MAY/JUNE 2023

LOCALAUTHORITY BUILDING& MAINTENANCE

HOUSING & REGENERATION

TECHNOLOGY IN CONSTRUCTION

ROAD TO ZERO CARBON FIRE PROTECTION & SECURITY

HOUSING 2023

We preview the biggest event on the housing calendar

EMBRACING NEW TECHNOLOGY

Wates Residential’s Geraint Sewell talks to LABM about the challenges surrounding housing decarbonisation and how innovative new technologies can help decrease construction and post-occupancy emissions

THE LEADING MAGAZINE FOR LOCAL AUTHORITY AND HOUSING ASSOCIATION SPECIFIERS

LABMONLINE.CO.UK

CoNTENTS

reguLarS

5 comment

Work of Art

6 news

VIVID secures £100m facility — Golding Homes adopts Sustainability Reporting Standard — Changeworks publishes research into fuel poverty in rural Scotland

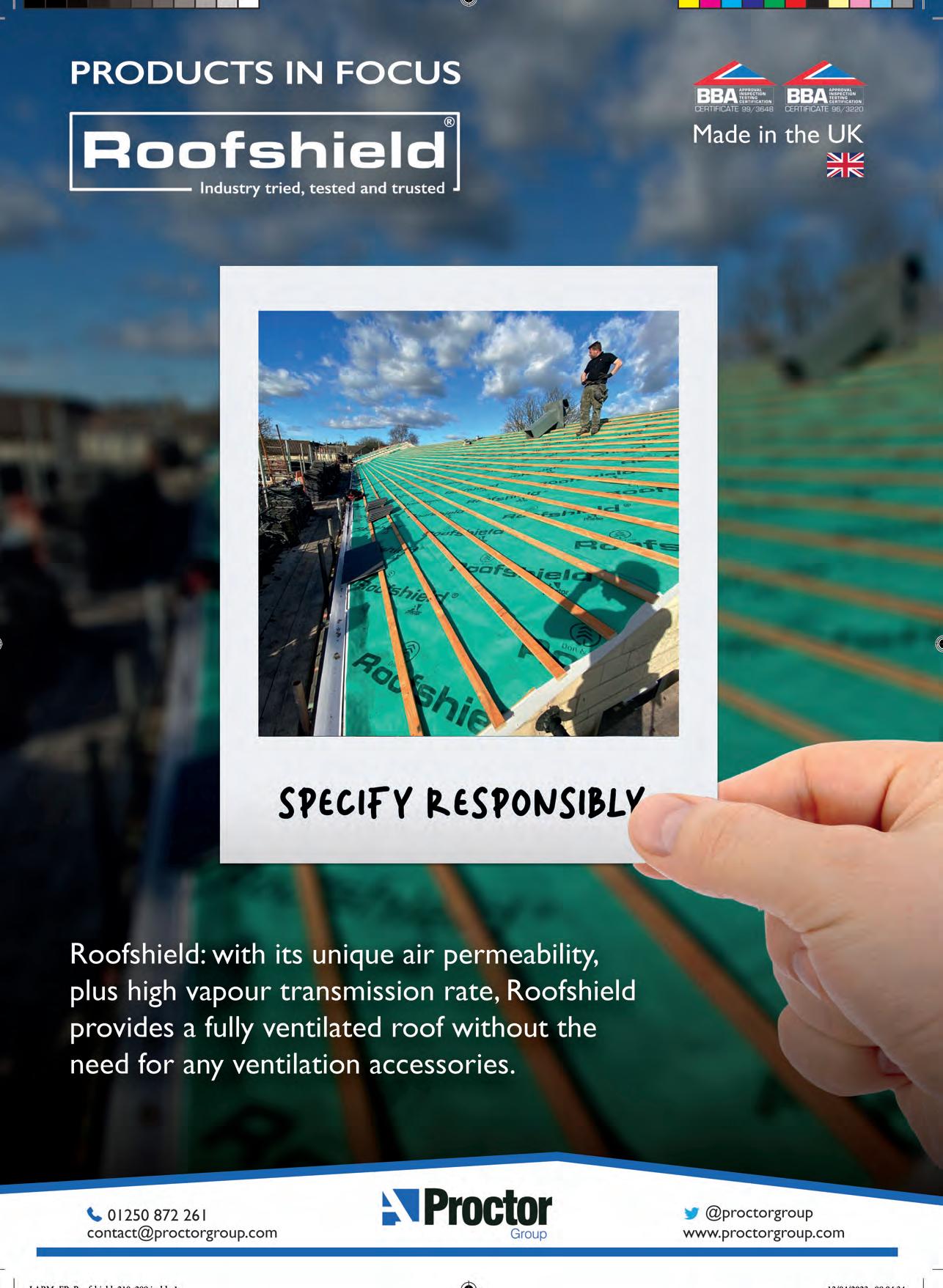

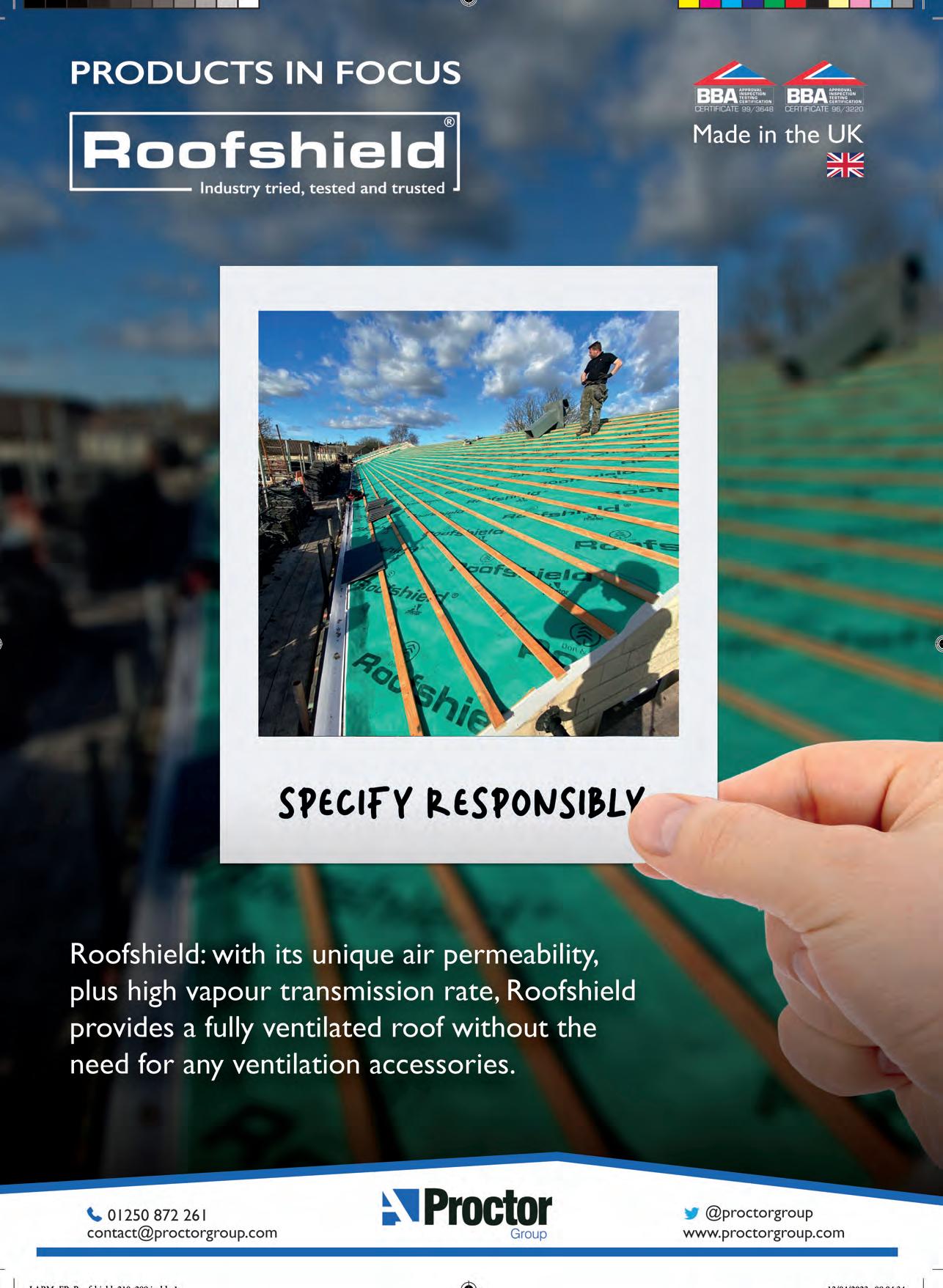

7 thermal Performance insights with a. Proctor group

Advice on improving the thermal performance of existing homes

8 Project update

North Lanarkshire Council’s Holehills

Regeneration — Bromford’s biggest-ever land led site — Karbon Homes’ Ponteland retirement living scheme

10 industry comment

Matthew Warburton, Policy Advisor at the Association of Retained Council Housing (ARCH) looks at the new Tenant Satisfaction Measures

12 Housing Fit for the Future

Nigel Sedman, Executive Director of Homes at ForHousing, discusses the importance of working in partnership

14 View from the Supply chain

John Mellor from Glidevale Protect highlights the need for greater data transparency in construction

15 under Warranty

Global Home Warranties tackles the issue of quality control in new homes

advice for local authorities and housing associations on improving the energy efficiency of existing homes

HouSing & regeneration

24 building a concrete Future

The specification of concrete bricks for New Gorbals Housing Association’s North Gate Development in Glasgow

27 digital transition

The role of technology in improving health and care in social housing

30 easing the Pressure

Why choosing electric showers can help ease financial pressures for property owners and occupants

33 From one Home to every Home

Improving the energy efficiency and environmental performance of existing social housing

35 round-up

tecHnoLogy

37 embracing new techology

Working with supply chain partners to embrace new technologies and decrease emissions during new home construction and throughout a property’s lifetime.

39 round-up

43 Low carbon construction with Structural timber

The STA tells LABM why it believes structural timber presents the greatest opportunity for low carbon construction

46 rising to the challenge

Frameworx addresses the challenges and opportunities surrounding the decarbonisation of existing housing stock

48 round-up

50 new building and Fire Safety Framework

