THE CORE ISSUE: WHY REMANUFACTURING IS GOOD FOR THE AFTERMARKET

Let’s get technical

INSTALLATION TIPS ON CLUTCHES & STABILISER LINKS

BEST PRACTICE ADVICE OFFERED ON ENGINE COOLANT SENSORS, BRAKE DISC SHIELDS, BRAKE VIBRATION,EXHAUSTS & ADDITIVES

BUSINESS SOLUTIONS FROM ALLDATA,AUTOWAVE & THE GEA

TOM DENTON ON EV SERVICING

THE POWER OF ADDITIVES

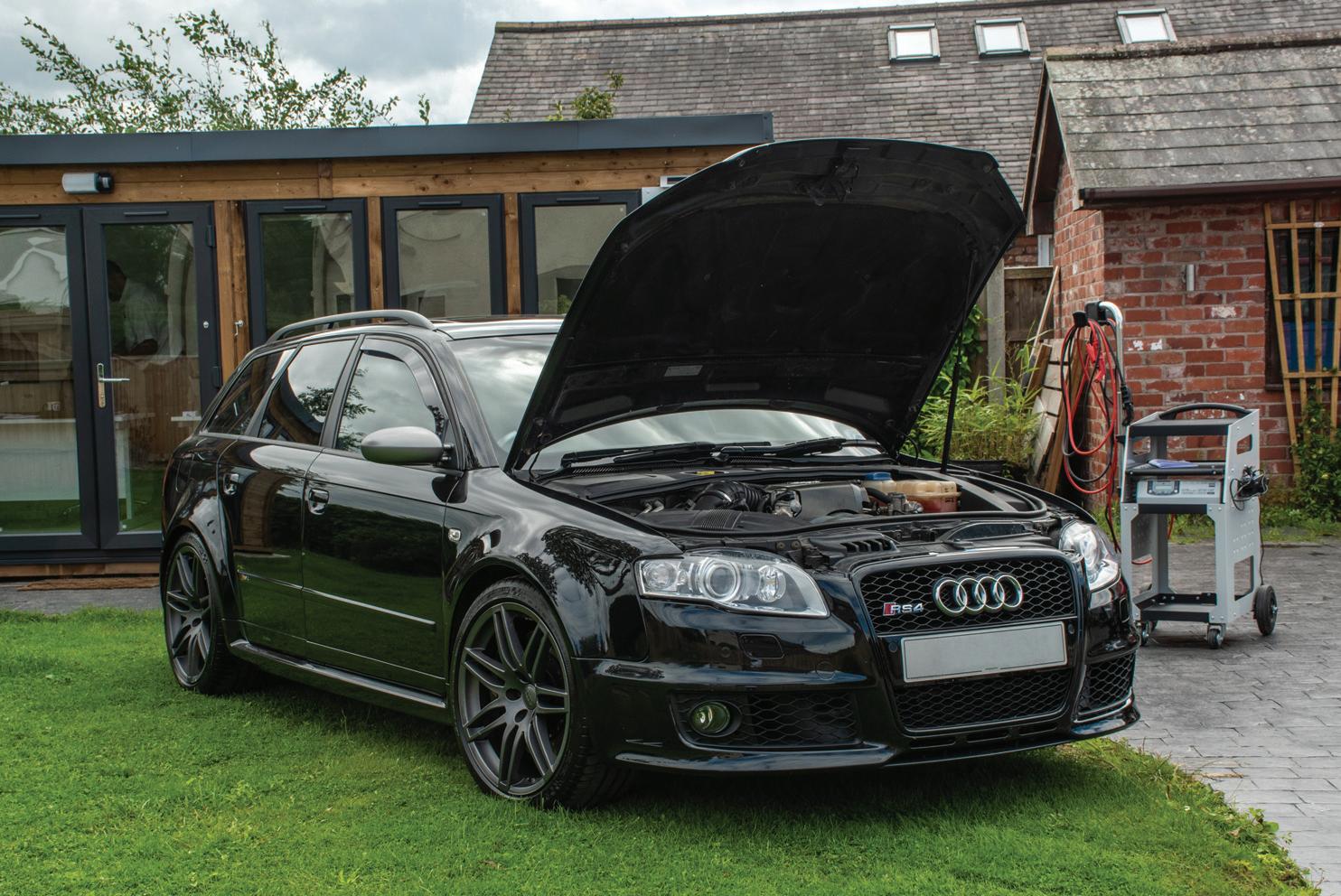

TONY POWELL’S DIAGNOSTICS

TOP TIPS REVEALED

HOW DIFFERENT IS LIFE IN THE PIT LANE ?

FREE TOTHE TRADE

MARCH 2023

PMM PROFESSIONAL M OTOR M ECHANIC

Editor’s Picks

Diagnostics

Tony

Read about how you can join workshops from around the country by signing up to NGK’s new training initiative featuring a portal with over 270 technical training videos.

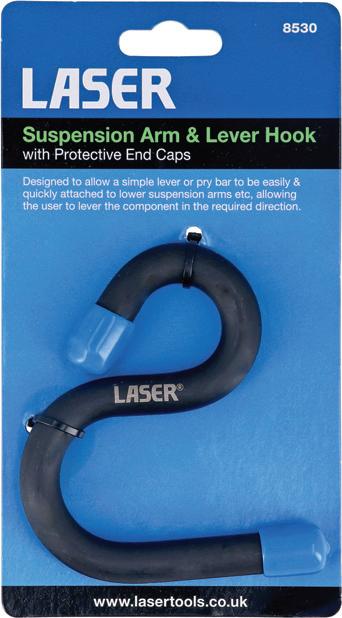

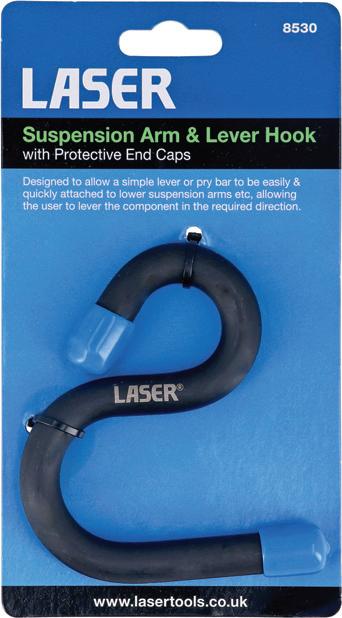

51 TOOLS FOR SUCCESS

Looking after your tools correctly is more important than ever. Sealey shares some best practice on making tools last longer.

60 STEP-BY-STEP

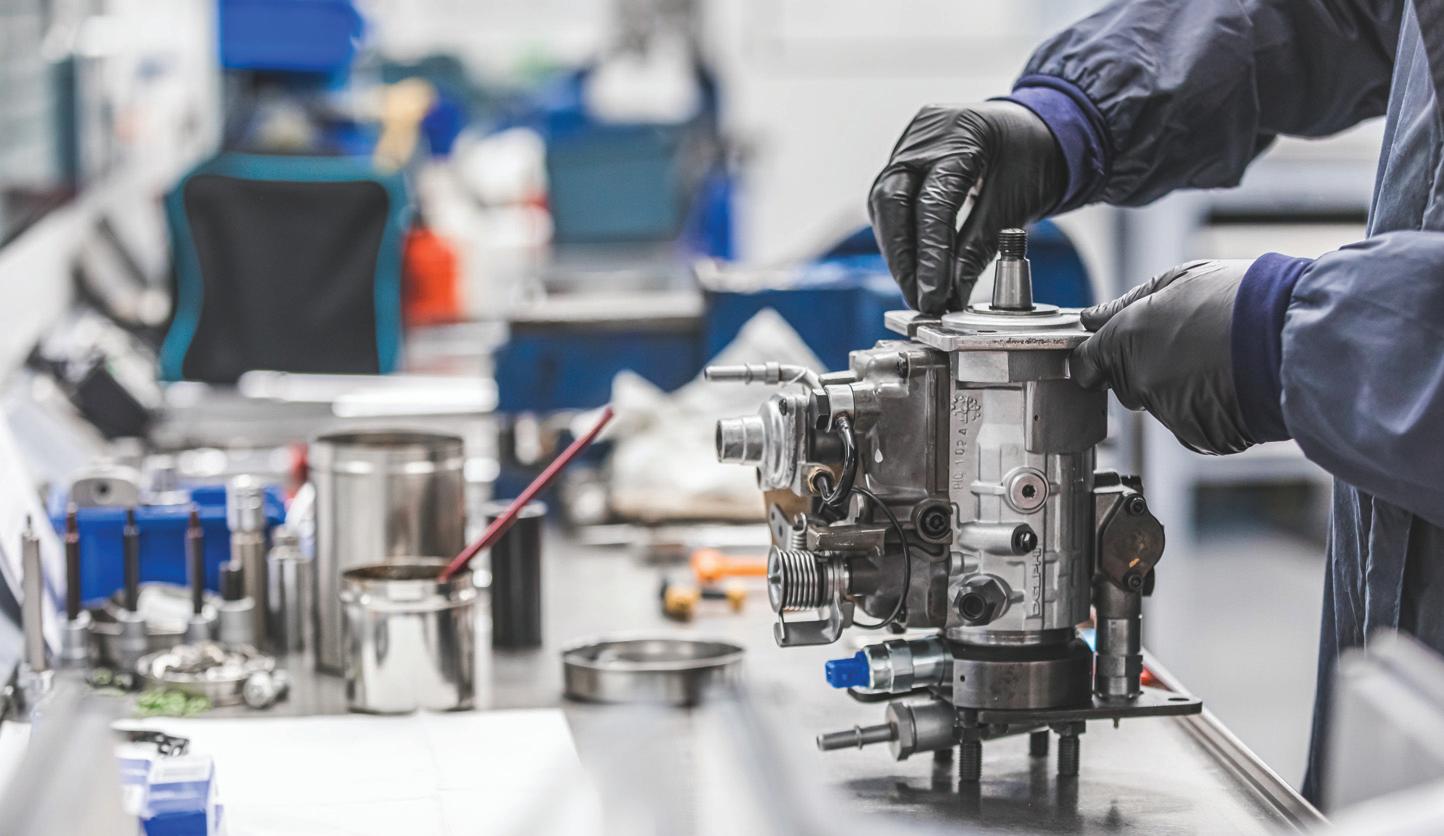

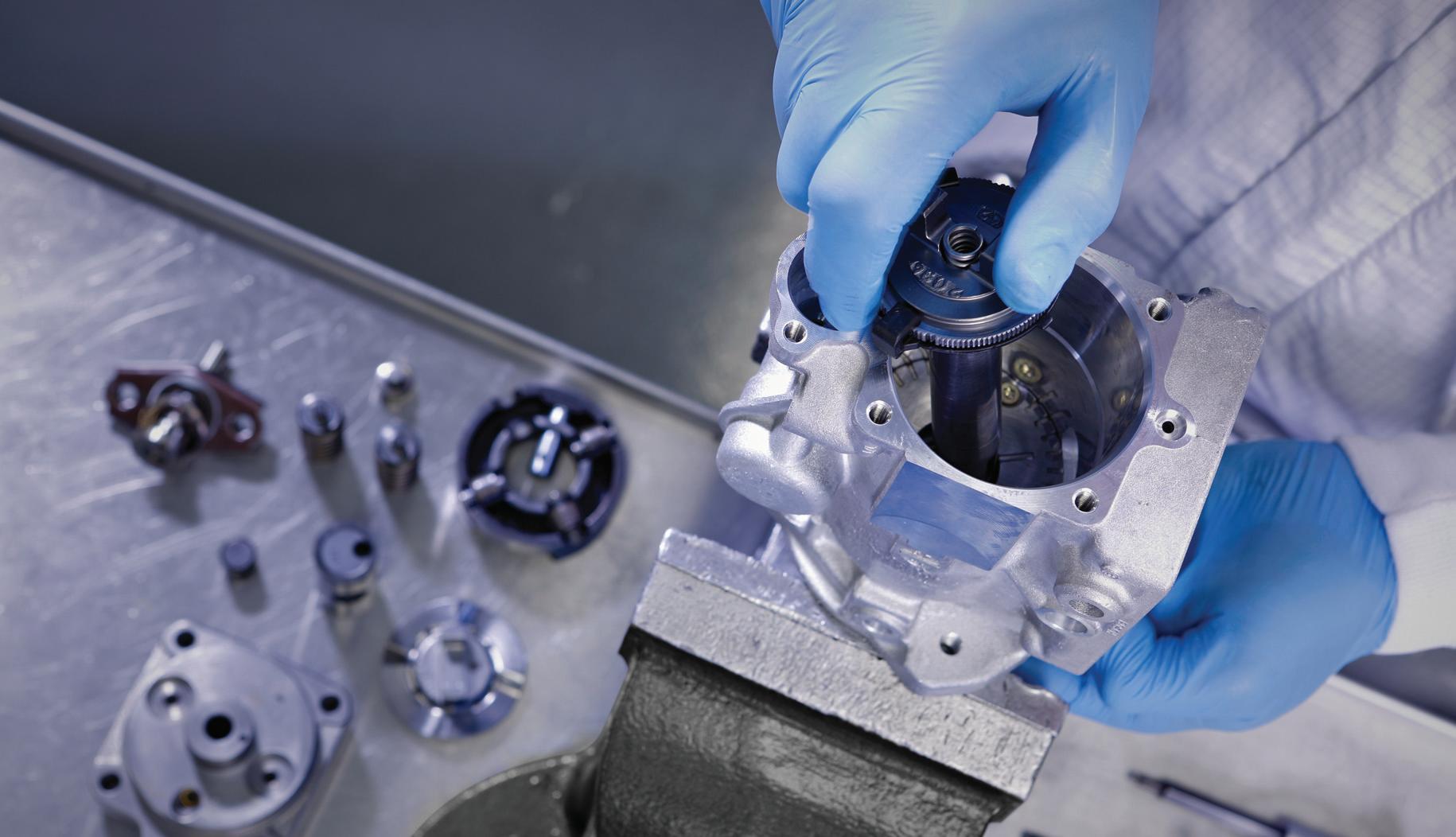

ACtronics’ Thijs Jasink takes PMM readers through every step of remanufacturing a part including diagnosis and removal to packing and sending.

Contents VOLUME 24 ISSUE 3 MARCH 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM MARCH 2023 3 41-49 EXHAUSTS & EMISSIONS 51-55 TOOLS & GARAGE EQUIPMENT 57-63 REMANUFACTURING Regulars 6-10 AFTERMARKET NEWS 12-13 TROUBLESHOOTER 14-15 CLUTCH CLINIC 17-26 TECH TIPS 29-31 BUSINESS & TRAINING 32 PIT STOP 34-39 SPECIAL REPORTS 64 ONLINE REPORT 65-66 WHAT’S NEW?

