Tectonics of Precast Concrete: Rare Book & Manuscript Library

Location Raleigh, North Carolina

Academic Creations in Concrete Studio, Spring 2024

Instructors Dana Gulling, Greg Lucier

Contributions Designed and detailed the project, integrating precast concrete through iterative studies. Produced all drawings, renders, and the physical model displayed in the project.

The Rare Book and Manuscript Library is a design proposal for a dedicated archival facility in Raleigh, North Carolina. The project explores the use of precast concrete as both the structural and enclosure system to create a durable and controlled environment for the preservation of rare books and manuscripts.

The program includes climate-controlled archival stacks, a reading room, restoration spaces, and public exhibition areas. The design balances daylighting strategies with material performance, ensuring that the library remains both functional and architecturally expressive.

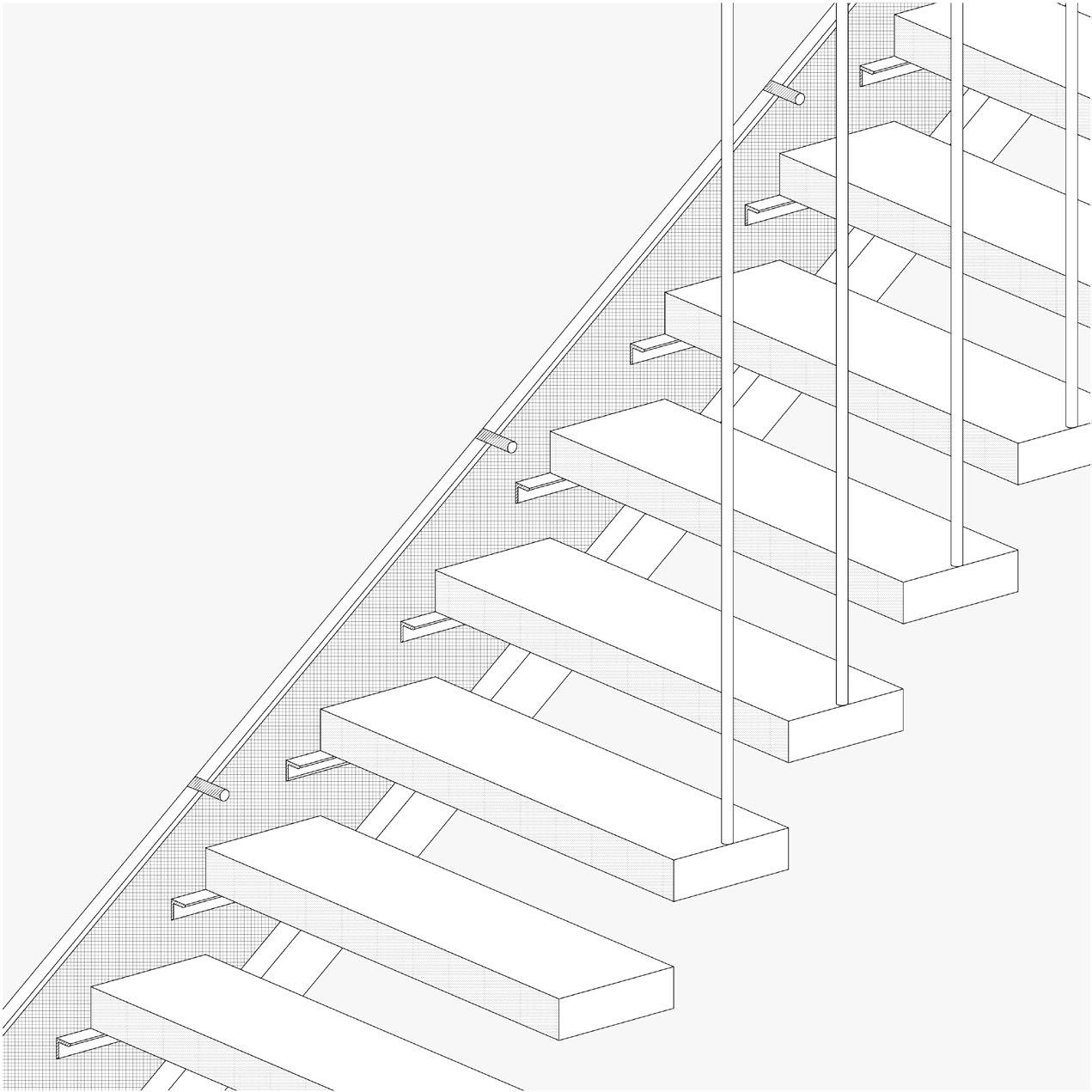

The design features a veil-like precast concrete envelope that defines openings and controls daylight. The form is split into two blocks, separated by an atrium that directs circulation and frames views. Precast panel widths vary based on daylight needs, guiding movement and differentiating public and restricted areas.