A guide to the new framework launched by Pretium Frameworks and the Hyde Group

53 breaking point

The safety risks surrounding the use of monolithic glass in high-rise residential buildings and an alternative solution

56 round-up

How new tech can help deliver net zero

40 award Winning Performance

CIBSE discusses Swansea Council and the Welsh School of Architecture’s award winning project to energy-efficiently retrofit to six bungalows

new framework for housing providers

MAY/JUNE 2023LABM I 3

in

conStruction

|50

|37

|33

May/June 2023 Vol.39 No.3

to Zero carbon

Protection & Security

road

Fire

Editor

Claire Clutten labm@hamerville.co.uk

Advertisement Manager

Jacob Tatum jtatum@hamerville.co.uk

Group Advertising Manager

Craig Jowsey

Digital Manager

Jasmine smith Jsmith@hamerville.co.uk

Digital Assistants

david molloy

Toby Richardson

Design

Adeel Qadri

Group Production Manager

Carol Padgett

Circulation Manager

Kirstie day

Printed by WALsTEAd RoCHE

Published by Hamerville media Group Regal House, Regal Way, Watford, Herts Wd24 4YF 01923 237799

Email: labm@hamerville.co.uk

Work of a rt

Public art has a vital role to play in connecting people to places, especially on new developments, helping to promote thriving communities and create a sense of identity. so it was a real privilege to be asked to be part of the judging panel for this year’s Blunden Prize public art competition, run by housing association, stonewater.

stonewater has been commissioning local artists to deliver public art pieces for its new developments for a decade now. in 2021, the housing association launched the Blunden Prize national competition as a retirement gift for former stonewater Chair, George Blunden, who believed passionately that ‘homes are more than bricks and mortar’, and that the area around people’s homes ‘should impress not depress’.

The brief for this year’s competition was to design a concept for an art installation within a set budget for the housing association’s new Calverley Lane scheme in Horsforth, Leeds. When complete, the development will provide 152 new affordable homes on the site of the former Leeds City College campus, close to the Rodley nature Reserve and the high street in Horsforth.

encourage people to the visit area? The last thing anyone wants to do is deliver something that no one understands. For stonewater, the extent to which the artist considered engagement with the local community to influence their final design was also important. over 50 entries were received and whittled down to a shortlist of just eight. i was invited to stonewater’s offices in Reading for the day to join fellow judges stonewater Chairman sheila Collins, CEo nicholas Harris, and Chief Growth & development officer Jonathan Layzell in interviewing the final eight.