12 FAULT FINDERS

vehicle faults.

expert

Powell shares some tips and tricks he’s picked up during his career diagnosing

29 TRAINING UP

Editor KIERAN NEE

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50

Airmail 1 year (11 issues) £65

Location, location, location

Where is your garage? Does it even matter? There are certain places where garages tend to congregate: on the edges of towns, larger ones in industrial estates, smaller ones wedged in between shops along main throughfares and, of course, the ones tucked in under the railway arches. Where your garage is located might depend on a number of factors. Maybe you didn’t have much choice – in big cities space is at a premium and businesses find they have to make do with whatever is available. Perhaps you chose an industrial unit which would provide you with plenty of space, cheap rates and less headache, but without the potential business from passing traffic. Or maybe you inherited the space along with the business and you’re working within the same four walls that generations did before you.

I ask because I have recently purchased my first home, on the same street of which is a garage in a beautiful old yellow brick building which has been holding out against the developers – but perhaps not for much longer, unfortunately. Renovating what my partner and I will call home for potentially a very long time inevitably brings to mind the considerations surrounding the places we live and work in. The pandemic changed where many of us work, and although vehicle technicians are unable to work from home, it will have altered many of the habits of their customers. Customers who would bring their car into the garage next to their work may now find it easier to bring to their local.

Printed

by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

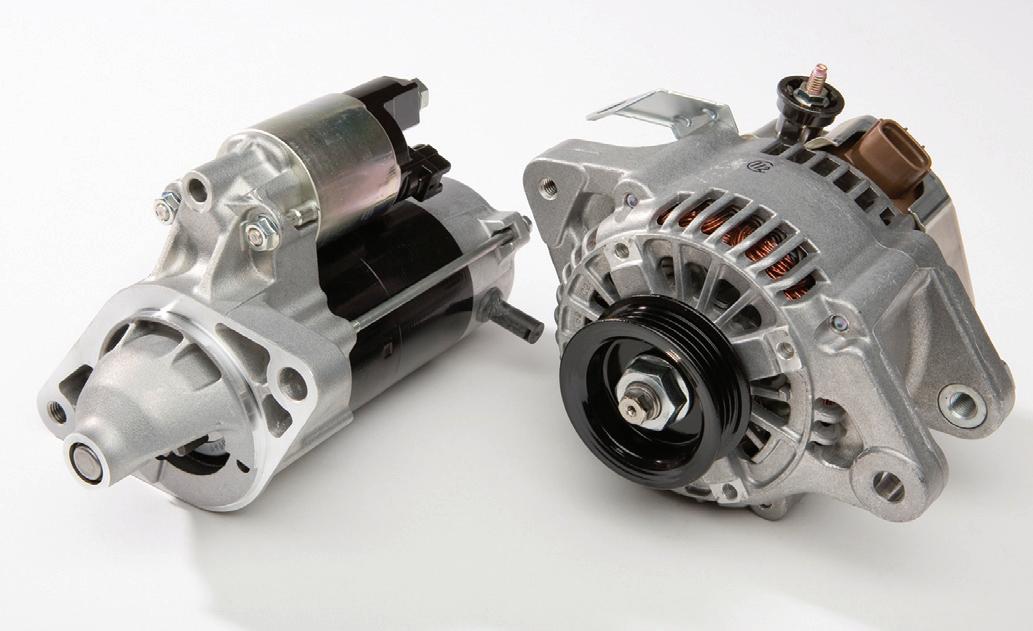

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic

Twitter: @pmmmagazine

Copyright © 2023

publishers

Choosing where to live, or indeed where to start a business, is necessarily a compromise and a balancing act. It’s more expensive to live in the town, but you will be closer to other people –friends, family, customers. You might need more space to expand, but where there is space there might not be sufficient infrastructure to facilitate much expansion. If you open a workshop near other workshops, there will be more competition but also a wider pool to recruit from. Whatever you choose, or have chosen, will come down to what your priorities are.

I think I have chosen a good place for a home and I hope the local garage stays put well into the future – if they move, they won’t be the same without the place and the place won’t be the same without them.

Kieran

Editor

Nee

VIEWPOINT

Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

The

and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication.

‘‘

I think I have chosen a good place for a home and I hope the local garage stays put well into the future”

PMM NEWS with

NEWSIN BRIEF

■ BEN

Ben, the automotive charity, has launched a new text service which offers support for those struggling in the aftermarket and beyond atany time of day.

■ THE SOCIAL MARKET FOUNDATION

The cross-party think tank is warning that Britain will not have enough EV techs to service the car parc come 2030. The think tank predicts a shortfall of 25,000, however emphasises that the technicians of the future will be more highly skilled than at present.

■ BOOKMYGARAGE.COM

BookMyGarage.com has announced the addition of mobile mechanics to its offering after a survey found that 68 per cent of its customers would consider using one.

■ GROVE GROUP

Automotive supplier Grove group has extended its portfolio of workshop services and products to encompass a range of electric vehicle charging systems. The service comes following customer requests to charge both customers’ and employees’ vehicles.

More MOT madness ahead

The government has put forward more MOT plans, proposing to change the required date at which the first MOT for cars is from three to four years. The Department for Transport says this could save motorists around £100 million a year in MOT fees.

This proposal comes following a public consultation that has also been seeking views on the frequency of MOTs and how to improve monitoring of emissions. Up for consideration is whether to introduce the testing of pollutants, whether EV batteries should be tested to improve their reliability and how the DVSA can continue to crack down against MOT and mileage fraud. Following the launch, the Independent Garage Association has announced that it will be carrying out an assessment of the proposed changes, consulting with its members and the wider industry to ensure representative feedback is provided.

Industry voices

Stuart James from the IGA has responded to the proposals, saying that it is inevitable that plug-in hybrids and EVs will impact the way the MOT works. He also commented that “the MOT plays a vital part in keeping the UK’s roads amongst the safest in the world, and the IGA will work closely with the government to safeguard this record and ensure a fair, viable and safe future for the MOT system which protects all road users.”

In the same vein, Karen Rotberg, cofounder of BookMyGarage.com, said: “The fact the government is pitching these proposed changes as a way to save motorists money is farcical. On average, drivers pay £35.52 for an MOT test booked through our

Freya Coleman

website – that’s less than the cost of half a tank of petrol in a typical family car.”

The IAAF has also said it will fight any proposals to extend the frequency of the MOT test, arguing that the increase in the first test frequency will see the number of defective vehicles on the road rise, causing an increase in accidents and fatalities.

SMMT chief executive Mike Hawes said: “Although today’s vehicles are safer and more reliable than ever, safety critical components such as brakes and tyres continue to wear through normal use and lead to millions of MOT failures every year, including at the current first test at year three”.

Whilst four years is the standard in most European countries including Belgium, France, Italy and Spain, data obtained by BookMyGarage.com from the DVSA via a freedom of information request showed that 13 per cent of three-year-old vehicles fail their first MOT on a major or dangerous defect, rising to 15.4 per cent for four-yearold vehicles.

6 MARCH 2023 PMM

13 per cent of three-year vehicles fail their first MOT on a major or dangerous defect raising to 15.4 per cent for four-year vehicles

FOR UP-TO-DATE NEWS, SIGN UP FOR THE WEEKLY E-NEWSLETTER AT WWW.RDR.UK/AAV001

A longer life

According to data from the European Automobile Manufacturer's Association from its ‘vehicles in use’ report, the average car in the UK is 10 years old.

The average age of UK cars is expected to climb further in the years ahead following a significant decrease in new-car sales. Of the 36.7 million cars registered in the UK, 21.5 million are less than 10 years old. Comparing

this to the European Union, the average age of cars there is 12 years old, up 0.2 years compared to figures from the previous year.

NEWSIN NUMBERS

58 %

of motorists are less likely to swap their car in 2023 due to the cost-of-living crisis, reports January’s Startline Used Car Tracker.

90 %

of independent garages expect rising costs, taxes and energy bills to be the biggest operational challenge in 2023.

1 in 5

breakdowns on the road are caused by tyre failure.

In pictures: Co-founder of the Speed of Sight charity, Mike Newman, dubbed “the world’s fastest blind man”, has been honoured with an OBEfor services to people with disabilities, including visual impairments, in the King’s New Year’s Honours List. Congratulations Mike!

Essentialoilchanges

The VLShas warned motorists not to put off essential oil changes and top ups, despite pressure on household spending. Workshops are the front line and can help play an important role in helping customers understand how important oil servicing is.

Mike Bewsey, chairman of the VLS, said: “Postponing or skipping oil changes or ignoring the oil warning light is a risk we are asking motorists not to take. Doing so could starve the engine of vital lubricants, risking increased wear and, at worst, lead to a catastrophic event like an engine seizure

and a much more expensive repair later on. OEMs set oil change schedules for a reason. They know their engines, how they run on certain fuels and in specific regions and they know how the engine oil, as well as other consumables, perform over time and mileage.”

£1.9 m

how much the James Bond franchise has spent on vehicle damages over the years –good news for the local garage, perhaps.

PMM MARCH 2023 7

with Freya Coleman

with Freya Coleman

NEWSIN QUOTES

“ The latest data outlines a decline in demand for electric vehicles, probably caused by the cost-of-living crisis and doubts about the government’s electrification ambitions. This has led to a dampening of forecasts, with EVs predicted to reach 50 per cent of all new car sales by 2027 rather than 2026 as previously expected. But the last thing we need now is for the sector to believe it has more time to get the workforce properly skilled.”

Steve Nash, IMI CEO, commenting on the latest Auto Trader Insights.

“ The upcoming budget shouldgo further, allowing vehicle producers and suppliers to qualify for additional measures in line with energy intensive industries, ensure climate change agreements are maintained and energy efficient capital investments are incentivised.”

Mike Hawes, SMMT chief executive, comments on the government’s new energy relief scheme which will last a year from the 1st of April. The scheme will offer businesses an automatic gas unit discount of up to £6.97/MWh and an electricity discount of up to £19.61/MWh.

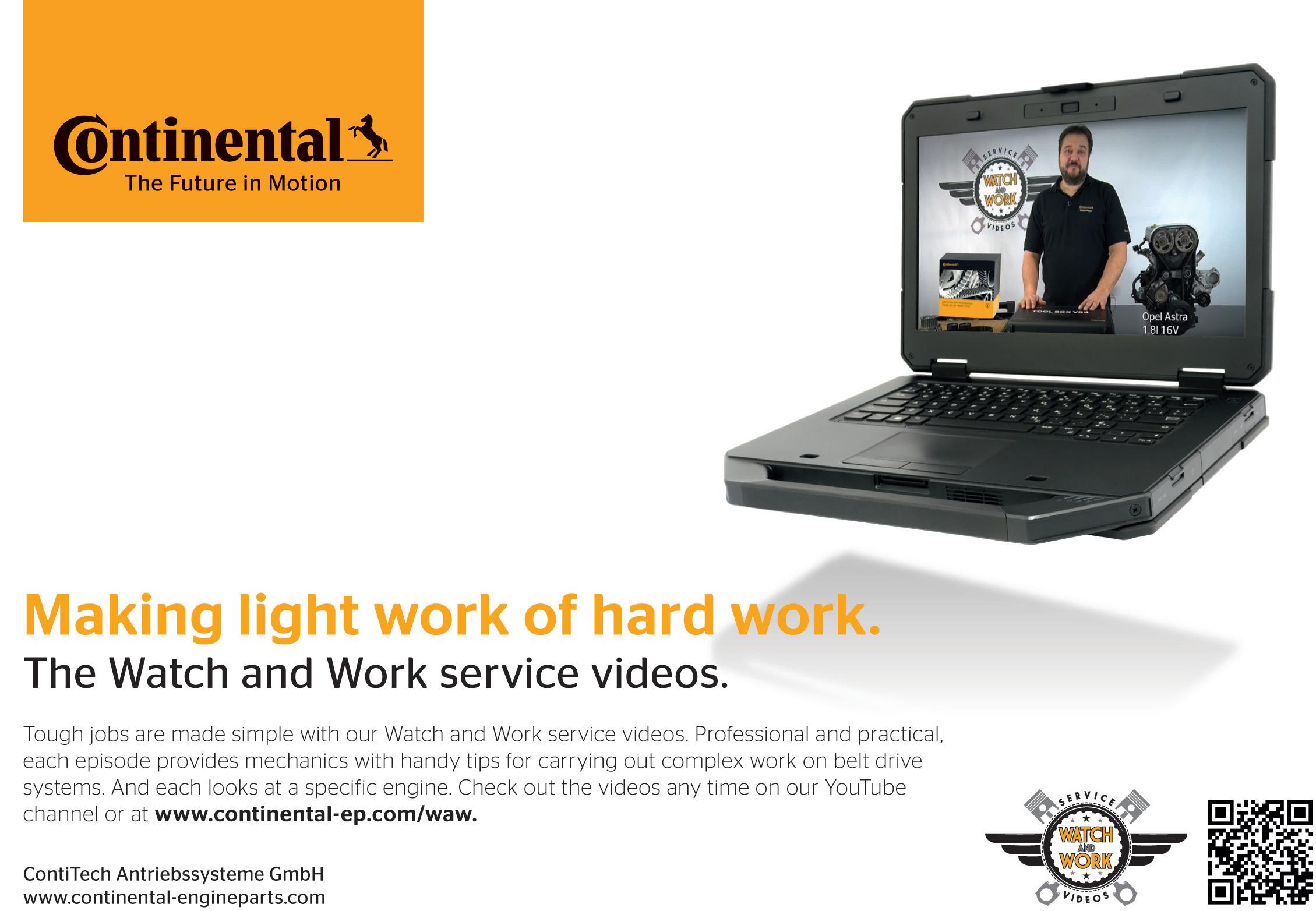

Online resource launched

Delphi Technologies has launched its new Masters of Motion online hub as the start of a sustained campaign to support technicians and workshops. The hub hosts content including ‘how to’ videos, infographics, articles, tips, training resources and advice. The resource also features sections such as ‘Advance your Workshop’ and ‘Need to Know’; these include articles on new technology, advice and expert insight. The company hopes the

‘how to’ section will prove popular as it contains a library of nearly 30 videos already covering issues around ADAS calibration, diesel injection, engine management and more.

Lastly, the ‘how to replace’ videos offer step-by-step guidance on completing a range of jobs from core mechanical work like changing brake pads and discs or wishbones, through to replacing sensors and ignition coils.

All about oils:the latest podcast episode

In this episode PMM editor Kieran Nee chats to the VLS’s Mike Bewsey and Witham Motorsport’s Nigel Bottom about what role modern motor oil plays in vehicles, why they’re so complex and, most importantly of all, why they’re so expensive at the moment! As ever, news and products editor, Freya Coleman brings you the latest aftermarket news, while PMF ’s Tom Henman shines a light on factors and distribution.

Oil has been in the news more in the past year than at any time since the early seventies. So we thought, considering engine oil and the additives packages it carries are the unsung heroes of modern cars, why not dedicate an episode of the podcast to the stuff?

Big thanks to Delphi, supporters of this episode!

