EDITOR

LEE JONES

EMAIL: ljones@hamerville.co.uk

ASSISTANT EDITOR

EDWARD KELLY

EMAIL: ekelly@hamerville.co.uk

EDITORIAL ASSISTANT

FINLEY CANNON

EMAIL: fcannon@hamerville.co.uk

GROUP ADVERTISEMENT MANAGER

CRAIG JOWSEY

TEL: 07900 248102

EMAIL: craig@hamerville.co.uk

NORTHERN ADVERTISEMENT MANAGER

IAN DUFF

MOBILE: 07810 353525

EMAIL: probuilder@sky.com

GRAPHIC DESIGNER

DONNA BOOTH

GROUP PRODUCTION MANAGER

CAROL PADGETT

DIGITAL MANAGER

JASMINE SMITH

EMAIL: jsmith@hamerville.co.uk

DIGITAL ASSISTANT

LYDIA MCFARLANE

EMAIL: lmcfarlane@hamerville.co.uk

DISTRIBUTION MANAGER

KARL CLARK

PRINTED BY PCP TELFORD

PUBLISHED BY

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Fax: (01923) 246901

Email: pb@hamerville.co.uk

Professional Builder is a business magazine for firms and individuals involved in all aspects of the building industry. It is available nationally –free to the trade through leading builders’ merchant outlets. © 2024

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Subscriptions to Professional Builder are available at the following rates: UK: 1 year (11 issues) –£30.00 post paid Europe & Overseas: 1 year (11 issues) –

£50.00 post paid

Airmail: 1 year (11 issues) –

£80.00 post paid

The majority of builders, especially those operating in our towns and cities, will have become accustomed to running the daily gauntlet of traffic calming measures and safety cameras. Big Brother’s beady eye has everything from box junctions to bus lanes covered, not to mention the added complication of our capital’s Ultra Low Emission Zone (ULEZ) and Congestion Charge. Indeed, it’s entirely possible you could accumulate a licenceendangering tally of points on just one journey.

Having arrived at your destination relatively unscathed the additional pain point of parking presents itself, with what has emerged as eye-watering amounts of fines issued in just one year. New research from Direct Line has revealed that, over only a twelve-month period, tradespeople have been subject to 3.5 million fines worth a total of £177 million. More than half find it difficult to park at, or close to, the job, whilst parking charges can frequently be exorbitant – so much so, in fact, that it may well be cheaper to cop a fine, that is if you want to run the risk of being towed or clamped into the bargain. Not only that, but leaving your van further away opens you up to becoming the victim of an opportunistic thief and taking a considerably larger financial hit in losing the tools and equipment that it could have taken an entire career to accrue.

The end result, of course, is that many builders will simply vote with their vans and avoid certain areas. For the homeowner that means competent and skilled tradespeople which, thanks to a worsening skills crisis, are already a scarce resource, are likely to be even harder to secure on anything like a favourable timeline. Builders will need to pass on all these additional costs to their own customers, or risk squeezing profit margins still further, and the badly needed upgrading of our existing housing stock in order to achieve our net zero ambitions becomes all the more unlikely.

As the Direct Line study points out, the more builder-friendly local authorities have

made discretionary permits for tradespeople available, but they’re not always that straightforward to access and can be expensive. Moreover, if you’re working across a wider area, it is conceivable that multiple permissions might be required from different councils.

The answer, of course, is to recognise tradespeople for what they actually are –and support them accordingly. Builders are the lifeblood of a local economy, sourcing tools and materials from trusted suppliers on their own patch, employing other trades, and providing often vital services to the general public. It makes precious little economic sense to put as many obstacles to making a profit in their way as there are pot-holes blighting our highways and byways.

Pedestrian and road safety should, of course, remain paramount, but there are far too many parking restrictions and cameras that can be seen for what they all-too visibly are – a money making vehicle for their operators. As to where those funds are then allocated it’s certainly not for the upkeep of local roads, many of which are as pockmarked as ploughed fields.

Similary, the health and environmental principles behind cycle lanes and low traffic neighbourhoods are commendable but too many have relegated motorists to the level of second class citizens – firmly shunted into the slow lane in favour of miles of bicycle branded pathways that are conspicuously short of any two wheeled pedal power for much of the day.

Transport policy is not just about the environment, local air quality, or the welfare of road users – as important as all those issues are. Our road networks are the arteries of our economic well-being. Hindering their access is an act of selfharm, and those that seek to merely profit from beleaguered motorists should be made to hit the road.

If you would like further information on Direct Line Business Insurance visit WWW.RDR.LINK/BBE002

CITB unveils its Business Plan and direction for 2024-25

The new direction sets out to build on previous plans and support and empower employers by investing £267m over the coming year. Tim Balcon, CITB Chief Executive, said: “Our new Plan sets out how we will invest in the skills system to ensure it is fit for purpose and fit for the future. We will work in partnership with employers, from the smallest to the largest, so that the training demands of the construction industry can be met with high-quality training provision. Changing the skills

Tradespeople slapped with 3.5 million parking fines costing them £177 million (See PB’s Viewpoint on Page 7) These figures come from Direct Line research, which also revealed that 55% of tradespeople say they face a weekly struggle to park at or close to the site (54%) where they are working. Many local authorities offer tradespeople discretionary parking permits so that they can avoid unnecessary parking charges, but just 13% of tradespeople find getting trade parking permits through a council a quick and simple process.

landscape is not an easy task and not one that can be achieved overnight, but this year’s Plan is a significant step forward.”

Construction workers reminded of the importance of hearing protection Phoenix Health & Safety have teamed up with Boots Hearingcare to share why construction workers are at risk of ear health damage, and what preventative measures should be put in place by safety professionals. The industry ranks as the 5th noisiest profession.

Ford Pro study reveals tradespeople work harder if they are given a warm welcome

The study showed that while customers are keeping up the tradition of offering a hot drink when they have work done in their home (70%), nearly 40% of tradespeople say they don’t have a friendly chat and 56% don’t get offered the use of the toilet. To highlight the importance of the relationship between tradespeople and homeowners, the Dream Job campaign has enlisted the help of Tom Skinner to give a tradesperson the warmest possible welcome.

Lucky Carhartt ‘Win a Handyman’ winners get their Handyman

Aimed at those hard workers who struggle to get on top of their to do list and need some TLC of their own, over 10,000 entrants took part in the online competition by letting Carhartt know which niggles they would like to cross off their list. True to their word, in February, Carhartt’s Handyman surprised the first lucky winners in the UK, Netherlands, Germany and Ireland.

FMB launches its ‘Growth from the Ground Up’ General Election Manifesto

Brian Berry, Chief Executive of the FMB, said: “The FMB’s General Election manifesto calls on the new government to take urgent steps to boost house building rates; tackle the ongoing skills crisis in construction; support the rollout of energy efficiency upgrades to existing homes and introduce a scheme to set a minimum competency level for builders.” Brian goes on to conclude: “The FMB is showing that local builders, who are too often forgotten about by politicians, are part of the solution to creating a more dynamic country.”

Van drivers can be charged £300 and receive penalty points for overloading their vehicles

Motoring experts at Lease Van have offered advice to van owners on how to safely secure goods in their vehicles to prevent steep fines and help reduce the risk of potential accidents.

Under Section 41B of the Road Traffic Act 1988, it’s a serious offence to drive an overloaded vehicle which exceeds weight restrictions and requirements.

Online interactive tool launched for sole traders affected by changes to reporting profits

Sole traders who need to comply with the new requirement to report their profits at the end of the tax year can access a GOV.UK interactive tool to help them navigate the changes. These businesses will now need to report their profits up to the end of the tax year, even if their accounting year ends on a different date. Those affected will be required to do this is by 31 January 2025.

Keylite continues its successful safety campaign for the construction sector

Keylite Roof Windows’ ‘Work Smart, Stay Grounded’ campaign has seen the team visit builders’ merchants across the UK and Ireland to encourage merchants and their customers to get involved with a ‘Challenge yourself, not your safety’ virtual reality game. The game sought to start a conversation around working safely on-site and at heights with the support of the National Federation of Roofing Contractors (NFRC).