© 2023

subscriptions to LABm are available at the following rates: UK: 1 year — £30.00 post paid Europe and Overseas: 1 year — £50.00 post paid

Airmail: 1 year — £65.00 post paid

11,374 (1 July 2021 — 30 June 2022)

To be removed from LABM’s circulation please call 01923 237799 or email: circulation@hamerville.co.uk

Prospective artists were tasked with designing an art installation that reflected the local area and vernacular, with a nod to the new development in some way. sustainability is hugely important to stonewater; all their new developments embrace low carbon technology, are designed with energy efficiency in mind and include provisions for green space. so it was essential that the artists’ factor this into their choice of materials, taking into account the use of local materials, ethical sourcing and environmental impact for example. The winning piece of art will need to stand the test of time too, so durability and resilience were also essential ingredients.

Will the art installation create a striking visual impact and sense of identity? Will it resonate with the local community, create a focal point and leave a positive lasting impression? Will it

COVER STORY:

it was an incredibly tough job. The variety and quality of the shortlisted entries was impressive, clearly a great deal of time, thought and effort had gone into the submissions. The level of research some had done into the local area and its rich history particularly impressed me, especially how they managed to translate that into the designs. Using art to foster and reinforce a sense of community and belonging can be incredibly powerful, and this was also reflected in the designs.

The competition provides a fantastic opportunity for local artists to be a part of something extremely positive and enduring. i’d like to say a big thank you to the artists for sharing their wonderful ideas with us, and also to stonewater and see media for inviting me to be on the judging panel, it was a great experience. After much deliberation, the finalists were chosen and all that remains is for a winner to be announced at an event in the summer. Watch this space.

Wates Residential is working with Cardiff Council to deliver the Cardiff Living development programme, which will to provide 1,500 new homes across the city over 10-years. Turn to page 37 to find out more about the development programme and how working with supply chain partners to embrace new technologies can help reduce emissions.

mAY/JUnE 2023LABm i 5

EdiToR’s CommEnT

LABMONLINE.CO. EMBRACING TECHNOLOGY Residential’s raint Sewell to LAB the challenges surrounding housing decarb and how new technologies can decrease construction and post-occupancy emissions MAY/JUNE 2023 LOCALAUTHORITY BUILDING& MAINTENANCE 2023 We preview the biggest event on the housing calendar

“ Using art to foster and reinforce a sense of community and belonging can be incredibly powerful… ”

Atkins to deliver masterplan for Homes England’s Rugby scheme

VIVID secures £100m facility

Affordable homes provider VIVID is continuing to use its ESG credentials to attract investment, this time announcing a new £100m Sustainability Linked Facility from ABN AMRO. Access to this funding and facility supports VIVID’s objective to build and develop more energy-efficient, affordable homes. The facility is unsecured and has metrics linked to the organisation’s environmental, social and governance (ESG) work, helping incentivise a positive impact for the organisation’s customers and communities. The new facility was announced three months after VIVID secured the sector’s first green loan.

Golding Homes adopts Sustainability Reporting Standard

Maidstone based local housing provider, Golding Homes, has adopted the Sustainability Reporting Standard (SRS) for Social Housing, a voluntary reporting framework that takes account of the work the organisation is doing to address its impact on the environment.

David Hart, Director of Finance and Procurement at Golding says: “Adopting SRS is a natural progression for us in our desire to make Golding greener and we’re delighted to take this step forward. Last year we produced our first ever Environmental, Social and Governance Report setting out our commitment to reducing any negative impact of our work on the environment. Our new Environmental Sustainability Strategy builds on this. The SRS framework covers 48 ESG criteria and will support us to focus on affordability, carbon emissions and energy efficiency, safety, equality, diversity and inclusion and the customer voice.”

The scheme will make a significant contribution to meeting housing needs, including affordable housing, in the area, while also providing new schools, healthcare, retail provision, green areas, community spaces and infrastructure improvements for the wider community.

The engineering and design consultancy, working with supply chain partners LDA Design and Levitt Bernstein, has been appointed as masterplanner and multi-discipline designer for Homes England’s portion of the 4,000 homes that remain to be delivered as part of the South West Rugby Urban Extension.

Alongside this, sustainability and biodiversity net gain are embedded in the approach as Atkins will ensure the environment plays a key role in benefiting communities, whilst minimising the impact on nature.

Joanne Farrar, Project Director for Atkins, says: “This is a hugely significant development that will help to meet the real need for housing in this part of the West Midlands. But this is about more

than simply building houses to meet the acute demand. This project and the physical and social infrastructure that it will deliver will create truly thriving places based on safe and secure homes, producing better social value outcomes. It also represents a priority development with a clear focus on creating a sustainable community where people can live, work and play for generations.”

Ben Frodsham, Senior Planning and Enabling Manager for Homes England adds: “Atkins has been providing services for Homes England for many years and has a strong track record of delivery both nationally and in the Midlands region.

“The team was able to demonstrate a joined-up and efficient approach to the scheme, bringing some trusted supply chain partners in to add additional value including LDA Design and Levitt Bernstein.

“We have great confidence they will deliver what is needed to support Homes England in the delivery of a vibrant, sustainable and successful new community in South West Rugby.”

IN BRIEF NEWS

Atkins, part of the SNC-Lavalin Group, is set to deliver planning and design services for a major urban extension in the West Midlands.

CGI from LDA Design

Fuel poverty in rural Scotland

The impact of far higher levels of fuel poverty on the physical and mental health of people living in rural areas of Scotland is outlined in new research published by Changeworks.

Comparing three regions — Caithness and Sutherland, Highlands and Islands and remote rural areas — the analysis shows not only that fuel poverty affects proportionately more households in these areas compared to the rest of Scotland, but that the depth of fuel poverty is worse.

Interviewed for the report, people with lived experience of fuel poverty and frontline advisors told researchers that the far higher levels of fuel poverty have clear impacts on individuals, often resulting in poorer health and social isolation.

Commissioned by the Rural & Islands Housing Associations Forum (RIHAF), the Highlands & Islands Housing Associations Affordable Warmth group (HIHAAW) and Highlands and Islands Enterprise (HIE), the report sets out the drivers, impacts and extent of fuel poverty in rural Scotland.

The report also outlines clear solutions that the Scottish and UK Governments and Ofgem can take to alleviate the issue. This includes improving the identification of those with enhanced heating needs, broadening the eligibility of existing support, delivering more support on the ground through community anchor organisations and wider reforms of the energy market.

More details on the research here www.rdr.link/lak001

A copy of the full report is available to download here www.rdr.link/lak002

A copy of the solutions paper is available to download here www.rdr.link/lak003

Thermal Performance Insights with

Increasingly within the housing sector, there is recognition of the urgent need to improve the energy efficiency of our existing housing stock. In doing so, strategies for retrofitting existing buildings are of crucial importance. Equally, preserving the lifecycle of buildings is a priority, more than ever due to the rising energy costs.

The objective is securing the future of our ageing housing stock by providing warm, damp/mould-free living space. When considering the insulation of buildings, we refer to U-values, which quantify the rate of heat loss through a building element such as walls, roof, windows, and doors. The lower the U-value, the slower the heat generated by the heating system will escape, and less energy input is required to maintain a comfortable internal temperature.

Where thermal performance is poor, this has a significant impact when occupants are in fuel poverty or belong to a vulnerable social group such as the elderly. This can lead to health problems for these groups, so upgrading such homes is a priority.

With improved performance in mind, the A. Proctor Group developed Spacetherm WL, a high-performance laminate specifically intended for use where internal space is limited. Spacetherm WL is fixed to the internal surfaces of existing walls without the need for mechanical fixings. Consisting of a Spacetherm aerogel insulation blanket bonded to 3mm Magnesium Board (MgO), at just 13mm thick, there is often no need to remove skirting boards and cornices, saving time and cost. For example, a typical solid wall will have a U-value of around 2.1 W/m2K, and after installing Spacetherm WL, this can be reduced to around 0.8W/m2K, dependent on the wall structure.

This makes Spacetherm ideal for use in rooms with limited floor area, at door and window reveals, and in other areas where retaining existing features would otherwise limit the use of thick and bulky insulation. The thermal conductivity of Spacetherm, at 0.015 – 0.0195W/m2K, makes it among the best thermal insulants in use today, combined with its high vapour permeability, making it ideal for refurbishments.

MAY/JUNE2023 LABM I 7 n More information on Spacetherm here: www.proctorgroup.com/products/spacetherm

John Johnston, Sales Director at A. Proctor Group, addresses the thermal performance of existing housing stock.

New solar batteries will help North Lanarkshire Council tackle fuel poverty

That is the view of Arc-Tech (Scotland) Managing Director, john Gallacher, whose company is responsible for the installation of north Lanarkshire Council’s first solar battery storage units at the Holehills Regeneration in Airdrie.

Located on Dykehead Road northeast of the town centre, 150 two- and threebedroom homes for social rent are replacing a series of multi-storey flatted blocks as part of the Council’s target to build 5,000 new homes across the local authority region by 2035.

Of the 150 homes, 19 are being delivered to a piloted net zero carbon standard of build that has been developed by main contractor, CCG (Scotland), with the support of Arc-Tech who specialise in the delivery of Mechanical & electrical (M&e) services and the design and installation of renewable energy systems. each net zero home has its own battery storage unit; known as the ‘Powerwall’, it is

supplied by the world-renowned car-maker and clean energy company, Tesla.

The battery links to solar PV panels installed on the roof, which capture energy from the sun during daylight hours. under normal circumstances, the occupier will only benefit if the energy is used at the time of generation, however, if it is not, the energy is exported to the national Grid.

Rather than losing out on energy being lost, the battery retains energy for later use, even during a power outage, which allows the occupier to benefit from variable tariffs during the evening.

The combination of the renewable energy system and the enhanced built form delivers a minimum energy Performance Rating of 104 (A) — the average rating in Scotland is 61 (D) — representing significant betterment for the occupier and the environment.

john Gallacher, Arc-Tech (Scotland) Managing Director, says: “Arc-Tech is one of the few companies that are certified to

install these hugely innovative solar battery storage units, alongside eV connector points, on behalf of Tesla in Scotland. It is an exciting time for renewable tech; the system in place here is incredibly intuitive and, when combined with excellent fabric performance characteristics, it will go a long way to supporting residents during this prevailing cost-of-living crisis.”

Dykehead Road is supported by a grant funding contribution of £9.7m from the Scottish Government and is due for completion later this year.

north Lanarkshire Council, Housing Convener, Councillor Heather BrannanMcVey, adds: “I’m delighted to see our first net zero homes available for tenants here in north Lanarkshire. These homes reaffirm our commitment to embracing and investing in new technology that improves energy efficiency and comforts for our tenants, reduces emissions and consumption while minimising fuel poverty.”

PROjeCT uPDATe neWS:

8 I LABM MAy/june2023

Solar batteries installed at a new affordable housing development in North Lanarkshire are seen as a major step forward to tackling fuel poverty and climate change.

Bromford secures planning permission

Housing association Bromford has secured planning permission for its biggest-ever land led site in Gloucestershire. Tewkesbury Borough Council finalised its approval for the construction of 100 new homes at Bromford’s 16.8 acre site at Delavale Road in Winchcombe.

The development will comprise 50 affordable homes for rent and shared ownership, and 50 homes for outright sale. Homes will range in size from one-bedroom flats to five-bedroom houses, some of which will have dedicated home office space to encourage flexible working. A number of new trees will be planted across the site, which also includes a play area, while a new pedestrian and cycle link will be created to link the new homes to nearby Mercia Road.

Matt Batham, Head of Pre-Construction at Bromford says: “By providing 50% affordable housing on the site, this development will give more local people the opportunity to stay living in the area who otherwise couldn’t afford to live in the town. This is the biggest site we have purchased so far and forms part of our strategy of increasing the amount of land we buy and develop ourselves.”

Energy-efficient retirement living scheme

Good progress is being made on the development of a new energy-efficient retirement living scheme in the Northumberland village of Ponteland.Karbon Homes’ £5.5m ‘Athol House’ scheme on Callerton Lane will provide 34, much-needed affordable apartments for over 55s, with one- and two-bed homes available for a mix of affordable rent and shared ownership.

The scheme is being constructed by EQUANS and will benefit from a communal green heating system, powered by commercial air source heat pumps, which will supply the communal areas of the scheme and each apartment with underfloor heating and hot water.

Zoey Hawthorne, Assistant Director of Development Delivery at Karbon Homes, says: “We’re delighted to bring these much-needed apartments to Ponteland and have worked hard to create a scheme which meets the needs of the local community. We’re particularly excited about the inclusion of a low carbon heating system, which will not only help residents save money on their energy bills but will also significantly reduce carbon emissions produced by the scheme.”

Pictured from left to right: Gary Hall from EQUANS, Sara Armstrong from Karbon Homes, Louise Buckton from EQUANS and Shaun Sinclair from Hall and Partners

Pictured from left to right: Gary Hall from EQUANS, Sara Armstrong from Karbon Homes, Louise Buckton from EQUANS and Shaun Sinclair from Hall and Partners

Tenant Satisfaction Measures — the challenge ahead

Matthew Warburton, Policy Adviser at the Association of Retained Council Housing (ARCH), discusses the new tenant satisfaction measures, which are being introduced by The Regulator of Social Housing as part of a new system for assessing how well social landlords in England are performing.

The requirement on social landlords to collect information for the new tenant satisfaction measures (TSMs) came into effect from 1st April. For some of the TSMs, this means landlords should already be collecting the relevant information, for example, on the number of repairs carried out within target times, or the number of complaints received.

For the 12 TSMs to be collected from tenant participation surveys, the task is to commission and schedule appropriate surveys at some point during 2023/24 and arrange to repeat them annually. But for other indicators, including arguably the six most challenging, 31st March 2024 has become an unyielding deadline that is likely furrowing brows and keeping managers awake at night — or ought to be — in many councils and housing associations just now.

The six TSMs in question are RP01 — the number of homes that do not meet the Decent Homes Standard, and the five BS indicators that relate to the percentage of gas, fire, asbestos, water and lift safety checks carried out. These are the most challenging indicators because for each of them there is only one score that can be reported to the Regulator next year without fear of regulatory comeback, and that is 0 for RP01 and 100% for the other five.

Which is not to suggest that landlords don’t have to worry about regulatory comeback until summer 2024. Until the Social Housing (Regulation) Bill is enacted and comes into force, the Regulator’s powers to enforce the Consumer Standards, including the Homes Standard to which all these indicators currently relate — are limited to cases where there is a risk of, or actual, severe harm to tenants. But precisely because the BS indicators relate to key safety checks there can be a strong presumption of a risk of serious harm if they have not been carried out.

Decency criteria

On decent homes, landlords might be able to justify reporting homes that do not comply with the decency criteria requiring a reasonable state of repair, reasonably modern facilities or a reasonable degree of thermal comfort, especially if they can show budgeted plans to improve them in the near future. But no excuses are likely to be accepted for the continuing existence of serious (category 1) hazards as defined in the Housing Health and Safety Rating system.

Recent action by both DLUHC and the Regulator in relation to damp and mould has demonstrated both that the issue is, rightly, judged of high priority and high enough risk to meet the serious detriment

test and justify action under current legislation. It should not be forgotten that the same principles apply to any other category 1 hazard found to exist in the social housing stock.

Matters are made more complicated by the fact that the Government has just renewed its efforts to complete its review of the Decent Homes Standard, which will need to reflect an updated version of the HHSRS, which has also been subject to review. Early decisions on the new Standard are needed so landlords planning to update their stock condition surveys during the year can be sure they will be collecting the right information.

INDUSTRY COMMENT IN ASSOCIATION WITH

www.arch-housing.org.uk

n

10 ILABM MAY/JUNE2023

“ These are the most challenging indicators because for each of them there is only one score that can be reported to the Regulator next year without fear of regulatory comeback... ”

Strength in numbers

Form lasting partnerships to build more, truly affordable homes, recommends Nigel Sedman, Executive Director of Homes at ForHousing.

With housing waiting lists

groaning, building new homes is essential. In fact, research from housing charity Shelter earlier this year reveals 1.2 million households are stuck on social housing waiting lists. That’s up by 5% in the last two years.

The social housing sector’s role in tackling the housing crisis is crucial. Throughout my career at ForHousing, I have overseen the development of thousands of high-quality homes. This year marks a decade of developing homes in Salford and across the North West. Since 2013, we have either built or have on-site 1,900 new homes — 70% of which are offered at a social or affordable rent. We understand that having a safe place to call home increases people’s life chances. That’s why we have 1,330 more homes in the pipeline.

Leading role

None of this would be possible without partnering with like-minded organisations, charities, and national, regional and local government. The Chancellor’s recent announcement that the Greater Manchester Combined Authority (GMCA) will have greater control over funding and building affordable housing, is good news. It provides an opportunity for us to step up our partnership working across the region to build much-needed homes, and we look forward to playing our part.

In Salford, ForHousing’s role leading the new development element of the Salford Strategic Housing Partnership means I see first-hand how working in partnership makes

more things possible. Collaborating closely with Salford City Council means we can regenerate disused council land. We have done this many times over the years, for example Amblecote Gardens, an extra-care scheme in Salford launched in 2014.

As with every extra-care scheme we develop, we worked closely with the council to align the project with their older person’s strategy. The transformation of the wider Amblecote neighbourhood had already been underway with 100 new family homes, but the completion of Amblecote Gardens was the icing on the cake. By working together we provided new amenities including shops, a library, GP services, a pharmacy, and hairdressers — benefitting not just new tenants but local residents too, helping create a vibrant community.

Working together

The Willows in Weaste, completed in 2017, is another flagship development from the past decade. It provided more than 100 new affordable homes on the former Salford Red Devils rugby ground.

We are now doing something similar with the former Salford City Roosters grounds. By working together with the club and the council, we are ensuring that the Roosters retain a smaller site and will benefit from better facilities, while providing almost 50 eco-friendly social rent homes.

Partnerships also mean strength in numbers when it comes to funding bids. Thanks to working closely with Salford City Council, we have successfully secured funding for specialist housing schemes, for

example, to tackle homelessness.

