Last month JCB notched up 80 years in business. From a lock-up garage in Uttoxeter to a global footprint, it’s been quite a knock, to put it in cricket parlance . And the innings looks set to continue .

The company seems to fizz with new ideas, product development and innovation It seems slightly ironic that big US firms talk about the metric product vitality, yet JCB seems to deliver that in spades without breaking sweat

Its machines, developed with a laser focus on making the operator’s life easier, more productive and more comfortable, have become design icons The backhoe is probably the most obvious choice, the Loadall one of the most successful

The sheer longevity of its products is also a massive driver of value 1953 marked the launch of the first backhoe and 71 years later the latest incarnation was launched with DualDrive This Januar y marked the one millionth model to roll off the production line Talk about a machine for the ages!

Despite being an engineering business, the company has never shied away from marketing and promotion, often putting its machines in a context that captured attention or turned heads The Dancing Diggers, can you believe, first performed in 1962 The JCB GT was a backhoe capable of 100mph, The JCB Dieselmax streamliner car reached speeds of 350mph, a fantastic plug for its own engine business It was all about the art of the possible Innovation was also a driver for making things possible Those of you old enough and can cast their minds back to 1990, the launch of the Fastrac tractor was a momentous event It looked different with its same size wheels, not like a tractor at all, it went like a rocket on the road, not like a tractor at all, and was comfortable, not like a tractor at all Today Fastracs abound, working across farms the length and breadth of the UK At the time JCB invested £12m in its development, not an insignificant chunk of change, but it wasn’t going to get this wrong and so it proved.

That same attention to detail, belief in getting the job done and bringing an idea to fruition is evident with the company ’ s drive for hydrogen as an alternative fuel to both diesel and batter y-electric Seemingly often a lone voice in the whole hydrogen debate , the number of milestones is racking up with the first full EU type-approval for hydrogen engines in non-road mobile machiner y secured this year, followed by the UK Government changing the law to allow hydrogen fuelled construction machiner y to use the public highway According to Lord Bamford “JCB’s customers are patiently waiting for our hydrogen-powered equipment to make a difference on their job sites They won’t have much longer to wait ”

Founder Joseph Cyril Bamford was described, on his death as possessing a rare combination of ‘engineering genius and marketing flair’ by the Financial Times Today those attributes seem as much in evidence as they were all those years ago.

Happy reading

Editor JOHNNY DOBBYN

JOHN LEVICK

cpn@hamer ville co uk

Advertising Manager PAUL FITZGERALD

pfitzgerald@cpnonline co uk

Magazine Designer DONNA BOOTH

Production Assistant CLAIRE PICTON

Subscriptions

C on s t r u ct ion Pl a n t New s is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities If you are not on our circulation list and would like to subscribe email cir cu la tio n @ h a m er v il le co u k

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamer ville co uk

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Her ts WD24 4YF Tel: Watford (01923) 237799 Fax: (01923) 246901

Copyr ight © 2025

The publishers and editor do not necessarily agree with the views expressed by contributors nor do they accept responsibility for any errors of translation in the subject matter in this publication

A NEW GUIDE WHICH DEMYSTIFIES COMMON MISCONCEPTIONS SURROUNDING BATTERY ENERGY STORAGE SYSTEMS (BESS) AND HIGHLIGHTS THE EXTENT OF THE TECHNOLOGY’S APPLICATIONS IN THE SECTOR, HAS BEEN PUBLISHED BY ENERGY SOLUTIONS SPECIALIST AGGREKO. Building with BESS showcases how construction professionals can reduce both noise and emissions when operating in urban areas, all while increasing energ y resilience and on-site efficiency.

Tom Adlington, sector sales manager, building ser vices & construction, said: “We aim to demonstrate how BESS can address some of the major challenges that construction sites face on-site ever y day – from the need to minimise noise, to cutting energy consumption, saving on fuel and reducing carbon emissions ”

The guide highlights the real-world applications for batter y storage , from efficient load management to overcoming grid challenges and scheduling power, including many that are not yet well-known to the industr y

THE CEA HAS ANNOUNCED THE APPOINTMENT OF PHIL BATTLE, DIVISIONAL DIRECTOR VOLVO CE – PRODUCT & SERVICES AT SMT GB, TO ITS BOARD. HE WILL TAKE ON THE PORTFOLIO OF ESG AND ENVIRONMENTAL SUSTAINABILITY, REFLECTING HIS PROFESSIONAL EXPERTISE AND COMMITMENT TO SUPPORTING THE SECTOR’S TRANSITION TO A LOW-CARBON FUTURE

Commenting on his appointment, Battle said: “I am delighted to be joining the CEA Board and to have the oppor tunity to work more closely with the association and its members. The CEA has made significant progress in recent years – becoming more engaged, relevant, and ambitious in its suppor t of the industr y I’m par ticularly pleased to take on the ESG and Sustainability por tfolio, which is such a critical focus for our sector’s future I look forward to contributing my experience from the dealer and distributor side , and to helping the CEA continue this positive momentum ”

WWW.RDR.LINK/CBF003 i

THE CEA, SUPPORTED BY JCB, RECENTLY HOSTED A HYDROGEN WORKSHOP TO EXPLORE THE BARRIERS TO BRINGING HYDROGEN-POWERED CONSTRUCTION MACHINERY TO MARKET. IT MARKED THE FIRST IN A PLANNED SERIES OF CEA-LED TECHNICAL SESSIONS FOCUSED ON ALTERNATIVE ENERGY SOLUTIONS.

The workshop attracted around 60 delegates, including senior representatives from OEMs, regulators, and the wider hydrogen sector

The session was initiated by Victoria Hutson, group standards and legislation manager at JCB, who approached the CEA with the idea of creating a neutral, cross-industr y forum to examine the challenges of bringing hydrogen-powered construction machiner y to market

Viki Bell, chief executive of the CEA, said: “This workshop was an impor tant step in bringing the industr y together to address real-world barriers to hydrogen adoption We remain fuel and technolog y neutral our role is to help members navigate change , share knowledge , and ensure the regulator y landscape suppor ts safe and practical innovation ”

WWW R DR LINK/CBF004 i

THE FEDERATION OF PILING SPECIALISTS (FPS) HAS PUBLISHED THE LATEST EDITION OF ITS WORKING PLATFORM CERTIFICATE (WPC/4E). THE NEWLY RELEASED GUIDANCE BRINGS ADDITIONAL CLARITY AND DETAIL TO THE REQUIREMENTS FOR

“Having listened to sector stakeholders, we believe this is the show the plant and tool market needs,” said HIREland show director Brian Coogan “It will be a ‘shout out to the sector’, to meet on one day in March, in Tallaght, to search, find and connect with the suppliers and providers who will suppor t their growth plans for 2026 and beyond ”

WWW RDR LINK/CBF005 i

DESIGN, VERIFICATION, AND ONGOING MAINTENANCE IT INTRODUCES MORE COMPREHENSIVE DESIGN DATA, INCLUDING INFORMATION ON PLANT CONFIGURATION, PLATFORM MATERIAL, DRAINAGE PROVISION, AND GEOTEXTILE REINFORCEMENT. IT ALSO PLACES GREATER EMPHASIS ON SUSTAINABILITY BY ENCOURAGING DESIGNS THAT ARE SAFE, EFFICIENT, AND CONSCIOUS OF BOTH COST AND CARBON. A REVISED INSPECTION LOG HAS BEEN INCORPORATED, REQUIRING WEEKLY CHECKS AND RECORDING OF ANY REPAIRS OR REINSTATEMENT AFTER EVENTS SUCH AS HEAVY RAINFALL, EXCAVATION OR FLOODING, ENSURING THAT PLATFORMS REMAIN COMPLIANT THROUGHOUT THEIR WORKING LIFE. Commenting on the update, Andy Heathcote, technical director at Keller and lead on the revision, said: “Working platforms remain the first line of defence against rig instability This update ensures the certificate not only reflects current best practice but also addresses emerging issues such as the performance of recycled aggregates, drainage and sustainability in design It remains a vital tool in raising and maintaining safety standards across our sector”

WWW R DR LINK/CBF006 i

KU B O TA ( U K) W O N THE A LTER N ATIV E

PO W ER IN N O VATIO N CATEG O RY, IN THE

PL A N TW O R X 2025 IN N O VATIO N AWA R D S

FO R ITS EL ECTR IC R ETR O FIT

TECHN O L O G Y, THAT A L L O W S CU STO MER S

TO MO V E FR O M D IESEL PO W ER TO A FU L L

B ATTERY EL ECTR IC D R IV EL IN E A CR O SS A

G R O W IN G R A N G E O F KU B O TA’S MIN I

EX CAVATO R S.

