Over 40 years of experience has given us valuable know-how and expertise in producing baling equipment. No matter if you’re baling dry hay, high-density baleage or anything in between, there is a KUHN round baler for you. Extreme durability of components means minimum downtime for maximum baling time. Thanks to its heavy-duty design, the balers provide you the robustness and reliability you need.

KUHN offers the most efficient and versatile range of fixed and variable chamber round balers available on the market. KUHN round balers ensure perfectly shaped, consistent round bales and produce exceptionally high bale densities even in the most demanding conditions.

Alfalfa is key to healthy soils and provides more protein per acre than other cropping choices. It is the ultimate regenerative crop, increasing biodiversity and enhancing ecosystems. Quality alfalfa rations enhance your dairy operation’s overall ROI while strengthening your environmental footprint.

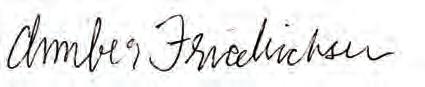

During the heat of the summer in the Show-Me State, Bruce Lackman is using native grasses to his advantage and extending the grazing season for his beef herd in central Missouri.

The sun won’t set on their stargrass pastures

This Florida family navigates the transition to new ownership of their pasture-based dairy.

These tools are useful for pasture seeding, spraying, and fertilization.

MANAGING EDITOR Amber M. Friedrichsen

SENIOR EDITOR Michael C. Rankin

ART DIRECTOR Todd Garrett

EDITORIAL COORDINATOR Jennifer L. Yurs

DIRECTOR OF MARKETING John R. Mansavage

DIGITAL MARKETING

Sam Rasmussen Sidney Hebbe

ADVERTISING SALES

Kim E. Zilverberg kzilverberg@hayandforage.com

Jenna Zilverberg jzilverberg@hayandforage.com

ADVERTISING COORDINATOR Patti J. Kressin pkressin@hayandforage.com

W.D. HOARD & SONS

PRESIDENT Brian V. Knox

EDITORIAL OFFICE

28 Milwaukee Ave., West, Fort Atkinson, WI, 53538 WEBSITE www.hayandforage.com

EMAIL info@hayandforage.com

PHONE 920-563-5551

A little hay and grain are consumed by the cows and “Muddy” the Boer goat at Marcoot Jersey Farm after they return from pasture, which accounts for over 80% of their diet. Seven generations of Marcoots have milked Jerseys on their Greenville, Ill., farm since the 1840s. The current operation uses robots to milk the 65-cow herd and operates its own creamery to produce cheese and ice cream. Learn more at marcootjerseycreamery.com.

by Mike Rankin

HAY & FORAGE GROWER (ISSN 0891-5946) copyright © 2025 W. D. Hoard & Sons Company. All rights reserved. Published six times annually in January, February, March, April/May, August/September and November by W. D. Hoard & Sons Co., 28 Milwaukee Ave., W., Fort Atkinson, Wisconsin 53538 USA. Tel: 920-563-5551. Fax: 920-563-7298. Email: info@hayandforage.com. Website: www.hayandforage.com. Periodicals Postage paid at Fort Atkinson, Wis., and additional mail offices. SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Non-qualified subscribers may subscribe at:

USA; call: 920-563-5551, email: info@hayandforage.com or visit: www.hayandforage.com. POSTMASTER: Send address changes to HAY & FORAGE GROWER, 28 Milwaukee Ave., W., Fort Atkinson,

S OF this writing, I can officially check the Pacific Northwest off my list of regions to visit. Even though I was in Oregon to visit grass seed farms during the thick of their harvest season, I was intrigued by a totally different crop with a major presence in the area that took me down a rather forage-unrelated rabbit hole: the hazelnut.

Driving along State Highway 99 through the heart of the Willamette Valley, I was surrounded by endless rows of bushy, mid-sized trees. I later learned these were hazelnut orchards when one of the grass seed farmers I met informed me that some of them belonged to her family. At first, I wasn’t interested in hazelnut production — partly because I personally don’t like hazelnuts, and partly because I was there to talk about grass seed. But then the topic kept coming up throughout the week.

In addition to being the official state nut, hazelnut trees occupy over 90,000 acres in Oregon, which are almost all exclusively located in the Willamette Valley. The soil and climate there are nearly perfect for hazelnut farming, and many new orchards have recently been established in the valley because of an uptick in consumer demand. Virtually all of our nation’s hazelnuts come from Oregon, although Turkey is the world leader in production, accounting for about 70% of global supply.

One defining feature of a hazelnut orchard is its incredibly smooth orchard floor. Upon first glance, I was dismayed by the seemingly parched and severely compacted soil surface beneath the trees until I learned that orchard floors must be regularly dragged and diligently maintained to provide a pristine landscape for harvest activities.

Hazelnuts drop when they ripen, littering the ground below the trees, and then farmers gather the nuts into windrows with blowers and sweepers. Therefore, a smooth orchard floor prevents hazelnuts from falling into ruts or depressions in the soil, and it reduces the amount of debris that gets mixed up with the harvest. At this point, farmers make another pass over the windrows with collectors to pick up the nuts and sort out sticks and leaves. Then, hazelnuts are processed, undergoing several steps, including dehusking, cleaning, sizing, and cracking before being roasted, steamed, or coated in an endless combination of spices and seasonings.

According to Oregon State University Extension, a mature orchard can produce anywhere from 2,000 to 4,000 pounds of hazelnuts per acre, and if managed well, orchards can be productive for 40 to 50 years.

Upon some more research, I learned that hazelnuts and their healing properties have been celebrated for hundreds of years. First-century physicians mixed ground hazelnuts with honey or black pepper to cure chronic coughing and common colds. Ancient Chinese manuscripts claimed hazelnuts were one of the five sacred foods bestowed upon humans from the heavens above. And apparently, if one experienced a receding hairline or normal baldness during the Roman Empire, smearing mashed hazelnut shells on their head was recommended to encourage new hair growth.

I also learned hazelnuts are called filberts, which is an acceptable name for both the nut and the tree, and quite frankly, “filbert” is more fun to say.

In the midst of my filbert frenzy, I stopped at souvenir shops and convenience stores to buy bags of dry roasted, chocolate-covered, and butter pecan-flavored hazelnuts to bring back to my family and friends. I got some for myself, too. And on my way to the airport to catch my flight home, I poured myself a cup of coffee in the hotel lobby, adding a generous serving of the hazelnut creamer that was provided on the counter.

To be honest, I still don’t like hazelnuts. But after developing a newfound appreciation for the crop and the farmers who grow it, snacking on filberts and drinking hazelnut-flavored coffee was my way of paying homage to the industry. It also just felt like the right thing to do while visiting the hazelnut capital of the country.

All hazelnut humor aside, a similar sentiment can ring true for other avenues of agriculture that we may find ourselves venturing along. We don’t have to grow the same crops, we don’t have to raise the same livestock — we don’t even have to consume the end-products. But exploring different production systems and expanding our perspectives on the various resources that provide us with feed, food, fuel, and fiber is a worthy endeavor that offers a lifetime of learning and revolving fund of curiosity. •

by Amber Friedrichsen, Managing Editor

RUCE Lackman hasn’t always rotationally grazed his cattle. It wasn’t a widely adopted practice when he was growing up, and it still isn’t popular in his region of central Missouri today. But he was determined to improve the forage utilization of his pastures, and after reading about rotational grazing and attending workshops, the concept of moving cows through paddocks to give grass rest and facilitate healthier regrowth piqued his interest. Marrying the daughter of a state grazing specialist helped move the needle, too.

Lackman’s farm is nestled in the rolling hills of Cole County, Mo., about an hour drive northwest of the Lake of the Ozarks. Growing up on a cow-calf operation a few miles down the road, he joined the Marines right out of high school and served four years before returning home, renting some ground, buying some cows, and starting a cattle operation of his own.