To listen, scan the QR code:

PMM MARCH 2023 9 PMM NEWS

DATES FORTHE DIARY

■ The IMI’s 2023 awards is set to take place at the IMI Annual Dinner on the 15th of March. Two new categories have been added to reflect the everchanging automotive landscape; the President’s Award focusing on sustainability and the environment and the EDI Award, aiming to celebrate diversity in the industry.

■ The BIG Awards are back this year on Friday the 22nd of September at Leicester City Football Club. The awards celebrate the best garages in the aftermarket. Entries are now open, and categories include the business improvement award, the diversity equality and inclusion award and the training and development award among many others.

■ PMM has confirmed it will be hosting a stand at this year’s Automechanika Birmingham, which will take place at the NEC in Birmingham on the 6th, 7th and 8th of June. Come and visit our stand for your chance to be featured on the PMM Podcast!

Confidence to grow

Business has boomed for TR Autos in Yeovil following itsswitch tocommunityfocused garage management system Garage Hive.

The independent Saab specialist, founded in 2008, is run by Tom and Kayleigh Butler and turnover at the four-person garage grew by £113,000 in the last year.

TR Autos says the first six months after moving onto the garage management system

did present challenges, but a member of the team was there to help. Customer online authorisations, vehicle health checks and job checklists have also helped drive business growth by offering total transparency on what’s needed. The garage has reinvested the proceeds of this extra business, moving from a two-bay workshop to one that is three times the size, adding an MOT bay for the first time too.

MOT fines

An MOT tester has been fined with £1,300 and 200 hours of community service for issuing fraudulent MOT certificates.

The mechanic at the Surrey garage was accused of issuing MOT certificates to seven vehicles without performing the test for

financial gain. He admitted to seven counts of fraud by false representation that took place between February and April last year. This comes at a time where the DVSA has recorded a total of 1,324 counts of MOT fraud from 2021 to 2022.

10 MARCH 2023 PMM

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: The Clenchwarton Youth Football Club’s under 16s team whose away and training kits have been sponsored by MAHA.

BEST PRACTICE

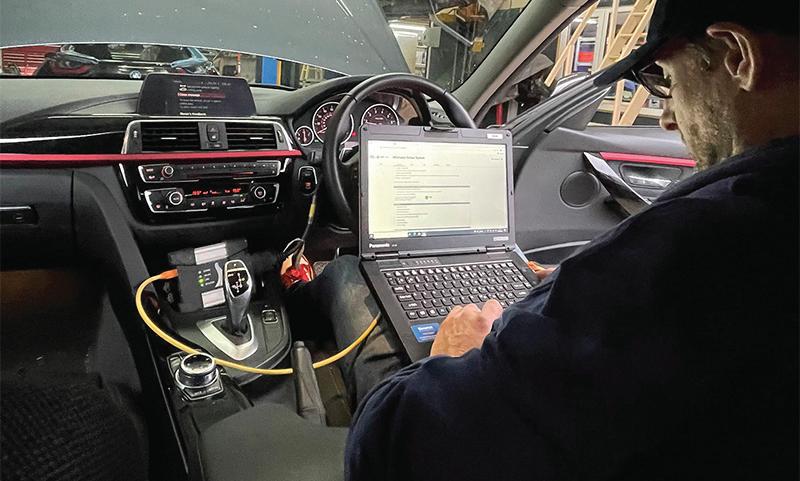

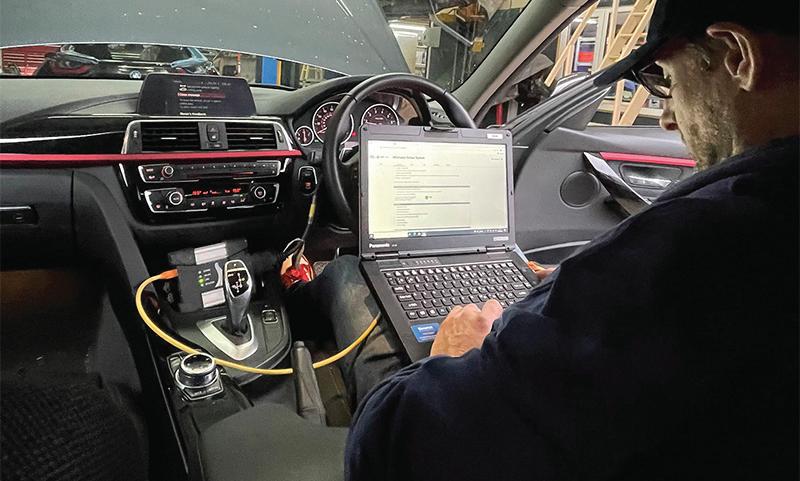

Tony Powell’s diagnostics advice

We asked PMM product tester and diagnostics expert Tony Powell to share some of the techniques and knowledge he’s picked up along a career diagnosing vehicle faults stretching over four decades.

When I first started learning to diagnose things over 40 years ago, there was very little in the way of training outside of college, plus it wasn't called diagnostics back then!

We learnt stuff the hard way: by making mistakes and getting burnt (literally). I remember being told as a young apprentice to put a 1/4 in. bolt into a fuse holder (the old glass type) and then having to pull it out fast when the wire started to smoke where it was shorting out, this is the getting burnt bit as the bolt was very hot and no one told me to use pliers. These days everyone has a scanner that you just plug in and it tells you what's wrong – or so some customers think anyway.

The modern world of diagnostics has changed dramatically and at a fast pace in

recent years, with new tools appearing every day. However, you don't always need to spend thousands of pounds on tools to be effective at diagnostics.

The biggest and best tool we all have is our brain, working in conjunction with our sight, touch, hearing and even our smell; used in the right way these can be very effective and they’re completely free.

Over the years I have learnt that you never stop learning and every day is a school day.

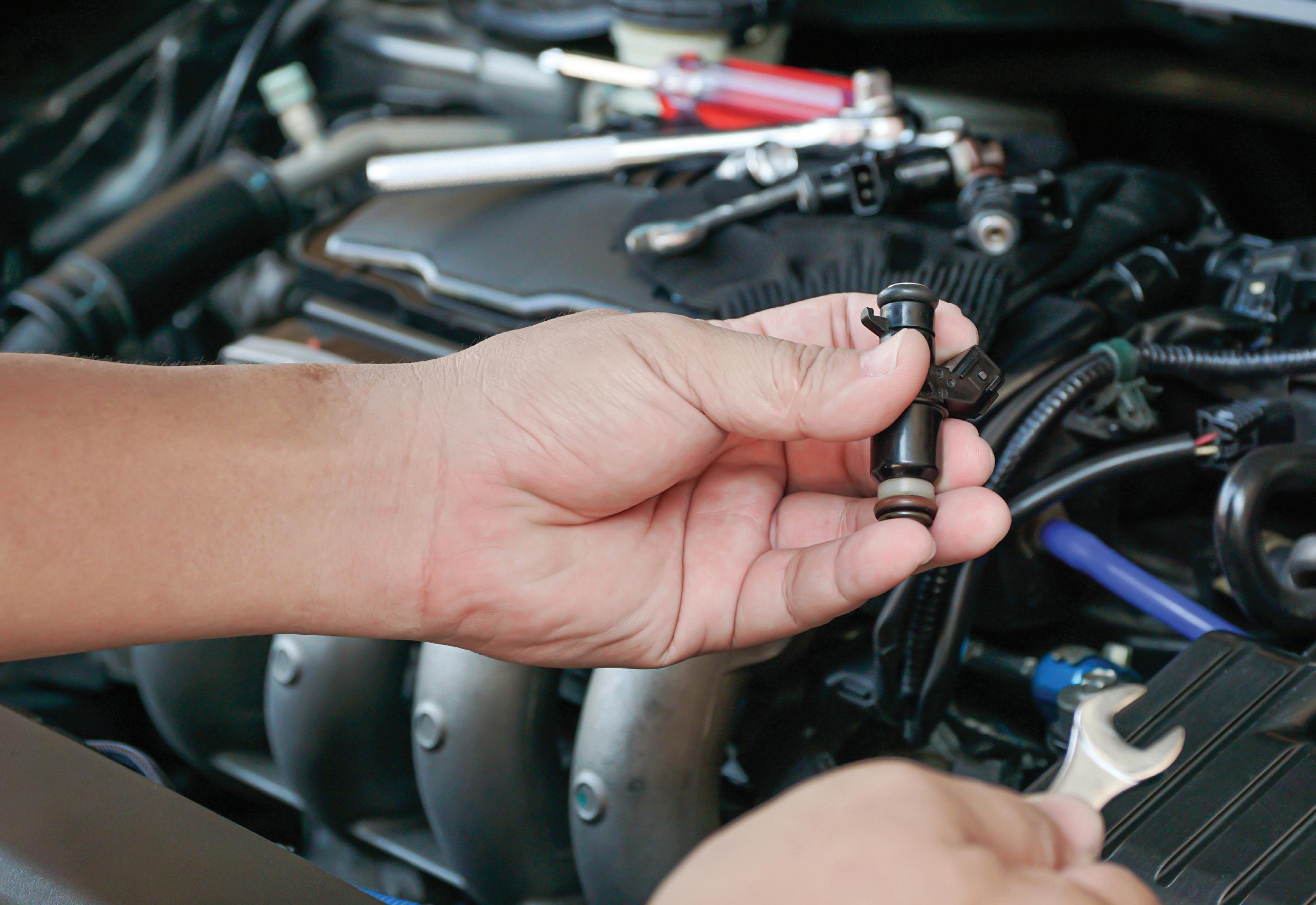

There are many opinions on how to diagnose a fault but I always start with the basics, for example checking for blocked air intakes. I know of one garage that fitted a new set of injectors, a turbo and a fuel pump – when the fault was found, it turned out to be an old crisp packet that was flapping up and cutting the air off at 35 mph. It was an expensive mistake with a simple cause and an even simpler fix.

Start by looking at things first, you are looking for something that doesn’t fit: green fur on copper wires, broken wires that stick out, loose bolts or nuts, burn marks or rubbing marks from loose parts are always a giveaway. Can you smell fuel or anti-freeze? Do you hear a funny noise? If there's nothing obvious, move on –although experience can play a big part here, we can

TROUBLESHOOTER 12 MARCH 2023 PMM

“The biggest and best tool we all have is our brain, working in conjunction with our sight, touch, hearing and even our smell”

all be led down the wrong path. Be careful, because touching can alter things and that fault may disappear for a while.

A code scan can give you a guide as to where to go first, but remember just because it says “X” it doesn’t mean that “X” should be replaced, it could be power or earth or signal fault toor from“X”,notjust thepart and a solid, structured diagnostic plan is the way to go.

Take a recent “no start, no communication with the ECU” job I did. A code scan said no communication and a low battery fault along with many fault codes for CAN Bus and communication across the vehicle. Just to make things weird, the wipers were permanently running.

I started by putting a decent battery support unit on as there is no point in chasing a low power fault when the battery is flat. The giveaway here was that I still had the low power fault after doing this. Returning to the battery to check my support unit was on ok I noticed the odd one out, the bolt holding the positive lead onto the distribution module was very, very rusty. When I did a few preliminary voltage drop tests the readings I got were nicely over 12 V as they should have been, with no drop off. But using a test light gave me more information as the voltage disappeared. Further investigation showed that the fuses were badly corroded and one even looked fine yet disintegrated when I touched it (this just happened to be the one that fed power to the ECU). This explained the noncommunication code and the no start along with the low voltage code. A new module and fuses fixed all the issues here.

Using a decent test lamp that draws a small current can show up a wire that although it

allows 12 V along it or it passes a resistance test can soon fail when it is tested under load. Don’t rely on an LED test light for this job!

The same applies when checking fuses they may look ok but using a test lamp puts them under load which shows up the invisible crack or break that a voltmeter may miss.

Voltage drop testing is also a very effective method for tracing faults and is a skill you really need to master. So far, we have only scratched the surface but it’s easy to see that basic tools can still do the job.

As you progress through the years in this trade, you end up with more and more tools and getting off that tool van empty handed, especially in my case, becomes harder and harder –it’s sad to say but Covid saved me a fortune!

Scan tools

Some tools, though, are worth their weight in gold –take the Picoscope oscilloscope, for example. If you can master this tool you can fix some incredibly difficult faults with ease, getting into wiggly lines on a screen can show up some of the most awkward and difficult faults to diagnose in the most easy-to-see way. I for one wouldn't be without mine. There is a lot of training and back up for this one as well.

Scan tools come in two categories: dealer and aftermarket. Whilst the dealer tool can be brilliant it can also be hard to master and very costly to buy and maintain with minimal back up or support outside the facebook groups that have sprung up.

Aftermarket scan tools are usually cheaper and normally easier to use but often miss some important job options found on the dealer tools or only provide half the details required and many use the same software re-branded.

Yet without these tools many of us wouldn’t be able to perform to the levels we do.

PMM MARCH 2023 13 TO LISTEN TO OUR DIAGNOSTICS PODCAST WWW.RDR.LINK/AAV002

“A code scan can give you a guide as to where to go first, but remember just because it says “X” it doesn’t mean that “X” should be replaced, it could be power or earth or signal fault to or from “X”.”

HOW TO

Replace the clutch on a Citroën Berlingo1.6 HDI

In this month’s Schaeffler LuK Clutch Clinic, REPXPERT Alistair Mason is replacing the clutch in a 2012 Citroën Berlingo van, that has covered nearly 218,000 miles. The customer had reported that the clutch was ‘slipping’, which a short road test confirmed, and the clutch replacement was advised and authorised.

With a scheduled book time of six hours and very little investment in equipment, this makes a profitable repair for any independent workshop.

Gearbox removal

With thevehicle placed on thevehiclelift, open the bonnet, remove the engine cover followed by the battery cover and then disconnect and remove the battery and battery tray.

Note – there is a retaining bolt that is accessed from the N/S inner wing hidden behind the plastic wheel arch liner (Fig.1). With the top of the gearbox now accessible, disconnect the gear cables and the gearbox wiring loom, by disconnecting its multiplugs,

then remove the wiring loom bracket from the top bell-housing bolts and stow the gear cables and the loom out of the way. Whilst in this area, the top bell-housing bolts and top starter motor bolt can be removed, followed by the bolts from the gearbox mounting plate to the inner wing (Fig.2).

CLUTCH CLINIC

14 MARCH 2023 PMM

Raise the lift to waist height and remove the N/S/F wheel, then raise it again to gain access to the underside of the vehicle and remove the plastic under-shield and the front subframe side brace (Fig.3).

Drain the gearbox oil, remove the N/S bottom ball joint nut and disconnect the ball joint from the bottom arm. Lever the inner CV joint out of the gearbox, then pull out on the strut assembly and the drive shaft will come out of the gearbox and can be positioned away from the gearbox (Fig.4).

slightly to aid its removal, unscrew the final bell-housing bolts, ease the gearbox away from the engine, and when clear, lower and move it away from the vehicle.