Currently available for its 1.8-tonne KX019-4e and 2 5-tonne U27-4e mini excavators, Kubota has developed a modular retrofit batter y pack, that can be used in place of a standard diesel model’s engine The batter y pack and electric motor can be installed in place of the diesel engine by the customer or dealer, when a zeroemission machine is required. The machine can be returned to diesel power for other types of work, to ensure maximum utilisation

R o b W h i t e , Ku b o t a ( U K ) c o n s t r u c t i o n

d i v i s i o n m a n a g e r, c

t h a t t h e re t ro f i t k i t o f fe r s c u s t o m e r s a

c o s t - e f fe c t i ve

KUBOTA (UK) IS ADDING TO THE TERRITORIES OF CONSTRUCTION EQUIPMENT DEALERS SHELLPLANT AND BOSS PLANT SALES FROM JANUARY 1, 2026, CONSOLIDATING ITS NETWORK ACROSS THE SOUTHEAST OF ENGLAND.

NORTHAMPTONSHIRE-BASED SHELLPLANT WILL ADD NORFOLK AND SUFFOLK TO ITS EXISTING SALES A R EA , W HIL E HERTFO R D SHIR EB A SED B O SS PL A N T SA L ES W IL L A SSU ME R ESPO N SIB IL ITY FO R N EIG HB O U R IN G ESSEX .

“We are delighted to be able to increase the territor y of these two exceptional dealers, as we continue to grow our product range across the construction business,” said Rob White , Kubota (UK) construction division manager

“This is an exciting time for Kubota, with the addition of larger excavators, wheeled excavators and compact tracked loaders to the line-up We will be offering customers and dealers a whole range of new oppor tunities next year, including new driveline technologies such as Requip, Kubota’s award-winning electric retrofit for mini excavators We will have the best network of dealers to suppor t those new machines ”

WWW.RDR.LINK/CBF008

MACHINE CONTROL AND SURVEYING EQUIPMENT SPECIALIST LEICA GEOSYSTEMS HAS LAUNCHED A NEW THREETIERED TRAINING PROGRAMME FOR INSTALLATION ENGINEERS AND TECHNICIANS. THE PROGRAMME ROLLOUT, WHICH BEGAN IN SEPTEMBER 2025, IS OPEN TO ALL CUSTOMERS, DEALERS, AND PARTNERS.

Commenting on its investment in training Mark Laud, business director UK Distribution at Leica Geosystems said: “Thousands of machines now use Leica Geosystems 3D machine control on some of the largest and smallest projects in the UK and Ireland. With new machines getting fitted daily and new entrants to the industr y, we recognised we could fur ther suppor t our dealers and customers as they expand their capabilities for both the installation and maintenance of our solutions

“By developing a progressive learning programme with three levels, delivered by our exper t team from our own Leica Geosystems School in Shropshire , we can not only share our knowledge but also practically show how our ecosystem works ”

WWW R DR LINK/CBF009 i

ORGANISERS FOR PLANTWORX 2025 HAVE CALLED THE EVENT A ‘RESOUNDING SUCCESS’ AFTER THREE PACKED DAYS AND ENCOURAGING FEEDBACK FROM EXHIBITORS. MORE THAN 10,000 VISITORS FLOCKED THROUGH THE GATES TO SEE OVER 300 EXHIBITORS, AS THE SUN SHONE (MOSTLY) ON THE LARGEST WORKING CONSTRUCTION EQUIPMENT SHOW IN THE UK.

Viki Bell, CEO of the CEA, said: “As my first PlantWorx, the show exceeded my expectations in ever y way. The main thing I took from the event was the passion of all the exhibitors and visitors, and how much they genuinely love this show The CEA Stand in the Indoor Pavilion was busy from the get-go, and it was lovely to see so many members stop by for a coffee and a catch-up We had so many new member enquiries that the stand team had to book appointments.”

WWW R DR LINK/CBF010 i

FOLLOWING A RISE IN DEMAND FOR HIGHCAPACITY TEMPORARY POWER SOLUTIONS, STAR POWER HAS INVESTED OVER £3 MILLION IN NEW EQUIPMENT, SIGNIFICANTLY INCREASING ITS FLEET CAPACITY AND NATIONWIDE SERVICE COVERAGE. The investment includes the addition of over 100 generators, cable packs, multiple batter y energ y storage systems (BESS) and distribution boards The new equipment is being deployed across the company ’ s depot network to improve availability and response times nationwide .

Marc Cooper, commercial director, commented: “This is a carefully considered investment that strengthens our core fleet and allows us to respond even faster to customer demand We’ve worked closely with our key supply par tners to ensure ever y addition to the fleet aligns with our focus on reliability, efficiency and site-ready solutions ”

To fur ther strengthen national coverage , Star Power has recently opened a new depot in the Nor thwest, is relocating its Bristol depot and expanding its Kent depot to meet increased demand

WWW R DR LINK/CBF011 i

NATIONWIDE PLATFORMS HAS EXPANDED ITS SPECIALIST TRAINING WITH THE INSTALLATION OF ITS FIRST FIXED IPAF PAL+ TRAINING RIG IN THE EAST MIDLANDS. THE NEW RIG, NOW OPERATIONAL AT THE COMPANY’S LEICESTER DEPOT, OFFERS ADVANCED OPERATOR TRAINING FOR POWERED ACCESS PROFESSIONALS ACROSS THE REGION.

The rig is purpose-built for the IPAF PAL+ course: a one-day, advanced qualification for experienced operators of mobile elevating work platforms (MEWPs). PAL+ is increasingly mandated by Tier 1 contractors and large infrastructure sites and is rapidly becoming the expected standard for complex, high-risk MEWP operations

Rebecca Myers, external training manager at Nationwide Platforms, said: “Customer demand for advanced operator training is rising fast, par ticularly on sites where there’s zero room for error PAL+ offers a higher level of assurance and practical capability, and we ’ re seeing more clients request it as standard. Adding a dedicated rig in the East Midlands gives our regional customers better access to that level of training.”

WWW RDR LINK/CBF012 i

Big enough to matter, small enough to see everything you need to, this year’s edition of PlantWorx had something for everyone. CPN looks at a few highlights.

PlantWorx’s first outing at the Newark showground is deemed to have been a success The organisers are citing good numbers: over 10,000 visitors, more than 300 exhibitors, of which 107 were new and plenty of deals struck over the three days.