Because of the state of the beef market at the time, Lackman said there wasn’t money in a small herd of commercial cows. So, he started artificially inseminating cows and eventually registered his animals with the American Simmental Association. Today, he rotationally grazes 90 registered Simmental-Angus pairs on about 350 acres of owned and rented pasture — most of which are anchored in Kentucky-31 tall fescue.

When Lackman decided to implement rotational grazing, his fatherin-law, John Turner, who retired from the Natural Resource Conservation Service (NRCS) in 2011, offered some input. Turner helped Lackman design paddocks and install fencing, despite the differences in soil texture and topography of the two men’s respective locations.

“John is from north Missouri, and when he came down here with step-in posts and high-tensile wire, he found

out how rocky it is,” Lackman chuckled. “It wasn’t quite as easy to put in a temporary fence down here as it is up there where the dirt is a lot deeper.”

For a while, Lackman mitigated the negative effects of the endophyte-infected tall fescue by rotating cattle and interseeding clover into grass stands. And for a while, it seemed like his closed herd had become adapted to hot fescue, displaying few symptoms of toxicosis. That is, until the exceptionally dry summer of 2018.

After his stint in the Marines, Lackman joined the National Guard where he spent time being deployed and serving active duty. While he was deployed in 2018, his wife, Linda, managed the herd, quickly rotating cattle through paddocks to avoid overgrazing the drought-stressed grass. To try stretching forage availability, she fertilized the fall stockpile as well.

“We got some rain after that and the tall fescue stockpile was 12 inches tall,” he recalled. “Then, we turned the cattle in on it and they were losing tail switches. One ended up losing a claw altogether.”

That was a major turning point to stop grazing tall fescue when it rears its toxic seedheads during the hottest months of the year. Instead, Lackman opted to seed a mix of native warm-season grasses that thrive in the heat and would provide

ample forage when cool-season grass pastures hit the snooze button during the summer slump.

After experimenting with native grasses on a small scale, Lackman converted a tall fescue pasture by burning it down with glyphosate in mid-August 2023. Then in September, he planted rye, oats, turnips, and radishes. The following spring, he turned cows out on the cover crops to graze before spraying a second dose of glyphosate and seeding a mix of 60% big bluestem, 30% indiangrass, and 10% little bluestem in mid-April 2024.

This spray-smother-spray method is a common strategy for native grass establishment, and according to Turner, Lackman’s attempt was nothing short of successful.

“It’s the most phenomenal stand that I’ve ever seen,” Turner affirmed. “Bruce got a little lucky with the weather,

but he followed the prescription to the letter, and that helped.”

But establishment is only the first step. Management is as much of an art as it is a science. And it is drastically different than the management of the introduced cool-season grasses that many livestock producers are accustomed to, Turner said.

Lackman could have grazed the native grasses during the establishment year, but by the time he got around to it, the stand was too ripe and turning brown. He turned some calves in on the pasture, but they didn’t seem to care for it. So, he bushhogged it instead.

Fast-forward to this spring, he divided the 22-acre pasture into roughly 3.5-acre paddocks, giving cows access to the native grasses for a quick pass in mid-May after they rotated through the spring flush of tall fescue.

“You need to be prepared to get on it and back off it again,” Turner said about the early-season graze. “If you

don’t do that, the grass will get too mature and the quality will drop like a rock.”

An initial graze down to about 8 to 10 inches locks in the height of plant meristems, which is key to facilitate regrowth throughout the summer. Otherwise, if farmers wait until their herd is through all of their tall fescue to start them on natives, cows can defoliate elevated growing points and limit stands to a single grazing event.

Being proactive, on the other hand, essentially kills two birds with one stone. “If you do what Bruce is trying to do and maintain a vegetative state into August and early September, cows can get a lot more grazing days and a lot higher quality forage,” Turner said.

Other farmers have taken notice of Lackman’s native grasses, stopping by to size up the stand and ask about his experience growing them. He said the biggest roadblocks for others to grow their own is taking acres out of production during the lengthy establishment period and stomach-

Lackman rotated cattle through the native grasses early in the season to capture high forage quality and set the grazing height for the rest of the season.

ing high seed costs. But, as he has demonstrated, a smother crop can be a viable forage source during pasture renovations, and there are many costshare programs to subsidize establishment expenses.

Although the big bluestem, indiangrass, and little bluestem will primarily be managed for pasture, the mix was created for dual-purpose grazing and haying. Lackman doesn’t have any dedicated hayfields, but he occasionally takes a first cutting of tall fescue in some stands by mid-May.

“I try to jump on it early,” he said. “A lot of people say you don’t get much hay in the middle of May, but it’s a lot better quality. If you wait, you might get a little more rain, you might get a little more growth, but there will be a lot more dry stems.”

The self-taught mechanic runs a humble fleet of haying equipment and does most of his own maintenance work. “I try to get by on old equipment,” he said, referring to his H&S bifold wheel rake, New Holland 163 tedder, and 1475 Gehl round baler. But after his old disc mower bit the dust last year, he did invest in a new Kubota 5028.

Lackman unrolls bales for cattle in the winter. Before he started rotationally grazing, he routinely fed hay from December through mid-April. Now, with better forage management and a more robust stockpile to graze through

the fall as a result, his goal is to wait until February to feed hay and do so only until the grazing season begins around the first of April.

“My goal is two and a half months of hay or less, and that’s it,” Lackman said. He is also adamant that making his own hay versus buying from outside sources is a form of quality control, since purchased bales could contain spoiled hay or introduce weed seed to pastures.

Lackman’s cows are not supplemented with any corn grain or silage — they are exclusively raised on pasture and hay. They average 1,200 to 1,300 pounds, which is the size he targets for optimal feed efficiency on an all-grass diet.

“I don’t believe in those 1,400- to 1,500-pound cows,” Lackman said. “People love it when they send one down to the sale barn that brings in a lot of money, but they eat a lot, too.”

The majority of the herd calves in the fall. By the time calves are weaned, weighing about 550 pounds on average, the spring flush of forage growth is in full swing, making it a no-brainer to background them. In fact, Lackman backgrounds all of his calves, adding about 100 pounds of gain to each animal by the time he sells them. He also raises his own replacement heifers to stock pastures, though he ultimately plans to start selling these animals, too.

In addition to cows and calves, Lackman raises several bulls, grazes some sheep, and has a few horses. And looking out across the cattle pasture, one animal in particular stands out from the rest — a lone Texas Longhorn cow. She belongs to Lackman’s youngest son, 10-year-old Virgil, who stays involved on the farm scene with daily feeding chores and by showing steers at the county fair.

Outside of Virgil’s assistance, Lackman said his biggest challenge is finding available labor — especially when the first hay cutting occurs during the busy beginning of grazing season. But considering his four older children — Kayla, Clara, Dorothy, and Levi — have embarked on different paths of interests, education, and successful careers, he is happy to clock in a few extra hours on his own. With help during hay harvest from his brother, Patrick, and some grazing advice from Turner, Lackman has everything covered. And now, since retiring from the military in 2020 after 27 years of service, he looks forward to being a full-time farmer. •

From cutter drums to spouts, shearbars to feed rolls, we have what you need to keep your equipment running smoothly.

by Gonzalo Ferreira

HAVE you ever seen a forage analysis report where the concentration of acid detergent fiber (ADF) in a forage sample was similar or even greater than the concentration of neutral detergent fiber (NDF)? If so, you have likely wondered how such a thing is possible.

Although unusual, we can find an ADF concentration similar to or greater than the NDF concentration in some forage analysis reports. Some of the limitations of the detergent system used in forage analyses can explain this outcome.

Various analytical methods exist to measure analytes or constituents of interest in a forage or feed sample. These analytes may include specific elements or molecules like nitrogen, calcium, glucose, or amino acids. Among the various analytical methods, rational or theoretical methods are used to quantify an identifiable analyte. Here’s an example: When we want to quantify glucose, the analytical technique can identify glucose and ensure that glucose is the entity quantified. On the other hand, empirical methods quantify substances or residues that are not specific. Therefore, the results of the empirical methods depend heav-

ily on the protocol utilized for quantifying these nonspecific residues.