Clutch Replacement

Remove the clutch assembly from the flywheel. In this case, we could see the clutch plate was at the end of its service life as the lining had worn close to its retaining rivets. Inspect the back of the engine for any oil or coolant leaks and rectify as required, remove the glaze from the solid flywheel face using emory cloth, and clean with clutch and brake dust cleaner.

point grease to the gearbox input shaft splines, mount the new clutch plate onto the input shaft (Fig.7), and allow the clutch plate to travel up and down the input shaft as this will ensure the grease is distributed evenly and that the clutch is correct for the vehicle, but remember to remove the clutch plate and wipe off any excess grease before fitting the cover.

Remove the three bolts from the O/S inner driveshaft seal housing flange, the final starter motor bolts, the lower bell-housing bolts and then, the lower gearbox pendulum mount. Top tip – there is a bolt located by the Diesel Particulate Filter, so remove the nut and stud from the DPF bracket as this will allow the bell-housing bolt to be unscrewed from the gearbox (Fig.5). Remove the two slave cylinder retaining bolts and position the slave cylinder away from the gearbox, without disconnecting the hydraulics.

Support the engine using an engine support and the gearbox with a transmission jack and remove the gearbox mounting. Lower the engine and gearbox assembly

Turning to the gearbox (Fig.6), remove the release bearing and release arm, but always check the pivot points and guide tube for wear, replacing them if required and then wash out the clutch dust from the bellhousing using clutch and brake dust cleaner.

Using a universal clutch alignment tool, mount the clutch plate with “gearbox side” facing away from the engine onto the clutch pressure plate and secure in position. Mount the clutch assembly onto the flywheel, insert all clutch bolts, tighten in an even and sequential sequence and finally, torque to the manufacturer’s specification. Then remove the clutch alignment tool.

Gearbox fitment

Before re-fitting the gearbox, so they do not get caught or trapped when refitting the gearbox, ensure all cables etc are clear of the bell-housing area. Place the gearbox on the transmission jack, ease the gearbox onto the clutch and then the alignment dowels and secure in place with an easily accessible bell housing bolt and tighten. Refit all the other components in reverse order of removal and torque all bolts to the manufacturer’s specification.

Refill the gearbox with oil through the gearbox breather. After the battery lead has been connected, reset all electrical consumers, and always carry out a road test to ensure a quality repair has been made.

Fit the new release arm and release bearing, apply a light smear of high melting

PMM MARCH 2023 15

MORE INFORMATION WWW.RDR.LINK/AAV003

WANT TO KNOW MORE? FOR

KNOW YOUR PARTS

Brake disc shields

Febi outlines everything you need to know about brake disc shields.

Avehicle’s braking system aims to create the necessary braking force to reduce the vehicle’s speed and prevent it from moving when parked. The vehicle’s braking system must give a rapid, balanced response when required, resulting in a short stopping distance, with even braking effect and precise control. It should also be resistant to road debris and corrosion, giving high reliability and durability.

Protecting discs

There are two main types of friction brakes used on vehicles; predominantly, disc brakes are used on most cars, whereas drum brakes are generally used for the rear brakes of smaller passenger cars. A characteristic of disc brakes is that they have a much greater resistance to heat loads and heat dissipation capacity than drum brakes. In addition, the direct contact of the friction material with the rotating brake disc results in maintaining a high braking torque for a more extended period. This means they do not undergo mechanical distortion during operation due to temperature build-up compared to drum brakes. In addition, rapid distortion is prevented by the uniform distribution of the friction metal pressure on the brake disc’s contact surface.

However, there is a risk to the exposed brake disc surface from road debris and rapid temperature changes, leading to brake disc fractures and distortion. Therefore, protective shields are mounted behind the disc brake assembly, protecting the discs, pads and hoses from constantly being exposed to dirt, and dust contamination from both the road and the friction material produced as the pads and discs wear while being used. Consequently, they help to maintain the vehicle’s braking performance.

In turn, they also protect hot discs by reducing the amount of sudden cold water that can splash them and cause them to distort or crack whilst driving in wet road conditions.

They also protect the electronic components in the brake system, such as the wheel speed sensors, brake pad wear sensors and the associated wiring, from heat and debris, along with all the associated steering and suspension components that are close to the disc brake assembly.

This protective part of the disc brake system and other parts of the brake system are subject to evaluation. In addition to routine maintenance and the regular vehicle inspection procedure, a vehicle is inspected to ensure that it conforms to safety and emissions regulations.

If the shields deteriorate due to corrosion or distortion, this can be caused by the following:

■ Premature wear and corrosion of the brake discs.

■ Possibility of excessive contact with external factors, such as water and road debris, due to shield material losses caused by corrosion.

■ Risk of damage to any of the fixings to the suspension and steering joints.

■ Noise due to distortion, causing contact with rotating or moving parts.

■ Excessive heat from the brakes affecting rubber or plastic components, causing melting or burning if the shield is missing or completely corroded.

febi brake disc shields are manufactured from pressed steel and are precisely formed to match OE. The steel is treated with a galvanised coating and then painted to give excellent anti-corrosion protection. An efficient and effective brake disc shield prevents the causes mentioned above and extends the service life of the braking system, providing safety for the driver and other road users.

PMM MARCH 2023 17

TECH TIPS

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAV004

WANT

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

WILL SERVICING AND REPAIR WORK REDUCE WITH

EVS

As with work on any type of vehicle, training, skill and access to information is essential. With hybrid and electric vehicles, it is even more important. I am sure by now most of you have heard the horror stories of somebody draining oil from a Toyota Prius –at which point the car starts its engine because the high voltage battery is discharging. You don’t need me to outline the consequences. Manufacturers’ information is therefore essential.

Hybrid cars require the same service as traditional ICE vehicles with additional checks of the EV systems. Pure EVs are different, they have fewer moving parts and because of regenerative braking, even the friction brakes are used less often. However, an electric car still needs to be serviced regularly.

The actual service is vehicle specific, so some cars will need more checks than others. The MOT test (often done at the same time as an annual service) covers some of the basic safety checks, but as a general guide an EV service will include:

> Tyre condition, wear and pressure check

> All lights for correct operation

> All steering and suspension components inspected for security and wear

> Windscreen washer top up and wipers checked/replaced

> Pollen filter change

> Checking the auxiliary battery (even a pure EV has a ‘normal’ 12 V battery)

> Checking the brake fluid moisture content and replacing if needed

> Additional brake checks –due to reduced use corrosion can build up

> Diagnostic scan to check for stored fault codes

> Check charging connectors for corrosion or dirt, which could lead to a build-up of heat

> Check charging cables, if in the vehicle, for any external damage to the insulation and the plugs/sockets.

> Check on high-voltage batteries and components in general should include:

> Cracks or deformation of housings

> Colour changes due to temperature and tarnishing

> Escaping electrolyte or coolant

> Damage to high-voltage contacts

> Information stickers are fitted and legible

> Equipotential bonding is in good order

> Corrosion and damage in general

> High-voltage cables for the battery, air conditioning and heating, electric drive, on-board charger and charging socket.

Always refer to the manufacturer’s information for what is required at a service. For example, at specific mileages some EVs require coolants to be changed. Overall, there is less work to do when EV servicing. This means less time is spent so more vehicle throughput will be needed to ensure the workshop is fully loaded.

What is certain is that things are changing and that the amount of work and sale of parts will reduce. Perhaps some lateral thinking is needed and other sources of revenue could be explored. For example, electric scooters and eBikes will need servicing. We are in a time of rapid change – the best option is to be prepared.

TO KNOW MORE? FOR MORE INFORMATION GO TO WWW.RDR.LINK/

But it’s not all bad news if we are qualified and ready for it. Sponsored by

WANT

Yes!

FIG.2 High voltage cables should be checked for signs of insulation damage

FIG.1 Domestic mains socket and charge point cables

HOW TO Replace a stabiliser link

Delphi Technologies, a brand of BorgWarner, has supplied this step-by-step guide courtesy of their recently launched Masters of Motion hub for independent garage technicians.

Delphi’s new training resource has articles, tips, training, resources, advice and more. There are sections called ‘Advance your workshop’ and ‘Need to know’ to support on new technology and other challenges.

Delphi says through Masters of Motion, it is committed to helping garages meet the demands future vehicles will present. The aim is to develop a stronger connection with the independent garage and workshop technicians that form ‘the backbone of the aftermarket’.

Getting down to it

This guide comes from a selection of around 30 ‘How To’ videos covering a range of workshop jobs including ADAS calibration, diesel injection, engine management and more.

This video sees Matt from Delphi working to change a stabiliser link, also known as an anti-roll bar drop link, on an Audi A3 e tron at Delphi’s in-house training workshop in Warwick.

STEP Clean the threads

Cleaning away loose debris and any corrosion with a wire brush makes it easier to undo the locking nuts. Rolling the strut around is recommended to give better access.

WATCH!

To watch this stabiliser link being replaced, scan the QR code below

STEP Remove the bottom lock nut This involves ‘working it backwards and forwards’toreleasethenut frombinding on the thread.In thiscasethenutstillwouldnot release, so some lubricating oil was added to free it.

TECH TIPS

STEP Remove the wheel

STEP Remove the top lock nut

STEP Raise the vehicle

This improves access to the bottom lock nut.

STEP Clean the threads

20 MARCH 2023 PMM

“Delphi says through Masters of Motion, it is committed to helping garages meet the demands future vehicles will present.”

STEP Compare the parts

Having removed the part, take time to make a visual comparison before fitting the new part.

STEP Remove the nut from the component

The nut is removed from the lower fixing point of the component. In this case, the size of the nut is different to the one on the part that was removed but the part is fully compatible.

STEP Tighten bottom lock nut fully with torque wrench

STEP Hang the top fixing

The new component is hung loosely from the top fixing to take the weight before the bottom section is fully secured.

STEP Secure the bottom lock nut

After a change of spanner, the centre of the fixing is held by an allen key whilst the lock nut is tightened up until there’s some tension.

STEP Secure top lock nut

With the bottom fixing secured, the car is lowered again so the top locking nut can be tightened in the same way with the rachet spanner and allen key.

STEP Set torque wrench to manufacturer’s specification

In this case, the wrench is set to 65Nm.

STEP Tighten to manufacturer’s specification

Complete the tightening process with the torque wrench once again.

PMM MARCH 2023 21 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAV006

BEST PRACTICE

Brake fluid: everything you need to know

each variation of brake fluid.

When it comes to vehicle maintenance, monitoring the condition of brake fluid rarely makes most driver’s to-do lists. This can lead to dangerous consequences for customers and a missed service opportunity for garages.

The best characteristics of a good brake fluid starts with the research and development work that goes into it, to ensure safety is paramount before it’s offered to the market. Without research and development first looking at the chemical composition and identifying the properties for the correct fluid for the application of vehicle, the brake fluid would not meet all the safety requirements that are needed.

The main requirements for brake fluids are high operation temperatures, good lowtemperature and viscosity-temperature properties, physical and chemical stability, protection of metals from corrosion, inactivity with respect to mechanical rubber articles, and lubricating effect. If a brake fluid does not meet all safety requirements, such as high operation temperatures, good low-temperature and viscosity-temperature properties, physical and chemical stability, protection of metals from corrosion, inactivity with respect to mechanical rubber articles, and lubricating effect, the required safety requirements will be affected.

It’s safe to say that brake fluid is safety critical and if the quality is insufficient this can lead to system failures in the brakes.

Brake fluids for hybrid or fully electric vehicles

Electric and hybrid vehicles are gaining popularity in the aftermarket and for such vehicles, you need to ensure you know what fluid is available that meets the needs of these vehicles. When the vehicle battery is full, the brake system can’t take advantage of regenerative braking and so the brakes will have to do all the work without any support from engine braking. This creates a

PMM MARCH 2023 23 TECH TIPS

Scott Irwin MIMI, head of technical training at TMD Friction’s aftermarket brake brand, Mintex, discusses why garages need to educate their customers on the technicalities around

need for a high dry and wet boiling point. In normal conditions, brakes will be used less due to the proportion of the work carried out by the regenerative braking, but they must still be in perfect working order when needed. This creates the need for enhanced corrosion protection.

Due to major electrical currents in the vicinity of the brake system, a lower conductivity fluid is advisable. As with all modern vehicles, the developments in ESP, ABS, ADAS and AD, means cars are going to put great emphasis on cycle time and frequency.

In turn this will place increasing demands on brake fluid lubricity and viscosity in the electric and hybrid vehicle braking systems.

Common mistakes

It’s true to say that mistakes will happen, but the main major mistake TMD experiences is not using the correct brake fluid tester to check the amount of moisture absorbed in the brake system. As most garages will know, brake fluid is hygroscopic.

This means they attract and absorb moisture from the atmosphere. This process will take place throughout the service life even though brake fluid is in a ‘sealed’ brake system, as water vapour molecules are able to slowly penetrate the flexible rubber brake hoses.

Over time, this results in a decline in the boiling point of the brake fluid and increases the risk of corrosion to metal components.

As the volume of moisture in the brake fluid increases, the boiling point will eventually reach a critical level where it is dangerous. This is why all European vehicle manufacturers recommend a complete fluid change periodically.

When testing brake fluid, the correct tool should be used. TMD recommends testing with a brake fluid boil tester. Something that the brake fluid manufacturer has also recommend over the years. While some testers only check the conductive element of the fluid, this is not the best way to test. The solution is to use a brake fluid boil tester that

will give you a more accurate test result. According to the braking firm’s experts, any brake fluid tester that does not actually heat the fluid is likely to give misleading or even dangerous results.

Changing brake fluid

Brake fluid should be changed every two years or if the boiling point falls below 200°C. If the boiling point falls below 180°C, the brake fluid must be changed immediately.

Brake fluids conforming to DOT 3, Dot 4 and DOT 5.1 can safely be mixed although the performance of the higher specification products will be diluted. Silicone (DOT 5) and mineral-based brake fluids should never be mixed with any other type.

If the bottle has been previously opened it is probably better to discard it and buy new, unless the technician knows the product is less than three months old and the bottle was resealed tightly.

For unopened bottles technicians should ask whether they know how old it is and how it has been stored. If it is still in a sealed bottle, less than 18 months old and stored in a cool, dry place, then it is likely to be quite

safe to use. If you don’t know how old it is, work out the age from the batch number.

If the level in the reservoir drops too far, there is a risk that air bubbles will be introduced into the braking system, which could result in the brakes no longer working.

The dangers of ‘wet’ brake fluid

Vehicle brakes work by clamping a brake pad or shoe against a moving disc or drum. The resulting friction generates significant quantities of heat. While much of this heat is intentionally dissipated to the atmosphere, some of it will inevitably be transferred to the calipers and wheel cylinders which contain brake fluid.

This will cause the fluid to heat up. If the temperature is allowed to approach the boiling point of the brake fluid, bubbles of vapour (gas) will form in the brake system. Unlike a liquid, a gas is compressible. Consequently, the next time the brake pedal is pressed, its travel may all be used in compressing the vapour, resulting in a complete loss of braking.