There was literally something for ever yone from the outdoor displays to the indoor pavilion that was described as an “Aladdin’s cave ” of products and solutions, drawing crowds and offering a wide range of offerings, from compact tools to high-tech software

T h e O p e r a t o r s C h a l l e n g e , s p o n s o re d by

J C B , w a s a h u g e h

e n e r g y h i g h

The Site Sustainability Showcase also proved a major draw, with visitors exploring batter y storage solutions, hydrogen-powered machiner y, solar-hybrid generators and electric NRMM Prolectric , as headline sponsor, and DF Capital, sponsors of the Recharge Café, repor ted excellent engagement from visitors keen to discuss low-carbon site solutions.

For anybody with a view to purchasing a compact loader anytime soon, the show was

a great oppor t new launches

Takeuchi m debut of its TL (TL8R-2 and T showing its SWL2830 Kubota had its SVL753 hard at work on its stand Not to be outdone Finning UK & Ireland displayed the new Cat 285 XE compact track loader marking its first UK appearance It’s the largest and most powerful model in the range , and features a 3 6 litre Cat engine , built just down the road in Peterborough

Talking about the rationale behind the Cat 285 XE, product exper t Jas Kundra said: “The 285 XE is perfect for operators wanting to lift larger payloads and traverse longer distances With a bucket pin height of over 3 7m, it’s also great for loading applications You can raise the bucket while still opening

about experiences with the ROTO 50 30 S PLUS and operator platform Many visitors accepted the invitation to rise 35m into the sky, enjoying a bird’s-eye view of the show

while seeing first-hand the machine’s stability, reach, and height in action The extendable three-person basket made the demonstration a memorable highlight of the event. Displayed with a hydraulic winch, the ROTO 50.30 S PLUS combines a five-tonne capacity, 30m lift height, Stage V 170hp engine , 360° turret rotation, unique tilting cab, and multi-position stabilisers, making it well-suited to infrastructure , steel erection, forestr y, and high-rise construction

Across the way Manitou UK previewed the brand-new MRT 4070 – a 40m, 7-tonne capacity rotating telescopic handler with an overall 27m of forward reach It has the same four points of access as the Vision Plus machines, with a flat deck and no trip hazards, keeping safety in mind for all operators. The

cab is spacious with a capacitive joystick, flat armrests, and an easy-to-use touchscreen

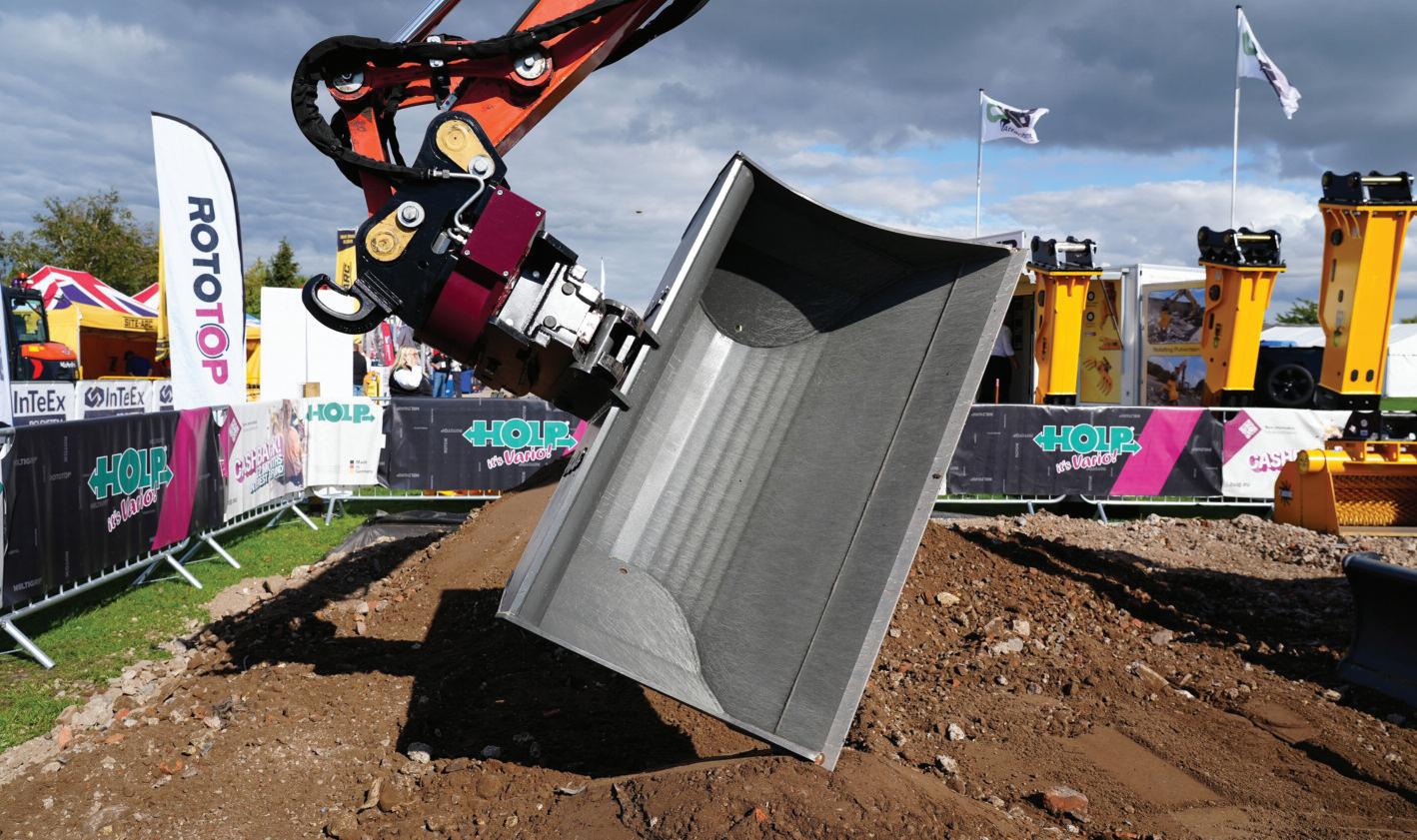

An area of par ticular interest was the battle for the hear ts and minds of operators from the tiltrotator brigade . This pitted the Scandinavians versus the Germans versus the Brits, all of whom had invested some time and money in their effor ts, most notably the demo displays Steelwrist and Rototilt are names that we are pretty familiar with and have been leading the tiltrotator charge for some time , while Versaffix is providing some competition from its Nor thern Irish base –check out The Dig’s column on page 14. Holp from Germany is offering something slightly different, RotoTop, a 360o limitless rotation drive , that is claimed to do 95% of what any tiltrotator can do

The hallmark of a good show is when visitors don’t tyre kick, they buy This was reflected in the number of machines displaying ‘SOLD’ stickers by the end of the event with XCMG, Hightop and others repor ting strong sales and orders placed during the event Cer tainly, we heard plenty of talk of offers being made on kit and there was official notification from the likes of SANY UK & Ireland, who announced that Lynch Plant Hire is taking deliver y of its new 3 5-ton fully electric excavator, saying it was “ a real milestone in our shared commitment to sustainable construction ”

month JCB had a ble celebration as it lded 80 years of being in ness and Lord ford’s 80th birthday. N chooses ten landmark pment launches that ure the company’s ethos.

Some say he’s king of the cab, others that he’s peerless on the joystick All we know is that we call him The Dig This month he finds himself getting attached to a Versaffix tiltrotator

saffix) to be a ver y ny, who were keen to listen equests and add value to

supplied and installed by bucket and attachment en Attachments, based in hepstow, and who was ed the dealer for Versaffix Attachments has been

excellent to deal with all through the process and I’m sure our collaboration with them will continue in the future , ” added Bird

We visited the machine on a large Barratt Homes site in Fiddington, Tewkesbur y. At the time of our visit, the team was currently 65 plots into the build programme , which had already seen it complete the associated infrastructure works, including roads and sewers, a pumping station and a balancing pond, so there was plenty of work for the Takeuchi to get on with

KW Bell’s project manager, James Beale , commented: “The Takeuchi TB290-2 has already proven to be a ver y capable machine , and ever y single operator who has driven it has been ver y complimentar y about its power, smoothness of operation and general workability.