Adjacent to NC Freedom Park, the project responds to key civic structures like the General Assembly Building, State Archives, and Governor’s Mansion. The building height and verticality of the precast panels align with the surroundings. A modified pathway from Freedom Park enhances site connectivity.

The relationship between the façade and wall section highlights the building’s response to light, program, and materiality.

The reading room on the ground floor receives ample daylight, while the archival stacks on the second floor are enclosed by precast sandwich panel walls and a precast concrete veil, limiting sunlight exposure to protect the books.

On the third floor, a rooftop deck offers users an open space with views of the urban context.

Tectonics of Precast Concrete:

Full-Scale Roof Panel

Location Raleigh, North Carolina Academic Creations in Concrete Studio, Spring 2024 Instructors Dana Gulling, Greg Lucier Team Harsha Raju, Kunal Bhardwaj, Gabrielle Schiltz, Isabella Powell, Arianna Lotfi, Wayne Holness, Christian Gonzalez, Aakriti Khadka, Zoe West, Khaled Al-Sakaji

Contributions Involved in design development, coordinated with civil engineering students on structural reinforcement, assisted in mold fabrication and casting, and documented the process.

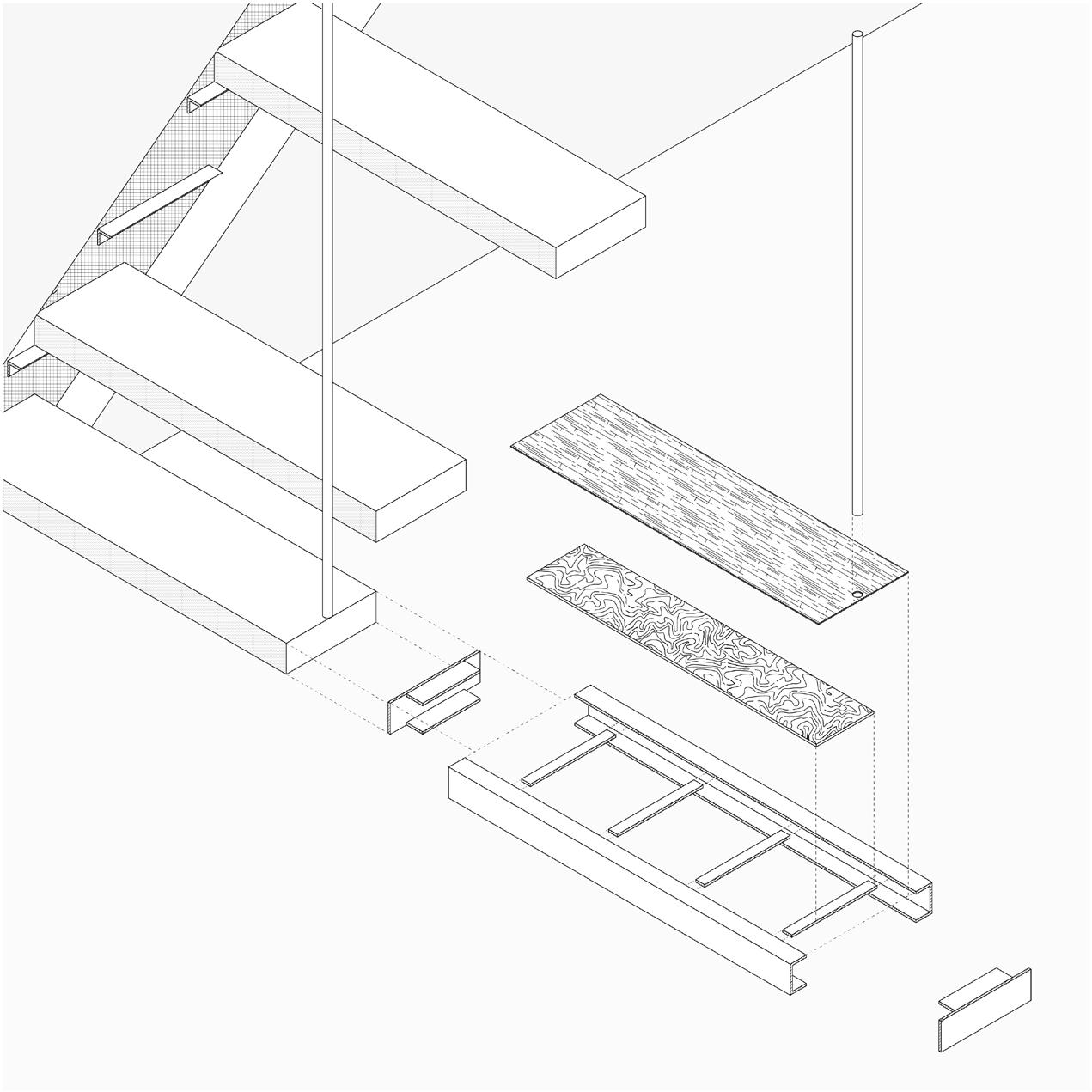

The Full-Scale Roof Panel project is a fabrication and testing exercise exploring precast concrete as a spanning structural system. Designed and built in collaboration with civil engineering students, the panel was tested for strength, durability, and aesthetic qualities to assess its viability for real-world applications.

The project involved mold-making, concrete casting, and structural load testing, integrating material research and fabrication techniques. The design considerations included surface finishes, formwork innovations, and modular assembly, providing key insights into the application of precast systems in architectural design.

03. Structural Reinforcement

Top Mat Reinforcement

Primary Reinforcement

Exploded View of Formwork & Reinforcement Assembly

CNC cutting MDF layers for the mold.

Preparing and cutting MDF layers.

Applying Bondo and mold release.

Casting concrete into the mold. 01.

Placing the mold inside formwork.

Curing the concrete.

Stacking and aligning MDF layers.

Securing the mold for stability.

Sealing formwork with silicone.

Placing reinforcement in formwork.

Removing the formwork.

Demolding the panel.

The precast panel was tested for stability and later subjected to a load-to-failure test to assess structural performance. The process helped evaluate material behavior, reinforcement effectiveness, and failure patterns , providing key insights for future applications.

Center for Student Athletes

Location Raleigh, North Carolina

Academic Integrative Design Studio, Fall 2023

Instructor Dr. Jianxin Hu

Team Harsha Raju, Weatherley Tripp

Contributions Developed the schematic design, produced exterior renders, created wall sections, and worked on mechanical and code path drawings