Sometimes partnerships are a requirement. For Homes England grant bids, we frequently work with local authorities to make sure our proposals include the necessary variety of homes. It strengthens our application and means we can deliver homes the local area really needs. For instance, we secured over £1m in Homes England funding with Cheshire West and Chester Council to build almost 140 mixedtenure homes in Wharton Green, Winsford.

And when it comes to planning permission, we all know linking with partners is crucial. Getting pre-planning advice and feedback from the council is invaluable, while continuing to meet with local residents and tenants to hear what they want means we create sustainable communities that stand the test of time.

Looking ahead, we know partnership working can be the catalyst to drive forward opportunities for new housing schemes that meet a range of needs. It’s tougher than ever for people to afford quality housing that gives them the best possible chance in life. But everyone deserves that chance. That’s why our focus for the next 10 years is on developing homes for social rent and making more things possible for more people.

n For more information on ForHousing visit www.forhousing.co.uk

HOUSING FIT FOR THE FUTURE

Amblecote Gardens extra-care scheme in Salford

12 I LABM MAY/JUNE2023

Data transparency in construction

With the Building Safety Act and Future Homes Standard on the horizon, along with the golden thread of information, manufacturers have a critical role to play in ensuring a safe and sustainable specification process, and data transparency is a way to provide added reassurance to clients. As John Mellor from Glidevale Protect suggests, this is a responsibility that must be shared by each member of the supply chain.

Successful construction projects are built on data. With hundreds of different manufacturers both in the UK and overseas, potentially involved in any given construction project, understanding the provenance of each material specified is complex and challenging.

Clarity: Honesty is the best policy

A lack of data transparency during construction can effectively widen the ‘performance gap’ of a building, so it follows that by sharing accurate information at every stage we can ensure that buildings are as energy-efficient in operation as they were designed to be.

With specifiers relying on the information manufacturers like ourselves release to them, it’s crucial to be upfront and honest about test results and the specific testing conditions employed to enable specifiers to make an informed decision. Transparent technical claims can have an impact on whether a product will pass or fail in situ which could affect everything from the energy efficiency to the safety of a building.

Compliance is not just about individual products in isolation but needs to factor in the entire system, including any related products or product variations. For example, reflective wall membranes should be tested to the required thermal and emissivity performance standards, claiming both aged and unaged thermal resistance ‘R’ value figures in order to help a specifier make an informed

decision about performance in a worstcase scenario.

Glidevale Protect provides both aged and unaged thermal resistance values on our external and internal reflective membranes to demonstrate transparency and highlight any difference in performance levels. Aged thermal resistance values accurately reflect real life performance figures, take into account any logo that is printed on the low-emissivity surface and are based on the recommended fixing centres as detailed in the Structural Timber Association’s (STA) Advice Note 18 for external wall breather membranes.

Reliability: Get a second opinion from a third party

Providing reliable and substantiated technical information that is fully supported by trusted third-party accreditations gives added creditability to any claims being made as all performance results are independently checked and verified. This process offers specifiers a clearer view of how the products can help achieve compliance as part of the building as a whole.

It is also good practice for all manufacturers to clarify and verify technical data. Relying on UKAS accredited certification bodies such as BM TRADA is one of the best ways to guarantee compliance.

Specifiers can also look out for manufacturers like Glidevale Protect who

are working to recognised standards such as ISO 9001 and ISO 14001, which are international standards that demonstrate a company’s ability to consistently provide products and services that meet customer, regulatory and environmental requirements.

Accessibility: Make sure data is readily available

It goes without saying that any product data should be made readily available and in an accessible format for all key stakeholders from architects to installers and end clients. We’re all working towards the same goal — to create healthy, sustainable buildings — and this relies on being open, collaborative and sharing data.

We’re continually reviewing our product information and installation guides, which are all freely available to download from our website along with digital BIM objects for many of our products, and all our specifications are written to be comprehensive and clear so that nothing gets lost in translation.

When it comes to data transparency, the supply chain is only as strong as the weakest link so it’s up to manufacturers to make sure they’re playing their part.

n To access Glidevale Protect’s product information or to discuss how the technical team can assist you with your next project, please visit https://glidevaleprotect.com/technicalresources/

14 ILABMMAy/jUNe2023

The Protect TF200 Thermo & VC Foil Ultra construction membranes from Glidevale Protect being installed on a project. Image ©Matthew Nichol Photography

The Protect Thermo Extreme membranes from Glidevale Protect were specified for a One Manchester housing project

FROM THE SUPPLY CHAIN

VIEW

UNDER WARRANTY in association with

Quality control

Affordable quality homes for housing associations — there is a solution, says Global Home Warranties.

It is an inconvenient truth, but some developers do not like to build affordable homes. Many claim they will suffer from significantly reduced profit margins — taking their earnings below 20% — and this is the prime excuse given at the planning stage to try and avoid the issue, according to Global Home Warranties, but, says the company — it does not have to be like that.

Most developers do not have a choice and planners will insist that they will have to include some element of affordable properties into the mix, but with the pressure on margins it is inevitable that some will cut corners and deliver poor quality. This in turn can put even more of a strain on margins — a situation, claims Global that could be avoided by getting it right first time.

Current planning conditions state that developers building between five and nine homes must ensure 20% of them are affordable — more than nine, and then this figure rises to 30%. That figure can further rise to 40% for greenfield sites.

Recurring issues

Global, who partner closely with many of the country’s housing associations to provide a robust inspection and risk management process on site, are seeing many recurring issues in new-build affordable homes, such as faults in bay windows and sunrooms, issues with workmanship on cold bridging affecting

energy efficiency, lead flashing problems on chimneys and lead tray installations incorrectly installed.

“It is also common for us to note dirty cavities and ties along with a host of other problems, which mainly seem to be associated with affordable homes,” says Maurice Johnston, Managing Surveyor at Global Home Warranties. “We do not see anything like the same issues in quite the same number on more conventional houses.

“It is clear that developers are trying to cut costs when building affordable properties and this is understandable when margins are under attack, but at some stage they will have to go back and correct those problems, putting even more pressure on those margins. They would be better to work more closely with us, and our housing association partners, to get it right first time.”

Global work with clients before ground is broken, acting as another level of quality control. This works extremely well for developers helping to keep costs down, with Global able to inspect every new home on site throughout the build process with the same rigorous standards whether it is classified as affordable or otherwise.