“Since having the tiltrotator fitted, we have noticed how it’s become an even more useful machine to have in the arsenal here; with the integrated gripper we notice a lot less requirement for additional labour on the ground working with the machine , which can only be a positive thing.”

Some would suggest it’s a brave move to take on the big Scandinavian tiltrotator brands, but Versaffix, based in Newr y, Nor thern Ireland, boasts a ver y knowledgeable team of skilled design engineers, mechanical fitters and sales team It has impressively attained ISO 9001 Quality Management Systems & Cer tifications over the last three years and won an industr y award in 2024.

At its state-of-the-ar t facility the team is dedicated to maintaining a meticulous and

controlled production and assembly process to ensure the highest quality standards for its products

The in-house engineering team takes care of all the design work internally, whilst all profiling, machining and welding is also under taken in-house , fur ther ensuring stringent quality control standards throughout the process and allowing any adjustments as and when needed

Casting of the main tiltrotator body is carried out overseas, to strict control standards during each step of the process, with extensive and rigorous testing being under taken to ensure that all casts are free from impurities and are of a high standard

The company also sources the finest components from leading blue-chip suppliers primarily in Ireland and the UK.

Talking about the tiltrotators in general, managing director of Versaffix,

, which is also Versaffix, is gh the Takeuchi’s own quick circuit r, which offers 45˚ tilt range s the much-lauded SVAB hat allows the end user to eeds of tilt and rotation ons individually es that each installation is e individual excavator the machine’s own were controlled through icks, are still available joysticks r unit is, as mentioned with the optional gripper s built-in safety check up and placing items, and extremely popular on ddition, this one also onal hi-flow quick release itch which facilitates the

use of attachments such as a mulcher or sor ting grab

The operator on the day of our visit was Paul Worsfold, who has been operating the machine since it was delivered, but the tiltrotator had only recently been fitted

Paul is relatively new to machine operating having come through the AccXel Construction School in Cinderford, taking an apprenticeship via the plant operating course at the in-house training centre , where he gained his red ticket for 360 excavator, roller, dumper and telehandler, and following his on-site experience his card

has recently been upgraded to fully competent blue status

It’s quite unusual to see someone so new to operating being put on a tiltrotator- equipped machine , but Paul has grabbed the oppor tunity with both hands and is enjoying the challenge , referring to the machine and the set up quite simply as “fantastic”

I took a good look around the unit and was suitably impressed with the quality of the build, which appeared to be as good as

anything else on the market; the installation looked good too, with nice routing of all the pipework, and easy access to those allimpor tant greasing points

I was keen to see how it performed so I took to the seat to tr y out the Versaffix for myself Naturally, I’m ver y familiar with the Takeuchi TB290-2 which allowed me to focus on the tiltrotator element

Having spent some considerable time with cer tain other brands I wasn’t quite sure what to expect, but after 15 minutes or so of running it, I was back in the tiltrotator groove and enjoying the Versaffix

Ever ything was reacting just as you would want it too, positive and smooth movements from the propor tional controls and comfor table joysticks to use There was a good power from the tilt rams and a nice flow of power when combining tilt and rotate functions It just got me thinking, if it wasn’t painted silver would I really know the difference , probably not in actual fact!

It will be interesting to see how these UK and Nor thern Irish built units are received by end users going forward, and at the recent Plantworx the team was riding high on positivity, repor ting good sales and interest in the products It will be interesting to see how things pan out over the coming years

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

CPN talks to Stefan Stockhaus, CEO of Steelwrist and co-founder of the Open-S Alliance, about where the tiltrotator market is heading in the UK

Talk about tiltrotators with Stefan Stockhaus, CEO of Steelwrist and initiator of Open-S, and inevitably comparisons are drawn between the Scandinavian and UK markets Nordic contractors have shown a huge appetite for the devices, their UK counterpar ts less so Stockhaus points to the statistic that tiltrotators were introduced in Sweden in 1986 and in less than 10 years had achieved over 90% market penetration. He illustrates this by saying that, if we were to do a tour of construction sites in his native land, he would buy us a beer for ever y excavator that wasn’t fitted with a tiltrotator Now while the prospect of a dr y night out in Stockholm doesn’t necessarily appeal, it does demonstrate that tiltrotators have become ver y much par t of the landscape

The reasons for this success? Stockhaus puts this down to many factors including an innate willingness to tr y new technolog y, a much smaller workforce requiring more

work to be done by less people so you need ever y advantage you can get your hands on and a laser focus on productivity and earning power He believes that the UK faces different challenges that potentially dampen the appetite and adoption of the technolog y including high perceived costs and the fact that many jobs are on hourly rates so where’s the incentive to get things done more quickly?

He also reels off more compelling facts that should act as incentives for purchase and use for any excavator operator : better fuel consumption, greater breakout forces, one machine that can do the work of three or four other machine types with the right attachments And he points to numerous studies that show that on average that a tiltrotator gets the job done 30% faster.

So why the lukewarm reception here in the UK? Some obser vers mention

cost, as alluded to above , others that our mindset proves to be a bit of an obstacle It’s not necessarily a question of age as some might believe Stockhaus recounts how Steelwrist’s first sale here in the UK in 2009 was to an operator aged 60, who within three to four weeks of getting used to his new tool, spent the next four years saying he couldn’t do without it The received wisdom is that a good operator can get up to speed in two weeks and within a few months transform his or her capabilities

There’s also the wider question about proprietar y systems that limit the choice of attachments to one brand or manufacturer. Forcing brand loyalty on a customer might seem to make business sense but Stockhaus takes the opposite view that attachment manufacturers should have the customer’s interest at hear t not their own The only way to do that is to ensure some kind of interoperability that lets the customer choose couplers, tiltrotators and tools

from a variety of manufacturers which are all compatible

Which is where Open-S comes in A centrepiece of the Open-S Alliance, the Open-S enforces a standardised coupler design that allows seamless transition between different attachments. The brainchild of Stockhaus and Rototilt CEO, Anders Jonsson, the organisation is the driving force behind attachment compatibility, freedom of choice for users and continued innovation that benefits ever yone

Stockhaus refers to it as the attachment world’s equivalent to the USB-C connector type, now the universal standard for charging and data transfer across a wide range of devices, including laptops, smartphones, tablets, and other devices.

It makes sense in many ways Remove the barriers to adoption, create a level playing field where customers have more choice , can mix and match attachments without fear of being locked into one brand and let them build an armour y of tools that suits their needs in a bespoke way.

Returning to the question of tiltrotator adoption in the UK, anecdotal evidence suggests that when a contractor or operator makes the investment, the results are encouraging The early adopters talk about the transformational nature of the tool, how productivity improves, how the need for manual labour on the ground decreases and perhaps, most tellingly, how on earth did they ever do without it!

James Venerus, general manager product marketing at Komatsu Europe, discusses how original equipment manufacturers (OEMs) can accelerate tiltrotator adoption through deeper collaboration with leading manufacturers and simplified integration that puts operators first.

and ensure customers can adopt this technolog y seamlessly

Driving true value for customers means eliminating complications through closer collaboration with tiltrotator manufacturers.

