because less substrate is available for fermentation with less volatile solids, and therefore, less methane is produced.

In the case of the biodigester, the fermentation process of the volatile solids in a controlled environment allows the gas produced to be captured and used on the farm, such as generating electricity or being burned to heat water on the farm. When burned, methane is converted to carbon dioxide, then returning to the natural carbon cycle, not being accounted for in GHG emissions.

The reduction associated with the use of sand as a bedding type is due to the significant reduction in the amount of volatile solids reaching the manure lagoon. These solids have the potential to be biodegraded and produce methane gas as a result.

Although there is currently a lot of research focused on reducing enteric methane emissions via diets, nutritional additives, genetics, and so forth, we think there are low-hanging opportunities regarding potential GHG emission mitigation by better managing manure and using it as an energy source for the farm. As shown in Figure 3, in terms of absolute ammonia emissions, we can see that a manure lagoon emptied twice a year slightly reduced ammonia emissions.

On the other hand, the biodigester scenario elevated the total ammonia emissions and also the contribution of manure storage emissions compared to the baseline. The rise in ammonia emissions with the use of biodigesters is explained by the fact that part of the N is converted from organic to inorganic form during the fermentation process. Therefore, there is more N available for volatilization in the manure storage, increasing losses to the atmosphere.

Our main objective of this example was to demonstrate the ability of the DairyPrint Model to provide rapid diagnosis and answer “what-if” questions to help in the decision-making process. The DairyPrint Model is available at https://bit.ly/DairyPrintModel.

14 | Journal of Nutrient Management | August 2023 jofnm.com

Figure 2. Methane (CH4) emissions from the scenarios evaluated.

Figure 3. Ammonia (NH3) emissions from the scenarios evaluated.

The authors are with the University of Wisconsin-Madison where da Silva is a postdoctoral researcher and Cabrera is a professor and extension specialist.

Baseline Manure pond emptied twice a year Biodigester

CH4 54.7 ton/year CH4 37.0 ton/year CH4 34.6 ton/year NH3 5.40 ton/year NH3 5.37 ton/year NH3 6.05 ton/year Manure storage Barn

Herd Barn 96% 52% 96% 77% 86% 83% 4% 1% 1% 1% 4% 14% 16% 22% 47%

Baseline Manure pond emptied twice a year Biodigester

Herd

THE SOURCE DEPENDS ON PROXIMITY

Livestock manure serves as a valuable nutrient source for an array of crops, from corn to peanuts. A challenge of utilizing manure is that it cannot be transported far distances, and for this reason, farmers typically apply manure from the species of livestock most abundant in a particular area. For example, since most hogs are raised in the Midwest, many corn and soybean acres grown in this region receive hog manure applications. In the Southeast, where poultry farms are more plentiful, poultry litter is used on the cotton and peanuts fields that are common in that area.

According to the USDA, manure was applied to about 8% of the 240.9 million acres planted in 2020 to the seven major field crops of corn, soybeans, barley, oats, wheat, cotton, and peanuts. This chart shows the distribution of manure type by species that is applied to each crop.

Source: USDA’s “Increasing the value of animal manure for farmers” report, published March 2023.

jofnm.com August 2023 | Journal of Nutrient Management | 15 MANURE MINUTE

INVEST IN QUALITY ® www.kuhn.com Visit our website today to locate a Dealer near you! PXL 100 SERIES PROSPREAD® Commercial Apron Box Spreader 865-1,230 cu. ft. capacity • truck & trailer models

Withstand heavy loads with stout, commercial-grade undercarriage

HIGH-USAGE , HIGH-CAPACITY SPREADING

Multiple discharge options to best suit the needs of your operation Reversible apron easily clears any unforeseen obstruction or blockage Guillotine endgate increases material flow management

and metering

Manure solids are separated by a centrifuge and then loaded into a dump truck for transportation to the field where they will be placed in windrows and composted.

Making manure shine

The addition of a centrifuge helps this farmer better utilize the already valuable manure produced on his southern dairy farm.

by Abby Bauer, Managing Editor

Not all that glitters is gold, and not all that has worth sparkles or shines.

Louisiana dairyman

Brent Duncan considers manure to be “a diamond in the rough.” Manure has always played a key role on his farm in terms of fertilizing crops, but an investment in manure processing technology helped him add a little polish to that plentiful resource.

Duncan is a third-generation dairy farmer. His parents, Ray and Neta

Duncan, still live on the farm and have enjoyed watching their son and his wife, Laurie, grow the business since they took over operations in 1989.

Just a mile from the Mississippi state line, their location in the Deep South faces extreme heat. Just days before our conversation, they were dealing with a 115°F heat index, and heat indexes over 100°F are the norm for their summers. Duncan noted that relief from the hot conditions typically doesn’t come until mid-October.

To keep animals cool, they ensure all fans are running in the barns. They offer shade in the pastures for heifers and cows, and they make certain all waterers are clean. Still, the hot weather is hard on the cattle, and milk production often drops 10 to 12 pounds per cow per day during these heat waves.

“You have to go with the flow and do the best you can,” Duncan said.

Duncan grew up with his parents and siblings on the farm, spending many hours milking with his mom in

16 | Journal of Nutrient Management | August 2023 jofnm.com

their small flat barn parlor. The farm has grown from the 80 cows they were milking in the 1980s to between 500 and 600 lactating cows today. With an excellent calf program headed up by Laurie and the use of sexed semen, the Duncans have plenty of heifers, but encroachment from growing cities nearby puts a limit on how big their herd can be. Instead of milking more cows, they cull heavily, replacing the older cows with 2-year-olds.

Willing to invest

Duncan said his philosophy has always been to invest in the dairy. At one point, they were milking 600 cows in a 32-stall flat barn parlor, a system that worked for the cows but burnt out their employees. On a trip to California, a rotary parlor caught Duncan’s attention, and he told Laurie that was what they needed.

In 2013, they installed a 40-stall rotary, the first rotary parlor in the state. Today, cows are milked twice a day, and the Duncans maintain excellent milk quality, with an average herd somatic cell count around 150,000 cells/ mL, sitting below the national average.

Technology in the parlor records daily milk production. The cows also wear neck collars with monitors that track activity. Cows can be diverted electronically using a sort gate and are bred in the old flat barn parlor. For the most part, heat detection is based on activity levels, and Duncan said the animal tracking system is “worth a million bucks right there.”

The lactating cows are housed in three barns, with stalls that are bedded with sand. Cows also spend time on pasture.

Their herd is certified organic, and the Duncans have been shipping organic milk to a major grocer in the Southeast for more than 15 years. That transition was, interestingly enough, initiated by the use of poultry litter. A friend of Duncan’s put up several poultry houses, as did a few other farms in the area. Duncan began using the litter to fertilize fields where he was planting rye and pearl millet to graze and greenchop. Since they were already grazing, his friend suggested he look into organic milk production. Duncan said he wasn’t using antibiotics on his cows anyway, so he followed his friend’s advice. Their first load of organic milk

was sold in 2007, and Duncan said he is extremely satisfied with the decision to go this route.

Nothing better than manure

Using manure as a nutrient source is something Duncan is passionate about.

“We are taking a product we have

and utilizing it. Nothing grows crops better than manure. Nothing works better,” he stated.

The Duncans manage 1,300 acres of owned and rented cropland and pastureland. They do all their own fieldwork, including liquid and solid manure application.

Digester Tanks

jofnm.com August 2023 | Journal of Nutrient Management | 17

Manure Tanks jptank.com • 920-948-2286 NRCS PRE-APPROVED! WE

TANKS

BUILD

Manure from the cows is scraped out of the barns and stored in a lagoon. Duncan had tried his hand at composting in the past, but he found the manure to be too wet to dry down in a reasonable time frame. He wasn’t sure exactly what he was looking for, but he wanted something more to add to their manure system and started looking into options.

A window of opportunity came in the form of a phone call from Jason Edwards, who at the time worked for an oil field solids control company. When the oil business crashed in 2020, that business was looking to get into the environmental side of things and transition into working with dairy farmers wanting to separate solids from manure.

Based in Colorado, they had their eyes set on installing equipment on farms in the Southeast. A cold call to Duncan turned out to be a perfect match. After Duncan heard their initial pitch, he told Edwards, “I’ve been looking for someone like you.”

The dump truck hauls the solids out to the field where they create windrows, turning them to aid in the composting process. These solids are eventually distributed onto the crop fields using a poultry litter spreader.

Some of the solids are also sold to locals who utilize them as a fertilizer source in their gardens. The farm is simply selling by word of mouth right now, but Duncan is considering other options for packaging their product.

The benefits of the manure solids are apparent to Duncan. Using these solids on their fields “makes a world of difference,” he said. “It does an excellent job, and it is all the nutrients you need.” He has found that fields that used to yield two cuttings of hay are now able to produce three or four cuttings.

They also use the solids on the alleyway floors in their barns to help prevent slipping. They used to purchase sawdust for this purpose, but Duncan said they can now make use of this product they already have.

utilize it,” he said. He feels the centrifuge speeds up the composting process, making it much quicker and more efficient to use the manure as fertilizer. The system also allows them to process manure as soon as it leaves the barn.

He takes pride in the fact that their farm is a closed loop. All feed grown on the farm is fed to their animals, and the cows turn that feed into milk. Heifers raised will someday fill the milking stalls. Manure produced by their animals is used as fertilizer, which they apply to their cropland and pastures as an investment in future soil health. It’s a simple model of sustainability.

After the installation, manure from their lagoon now goes through a dredge to sort out the biggest solids, then through a screen, and then to the centrifuge manufactured by Kayden Industries, the company where Edwards now works. It spins and further separates the solids from the liquid.

The centrifuge is located on a platform so a dump truck can be placed underneath it to catch the material. Duncan said this makes the system more efficient, eliminating the need for someone to load those solids into the truck.

As for the liquid that comes out of the centrifuge, it is either pumped back into the lagoon until it is time for application or put directly into their 4,000-gallon tanker and applied to the land. This nutrient-filled water is applied to pastures and hayfields three to four times a year. Duncan said that with the solids removed, it really penetrates the soil, getting the nutrients down where the plants need them.

Maintaining a closed loop

Duncan was inspired to do more with manure because he didn’t like seeing any of it go to waste. “I wanted to capture and

However, from the rotary parlor to the centrifuge, Duncan has not shied away from bringing technology to his farm that is uncommon in that part of the country. He is the only dairy in Louisiana to milk with a rotary parlor, and as far he knows, he’s the only farm utilizing a centrifuge system in that region.

“I’m always thinking outside the box,” he said. “I have always tried to be innovative and look for better opportunities.”

Duncan acknowledged that the centrifuge, compost turner, and new manure pump were expensive, but he is pleased with the product he receives in return.

“I invested quite a bit in the system,” he said, “but it was absolutely worth it.” For Duncan and many other livestock farmers, a commitment to proper manure management and further processing helps this valuable nutrient source shine a little brighter.

18 | Journal of Nutrient Management | August 2023 jofnm.com

Laurie and Brent Duncan own Duncan Acres Dairy in Franklinton, La.

With a desire to keep investing in their dairy, the Duncans installed the state’s first rotary milking parlor in 2013.

BAZOOKA FARMSTAR UNVEILS THE DRIBBLE BAR 2

Bazooka Farmstar is pleased to announce the release of its latest product, the Dribble Bar 2. This upgrade to the original Dribble Bar offers even greater precision, durability, and efficiency, making it an indispensable tool for any pumping operation.

The Dribble Bar 2 has been designed to withstand even the most challenging conditions, from rocky, uneven terrain to heavy use, ensuring years of reliable service. Additionally, the Dribble Bar 2

is easier to use than ever before, with a range of state-of-the-art features that make manure application a breeze. With its Y-shaped drop tubes and upgraded 3-inch Bumblebee hose, the Dribble Bar 2 ensures a more direct path for trash to exit the system, reducing the risk of plugging and ensuring uniform distribution. Other features of the Dribble Bar 2 include hydraulic, rear folding wings for safe and fast transport, a standard flux manifold for accessible

PUCK ADDS FEATURES TO THE TTR 20

Puck Enterprises is ready to introduce the latest innovative updates to our flagship product TTR 20. The TPU hose used today gives manure applicators a more reliable hose and more capability to inject at higher rates (gallons per minute) than before. As the durability of TPU hoses continues to evolve and get thicker, more room is needed to carry these improved hoses. To accommodate for the larger TPU hoses without losing efficiency, the TTR 20 now has room for two additional 8-inch hoses, or room for 2 miles of 8-inch plus two drags. If you have a larger hose, the TTR 20 can manage 1.5 miles of 10-inch hose plus drags. Alongside the increased capacity, the TTR 20 will now come standard with a hydraulic jack, step pockets

in the rear, new sheet metal, and an increased balance when running up and down the road. The covered slewing bearing swivel was maintained to keep mud and the hose from damaging the body of the cart. Additionally, the new modular components, like the widened bolt-on fenders, will help keep debris off the cart. When working in the field and getting equipment dirty, operators don’t have to worry about slipping or falling off the hose reel; Puck has added widened steps and grip tape along the sides.

The rugged A-frame chassis and 710 radial tires give the turn table reel a robust look while maintaining traction in the field. The hose reels feature our patented Arch Guard and domed reel ends to allow for safe placement and

cleaning and even manure distribution, and a coverage width of 44 feet. Operators can apply anywhere from 5,000 to 25,000-plus gallons per acre through the dribble lines spaced one foot apart.

The Dribble Bar 2 is available now, with optional upgrades, including a pipe swivel with hose swivel for easier turning and a 6-inch Krohne Flowmeter for precise flow measurement. To learn more, please visit www.bazookafarmstar.com or call 1-800-775-7448.

overlap as you roll and unroll your cart, without worry of the hose twisting, kinking, or falling off. To help the operator safely load the hose, rear LED lights help illuminate the cart where the tractor lights cannot reach.

For more information, visit www. puck.com or call 712-655-9200.

FRESH PAINT

jofnm.com August 2023 | Journal of Nutrient Management | 19

Why these farms chose digesters

Three farms shared a few reasons why they utilize anaerobic digesters on their dairies.

by Abby Bauer, Managing Editor

naerobic digesters are one way to capture more value from manure, but they come with a substantial price tag. Farm owners must consider the pros and cons before committing to this longterm investment.

During the Dairy Business Association’s Dairy Strong conference held in Madison, Wis., a panel of three dairy farmers discussed their vision of the industry in the next 10 years. Knowing that these three farms all operated anaerobic digesters, an audience member asked the panelists why they chose to go that route and what they hoped to get out of a digester on their dairy.

For Brian Houin of Homestead Dairy in Plymouth, Ind., he said they invested in a digester in part to improve the farm’s sustainability. “Our goal is to continue to work on our environmental stewardship and work toward net zero,” he said.

“Of course, we want there to be an economic return, too,” he continued. “We are all entrepreneurs. We want to invest in ourselves and our business.” The dairy made the financial investment in their first digester 10 years ago, and Houin said they’d likely go the independent route again rather than signing a long-term contract with a partner if they decide to install another one.

Christina Zuiderveen, a managing partner of Black Soil Dairy, Hope Dairy, and Dakota Plains Dairy, said that access to upfront dollars allowed them to invest in some expansion,

including a digester. She also noted the need for the project to make economic sense. “We are running a business, and we need to be profitable,” she said.

As for benefits, installing a digester and a sand separation system on one of their dairies improved their manure management, along with cow comfort and bacteria counts. Zuiderveen also touched on the sustainability piece, noting that it is not a requirement but their processer encourages them to work toward environmentally friendly goals.

Lee Kinnard, a dairy farmer from Kewaunee, Wis., shared another reason why their family chose to go the anaerobic digester route.

“Digesters are very expensive, with a

wide learning curve and a lot of things to understand. What attracted us was not the digester itself, but the technology that is available off the back of the digester,” he said. Kinnard is excited about options such as evaporative technology that can be used to condense digested manure into a denser product that is more cost-effective to transport to fields farther away if needed.

Their answers to the question placed sustainability, economic benefits, and technology opportunities at the top of the list for why these farms operate anaerobic digesters. A longer conversation with each producer would no doubt unearth many more benefits, challenges, and lessons learned.

20 | Journal of Nutrient Management | August 2023 jofnm.com

Anaerobic digesters were the topic of discussion for these panelists during the Dairy Business Association’s Dairy Strong Conference held earlier this year. Pictured are moderator Spencer Chase and dairy producers Lee Kinnard, Christina Zuiderveen, and Brian Houin.

MANURE MINUTE CORN RECEIVES THE MOST MANURE

When it comes to manure application of field crops, corn acres are the main target. In 2020, the United States Department of Agriculture (USDA) reported that 90.8 million acres were planted to corn, more than any other field crop. Of all the acres that received manure, 78% of them were planted to corn. A larger percentage of corn acres — 16.3% — receives manure than any other crop.

According to USDA’s “Increasing the value of animal manure for farmers” report, corn also had the highest manure application rates, at 92 pounds of nitrogen per acre. In all, those corn acres received 410,000 tons of manure nitrogen, which was 81% of the total applied nitrogen from manure that year.

For the field crops, soybean followed in second place, representing 9.9% of all manured acres, but just 2.3% of the nearly 83.1 million acres planted with soybeans received manure. Peanuts followed corn in terms of percent of acres manured, with 12.2% of the almost 1.7 million acres planted receiving manure application. Oats followed right behind, with 12% of almost 3 million acres receiving manure.

Overall, just under 19 million acres planted to field crops in 2020 received manure as fertilizer. In addition to these field crops, manure

is obviously also applied to hay and grassland. USDA data from 2006 showed that 26% of manured acres were planted to hay and grass.

Reimagine youR ResouRces

High-performance separation

Maximize your manure’s potential with the new GEA SlopeScreen™ separator and OptiClean™ automatic cleaning system. The improved modularity of the SlopeScreen combined with the superior cleaning power of OptiClean delivers adaptability, reliability and efficiency using less labor.

Source: USDA, Economic Research Service. 2020 planted acreage estimates are from USDA, National Agricultural Statistics Service (NASS) Acreage report. Manure share is based on USDA, ARMS Phase II surveys, 2013 through 2019. 2020 manure acreages are estimated by multiplying 2020 planted acres by the share of crop acres manured from the 2013-19 ARMS Phase II surveys.

jofnm.com August 2023 | Journal of Nutrient Management | 21

the GEA SlopeScreen in action

Watch

Field crop Share of acres manured (%) Share of all manured acres (%) Corn 16.3 78.1 Soybeans 2.3 9.9 Wheat 2.0 4.8 Cotton 4.2 2.7 Barley 5.0 1.6 Oats 12.0 1.9 Peanuts 12.2 1.1 Total 7.7 100

Industry efforts drive sustainability

Animal agriculture as a whole will play a role in future environmental solutions, and a variety of industry organizations have already made commitments to improve sustainability.

by Liz Matzke

Sustainability is a word we hear all the time, but what does it mean for animal agriculture? No one program or initiative encompasses all of agriculture, but that doesn’t mean that progress isn’t being made.

Take the poultry industry, for example. According to the American Egg Board, between 1960 and 2010, the egg industry enhanced efficiency while reducing its carbon footprint, including a 71% reduction in greenhouse gas emissions and using 31% less energy. Still, there is more work to be done and improvements to be made in how we measure and track sustainability efforts.

That is why the organization conducted a life cycle evaluation, measuring the use of water, land, and energy; levels of carbon dioxide emissions; waste; and more. It’s a way of calculating the environmental impact across the industry using validated and science-based formulas.

Verifying pork’s commitment

“Sustainability looks different to everyone, depending on perspective. It looks different to Pepsi, it looks different to Walmart, and it looks different to pig farmers,” said Marguerite Tan, director of environmental programs for the National Pork Board, during a webinar hosted by the Livestock and Poultry

Environmental Learning Community.

“I think of sustainability as a vehicle, driving to the same location,” she continued. “We are driving different makes and models, and we are taking different routes, and that’s okay.”

For the pork industry, Tan said their efforts are best defined using the United Nations’ sustainability goals. “The United Nations created a global framework for alignment and communication of sustainability through 17 goals, including zero hunger and responsible consumption and production,” she explained. “The United Nations defines sustainability as meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

To align with these goals, the National Pork Board leveraged the pork industry’s existing We Care Ethical Principals, which was a program established more than a decade ago. It is based on producer commitments to continuous improvement. This program focuses on six key areas: food safety, the environment, people, animal well-being, public health, and community. Overall, a holistic approach is taken when defining goals, realizing that raising pigs is a biological process and has a delicate balance to ensure the best quality of life.

“Everything is interconnected,” Tan said. For example, she said that

reducing stocking density may raise heat and fuel needs in a barn. “We need to balance impacts from one area on another.”

The We Care program is a producerled initiative that unifies the voice of the pork industry and provides third party verification. Since the program is 100% voluntary, it focuses on farm practices that are practical, affordable, and easily implemented.

In late 2021, the National Pork Board launched the Pork Cares Farm Impact Reports powered by the Eco-Producer Platform to track data, measure improvement, and provide third-party verification. These reports are available to producers nationwide. In addition to the Pork Cares Farm Impact Reports, in 2023, the We Care Application was launched. This application is a data warehouse which aggregates data collected in the Pork Cares Farm Impact Reports and via other platforms to ensure the accuracy of the pork sustainability story and provide benchmarks against the pork industry’s sustainability goals and metrics, such as land use, carbon footprint, and biodiversity, to name a few. The Pork Board is using these metrics as a springboard to develop continuous sustainable improvement plans and show overall sustainability progress. “This framework is focused on real

22 | Journal of Nutrient Management | August 2023 jofnm.com

pigs, real pork, and real sustainability,” says Tan. “We are confident we can show proof of our commitment to continuous improvement and sustainability.”

The pork industry has already made strides in efficiency. According to Tan, we need almost 20% fewer pigs today than we did to produce the same amount of pork in the 1990s. That equates to 25.9 million fewer hogs.

Tools for the beef supply chain

Founded in 2015, the U.S. Roundtable for Sustainable Beef has a mission to advance, support, and communicate continuous improvement of sustainability across the nation’s beef value chain.

“The U.S. beef value chain is the trusted global leader in environmentally sound, socially responsible, and economically viable beef,” stated Samantha Werth, Ph.D., executive director of the U.S. Roundtable for Sustainable Beef. This volunteer-led and member-run organization has 145 members across all sectors of the beef industry, including cattle producers, packers, processors, retailers, restaurants, civil society, and more.

The organization identified six high-priority indicators of sustainability across all sectors of the beef industry, including water resources, land resources, air and greenhouse gas emissions, employees and well-being, animal health and well-being, and efficiency and yield. The key indicators build upon the primary pillars of sustainability — environmental, social, and economic — emphasizing well-rounded sustainability at each stage of the beef supply chain.

The USRSB developed sustainability assessment guides for each of the member sectors of the industry. These guides are fact- and science-based and provide key performance indicators. Each sector helped develop their own assessment guide, leading to greater support and implementation. The guides were open to public comment and received a number of revisions over two years before final approval by all members in 2019.

In 2022, the USRSB launched their High-Priority Indicator Goals and Sector Targets for the entire beef supply chain. The goals, also centered around

the six key indicators, include targets for each sector, specific to the needs and opportunities of each part of the supply chain. These goals and targets aim to identify and supplement sustainability practices and support the collection of benchmarking data for current indus-

try sustainability efforts.

“The USRSB goals and targets are unlike any others. They aim to enhance beef industry sustainability from farm to table and provide an opportunity for fully supply chain collaboration,” said Werth.

BIG PUMPS TO HANDLE BIG JOBS

Cornell’s 81022MPL with the robust, yet compact EM19DBK Frame and Run-Dry™ Option tackles the toughest manure slurries. Featuring:

6000 GPM / 420’ TDH at BEP at 1800 RPM

7500 GPM max flow

High Efficiency

Low NPSHr

Proven Cornell construction for handling sand laden manure

Hard face seal with run-dry seal protection

With an 8” discharge, 10” suction and 3.5” solids handing, and built for high-operating pressures, MP pumps are specifically designed for coarse-abrasive slurry applications. Constructed of high chrome iron, with a Brinell hardness rating above 650.

Talk with your authorized Cornell dealer about finding the best model for your application.

jofnm.com August 2023 | Journal of Nutrient Management | 23

CORNELL PUMP COMPANY www.cornellpump.com P +1 (503) 653-0330 I F: +1 (503) 653-0338 manure@cornellpump.com

Cornell now offers cell connect monitoring of temperature, vibration, GPS, pressure and more.

To help the industry work toward achieving these goals, USRSB continues to create and build upon their existing free tools and resources. The USRSB offers a self-assessment tool for individual users. This tool measures users against the benchmarks provided in the guides and offers opportunities for improvement. For ease of use, the guides, benchmarks, and self-assessment tools were brought together under the U.S. Beef Industry Sustainability Framework.

The USRSB also offers a sustainability module series based on the Framework. The interactive series incorporates the USRSB self-assessment tool around key indicators and metrics to help industry professionals recognize areas where they excel and offer solutions in the areas which need further development. The modules are available to each sector of the beef supply chain. In May of 2023, USRSB launched a Grazing Management Plan learning module, focused on providing producers with science-based guidance on key grazing principles and development of written GMPs — a critical component to USRSB’s goals efforts. All USRSB resources can be accessed at USRSB.org.

Dairy looks to the future

The Innovation Center for U.S. Dairy has a vision that the American dairy industry can be an environmental solution, and that is possible, according to Karen Scanlon of Dairy Management Inc., which manages the national dairy checkoff. “By 2050, the U.S. dairy industry collectively commits to achieve GHG neutrality or better, optimizing water use while maximizing recycling, and improving water quality by optimizing the utilization of manure and nutrients,” she noted.

The year 2050 is nearly 30 years away, but that doesn’t mean there isn’t a lot of work going on right now. That includes the U.S. Dairy Net Zero Initiative (NZI), a collaboration of dairy organizations and partners to advance research and technology, on-farm pilots, and new market development. This is an essential first phase to accelerate progress toward the 2050 environmental goals.

NZI is about breaking down barri-

ers to empower all farms to reduce their environmental impact – in an economically viable way that positions them to thrive for generations to come. Overall, NZI is designed to accelerate progress toward the three goals listed above.

Realistically, Scanlon said not every farm can achieve GHG neutrality status, but the effort is collective across farms of every size and management style. NZI is designed to offer a range of practices and recommendations depending on size, location, technology, and more.

There are four key areas of focus in the initiative:

1. Enteric methane

2. Feed production changes

3. Manure

4. Energy

Each of these focus areas encompass practices that can be incorporated on farms of various sizes, and these opportunities present on-farm and offfarm benefits.

“NZI is working to close knowledge gaps and advance innovation by focusing across the four key areas of dairy production,” Scanlan said. “The practices and technologies needed to reach the goals largely exist, but they require further development, investment in operational changes, and advanced technical assistance.”

Collaboration across the industry is important. To date, NZI has leveraged $37.7 million in support. Major partners and collaborators include Nestle, Starbucks, Foundation for Food and Agriculture Research, and The Nature Conservancy. Additionally, NZI is putting the plan into action by partnering with a series of farms of various sizes and geographies to prove the viability of practices and identify the key lessons learned.

“This work is accelerating progress across the entire U.S. dairy industry,” Scanlan concluded. “It is incredibly gratifying to be a part of such a largescale initiative supporting all U.S. dairy producers.”

PLACES TO BE

North American Manure Expo

August 9 and 10, 2023 Arlington, Wis.

Details: manureexpo.ca

U.S. Poultry and Egg Association’s Environmental Management Seminar

September 28 and 29, 2023 Destin, Fla.

Details: uspoultry.org/programs/ education/seminar

World Beef Expo

September 28 to October 1, 2023 West Allis, Wis.

Details: www.worldbeefexpo.com

World Dairy Expo

October 1 to 6, 2023 Madison, Wis.

Details: worlddairyexpo.com

Sustainable Agriculture Summit

December 6 and 7, 2023 Charlotte, N.C.

Details: sustainableagsummit.org

National Cattleman’s Beef Association Trade Show and Convention

January 31 to February 2, 2024 Orlando, Fla.

Details: convention.ncba.org

COMPOST2024

February 6 to 9, 2024 Orlando, Fla.

Details: compostconference.com

Minnesota Pork Conference

February 13 and 14, 2024 Mankato, Minn.

Details: mnporkcongress.com

If you would like us to include your event on our list, please send details to info@jofnm.com.

24 | Journal of Nutrient Management | August 2023 jofnm.com

The author is a freelance writer from Monroe, Wis. She owns Denim Works LLC.

PROFESSIONAL DIRECTORY

AGRICULTURAL CONCRETE

JP Tank

317 Kohlman Rd. Fond du Lac, WI 54937 920-948-2286

jptankconcrete@gmail.com

jptank.com

Pipping Concrete

N6106 County Rd. C Rosendale, WI 54974 920-948-9661

dennis@pippingconcrete.com pippingconcrete.com

ANAEROBIC DIGESTER SERVICES

Agricultural Digesters LLC

88 Holland Ln. #302 Williston, VT 05495 802-876-7877

info@AgriculturalDigesters.com AgriculturalDigesters.com

APPAREL

Udder Tech Inc.

2520 151st Ct. W Rosemount, MN 55068 952-461-2894

dana@uddertechinc.com uddertechinc.com

BEDDING SEPARATION

McLanahan

200 Wall Street Hollidaysburg, PA 16648

814-695-9807

sales@mclanahan.com mclanahan.com/solutions/dairy

COATINGS

Industrial Solutions

5115 S. Rolling Green Ave. Ste. 211 Sioux Falls, SD 57108 605-254-6059

isusananoclear.com

ENVIRONMENTAL SOLUTIONS

Future Enviroassets LLC

Cincinnati, OH 45215

513-349-3844

LF@futureenviroassets.com futureenviroassets.com

Hall Associates

23 Evergreen Dr. Georgetown, DE 19947-9484 302-855-0723

hallassociates@mediacombb.net

Tomorrow Water 1225 N. Patt St. Anaheim, CA 92801 714-578-0676

info@bkt21.com tomorrowwater.com

Trident Processes Inc. 10800 Lyndale Ave. S. Bloomington, MN 55420 1-800-799-3740

frank.engel@tridentprocesses.com tridentprocesses.com

MANURE SEPARATION

Boerger LLC 2860 Water Tower Place Chanhassen, MN 55317 844-647-7867

boerger.com

MANURE STORAGE

Pit-King®/Agri-King® Inc. 18246 Waller Rd. Fulton, IL 61252 1-800-435-9560

agriking.com/pit-king

WASTE HANDLING EQUIPMENT

Cornell Pump Co. 16261 SE 130th Ave. Clackamas, OR 97015 503-653-0330

cornellpump.com

Doda USA

255 16th St. S. St. James, MN 56081 507-375-5577

dodausa.com

GEA Farm Technologies, Inc. 1385 N. Weber Road Romeoville, IL 60446 + 1-800-563-4685

contact.geadairyfarming.na@gea.com

R Braun Inc. 209 N. 4th Ave. St. Nazianz, WI 54232 920-773-2143

RBrauninc.com

WASTE HANDLING NUTRIENT SPREADERS

Kuhn North America

P.O. Box 167 Brodhead, WI 53520

Kuhn-usa.com

New Leader

1330 76th Ave. SW Cedar Rapids, IA 52404

1-800-363-1771

newleader.com

Oxbo International 100 Bean St. Clear Lake, WI 54005

1-800-628-6196

oxbo.com

WATER TECHNOLOGY

Bauer North America Inc. 107 Eastwood Rd. Michigan City, IN 46360

1-800-922-8375

bnasales@bauer-at.com

bauer-at.com

Press Technology & Mfg. Inc. 1401 Fotler Street Springfield, OH 45504 937-327-0755

dberner@presstechnology.com

jofnm.com August 2023 | Journal of Nutrient Management | 25 Don’t see your company listed? Send your company information to marketing@jofnm.com with Professional Directory in the subject line. GEA ProMAnurE High-performance manure technology Find your dealer GEA.com

Nutrient management is the driver

by Thomas Menke

Has the time finally come? I have worked with all types of livestock and poultry projects over the past 46 years and have come to the following conclusion: Nutrient management determines success or failure.

I have dreamed and schemed about how to efficiently deal with manure, culminating in four patents to document my efforts. Others have taken this same path with variable success.

The fact is, there are already industrial processes that can treat manure to any degree desired. Unfortunately, they have been heretofore unaffordable for agriculture. However, agriculture facilities typically have access to something that most industries do not — land, and lots of it. Every farm raising animals is located in farm country where crops are grown, and many of these crops can be used to feed the farm’s animals.

We should never take for granted that these crops require huge amounts of nutrients and water — both of which are contained in manure. The problem has always been getting the right amount to right field at the right time in an efficient manner.

Joining as partners

What is driving current change for the innovators? There is one word: synergy. Envision three critical synergistic partners.

The first is the farm itself. I’ll use a 5,000-cow dairy as an example, which would produce 155 million pounds of milk annually. The second would be an anaerobic digester that could generate 52 million cubic feet of methane.

The third is a nutrient recovery facility. What does it produce? Reclaimed nutrients and water from

manure digestate. Nutrients in forms that are directly competitive with chemical fertilizers and managed in a similar fashion.

Don’t forget the water

And what about the water produced? This is key: The water quality the nutrient manager specifies must be compatible with perpetual land application on minimal acres con -

and is not beholden to the local crop farmers for manure applications.

Focus on strengths

How will this partnership work?

Each is run by experts in their respective areas. The dairy farm can focus on producing milk, not methane. Collectively, each partner shares in the three areas of income: milk, energy (which will include green energy