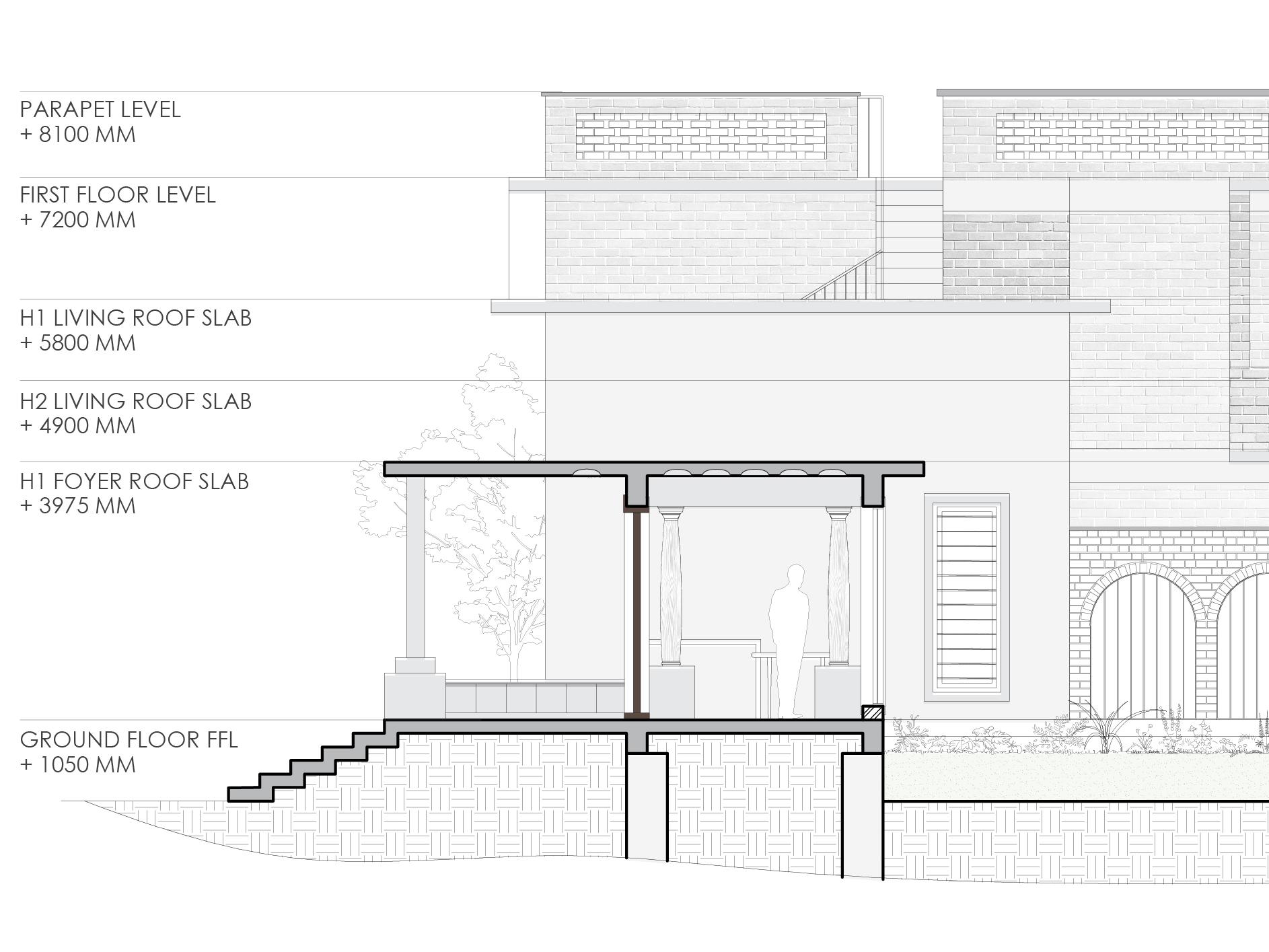

Center for Student Athletes is a design proposal to replace the outdated Case Academic Center on NCSU central campus. The overarching goal of the project is to enhance the academic, nutritional, personal, and professional development of student-athletes at NC State University.

The design program includes athletewellness facilities such as Kitchen, Dining, Nutritionist and Psychologist Offices; Learning and Tutorial spaces such as Computer labs and Classrooms; Common spaces such as Basketball court, Workout spaces, Media rooms and Lounges.

CatesAvenue

The design integrates into its context, complementing both the historic Reynolds Coliseum and newer campus landmarks like Talley Student Union and Carmichael Gymnasium. The facade combines terracotta panels and curtain walls in an eclectic approach, balancing NC State’s traditional brick architecture with modern elements.

the Reynolds Coliseum street activation

the building with Coliseum enhances activation and visibility.

Angular cuts create a funnel effect, drawing pedestrian traffic inward.

A water body guides circulation and extends space for the basketball court.

A central atrium channels movement through the building, connecting all facilities.

A

Clay Craft Continuum:

Ceramic Vessel Assembly

Location College of Design, NCSU, Raleigh, NC

Academic Architectural Ceramic Fabrication, Fall 2023

Instructor Shawn Protz

Team Harsha Raju, Srinath Sivakumar

Contributions Designed the vessel, involved in generating textures through Grasshopper scripting, ran 3D printing iterations, renovated and painted the site, fabricated and installed the support structure, and collaborated in glazing and firing.

This project explores 3D-printed ceramic assemblies, drawing inspiration from North Carolina’s clay craft tradition. The vessel was designed to channel water and integrate with a specific site at the College of Design.

Parametric designs were developed in Grasshopper, and iterations of 3D printing were tested using the WASP 3D printer and fired in the Skutt 1027-3 ceramic kiln.