By doing so, OEMs can enable qualityassured, factor y-integrated solutions This means a deep collaboration where the OEM brings its engineering exper tise to design the machine's electrical and hydraulic systems from the ground up, ensuring the excavator is built to recognise and communicate perfectly with specific tiltrotator brands

Making a machine more efficient also means making the operator's life easier Full utilisation of the tiltrotator's capabilities depends on intuitive control features. Modern excavators, such as the Komatsu PC220LCi-12 with Intelligent Machine Control 3 0, offer unique assistance features that simplify tiltrotator operation

The system can control rotation and tilting while also including features such

as posture hold control, which automatically maintains attachment orientation This makes digging and grading with a tiltrotator easier for the operator, especially for those new to tiltrotator technolog y

As technolog y advances and job sites become increasingly sophisticated, OEMs need to proactively develop machines with enhanced tiltrotator readiness However, this must be driven by listening closely to customer needs and understanding their specific operational challenges

The role of the OEM is to foster deeper collaboration with tiltrotator manufacturers to deliver integrated solutions that genuinely address customer pain points. By working together, OEMs and tiltrotator manufacturers can create seamless, factor y-integrated systems that reduce installation complexity and costs, making the technolog y more accessible to customers and help them be prepared to meet future demands

CPN hears from Holp about how its RotoTop is delivering for a growing number of users in the UK.

olution’ is underway. ed to adopt the phrase oTop transformed their way an excavator - less time on burned, less manual work encies, increased the prospect of more

rst customers was m Gilber t, who shor tly e of his Rototop said: “It ing used to it, but now I be without it. The elievable . It reduces r the groundworkers mproves the workflow on erhaps the biggest irony is previously been thinking urn a bucket and was on nting his own rotar y joint om M E Coad, a plant d screening company, had some time to find a costent to increase ite , before he found

RotoTop, which he quickly ordered for his Kubota KX080 It took him just one day to become accustomed to it and he was impressed with the incredible flexibility: “I could do so many things around manholes from one position without moving the machine and was also able to dig under ser vices with ease . ” One impor tant thing for him was that all of his attachments would fit and be rotatable as well. Only a few weeks later, he ordered a second

RotoTop RT 201 to boost the versatility of his Case CX130D With a pipeline of work secured he’s looking forward to getting the jobs done with less manual labour and within the timescales

Only a few weeks after Por teous Groundworks received its first RotoTop which has been utilised with its new 20 tonne excavator, it recently ordered another, an RT.092 that has been fitted to a new Takeuchi TB

290-2 Director Ben Por teous has appreciated both the improved machine utilization and versatility

For McCullough after two years of selling RotoTop and other Holp attachments such as special buckets or the CutWheel, the feedback from his customers is satisfying: “Together we have managed to star t a real revolution on building sites in the UK It’s a revolution towards more efficiency, less manual groundwork and satisfied employees that creates more value in less time Pure rotation is all you need ”

McCullough also believes that there is a financial imperative “With the cost of alternative options being so expensive and the need to purchase new buckets or hangers, on top of the running costs of repair and maintenance, I believe RotoTop is the future. Simplicity is often better and being manufactured in Germany you are guaranteed high-quality components Having put RotoTop on the map in the UK and Ireland, with just a little more brand awareness and the right attitude, we can achieve great things with our dealer network ”

ng for leaks and fittings for ced operatives need to be oading the attachment, using riate angle , or in an lication (climate , material potentially lead to cracks lure , with all the health and poses sed by multiple r than one consistent one , most We see this ctors where operatives hours ding all of this is to use m a manufacturer that offers Carried out by mobile can be carried out at between the manufacturer t a cost of just a few The fee covers technical f the moving par ts, and if ement of worn par ts tively, to keep downtime to machines up and running s based in the UK, with of spare par ts and next-day mention an attachment d welding ser vice for

custom repairs or reinforcements, and refurbishment/remanufacturing and custom capabilities, will complement this

But the match point also comes at the point of purchase , so serious consideration should be given to high-quality attachments that are built to withstand heavy use and offer better durability While they may cost more upfront, they often require less maintenance and have a longer lifespan

Manufacturers with sales teams that look beyond the sale itself are also invaluable These teams will drill their customers down on what the attachment is expected to do, how frequently and for how long, in what kind of environment, and whether they need features like reinforced edges or wearresistant coatings.

Back that up with the establishment of a regular lubrication schedule based on usage frequency which will optimise the longevity of the attachment the operator is buying Comprehensive online and printed product guides or manuals should be regularly referred to Best practice is regular checks, including the replacement of hydraulic filters and fluid at regular inter vals to avoid contamination. Low hydraulic fluid on attachments like quick couplers can damage seals, cylinders, and motors And just like cars, plant attachments need washing, dr ying and even the application of

a protective coating or lubricant to metal surfaces prone to corrosion

Storage off the ground in a covered dr y area away from extreme weather conditions will also help minimise rust, corrosion and other degradation, and protect hydraulic fluids and other lubricants.

We recently saved a longstanding client the cost of a new high tip bucket by repairing its existing one Work included shot blasting, replacing pins, bushes and bosses, and cylinders and hoses, strengthening the hockey stick corner suppor t, installing new bolts on the cutting edge plate , and hydraulic testing All this at the fraction of the cost of new

Did we take him to task about maintenance? We are pleading the fifth!

It’s been quite a year for compact machine launches. As we head to the year ’s end CPN takes a look at three of the most recent compact excavators to break cover.

nctionality and auxiliar y circuit priority added to the main control of auxiliar y line 1, to l hungr y attachments. An dant hydraulic line , routed m, is available to operate a n a quick hitch, leaving and 2 available for work ction has, says Yanmar, been e operator ver y much

in mind in a bid to increase comfor t and productivity The roomy cabin provides exceptional visibility, increased legroom and an ergonomic layout, putting the operating controls and switches within easy reach

The machine features a brand new 4 3in color display, including auxiliar y circuit settings for up to five attachments, providing easy and intuitive control. The handy joystick and button area, which includes a high-speed travel switch on the blade lever, are designed for ease of use and enhanced operational efficiency More ergonomic travel pedals fur ther improve the manoeuvering of the machine

Transpor ting the SV39-7 is effor tless thanks to its compact length of only 4,600/ 4, 650mm (shor t arm/long arm) and the inclusion of six tiedown points With a transpor t weight of 3,790 kg (cabin)/3,670 kg (canopy), the SV39-7 is easy to move between jobsites.

Moving up a weight and building on the success of its zero-tail range , which earned an iF design award, Sunward’s new SWE 50UF compact excavator is already proving its wor th on site

The zero-tail of the five-tonne model, which is positioned between the SWE 35UF and SWE 60UF, is ideal for the constrained spaces operators are increasingly having to work

in, on urban sites, landscaping and light civil engineering

Despite its small footprint, the SWE 50UF delivers impressive stability for material handling, trenching and fine grading An additional 175kg counterweight is also available for users who need added stability when operating heavier tools or working on more demanding terrain

Designed specifically with a low total cost of ownership to meet the demands of rental fleets and cost-conscious operators, it boasts a Kubota D1803-T Stage V compact but powerful and fuel-efficient engine that is well-known for durability, low noise and reduced emissions. This delivers 29.7kW power, backed up by a bucket capacity of 0.14m³.

An advanced hydraulic system features three factor y-installed auxiliar y lines with adjustable flow, ready for a wide range of tools such as buckets, breakers and augers, as well as dual propor tional joysticks that allow for highly responsive operation in detailed or delicate manoeuvres

The design is also operator-focused, with a spacious, air-conditioned cab featuring all-round visibility, a 7in colour touchscreen display with Bluetooth and intuitive controls, and low noise and vibration levels for optimum comfor t on the longer jobs Also designed for quick and easy maintenance , a critical feature for rental fleets and occasional users, the SWE 50 UF’s reduced ser vice times help minimise downtime In addition, all routine maintenance points are easily accessible from ground level, simplifying checks and ser vicing for any operator.