This phenomenon is known as ‘vapourlock’ and is, of course, extremely dangerous. The lower the boiling point, the greater the danger of vapour-lock occurring. By changing the brake fluid regularly this phenomenon can be avoided.

24 MARCH 2023 PMM

FOR MORE INFORMATION WWW.RDR.LINK/AAV007 TECH TIPS

WANT TO KNOW MORE?

“Brake fluid should be changed every two years or if the boiling point falls below 200°C. If the boiling point falls below 180°C, the brake fluid must be changed immediately.”

COMMON FAULTS

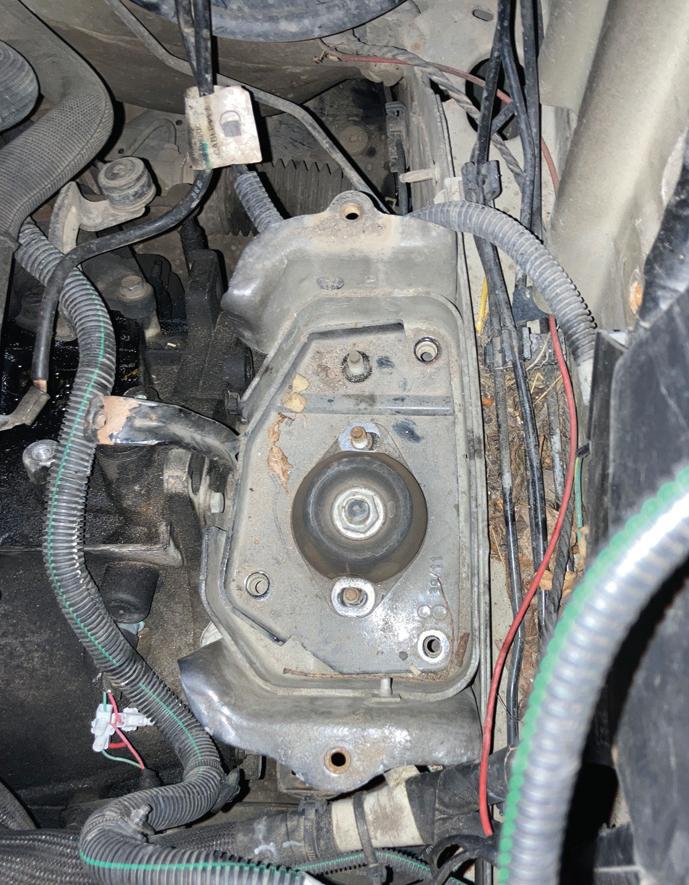

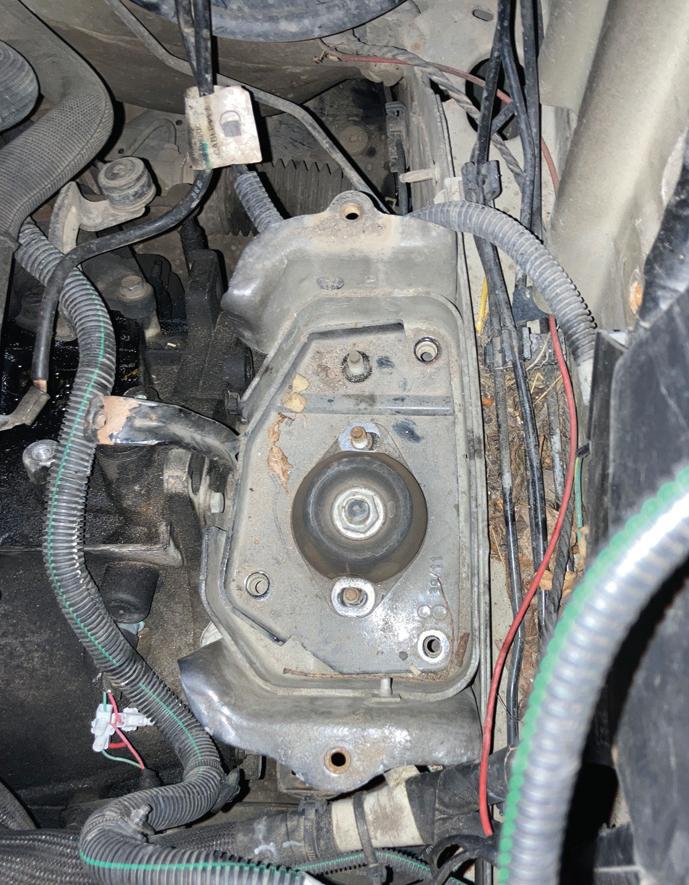

The importance of vibration damping

Vibration damping is critical for cars because it isolates noise and vibration from passengers and drivers. Overall, it restores driving performance as well as comfort and recreates the feel of driving a new car. Excessive vibrations of the engine and the road can even produce a leakage. Vibration damping is therefore important to lessen the transfer of vibrations through the chassis and into the steering and suspension systems, which can ultimately help to improve the vehicle's overall handling, stability and increase its service life.

Controlled material quality

Since the materials used can have a major impact on the damping's efficacy, highquality materials must be utilised for vibration damping in automobiles. Poorquality materials could make the damping components loose, requiring a steering correction. Moreover, ruptures or leaks in the damping material might lessen the material’s effectiveness, let vibrations through and ultimately lower the performance.

Potentially, premium materials can offer durable and efficient vibration damping, leading to a more comfortable ride and a longer vehicle lifespan. One example of a product when it comes to vibration damping would be Meyle’s original-hydro engine mount which is engineered for any type of transmission and useful for any combustion engine.

The company has an extensive range of engine mounts of solid rubber, hydraulic and even pneumatic switchable engine mounts. In fact, it is one of the first in the aftermarket that also offers switchable engine mounts for all common car brands. Its NVH (noise, vibration and harshness) range covers 80 per

cent of the EU registered car parc. In order to ensure a long lifetime for its engine mounts despite the large static, dynamic and thermal loads, the company has used quality materials for the parts which are selected specifically for the vehicle and are subject to strict quality control from development to the finished product.

■ All Meyle original engine mount specifications are true to OE and the manufacturing process meets the standard IATF 16949.

■ Strict quality assurance by Meyle’s quality team and engineers.

■ Leakage test during production for hydro mounts.

Common faults

Oftentimes workshops don’t change the material in time. The durability length is often underestimated despite high quality materials. The items are subject to natural wear and need to be frequently inspected and maintained to make sure they are in good shape and that they are working correctly. It is recommended to replace the vibration

damping parts after between 80 and 100,000 km and after five years at the latest.

Our engineers advise workshops to replace the hydro engine mount in order to restore the original driving comfort.

Installation problems at the workshop and premature failure could be prevented. Often, insufficient production processes in low quality copies are the reason.

However, inadequate installation can also result in malfunctions or even the complete failure of the damping components despite good quality materials. That’s why the company goes one step further and offers different smart solution kits for different engine fastening types that aim to make a car mechanic’s life easier in the workshop. Changing the hydro engine mount, for instance, is facilitated by offering a set consisting of a left and a right hydraulic engine mount, including mounting material. Here, engineers recommend the replacement of both sides for full function and durability.

TECH TIPS 26 MARCH 2023 PMM

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAV008

Michael Grimm, product manager of drive and power train at Meyle, gives his insights on why vibration damping is so important.

Join workshops from around the country who have been signing up to NGK’s new training initiative.

School for BRIGHTSPARKS

The ignition and sensor specialist launched the NGK academy last November and it has already attracted scores of leading independent garages eager to improve their vehicle knowledge.

The portal includes over 270 technical training videos across myriad technical subjects and components all delivered by automotive training experts Our Virtual Academy (OVA). The team has also created a suite of bespoke training videos on spark plugs with further NGK/NTK product-focused training being developed in the future.

Spark plug training videos, three of OVA’s core training videos and other existing NGK/NTK training content, are free to access for all once they have enrolled on the portal, but there will be a charge for accessing the full suite. OVA training videos cover topics such as:

■ Vehicle electrics

■ Petrol and diesel engine management

■ Chassis

■ Hybrid

■ HVAC

There are also comprehensive training videos on electric vehicles and access to

OVA’s dedicated content associated to the formally recognised qualification IMI Level 3 Award in electric/hybrid vehicle system repair and Replacement QFQUAL I.D 60314680.

Keeping up to date

Mark Hallam, marketing manager, NGK Spark Plugs said: “Many leading independent workshops have been quick to take advantage of our new training initiative.

WATCH!

To find out more about the NGK Academy, scan the QR code below

by providing the detailed information they need to fully understand the subject matter.

“In addition to the NGK training videos, NGK has purchased access to more than 270 training videos for hundreds of their customers on a wide range of topics including electric vehicles.

“It has been very well received. We have delivered hundreds of training courses and it is growing on a daily basis.”

“Automotive technology is changing rapidly and NGK academy will help technicians deal with the complex challenges that they face and which can help enable them to continue to have a successful career in the automotive industry for many years.”

One of the major attributes of NGK academy is the fact that as it is available online 24/7, 365 days of the year, training can be undertaken during downtime in the workshop which means there is no negative impact on business. Ben Stockton, managing director of OVA, said: “NGK Academy is designed to increase technicians’ knowledge

He added that the NGK technical introduction into spark plugs has proven particularly popular as has the leak-off testing solenoid operated diesel injectors course and the high voltage overcurrent protection course in the EV/Hybrid section.

Since launch NGK has been funding a three-month full access trial for members of its BoxClever independent garage loyalty scheme.