The installation site, a light well in the ceramics lab basement, was renovated. A custom support structure was fabricated and installed to suspend the vessel, completing the transformation of the space.

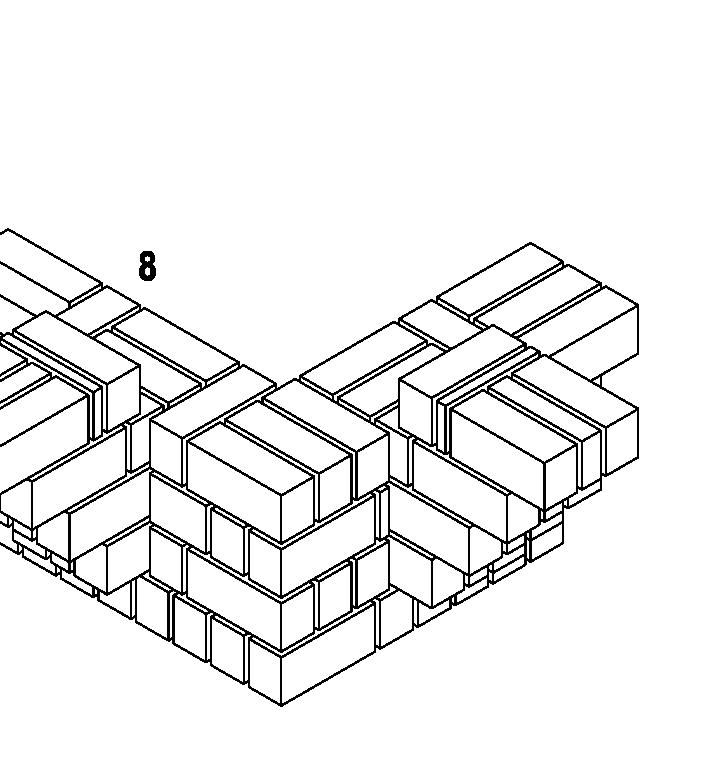

Vessel modules that have the same width and depth but different heights

Sketch showing all the individual modules being stacked over each other

Modules stacked with incremental heights to depict the act of gravity contrary to the nature of clay

Color Gradient from dark to light

Color gradient from dark to light in order to reinforce the illusion created by the modular arrangement

Surface protrusions from 5 mm to 1 mm

Surface manipulated in terms of Amplitude of clay protrusion and the Wave patterns

Final output showing the ceramic vessels, 3D-printed, glazed and arranged as per the design

Documentation showing the process of getting acquainted with the ceramic art, exploring the limitations and possibilities of ceramic 3D printing through trial and error.

Documentation vessel underwent

Documentation showing the production process of the vessels, ensuring they met the desired design and quality standards. Each underwent a sequence of steps, including clay wedging, 3D printing, bisque firing, glazing, and final glaze firing.

Before the installation

Clay Craft Continuum:

Tactile Tile Installation

Location Governor Morehead School, Raleigh, NC

Academic Freedom by Design, AIAS, Spring 2024

Mentors Shawn Protz, Bryan Bell

Team Harsha Raju, Kunal Bhardwaj

Contributions Involved in all aspects of the project from start to completion. Worked on design development, 3D printing, tile fabrication, glazing, installation, and grouting.

This project was part of the Accessible Outdoor Learning Environment at the Governor Morehead School, designed for visually impaired students. The Tactile Wall consists of seven precast panels representing North Carolina’s landscapes, with a niche running through them to accommodate tactile ceramic tiles.

The task was to design and install tactile ceramic tiles within the river element to enhance the sensory experience. The final installation transforms the Tactile Wall into an interactive and textured element within the school’s playground and park.

Taking paper templates on site.

3D printing ceramic cylinders.

Cutting individual tiles.

Refining templates for accuracy and fit.

Experimenting with textures.

Laying out tiles to dry before firing.

Creating wooden templates.

Testing wooden templates on site.

Unrolling cylinders into sheets.

Tracing and cutting ceramic sheets.

Glazing and firing for durability.

Installing tiles on site.