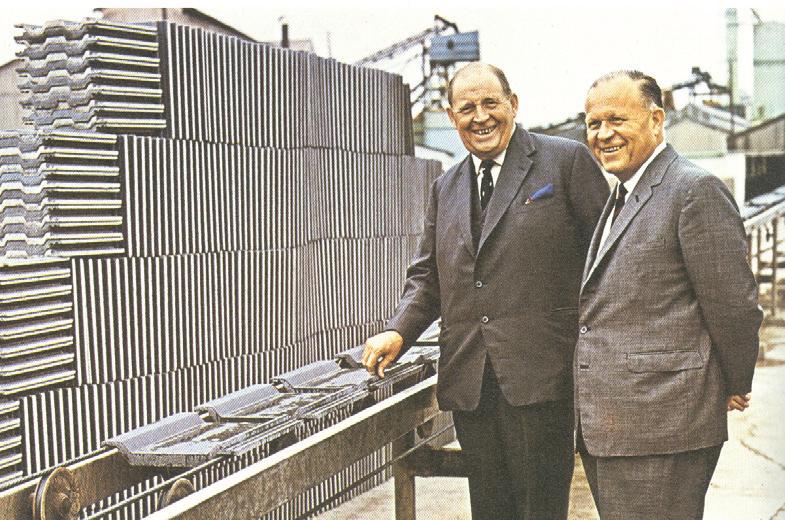

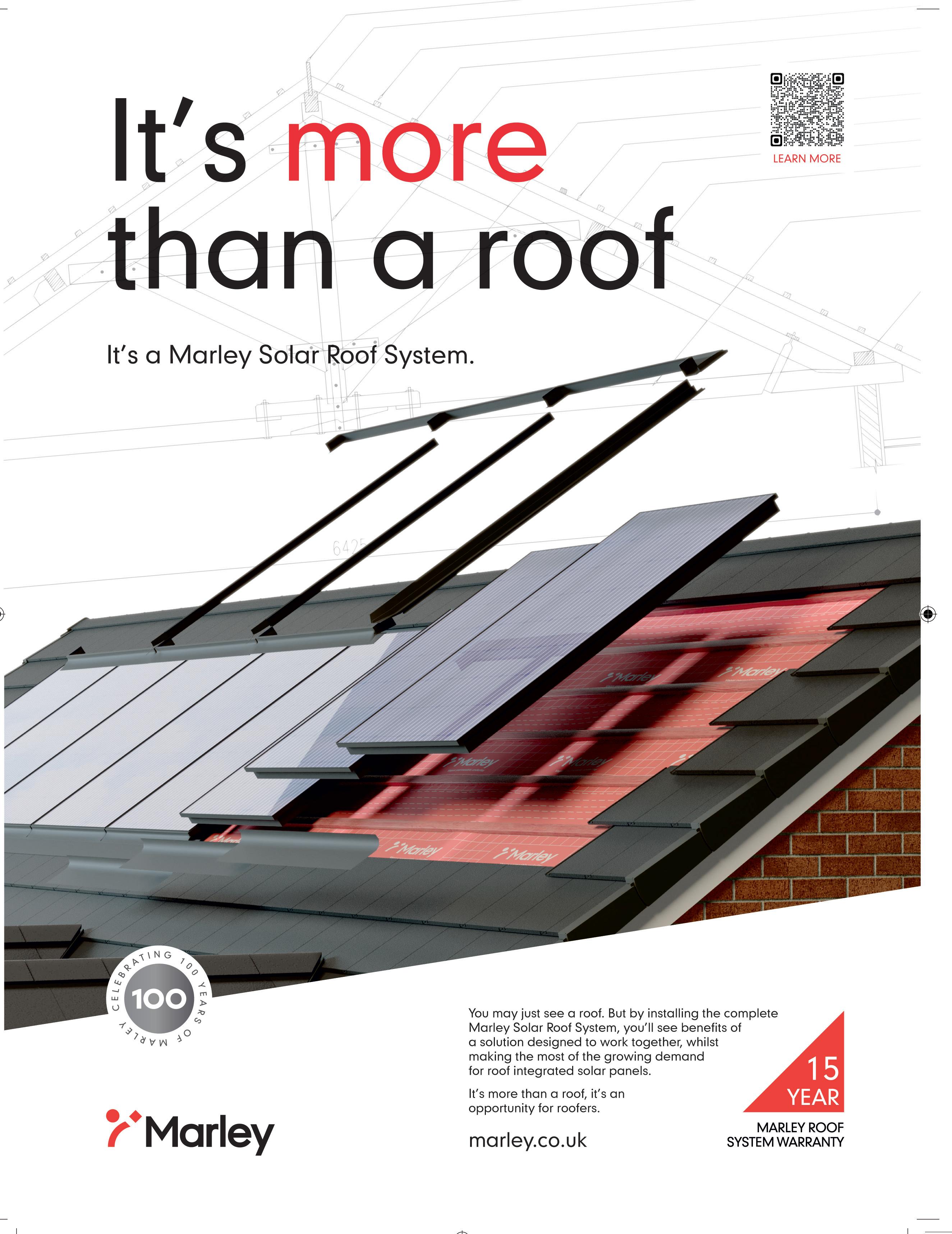

Founded by Owen Aisher, the company’s inception marked a crucial milestone in the evolution of the UK roofing industry, with the production of Marley’s very first concrete roof tiles beginning in a humble cowshed on Marley Farm in Kent.

Daniel Redfern for Marley says: “We are delighted to celebrate Marley’s 100th anniversary this year. The milestone is testimony to the hard work, diligence, and innovating spirit of colleagues across the decades who have contributed to our collective and ongoing success.”

Marshalls presents the future at latest installer roadshows

Landscapers from across the UK joined Marshalls to get a sneak peek of the manufacturer’s upcoming products and crown the regional winners of the Marshalls Register Awards.

Hundreds of installers and businesses, many of whom are part of The Marshalls Register of Accredited Landscape Contractors and Driveway Installers, joined the roadshows at 11 locations across the UK. Among other things, the manufacturer showcased new digital tools including the Marshalls Outdoor Reality app that helps customers visualise products in their garden.

MORE DETAILS VISIT: WWW.RDR.LINK/BBE013

Plantworx 2025 has a new location and venue

The CEA’s 6th biennial construction machinery exhibition will be held on 23rd - 25th September 2025, at the Newark Showground. Simon FrereCook, Plantworx Event Director, has emphasised this venue’s adaptability and quality: “The thorough selection process led us to Newark, which excels in infrastructure flexibility, accessibility, and the reliability of its outdoor spaces, which are crucial for hosting an event of Plantworx’s scale. While we can’t guarantee the weather, Newark is highly regarded for its grounds’ quality and reliability, ensuring events run smoothly regardless of weather conditions.”

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BBE014

Talon backs installer’s Anti-Tool Theft petition

Talon is backing its ambassador, Shoaib Awan, also known as @thegasexpert on Instagram, in his quest to successfully launch a petition aimed at curbing the rampant theft of power tools, a problem increasingly plaguing tradespeople across the UK. This petition seeks to impose a significant £10,000 fine on organisers who permit the sale of stolen tools at car boot sales and markets, a known avenue for the distribution of stolen goods.

FOR MORE DETAILS VISIT: WWW.RDR.LINK/BBE015

Finley Cannon attends Super Trowel 2024 to hear about the growing event, the participants, and the hopes for the future of the trade.

Bricklayers from across the UK have been competing against each other with the ambition to be named the UK’s fastest bricklayer, and be in with a chance of competing against the best in the USA in Las Vegas. In its second year, Super Trowel has seen 29 competitors come together across two heats. The events took place at Hertford Regional College in the south and Warrington and Vale Royal College in the north with the top 11 set to compete in a final held in August, alongside last year’s winner.

The brainchild of 29-year-old bricklayer Ashley Francis, Super Trowel began in 2023. Ashley thought up the idea after seeing a US competition for bricklayers. “I knew about the Spec Mix 500 event,” he recalls, “and I wanted to do that here. In the first instance we needed a following and that’s why I started the Bricklayers Social Club (BSC)”.

The BSC is a community of bricklayers and stonemasons with more than 670

and over 30,000

offers the opportunity to connect with others in the industry, share

contestants, this year we had over 70 people apply, and we had to bring it down to 30 competitors.”

Over a 45-minute period, the contestants – assisted by one hod carrier each – had to lay as many bricks as they can on a wall measuring 4,490mm long. After the 45 minutes, contestants had ten minutes for jointing up. In the final contestants will be asked to lay a 8,990mm wall, with 1hour to lay and 20 minutes jointing up. Judges then count the total number of bricks laid and made deductions for any discrepancies. Failure to meet any or all height points within the tolerances laid out, for example, resulted in a 20-brick deduction to the final tally.

In return for their generosity in hosting the events, all of the bricks – supplied by Wienerberger and mortar supplied by CPI

profession to get more young people involved and give back to the colleges: “We’re using the competition to supply 17,000 bricks and 20 tonnes of mortar to the colleges and we want to expand. Next year, in exchange for using their venues, we hope to provide the colleges with even more tools and materials.”

Among the competitors in Warrington were three generations of the Mahoney family. Father and son, Andy and Ashley Mahoney were competing against each other, with Andy’s youngest son Connor working as his labourer, while Ashley’s son was on filming duty.

Ashley was inspired by his father to get into bricklaying. “This man here is on a pedestal, I wanted to be just like him,” enthused the 2023 runner-up, who impressed with a particularly tall 440 brick

“Following the Super Trowel heats, the final will see the contestants compete for the chance to win £15,000 in prize money and tools”

against other bricklayers from across the country. Ashley continues: “I’ve always known I’m quick, so I wanted to put myself up against others and see just how quick I really am.”

The southern heat, held at Hertford Regional College, saw 17 competitors battle it out for a place in the final. Among the entrants was young bricklayer Tom Humphrey. A fan of bricklaying YouTubers, he applied with the aim of finding out how quick he is and recruited a friend and former brickie to be his labourer. “I follow all of the YouTube bricklayers; I’ve had a real passion for it since I started.” The 23-year-old has been plying his trade for seven years and now works with natural stone as well as bricks. “I came to last year’s and said if I get chance, I’ll be in it next year. I have no idea how quick I actually am, but I wanted to find out and here I am.” Tom added.

The final will see the contestants compete in front of more than 1,000 spectators and will be in with a chance of winning £15,000 in prize money and tools, as well as the opportunity to travel to Las Vegas to compete in Spec Mix 500 against the best the USA has to offer. The Super Trowel team will also be taking a young apprentice to the Nevada city who will also compete in the largest event of its kind.

Joanna Mulgrew, Managing Director of HBXL Building Software, shares her advice

Joanna Mulgrew, Managing Director of HBXL Building Software, shares her advice

Abuilding project spiralling out of control is possibly the worst nightmare for a builder. There’s so much riding on its success. Reputation. The amount of profit made. The next job starting on time. Staff satisfaction.

The stress for a builder can be next level. Always running around. Always juggling. Always being tripped up. You want to stop having to throw money at problems. You just want your subbies, materials and plant to be where they are supposed to be on the right day and you’re dream is for everyone to focus on doing their jobs well without the distraction that delays cause. And for you to have stress-free evenings and weekends off.

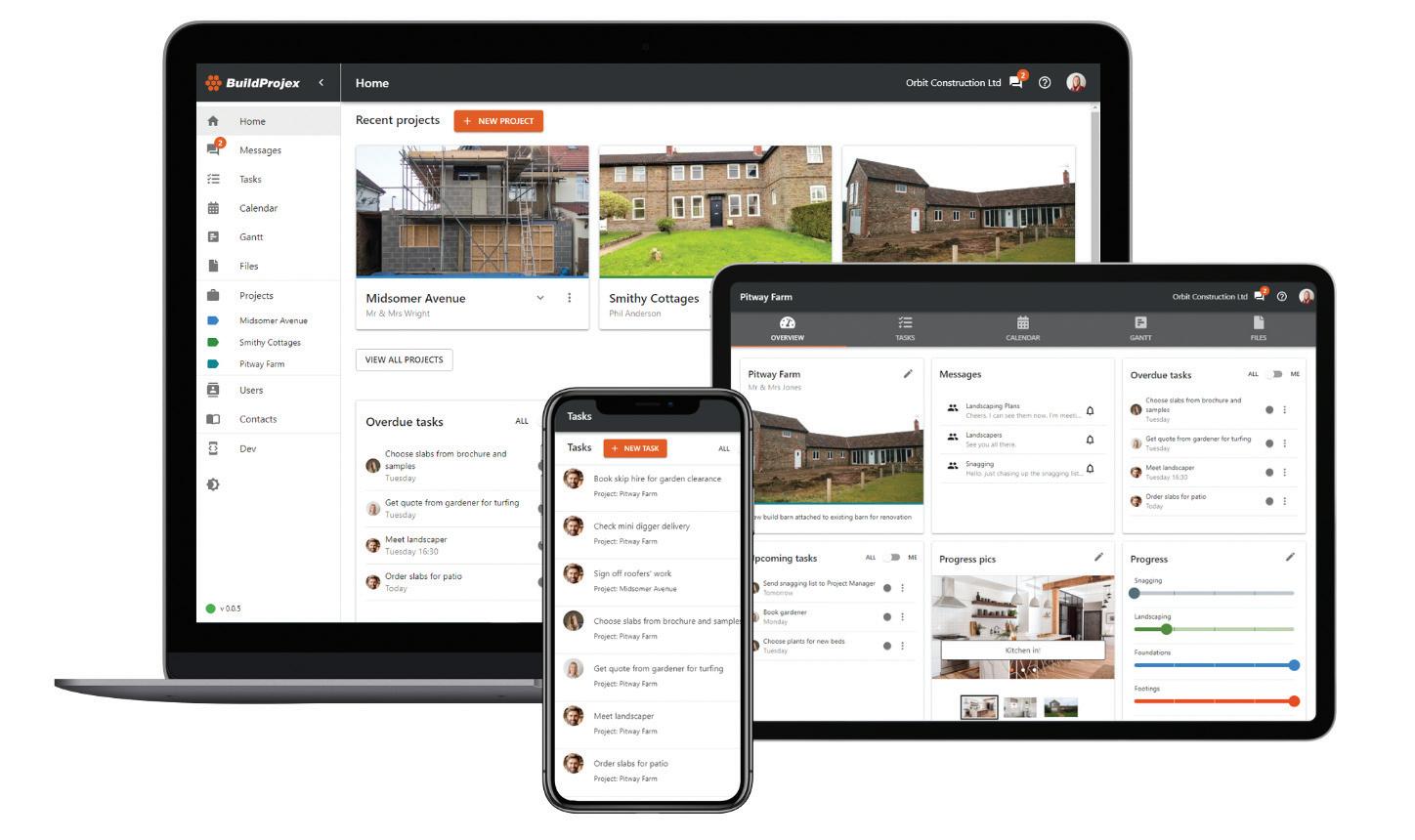

For some time now, the HBXL building community has been asking for a job management tool specific to small building firms. So, we know help is needed. After all, it’s virtually impossible to hold in your head, multiple projects and all their stages and differing issues. Then there’s the customer. How do you keep them in the loop and off your back? And that’s why we’ve recently launched BuildProjex, our first cloud-based software

tool. And it’s going down a storm.

But back to you. How do you rate your job management skills? Are you always in control? Do you have a clear view of all the jobs going through? Do you hit your deadlines every time? And most importantly do you make the profit you predicted at the quoting stage?

If you can’t quite say yes to all of the above, then read on!

Keep a complete overview

Sounds obvious but having a snapshot of ALL your projects at any one time makes a massive difference to the running of your business. Say you’ve got a couple of jobs in the quoting phase, another job is breaking ground soon, one at first floor, another that’s overdue for landscaping. How do you see at a glance, what might clash, who

can’t be in two places at once, and so on? It’s impossible. The ‘All Project’ dashboard in BuildProjex gives you a valuable (realtime) oversight. It helps avoid any clangers. And being cloud-based everyone can check the overview, wherever they are, whatever the time of day.

Get a tick next to the tasks you set Your team aren’t mind readers. They need a to-do list and a due date. And even if it’s obvious what should happen next, it’s worth noting down. And there’s a good reason for this. You want to know the work has been done. Everyone needs to be accountable. So, you want all your employees and sub-contractors to tick off their tasks. In BuildProjex the tasks are blue while in progress, green when completed and red when overdue.

“BuildProjex is proving an instant success. It’s the glue that holds your valuable construction projects together.

Eveything is in one place. You’re in control.”

All your team need to be on the same page for work to go smoothly. Literally. How annoying is it when a conversation starts on WhatsApp and finishes in Messenger? And then there are the hundreds of text messages, and email chains. It’s impossible to keep track. Whatever you do, make sure that you’re all using the same messaging channel. In BuildProjex, messaging is in-built. You can exchange direct messages or drop them into group chats. Whatever you do, keeping your conversations in one place is key to efficiency.

How many times has a site visit gone unattended because it’s slipped someone’s mind? What about that meeting with the electrician or Building Control? And wouldn’t it be handy if everyone can see that the PVCu quote request went on the 6th, the skip is being delivered on the 15th, the roofers will be on site on the 17th... You need a shared calendar. Everything in one place. BuildProjex has a colour-coded calendar for each job. The information is pulled through from tasks, so you don’t even have to do anything. You can share the whole company calendar or projectspecific calendars with the relevant people. Key dates, appointments, deliveries. Nothing gets forgotten.

Track progress of building phases

Not dissimilar to a calendar, a Gantt Chart (Build Programme) uses timelines to represent the completion of each task. Foundations 1.4 months, framing 22 days, dry in 22 days, Exterior finishes 19 days and so on. You can share individual charts or a combined chart for all the projects. It means you can track target progress versus actual progress. If you want to make the profit you set out at the beginning, you need to stay on track. Again, BuildProjex has a Gantt Chart in-built. All the information on each job automatically gets fed into the chart. And you can share it with whoever you want. So easy.

These pointers aren’t in any particular order, and for some, knowing where everything is could be the number one requirement. How can you effectively manage a job if you aren’t sure where all the paperwork is – and whether it’s the latest version. I’m thinking building plans, quotations, schedules of work, site photos, specifications, risk assessments –you get the idea. How do you file paperwork currently? Can everyone access the relevant documents? BuildProjex can receive your uploaded files and store them for you. And you and

your team can access them (if they have the right permissions).

I hope I’ve given you food for thought with these six key aspects of successful job management. It’s not easy, and using a range of different tools can cause more problems than they resolve. That’s why BuildProjex is proving an instant success. It’s the glue that holds your valuable construction projects together. Everything is in one place. You’re in control. Everyone is in the loop. You have everything at your fingertips and so does your team. And you can plan, track, share and manage from your mobile phone, tablet, laptop, computer. Building projects run smoothly and your profit margin is protected.

We give our verdict on new products in our unique site tests, but now we want to give you the chance to try them – AND KEEP THEM – for yourself! All you have to do to enter the free draws is simply just type in www.rdr.link followed by the unique code.

TALON MANUFACTURING PIPESNUG PRIZE PACKS

If you install pipework and haven’t tried PipeSnug by Talon yet then you’re missing out. It’s quick, clean, air and water-tight, and for use where a pipe exits a wall. PB has secured 5 prize packs of the award-winning pipe seal for five winners containing 2 x 32mm, 2 x 40mm plus a 110mm and the award winning FlueSnug. Great prizes every month is not just a pipe dream with Professional Builder. To be in with a chance of winning one of five of these prize packs use the rdr.link below.

JEFFERSON TOOLS

CARHARTT

MESH-BACK C PATCH CAPS & FORCE RELAXED FIT T-SHIRTS

20 OZ FIBREGLASS CLAW HAMMER

Precision-balanced for optimal use – and weighing only 0.8kgs – the Jefferson Tools 20 Oz Fibreglass Claw Hammer is crafted from high-quality carbon steel, ensuring durability. Featuring a robust fibreglass handle and ergonomic rubber grips, this hammer provides superior handling. The claw end is perfect for prying up floorboards or serving as a lever. Get your claws on this handy tool for free. We have five to give away.

The Mesh-Back C Patch Cap (106132) is made with a Carhartt Force sweatband, offering sweat wicking and antimicrobial properties. This cap features a Cpatch on the front and the brand’s label on the back. The Carhartt Force Relaxed Fit Midweight Graphic Tshirt (106653) is sweat-fighting and fastdrying while the mesh on the back keeps air circulating to help you stay cool when work heats up.

Carhartt has teamed up with PB to offer five readers the chance to get a cool look on site in the warmer weather.

HIKOKI POWER TOOLS

UR18DA DAB CORDLESS RADIO

Weighing just 1.8kg without the battery, the HiKOKI UR18DA is compact and lightweight. It is equipped with a hearty 8W speaker that delivers high-quality sound, ensuring clear and crisp audio even in the busy environment of a construction site. Bluetooth connectivity allows users to wirelessly connect their smartphones or other portable devices to the radio. This sounds like yet another great giveaway from Professional Builder!

FERNOX

TF1 SIGMA MINI FILTER, PROTECTOR F1, CLEANER F3 265ML AND LIMITED-EDITION

FERNOX HOODIE

To celebrate its 60th birthday, Fernox is giving away a TF1 Sigma Mini Filter, Protector F1 and Cleaner F3 265ml and a limited-edition Fernox hoodie. The TF1 Sigma Mini Filter is the latest launch from Fernox that is built upon its popular Sigma range, providing installers with a compact and efficient solution for smaller systems. It’s birthday time for Fernox and you could secure your very own present with this great prize package. As ever, use the rdr.link to enter.

SOUDAL

FIX ALL HIGH TACK

This all sealing, all bonding, hybrid polymer sealant and adhesive from Soudal exhibits super strong initial grab, holds firm in an instant, and is ideal for all heavy-duty bonding applications. It is suitable for bonding all materials and surfaces (excluding PTFE, PE & PP), porous and non-porous, and even in the wet. Optimum resistance against mould growth makes it perfect for use in sanitary areas, whether you’re bonding shower wall panels or sealing bathroom appliances. We’ve fixed you up with another great round of giveaways so grab a cartridge of this high performance sealant and adhesive.

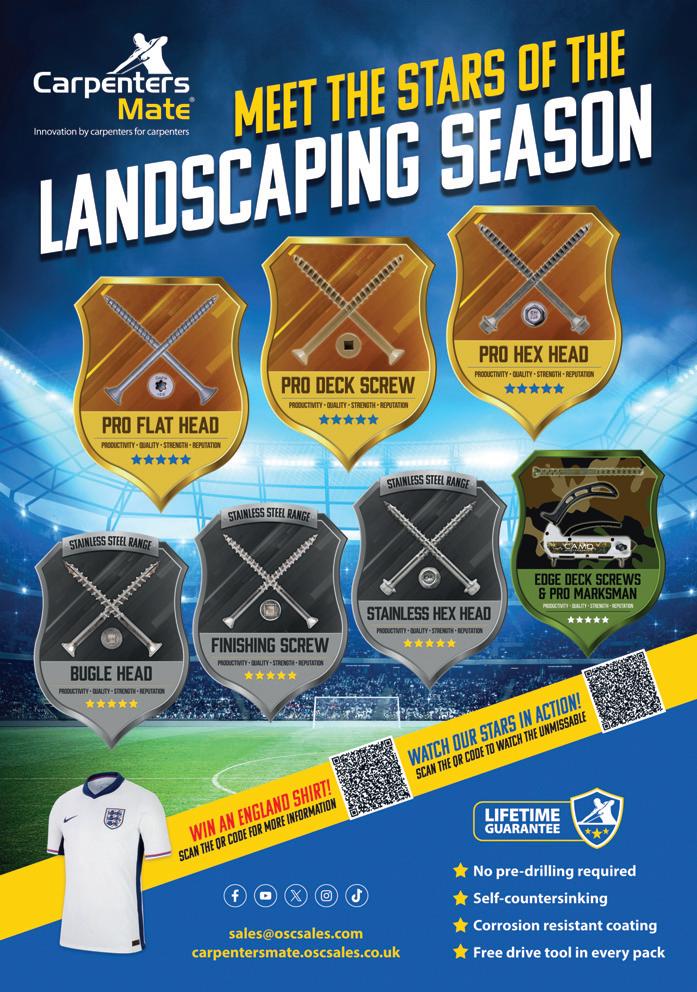

As part of the Carpenters Mate “Stars of the Landscaping Season” and to celebrate the upcoming Euros, we want to know which England player is most relatable to one of your team and why? For example – our apprentice Dan is our Declan Rice, because he’s always cleaning up after us! (Please keep it clean) The Best one – judged by the team at Pro Builder, will win a 4K 50in. SAMSUNG TV in time for the Euro’s – Good Luck!

For the full entry details visit the Professional Builder website at WWW.RDR.LINK/BBE026

We’d also like to know your preferred builders’ merchant and/or some feedback about our Carpenters Mate range of fixings – if you’ve used them before.

All Carpenters Mate fixings:

● Are self-drilling

● Corrosion resistant

● Come with a Lifetime Guarantee

● Come with a free drive tool

● Can be custom painted in any RAL colour on a selection of our stainless steel fixings View our full product range here:

Watch Connor Mcintyre, from Mcintyre Landscapes, talk about his experience using our “Stars of the Landscaping Season”, Pro Deck Screw, Pro Flat Head, Pro Hex Head, CAMO Hidden Decking Fastening System and Stainless Steel range. You can access the YouTube video here: WWW.RDR.LINK/BBE028

Thompson’s explores how to seal and revive hard landscaping, and make the most of your garden with a BBQ!

If you’re laying a new patio or paving for a customer, sealing the surface upon completion is an important finishing step, helping to retain the colour of the slabs or stones for longer. With a new patio marking a significant investment, and such a wide range of beautiful colours and effects available on the market, it would be a shame not to protect the finished aesthetic long-term.

More importantly, sealing the surface can help prevent moisture ingress from damaging the paving slab or stone, both in terms of appearance and structure,

Paving Seal is ideal. Suitable for granite, limestone, sandstone, flag stones or block paving, this powerful seal provides longterm protection. It’s touch-dry in just one hour and can be walked on after four hours. The super strong waterbased formula can resist future algae growth and even protect against oil and fuel spills.

For best results, it’s recommended to get the job done on a dry day with

If you’re refreshing an existing patio or driveway, prep first with Thompson’s Advanced Patio and Block Paving Cleaner. While many may choose to simply jet wash the patio or paving, this only removes surface level dirt, without tackling the deeper issues. With Advanced Patio & Block Paving Cleaner, the job is a breeze, removing any dirt, grime, mould or algae that has appeared during the wet and cold winter months. Not only does it revive and brighten surfaces, but this powerful cleaner can also protect the surface from algae growth for up to six months.

Reviving and protecting hard landscaping ready for summer? Bring it on!

The sun is out, which means it’s finally BBQ season! Fancy getting your hands on a new BBQ? To celebrate the start of the summer season, Thompson’s is giving away a Weber Classic Kettle Charcoal Barbecue to one lucky winner.

To enter, all you need to do is answer the following question:

Q) How long before Thompson’s One Coat Patio & Block Paving Seal

To enter, you can answer the question and provide your full contact details on the Professional Builder website at: WWW.RDR.LINK/BBE029

Schlüter KERDI-BOARD offers a versatile, lightweight and waterproof tile backerboard option

As one of the most versatile and widely specified products from SchlüterSystems, Schlüter-KERDIBOARD finds applications for both retrofit and new-build installations, with different thicknesses of the extruded polystyrene (XPS) panel providing a stable and waterproof substrate for natural stone and ceramic tiling.

The panels are available in thicknesses of 5, 9, 12.5, 19, 28, 38 and 50mm and are easily installed across existing masonry, concrete, timber stud frames or lightweight metal framing, with panels featuring parallel grooves also available for creating rounded surfaces, such as for seating or curved walls. With all thicknesses available in 1.25m or 2.6m lengths, both by 62.5cm wide, the board is frequently used to create worksurfaces, breakfast bars, and islands.

A handy guide can be downloaded from the Schlüter-Systems website which can assist both specifiers and tradespeople in picking the right panel for an application. For instance, 12.5mm is the minimum thickness recommended for use where a stud frame is constructed to 400mm centres. The largest three thicknesses should be considered for construction purposes, while there are also special L-shaped and U-shaped panels for use as pipe boxing, and prefabricated niches in different sizes –with or without lighting – to create storage within walls.

Both sides of the panels have a waterproof, cement-free reinforcement layer, which offers an ideal surface for standard tile adhesive, either fully embedded or using the dot and dab method.

This rigid foam panel is reinforced and laminated with fleece fabric on both sides for secure anchoring in tile adhesive. As well as having a BBA Agrément Certificate, it conforms to the requirements of NHBC Technical Guidance 9.2/06. Any residential construction in the UK beginning on or after 1st July 2024, and seeking an NHBC warranty, must comply to this guidance.

Specifically, the document prohibits the use of magnesium oxide boards and deems gypsum plasterboard/plaster unsuitable for wet rooms or bathrooms equipped with power showers. The boards cater to diverse application needs, providing level and waterproof substrates for tile and stone installations. Resistant to chemical stresses common in tiled environments, it can be integrated into certified waterproofing systems when

Fully embedded Schlüter-KERDI-BOARD

The adhesive should securely bond with the substrate while also mechanically fastening to the KERDI-BOARD anchoring fleece. Use a cementitious tile adhesive that complies with EN 12004 standards

Apply the tile adhesive using a notched trowel, ensuring even coverage either directly onto the substrate or onto the KERDIBOARD surface.

Fully embed Schlüter-KERDI-BOARD in the adhesive to establish a strong bond with the anchoring fleece. Be diligent in adhering to the specified curing time of the adhesive

“A handy guide can be downloaded from the Schluter-Systems website which can assist both specifiers and tradespeople in picking the right panel for the application –use the rdr.link opposite for more”

Ensure that the individual panels are aligned appropriately with abutting joints for a seamless installation.

joints and connections are properly installed. It’s easy-to-cut design and imprinted gridlines ensure precise installation.

Depending on thickness, the product can be fully embedded or attached with adhesive, with optional reinforcement using anchors. Installation on wood or

Following the adherence of KERDIBOARD, proceed promptly with tile installation using the thin-bed method. Employ a cementitious tile adhesive that complies with the specifications of the chosen tile covering. Match the notch size of the trowel to the tile format and ensure strict adherence to the curing time of the adhesive.

metal stud structures is facilitated with KERDI-BOARD-ZS fastening screws. Tiles are directly installed on KERDI-BOARD using the thin-bed method.

FOR FURTHER INFORMATION ON SCHLÜTER KERDI BOARD VISIT WWW.RDR.LINK/BBE031

Scott Wolters, Building Products

Director at EGGER UK, explores the structural flooring solutions available

Whilst there are many options available when it comes to structural flooring systems, including beam and block, concrete slabs and suspended timber floors, chipboardbased structural flooring boards remain a popular choice and are often seen on housing developments. This form of structural flooring comes with numerous

There are numerous advantages to flooring manufactured from P5 chipboard, including moisture-resistance and load bearing capabilities. Chipboard is also a sustainable choice, often containing a large portion of recycled content. As well as prolonging the lifespan of waste wood that would otherwise be burnt or sent to landfill, this locks in the CO2 that is captured during the growth of the tree for longer.

You’ll know all too well the wide range of installation and customer requirements that you may encounter on a project. Fortunately, there are a number of structural flooring options available that can meet these requirements, with P5 chipboard at their core.

Standard uncoated P5 chipboard is ideal for internal applications, from structural DIY projects to refurbishments and loft extensions. However, it is important to remember that uncoated P5 chipboard should be laid in dry conditions only.

For projects where structural flooring

will be left exposed to the elements, there are particleboards available, such as EGGER Peel Clean Xtra, with a slipresistant, peelable film top layer. This easy-to-peel film helps prevent moisture ingress from inclement weather and provides protection from second fix and finishing trades, such as painting or plastering. Once work is completed, the peelable layer can be easily removed, leaving behind a clean flooring surface.

For customers who want the highest product specification, consider installing a structural flooring board that incorporates a permanent, thermally bonded and hardwearing surface layer on both sides. For example, our EGGER Protect boards can be left exposed to the elements for up to 60 days and provide an anti-slip and hard-wearing surface that also protects against wear and tear from site traffic. As well as preventing moisture ingress from wet weather during the build, this product also offers protection against leaking pipes once construction is complete. These boards are ideal for new-build or timber frame homes where the roof is yet to be installed and are even suitable for use with underfloor heating systems.

We all want to do our bit for the environment and be mindful of our carbon footprint. By considering the green credentials of building products installed on site, you are able to demonstrate this awareness to customers and clients.

While some wood-based structural flooring boards are manufactured from 100% virgin wood, consider looking for more sustainable options that incorporate recycled material and sawmill by-products too, such as hackchips and sawdust.

Ensuring the correct installation of structural flooring is a key priority on any build. Always ensure you follow the recommended fitting guidance provided with the boards, as these are critical to the validity of performance guarantees.

For the best quality install, we always recommend using a combination of joint and joist adhesive and mechanical fixings, with the adhesive applied to all edges of the first row of boards and joists, with one mechanical fixing used per joist along the perimeter edge. Moving across the floor, adhesive should continue to be applied in the tongue and groove of each board, as well as following the fixing pattern every 1,200mm using mechanical fixings. We recommend that one bottle of adhesive is used per six boards, with it visibly foaming out between the boards. Once the adhesive has dried and the building is made fully watertight, any excess adhesive can be removed with a scraper.

To give optimum strength and longevity to the overall floor, boards should be staggered, with a configuration similar to a brick bond laying pattern, and expansion gaps left against all walls. Boards with a tongue and groove profile can help to ensure a consistent joint, with the boards locking together, providing enhanced structural integrity.

At EGGER, we are also proud to offer a lifetime guarantee that covers the structural integrity of our Advanced Structural Flooring Boards, when installed using our recommended fitting method.

SMARTPLY

how you can achieve effortless airtightness and vapour

In the UK and Ireland, the quest for energy-efficient buildings is challenged by an ageing housing stock. According to the English Housing Survey (2021 to 2022), 62% of dwellings in England were constructed before 1968, and only 47.5% have an Energy Performance Certificate rating of C or above, which is considered efficient. The Department for Business, Energy & Industrial Strategy highlights that the residential sector accounted for 19% of the UK’s total final energy consumption in 2021. Similarly, in Ireland, data from the Sustainable Energy Authority of Ireland shows that about 50% of homes were built before 1990, with only 38% achieving a Building Energy Rating of B3 or above in 2021.

At the same time, over half (58%) of privately rented households in England are dealing with damp, mould and/or excessive cold in their homes, affecting approximately 2.7 million households. These conditions degrade living quality and highlight the inefficiencies in building envelopes that fail to control moisture and retain heat.

These statistics underscore the critical need for modern construction practices that prioritise airtightness to minimise energy loss while ensuring proper vapour control and ventilation to combat moisture-related issues. The balance between airtight construction and adequate moisture management is essential, not only for energy conservation but also to maintain healthy

living conditions within these structures. Moreover, the rising popularity of the Passivhaus concept, which does not require traditional heating or cooling systems, further emphasises the importance of robust air barrier properties in building materials.

The balancing act: airtightness, ventilation and vapour control

Airtightness refers to the building shell’s

ability to prevent uncontrolled air leakage, a vital factor for thermal comfort and significant energy savings by reducing a building’s heating and cooling demands. Vapour control, on the other hand, manages the diffusion of moisture vapour within the building envelope, preventing the accumulation of interstitial condensation and mould. This is imperative for protecting the structural integrity of the building.

The push towards tighter building envelopes has led to a better understanding: while airtightness is essential for energy efficiency, it must be balanced with ventilation to prevent surface damp and mould issues, which are prevalent in poorly ventilated spaces, and lead to poor indoor air conditions.

This balance is critical in avoiding the pitfalls of condensation, which can lead to structural and health issues.

Innovative building solutions such as wood panels with integrated vapour control and air barrier properties are addressing these needs effectively. These products simplify the construction process while contributing to more energyefficient buildings. For instance, the use of Oriented Strand Board (OSB) panels, such as SMARTPLY AIRTIGHT, that has airtightness engineered into the panel substrate and provides an integrated vapour barrier with consistently high

Max Fordham House: a paradigm of energy efficiency using SMARTPLY AIRTIGHT

The Max Fordham House in the vibrant London borough of Camden is a prime example of energy-efficient construction utilising SMARTPLY AIRTIGHT wood panels. This contemporary threebedroom Passivhaus, designed by bere:architects, features a thermal envelope that significantly reduces heat loss, enhancing the building’s environmental efficiency.

vapour resistance over the entire surface. Used as structural sheathing in timber frame structures, such panels also enhance the buildings’ environmental

SMARTPLY AIRTIGHT has been crucial in achieving the airtightness required to minimise energy use significantly compared to standard building requirements. Selected by Bow Tie Construction, this product ensures durability, a high-quality vapour barrier, and consistently high vapour resistance over the entire surface. It also supports sustainability through its use of guaranteed sustainably manufactured and sourced timber products.

Max Fordham House has successfully achieved an Energy Performance Certificate rating of B 83. Unlike traditional membrane-based systems that are prone to damage, SMARTPLY AIRTIGHT provides a robust, reliable and efficient solution that excels in maintaining airtightness, even under rigorous testing. It’s an innovative approach that has positioned this solution as a preferred material for Passivhaus projects across the UK, contributing to the structure’s stylish, light-filled design and minimal environmental impact.

need for additional Air and Vapour Control Layout (AVCL) membranes. The coating also provides a smooth, durable surface for superior bonding of airtight tape at panel joints, simplifying both new build and renovation projects and shortening the installation time. It is easy to handle and can be readily cut and fixed using standard timber frame fixings. Being robust, there is minimal risk of damage during assembly, transport or erection, which means the airtightness is not compromised.

The trajectory for future building practices is clear: energy-efficient buildings that provide healthy spaces for occupants. This involves a deeper focus on the materials and technologies used in construction, particularly those that offer comprehensive solutions to the challenges of airtightness and vapour control.

As we look towards a future of sustainable buildings in the truest sense –economically, environmentally and socially –the principles of airtightness and vapour control become critical. Ensuring these standards will not only mitigate the sector’s extensive energy use but also elevate the living and working environments of millions, ultimately contributing to the broader goals of energy efficiency and sustainability.

The Knauf Take Back Scheme is a a sustainable solution for plasterboard

In the construction industry, managing waste responsibly is a critical challenge, especially when it comes to materials like plasterboard. For professionals involved in purchasing and utilising plasterboard, finding effective disposal methods can be a complex issue. However, Knauf, a leading provider of construction materials, is stepping up to offer a sustainable solution, Knauf ‘Take Back Scheme’. By working with Encore, a total waste management, environmental consultancy, ‘Take Back’ offers a total solution to a pressing waste management issue that repurposes a passive material.

The Scheme is a pioneering program designed to facilitate the recycling and responsible disposal of plasterboard waste. It allows contractors, builders, and project managers to efficiently manage their plasterboard waste by returning unused materials directly to Knauf via its sustainable partners Encore, or the plasterboard industry as recycled content. Moreover, the data collected from the initiative provides information that helps promote a more circular industry which participating companies can use to promote their own sustainability programmes through waste reduction.

Plasterboard, commonly used in construction projects for wall linings and ceilings, often generates significant waste during installation and renovation processes. Disposing of unused or surplus plasterboard can be problematic due to its composition, which includes gypsum and paper liners. Landfilling

waste is not environmentally friendly and can contribute to resource depletion thorough lessening the impact on basic raw materials needed when manufacturing new.

To address these challenges, the launch of the Knauf Take Back Scheme, is an initiative designed to tackle plasterboard waste sustainably. This scheme enables trade professionals to return unused plasterboard to Knauf, ensuring that it is recycled and repurposed instead of ending up in landfills. By participating in this scheme, businesses not only contribute to reducing environmental impact but also adhere to responsible waste management practices.

How does the take back scheme work?

The process is straightforward:

1. Registration: Trade professionals can register for the Take Back Scheme via Knauf’s website: WWW.RDR.LINK/BBE097

This step is essential to access the benefits of the scheme.

2. Collection: Once registered,

collected plasterboard is recycled efficiently. This involves separating gypsum from paper liners and processing it for reuse in new plasterboard production or other applications.

Benefits of joining the scheme

● Environmental Responsibility: Reduce your project’s carbon footprint by diverting plasterboard waste from landfills. Data sharing and reporting that offers a more transparent approach to waste and recycling within the industry.

schemes which ultimately do nothing to reduce waste or actually deal with the issue of waste. This is especially important not just within the realms of the circular economy but corporate social responsibility and Environmental Social Governance protocol.

● Compliance: Meet sustainability standards and contribute to a circular economy.

Message from Jon Watts, Knauf’s National Client Development Manager UK & Ireland: “As Knauf’s National Client Development Manager, I am excited to introduce the Knauf Take Back Scheme to the trade community. This initiative underscores our commitment to sustainability and provides a practical solution for managing plasterboard waste.”

“Our Take Back Scheme is a testament to our dedication to environmental responsibility,” says Watts. “We are committed to supporting our customers in adopting eco-friendly practices and providing them with practical solutions to manage plasterboard waste effectively.

Join us in making a positive impact on the environment while streamlining your construction processes.”

For construction professionals looking to streamline their waste management processes and contribute to a greener future, the Knauf Take Back Scheme is the answer. Register today on the website to join the movement towards sustainable construction practices and a waste management system that contributes to a more environmentally conscious construction industry.

In conclusion, the Knauf Take Back Scheme presents a sustainable and responsible solution for dealing with plasterboard waste. By embracing this initiative, trade professionals can play a vital role in advancing sustainability within the construction sector.

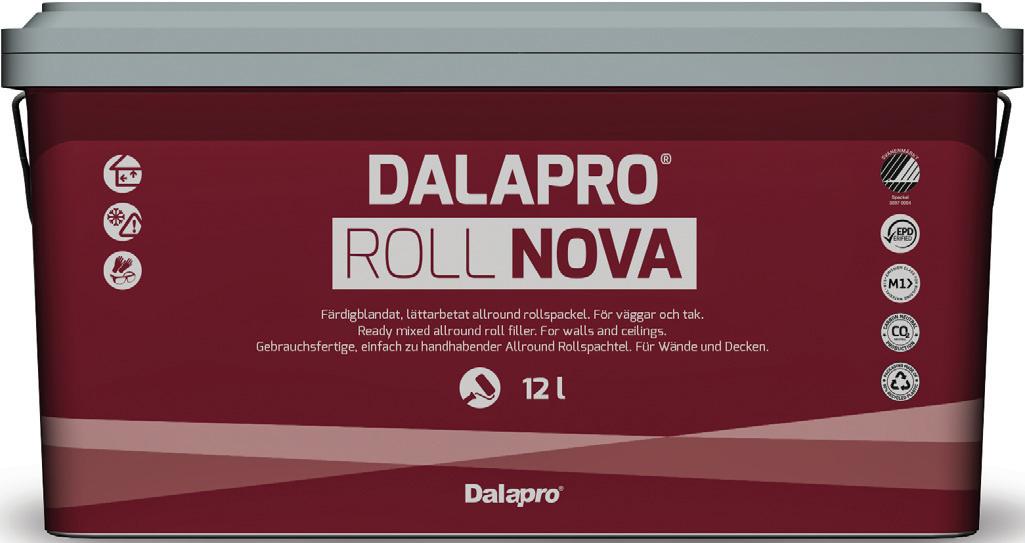

Martin Spalenice, Head of Trade Sales at Okarno, has looked at why contractors should consider the benefits of using roller fillers on site.

Fillers that can be easily rolled onto plaster or concrete walls mean that you can get the job done 30 – 40 per cent quicker. These kinds of products can be used to level the surface of existing walls and ceilings as well as concealing cracks and other imperfections. Being able to easily skim the wall or ceiling without having to take it back to the bare substrate can really make a difference to the overall schedule. The product is suitable for joint filling and thin smoothing in both renovation and new construction. Dalapro is also suitable for paper tape embedding.

STEP 1

Sand the existing finish smooth in order to remove any loose surface materials.

STEP 2

Products like Dalapro can be applied using a standard roller.

STEP 3

Step 1

Step 2

Step 4

Step 5

Step 4

Smooth the material using a skimming blade.

Step 5

Allow 8 hours drying time before lightly sanding the surface and then brushing clean.

Step 6

You’re now ready to apply the paint or other wall finish.

Step 7

Being roller applied means that is it 30 – 40 per cent quicker to apply than other methods.

Dalapro is available from merchants and stockists around the UK. For more information visit: WWW.RDR.LINK/BBE035WWW.RDR.LI NK/BBD000

This calculation tool is a quick and

Step 7

Step 6

When speed is the greatest asset reach for British Gypsum’s ThistlePro FastSet Finish

When your profession is in high demand, booking in a full day’s work, keeping customers happy and still getting home at a reasonable time can be difficult to juggle. For plasterers, balancing time is essential, but in the pursuit of speed, some look to increase their efficiency for small repair and patching jobs by turning to off-the-shelf ‘accelerator’ sachet packets in powder form that can be added to finishing plaster to create quicker drying times.

be around the 70-minute mark. On-site practices can vary, and finishing times are reduced by suction and temperature conditions.

Even homemade remedies are being used, such as adding cement, and dirty or warm water. However, such methods can invalidate product warranties, especially for British Gypsum, as they have not been tested by them and are not standardised.

It is why British Gypsum produced ThistlePro FastSet Finish, as this quicker setting finishing plaster provides an all-inone bag that removes the gamble of adding unapproved accelerators or additives. One 25kg bag will cover approximately 10m2 and set in 60-70 minutes when used in accordance with the installation guidance.

When using the same mix for the first and second coats, working in normal temperatures, British Gypsum’s on-site trials have shown the product will set at approximately 60 minutes when being applied to wallboard. The final trowel will

The product gives a smooth finish and is ideal for patch work and repair jobs as well as smaller internal walls and ceilings, electrical patching, chimney breasts etc. and provides a durable base for applying decorative finishes. In comparison, Thistle MultiFinish plaster takes between 90 to 120 minutes to set and can create a lot of waiting around for smaller jobs.

British Gypsum decided to ask Certified Plasterers, a group of experienced plasterers who have been in the trade for many years and have had their work assessed at one of British Gypsum’s training academies, what they really thought about ThistlePro FastSet Finish. A survey was sent out asking a set of questions including:

● How often do you use ThistlePro FastSet Finish?

● What jobs do you find suitable for the use of ThistlePro FastSet Finish?

● How would you rate the product’s performance?

● Has anything changed about how you work, day-to-day, now that you use this product?

Does it really save you time? If so, what benefits has that brought to you?

In the latest Professional Builder video, we’re comparing ThistlePro FastSet Finish and Thistle MultiFinish to see which product is faster to use. Use the rdr.link below to view the video on YouTube. WWW.RDR.LINK/BBE038

● How likely are you to recommend this product to others?

● Do you think the product is good value for money?

The majority said they either used the product weekly or monthly and it was especially useful for patching, small walls, ceilings, electrical chases, small and ‘on the way home’ jobs.

The majority of the surveyed plasterers rated the product’s performance as excellent and also felt the product provided good value for money. Most agreed that it had improved their day-today work life, as smaller jobs were completed more quickly.

Many stated that they were able to fit in extra jobs on the way home or on a weekend, and have earlier finishes with less time waiting around, while smaller projects were quick and easy to complete. Using the right product, in the right way, for the right job can help to make life’s juggling act a little more straightforward.

product round-up

For architects and designers looking to avoid traditional skirting boards, architraves and cornices, Renderplas is offering a range of PVC plasterboard shadow gap beads. The product can be installed where interior wall dry lining systems meet floors, ceilings, windows, doorframes and staircases to draw a clean line and enable a minimalist aesthetic.

A new range of architectural panels has been launched by James Hardie

The Hardie

Architectural Panel Metallics range comes in gold, copper, gunmetal, silver, steel and bronze and is available for all 8mm and 11mm Hardie Panel products. The material is resistant to UV, fade, rot and has the further advantage of being fully weather-resistant.

Kilwaughter Minerals has launched its latest general-purpose render, GP Mix. With reduced drying times and improved workability, the material is suitable for use as a float coat, scratch coat and masonry mortar. The product gives the same final appearance as traditional sand and cement render mix.

WWW.RDR.LINK/BBE042

The innovative fischer PowerFast II screw offers a low expansion effect and a high load-bearing capacity. Suitable for wood on wood and wood on metal connections, there’s a wider range of applications compared to traditional chipboard screws.

Panel and sheet provider, Panelco has partnered up with Polyrey to bring a new collection of laminate panelling. The Galerie range gives fabricators, manufacturers and specifiers more than 800 designs to choose from. The collection presents specifiers with an additional set of premium designs available in HPL and

Manufactured by West Fraser UK, CaberMDF is designed as an economical and versatile alternative to hardwood. The panels have a highquality surface, are strong, resist impact and accept fasteners securely. They can be sawn, drilled, shaped and routed cleanly with minimum fuss, using hand or machine tools.

Five new high-quality finishes have been added to the range of shower and wall panels from Freefoam. Geo-panels can be fitted to any interior wall to quickly refurbish and restyle rooms. The tongue-and-groove PVC sections are quick and easy to handle and fit. They can be applied over almost any surface, with little preparation

WWW.RDR.LINK/BBE046

Independent timber and panel distributors, James Latham, has launched what it desribes as a pioneering new timber product – quarter sawn Tulipwood. The sustainable product has been developed for a range of specific interior joinery purposes, including kitchen doors and cabinetry.

MAN TGE is taking excellence in van design to the next level

It may be something of a cliché to say that the best just got better, but it’s particularly true of the new MAN TGE range of premium vans. Advances in cabin design and driver assistance systems not only add a new dimension to driver comfort and safety, but also conform to forthcoming legislation. Further evolution of the powertrain and the development of a new digital architecture also reflect MAN’s mission to enhance every workday – both today and tomorrow.

It’s why MAN calls its latest model the MAN TGE Next Level, because it incorporates the next level of thinking and design.

MAN has long been a brand associated with proven, very high-quality

tipper lorries and trucks familiar on construction sites across the country. It brought the same quality of engineering, design and thought into its first generation of TGE premium vans now widely used by professional builders throughout the land. But on the basis that standing still is in fact going backwards, it has now taken its original design, which first made its debut in 2017, and significantly improved upon it. As the company says, it may not have reinvented the wheel, but it has reinvented just about everything else!

A major area of focus has been the interior, and a complete redesign of the

cabin with an emphasis on comfort. It has a new, ergonomic multifunction steering wheel through which the driver can access and control the new assistance systems while on the go, a MAN Media Van Navigation and infotainment system with a 10.4" or 12.9" display and voice activation, and a fully

functional digital driver display with MAN SmartLink smartphone integration.

With an electronic parking brake, Keyless Go functionality, USB-C interface and automatic gear-shift lever the interior features all the modern technological comforts and ergonomic thinking to enable the driver to focus on the essentials, whether they’re navigating traffic on the way to a site or taking a well-earned break.

Alongside interior comfort, the new MAN TGE Next Level features a whole range of advanced assistance systems as standard. The comprehensive suite of systems includes Emergency Brake Assist, Traffic Sign Information and Active Lane Guard System as standard.

Brake Assist warns the driver visually and audibly of any obstacles or other vehicles ahead to prevent avoidable collisions and can even initiate braking if necessary. Traffic Sign Information helps warn the driver if they are driving in the wrong direction and keep within the speed limit, while the Active Lane Guard ensures the vehicle stays in its designated lane, warning the driver by means of vibrating the steering wheel if a lane marking is crossed unintentionally.

To the standard equipment can be added further optional technologies. These include Emergency Assist to continuously monitor the use of the accelerator, steering and brakes to assume control of the vehicle if it detects a potentially dangerous variance in control, and a Cruise Assist plus feature to aid the driver in consistently managing

distance, speed and lane position. Options also include Drive Off Warning and Blind Spot Warning features where in-built cameras and radar can warn of potential hazards and risk of collisions, especially with cyclists or pedestrians, when turning or pulling away.

The importance of these new features cannot be overstated. Mandatory regulations are coming into force shortly (General Safety Regulations II) from the European Commission and impacting British and Irish firms that place new requirements on driver assistance systems, and especially improving passive safety technology to protect the more vulnerable road users on foot or two wheels.

obliging manufacturers to create new electronic architecture that makes it more difficult for criminals to break into a vehicle or hijack its control systems. The new MAN TGE Next Level complies with both sets of regulation, protecting customers now and into the future.

■ Innovations to the vehicle are not only evident on the inside; externally, the new MAN TGE Next Level has also evolved. A new ‘limited edition’ model is now available featuring pale copper metallic paint, piano black mirrors caps, silver bumper boomerangs and 17” black or silver alloy wheels. This stunning new style is rounded off with exclusive ‘Next’ branding on the front grille for an extra touch of class.

As with all of MAN vehicles the new MAN TGE Next Level comes with 24-hour assistance all year round with an uptime guarantee to keep your vehicle on the road when you need it most. Buying a TGE also means buying direct from the manufacturer, dealing personally with the MAN sales team and a guarantee of unrivalled knowledge and best advice.

The company you keep says a great deal about the person you are. Keeping company with a new TGE Next Level van from MAN says you value a vehicle that helps you go about your everyday business in comfort and style, and protected long into the future.

TO DISCOVER MORE ABOUT MAN AND THE TGE VAN VISIT: WWW.RDR.LINK/BBE048

With open plan living the order of the day, steel beam lifts for extensions are becoming ever more complex undertakings, especially on tight sites, but one company has an answer that could have you hooked.

For the homeowner extending an existing property to create one uninterrupted space is very much in vogue. Structurally, that demands ever bigger steel beams, with 5 – 8 metre long RSJs, weighing anywhere from 500 to 1,800kg, not uncommon. Regardless of your experience, that’s always going to make for a daunting lifting operation, especially if you’re simultaneously challenged by restricted access, but there is a company that can take that load right off your mind.

Designed and built in the UK, the Hooka is the brainchild of Hook-up Solutions directors Mark Underdown and Charles Sterling. This go-anywhere tracked green machine was originally developed to carry bulk bags and pallets, with its compact 1m width perfectly

down a tight access path into a back garden it’s a tool that can relieve you and your team of what could be hours of brutal wheelbarrowing and shovelling.

Steel beam lifts

The real game changer, however, came with the addition of a lifting function for the installation of anything from steel beams, to glazing units and pizza ovens. Today, the 20-strong hire fleet has completed over 4,000 RSJ installation alone, and the result is a unique pick, lift and carry, mini tracked crawler handler that can be put to work across a whole range of projects.

Charles explains how the Hooka has caught the attention of builders: “Our

patented Load Lock system prevents the pendulum effect of a bulk bag swinging when the machine carrying it is in motion, which can destabilise other carrying solutions and tip them over. By contrast, the Hooka has been designed so that the payload is positioned over the bed and then locked in place. With the weight located right over the mini crawler’s centre of gravity – rather than hanging at the front – a unit that comes in at just 1,800kg has an impressive maximum carrying capacity of 1,500kg.”

Moreover, because there’s no slewing function, the weight will never move from outside the footprint of the Hooka, which means it maintains its stability at all times, but the tracks will still allow you to rotate

the whole machine around a given point. Outrigger legs provide an even firmer foundation when deployed but, if you still want to move a payload left or right, then those same outriggers are equipped with 800kg-rated castor wheels. The machines relatively light weight also means that it can be transported to site on a plant trailer behind a 4x4, so there’s no issues with squeezing a sizeable plant lorry up your customer’s cul-de-sac and antagonising the neighbours into the bargain.

Charles continues to recount just how the trades can take advantage: “When it comes to materials handling, whether bulk bags or pallets – or if you’re carrying in beam and block flooring – the Hooka is very easy to use and can be hired in a self-drive capacity. The controls are compartmentalised for safety and ease of use and can be explained in a 45minute to 1-hour handover. This is a stand-on piece of plant and there’s two speeds –high for tracking in a straight line to cover distance, and low for manoeuvring and loading/unloading. There’s additional levers for the boom and outrigger controls – all separated out so there can be no confusion as to what does what.”

“If, on the other hand, you’re looking to lift a steel beam or a pizza oven then you’ll need to employ the services of one of our highly skilled operators, who are all accredited to an A66B Compact Crane standard. We’re also working under LOLER, Lifting Operations and Lifting Equipment Regulations, so we will compile a lift plan prior to commencing, and the lift will come under our insurance. All the builder needs to do is send us over the plans together with a short video that illustrates the site’s access and installation zone, which can easily be recorded on any smartphone.”

In terms of its construction the Hooka benefits from a robust and manoeuvrable Hinowa track base, powered by an equally reliable Honda V-Twin petrol engine. “We’ve got machines that have clocked up three thousand hours in operation and, with the right maintenance, they’re good to go every time,” enthuses Charles. “For very long RSJ jobs two machines can be employed to work in

“In addition to its usefulness in steel beam installations for extensions, the Hooka can unload a whole range of materials on site from a lorry, navigate it through tight spaces –and across difficult terrain –and then install exactly where you want it. Whatever your project the Hooka from Hook-up Solutions is compact plan solution that can get you off the hook”

tandem and there’s a total of four attachments available: a bulk bag lifting frame, fork tines and straps for pallets, a fly jib, an up-and-under beam lifter.

With a head office in Baldock, Hertfordshire – and depots or franchisees located at other strategic locations around the country – Hook-up Solutions can boast nationwide coverage, with five fully ticketed operators on the books. The majority of those customers are the local jobbing builder looking for a versatile load

carrier that can operate in a tight spot. It can unload a whole range of materials on site from a lorry, carry it across difficult terrain, and then install exactly where you want to. Indeed, whatever your project the Hooka is a compact plant solution that can get you off the hook.

Johanna Elvidge, head of design at Marshalls, delves into the evolving demands for driveways and how landscapers and builders can navigate these requirements

The demand for driveways is growing, and customers are increasingly placing importance on the driveway itself. In a survey of 2,000 homeowners, we found that – if choosing their next home – two-thirds (64%) would want a private driveway, and for 17% of people, it would be a deal breaker if their property didn’t have one.

We also explored some of the reasons why driveways are so important. These include household costs and security, with 61% of people agreeing that a private driveway helps manage the cost of car

evolving. Greater electric or hybrid car ownership means more consumers are using their driveways as charging points plus vehicles are also increasing in size and weight requiring surfaces to withstand heavier loads. At the same time, we’re seeing a shift in the prominence of the front of the house, where driveways are often the forefront, with more than twofifths of people (43%) saying they care more about the appearance of the front of their home, including their garden, driveway and front door, now than compared to two years ago.

In the same research, we also

for a house built with sustainable materials. To this end, builders and landscapers may well find themselves getting enquiries about their sustainability credentials and how a project can be delivered with minimal environmental impact, especially as the Future Homes Standard is on the horizon.

These evolving demands, coupled with pressure on cost and the need to consider sustainable draining legislation when working on a new driveway over 5m2, are among the growing list of things builders and landscapers need to consider when planning a driveway project.

Fortunately, forward-thinking manufacturers are constantly innovating products that combine the best of all worlds to help trades find the balance between sustainability, affordability, aesthetic appeal, legislative requirements and ease of installation.

One such area of innovation is granite alternatives. Traditionally, granite has been a popular choice for paving due to its durability and style. However, concrete-based alternatives can bring many additional benefits. Unlike granite, concrete can be laid on a flexible, unbound bed, requiring lower-priced materials and reducing installation time and costs.

These time, cost, and carbon-saving advantages are also available without

compromising on quality or aesthetics. Innovative ranges, for example, include a broad range of carefully curated colours, including popular greys and neutrals. Plus, patented colour application technology can ensure a subtle blending of shades reminiscent of granite while offering excellent resistance to UV fading and weather damage.

The latest granite alternative ranges include different paving formats, such as modern linear units, helping customers delineate spaces. At the same time, smaller elements can be used for finer detailing and edging, creating character and unique design elements.

Many of these latest innovations also include products made in Britain. These locally manufactured solutions help to reduce carbon emissions versus an imported natural product, plus support the local economy. Moreover, the supply

Legislative compliance is another factor in the growing list of driveway demands. Since 2008, any new driveway in the UK over 5m2 must use permeable materials or provide a drainage system for the water to run to a permeable area. If neither approach is followed, the homeowner must get planning permission. When not using permeable materials and instead creating a drainage system, the rainwater that falls on the surface must be directed back onto the homeowner’s

linear drainage solutions provide a more subtle option that helps comply with legislation while being simple to install and easy on the eye. Generally manufactured from concrete in popular driveway paving shades, these new drainage systems integrate into block paving for an almost seamless finish that’s easy to access and maintain.

In the evolving landscape of driveway construction, builders and landscapers face the challenge of meeting consumer demands for sustainability, aesthetics, and functionality while adhering to regulations and ensuring practical and straightforward installation. By embracing innovative solutions, professionals can deliver exceptional results that exceed customer expectations, contribute to a more sustainable built environment and make their working lives easier.

Matthew Evans, Director of Technical and Regulatory Affairs – GB at Kingspan Insulation, discusses the insulation targets you need to hit when extending a home.

Making sure all elements on your project achieve the right U-value is a standard part of all building work. However, when it comes to adding extensions, there can be some confusion on what targets you need to meet for the walls, floor and roof of the new space, and whether this work triggers any other changes for the insulation levels in the rest of the house.

As you’ll probably know, the regulatory requirements are different in England, Scotland and Wales. This may affect the U-values you need to meet on extensions.

In all three countries, the Building Regulations and Standards provide a standard approach for extensions. This basically sets worst case U-values for the walls, floor and roof of the extension which you need to meet or improve on. These U-values are area-weighted, which means it is possible to insulate certain areas to a worse standard providing you compensate for this elsewhere in the construction. In all cases, no point in the construction should achieve a worse U-

value than 0.35 W/m2K for the roof or 0.70 W/m2K for the walls and floor.

The worst-case U-values are shown in the table below. In Scotland, there is a single set for all extensions. In England and Wales, alongside the standard worst-case U-values for new elements, there is also a separate set of values which apply to any parts of the structure which are retained from the existing building (renovated elements). For example, if the extension is built against or incorporates a garage which was previously unheated these Uvalues would apply to the garage space.

In Wales, adding an extension may

also trigger some consequential improvements to the rest of the home. Depending on the size of the extension, these may include adding loft insulation (if existing is less than 200 mm) and adding cavity wall insulation to any currently uninsulated cavity walls where appropriate. England also has consequential improvements, but they only apply for buildings which will have a total useable floor space of over 1000m2 (including the proposed extension).

If you need more flexibility on Uvalues, all three countries also provide two alternative approaches. These require

you to either calculate a single U-value for the total area of the construction and to prove this is no higher than for an extension of the same size built using the standard approach, or to carry out energy modelling on the extension and home, looking at expected carbon emissions and energy demand. In most cases, it’s simplest and cheapest to stick with the standard approach using the aforemntioned Uvalues.

Once you’re clear on the U-value you need to meet, it’s worth having a think about which products you’re fitting, and in particular their thermal conductivity (lambda value). The lower this is, the more effective the insulation is at preventing heat transfer. This can mean a slimmer thickness of insulation can be installed. Several manufacturers now provide online U-value calculators which allow you to enter details about the construction you’re building, including the target Uvalue. They will provide suggested products and thicknesses for the job.

Phenolic insulation boards tend to have the lowest thermal conductivity of commonly used insulation materials (typically as low as 0.019 W/mK). This makes them a good choice for a range of applications including floors, pitched roofs

Kooltherm K106 Cavity Board is a full-fill phenolic insulation with a thermal conductivity of 0.019 W/mK which can be fitted with a residual cavity of just 10 mm in suitable applications.

and external walls.

Phenolic boards can be particularly useful for new cavity walls, where they can help achieve the required U-values with a slimmer construction than would be possible with worse performing materials. Standard partial-fill phenolic cavity boards are typically fitted with a 50mm residual

Detailing guides are available for common thicknesses and applications for both Kooltherm K106 and K108 Cavity Board products. These include process sequences and diagrams showing best practice at key junctions.

most suitable option for a project will depend on how likely the property is to be exposed to wind-driven rain. Depending on the risk, the warranty provider may prohibit the use of full fill insulation, require different construction approaches to be adopted and/or require the residual cavity width to be increased. In all cases, it is important to ensure that the insulation boards are cut and fitted so there are no gaps within the layer. Particular attention needs to be paid at the junctions between the wall, roof and floors and around openings. Some manufacturers can provide detailing guides with practical process sequences and diagrams, illustrating best practice when fitting products in these areas.

The standard approach to compliance provides a clear set of U-values for installers working on extension projects to look to achieve or better. By making use of manufacturer U-value calculators and using insulation materials which achieve low thermal conductivities, it should be relatively straightforward to hit these values on all home extension projects without needing bulky constructions.

Due to their angle in relation to the sun, a rooflight lets in twice as much daylight as an equivalent sized vertical window. As a result, rooflights are a great way to improve the natural lighting of a project, whether you are working on a new build, refurbishment or extension. However, due to their location, there are serious safety implications to consider when specifying and installing rooflights.

When looking to specify a rooflight, there are two primary choices of glazing for domestic projects: laminated and toughened glass. Both are considered a type of ‘safety glass’ because – unlike standard float glass – they have been engineered to resist breaking as much as possible.

Furthermore, when they do break, they do so in a way that minimises risk for anyone in proximity. However, there are significant differences in how the two types of glass can break, with toughened glass still posing a potential health risk when used in a rooflight that could break overhead.

Toughened glass is made from float glass which has been exposed to heat after the panes have been formed. The glass is uniformly exposed to temperatures of over 600°C as it passes through a furnace before being rapidly cooled or quenched. This process, known as tempering, makes the glass considerably stronger than conventional float glass.

However, whilst toughened glass is highly resistant to impacts compared with standard glass, it can be broken with a focused impact from metal object, such as the foot of ladder, or if the edges are damaged during transportation or installation – posing a danger to the contractor. Poorly manufactured

toughened glass is also susceptible to thermal stresses, which has resulted in panes ‘popping’ seemingly without cause. Furthermore, should the pane break, the entire piece shatters, causing small pieces of glass to rain down into the room below.