PMM MARCH 2023 29 BUSINESS & TRAINING

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/AAV009

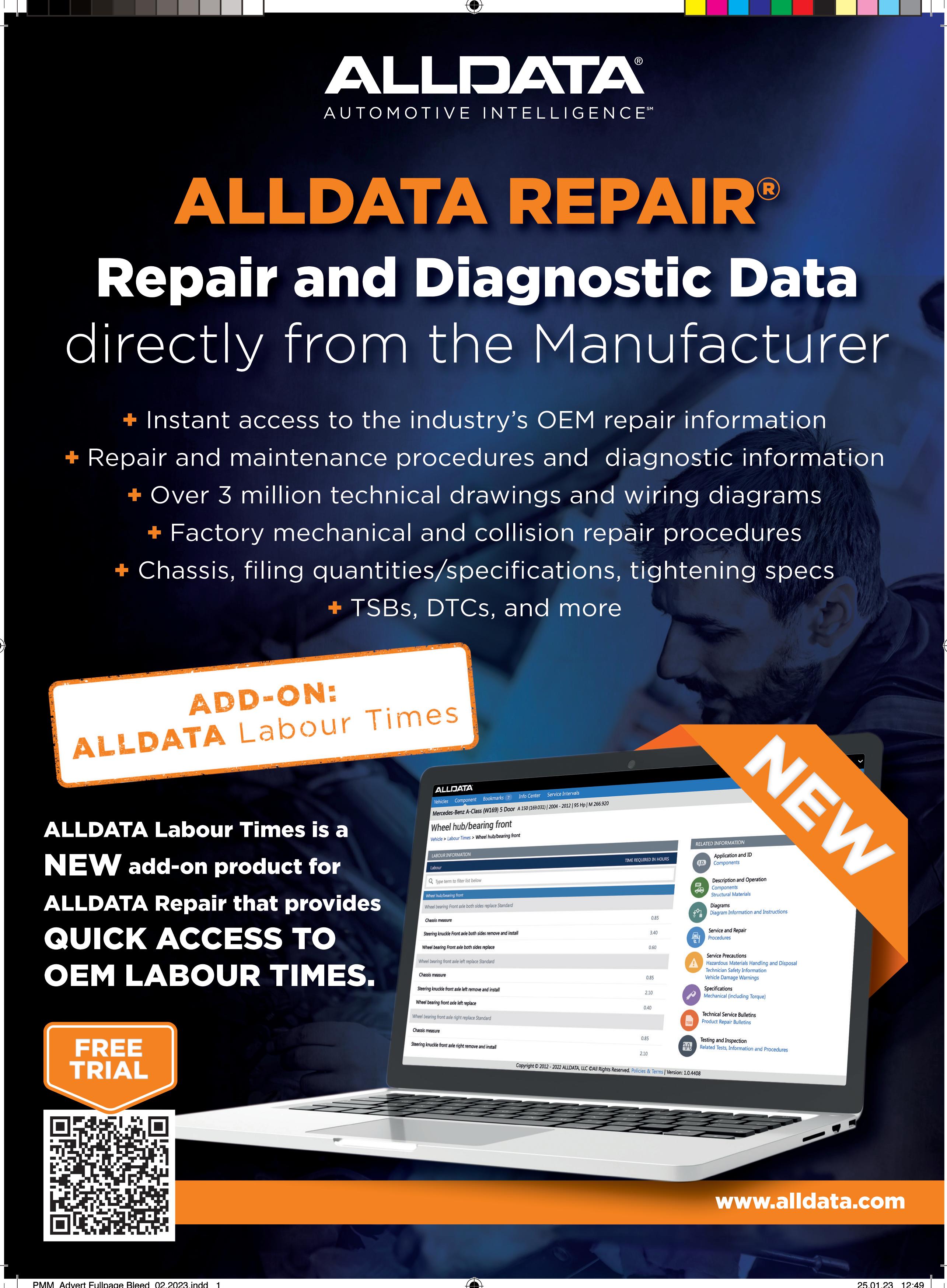

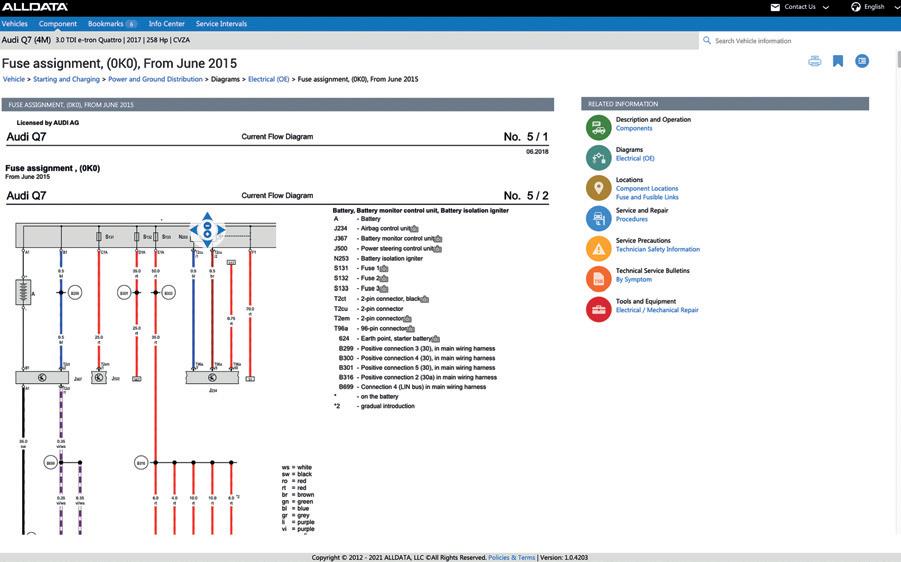

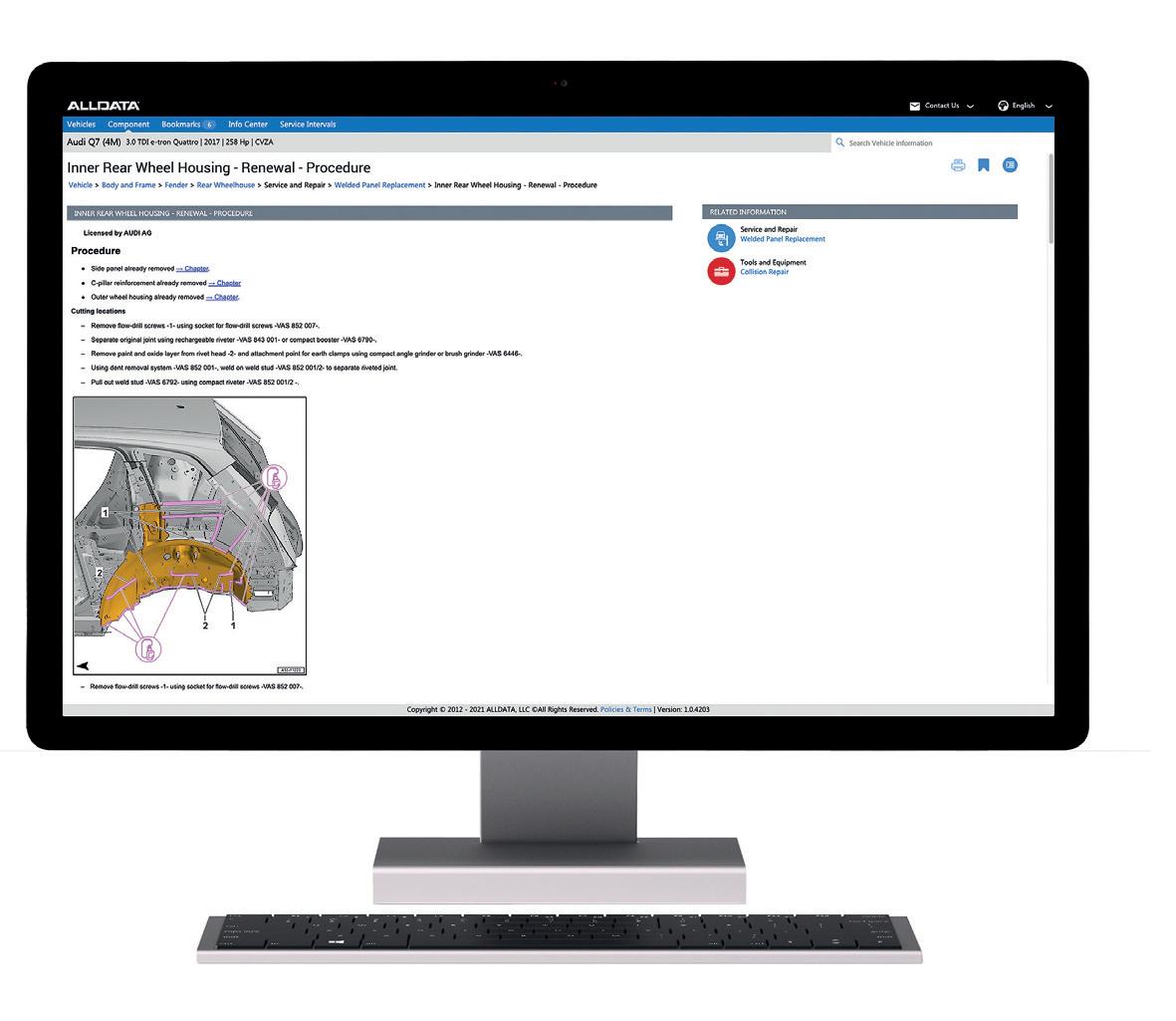

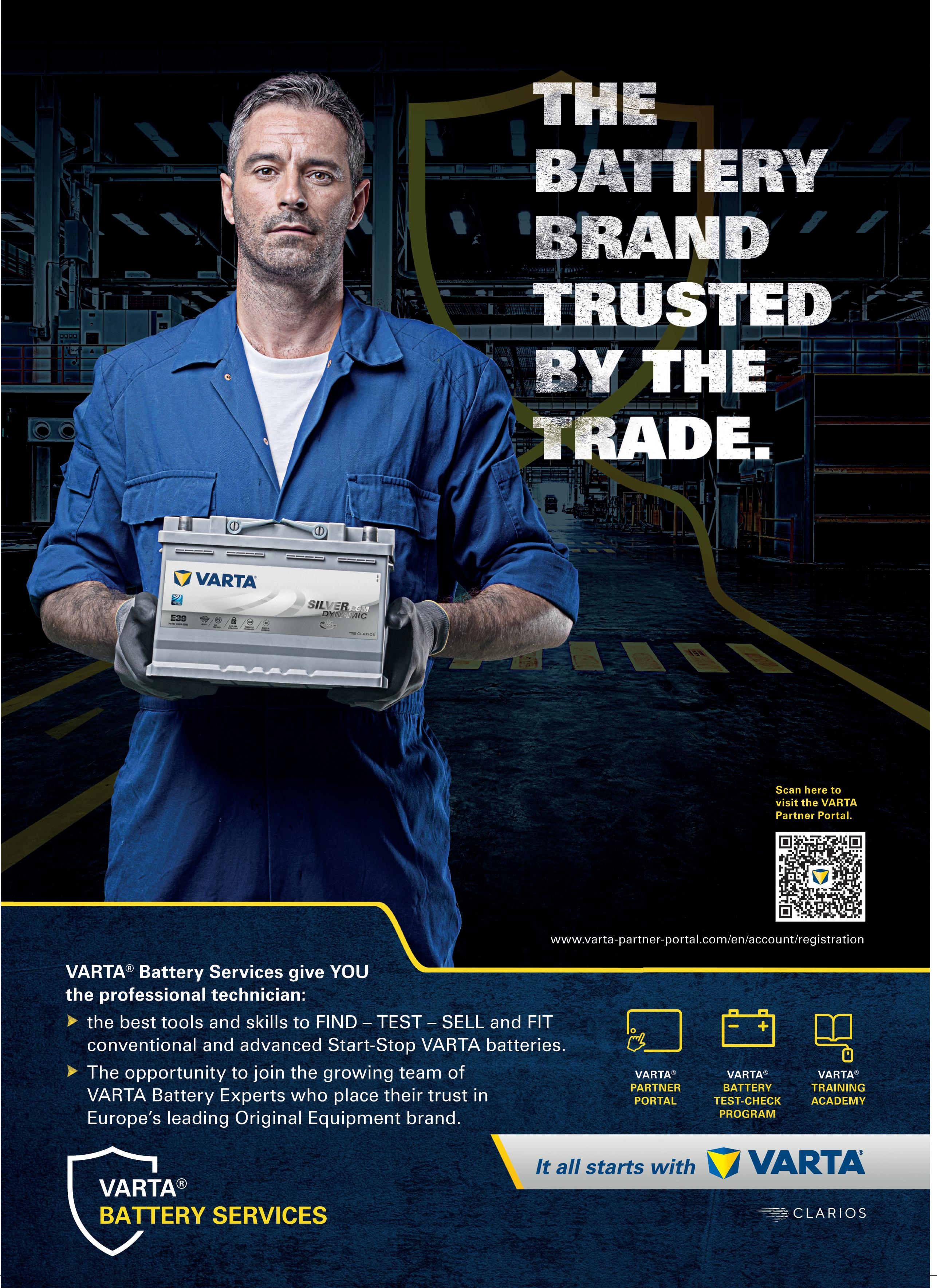

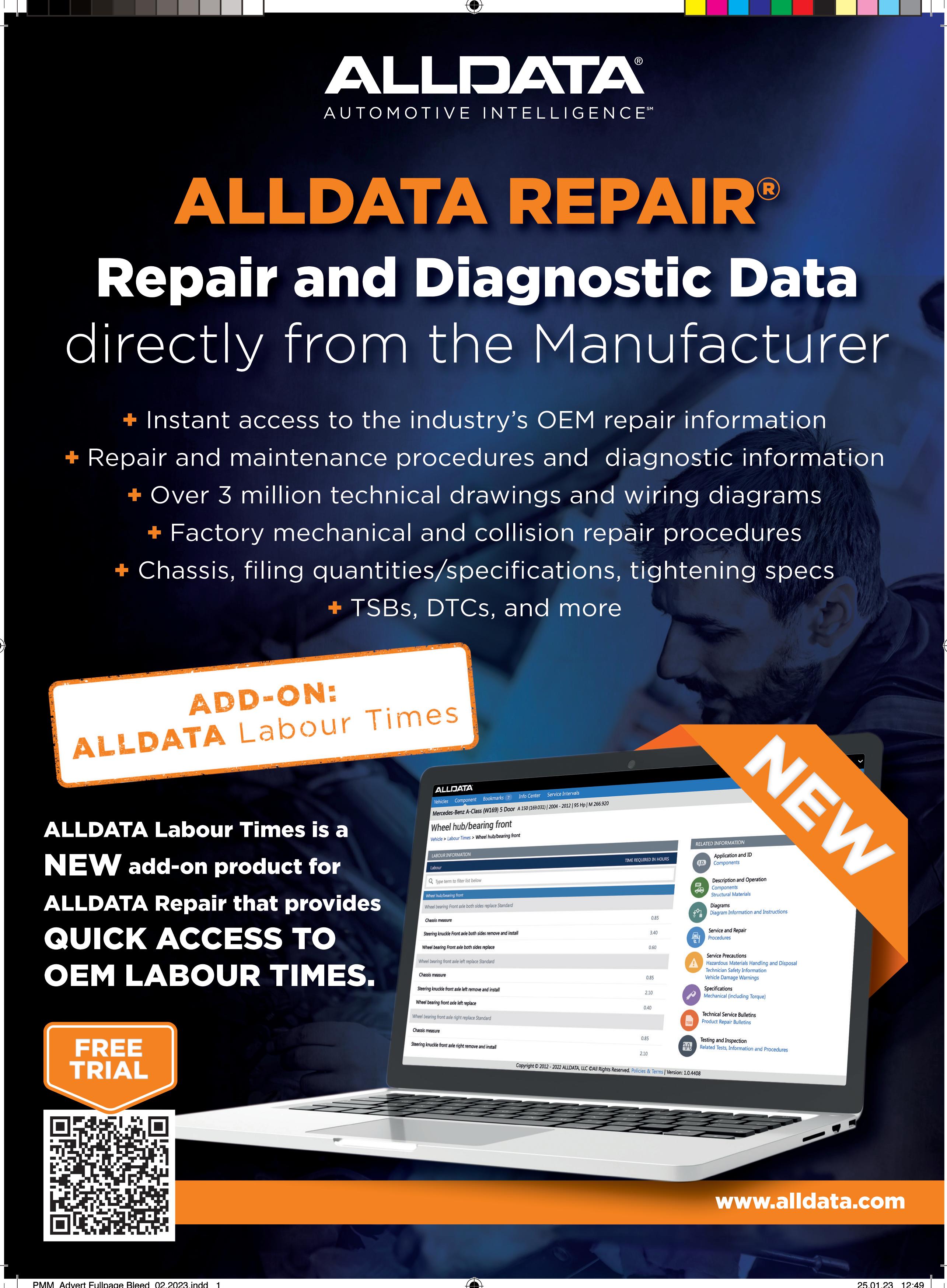

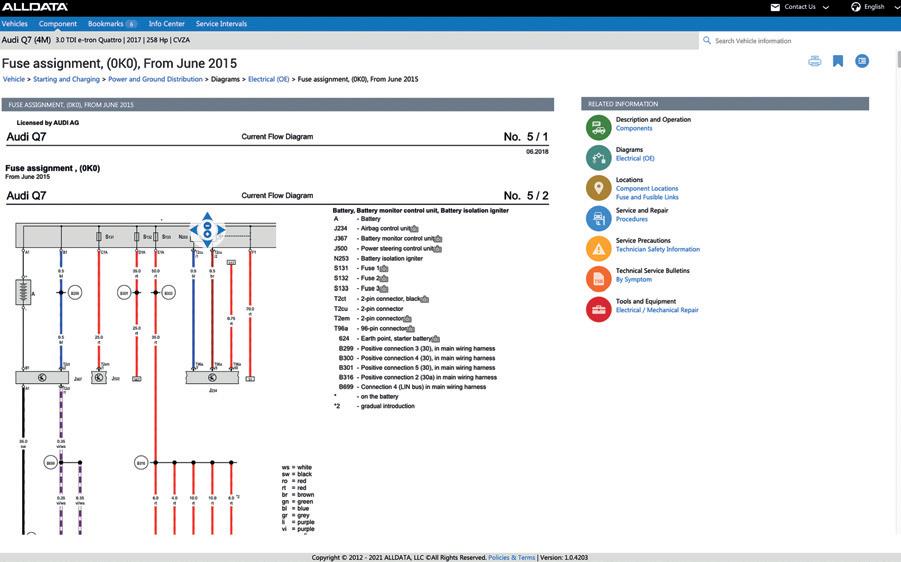

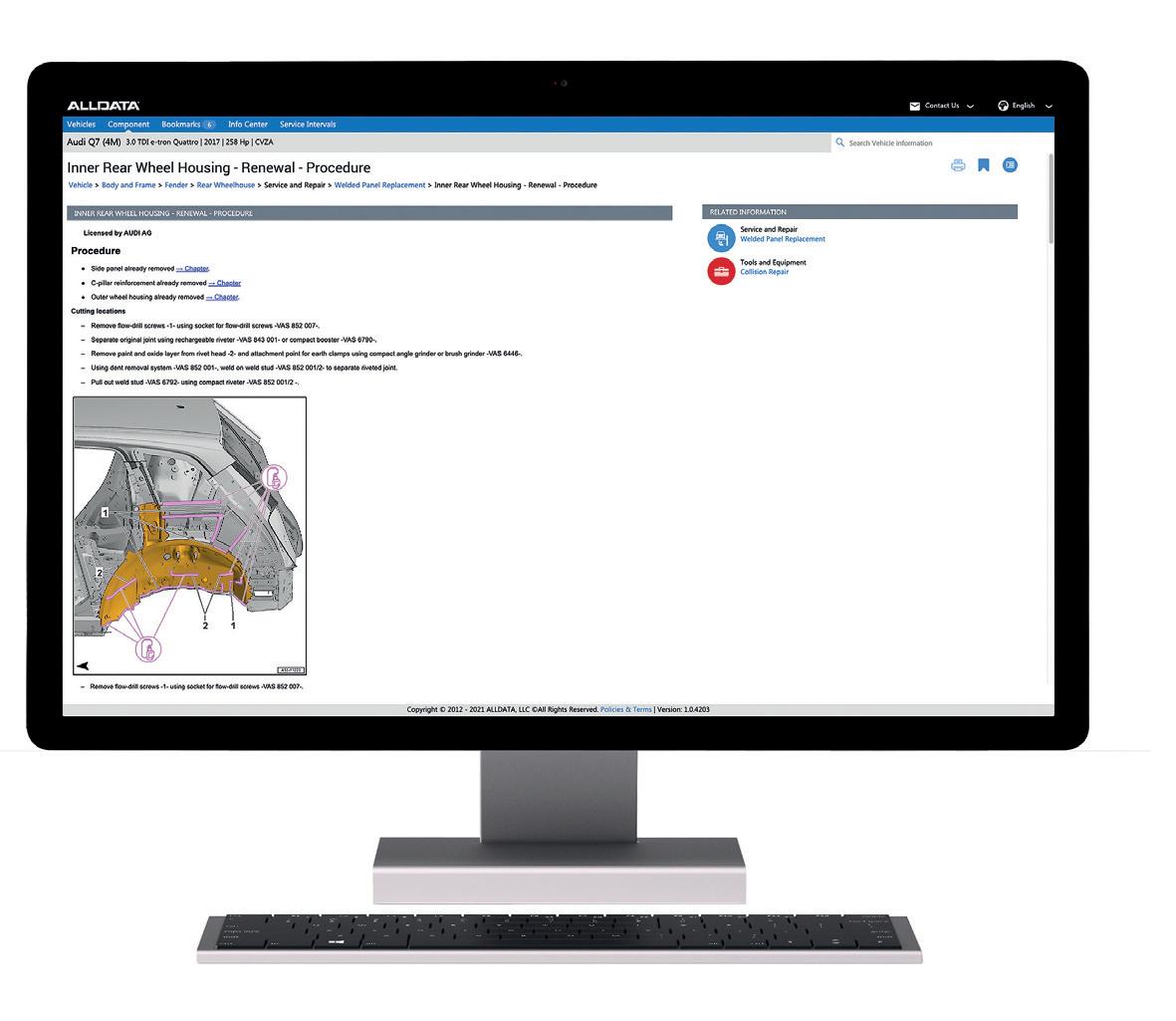

Alldata is adding labour times to its service data to help UK workshops further.

A UK INTRODUCTION

With more than 400,000 users worldwide, Alldata has spent the last 35 years establishing itself as a trusted partner to garages and bodyshops around the world. For any readers as yet unfamiliar with the service, the company republishes original and unedited OEM repair data to aid technicians working in the aftermarket to accurately diagnose and repair vehicles in their care.

With the increasing complexity in vehicle maintenance and repair in the market, the rate of change in the automotive industry is

accelerating at a faster rate than at any time in the past. More than ever before, garages need comprehensive and reliable repair and maintenance data. This allows technicians to offer a confident and professional diagnostic and repair service to their customers.

Alldata Repair launched in Europe in 2012. While the brand has gained a loyal following of subscribers in that time, to many garage technicians in the UK and Ireland, it remains a well-guarded secret. Following success in the German market, the UK operation is now scaling up its sales team, appointing a national team to widen the awareness of the product.

Furthermore, it will appoint selected valueadded resellers throughout the UK and Ireland to rapidly grow its subscriber numbers.

What data does the software contain?

With more than 12 million English language technical documents, original OEM repair information from 29 vehicle manufacturers is re-published in the software and the company recently added models from Toyota, Lexus and Cupra. The data is available under license from each OEM and brought together in one place –the Alldata website, accessible with one username and password.

Vehicles become more complex with the release of each new model. An annual subscription to Alldata Repair gives instant access to all repair data, as well as Technical Service Bulletins, diagnostic trouble codes and electrical systems/wiring diagrams. The data is offered with an intelligent search engine (offering text string matching technology) to enable the technician to find the data they need in seconds.

The portal offers 89,000 make, model, engine, year vehicle combinations, which equates to 95 per cent of vehicles on the road today. It also offers a library of three million technical drawings and wiring diagrams, with a database that is regularly updated.

It’s not just in the service, maintenance and repair garage environment where the service

BUSINESS & TRAINING

30 MARCH 2023 PMM

is instrumental: bodyshops with access can deliver OEM-quality mechanical and collision repairs. This includes body and frame, electrical systems, panel replacement and structural procedures.

Craig Scragg, a Retail Motor Industry Standards and Certification technical trainer gave his verdict on the software: “Alldata has helped me in various ways, from OE wiring diagrams to diagnostic codes, also including manufacturers’ removal and replacement procedures, including body panel procedures.

“I particularly like the wiring diagram aspect, as I know it is OE and comes directly from the manufacturer. I know it is as accurate as it can get.”

Labour times

Launched last month, Alldata Labour Times is designed to enable technicians to

confidently make repair estimates regardless of which make and model of vehicle rolls onto the forecourt.

Thanks to the collaboration with TecAlliance, a leading provider of aftermarket data, the software is now able to publish OEM repair times alongside its repair and maintenance data.

The labour times service is available to both garages and bodyshops as an add-on product to the standard subscription.

WATCH!

Scan the QR code below to learn more and discover how ALLDATA Repair works in practice

While this article marks Alldata’s debut in PMM, the brand exhibited at Mechanex in November last year. Product and technical experts travelled from its European headquarters in Cologne to highlight the product’s credentials and offer

demonstrations. According to the team, early feedback was encouraging.

Building on that momentum, Alldata’s exhibition trail will continue in 2023 with Automechanika Birmingham. The event will take place at the National Exhibition Centre between the 6th and 8th June. These events, with more potentially on the horizon, represent fantastic networking opportunities for existing customers and prospects. WANT

WWW.RDR.LINK/AAV010

TO KNOW MORE? FOR MORE INFORMATION

MAKE A PITSTOP

REPORTS FROM THE RACETRACK WITH LUCAS OIL-SPONSORED DRIVERTONY LYNCH

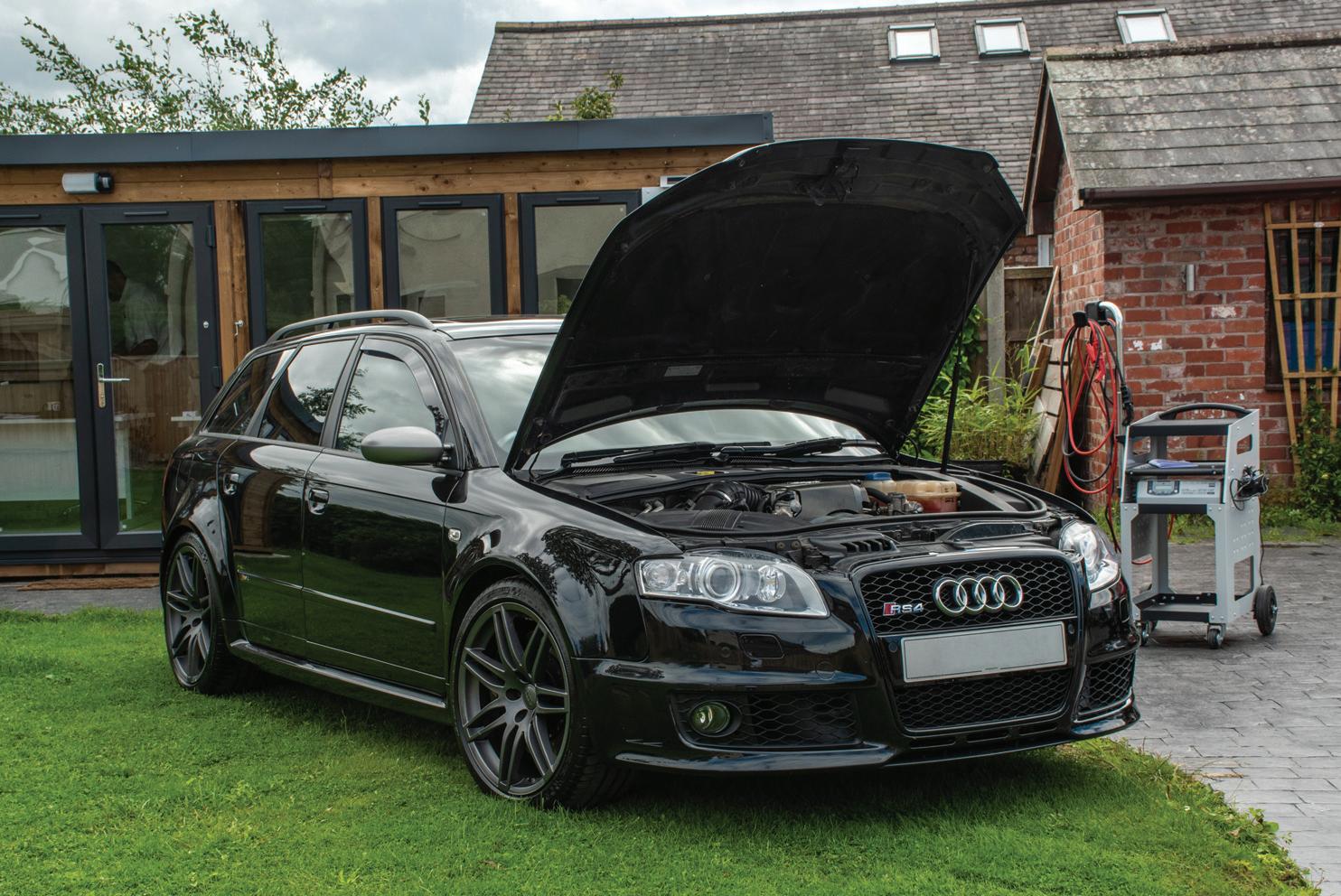

We’re at Lydden Hill Race Circuit, in Kent. It’s day one of a two-round racing weekend in the Retro Rallycross Championship. After a splendid start in Heat 1, gearbox problems adversely affect the performance of our Toyota MR2. We struggle around and finish back in fifth place.

Ahead of the season, the MR2’s racing gearbox had been custom-built and professionally remanufactured. It was all part of a plan to boost acceleration. The crown wheel and pinion had been changed, the gear ratios had been altered, which had certainly made the car faster.