ECU Brody School of Medicine

Location Greenville, North Carolina

Professional Internship, Summer & Fall 2024

Firm BSA LifeStructures

Mentor Kevin Hunt, Architecture Lead

Contributions Worked on construction documentation, including parapet details, plan details, wall section details, material specifications, and code path drawings. Collaborated with the architects at BSA and SmithGroup to resolve documentation challenges. Engaged in team discussions to refine technical details

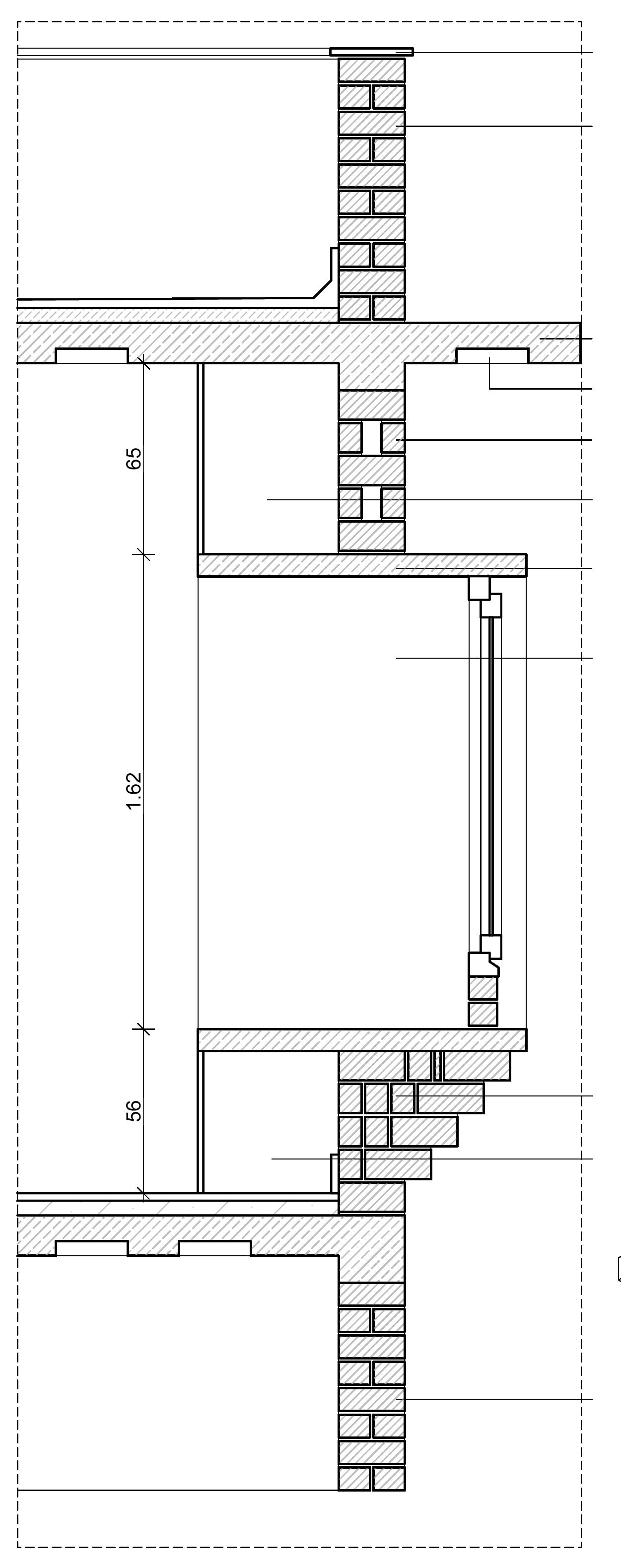

The ECU Brody School of Medicine’s New Medical Education Building is a 195,000 sqft, $265 million project designed to expand ECU’s medical education facilities.

The project required architectural, structural, and systems coordination between BSA LifeStructures and SmithGroup to develop a comprehensive construction package.

During my internship, the project was in the construction documentation phase, where efforts were focused on refining technical drawings and material specifications.