At the end of the build process, the company provides a comprehensive latent defects warranty supported by an ‘A’ Rated insurer, but more importantly it is giving the developer, the housing association and the end customer, total peace of mind and the confidence that

the home has been delivered to the highest standard.

Tackling housing defects

According to a recent House of Commons report, there is growing evidence of more and more owners of newly built homes struggling to achieve satisfactory resolution when defects are reported to builders. This confirms the findings of an earlier survey by the Charity Shelter, which revealed that, of the 241 English respondents that had bought a new house in the past 10 years, some 51% had experienced major problems as a direct result of the initial construction.

If these issues are not rectified, tenants and housing associations will continue to complain about quality, builders and developers will in turn rack up even more costs as they try to put right all of the problems adding even further pressure on margins, planning applications will be held up and the cycle will carry on — but it does not have to be like that.

Global is taking a proactive step in helping developers to solve these problems with its new Clerk of Works offering. Being on site on a weekly basis to monitor progress and workmanship will inevitably help to control costs.

n More information on Global Home Warranties and its services here www.globalhomewarranties.com

MAY/JUNE2023 LABM I 15

Maurice Johnston, Managing Surveyor at Global Home Warranties

Network and innovate

Housing 2023 returns to Manchester Central in June with a packed conference programme, offering ample debate and networking opportunities, as well as the chance to check out the latest technologies available for social and affordable housing providers in the exhibition, plus two award ceremonies to celebrate the achievements of those in the sector. Here, event organisers Ocean Media share with us why this year’s show is one not to be missed.

Throughout the whole of the UK, the housing sector is facing unprecedented challenges. From uncertainty in government funding; new regulations; the pressing need for more homes; the equally pressing need to maintain and improve the homes we have while modernising procedures and services to meet the expectations and needs of tenants and residents. And that’s without mentioning external pressures such as the continuing cost-of-living crisis and the pressure on all other public sector services.

That’s why, for Housing 2023, we have put together a fantastic programme of content that packs in lots of learning. With an abundance of thought-leaders and expert-thinkers joining us across three days, the event is an opportunity to come together with peers from across the sector

SHOW PREVIEW: HOUSING 2023

Discover new and innovative solutions in the exhibition that could help you deliver better quality homes

Attendees will have the opportunity to hear essential updates and guidance from leaders across housing including DESNZ, DLUHC, Homes England and RSH

to network and innovate. And through all of this, we’ll make sure improving professionalism is at the heart of every discussion, to ensure you continue to provide the best outcomes for your tenants and residents.

Why attend Housing 2023

Learn something with 150+ hours of CPD accredited sessions across six stages on the show floor — the award-winning Fringe stage, Unlock Net Zero Live stage, Tenant and Resident Engagement stage, Knowledge and Insight stages and PfH Live. Engage with government at Housing 2023 and hear essential updates and guidance from leaders across housing including DESNZ, DLUHC, Homes England and RSH. Hear from over 450 speakers covering topics including the net zero challenge, the cost-of-living crisis, building safety, affordability, funding, housing delivery, tenant engagement, specialist housing, data, mental health and wellbeing, innovation and much more.

Plus network with over 8,000 housing professionals and find the whole supply chain under one roof, from the main procurement frameworks to government bodies, from development and asset management experts to green home suppliers and engagement specialists, Housing covers the entire supply chain. Discover a show floor packed with 350+ exhibitors and discover new and innovative solutions that could help you deliver better quality homes.

The Housing experience

Housing also provides the chance to meet, share, collaborate and take the opportunities on offer back to your teams and organisations. This year, there are more tangible outcomes and takeaways than ever before, and a programme of events and activities for local authority and housing association teams to take part in:

l Celebrating Brunswick — an anniversary tour (26th June) — join a study tour to see the Brunswick Village development showcasing great community spirit, regeneration and extra-care living.

l Women in Housing/Housing Heroes Awards (26th June) — the opening ceremony at Housing 2023. Celebrate the leaders, innovators and changemakers across the sector, shining a light on the incredible work carried out by teams and individuals in the past 12 months.

l Attend the Unlock Net Zero Live Awards (27th June) recognising and championing progress on the journey to decarbonisation for the UK housing sector and the supply chain that supports it.

l Take part in a charity walk to Castlefield Viaduct (28th June), the National Trust’s Manchester garden in the sky. This is one not to be missed and a great chance to keep fit whilst giving back.

l Housing Rocks, charity fundraiser (28th June) — join up to 900 people who want to give back at Housing Rocks and raise as much for charity as possible.

Submit ‘bands’ for rock-a-oke followed by a true Mancunian DJ!

l Housing jobs fair (29th June) in partnership with GMCA Careers Hub, GM Housing Providers, Manchester City Council, Manchester Evening News, Inside Housing and supported by Cllr Bev Craig, Leader, Manchester City Council.

l For all those looking for a career with purpose. The housing jobs fair will bring together the largest recruiters in the region and those looking for opportunities to join a long-term career in a sector that supports local communities.

Housing is the biggest event in the housing calendar. This year, there are more tangible outcomes and takeaways than ever before. Housing has something for everyone. Join the conversation #bettertogether #ukhousing

Housing 2023 – 27-29th June, Manchester Central

3 days | 8,300+ attendees | 450+ speakers | 10 streams of content | 350+ sponsors and exhibitors | 60 official fringe events

Register for your free* visitor pass now: housingevent.com or use the link here www.rdr.link/lak004

*Visitor passes are free to housing associations, local authorities, public sector, housebuilders, master developers, funders, architects, planners and BTR landlords, student accommodation, retirement living and extra-care providers. Fees will apply to other commercial organisations and will be automatically added so please ensure you register using your work email address.

MAY/JUNE2023 LABM I 17

“Hear from over 450 speakers covering topics including the net zero challenge, the cost-of-living crisis, building safety, funding, housing delivery, tenant engagement and much more. ”

There are 60 fringe events at the show

Q&A: METRO ROD

Drainage support

LABM speaks to Peter Molloy, Managing Director at Metro Rod, about the regulatory requirements governing drainage, the importance of carrying out regular surveys and inspections, and the services the company provides for councils and housing associations.

What are the main regulations governing drainage in the UK that local authorities and housing associations must comply with?