A clearer example of this is lignin. Generally speaking, we tend to refer to lignin as an unambiguous term. However, at least three methods exist for quantifying lignin, including the acid detergent lignin (ADL), the acetyl bromide lignin (ABL), and the Klason lignin. All these methods will likely provide different answers when a single forage sample is analyzed. How is this possible? It is because methods vary, and the amounts of the resulting residues of these methods differ.

Coming back to the original question, both NDF and ADF methods in the detergent system of forage analysis are empirical methods. As such, their results vary depending on how we perform these methods.

Generally speaking, NDF includes hemicellulose, cellulose, and lignin, whereas ADF includes only cellulose and lignin. Therefore, we should expect a concentration of NDF greater than the concentration of ADF because NDF has hemicellulose in addition to the components of ADF. Understanding the limitations of analytical methodologies may help explain a contradicting outcome. At least four reasons exist for

these odd observations.

One reason for having greater ADF concentration than NDF concentration could be related to the contamination of the sample with inorganic matter. When the NDF residue is subjected to combustion to obtain NDF corrected for organic matter (aNDFom), a substantial drop in NDF concentration can be observed after combusting or ashing the residue. If the ADF method does not similarly correct for organic matter, the inorganic matter may remain in the ADF residue, overestimating the ADF concentration. To overcome this issue, it is important to correct the organic matter in both NDF and ADF procedures.

A second reason for having a greater ADF concentration than NDF concentration could be related to the partial solubility of pectin in acid detergent. When we perform NDF and ADF analyses independently, the pectin excluded from the residue during NDF analysis may be included in the residue during ADF analysis, which would consequently overestimate the ADF concentration of the forage. To solve this issue, perform an ADF analysis on the resulting residue of NDF analysis, also known as sequential analysis of ADF after NDF. However, because the NDF residue is not subjected to combustion for organic matter correction, these sequential analyses should be replicated exclusively to correct for organic matter.

The solubility of tannins in the neutral detergent is a third reason for having a greater ADF concentration than NDF concentration. Tannins are polyphenolic compounds that are soluble in neutral detergent — at least partially — but not in acid detergent, so these tannins would underestimate the NDF residue. To overcome this, difference sequential NDF and ADF analyses might be warranted.

Finally, the use of sodium sulfite in the NDF analysis can solubilize some of the polyphenolic compounds of lignin that remain in the ADF residue. Either the removal of sodium

sulfite or a sequential NDF and ADF analysis could be performed to solve this issue.

At the Dairy Forage Research Laboratory at Virginia Tech, we evaluated the impact of performing NDF and ADF independently and sequentially on samples of alfalfa hay, corn silage, and grass hay. In the case of corn silage and grass hay, the difference in ADF concentrations between the independent and sequential analyses was minimal (less than 2 percentage units of ADF). However, in the case of alfalfa hay, the difference in ADF concentrations between independent and sequential analyses was more pronounced (4.2 percentage units).

In conclusion, we must be aware of the nuances and limitations of analytical methodologies for interpreting forage analyses as their implications can be relevant to dairy farmers and nutritionists. For example, we sometimes use the relative feed value (RFV)

as a metric of forage quality for pricing alfalfa hay. Because ADF is a determinant of the RFV, knowing the nuances of the detergent system of forage analysis can provide answers to those hard-to-explain forage analysis reports that affect alfalfa hay pricing. •

The author is a professor and dairy management extension specialist with Virginia Tech.

Hay & Forage Grower is featuring results of research projects funded through the Alfalfa Checkoff, officially named the U.S. Alfalfa Farmer Research Initiative, administered by National Alfalfa & Forage Alliance (NAFA). The checkoff program facilitates farmer-funded research.

WHEN adult alfalfa weevils began appearing earlier than usual in Montana fields, agricultural researchers took notice. “Adult alfalfa weevils have become increasingly problematic in total recent years,” said Hayes Goosey, assistant professor and extension forage specialist at Montana State University in Bozeman. He served as the principal investigator on the project titled “Controlling Adult Alfalfa Weevils: A Multi-State University/Industry Collaboration.”

HAYES GOOSEY

Funding: $50,000

The issue came to light when producers across the state reported reduced first-cutting yields.

“A colleague, Kevin Wanner, and I started hearing from producers across Montana that their first-cutting yields were down,” Goosey explained. “When we got into the field, we found adult weevils were active earlier than expected, leading to earlier egg deposition and damage from larvae.”

Historically, most weevil management focused on larvae, but this shift in timing sparked a critical question: Could targeting the adult stage make a difference?

“If the number of egg-laying females is reduced, the number of eggs and subsequent damaging larvae will also be reduced,” Goosey emphasized. “That sparked the questions: How effective are commercially available insecticides against adult weevils, and how long do they persist in the field?”

To find out, Goosey’s team conducted a study at three Montana locations using a randomized block design. They tested insecticides with different modes of action — Steward, Mustang Maxx, Warrior II, Exirel, and Endigo ZC — during the early spring weevil activity period. Before insecticide application, adult and larval numbers

were estimated with sweep nets followed by seven- and 14-day post-application estimates to monitor total adult and larval populations and insecticide residue persistence. Each test product significantly controlled alfalfa weevils at seven and 14 days after treatment compared to the untreated control (see figure).

The results carry a strong message for producers: “Early spring alfalfa weevil numbers can be reduced with multiple insecticides, and the timing of insecticide application matters just as much as the product itself,” Goosey stressed. “Some insecticides can lose effectiveness, especially in rainy conditions, so relying on a single early spray

without follow-up scouting can lead to underwhelming results.”

Rather than waiting to see larval damage, farmers are encouraged to be proactive. “Our research can help farmers make more informed product selection and timing decisions,” Goosey noted. “We also recommend that producers not wait until they see larval feeding damage. Rather, we recommend scouting for adults and early instar larvae to make the best management decisions for field-level population control.”

Executing such a study across a wide area wasn’t without logistical challenges. “As with all fieldwork, coordinating my team across the large geographic area of southwest Montana while maintaining rigorous sampling protocols is always challenging,” Goosey

• Laboratory bioassays determined similar degrees of resistance among Type II pyrethroids. In contrast, resistance was not found with the Type I pyrethroid, bifenthrin, which is registered for alfalfa seed production.

• T hree trials were conducted and concluded that each test product (Mustang Maxx, Steward, Warrior II, Exirel, Endigo) significantly controlled adult

alfalfa weevils at seven and 14 days after treatment when compared to the untreated control.

• S amples collected by Erika Rodbell and Kevin Wanner were processed and revealed that egg-laying activity in these samples was low and insufficient to generate a reliable degree-day model that would improve existing models.

said. “But that’s the reality of applied field research.”

Looking ahead, the team plans to deepen the study. “I want to expand this work by linking alfalfa weevil adult management to reduced egg numbers, which leads to fewer damaging larvae. At this point, there is no data linkage,” Goosey explained. “In

the short term, I already have plans to disseminate this information to alfalfa growers by working with extension agents. In the long term, I hope this research contributes to additional studies that assess threshold levels for adults, which will update and contribute to a more effective integrated pest management framework.”

Though the study offered no big surprises, it delivered solid confirmation. “I was relieved when the data showed that commercially available insecticides work,” Goosey concluded. “It adds an important tool to the toolbox for alfalfa producers.”

A full copy of the final report can be found at https://alfalfa.org. •

by Joe Lawrence

THE number of moving parts and pressure to get everything correct during corn silage harvest can be daunting. It is worthy to recognize that the harvest season is a valuable learning and planning opportunity. Documenting crop progress and challenges throughout the season is a good practice, but information collected during the harvest of the single most utilized ingredient in many dairy rations can be particularly valuable.

There are numerous resources — from seed selection and plant nutrition to pest management — for growing a good corn crop. Late-season evaluation of these factors is critical to an accurate analysis of what worked well and what needs more attention.

Particularly in the era of pest resistance challenges, end-of-season scouting and documentation of pest damage are critical to informing crop rotation, trait selection, and pest management plans for next season. Whether it is goosenecked corn in a field planted with a hybrid containing a Bacillus thuringiensis (Bt) protein for corn rootworm or a concerning patch of an unfamiliar weed, it is critical to stay on top of potential

pest control breakdowns.

Corn rootworm damage can be confirmed by checking roots, and if observed, review hybrid trait packages, crop rotation, and documented resistance in your area. Trait information can be obtained from your seed supplier or the “Handy Bt Trait Table” (https:// bit.ly/HFG-traits), which provides an overview of all traits and notes those with known resistance challenges.

Many weeds found in cornfields are prolific seed producers, and a small breakthrough of an herbicide-tolerant weed can quickly turn into field- and farm-wide challenges. If this is noticed, immediately acquire a proper identification of the weed and review your spray program. If a breakthrough is suspected, check with an extension weed specialist on known resistance cases in the area and evaluate your next steps.

Harvest is also a good time to assess your plant nutrition program. It is often difficult to pinpoint the cause of underperforming fields, but too often, resources are wasted on extra fertilizer when the real culprit may have been weather, soil compaction, or a pest. Any opportunities to parse this out are enhanced with late-season documentation to accurately connect the dots

Table 1: Considerations for corn silage harvest height decisions

Favoring higher cutting height

•Weather conditions known to reduce fiber digestibility

•Abundant inventories

•E xpectation of high yields

•Lower quality hay-crop silage

Favoring lower cutting height

•Low inventory

•Low yield

•Brown midrib hybrids

•H igh quality hay crop silage

•Fields intended for rotation

between how the fertility program was implemented and the outcomes.

Beyond the focus of growing a good corn crop, the importance in dairy diets has created an immense interest in gaining a better understanding of what factors most influence corn silage’s nutritional value. When considering the various metrics that make corn silage a valuable feed ingredient, each is impacted by the growing environment and production decisions to varying degrees. While there is still more to learn

in this area of research, applying current knowledge and collecting farm-specific information are both valuable to optimizing the utilization of this feedstuff.

As the industry continues to study specific mechanisms responsible for differences in forage nutritional value, certain trends are becoming clear. The New York and Vermont Corn Silage Hybrid Evaluation Program has added to this body of evidence. It has shown that when corn is grown following best agronomic practices, differences in growing environment (precipitation, heat, and soil characteristics) between locations result in greater differences in crop performance than the impact of agronomic inputs and management within a location.

A two-year study by Cornell, the University of Vermont, and Penn State University evaluated a common set of hybrids grown at multiple locations across the three states to assess differences in yield, fiber digestibility, and starch content. For these parameters, the difference in measured values were three to four times greater between locations than between hybrids at the same location. For example, neutral detergent fiber digestibility at 30 hours (NDFD30) varied seven to eight points between locations, while the greatest range in values between different hybrids at the same location was only two points.

A machine-learning exercise, utilizing seven years of Cornell hybrid evaluation program data, examined factors with the greatest influence on several key forage metrics. Seasonal precipitation and year/location were the common factors of greatest influence for overall yield, starch content, fiber digestibility, and crude protein content.

In rainfed cropping systems, there is little that can be done to influence the growing environment; however, understanding the impact can refine decision-making. For example, seasons with high precipitation are associated with lower fiber digestibility. When experiencing a higher precipitation growing season compared to previous crop year, lower fiber digestibility would be expected in the new crop. With this information, begin discussions with the farm team regarding how this new crop will affect the ration and feeding program. Moreover, this information provides valuable insight into hybrid selection. Public data sources, such as land-grant university hybrid trials, along with seed company data, provide a bench-

Factor

Relative movement Explanation

Dry matter

Dependent on level of dry matter (DM) loss (shrink) during fermentation.

Starch digestibility Ferment minimum three to four months.

Starch content - No consistent changes with normal fermentation.

Processing score - Changes observed have been inconsistent.

Fiber digestibility - No consistent changes with normal fermentation.

Yeast and molds (if present) Increased risk with poor fermentation, low silage density, and poor face management.

Mycotoxins (if present)

By-products of certain fungi (molds). Not alive — will not “grow.” Proportionally, more originate from fungi affecting plants in the field relative to fungi that grow in storage. An increase postensiling is associated with unstable feed and enhanced concentrations through DM loss.

mark for nutritional metrics to calibrate expectations for the growing season. Understanding if the average corn silage in each season had exceptionally high or low fiber digestibility helps determine if the data presented on a given hybrid represents average performance or a hybrid that really stood out relative to the growing season. Several studies have evaluated the impact of chop height on corn silage. While the magnitude of the impact varies by study, the overall conclusion is chopping corn silage higher results in less yield, but higher fiber digestibility and starch content. Considering this information in the context of the current growing season can help you refine your harvest strategy (see Table 1). In the event of a wet growing season, we might expect average to above average yields with lower fiber digestibility. Coupling this outlook with adequate feed inventory would suggest that a higher cutting height could help offset the effects of the wet season.

With the recognition that growing environment plays a significant role in the nutritional value of corn silage, it can still be beneficial to track trends at the farm level. Understanding the influence of field level interactions (hybrid, population, agronomic inputs, soil characteristics, and chop height) allows a farm to evaluate the suitability of a specific hybrid under certain practices or micro-climates.

In addition to note-taking, collecting field-specific fresh samples during harvest is a valuable tool for evaluation

and decision-making. Collecting this data for one season is often not sufficient to determine if changes are warranted to impact the nutritional content of the forage; however, accumulating data over several years can help identify trends.

Fresh-chopped samples are also a useful way to begin strategizing for feedout. Except for starch digestibility, which improves with fermentation, there are few significant changes that take place during storage. Table 2 provides general trends and considerations for key silage metrics.

While samples of the fermented silage should be used for final ration formulation, pairing green sample data with the location of the silage in storage is valuable for determining which feed should be used for a specific group of animals and noting any changes to other ingredients in the ration that may be needed with each silage.

A successful harvest season requires planning and assuring each member of the team understands their role. Identifying a member of the harvest team to record observations, monitor chopping performance, and collect samples can significantly enhance your ability to manage the crop during feedout, begin strategizing for next season, and help to understand long-term trends. •

JOE LAWRENCE

SOIL can become compacted from heavy trampling with livestock grazing on pastures or frequent tractor traffic over hayfields. Severe compaction can reduce plant growth by restricting rooting and limiting water infiltration. But when is soil considered to be severely compacted? This question could be diagnosed visually, which is a good first step of recognition, but doing so might not accurately assess the underlying conditions.

From a soil science perspective, compaction is typically diagnosed with a cone penetrometer, by sampling soil for bulk density, or by deploying an in-field water infiltration test. A variety of tools and methods can be used for each test, though some are more accurate than others. Although it might seem redundant to use all three methods, each approach assesses compaction from a different perspective, and these different perspectives offer unique insights. All methods are sensitive to moisture variations, but the penetrometer is particularly sensitive. With that said, the penetrometer is the easiest method to deploy — one can simply count the number of hammer hits needed to insert a metal rod into the ground to a 6-inch or 1-foot depth. This simple approach can be used on fields you think are compacted and compared to results with fields you consider not compacted. Again, soil moisture plays a large role in the results, such that wet soil is much easier to penetrate than dry soil. Standardize the approach by taking measurements two days after a 2-inch rainfall and use the same hammer and stroke force. Repeating observations in different locations will give you confidence in the results.

Once you are convinced you have compaction, you should also assess how the field got to this condition. Repeating the same management as before will not be a good strategy moving forward. Alleviation of compaction is typically achieved through mechanical means, such as running a ripper that has straight shanks, V-shanks, or bent

shanks. These tools fracture the soil to create more pores but leave surface residue and sod more or less intact. The spacing of shanks, depth of penetration, and soil moisture conditions will determine the horsepower needed to effectively alleviate compaction. Approximately 30 to 40 horsepower is generally needed per shank. It costs about $75 per hour to run the tractor and ripper.

The slices through the sod will heal with time, and the disturbance may enhance tillering or encourage spreading of rhizomes, depending on forage type. Since this disturbance can be considered a surgery on the soil, it would be wise to allow the sod to rest and recover for a few months. Depending on the type of forage present and whether there is a need to enhance species diversity, overseeding with annual or perennial forages may be advantageous prior to ripping to allow seeds to be incorporated into the soil. Assuming there is a rest and recovery period, this will allow new roots to penetrate the disturbed soil and help stabilize fractures in soil with organic inputs from fresh roots. Soil will slowly reconsolidate with precipitation events but quickly reconsolidate if the return of livestock or equipment traffic comes too soon.

The best time to consider renovating a pasture with ripping is in the fall, preferably when the soil has dried out so the shanks effectively fracture the soil. Some moisture will require less energy to run the ripper, but wet soil can result in smearing of soil that may only exacerbate the compaction issue. If the perennial sod is a cool-season forage, then regrowth may be more vigorous during the recovery period in the fall. If the perennial sod is a warm-season forage, then it would be advisable to overseed with a cool-season annual forage species or mixture of species to get active rooting during the recovery period. Proliferation of roots is necessary to avoid too much reconsolidation right away. If soil testing indicates a need for lime or nutrients, it may be a good time to supply these amendments shortly before the renovation as well.

After you’ve successfully renovated the pasture, manage the sward with attention to avoid overgrazing. Limit grazing events to short periods when soil is wet. When you invest a considerable amount of your time, deferred grazing time, and money into the renovation, having a solid grazing or forage management plan to keep the sward in excellent condition will yield long-term dividends.

Leave it in the shed

Renovating pastures with a ripper or subsoiler may not be the right choice if compaction is not severe. Employing more intensive grazing and forage management to improve rooting may be a more economical strategy and heal soil conditions just as effectively. Even with trampling by livestock, the top 4 inches of soil is typically of low bulk density in perennial stands.

In North Carolina, the middle 50% of soil bulk density values under pastures ranged from 1.11 to 1.24 grams per cubic centimeter (g/cc) in fine- and medium-textured soils and ranged from 1.21 to 1.38 g/cc in coarse-textured soils across 309 fields. If bulk density exceeds about 1.5 g/cc, then you might want to consider ripping. Otherwise, focus on improved management.

The health of soil on your farm will lead to greater potential for profitability in the long term. Stewarding the land with a focus on soil health gives you and your community numerous other ecosystem benefits. These include better water quality, reduced greenhouse gas emissions, biodiversity enhancement, wildlife habitat, and landscape beauty. If pasture renovation to alleviate compaction is needed to achieve your goals, then it may be an opportunity to further improve forage and grazing land management into the future. •

ALAN FRANZLUEBBERS

With the most experienced team in the industry, Liphatech Ag has the in-field and on-farm knowledge to provide farmers and producers with expert solutions and care.

Despite a change in ownership, the future is bright for this Florida dairy.

by Amber Friedrichsen, Managing Editor

THE farm is for sale.”

It was the plot twist to conclude Brittany Nickerson-Thurlow’s recounting of her family’s seven-decade history in the Florida dairy industry. Though it made for more of a cliff hanger than a happy ending, the decision to sell out is one pondered by many farmers in the same position who contemplate the surging costs of milking cows and the toll it can take on them and their families.

Their story begins with a bad case of arthritis and a doctor’s recommendation to move south, prompting Earl Nickerson to relocate the family farm in Clymer, N.Y., to Wauchula, Fla., in the 1950s. His farming legacy was carried on by son Norman, and later by grandsons Chris and Joe, who stayed on the farm after graduating high school. Together, Norman, Chris, and Joe expanded the operation across three locations, establishing Norm Nickerson and Sons.

“They knew they weren’t necessarily great at raising heifers, and they knew they weren’t the best at mixing feed,” said Nickerson-Thurlow. “My grandfather, dad, and uncle went to a farm in Texas where the farmers were rotational grazing, and that resonated with them. Then, they reconsidered how they were managing the business, they outsourced everything but milking cows, and they restructured the farm for an intensive rotational grazing system.”

Rotational grazing was the focus for the Nickersons’ next farm acquisition in Zolfo Springs in 2003, where they built Ten Mile Grade Dairy. They later established Nickerson Brothers LLC, the successor entity that would eventually own the three farms formerly owned under Norm Nickerson and Sons. With the addition of Ten Mile Grade Dairy, the family had grown their herd to over 5,000 head. Norman was able to semi-retire while Chris and Joe took over the business and began raising the next generation of Nickersons to dairy.

Chris’s children, Nickerson-Thurlow and her brother, Holden, and Joe’s children, Courtney Nickerson Campbell and Logan Nickerson, all worked for the farm in different capacities and were given the same opportunity for ownership when the partnership split in 2017. The split allowed each family unit its own business entity: Chris’s family started Nickerson Cattle Company and Joe’s family started Nickerson Bar III. Nickerson Cattle Company took ownership of Ten Mile Grade Dairy while Nickerson Bar III acquired ownership of the other three farms,

dividing total cow numbers evenly.

But the momentum of farm succession started to slow as cattle prices and real estate values soared. There were 99 dairies in the state of Florida when Nickerson-Thurlow started farming full time in 2017. Today, there are 46, and Ten Mile Grade Dairy is the last one in Hardee County. Although cow numbers aren’t declining as drastically as farm numbers, the ability for farmers to stay afloat financially is. And without a segregated market for grass-fed milk, the benefits of a grazing system seem to get lost in the bulk tank.

“It comes down to this: Is the way that our farm is designed a way of the future or is the industry evolving in a way that is leaving this simple, pasture-based model behind?” Nickerson-Thurlow posited.

It’s the latter, she believed. Many interacting factors formed the verdict to sell the farm in early 2022, and the passing of Chris several months later solidified the decision to seek a solution beyond the family. But the siblings decided they weren’t going to sell the farm to just anyone. Ideally, it would go to a buyer with a background in dairy and an interest in rotational grazing — someone who would maintain their pasture-based system for the benefits it brings to the cattle, the milk, and the land.

Ten Mile Grade Dairy encompasses about 1,800 acres. Nearly 700 acres that surround the milking barn are divided into six pastures for grazing. Well-fed water troughs are situated between fence lines, and each pasture is equipped with a cooling pond for reasons obvious to Florida weather. These pastures are further divided into oblong 5- to 10-acre paddocks that stretch from the edge of the cooling ponds to field perimeters like spokes on a wheel. Cows are moved to a new paddock every 12 hours after they return from the milking barn.

The milking herd is split into six groups of 250 to 450 cows that occupy

pastures according to their stage of lactation. For example, one group contains the freshest cows that graze closest to the barn so employees can monitor their transition. A different group hoofs it to the most distant pasture when they leave the parlor since these cows are latest in lactation. “They can expend more energy because their milk production isn’t as high,” Nickerson-Thurlow said.

Stargrass is the star player of the pasture base as a subtropical species that grows best in hot and humid conditions. The warm-season perennial really comes to life once the area receives sufficient spring rains and nighttime temperatures hit 70ºF. Nickerson-Thurlow said this typically occurs by mid-April or early May; however, dry starts to recent growing seasons have stalled stargrass regrowth until June.

“That has hurt us a little bit,” she said about the interruption to spring grazing. Seasonal calving creates another trade-off between grass production and animal performance.