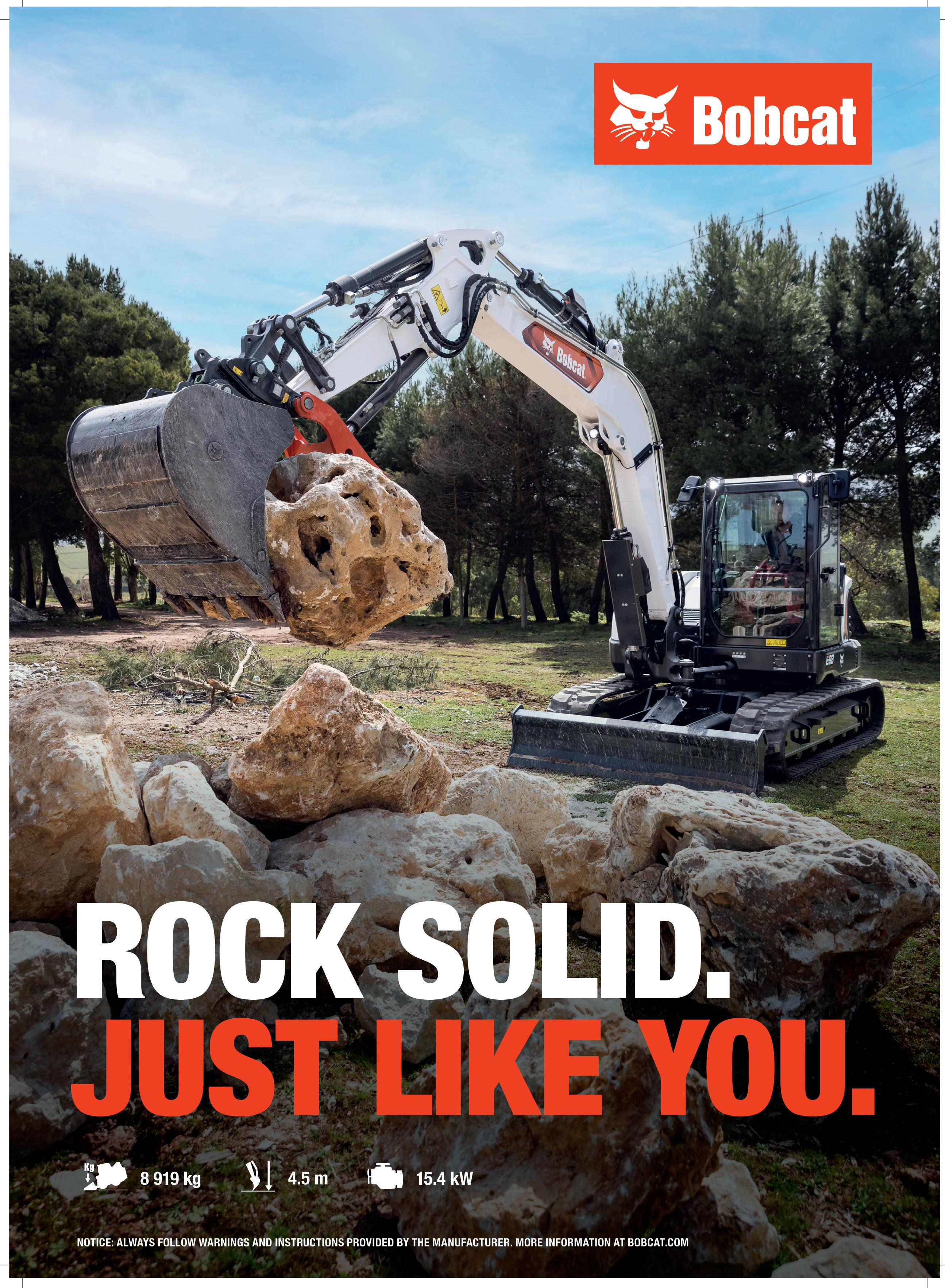

Our heavyweight choice is Bobcat’s new enhanced version of its topof-the-range E88 9-tonne R2Series mini excavator It is said to offer enhanced operator comfor t, an improved fit and finish, additional standard features and the availability of multiple predefined configurations. In all,

there are now nine predefined configurations of the E88 with several selectable options, comprising two standard arm specifications, five long arm specifications and two ar ticulated-boom specifications. There are several selectable options for each specification, including an add-on counterweight, travel motion alarm, steel tracks and a rear-view camera

The Fritzmeier cab, also found on Bobcat’s E60 mini excavator model, offers improved window and windscreen opening and closing, reduced noise and vibrations and additional standard features and options These include direct to tank and an intermittent wiper – standard in all configurations; a rear-view camera – optional for machines with a 7in display; and a new radio FM/AM/DAB/phone ready function –included in some specifications as standard

Bobcat claims the E88 delivers outstanding performance for a compact dimensioned machine and excellent stability with high digging output The proven Bobcat D24 Stage V 4-cylinder engine offers a maximum power output of 48.5kW (65hp). The high breakout forces and fast cycle times in the E88 continue to be an essential par t of Bobcat’s DNA. Like all R2-Series machines, the E88 is designed to achieve superior 360˚ stability in any situation, even when digging over the side or when handling heavier loads

Swansea plant and tool rental business,KJ

Hire , has added a number of Kubota 1 8tonne , 3-tonne , 5-tonne and 8-tonne compact excavators to its rapidly growing fleet, as it aims to keep pace with demand from a busy construction sector across South Wales. While some of the equipment has replaced existing models, the majority are additions to a total fleet of more than 200 machines

“Our yard was almost cleared of equipment, so we expanded the fleet to ensure we could meet customer demand,” said managing director Laura Williams.

The company operates more than 48 Kubota excavators of all sizes, from the U105 micros and 1 5-tonne U17-3a, through to the 5-tonne U50-5 and the KX085-5 8-tonne midi excavators, all supplied by local dealer Chepstow Construction Equipment (CCE Plant Sales). In addition to the base machines, KJ Hire offers a range of specialist attachments for the excavators This includes riddle buckets, breakers, pallet forks, compactor plates and post hole borers, providing the potential for increased versatility and productivity for customers

“Our dealer, Chepstow Construction Equipment, provides an excellent ser vice and they consistently go above and beyond for us, ” said Williams “Kubota machines are recognised for their reliability which is essential for us We rely on that

dependability to deliver consistent ser vice to our customers.”

The business was star ted by Ms Williams’ late father John, in 1983 Various family members work within the company, in the workshops and on the hire desk Much of the business is local to the firm’s Swansea base , close to the M4

Midlands plant hire specialist Chase Plant

Hire has doubled its fleet of Sunward

machines The Walsall-based company, which is celebrating 35 years in business, had already purchased nine Sunward skid steers from dealer Hamstead Plant

The business has now bolstered its fleet with nine mini excavators – six SWE

motorway, although KJ is more than happy to travel to look after existing customers, many of whom are national businesses with long term hire requirements WWW

18UF four-pole canopy minis, two SWE 35UFs and a SWE 25F - also from Hamstead Plant

It was the Sunward skid steers’ performance that convinced Chase Plant Hire to branch out into Sunward excavators.

According to Chase manager Ritchard Jukes, “their resilience in some of the harshest working environments really made us consider fur ther Sunward machines such as the excavators ”

Jukes added: “We bought the latest Sunward machines due to the excellent backup and ser vice from its dealer Hamstead Plant, and the simple fact that we are getting ver y decent machines with all the bells and whistles on for a fair price

“Sunward seem to have their act together, unlike some! And dealing with Joe Bayton, the managing director at Hamstead Plant, is great. He always answers the phone , always has a solution, and never says no ”

Derby-based Total Hire and Sales, a supplier of a wide range of tools, plant, temporar y accommodation, and powered access equipment, has purchased a fleet of 10, 20, and 45kVA generators, manufactured by power generation specialists, Trime

These sets complement the hirer’s existing Trime lighting towers and generators.