As in F1 racing, quick engineering solutions are essential to rallycross racing success. The pressure to find them on race-days is intense. Unlike the mechanics in F1 pit lanes, once a rallycross heat is under way, paddock mechanics can’t influence the car in any way and there isn’t much time between heats to carry out major repairs.

GARAGE GAG

A friend has gone into business by setting up a garage that fixes car ignitions. It’sastartup.

The paddock mechanics can only respond with temporary clutch adjustments between heats. We struggle through qualifying and against all the odds, collect enough points to take third place on the front row of the Round One run off. Dramatically, the race-day ends in anti-climax and clutch failure just 10 yards after the start.

When we open up the gearbox, all the cogs are shot to pieces. What seemed like a good idea to improve performance failed after less than 30 miles of racing. Luckily for us, the limited slip differential (LSD) inside -which makes both wheels spin at the same time and gives us much more traction - was still in good shape. It is going to be a bit of a risk, but we decide to clean up the LSD and rebuild it into a spare gearbox that we always take to every race meeting.

Fancy a crack at a joke? Send in your (clean) attempts to fcoleman@hammerville.co.uk

The race might be over, but the real work has yet to begin. We are going to make the starting line-up for Heat 1 of Round 2 in the morning.

After a long night, day two racing is a completely different story. We get away quickly and the car is competitive. With reliability restored and confidence flowing, we race well in all three qualifiers. From front row of the final run-off, we finish the round on the podium in second place

Happy days, but let’s hear it for the mechanics in the paddock.

WITH

CONNECTIONS QUIZ

Try and figure out what connects each of the answers!

1. The Evora, Elise and Exige are all models of cars produced by which car manufacturer?

2. Which character did Danny DeVito play in the 1992 film Batman Returns?

3. What is the name of the 1976 sports drama written by and starring Sylvester Stallone?

4. Jim Beam and Jack Daniels are both producers of what type of alcoholic drink?

5. Name the missing suit of cards: Diamond, Heart, Spade and...?’

6. The oesophagus, stomach and large intestine are all part of which bodily system?

7. Which city is the fifth most populous in France, home of their largest airport?

8. Jacques Clouseau is the fictional, inept detective from which TV series?

9. Annapolis, Baltimore and Frederick are all cities in which American state?

Answers:1.Lotus 2.The Penguin 3.Rocky 4.Bourbon Whiskey 5.Club 6.Digestive 7.Nice 8.The

9.Maryland. The ?connection Biscuits

Pink Panther

To EV, ornot to EV?

Whether or not to buy an EV or hybrid or stick to petrol or diesel is fast becoming the most confusing factor for a car buyer. Andy Brooke from Maverick diagnostics is here to clear some things up for PMM readers.

This is a hotly debated topic that everyone seems to have an opinion on from the EV ‘fanatical owners’ to die-hard petrolheads and everyone in between. So, let’s start by breaking down the different types of electric and hybrid vehicles available, both new and second-hand. This will also help garages decide if they should be offering EV servicing and to better understand the market.

Plug-in hybrid vehicles

A plug-in hybrid electric vehicle is probably the best solution for drivers who stick within their city limits; you will suffer no range anxiety because you’ve already got an engine attached to it. However, when it comes to the winter, all battery electric vehicles, whether hybrid or full electric, have a weakness. As soon you hit the heater or the heated seats button, your range drops dramatically.

Self-charging hybrids

Self-charging hybrids are a different to a PHEV as it doesn’t need to be plugged in and

generally contains a very small battery. It uses the petrol engine most of the time, and it cruises and pulls away from a junction with the electric power it charged when braking or slowing down. The range of a hybrid car running on full electric is only around one mile and is why I recommend a full PHEV for local runs on full electric. Overall, the hybrid system gives you a balance of economy that you can never achieve in a normal petrol car. Instead of delivering 30 MPG, a Prius will deliver 45 to 50 MPG on every occasion: from town to motorway.

MHEVs (mild hybrid electric vehicles)

MHEV is what it says it is; unlike a hybrid or self-charging hybrid, it is based on a 48 V rather than a 200 V (or higher) system. VAG group cars have a motor built into the flywheel. Other systems use a type of alternator/starter unit alongside a conventional starter motor which assists a conventional petrol engine for better economy. As with the self-charging hybrid, it also regenerates and charges its own battery when the vehicle is slowing down or braking. In reality, these cars will not be around after 2030 as their main benefit is tax reduction rather than emissions reduction.

Early BEVs

Older BEVs including the Nissan the leaf are very ugly but very functional, and it had a realistic range of about 70-odd miles on a good day in fair weather. The one I had was a very early 2011 24KWH model and it was utterly useless for longer journeys. Users immediately suffer from ‘range anxiety’ and even ‘range-apoplexy’. Eventually, the battery

SPECIAL REPORT

34 MARCH 2023 PMM

on my Nissan leaf gave up, which was very common in these early vehicles. Many Leaf owners went on to purchase modified larger battery packs, but this has become very expensive (anything up to £14K) and outweighs the cost of the vehicle.