“We try to have our primary calving season from October to December. That allows those cattle to peak on milk production in the months when weather is most favorable — January, February, and March — and they have the least amount of environmental stress,” Nickerson-Thurlow said. But during this time, stargrass is dormant.

Despite some experimentation with annual forages, the finicky Florida climate often nips the potential for a successful stand in the bud. Therefore, nutritional needs that are not met in winter pastures are made up for in the barn. Cows receive a one-shot ration at the feedbunk and in the parlor. They supplement the grain mix with dry hay and baleage.

“When the weather is changing and the grass is starting to wake up, we will

pull back their available feed so they are eating less in the barn and have to work for their food a little more on the pasture,” Nickerson-Thurlow said.

“My grandpa always used to say we don’t work for the cows, we make our cows work for us,” she continued. “They spread their own manure, they harvest their own forage, and then sometimes, we got to go fishing,” she smiled.

The rest of the farm’s acreage is dedicated to dry cow grazing, manure hauling, and more recently, in-house hay production.

Ten Mile Grade Dairy started baling dry hay and making baleage in 2024 — two jobs that had been hired out until then. Hayfields are seeded to limpograss, which was established after taking a sod cutting and a watermelon harvest on 400 acres across the road from the grazing dairy. Nickerson-Thurlow explained that the preliminary fieldwork and custom watermelon crop were essential to prepare seedbeds that were suitable for the new forage stands.

“By cutting the sod and having the watermelon guys farm it, they were able to disk the ground afterward and create a really nice, level field,” she said. “Then when we planted the grass, we fertilized it and took a couple of cuts off just to get the weeds out and control the forage.”

Holden managed the first forage harvest, cutting grass for baleage in the spring and baling a second cutting of dry hay in the fall. He put these bales in ring feeders that encircle pasture cooling ponds, feeding dry hay when

stargrass was dormant and supplying baleage for a short period pre- and postcalving to support cows’ elevated energy demands.

“We worked with a nutritionist whose idea it was to start wrapping bales and making baleage for transition cows,” Nickerson-Thurlow said. “We saw a boost in milk production, we saw a decrease in mortalities, and we just saw an overall improvement in our transition cows eating that fermented product.”

The impetus for on-farm forage harvesting was instigated by steep hay prices despite a less-than-desirable product. As they compared the costs and benefits of renting acres, buying equipment, and renovating cropland into perennial hayfields, Nickerson-Thurlow said the payoff seemed like it would be substantial — and immediate.

“That was just for a conservative number of bales, not to mention the added nutrition that our cows were able to get from better forage quality,” she explained. That bump in forage quality comes from their ability to control the harvest schedule and adjust cutting intervals according to their feed needs. They can tighten up harvest windows to secure higher quality forage or let grass grow longer to take advantage of more tonnage.

They’ve also started making bigger bales — 5-foot to 6-foot round bales — to reduce the number of ring feeder refills needed throughout the hay-feeding season. And gone are the days of footing the bill for transportation costs.

“Bringing our forage program in-house has made a lot of difference for

us,” Nickerson-Thurlow said. Even so, the merits of having homegrown forage are still at the mercy of Mother Nature, especially in central Florida.

“This year, we had an 85°F February, which is nice for forage growth, but that’s when my cows are peaking, and I really need it to be 65ºF so they’re more comfortable,” Nickerson-Thurlow said. Extreme heat isn’t always the biggest enemy. Delayed rainfall and extended cold seasons have also defined previous springs and early summers, not to mention heavy rains and hurricane damage that can cut grazing short in the fall and interrupt feed supply chains in general. Greening disease is another obstacle that has raised the Nickersons' feed costs. What was once a cheap by-product and a staple in their one-shot ration, citrus pulp is now hard to come by as greening disease has wiped out a large portion of Florida’s citrus industry. They’ve resorted to replacing that fiber component of cow diets with more expensive commodities. All of these challenges are thorns in the side of a dairy trying to maximize its margins. But wait — the story doesn’t end here. After months of waiting, it was as if someone pressed the fast-forward button on the farm sale. Earlier this year, a buyer with the resources to maintain the business, modernize the dairy, and tap into value-added markets for pasture-based milk answered the call. Though it’s still early in their relationship and the two parties are working together to navigate the transition, the Nickerson family looks forward to seeing the changes they had always envisioned for their farm finally begin to take shape. It’s a cliff hanger that turned into a happy ending after all — or rather, a new beginning.

“It’s a dream come true, but the heartbreak is real.” Nickerson-Thurlow said. She may be passing the baton to the next farm owner, but she won’t turn her back on dairy. As the former first vice president of Southeast Milk Inc., she’s developed a deep-rooted love for the industry and will continue to support dairy producers, especially those who implement sustainable practices similar to the ones at Ten Mile Grade Dairy. The larger mission of the sixstate marketing cooperative aligns with her personal goals, as well as her desire to preserve the roots that anchor the Nickerson family tree. •

A delayed hay harvest may not only reduce forage quality, but it can negatively affect livestock condition and field management in the long run.

by Jennifer Tucker

FTER 13 years of working in extension, I can say that the only constant is change. The same can be said about our weather. During our regular research updates, one key topic we must focus on during each summation is variances in production outcomes due to environmental differences each year — even in the same research station field. During my time in Georgia, I’ve learned that May is unusually dry — except when it’s not; drought is guaranteed in the summer — except when it rains; and a killing frost in the fall will shut down a forage crop — except in years that a killing frost does not occur until January.

As such, unpredictable rainfall can wreak havoc when your operation is

heavily reliant on the successful production of stored forages. The overall goals for producing stored forage should be efficient and profitable production and optimum utilization of a forage base that is able to provide high-quality stored feed during forage deficiencies.

How do we achieve this? As the old saying goes, “Timing is everything!”

Good timing is not only essential for a prompt arrival at the E gates of the Hartsfield-Jackson airport in Atlanta but is also important in hay production. The timing of fertility and stage of maturity at harvest can govern enhancements or deficits in forage quality and the profitability of the product being harvested. Mechanically harvesting forage results in high amounts of fertility being removed from the soil annually. Taking annual soil tests and making split applications of fertilizer as recommended by soil anal-

ysis will have a positive impact on stand persistence and forage quality. However, the stage of maturity at harvest is the single most important producer-controlled factor influencing forage quality, and thus, profitability.

Harvesting forage at the recommended stage of growth can deliver a palatable, digestible, and high-quality product. Delaying harvest for even a short period and allowing forage to exceed the recommended stage of maturity will result in a lower quality product. Remember, as the quantity goes up, quality goes down, and forage quality deteriorates at a faster rate as our forage continues to mature.

Delaying harvest has significant visible and nonvisible impacts. The folowing photo was captured during a har-

continued on following page >>>

vest date evaluation at the University of Georgia Tifton Campus. This is a great visual of what happens when we delay our harvest. We can easily see that as time progresses, forage grows taller. As such, there is lower leaf and greater stem growth. What we might not be able to see, however, is the inversely related impact on quality (Table 1). The more we delay harvest beyond optimum maturity, the more fibrous the material becomes, the more lignin is produced, and the less digestible the product is for our livestock. An efficient utilization of our forage base can easily be determined by animal performance.

The summer of 2013 will be one of those summers that I, as well as many others in the region, will remember forever. Continuous, almost daily summer rainfall caused significant delays of harvesting any forage material, hay or silage. When the weather cleared enough to finally put up some dry hay, the hay was several weeks beyond peak performance, and the quality was poor at best. For reference, the average relative forage quality (RFQ) of bermudagrass samples submitted to the University of Georgia was 80 that year, compared to the prior seven-year average of 95 RFQ. The impacts of storing poor-quality forage linger and compound in many ways, creating a domino effect, especially in adverse weather conditions.

We can’t meet livestock needs. If we consider when we are most prone to feeding hay, it is not when the weather is good and growing forage is abundant, but rather when forage is dormant and animal needs cannot be met by grazing. Historically, forage deficits occur during the winter months in the Southeast when days are short and temperatures are cold; however, over the past 10 years, significant periods of unexpected spring and extensive summer droughts have led to hay feeding much earlier and/or much longer in the year. This leads to an even greater reliance on high-quality hay.

Under these conditions, it is hard to meet the energy needs of our livestock, and it is near impossible to do so with poor-quality hay alone. For example, the nutrient requirements of a dry pregnant cow in terms of

As harvest is delayed, forage experiences less leaf growth and more stem growth.

energy and protein are 48% total digestible nutrients (TDN) and 7% crude protein (CP). If we refer to Table 1, these forage products are at acceptable levels even in the later harvest — but only for maintenance. If our cows are in peak or late lactation, those needs jump significantly to 60% and 55% TDN and 12% and 9% CP, respectively. Instead, we see that supplementation would be required to meet the needs of these cows based on our products above, especially in those later cuttings. This forage is also inadequate to meet the requirements of growing calves or breeding heifers. What’s more is that these energy needs are elevated by adverse weather, especially in the cold.

DOMINO NUMBER TWO:

Loss of animal body condition. When nutritional needs aren’t met, animal body condition will drop. The goal is to maintain a body condition score (BCS) of 5 or greater, especially going into the winter months. If BCS drops below this level, animal reproductive efficiency can be negatively impacted, resulting in lower conception rates and longer calving intervals. A drop in body condition is not easily corrected and can take up to 70 days to reverse.

Setting a goal of maintaining a BCS of 5 or greater in the herd, as well as keeping a close eye on animal performance, helps manage and protect our operations when we get into situations

of nutrient deficiencies and restriction. One key tool in our forage toolbox is a forage test. By testing our hay and knowing the nutritional value, we can keep track of the nutrients available and make well-informed decisions for feeding, supplementation, and meeting animal needs. In essence, we can match our feed to our animal’s needs before we see a drop in BCS.

DOMINO NUMBER THREE:

Amending the impacts of a delay. Recent weather patterns in the Southeast proved challenging for dry hay producers earlier this year. A sustained spring drought followed by continuous rain in some areas led to significant harvest delays. As we talk about harvest timing, often we are posed with the question, “What happens when I can’t get into my field?” One opportunity that is often overlooked in the region until we get into more significant wet seasons is harvesting our forage as baleage.

Baleage is forage that is harvested, wilted, baled at 40% to 60% moisture, wrapped in polyethylene plastic, and allowed to ensile. This is achievable in approximately two days, which is advantageous because we can maintain a more desirable harvest interval, targeting optimum quality and quantity. It is much easier to get a two-day window of ideal weather than it is to have a rain-free week, and the weather waiting game is where we often find ourselves in trouble.

If baleage isn’t feasible, there are few other options to consider. First, if forage is very overmature, consider harvesting the field as a straw for bedding. We consider forage with 45% TDN or less to have no substantial feed value. Straw is still a beneficial and marketable alternative; however, it’s not a sole feed option, especially during a hay shortage, which often occurs during adverse weather years. A forage test can best help you determine how the material should be used.

Avoid applying feed additives that encourage intake to very low-quality hay, as this can lead to impaction in the rumen and even death. Another option to consider is utilizing standing material as fertilizer in the field. As mentioned above, baling removes a significant amount of soil nutrients. If the field is significantly delayed, we can

recapture some of that fertility by simply mowing the field and allowing the mulch layer to deteriorate and redistribute itself into the soil. This method works best when you are already going into a seasonal forage transition and aren’t likely to be able to get an additional quality from cutting until the next hay season. This mulch layer can provide cover, weed control, and fertility while the field is resting.

A third option is to graze forage. There are many times when we may not be able to get the right weather window to get our heavier equipment in the wet field, but we can easily get around on all-terrain vehicles (ATVs) or on horseback. Grazing to better utilize the slightly delayed forage is a great way to efficiently harvest the material and get some feeding value from it while also resetting the field for the next harvest. Grazing is most effective when you are able to stock the field heavily and graze

Adapted from Studstill et al. (2014), University of Georgia.

does not impact your operation. In the instance that you aren’t able to avoid it, remember that unless you test, it’s just a guess! Get a forage test and know the

This 80-page manual explains best practices and references for each stage of corn silage management, as five expert authors detail guidelines for production, harvest, storage, and feeding. ©2022. $24.95

IN THE Ozarks of southern Missouri where my wife, Judy, and I have been grazing cattle for the last 40 years, the predominant forage our cows consume is endophyte-infected Kentucky-31 tall fescue. While the grass is not native to the Ozarks, it sure thinks it is, which brings both challenges and rewards because of its unique characteristics.

Since we no longer make hay, our challenge in managing forage year-round is determining how we graze to best utilize what grows on our place — especially during the spring flush. The cow-calf business is rarely so profitable that a lot of money can be thrown at problems, so the challenge is to work with what forages the farm has. And that can surely come in a hurry as 70% of that growth is from mid-April to mid-June. Our approach has been to breed and

graze animals that fit the farm’s grass and climate and to manage grazing so the cattle can best utilize those forages efficiently and profitably. Managed grazing has been a centerpiece of our farming life; however, a change we made in our business model of even more importance to our profitability was managing the seasonality of grass growth with cattle prices in mind.

Over the years, we’ve made plenty of changes in our grazing management and marketing strategies, eliminated haymaking, and switched cattle breeds. But in three decades, we have never changed our perspective in the seasonality of both forage growth and cattle prices to lower inputs and boost profits. It was a big change from how we started.

In 1987, we bought the farm, and

with it came close to 200 mama cows. This was during the farm crisis with falling land and commodity prices. The extremely low land prices were an anomaly due to a credit crisis in rural America. The low cattle prices were part of the normal 10-year cattle cycle — something we then knew little about. We decided to keep the cows, and since they began calving in mid-January, we became winter calvers by default. Since we bought the cows at the bottom of the cattle cycle, we were able to ride the increasing prices to overcome the mistakes we made in those early years — like overstocking our pastures.

Winter calving gave us big calves to sell as we ran out of grass in November, just in time to hit the historically lowest priced month of the year to sell weaned calves. Unhappy with that,

we began weaning and feeding the calves to feeder size and selling them in March — just in time to hit the historically lowest priced month of the year for feeder calves.

To make this a trifecta, we pregnancy tested in November and immediately took the open, often thin cows directly to market, and once again, hit the historically lowest priced month for slaughter cows. You would think successfully hitting all three of the lowest priced months for selling three different classes of cattle would take some thought and planning, but it seemed to come kind of naturally to me.

On top of this, we found the cows were difficult to breed back without a good deal of supplement and expense. Even then, the breed-back percentage in a 60-day window was not ideal.

After attending a grazing conference in Mississippi where I learned from some wise men about the importance of seasonality to a grazing business, I came home with the simple business model built around utilizing the spring flush to add value to livestock and to think of fall and winter grass as a precious commodity. The seed of the idea to match animal needs with the seasons had been planted, but the changes didn’t come all at once. However, we never wavered from this goal.

First, we moved to a true spring calving in April and May. This gave us calves born on green grass, but more importantly, it allowed cows to easily and cheaply put on weight between calving and breeding. We found that cows putting on weight after calving are highly likely to breed back in a short window. This timing also allowed yearling heifers to cheaply put on weight and have them cycling early — just on forage — before turning in with the bulls.

Then, we weaned the calves in January or February and kept them to graze. This way, we could take advantage of the excess spring flush of grass, and with good grazing management, cheaply put value and weight on the steers to be sold as feeders in July and August — often the higher priced months of the year for feeder cattle. Another key was starting to treat the open cows as an enterprise. Moving to a true spring calving meant we needed

cows to breed back in the heat and humidity of July and August. Since our predominant grass is endophyte-infected Kentucky-31, this added another hurdle to successful breeding. For decades now, we have bred and selected cows for heat and fescue tolerance, and our herd has a very respectable breed-back percentage. However, in the first decade of this program, we had plenty of open cows that we had to learn how to manage and when to sell them.