Carl Tidey, managing director of Total Hire and Sales, commented: “We have always received a good ser vice from Trime , and when we decided to renew our power generation offerings, we had no hesitation in selecting Trime products

"We have a policy to remain loyal to suppliers that provide us with an excellent back-up ser vice , and Trime stand out in this respect ”

Total Hire and Sales was originally founded as City Plant Hire Ltd in 1968, and has grown into one of the leading suppliers of tools and equipment, operating from five depots in Derbyshire and the surrounding areas

Aggregates and waste management specialist Cheltenham-based Elliotts has recently invested in another Yanmar V120 wheel loader supplied by dealer Johnston Plant Sales. It’s the sixth machine of its kind to join the business and is already hard at work in

the company ’ s aggregate yard From loading bulk tippers and transit vans, to feeding the bagging plant and shifting materials across the site , the V120 operates near constantly throughout the day.

“We’ve looked at other machines, but nothing matches the V120 in terms of size , strength and dependability”, says director Nick Elliott “It’s compact enough to work safely in confined spaces, but powerful

enough to load 32-tonne eight-wheelers without breaking a sweat ”

For Elliott power, comfor t and visibility are the machine’s standout features “It’s wellbuilt, comfor table for long shifts, and offers great all-round vision We replace ours ever y few years to keep downtime to a minimum –but we ’ ve had vir tually no issues with them That’s why we keep coming back ”

The latest V120 was supplied by Johnston Plant and was Elliot’s first time working with the Wolverhampton-based Yanmar dealer “I found them online after our previous dealer closed Richard Johnston was really responsive and easy to deal with We already knew the machine we wanted; he made sure it arrived on time , and we’ll be relying on them for ser vicing too.”

With customer demand showing no signs of slowing, the company is focused on delivering the same high standard of ser vice that’s defined its centur y in business Elliott sees the V120 as a non-negotiable par t of the operation: “It’s central to how we work,” he says. “We don’t take chances with it – and with Yanmar, we ’ ve never had to.”

CASE CE has updated its popular 580SV backhoe loader, bringing in a host of improvements that, it says, will cut operating costs for customers and increase productivity for operators. The company claims that with best-in-class engine power and torque, the 580SV delivers improved lifting and digging performance, with increased fuel efficiency

A new transmission option incorporates automatic direct drive , which engages in third and four th gear, locking the power of the engine to the transmission This reduces losses in the transmission, increasing gradeability and acceleration, resulting in reduced travel times for the operator and improved fuel consumption while travelling The machine also benefits from lower noise levels at higher travel speeds, as the engine and transmission work together

The 580SV also comes with a brake enable idle system, that allows the operator to use the machine in a cruise control manner, using the hand throttle to maintain engine and machine travel speeds When it is necessar y to slow the machine, pressing the foot brakes automatically switches the throttle to an idle position, making it easier to reduce speed

Upgraded hydraulics offer increased operating pressures and flows, apparently resulting in a 20% faster cycle time in dig and load operations The machine delivers best-in-class breakout and lifting capacities with the tool-carrier load arm set-up, maintaining high productivity for the customer There is also a provision for a hydraulic quick coupler on the tool carrier arms and on the machine’s in-line cylinder backhoe .

Power lift and power boost are new functions that are offered as standard Power lift increases the hydraulic relief pressure on the backhoe circuit, while simultaneously reducing engine rpm to 1,500, to deliver 15% higher lift capacities with increased precision Power boost gives a four second increase to the backhoe’s hydraulic pressure with no limitation to engine rpm, providing 15% more breakout force , to break through frozen ground, or to tackle a tree stump or a stubborn section of broken asphalt

In the cab, along with a deluxe heated and air-suspended operator’s seat, there is plenty of storage capacity and an increase in floor space By using a switch on the right-hand panel, operators can now instantly disable the Return-to-dig function, for pallet fork applications, where Return-to-dig could cause objects to fall if the lever is inadver tently moved.

There is a comfor t steering option for low-speed manoeuvring on site Standard steering requires 3 5 full turns of the wheel to go from lock to lock Comfor t steer reduces that to just 1 7 turns, making life easier for the operator and reducing fatigue through the working day

C ASE has also made life easier for the technician, with improved access to the machine’s cooling pack. A single latch now opens and closes the front of the machine , automatically holding open the grille , the charge air cooler and the oil cooler, providing improved access to the radiator FOR

JCB’s new 6T SiTESAFE ROPS site dumper is compliant with the new EN474 standard, and was conceived with operator safety as the highest priority.

The ROPS machine joins the full-cab 6 and 9-tonne models in JCB’s SiTESAFE site dumper line-up The ROPS structure features large opening gates to either side of the machine , with heavy-duty latches The design allows three-points of contact when climbing onto or leaving the machine The gates also provide additional operator stability when traversing rough ground and there is no impact to all-round visibility

WWW R DR LINK/CBF026 GO TO SIX OF THE BEST

The new dumper is powered by a 55kW (74hp) JCB DieselMAX diesel engine, that has been paired with a new JCB SS670 4-speed synchroshuttle transmission Driving through a torque converter, this new transmission is said to deliver best-in-class gearshifting and superior off-road performance The transmission boasts a 45% shorter gear lever throw, 35% less shifting force and up to 80% less gear lever play than the previous model

With up to six litres less oil, contributing to a reduced total cost of ownership, ser vice inter vals for the gearbox have been increased to 2,000 hours. An easy access filter helps to cut ser vice downtime and the transmission contributes to increased productivity. The new gearbox will become standard on all JCB 6and 9-tonne capacity site dumpers

The 6T model is available with a swivel tip, allowing the machine to tip to either side , or the SiTESAFE front tip skip, which offers up to 30% better visibility than a conventional front tipping model, thanks to its lower overall skip height The machines have a large , gas-strut assisted engine canopy, with additional lockable hatches under the operator’s seat All daily checks and ser vice items can be easily reached from ground level for shor t ser vice times

Additional EN474 changes that came into force in Februar y include a bubble inclinometer as standard, to prevent the operator exceeding the maximum safe slope , rear view mirrors and a front camera The SiTESAFE dumpers also benefit from a new operator’s seat with improved adjustment

Options include fully compliant road lighting, LED working lights and SiTESAFE 360° camera and front object detection systems, which are already an option on cabbed models Factor y-fit highvisibility steps and handles can also be specified.

FOR MORE INFORMATION

The new Cat MH3295 material handler comes loaded with a host of technologies to make an operator ’s life productive. Electrohydraulic controls, swing assist, Cat payload and smartboom, all combine to boost efficiency, while VisionLink provides details such as hours worked, location, idle time and fuel consumption.

The machine , which is based on the Cat 395 excavator, features a 17 6m reach with two counterweight configurations depending on the working environment Power comes from a Cat C18 engine which produces 405kW, while three power modes – power, smar t and eco –allow the operator to match machine performance to the job in hand Together with the machine’s wide 4.8m track gauge , the undercarriage’s 7.2m track length helps deliver smooth, stable operation even at extended reach

From the cab the operator is guaranteed a good working vantage point The fixed cab riser provides a 360˚ view and includes floor windows to help improve visibility when loading material The new Premium Plus cab design includes small pillars and large windows, plus rear view, left-side, and right-side-view cameras to enhance safety while operating. The rear cab door entr y design features enclosed stairways and integrated lights to safely access the cab Wide walkways provide quick, easy and safe access to upper ser vice platform maintenance areas

Incorporating new undercarriage, arm and boom, elevating cab and counterweight designs, Develon says its new DX270WMH-7 is built to offer next level performance for the toughest tasks across a wide range of material sorting and handling applications. The DX270WMH-7 is claimed to offer a greatly improved performance without compromising on dimensions, with a longer reach and a higher lifting capacity, smart features such as a virtual wall safety system and greater cooling pack protection with a reversing fan. To meet the demanding nature of recycling work, the machine can be equipped with enhanced cab filtration and fire suppression systems.