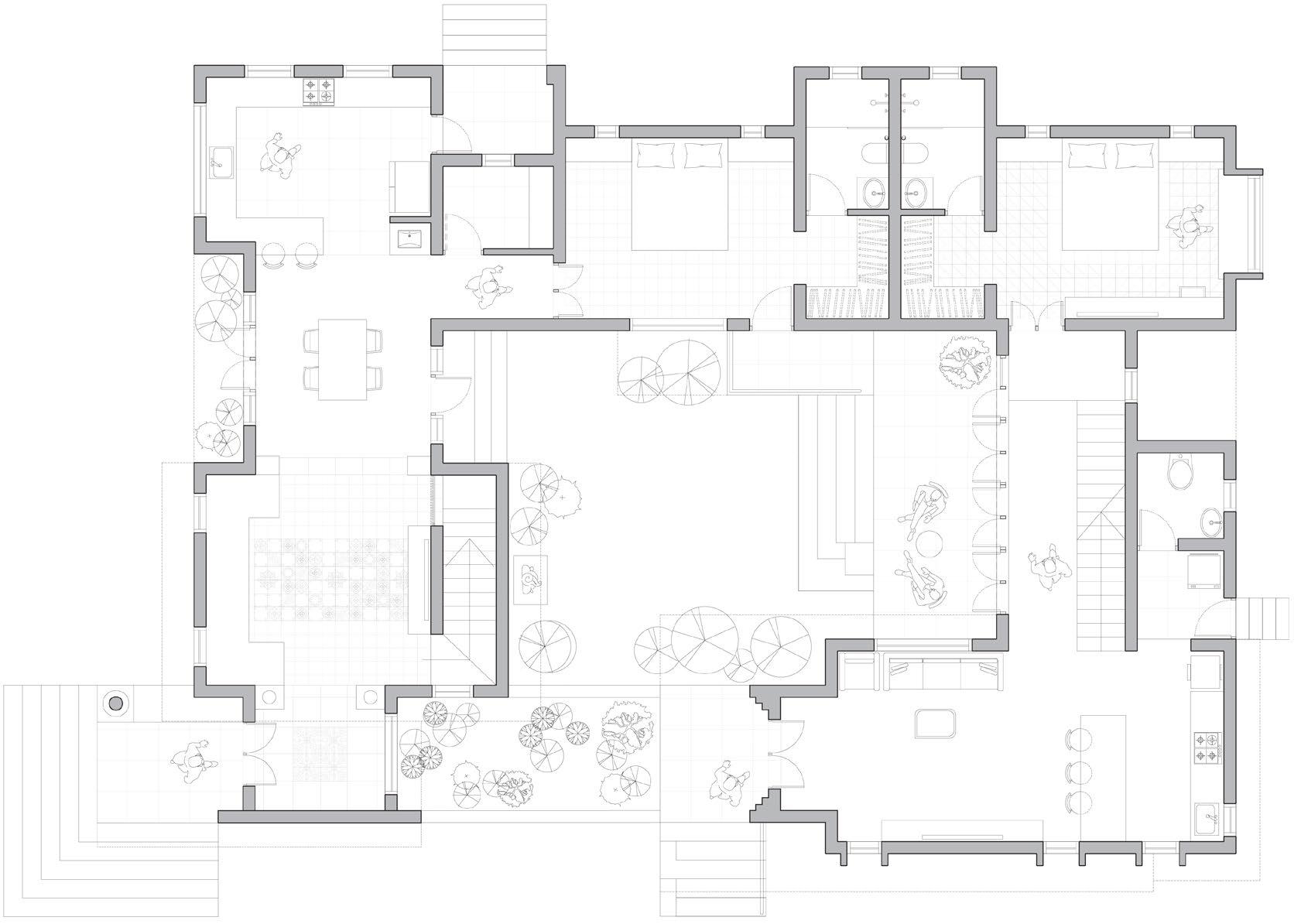

Floor Plan

The Brody School of Medicine project is an addition to the existing building, requiring careful integration of expansion joints and structural connections. Work focused on refining key details to ensure seamless coordination between new and existing construction.

Mockup Panel

Led the development of a full-scale mockup panel, refining the design through collaborative iterations. The design progressed to the approval drawings stage without revisions from others. The panel incorporated a specialty brick wall, multiple cladding types including brick and composite metal panels, different mullion types, parapet caps, and lintel and sill connections.

Parapet Details

Developed critical façade details, focusing on the integration of thermal, air, and moisture barriers to enhance building performance. Work involved understanding metal flashing details, roofing systems, and metal composite parapet caps.