New BEVs

Moving on to modern fully electric vehicles, like from Tesla, BMW, Toyota, Skoda, Audi, VW, Polestar, Kia, and MG. I have been lucky enough to drive them and they are totally different to drive; totally smooth and a bit of a revelation for an old petrolhead like me. It’s just a different experience altogether –you end up not looking at how fast you can go but how much battery you can save; driving does become a pleasure if you adjust your attitude to it. I think Tesla cars are the easiest to live with simply because a Tesla driver has access to lots of charging infrastructure, and if you buy the right model, you get free supercharging but these are getting busier every year.

Battery technology

In terms of battery technology, the difference between early and later BEVs is huge; the battery technology and chemistries are very different. The old Nissan Leaf had air-cooled nickel metal hydride (NMH) batteries with no heating or cooling –basically, the batteries were in a tin box. The modern EV often has an optional heat pump to warm the batteries in the winter and air conditioning or liquid cooling to cool the batteries in the summer. Its chemistry, being lithium polymer, is totally different. This type of battery extends the range massively and has evolved from mobile phone technology. As technology moves on, batteries have become far more efficient, and

battery life has been drastically extended. Tesla claims they will have the first millionmile battery soon, and Mercedes are making similar claims with their EQS model.

How far away is electric?

The answer to this will depend on the UK government’s policy. They have set a deadline for pure petrol and diesel vehicles to be replaced with electric or hybrid vehicles by 2030. In my honest opinion, the UK’s already overstretched infrastructure will not be ready. In part due to the average cost of a multiple high kilowatt charging station being over £500,000. Let’s use some simple maths to explain. The average petrol station has approximately eight pumps, services 20 cars

per hour and is open for eight hours a day — that’s 1,280 cars refuelled daily. Imagine the size of the field needed to charge all those cars for 40 minutes to 1 hour each.

To combat this, some manufacturers are already working on hot swap batteries, but again, this is pie in the sky at the moment. Others have been talking about installing inductive charging loops in the road — again, this is incredibly costly and could only really work in cities. Some UK cities are installing charging points in lampposts, which seems very good until you realise they can only provide very low kilowatt charging as the wiring infrastructure does not have the capacity for more. Although all these things will make a difference in the long run, the most significant impact will come from whether the government decides to ramp up tax for older diesel and petrol vehicles.

WANT

WWW.RDR.LINK/AAV011

TO KNOW MORE?

FOR MORE INFORMATION

In my honest opinion, the UK’s already overstretched infastructure will not be ready for the government’s 2030 deadline

The PRICE is RIGHT

With new car sales falling fast and motorists keeping their cars on the road for longer, the professional motor mechanic holds the keys to long term vehicle vitality. Recent years have seen the migration from parts to products as reliable vehicle fixes, not to mention the emergence of repair over replace. Underpinning all this is recent research confirming that motorists trust their mechanic to suggest high quality additives and lubricants, expecting these products to be top tier, not bargain basement. (Darren Darling refers to cheap as chips DPF Refill Fluids and DPF cleaning products for example as ‘Fire Juice’!) So, where’s your opportunity in this?

“The independent professional motor mechanic is, in effect, the fourth emergency service,” says Mike Schlup from Kalimex. “And for those workshops offering DPF services, they should have the JLM Lubricants range of DPF products centre stage. Because even the most badly blocked DPF can be cleaned on the vehicle and restored to normal settings – without a forced regen in sight.”

Here’s what Darren had to say about the JLM DPF Clean and Flush Professional Toolkit at the JLM Lubricants conference,

December 2022: “This toolkit is our friend. Data is of course key in determining the condition of the DPF so when the JLM DPF Cleaner is not the right choice we use this because it thoroughly cleans a badly blocked DPF. I can clean the DPF on a vehicle and not have to raise the DPF temperature to extremely high levels which incidentally runs the risk of thermal damage. A vehicle with a blocked DPF can come into my workshop at 5000mb idle engine spec, when it should be below 10mb. And I can safely use this toolkit to bring it back within good operating specification. After the clean, I will take the vehicle on a 20-30 minute road test. It’s always satisfying to return and see the pressure back in alignment – right down, job done!”

Forced regenerations

Darren is forthright about forced regenerations of the DPF, commenting: “Every month we see hundreds of damaged beyond repair DPFs due to poor attempts at repairing the car. This is frustrating for the motorist and for us having to tell them they must now replace the DPF at a cost of thousands. In principle, cleaning a DPF is simple. However, they’re easily damaged by high temperatures and a misuse of additives.

Kalimex, the UK distributors of JLM Lubricants products, argues that DPF specialists should take special care amidst the cost of living crisis to ensure customers aren’t hit with a hefty bill to replace their DPFs.

SPECIAL REPORT

36 MARCH 2023 PMM

This tends to happen when garages reset adaptations to get warning lights out when it’s not safe to do so or, when they conduct forced regenerations. The problem is on the rise with more garages now keeping DPF repairs and cleaning in-house. Most DPF cleaning equipment is advertised as a straightforward way to make a fast buck when it is not. But at whose expense? The motorist. This is why I only endorse the JLM Lubricants range of DPF products. They get it right first time, on time, every time.”

Of course, if you’re offering a premium service using best-in-class products this should not come at a bargain basement price. Reassuringly many motorists are not looking for the cheapest service at the lowest price –they want a service they can rely on. However, it’s worth pointing out that with the JLM kit, because it’s simple and low cost, the workshop’s investment is a fraction of the expense compared to leasing or buying a big machine, which means payback within only a

handful of jobs. For those workshops that still believe the only way to clean a blocked DPF is to either send it to a specialist or remove it from the vehicle, this is game changing stuff.

“You can be cost competitive using JLM products and still make a decent profit for your workshop,” says Barry Lawson, Ewan Lawson Motors. “Our sales are up on last year because our customers not only trust the products we use at the point of servicing and repair, but they also use them in between workshop visits as recommended by us.”

The JLM Lubricants range of DPF products also includes a Cerium Platinum DPF Cleaner to use at the first sign of a DPF blocking and a DPF Refill Fluid. JLM Lubricants also offers a Diesel and a Petrol Emissions Reduction Treatment – high specification formulas that are used in between workshop visits.

WANT

WWW.RDR.LINK/AAV012

TO KNOW MORE? FOR MORE INFORMATION

Do you work in an independent workshop? Are you an experienced technician with plenty of knowledge to share? Do you want to raise the profile of your workshop and be at the forefront of new

PMM

aftermarket. We care about educating and informing our sector and we know you do too! We want your help to make our media output the best it can be.

If you’re interested, email Kieran Nee at PMM@hamerville.co.uk We can’t wait to hear from you! SPECIAL REPORT

camera,

YouTube

LIGHTS,

ACTION! This is an opportunity for technicians and MOT testers of all ages and from anywhere in the UK to get their hands on the latest tools and products, get in front of the camera and provide cutting edge product reviews for the PMM

channel.

industry developments? If you have answered yes to all of the above, then we have the perfect opportunity for you and your workshop. We are looking for the best technicians in the country to join the PMM team at the forefront of the independent is looking for the next star

for its YouTube channel.

ADDITIVE strategies

Jody Bevan, owner of MnJ Autocare in Oldham, explains how garage efficiency and customer satisfaction can benefit from a clever use of additive technologies.

About this time each year, garages can expect distress calls from soft-top owners or classic car enthusiasts who can’t get their car started after a winter lay-up in the garage. “You can bet that it’s going to be a stale fuel problem, rather than a contaminated fuel problem”, says Jody.

“Because fuel octane levels fall quite sharply very quickly, re-starting problems after a lay-up can occur with cars that are either young or old, but it’s easily preventable. I use Lucas Oil’s fuel stabiliser in my own classic cars and advise all my customers to use it in theirs. It prevents the breakdown of petrol during vehicle storage, which works especially well with classics that only come

out for the summer months. It also means no need to drain the tank. As the product also cleans, lubricates and maintains fuel components, there are added benefits for both the user and the garage that supplied it.”

In the workshop

Jody introduced an additive strategy at MnJ after being hearing of the additives range by her local motor factor. Consequently, she was well informed and ahead of the pack on additive responses to the potential fuel problems generated by the introduction of the E10 petrol standard in September 2021.

“I knew Lucas Oil had a product called safeguard ethanol fuel treatment and I knew how to use it with my customer base. I think

this is a basic essential worth keeping handy in every classic car, in fact any car that wasn’t designed to run on ethanol fuels. If for any reason you can’t get any E5 fuel, you can add it to your tank and then use any available alternative fuel. I tell my customers it will help prevent internal component corrosion, combat the degradation of ethanol-based fuels caused by fuel separation and, consequently, protect their investment.”

WWW.RDR.LINK/AAV013

SPECIAL REPORT

TO KNOW MORE? FOR MORE INFORMATION

WANT

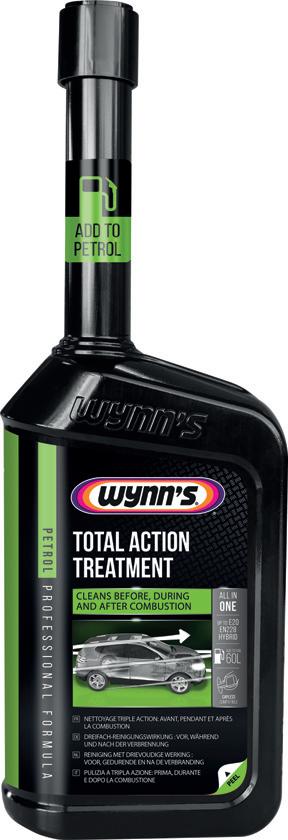

Maximise FUEL Savings

Could you increase your customers’ fuel efficiency this year? According to Wynn’s, cleaning the fuel system could maximise the mileage.

In the past year, the cost of living has increased, and as a result, motorists are feeling squeezed, particularly if they are unable to cut down on their journeys. Car owners need to get the most out of their vehicles by saving fuel and avoiding unexpected breakdowns and repairs where they can.

Current fuel prices present a massive opportunity for workshops to help drivers maximise fuel savings. For a vehicle to achieve good fuel economy, its fuel system must function efficiently.

Wynn’s advises that the easiest and most effective way to improve fuel system efficiency is to clean the whole system using a fuel treatment.

Total Action Treatment is claimed to be the brand’s fastest-acting all-in-one fuel treatment, formulated specifically to clean the entire fuel and exhaust system. It offers workshops an easy way to clean the system, restore vehicle efficiency and maximise fuel savings in an affordable way.

Removing deposits

One 500 ml treatment is poured directly into a vehicle fuel tank. When the vehicle is driven, the treatment cleans the entire fuel system from tank to tailpipe, removing deposits built up over time and mileage. As a result, the vehicle’s performance is restored and the engine runs more efficiently, delivering better fuel economy.

The treatment uses the latest additives technology to provide a total clean. It differs from many fuel treatments in the

aftermarket, which only clean up to the point of combustion and do not survive the combustion process.

Triple action cleaning

■ Before combustion – cleans the injectors, inlet valves and combustion chamber

■ During combustion – cleans the combustion chamber and exhaust valves

■ After combustion – cleans the turbo, EGR, catalyst, DPF/GPF

Total fuel system clean-up

The solution cleans all major parts of the fuel system:

■ Cleans and lubricates injectors

Restores injector spray patterns allowing better fuel delivery.

■ Cleans inlet valves

Improves cylinder seal and restores combustion efficiency.

■ Cleans the combustion chamber

Removes deposits from the piston crown, increasing cylinder volume and improving combustion efficiency.

■ Reduces clogging of the EGR – Cleaning the fuel system and restoring combustion efficiency reduces EGR deposits.

■ Cleans the turbo

Additives active after combustion allows cleaning of the turbo variable vanes and turbo wastegate.

■ Cleans the CAT, DPF/GPF

Additives active after combustion cleans the catalytic converter and gasoline

particulate filter and aids the regeneration of the diesel particulate filter. For diesel vehicles, Diesel Total Action Treatment uses special catalysts to aid the regeneration of the DPF by reducing the soot burn temperature. For petrol vehicles, Petrol Total Action Treatment uses the latest additive technology; PEA (polyetheramine) to help remove stubborn deposits from the fuel system, combustion chamber and exhaust system.

Benefits:

■ Maximise fuel savings

Improves engine efficiency by cleaning the fuel system and removing any built-up deposits, resulting in better fuel economy.

■ Reduce emissions

Cleaning the fuel system reduces exhaust emissions and smoke.

■ Extends engine life

Provides enhanced protection for the entire fuel system from damage caused by corrosion from newly blended ethanolbased fuels

■ Prevent breakdowns

Cleans and protects all major parts in the fuel system from wear and tear, preventing breakdowns and unexpected repairs.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/AAV014

PMM MARCH 2023 41 EXHAUSTS & EMISSIONS

COMMON FAULTS

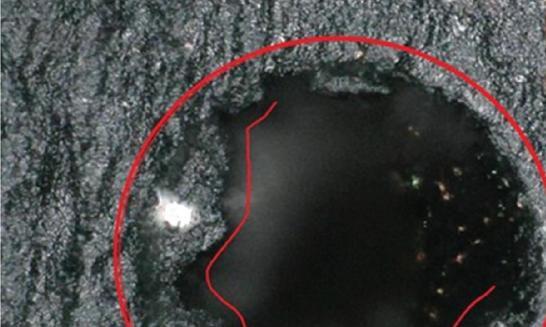

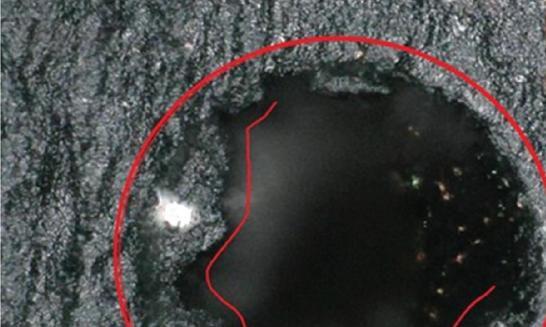

Engine Coolant Temperature Sensors

Nissens guides readers through the diagnosis of a faulty EC sensor

Although on first thought the engine coolant temperature sensor seems a relatively simple component, it plays a vital role in the overall engine management system, ensuring not only the proper working parameters for the engine and protecting it against overheating, but also the engine’s performance, particularly in regard to exhaust emissions and fuel consumption. A faulty sensor can therefore provoke various symptoms related to the engine’s operation, which can lead to problems with other parts or systems.

Background

The EC temperature sensor maintains the correct parameters within the engine cooling system, by monitoring and controlling the coolant’s temperature. However, many modern engines also utilise the sensor’s output signal for other engine functions, including to: