Rent or buy? The age-old dilemma. Commit to sinking your own money into a trusty new machine or trusting your friendly neighbourhood rental firm to help you out and give you a good deal for the required duration? On the one hand it’s a lot of capital to tie up but you own the asset, on the other you theoretically get the machine you want for the job with no added hassle if you go the rental route.

Decisions, decisions. The irony perhaps is that should you decide to make the investment, what do you buy? There’s been such a proliferation of new machines across all types that singling one out is a job in itself. What’s more with the arrival of batteryelectric powered equipment, do you take the plunge and overcome your ‘shift anxiety’ and become an eco-operator?

You could also ask yourself why take the risk in buying when rental is the easier path? After all, rental firms have the choice of equipment, you have the pick of what you want, and everyone is happy.

And this, it seems, is the way forward, well at least according to a recent study by construction industry experts, Barbour ABI. It says that ‘plant hire is fast becoming the preferred route for accessing vital equipment.’ Such is the demand for rental machines that the company believes that the hire market will be worth a whopping £3.6bn by the end of this year, even with an economic backdrop that is less than lively.

“...firms are under pressure to modernise fleets faster than ever...”

Editors JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager MATTHEW BOASE mboase@hamerville.co.uk

Group Manager ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer GEMMA WATSON

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

So, what is driving this growth? According to Barbour the construction industry, which accounts for around two thirds of all hires, is ‘facing mounting cost pressures, tightening legislation, and accelerating decarbonisation targets.’ To that end contractors are looking for efficiency and simplicity and by renting equipment it reduces their risks, while offering numerous benefits. Lower maintenance costs, greater flexibility and the chance to try out new types of machines provide them with peace of mind, when working on complex and difficult contracts.

One of the prime drivers is the need for compliant products that meet the requirements of the relevant legislation. As Barbour ABI’s chief analyst Ed Griffiths points out in the study, “with emissions regulations tightening and net zero targets looming, firms are under pressure to modernise fleets faster than ever, and plant hire offers a route to do that affordably.” To that end plant businesses are increasingly investing in more low-emission, battery-electric and hydrogen-powered equipment to help contractors meet environmental standards head on.

Encouragingly the report signs off by saying that the ‘plant hire market (will) continue its upward trajectory’ thanks to a pipeline of work it estimates to be in the £775bn ballpark. This means companies will have to scale up quickly when needed, so plant hire becomes ‘no longer just a cost-saving choice, it’s a strategic one.’

Happy reading

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2025

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

This is the fifth month in a row where sales have been higher than the same month in the previous year, indicating a recovery in market activity, says the CEA.

Sales in the month were just under 3,000 units and reached the highest monthly level since the first half of 2023. Following the increase in March, sales in the first quarter of the year reached

over 6,900 units and saw an 8% increase on Q1 2024 levels.

Excavators, the highest volume products, have continued to drive the increase in sales this year. This includes both crawler excavators and mini/midi excavators, where combined sales in the first quarter were nearly 19% above Q1 2024 levels.

HYUNDAI CONSTRUCTION

EQUIPMENT EUROPE (HCEE) HAS APPOINTED RYGOR PLANT AS ITS DEALER FOR GREATER LONDON, THE WEST MIDLANDS, AND THE SOUTHWEST INCLUDING BRISTOL AND WALES.

The company will offer a dedicated plant machinery service from its facility in Swindon, with mobile technicians working from the network of Rygor sites throughout the region, offering customers local service and after-care.

Commercial director Rish Channa said: “As a group, we already cover a vast geographical area throughout the UK, via our 17 locations, so we really know what it takes to partner with an OEM of Hyundai’s stature and how to develop an impactful, long-term relationship.

“Rygor Plant will be one of the largest Hyundai Construction dealers in Europe, and this is a very proud moment for our team. We are delighted to be partnering with Hyundai to offer its complete construction range across our entire territory and beyond. Rygor Plant has a strong foundation on which to offer our customers end-to-end solutions, focusing solely on providing capital equipment directly to the end user.”

For further information WWW.RDR.LINK/CBB002

After this, telehandlers (for construction) were the best performing product, and saw sales at similar levels to last year in the first quarter. Telehandlers were the strongest performing product group in 2024. Wheeled loaders have

been the weakest high volume product this year, with sales at 33% below last year’s levels in the first quarter.

For more information

WWW.RDR.LINK/CBB001 i

FUEL DISTRIBUTOR, CERTAS ENERGY, HAS LAUNCHED A NEW FUEL TANK HIRING INITIATIVE FOR ITS HYDROTREATED VEGETABLE OIL (HVO).

The campaign aims to support customers for whom cost is a barrier to transitioning to low carbon fuel, while also strengthening their fuel security and offering more buying options for their specific needs. Opting to hire an HVO tank, rather than purchasing one outright, can reduce year one costs by almost 90%, which can free up capital for other site improvements and investments, claims Certas.

Darren Holloway, commercial director for energy solutions, said: “Our ‘Tanks for Hire’ offering is all about putting our customers in control of their fuel management, addressing the high upfront costs associated with buying a tank while making the whole process more convenient. Businesses have told us what they’re looking for and we’ve developed precisely that - this is fuel management on customer terms.”

Consumption of HVO in the UK almost reached 700m litres in 2024, and demand is expected to continue rising for the rest of this decade.

For further information

JET PLANT HIRE’S LATEST GRADUATE FROM ITS DEDICATED TRAINING SCHOOL IS TYLER ROCK.

After completing the intensive nine-month Jet School programme, Tyler officially qualified as a road planer operator, marking another success story in the company’s mission to inspire the next generation of skilled professionals.

“It’s been a brilliant opportunity for me and the next steps in my career, learning from experienced colleagues to develop new skills.

I’m looking forward to what the future holds for me,” said Tyler.

The programme is designed to equip trainees with essential industry competencies, providing them with hands-on experience under the guidance of seasoned professionals. Participants gain expertise in operating road planers, setting machine levels, depth checking, kerb cutting, general machine competency, basic maintenance, and crucial aspects such as health and safety and sustainability.

STAR POWER, THE PROVIDER OF SPECIALIST TEMPORARY POWER SOLUTIONS, IS EXPANDING ITS OPERATIONS INTO THE NORTHWEST.

Based at the recently enhanced Star Platforms depot in the region, the intention is to serve both new and existing customers with high-quality, reliable power solutions.

Richard Miller, managing director, Star Power, commented: “This expansion is a key step in our growth strategy, strengthening our ability to deliver temporary power solutions across the UK. By establishing a stronger regional presence, we can enhance service levels for our existing customers while also supporting new businesses with our reliable and responsive power solutions. With a dedicated team and the backing of our sister company, Star Platforms, we are well equipped to provide outstanding service across the region and beyond.”

For further information

WWW.RDR.LINK/CBB007 i

For further information

WWW.RDR.LINK/CBB005 i

A CAT 444 BACKHOE LOADER LIVERIED IN THE CENTENNIAL GREY TO MARK 100 YEARS OF THE COMPANY WAS ON PROUD DISPLAY AT THE BALMORAL SHOW RECENTLY. IT IS JUST ONE OF 10 UNITS FINISHED IN THE SPECIAL COLOURS.

David Glenn, regional sales manager at Finning UK & Ireland, said: “The Cat 444 Centennial backhoe offers a nod to Caterpillar’s strong history, but also demonstrates the company’s intent for fuel-efficient technologies of the future. More of our customers are now turning to subscription-based maintenance and using platforms like VisionLink to monitor machine health, fuel use and servicing needs. The Balmoral Show is a great oppor tunity for machine operators and owners to find out more about how this can enhance their operation and support efficiency savings.” For further information WWW.RDR.LINK/CBB006 i

MECALAC HAS ANNOUNCED THE APPOINTMENT OF HRN TRACTORS AS ITS NEWEST UK DEALER, EXPANDING ITS PRESENCE ACROSS NORTHERN AND CENTRAL SCOTLAND.

The new partnership will see HRN Tractors offer Mecalac's full portfolio of compact construction machinery, including excavators, wheel loaders, site dumpers, backhoe loaders and pedestrian rollers, alongside parts, servicing and expert product advice. The appointment of HRN Tractors aligns with Mecalac’s strategic growth plans to strengthen its UK dealer network and bring its next-generation machinery to more contractors, builders and ground workers. HRN Tractors is said to be a well positioned to support Mecalac's growth, ensuring customers receive not only high-quality machinery but also the critical support they need throughout the ownership lifecycle.

"Our goal has always been to offer choice without compromising on quality and Mecalac's range perfectly complements our existing line-up from other trusted manufacturers", said Ian Burton, construction sales director at HRN. For further information

THE CONSTRUCTION PLANT-HIRE ASSOCIATION (CPA) HAS ANNOUNCED THE PROMOTIONS OF THREE MEMBERS OF THE TEAM.

Peter Brown has been promoted to technical and development director, Chris Cassley has been made policy director and Katie Kelleher is now technical publications and careers manager.

WATES GROUP BELIEVES HYDROGEN CAN BE A MAJOR CONTRIBUTOR TO ITS PLANS TO REDUCE CARBON EMISSIONS ACROSS ITS OPERATIONS AFTER SUCCESSFULLY TRIALLING A JCB GENERATOR POWERED BY THE FUEL.

The company has been trialling a JCB 60kVA hydrogen combustion generator on a site near Wolverhampton. Coupled with a 104kWh Powerpack battery storage unit, the intelligent combined power system can operate on battery power alone, as a hybrid (using both battery and generator power), or hydrogen-powered only.

Adam Cannon, project director at Wates, said: “One of the questions we get from customers is how can you make site set-up more energy efficient and more carbon neutral? We’ve been trying other fuels, but they’ve been a bit of a challenge. Hydrogen for me is the way forward. It is completely new thinking for power for our accommodation on site and it really reduces the burden from the statutory authority having to bring new cables and infrastructure to site. It will allow us to be standalone and to offer a carbon neutral offering to our customers.” For further information WWW.RDR.LINK/CBB009 i

CPA CEO Steve Mulholland said: “The last few months have been extremely busy and productive for the CPA team, and I am delighted to announce these well-deserved promotions. Peter has the skills, experience and knowledge of working with members and stakeholders in various areas of technical guidance, standards setting and training for the benefit of members. Chris, in his new role as CPA policy director, will take forward the CPA’s work on lobbying the Government and policymakers on key issues affecting the plant-hire industry.

“Katie is a real force of energy for positive change in construction plant-hire and her new role will see her promoting all things career related where we know there is still progress to be made. At the same time she’ll maintain technical support to the membership regarding all things lifting.”

For further information

WWW.RDR.LINK/CBB010

FUNDING BY THE CONSTRUCTION PLANT-HIRE ASSOCIATION (CPA) AND OTHER ORGANISATIONS HAS HELPED LEAD TO THE SUCCESSFUL RECOVERY OF £890,000 OF STOLEN PLANT AND EQUIPMENT.

According to Superintendent Andy Huddleston, who leads the National Rural Crime Unit and the National Construction & Agriculture Theft Team (NCATT, over a 10-day period two NCATT operations resulted in multiple strikes on locations in West Yorkshire, North Yorkshire, Leicestershire and Warwickshire. The two operations led to three arrests and the recovery of £540,000 of stolen matting and fencing and 36 pieces of machinery valued at £350,000.

For further information

WWW.RDR.LINK/CBB011

Construction firms are ditching their own diggers as red tape, green rules and soaring costs fuel £3.5 billion hire craze.

That’s according to Barbour ABI’s recent plant hire market report. CPN digests the findings.

With the UK construction industry facing mounting cost pressures, tightening legislation, and accelerating decarbonisation targets, plant hire is fast becoming the preferred route for accessing vital equipment according to this new research.

Barbour ABI found that the UK plant hire market will reach a value of £3.56bn in 2025, growing nearly 24% since 2020 - despite a backdrop of economic stagnation and inflation.

Researchers found that contractors and developers are increasingly turning away from asset ownership in favour of flexible, on-demand access to machinery. Renting equipment reduces the contractor’s risks, and offers other advantages including tax relief, the availability of a call-out service, lower maintenance costs, greater flexibility and the opportunity to trial new products and types of equipment.

A key feature influencing the hire and safe operation of rental equipment in the industry is the need for compliant products that meet the requirements of the relevant legislation.

“With emissions regulations tightening and net zero targets looming, firms are under pressure to modernise fleets faster than ever, and plant hire offers a route to do that affordably,” says Barbour ABI’s chief analyst Ed Griffiths.

“...firms are under pressure to modernise fleets faster than ever...”

Legislation remains a key driver in the industry. Notable examples include regulations relating to health and safety in the workplace (which encourage the use of certain types of equipment) and laws aiming to improve environmental performance and energy efficiency.

Plant hire companies are investing in lowemission, battery-electric and hydrogen-powered machinery, helping contractors meet new environmental standards without costly investment. And with rental penetration in the UK already around 75%, the trend away from ownership looks set to continue well beyond 2025.

Barbour’s reporting highlights that earthmoving and lifting equipment alone account for 68% of plant hire value, with demand being supercharged by major projects like HS2, The Great Grid Upgrade, and the upcoming AMP8 water infrastructure investment plan.

“Hiring gives firms the ability to scale up quickly for major infrastructure or energy projects, while avoiding the financial and legislative burden of plant ownership,” adds Griffiths. It is estimated that construction accounts for around two-thirds of the total plant hire market, with the remaining share taken by the non-construction sector. Demand for plant hire is therefore heavily dependent on the level of construction activity, with recent growth having been the highest in sectors such as infrastructure and, until recently, housebuilding.

There is still a significant pipeline of work within the sector relating to energy projects, estimated at between £700bn and £775bn.

“As we look toward 2029, we expect the plant hire market to continue its upward trajectory, supported by a projected £700£775 billion in UK infrastructure investment and a growing push for low-emission equipment,” concludes Griffiths.

“With rental penetration already sky high and sectors like renewable energy, data centres, and utilities driving demand, hire is no

longer just a cost-saving choice - it’s a strategic one. The shift to smart, sustainable, and flexible solutions will define how construction firms operate over the next five years.”

Summer’s here and he’s ready for some sun. Some say he’s a stickler for detail when reviewing machines, others that he leaves no stone unturned. All we know is that we call him The Dig. This month he gets back on track with Cat’s 265.

Such is the demand for the highly versatile compact tracked loader, the global CTL market was valued at $27.3bn in 2023 and is predicted to register a rise in value by over 5% annually up to 2032.

It’s not hard to see why either, as in the right hands these machines, which are able to run an infinitely wide range of static and hydraulically powered attachments, can turn out a lot of work across a wide range of industry sectors, and offer a far more comfortable operating experience than a traditional wheeled skid steer variant.

So it was with great delight that we accepted an invitation to Finning’s headquarters in Cannock, Staffordshire to

undertake a test drive of the latest Caterpillar next generation 265 CTL model which, in line with its other tracked siblings, is built in Caterpillar’s North American facility in Sandford, North Carolina.

The 265 which along with the 255 was officially revealed towards the end of 2023, has an operating weight of 4759 kg, and is effectively the replacement for the previous 279 D3 and 289 D3 models.

However, in terms of breakout force and torque power it’s been increased in this size class to make it comparable to the previous larger 299 D3 model. To get acquainted with the new machine I was

given a walkaround tour by Finning UK & Ireland’s BCP (Building Construction Products) product manager Helen Day.

Popping the heavy-duty metal rear door reveals access to the Stage V emissions compliant Cat C2.8TA four-cylinder, turbo after-cooled diesel engine, which produces a net power output rating of 54.9kw (74hp) between @2200-2400 rpm and a maximum torque of 380Nm @1360 rpm.

The wide opening facilitates ease of access for daily checks and routine maintenance during service intervals, with dipstick, oil, fuel and air filters and coolant expansion bottle all easy to hand. In addition, the battery and electrical isolation switch are nicely located at the lower righthand side of the engine bay.

The roof of the engine bay can also be lifted up or removed easily if preferred to allow for debris cleaning of the main engine cooling pack, mounted above the efficient ondemand variable speed hydraulic cooling fan.

Walking around to the side of the machine we notice that there has been a complete change in the undercarriage design, in that it now features a one-piece

“... the access is a lot easier on these models...”

torsion suspension undercarriage bar system. With an overall track length of 2126mm this, especially if combined with the optional speed sensitive ride control system, is said to offer improved stability and a much smoother ride in the cab. That is a bonus if operating on rough ground, while also ensuring better retention of the load in the bucket, something that I really got to appreciate during my time in the seat.

Continuing the ground up re-design the operator station is completely new. Access is via the familiar route, stepping up over the bucket or attachment via a couple of antislip steps, with the bucket attached on this example, a third anti-slip step is provided on the top left-hand side while a sturdy grab handle on the left-hand side of the cab further assists with access and egress. The access is a lot easier on these models as you are not having to climb over the loader arms cross member that was the design on the outgoing D3 model, it just has a much lower opening and accessible feel to it, and when seated in the cab it further enhances the forward visibility too.

superb and offers a crystal-clear view of all the functions that can be accessed via the menu. The top portion of the monitor hosts warning lights and indication dials for fuel level and engine temperature, while the lower portion of the monitor provides the operator with other machine status feedback, hours worked, time etc.

Below the screen there are six selection buttons for such things as camera view, track speed, audible alarm, radio mute and the main menu where you can find a whole host of settings including auxiliary hydraulic flow settings for attachments. When selecting reverse the monitor automatically becomes the rear-view camera, offering a superb view of the area behind the machine when backing up.

The monitor can be navigated by using the advanced joystick controls, which means when you are operating, you don’t even need to remove your hands from the joysticks, enabling you to do such things as adjusting the radio volume, activating creep speed and one-button smart attachment control to name a few.

Heating and air-conditioning controls are mounted in the roof of the cabin to the operator’s upper right-hand side, with hot or cold air being distributed via fully adjustable vents in the cabin. For those who like the fresh air, and don’t mind a bit of dust coming in, the side windows on both sides can be slid open fore and aft as required, with the usual mesh protection to keep the operator safely protected from the loader arms.

As previously mentioned, these machines are increasingly used to power hydraulic attachments such as flail mowers and planers. To facilitate this, these machines feature three levels of auxiliary hydraulic performance consisting of standard flow, high flow, and the high flow XPS option for those really oil hungry attachments. In standard flow you get a hydraulic pressure of 3,500 psi, with a hydraulic oil flow of 86 l/min (23 gal/min), whilst in the high flow XPS setting it puts out a whopping 4,061 psi with an oil flow of 129 l/min (34 gal/min).

The machine also features a class leading lift height of 3354mm (132in) at bucket pin height, that’s some four inches more than its closest competitor the Bobcat T76. Maximum overall height with arms raised and bucket curled right back is 4173mm (164.3 in).

I was keen to get in the seat to see what all the fuss was about. Once I punched in the four-digit code on the touch screen and

connected the large orange lap belt, which is required to enable you to start the machine, I flicked the ignition key and the Cat 4-cylinder power pack sprang into life, with a gentle thrum.

The machine features a foot throttle pedal, but on these machines, I much prefer to set the engine speed using the rotary dial which is mounted on the right-hand side front pillar just below the ignition key.

I cranked up the speed to around ¾ revs and was pleasantly surprised by how quiet it was in the cab; apparently it’s rated at 80dB(A) inside, while outside the cab the noise level is rated at 103dB(A).

“...in the dig this machine punched well above its weight...”

Lowering the additional safety bar across my lap from the right-hand side, and with a push on the red parking button on the dash, I was ready to set off. The controls are standard ISO configuration for these machines, with the boom lift and bucket tilt on the right-had joystick, whilst the forwardreverse and steering is accomplished using the left-hand joystick, all extremely intuitive and simple to use.

For the purpose of this test drive, I was just digging from the face of the pile of stone and hardcore travelling with it to the top and tipping it back down the face, a bit of a job creation assignment, but it did give me the chance to get a real feel for this new model.

In the dig this machine punched well above its weight and it certainly had some grunt as I powered into the heap, curling up the bucket to get a full load.Apparently, this new model gives you a massive 43% more torque compared to the old 289 D3 model, and you really feel that extra power as you push into the heap, which is super impressive. The view to the cutting edge of the bucket is on a par with the well-known white liveried brand if not better I would have to say.

Powering up the slope to tip the load I never once felt the need to drop down to the one speed option, and in its two-speed option you get a lively top speed of 13 km/h (8.1 mph), not that I could achieve that within the confines of the demo area, but we did get some decent speed going.

Sitting on 450mm rubber tracks, (other options are available) and with an overall width of 1925mm (75.8in) the machine which has an incredibly low centre of gravity, feels unstoppable and well balanced at all times. I got the feeling that you could work on some pretty extreme slopes in complete safety as it felt entirely planted during this test drive.

In terms of operator comfort, I could not find any faults whatsoever, and I am always looking to offer some constructive criticism, but it wasn’t to be on this test drive. The seat was a very nice place to spend a shift, the controls were light and easy to use, and the visibility was excellent in all directions, even allowing for the heavy duty and beefy looking loader arms to contend with, when looking out the side windows.

What I also enjoy with CTLs is that you are not constantly being bounced about as you often are with the wheeled variants; in these tracked versions, travel is smooth and turning is precise, controlled and powerful.

My concluding thoughts were of a wellbuilt and super powerful CTL for its size class, and a machine that left a lasting impression on me, I genuinely had a lot of fun running it on the day.

Whether it was the influence of Bauma or not, there seems to have been a flurry of new launches and updates in the compact equipment market. Probably for good reason. These small machines play a vital and expanding role on sites, enabled by a huge increase in their capabilities despite their mini dimensions. Basically, you get a lot of machine for your money.

One of the major names to up the ante is Hyundai Construction Equipment . It recently launched two skid steer loaders (SSL) and a compact tracked loader (CTL). Versatile and highly productive, these compact models are being targeted to take the company into new market sectors and provide additional options for existing customers.

The HS80V and HS120V skid steer loaders, along with the HT100V compact tracked loader, are powered by Hyundai Stage V diesel engines, delivering 49.5kW (66.4hp) in the smaller skid steer and 54.9kW (73.6hp) in the larger model and in the tracked machine. The engines meet EU Stage V emissions standards without the need for a diesel exhaust fluid after-treatment system.

The 3.2-tonne HS80V has a rated operating capacity at 50% tipping load of 885kg, while the larger 3.7-tonne HS120V delivers a maximum at 50% tipping load of 1,220kg. The tracked machine, which tips the scales at 4.4 tonnes, has a rated operating capacity at 50% tipping load of 1,490kg.

All three of the compact machines come equipped with vertical lift path loader arm geometry, which allows the boom to raise the bucket to full height without spilling material.

The vertical lift path delivers improved stability, increased lift height and a higher operating capacity, boosting productivity. An auto self-levelling system ensures that the bucket or forks remain level throughout the lift arc, without the need for operator input.

The HS80V has single speed travel motors, offering a maximum of 11.9km/h. The larger HS120V comes with two-speed travel motors, with a top speed of 19.8km/h. The tracked HT100V also comes with twin-speed travel, offering a maximum of 11.5km/h. The two larger machines also offer optional highflow hydraulics, with the skid steer delivering up to 128.8 litres/min of flow and the CTL offering a maximum of 82.9 litres/min.

The compact models are equipped with an industry-standard flat-faced hydraulic quick coupler, allowing operators to change attachments at the touch of a button from within the cab. A 14-pin electrical connector is also available, to control various attachments.

The machines are controlled through

They might be small in stature, but today’s compact machines are packing a bigger and bigger punch, making them a valuable addition to any fleet. CPN rounds up a few of the latest models that are making a splash.

two multi-function joysticks, with multiple thumb and finger switches for auxiliary hydraulics and other functions. The righthand lever operates the boom and bucket functions, with buttons for auxiliary hydraulic flow and an electrical supply. The left-hand lever controls all driving functions, with a button for two-speed driving where supplied. Engine speed can be controlled by a rotary dial on the control panel, or by a foot pedal. The rotary dial is particularly suitable for constant speed operation, such as when working with powered attachments like a planer or a sweeper.

All three are offered with a ride control system, which uses a hydraulic accumulator to allow the loader arms to float slightly during travel. This minimises shock loadings to the operator cab and ensures material stays in the bucket.

The skid steers and compact tracked loader can be specified with Hyundai’s Hi MATE telematic monitoring system. With access through the Hi MATE app or online, the system provides customers with realtime machine performance data, location and access to diagnostics. Service and maintenance can be planned more effectively, guaranteeing increased uptime on site.

“... the company says it arrived at the upgrades after listening to customers...”

the main vehicle screen.

For improved operator comfort a new air suspension seat comes as standard starting at the PC33MR-5. It is fully adjustable to ensure personalized comfort and ergonomics. And while in the cab operators will be able to get a better sight of what they are doing thanks to new LED lights across the whole mini HE range. These powerful, energy-efficient units provide bright, uniform illumination for enhanced visibility in low-light conditions. The lens design minimizes glare and light scatter, reducing eye strain and improving safety.

Not to be outdone Takeuchi has launched a new 7.5 tonne wheeled excavator, the TB370W. The manufacturer claims it is a powerful compact machine that doubles as a versatile tool carrier designed for maximum productivity on busy construction sites.

Its offset 2-piece boom delivers an increased working range and added in-field lifting capacity, complete with lift overload alarm and arm, swing and boom holding check valves, all as standard.

The powerful and responsive load sensing hydraulic system supplies up to four auxiliary ports with hi-flow and proportional control, with optional multifunction grip allowing the operator to assign buttons to frequently used functions.

It offers three different work modes Std, Eco and Eco Plus; Eco Plus switches between std and eco dependent on load. Operators can also switch to cruise control for consistent travel speed while simultaneously operating attachments.

As a multi-tool-carrier, the new TB370W with DPF, 4WD and 4-speed transmission delivers fast powerful productivity. The heavy-duty undercarriage with mudguards, switchable difflock and intelligent auto digging brake are said to deliver excellent safety and stability on site. The TB370W is available with optional outriggers.

The large comfortable cab puts the operator in control with touchscreen and jog dial technology for every function complete with maximum safety and visibility with three auto cameras and full LED lighting all-round.

Its tilt-up cab provides good ground level access to all service and component parts.The TB370W is supported by a 5-year telematics subscription to Takeuchi Fleet Management (TFM) and now features a 3-year/ 3000hour full warranty across the range.

next generation machines feature significant increases in lift height, breakout forces and ROC to elevate loader flexibility

Their new closed-centre auxiliary hydraulic system allows these machines to operate all Cat smart attachments with the standard hydraulics provided. Standard hydraulic system pressure increases 5% to 3,500 psi (24130 kPa) in the next generation models. Cat 250, 260, 270 and 275 machines equipped with standard hydraulic flow are shipped from the factory outfitted as “High Flow ready.” High Flow functionality is activated simply via a new software enabled attachment (SEA), permitting on-machine or remote activation of increased hydraulic flow to 30 gal/min (113 l/min) for the 250, 260, and 270 models and 34 gal/min (129 l/min) for the 275 at standard hydraulic system pressure.

Also available, the High Flow XPS factory option increases auxiliary hydraulic system pressure to 4,061 psi (28000 kPa) for the 250, 260, 270, 275 and 285 next generation models. Along with this, hydraulic flow is increased to 30 gal/min (113 l/min) on the 250, while flow increases to 34 gal/min (129 l/min) for the 260, 270, 275 and 285 models. Equipping the 250 with the High Flow XPS option gives customers auxiliary hydraulic performance not available before in a mid-size chassis SSL. Equipped for maximum hydraulic capability, the High Flow option for 270 XE, 275 XE and 285 XE loaders increases auxiliary hydraulic system pressure to 4,496 psi (31000 kPa) and hydraulic flow to 40 gal/min (150 l/min).

The four next generation CTL models feature a new E-bar (equalizer bar) undercarriage that provides increased

stability for grading and handling heavier loads. The E-bar undercarriage delivers the benefits of a rigid-style undercarriage design when lifting heavy loads or using heavy attachments like mulchers and dozer and grader blades, while simultaneously providing the benefits of an oscillating undercarriage when encountering uneven terrain or obstacles.

All next generation Cat SSLs and CTLs feature a larger cab design with 22% more overall volume and 26% additional foot space. With a 2.75-in (70-mm) increase in interior width, the new cab expands footwell-to-ceiling height by 1.8 in (46 mm) and allows for an additional 1.5 in (40 mm) of hip room and 1.1 in (28 mm) more width between the joysticks to improve operator comfort.

Next generation loaders are equipped with either a 5-in (127-mm) standard LCD monitor or an 8-in (203-mm) advanced touchscreen monitor, depending on the selected technology package. Like the advanced display on the D3 series, the standard monitor features Bluetooth connectivity and supports functionality for rearview camera feed, creep, job clock, maintenance reminders and 32 languages. The new advanced joysticks enable integrated control of the advanced touchscreen monitor, so all machine function control and adjustments can be made without the operator removing their hands from the controls.

Caterpillar believes that these new SSLs and CTLs offer the next level of integration between machine and technology. Both standard and advanced monitors provide the ability to run Cat smart attachments, such as the dozer and grader blades and backhoe. Attachment operation is integrated into the joysticks, and the machine automatically recognizes the type of attachment and the required joystick pattern for controlling it.

Available Cat Product Link Elite tracks machine hours, location, and asset utilization, provides fault code details, and delivers advanced monitoring and machine health with data remotely accessible via VisionLink. Additionally, Product Link Elite provides remote flash and remote troubleshooting capabilities and quickly enables the remote activation of the SEA High Flow feature.

Kubota first introduced its prototype 2.5 tonne electric excavator at Intermat in 2012, marking the beginning of its journey into electrification. Now, the company is taking another significant step forward by unveiling an electric retrofit option for the KX019 (1.8-tonne) and U27-4 (2.5-tonne) diggers. The whole idea is to make the transition to electric equipment more accessible and practical for owner/operators.

With global demand for sustainable alternatives on the rise, Kubota says it is addressing key industry needs, namely reusability and longevity of machinery. This new solution enables customers to replace the standard diesel engine of their excavator with a modular battery pack. Alternatively, machines can be fitted with the battery pack from new and later swapped out for a diesel engine or vice versa.

Cost has always been a barrier to adopting electric machinery. But with this retrofit solution, customers gain flexibility. They can enjoy the low running costs of electric and still have the option to switch to diesel if necessary. It’s about providing choice and easing the transition to a greener future.

Kubota’s solution also notably reduces maintenance costs and operational overheads. With no engine and associated components, servicing time and expenses are considerably reduced, saving customers both time and money. Additionally, with electricity costing far less than fossil fuels, it offers a highly economical advantage.

But this isn’t all, the retrofit solution delivers low noise levels, making it ideal for urban environments and indoor

applications. Noise levels at the operator station are significantly lower compared to the diesel equivalent, enabling better communication and safety with co-workers. Quiet operation also allows for longer working days, maximising time on-site and accelerating project timelines.

Kubota’s solution addresses the unique needs of construction operators, recognising that many machines only operate for a few hours a day, often less than two hours. The battery pack’s runtime aligns with this usage, and with the ability to top up charges throughout the day, working hours can be easily extended.

While electric models are yet to dominate the market, Kubota’s approach is focused and practical, aimed at providing an easier path to adopting electric technology without abandoning the flexibility of existing diesel setups. By offering a solution that bridges the gap between traditional and electric machinery, Kubota is looking to make significant strides towards a more sustainable industry.

The electric retrofit is expected to roll out throughout 2025.

For more on Hyundai WWW.RDR.LINK/CBB 014

For more on Komatsu WWW.RDR.LINK/CBB 015

For more on Takeuchi

WWW.RDR.LINK/CBB 016

For more on Caterpillar WWW.RDR.LINK/CBB 017

For more on Kubota WWW.RDR.LINK/CBB 018

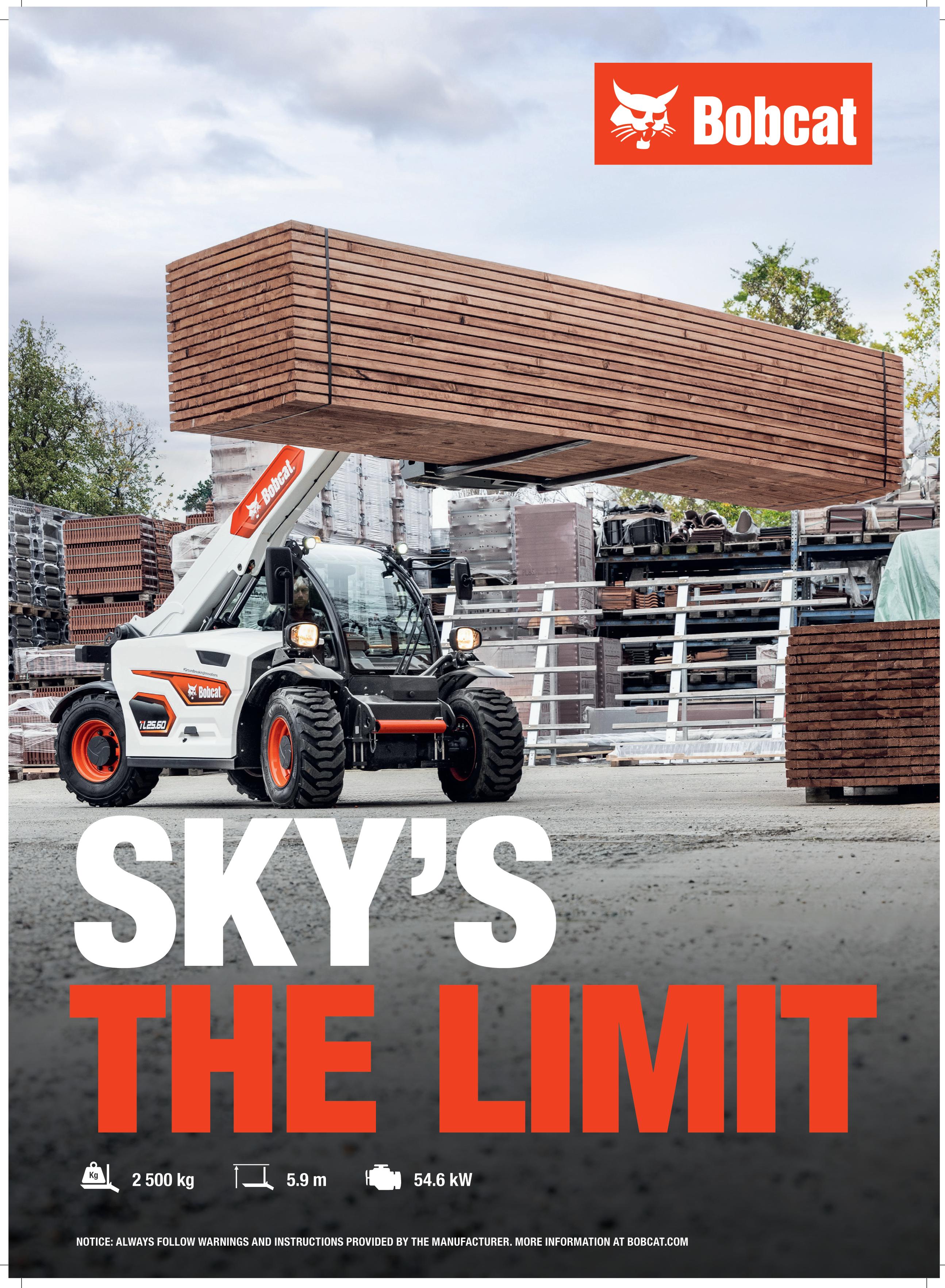

Lifting, shifting, placing and lowering, the telehandler is a jack of many trades and Merlo has a model for most applications.

CPN has a look.

Merlo is a name synonymous with telehandlers, a brand familiar with farmers the length and breadth of the land. But the manufacturer is also making inroads to the construction sector and its latest all-new ROTO range is tasked with doing just that. The company believes the line-up will deliver increased performance, thanks to a host of new features and an innovative fresh design.

Having undergone a significant programme of development the new ROTO generation heralds the arrival of increased lifting capacity while offering the lightest ground bearing pressure and market leading compact dimensions.

It’s not just the capacity (an increase in lifting capacity of 1,000kg per model) and upgraded lift heights, but the entire load chart has been enhanced. A significant number of new and improved components feature in the new design. At the heart of these models, a new chassis facilitates increases in capacity and output. A maximum travel speed of 40 km/h (where permitted or approved) ensures a timely arrival on site.

To meet the demands of the rapidly growing rental market, Merlo has also introduced the R rental models. Offering the same power, performance and reliability as the S Plus models the R models offer simplified management and operation, making them suitable for sites where multiple operators are present.

Talking of operators, a lot of work has

been done to improve day-to-day working. Refinements to the boom speed have allowed for an even smoother and more linear operation. In addition, the introduction of a ‘set point’ function allows the automatic return of the boom to a memorised position at maximum speed while maintaining safe operation. This feature is said to reduce operator fatigue and increase efficiency in repetitive work cycles.

Another feature is a new Cartesian movement function that automatically maintains the vertical trajectory of the attachment when raising or lowering, or a horizontal trajectory during extension or retraction of the boom. Additionally, the introduction of a load chart simulation function lets the operator know before commencing work as to whether it is feasible or not, simply by analysing the variation of the known parameters (attachment used, load to be lifted, stabiliser position etc).

And you don’t have to work from the cab either, thanks to a new patented design of Merlo’s radio remote control, which offers a greater range of machine information than previously. For example, if a dangerous manoeuvre or situation is detected the LCD display screen background will change colour to alert the operator, allowing only safe movements to return the machine to a stable and safe situation.

For the rough and tumble of your typical building site Merlo’s Panoramic range of stabilised telehandlers is probably a good choice. With six core models, including the P40.12, P40.13, P40.14, and P40.17 (all boasting a 4-ton lift capacity and lift heights from 12 to 17m), the range offers serious capability. Topping the lineup is the P50.18, featuring a 5-ton capacity and an 18m reach,

while the compact P35.11 delivers stabilised performance where space is at a premium.

At the heart of the Panoramic range is Merlo’s stabiliser design. Mounted in line with the front axle, the stabilisers extend within the machine’s overall width, preserving a tight footprint ideal for urban or congested job sites. This configuration provides optimal lifting stability even on uneven ground, allowing accurate load placement in challenging environments

Every Panoramic model comes standard with chassis levelling, a feature that hydraulically adjusts the front axle to level the machine before lifting. When stabilisers are deployed, the system enables up to 10˚ of tilt correction, enough to compensate for an 18˚ slope.

Add to that the boom side shift function –controlled via a joystick roller –and operators can laterally reposition the boom head with precision, without needing to reposition the entire machine. This is especially useful when loading materials, placing pallets, or positioning items on scaffolding with pinpoint accuracy.

Panoramics can be equipped as platformready for safe use with Merlo’s TreEmme personnel baskets. A mechanical locking pin provides added security against detachment, while remote lift control from the platform

allows for smooth, controlled positioning close to structures –minimising the risk of accidental contact or material damage.

Safety and operator protection are important too. The ROPS/FOPS II-certified cab includes reinforced glass, a windscreen guard, and roof protection to shield against falling debris. Visibility is assured in all weather conditions with wipers on the front, rear, and roof panels.

Under the hood, base models feature a 75hp Kohler engine that simplifies emissions compliance by eliminating the need for DEF (Diesel Exhaust Fluid). For more demanding applications, PLUS and TOP versions are powered by a 116hp Perkins engine.

All variants come equipped with a 2speed, 40kph hydrostatic transmission and Merlo’s ECO power drive (EPD) system. EPD optimises fuel use –cutting consumption by up to 18% –while features like a programmable hand throttle, cruise control, and a self-accelerating joystick give operators control and focus on the task at hand.

The adaptive stability control system (ASCS) provides real-time load monitoring to ensure safe operation at all times. TreEmme attachments benefit from automatic load chart recognition, while EN15000-compliant sensors enhance crane and winch operations, boosting operator confidence and load security.

From lifting roof trusses and positioning brick pallets to placing loads on upper floors or scaffolding, Merlo’s Panoramic range is purpose-built for the rigours of housebuilding and commercial construction. With impressive reach, compact stability, and cutting-edge safety and control systems, Panoramic telehandlers can be counted on in high-reach, material-handling tasks.

The MT 625 is one of Manitou’s best sellers. In order to keep it there and satisfy the growing demand for lowemission, site-compliant machinery, the OEM introduced its first 100% electric compact telehandler in 2022, the appropriately named MT 625e. Now it is fully available across key markets. The MT 625e combines zero emissions with the trusted build quality and performance Manitou is known for, redefining what a 6m telehandler can deliver on today’s low emission job sites.

The MT 625 had long been a best-seller thanks to its powerful yet compact design. The new MT 625e builds on that legacy, delivering the same 2.5t lifting capacity and 5.85m lift height. Whether operating indoors,

claims that the battery’s high useful capacity and long service life are among the best in its class. These features translate into benefits such as the MT 625e’s reduced operating costs and reliability in challenging conditions.

“...operators can achieve 25% charge in just one hour, or full charge in only four...”

Compared to its diesel equivalent, the MT 625e slashes maintenance costs up to 56%.

With fewer moving parts, no idling, and an integrated energy regeneration system, it’s a cost-efficient choice for contractors and

owner/operators looking to reduce downtime and improve their return on investment.

Despite its ultra-compact footprint, just 1.81m wide with a tight 3.31m turning radius, the MT 625e offers an impressive level of operator comfort. It features Manitou’s

intuitive Harmony display, JSM joystick, and a suite of smart safety systems, including seatbelt and charging alerts, operator presence detection and automatic parking brake with hill-start assist. There’s also an optional safety pack for risk awareness and operator feedback.

Like all Manitou telehandlers, the MT 625e is a true multi-tool carrier, compatible with a wide range of attachments from pallet forks and buckets to sweepers and big bag handlers, all easily interchangeable to suit the diverse needs of most sites.

As more contractors and site managers look to reduce emissions without sacrificing performance, the MT 625e offers a solution worthy of consideration: a compact, capable, and sustainable machine that meets the demands of the modern job site.

It comes as standard with a host of features including Perkins Stage V fuel efficient engine, hydraulic quick hitch, hydraulic adjustable forks, self levelling forks, electronic diff lock and reversing camera. If you fancy towing a telehandler to site, then JMAC has something right up your street.

Solihull-based J MAC is upgrading its popular JMT1500 telehandler. The compact, road towable machine gets a makeover for 2025 with a host of improvements. These include uprated hydraulic system, greater visibility, improved control system, additional safety features, improved towing equipment and a new lighting setup.

A new joystick allows operators to control the telescopic function directly with a button to give precise handling, while a power off switch has been added that allows a quick shutdown of the machine in case of emergencies. To enable work in low light conditions the company has upgraded the machines lights to improve visibility.

The machine, which is road registerable, has a 1.35 tonne lift capacity with a 4m reach and features four wheel drive.

Arnold Plant Hire has become the first UK rental company to invest in a fleet of JCB Teleskid machines - taking delivery of six 3TS-8W models in a landmark deal.

Supplied by Gunn JCB, the new machines are fully specified for the waste and recycling sector with factory-fitted guarding and heavy-duty solid tyres. The investment builds on the Stockport-based firm’s long-standing relationship with JCB, which includes operating the UK’s largest fleet of JCB Teletruks.

Director Stuart Hunter said: “We are delighted to add this innovative product to our existing range. The JCB Teleskid offers our customers the world’s safest and most versatile skid steer loader and makes a strong addition to our specialist machinery portfolio.”

The JCB Teleskid 3TS-8W is the only skid steer on the market with a telescopic boom, offering greater lift height, forward reach and dig depth than any other model in its class. A side-entry cab and single-arm Powerboom provide enhanced operator safety and visibility – key features for demanding waste environments.

Arnold Plant Hire operates a fleet of more than 500 machines and has over 30 years’ experience supplying equipment to the waste and recycling industry.

WWW.RDR.LINK/CBB022

Welsh rental company, RRC Crane Hire Ltd. has welcomed a new Liebherr LTM 1150-5.3 to its fleet.

Described as the jewel in its fleet, the all-terrain crane boasts impressive features and is said to be the perfect fiveaxle addition to the company's portfolio. It comes equipped with a 66m telescopic boom topped by a 10.8 to 19m double swingaway fly jib. A seven-metre insert can be added between the boom nose and the extension to take the hoist height to 92m and the maximum lifting radius to 72m. The lifting capabilities of the machine are greatly increased by VarioBase technology, which also improves the safety of the unit whilst in operation.

Furthermore, the crane has been taken with remote control, this concept allows for all superstructure function from outside the unit. Notably, the crane can carry 29 tonnes of its 45 tonnes of counterweight whilst travelling, obliging by the UK’s STGO regulations. Being able to carry over half its ballast enables the unit to complete the majority of jobs without the need for an additional vehicle.

RRC Crane Hire’s managing director, Ian Cross, commented: “The new LTM 1150-5.3 will be the perfect fit between our 100-tonne cranes and our LTM 1230-5.1. We would like to thank Steve Elliot and the Liebherr team for supporting us through the process. RRC Crane Hire now looks forward to the next Liebherr arrival in 2025.”

Based in Wrexham, RRC Crane Hire runs a fleet that includes road going pick and carry industrial cranes, city type, a selferecting mobile tower crane and all-terrain cranes ranging from two to six axles.

WWW.RDR.LINK/CBB023

One of the first new JCB 3CX Pro DualDrive backhoe loaders in Scotland is delivering time savings of up to 30% for road surfacing specialist, L B McRonald

The new model is used for pavement and road surfacing projects along with tarring, kerbing and concrete work.

Supplied by Scot JCB, the new machine benefits from DualDrive – JCB’s latest backhoe innovation which allows the operator to drive and reposition the machine while facing the excavator, without having to turn the seat to the front-facing position.

Owner operator, Derek McRonald, said: “I’ve operated a JCB 3CX for 33 years on road surfacing and kerbing tasks. I bought this latest model specifically for the DualDrive feature as I recognised it could bring major benefits to my work.

“When you are laying kerbing, you typically string out a line of kerbs and then return along that kerb track to concrete. With DualDrive I can reverse back and forth along the line without having to turn the seat around and remain looking at the work area throughout. This reduces the time spent on most of my jobs by 20-30%.

“The machine’s performance is perfect. There are lots of additional features on the new machine but it didn’t take me long to get up to speed with it. Visibility is excellent. Even in sunny and snowy conditions there’s no glare.”

L B McRonald is a family-run business which has been sub-contracted to road surfacing specialists Leiths Scotland Ltd for the last 30 years and is based near Aberdeen in North-East Scotland.

GOTO

WWW.RDR.LINK/CBB024

A Hyundai 30-tonne crawler excavator is the first machine to wear the striking new livery of Loughborough-based True Group. The business, with plant hire, grab lorry, aggregate supply, recycling, vehicle leasing and contracting divisions, is evolving from its original branding of True Plant Hire, to reflect the growing diversity of its operations across the region and nationwide.

The new crawler excavator is being put to work on the company’s new waste transfer station. With a storage capacity of up to 75,000-tonnes a year, the operation recycles more than 95% of the material that is taken in from sites across the region. The 30-tonne HX300A L has been equipped with a 2.5m wide Allu screening bucket, which will start the sorting process, as material is loaded into the mobile crusher in the waste facility. The machine will also be available through the plant hire fleet, where it will be offered with a range of attachments, including a hydraulic breaker.

The company first acquired a Hyundai excavator in 2018, adding a compact tailswing HX235A with a dozer blade to the fleet. The reliability and strong performance of that machine was a contributing factor in the purchase of the new HX300A L.

“The service that we get from our Hyundai dealer, Willowbrook Plant, is excellent,” said company founder and managing director Tom MacFarlane. “Plus, the deal that we were offered on the HX300A L was very good. Our previous experience with Hyundai machines is that they are bombproof, very reliable.”

GOTO

WWW.RDR.LINK/CBB025

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

Bedford-based ECL Civil Engineering is the proud owner of two new Bobcat T86 compact track loaders with matching GPS controlled grading attachments, having acquired the machines from Versatile Equipment Ltd, Bobcat’s dealer throughout the Southeast.

Talking about the new arrivals plant manager Steve Wright said: “At ECL, we see the Bobcat T86 compact track loader as a very effective compact dozer due to its optimised weight-to-horsepower ratio that makes it one of the most powerful and productive machines in its class. The T86 with super flow hydraulic capabilities allows for even more versatility and productivity as a tool carrier, working with a wider range of attachments across all applications in construction, landscaping, forestry and many other areas. As an illustration of this flexibility, we had one of the T86s supplied with forestry kit fitted by Versatile and we have that one running with the Bobcat FRC150 hi-flow forestry mulcher attachment.”

Phil Stoneham, area sales manager at Versatile added: “The in-line engine on the T86 increases reliability in high-intensity applications such as forestry work and to take advantage of this, one of the T86 loaders is equipped with a Bobcat forestry application kit, which is required when using the machine with a forestry mulcher. As part of the order, ECL has also purchased Bobcat 4-in-1 bucket, pallet fork and high tip bucket attachments.”

WWW.RDR.LINK/CBB026 GOTO

North West civil engineering contractor, Stockport-based Williams Construction, has invested in two of the first new JCB 145XR reduced tailswing excavators to roll off the production line.

The two 145XRs have been put to work on the construction of a new £108 million facility in Warrington for Novelis, a world leader in aluminium rolling and recycling.

Owner and managing director, Gareth Williams, commented: “We now have over 20 JCB machines including mini excavators, site dumpers, Loadall telescopic handlers and 140X and 220X excavator models. They are operator-friendly, reliable and fuel-efficient machines that are backed by the excellent service we get from the Gunn JCB team, whom we have been dealing with for three decades.

“As soon as I saw the 145XR I knew it would be an ideal fit for our operations. We already have the 140X which is a great machine. It’s a powerful and precise digger, it’s capable of fine grading work, it’s an excellent all-rounder, even handling a breaker with ease.

“The new models are suited to our contracts where space is at a premium including working in close proximity to concrete piles. The reduced tailswing will definitely make a difference on these jobs and reduce potential damage. Our machines are also often working closely with our lads on the ground and with the reduced size and great camera system, it should increase the safety aspect on site too.”

Williams Construction (Stockport) Ltd is a family-owned civil engineering and excavation contractor operating in the Stockport, Manchester and Cheshire areas. The company began with a single JCB 3CX Sitemaster backhoe loader 30 years ago, undertaking small, local contracts and now delivers multi-million-pound contracts for a range of large-scale clients.

WWW.RDR.LINK/CBB027 GOTO

Access rental specialist GT Access has continued to renew and grow its spider lift fleet by investing in six new Hinowa tracked spider booms.

It has recently taken three Hinowa Lightlift 17.75 Performance IIIS platforms and three Hinowa Lightlift 20.10 Performance IIIS models into its fleet. The move is in line with the company's strategy of providing its customers with only the best and most modern powered access rental options.

Billed as the market leading spider lift in the UK, investing in Hinowa platforms offers key advantages for rental specialists, according to GT Access sales director Steve Moody.

He explains: “The whole life cost of Hinowa platforms is less than their rivals because their resale value is so much higher. So, customers are very pleased to be able to hire quality platforms, and it’s a very sensible investment decision. That’s an important win-win for us.”

GT Access has had Hinowa spider lifts in its fleet since 2011, and currently offers four models: the Hinowa Goldlift 15.70; Hinowa Lightlift 17.75; Hinowa Lightlift 20.10; and the Hinowa Lightlift 26.14 Performance IIIS.

Linda Betts, key accounts director at Access Platform Sales, the UK and Ireland authorised dealer for all Hinowa machines, said: "We'd like to thank Steve and his team for continuing to put their trust in the Hinowa spider lift range.

Resale value and versatility appeal to rental company as it continues to invest in Hinowa. CPN reports.

“Hinowa works extremely hard to maintain and improve the performance standards that set its platforms apart. It means we’re confident GT Access will continue to realise the advantages that make them an excellent access rental investment choice.”

GT Access's new Hinowa Lightlift 17.75 spider booms have a maximum working height of 17.05m and a maximum horizontal outreach of 7.5m. For the Hinowa Lightlift 20.10, the working height is 20.1m and outreach 9.7m. Both platforms have a travel width of just 795mm and a travel height of 1996mm, so they can be tracked through narrow doorways, gates and archways, and along paths to otherwise difficult-to-reach worksites.

Once in place, their outriggers can be deployed and the platforms levelled ready to operate at the touch of one button. Afterwards, the outriggers can be raised, ready for tracking in the same way. Both also have unrestricted basket capacities of 230kg, which is appreciated by operatives, who know there are no weight limits at the outer limits of the working envelope, as there are with some rival platforms.

GT Access has selected bi-energy versions of the spider lifts, powered either by lowemissions diesel engines or by cabled 110v mains electricity.

“Our Hinowa spider lifts are very popular with maintenance contractors - for working on the exterior of buildings or in office and shopping centre atriums - and with tree surgeons, among many other customers,” continues Moody.

“They’re real working at height problem solvers. Whether that’s about tight access, unstable ground or sensitive flooring, or the need to work on complex structures. That’s what makes them so popular.”

This flexibility is enhanced by the ability of GT Access to deliver the Goldlift 15.70 and Lightlift 17.75 and 20.10 models to client sites on a lightweight trailer towed by a 4x4 car.

The Hinowa LL 15.70 platforms GT Access operate have a maximum working height of 15.4m and an outreach of 6.6m. While the Hinowa LL 26.14s have a maximum working height of 25.7m, with an outreach of 13.6m.

All the spider platforms share the same operating system, with the same unrestricted 230kg basket capacity, making it easy for customers to switch between platforms when different working heights are needed.

GT Access operates 13 depots across the Midlands, North West, London and the South East, South West and Wales. Its extensive hire fleet includes boom lifts, scissor lifts, push-around vertical lifts, truck mounts and its Hinowa spider lifts - as well as telehandlers and forklifts. For more information

With the launch ofthe all-new PC220LC-12 and PC220LCi-12 excavators, Komatsu says it has ‘successfully unified striking aesthetics, intuitive ergonomics, extreme fuel efficiency, ultralow emissions, effortless performance, revolutionary levels of digitalisation, and comprehensive safety measures into a single, truly exceptional operator-centric package.’

The PC220LC/LCi-12 is built on all-new powerful 129kW high torque Komatsu next generation engine, paired with a new high efficiency electronically controlled hydraulic system, translating to an 18% reduction in average fuel consumption, saving customers approximately 2.1l/h compared to the previous model. This means lower operating costs and a reduced environmental footprint with minimal CO2 emissions per tonne of material moved.

The new hydraulic system, combined with large-class hydraulic cylinders, and high-capacity hydraulic pumps, delivers 7% increase in arm and bucket forces, allowing for easier digging and material movement, ultimately reducing cost per tonne.

The advanced hydraulic system is said to provide razor-sharp reflexes and zerolag response to the operators’ input, creating an intuitive connection where the machine and driver become one.

Furthermore, the all-new P+ mode brings an 18% increase in productivity and 20% gain in fuel efficiency to offer substantial cost savings and improved output, ensuring an uncompromised return on investment.

Beyond intuitive ease of operation, the all-new cabin design takes operator comfort to new levels. A significantly

larger cab with 30% more legroom and an all-new premium seat option ensures operators can work in absolute comfort. 50% increase in lower right-hand side visibility, overhead cooling vents, joystick steering as standard, and numerous storage spaces, further contribute to an improved working environment.

Complementing these upgrades is advanced operator assist technology. A high definition, 8in touch-panel monitor, provides intuitive control and easy information access. Moreover, the machine features ultra-versatile, programmable super-ergonomic electronic control levers and fully customisable hydraulic settings that together allow operators to tailor the machine to their specific needs.

Thanks to the operator ID system, that stores up to 50 profiles, operators are recognised via electronic key or typed ID, and their personalised settings automatically loaded. On top of that, advanced technologies include an integrated payload meter, integrated 2D machine control designed for simple depth and slope grading, and 2D virtual safety wall, all provided as standard on PC220LC-12.

The PC220LCi-12 comes with next generation iMC 3.0 features that are compatible with tilt-rotator. iMC 3.0 offers advanced features such as 3D boundary control and automated steer-to-line. Moving towards autonomous operation, iMC 3.0 introduces auto swing, enabling semi-automatic truck loading. Features such as swing-to-line and travel-along-line functionalities further simplifiy trenching operations for operators of any skill level.

The new 10in iMC 3.0 monitor, with intuitive 3D graphics, is the latest in driver assist technology. With Smart Construction remote included as standard, customers can easily transfer design files remotely and trouble-shoot by taking over the screen, eliminating unnecessary site visits.

The PC220LCi-12 features an advanced payload meter, optimising loads and preventing overloading.For PC220LC-12 owners, these features are accessible via a factory-made upgrade. This comprehensive kit provides a straightforward pathway to integrate the full suite of iMC 3.0 features, keeping the machine up to date with the latest technology.

The demise of the backhoe loader is often put down to the inconvenience of switching position to either load or dig. It took time, was a bit of a physical hassle and cut into the day’s work.

Now Mecalac claims to have addressed the issue with the launch of its Revo990. The manufacturer believes it has revolutionized the operator experience with a rotating cab, eliminating the hassle and providing a seamless way of working.

The Revo990 functions as a high-reach excavator and a powerful loader, moving easily between the two functions in just a few seconds. At the core of its design is a commitment to operator comfort, exemplified by the innovative one-touch seamless cab rotation. This handy feature enables operators to maintain optimal posture when swinging from one function to the other, significantly minimizing the risk of back and neck strain caused by uncomfortable twisting.

The backhoe’s rotating cab offers an unparalleled view of the jobsite and ongoing operations. Unlike traditional models with limited two-way visibility, the Revo990 provides almost infinite cab positioning, allowing for clear sightlines in every direction. This enhanced visibility lets operators work more efficiently and stay focused on the task at hand.

While digging trenches, the Revo990 lets operators reposition the machine to continue digging further along the trench without having to stop to turn the seat and switch to loader mode or to push themselves forward awkwardly with the backhoe. All driving controls remain within reach whatever the mode, streamlining movement and eliminating interruptions. It is even possible to manoeuvre with the cab swung at a 90˚ angle, making it suitable for tasks alongside roads, such as ditch cleaning.

FOR MORE INFORMATION, PLEASE WWW.RDR.LINK/CBB030 GOTO

Bobcat ............................(page 36, Outside back cover)

www.rdr.link/CBB100

Manitou ..............................(Inside front cover, page 25)

www.rdr.link/CBB101

Plant parts ........................................................(page 16)

www.rdr.link/CBB102

Liebherr-Great Britain Ltd ..................................(page 4)

www.rdr.link/CBB103

Hyundai Construction Equipment Europe ........(page 22)

www.rdr.link/CBB104

Takeuchi MFG (UK) Ltd ......................................(page 9) www.rdr.link/CBB105

Witham Group ..................................................(page 11)

www.rdr.link/CBB106