Based around the successful Develon DL280-7 wheel loader, the new waste loader model is said to increase safety and efficiency for the operator It has a novel design featuring a strong, light weight loader frame that minimises the front end weight of the machine , providing a reach capability that delivers a higher dump height, whilst maintaining excellent manoeuvrability. The super high lift arm on the new Develon waste loader is designed for loading material into high sided containers such as walking or moving floor trailers specially developed for transpor ting waste

FOR MORE INFORMATION

WWW R DR LINK/CBF028 GO TO

Inside the cab, a wide seat adjusts to accommodate operators of all sizes, while easy-to-reach controls are positioned in front for comfortable machine control The easy-to-use high-resolution, 10in touchscreen monitor presents the jobsite dashboard in an intuitive format Productivity applications are displayed on the monitor in grid view to easily read on the go, and touchscreen functionality is programmed to ensure continued job performance without any interruptions.

WWW.R DR.LINK/CBF027 GO TO

JCB continues to expand its growing range of powered access equipment, with the preview of the A60E and A60EH articulated boom models. Offering a choice of full battery electric or electric hybrid drivelines, the platforms are capable of zeroemission operation and extended run times

Building on the success of the A45E and A45EH ar ticulated booms, the new A60E and A60EH will offer an increased platform height of up to 18 2m The booms have a horizontal outreach of 11.9m and they offer 360° rotation for maximum access to the working area An intuitive joystick control, with a functional speed control, provides full height to ground level functionality

Accommodating up to three occupants, the booms have an unrestricted capacity of 300kg, that can be taken to 454kg in restricted use . They have gate and drop-bar entr y, with three access points for ease of operation.

As par t of JCB’s commitment to delivering lowemission solutions without compromise , the A60E and A60EH have regenerative technolog y to recover electrical energ y during braking They also make use of IP67 ingress-protected drive motors, for maximum durability and reliability

The A60E is powered by eight 6V AGM batteries, with a 400Ah capacity This full electric model delivers zero-emission, low-noise operation suitable for indoor and urban work sites Those looking to extend runtimes, have the option of the A60EH, which combines its electric drive with a Kohler KDW1003 diesel engine , offering 14 8kW of power Equipped with a 40-litre fuel tank, this option provides additional flexibility on remote sites and extended working times

Both of the ar ticulating boom platforms, which share up to 52% of their components with the existing A45 models, have four-wheel drive and two-wheel steering, for manoeuvrability and productivity on site The machines are equipped with foam-filled, non-marking tyres, for use inside buildings, yet offer up to 40% gradeability for maximum performance on rough terrain.

With a stowed length of just 8 8m, the booms have an overall width of 2.5m. A compact tail swing of just 0.65m makes them easy to transpor t and to manoeuvre on site Equipped with a 7in base display, power to the platform and JCB LiveLink as standard, the A60E and A60EH deliver maximum safety, uptime and productivity

FOR MORE INFORMATION

WWW R DR LINK/CBF029 GO TO A D I N D E X

Bobcat .............................(page 36 outside back cover) www.rdr.link/CBF100

Finning UK Ltd (page 21) www.rdr.link/CBF101

Hydroscand Ltd (page 27) www.rdr.link/CBF102

Hyundai Construction Equipment Europe .........(page 4) www.rdr.link/CBF103

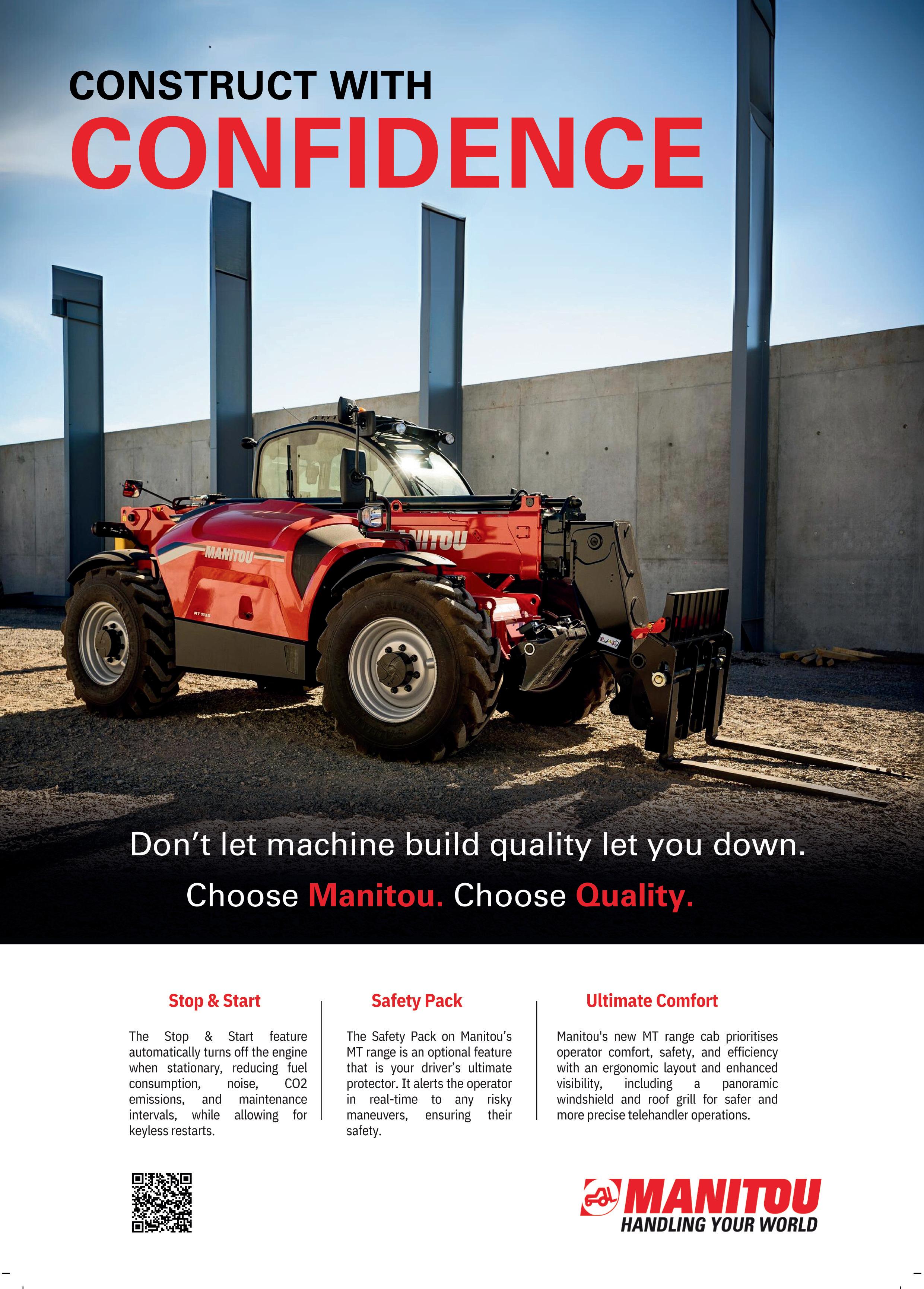

Manitou (page 2) www.rdr.link/CBF104