By matching spring grass growth with the cows’ requirements at calving, we were able to ensure there was plenty of grass at the time it’s needed most. Then, we closely rationed the grass during times when forage growth slows down and the cows’ nutritional needs decline. With the yearling cattle and open cows, we had a very liquid group of animals that quickly gained weight and value on excess spring grass yet could be sold anytime if dry weather

or drought began to threaten the main herds’ grazing. This gave us a flexible stocking rate to avoid running out of grass at inopportune times — it also gave us a good chance of selling closer to the seasonal high prices for feeder calves and slaughter cows.

Trying to synchronize cattle needs to the seasons has been helpful to us in lowering inputs and raising profits during the ups and downs of the cattle market and the swings in rainfall and temperatures. In future columns, I will explain more fully these changes and both the pitfalls and rewards these changes have brought about. •

WHEN walking a feedbunk filled with a total mixed ration (TMR) containing some haylage, it’s pretty easy to spot haylage chunks that didn’t get broken up and mixed. These chunks stick out like a pink sheep in a white sheep herd.

This likely resonates with your farm if you’ve fed a ration with any amount of haylage in it, though this month’s column isn’t exclusively centered upon haylage chunks in the feedbunk. Instead, I’m aiming to help your farm think through and smooth out other areas in your forage management and feeding plan.

Forage contributes nutrients, energy, structural fiber, and moisture to the ration. The moisture and sticky nature of some forages can contribute to overall ration consistency by holding the many ingredients together and preventing sorting. At the same time,

forage often contributes inconsistency to the ration through unrecognized variation in nutrients, energy, and feed hygiene characteristics. Bag silos are the most likely to deviate in quality day to day; however, my experience over the past five years with much larger silage bunker and pile silos has uncovered opportunities to improve by addressing issues that are rooted in nutrients and feed hygiene inconsistencies.

These opportunities can be found by addressing two general time frames when we manage forage, either within one day’s feeding or in the forage that is fed out day to day. The daily defacing and feed mixing strategies will differ dramatically from one farm to the next. However, our goal should be to present a uniform forage feed ingredient into the first and last batches of

mixed feed.

It can be easier to visualize field or crop driven variation in grass or alfalfa haylage within the bunker, pile, or pit. In some cases, we can analyze moisture or nutrient content for left, center-bottom, center-top, and right samples to showcase meaningful variation that should be smoothed out. Whether we take this step or not, it’s often a great idea to deface the forage and pre-mix it to some extent. This can be done by pushing the feed into a center pile and mixing it with a skid steer or payloader bucket prior to the day’s feeding.

Some farms go further, blending feed in a mixer and unloading a consistent forage for later feeding. This latter, more intensive step makes even more sense for farms feeding out of bags, and we can feed from multiple bags to help smooth out the bumps in forage

quality or moisture as well. Don’t assume corn silage is consistent either, as the left-to- right variation in many bunkers should also be smoothed out to some extent.

Shifting gears to day-to-day variation, many farms monitor moisture one to several times per week. If your farm is feeding several hundred or more cows, I’d suggest setting up a protocol to monitor moisture two to three times per week. Then, use a rolling average to manage moisture and dry matter adjustments. Don’t assume that moisture and nutritional quality changes trend together.

Historically, I’d use moisture as a canary in a coal mine to forecast nutritional changes. But over the past five years, I’ve experienced time and time again where starch in corn silage or protein in haylage change dramatically in the absence of any moisture deviation in that same time frame. This has been a strong talking point among colleagues, as we’ve been struck by how frequently feed energy or nutritional value change when sampling feeds one or more times per week. Our prior experience and assumptions — based upon monthly forage testing protocols or reacting to herd performance changes — are seemingly obsolete in light of these new, faster paced experiences.

Forage can also contribute some farm speed bumps by way of fermentation irregularities or feed hygiene flare-ups. Try as we might to manage fermentation, my recent experiences with many growers proves that Mother Nature still drives a majority of the silage or haylage fermentation outcomes that we experience.

The initial goal with ensiling forages is to pack and seal up a forage crop that has suitable sugar content to feed the fermentation bacteria. Many different factors such as less than ideal sugar content or higher ash content, which are often beyond our control, can create more challenging fermentation conditions. These situations often come about following an unexpected rain giving the wilting forage a soak. If possible, manage these rained-on acres separately from the rest of the crop.

If substandard fermentation prevails across the entire crop, ramp up efforts to monitor inconsistency in fermentation as it’s fed out. We can do this with moisture, temperature, or fermentation assessments, but don’t assume the crop will ensile similarly. I’ve found the inconsistency in this forage to be equally as challenging as the forage with substandard fermentation. In a lot of cases, I think the nutrition program can be improved by managing inconsistencies found within the lessthan-ideal forage.

Lastly, feed hygiene issues such as undesirable fungi, bacteria, or other contaminants can bring about major inconsistencies in animal health and performance. This last topic should be its own column.

I’ll reiterate what I’ve learned from mycotoxin expert Lon Whitlow — step up your monitoring efforts and do not

assume the contaminants are evenly dispersed across your forage. There are hot spots in feed hygiene cases, which can sometimes be managed without necessarily spending big money on expensive feed additives. Think of these like finding the haylage chunks in a TMR. Sometimes they’re indicative of a larger issue, but other times they are not.

Keep these different areas in mind as your farm continues to pursue greater consistency in forage production, management, and feeding. Dairy and beef cattle thrive on consistent feed, and there are likely ever-present opportunities to secure that on your operation. •

GOESER

The author is a dairy nutrition and management consultant with Progressive Dairy Solutions Inc., and an adjunct professor at the University of Wisconsin-Madison.

by Beth Reynolds

S THE end of the growing season is on the horizon and there is less forage regrowth, grazing hayfields, rather than harvesting a final cutting, is a cost-effective strategy where feasible. While producers all over the U.S. regularly graze alfalfa and other legumes, precautions to prevent bloat are necessary.

Bloat is commonly understood by producers as gas buildup in the rumen, but a better understanding of bloat type, cause, and effective mitigation are also important considerations before grazing alfalfa.

Simply put, bloat occurs when gas is produced in the rumen as a by-product of digestion and exceeds gas expulsion, primarily through cow belches while ruminating. In most cases of digestive bloat — and nearly all cases of bloat from forage diets — the gas produced is trapped in a stable foam, creating “frothy” bloat.

The main dietary components believed to attribute to foam formation include soluble leaf proteins, saponins, and hemicelluloses. All three of these compounds are found in elevated levels in alfalfa compared to most perennial grasses. Bloat risk is elevated in vegetative alfalfa because its highly digestible components allow plant cells to be broken down faster, making those compounds available at a more rapid rate, exacerbating foam production and gas entrapment. In more fibrous or higher lignin forages, digestion occurs slower. Plus, cattle ruminate more, aiding in saliva production, which has anti-foaming properties.

Bloat can and often does occur to a lesser degree in which no intervention is needed. However, when acute cases of bloat arise, rumen distention causes issues with respiration, and the ultimate cause of death is typically suffocation. In herds experiencing bloat, one can typically find a range of severity among animals.

To combat cases of frothy bloat, strategies to relieve the gas buildup, like inserting a tube down the esophagus, are not very effective. Rather, using something to break down bubbles is nec-

essary. Antifoaming agents that have been shown to be effective treatments in emergency situations include vegetable or mineral oils, poloxalene, and other surfactants. In mild cases, encouraging animals to walk or consume fibrous feed can help relieve symptoms.

Like most health challenges, prevention is the most effective solution for bloat. If grazing alfalfa this fall is an option for you, take a multifaceted approach and consider these recommendations to reduce the risk of bloat.