Peter: Building Regulations Part H centres on drainage and waste disposal and is relevant to every public and commercial building in the country. It shares details about how to safely discharge foul water, wastewater and rainwater, the separate systems within drains and how to manage buildings built over sewers.

Additionally, the Water Industry Act 1991 makes it a criminal offence for any building or organisation to discharge into public sewers any matter which may interfere with the free flow of wastewater. Furthermore, every commercial premises arranging collection and disposal of waste — including waste cooking oils and fats — must comply with the requirements of Section 34 of the Environmental Protection

Act 1990 and the Environmental Protection Act (Duty of Care) Regulations 1991. In terms of local authorities specifically, Section 59 of the Building Act 1984 enables a local authority to require satisfactory provision for drainage of an existing building by service of a notice on the owner. A local authority’s environmental health department should deal with any reported complaints of ‘statutory nuisance’ such as smells, effluents, accumulation of refuse or any premises in such a state that could be prejudicial to health or a nuisance.

How important is it to carry out regular drainage surveys and inspections?

Peter: It’s absolutely vital. None of us can ever truly know what is going on underground where drains are situated, without inspection. Fatbergs, tree roots, broken pipes and more, all have the potential to cause major infrastructural

issues if left for too long without being resolved, and repairs can cost thousands of pounds. CCTV drain surveys conducted on a regular basis can spot any potential issues before they arise, meaning property owners and local authorities can better plan for important maintenance. This will reduce repair costs overall, minimise the impact on their neighbourhoods and improve their reputation with residents and tenants.

MAY/JUNE2023 LABM I 19

Metro Rod offers a range of services, including clearing blocked drains, CCTV drain surveys, drain repair and septic tank emptying and management

Peter Molloy, Managing Director at Metro Rod

What are the different types of surveys available and what do they involve?

Peter: For a site to be fully compliant, it’s vital that a drainage map, or asset map, is produced so local authorities can understand where effluent is discharged. It’s an essential tool in developing a waste management and flood management plan. Unless there is a large extension built at a particular site, it’s unlikely the drains are ever going to change so once this job is done, it won’t need to be carried out again.

A CCTV drain survey can also be used to understand the condition of the drains and detect problems before they have the chance to become costly, inconvenient issues. A CCTV drain survey can also be used to find the cause of re-occurring blockages and damaged pipes.

What is drainage mapping and how can it help with flood management?

Peter: Asset maps go hand in hand with CCTV drain surveys — but asset maps provide even greater detail on the drains beneath a site. An asset map will be crossreferenced with an ordnance survey to provide a map of the drains and give an accurate indication of the depth, latitude and longitude of each drain within a 2cm accuracy. Should a spill happen on-site, an asset plan can be drawn upon to understand how any auto shut-off valve or containment will be put into effect to prevent any effluent from entering the drains.

What services do you offer to social housing providers?

Peter: We understand the drainage challenges and demands that social housing organisations face on a daily basis. Managing a portfolio of properties can be really difficult, juggling multiple requests and responsibilities all at once — so when a provider receives a call from a tenant telling them there is a blocked drain or burst pipe, it can disrupt their usual day-to-day activity, which can then impact other residents.

From keeping tenants happy to reporting on the frequency and cost of maintenance services, our expertise in the social housing industry is extensive, and allows us to tailor our approach to suit the needs of each customer.

We have one of the broadest portfolios of services of any national drainage contractor, including:

l Clearing blocked drains

l CCTV drain surveys

l Gutter clearance

l Drain repair

l Septic tank emptying and management

l Soil stack cleaning and maintenance

l Pre-planned maintenance

l Sewage pump station maintenance and installations

l Tanker services

l Wastewater treatment plant maintenance and installation

We have more than 500 qualified drainage engineers nationwide, meaning we have the resources to offer fast response times, high-quality service and 24/7/365 availability.

What are the most common drainage problems you encounter working with local authorities and housing associations?

Peter: Typically, the main issue we see is overflowing or slow-running drains. This is usually caused by blockages, from materials like fats, oils and grease, which cause a build-up of substances that stems the natural flow of water. We also find that blockages are caused by misuse and abuse when people dispose of nonflushable items such as wet wipes down the drain. All of these issues lead to foulsmelling drains and should be reported as soon as possible to avoid further damage to infrastructure and properties.

How is the adoption of new technologies shaping Metro Rod’s solutions and services for social housing providers?

Peter: Technology is at the centre of our lives today, and its capabilities in every sector advance at an incredible pace. New technology within drainage often comes with the benefit of improved speed of survey or repair, and the ability to provide customers with insight on the cause of reoccurring blockages.

We capture this data on behalf of our customers and share it through bespoke reporting software, detailing areas of overspend or anticipated challenges to give customers the knowledge to make informed decisions. As such, we embrace technology and how it enables us to broaden our portfolio of services.

We embed ourselves in the innovations taking place within the market and for any innovative ideas we have of our own, or technologies we adopt, we develop training courses and present them to CABWI for accreditation to demonstrate their relevance, currency and quality.

n For more information on Metro Rod and its services is available here www.rdr.link/lak005

20 I LABM MAY/JUNE2023

Q&A: METRO ROD

It’s absolutely vital to carry our regular drainage surveys and inspections

Many housing associations now prefer to sign documents electronically, saving the time and resource needed to facilitate ‘wet-ink’ signatures and/or the affixation of a common seal on hard copy documents. This is leading some to consider the merits of completely dispensing with their traditional execution methods and fully embracing electronic execution for all documents, including deeds registrable at the Land Registry.

For housing associations considering this approach, the first step is whether electronic signing is permitted under the housing association’s rules/articles. The NHF Model Rules, upon which most housing associations base their own, provide that in the absence of affixing a common seal, the board can “authorise the execution of deeds in any other way permitted by law”. The question, therefore, is what does the law permit.

Signed, sealed, delivered: No more!

Housing associations constituted as Community Benefit Societies (CBS), which is the norm, are governed by the Co-operative and Community Benefit Societies Act 2014 which makes clear that, as an alternative to executing under seal, a society can execute a document by the signatures of (a) any two members of the society's committee or (b) a member of the committee and the society's secretary. The meaning of ‘signature’ is not further defined in the legislation but, in the absence of any specific restriction, it has become normal industry practice to accept electronic signatures as a valid form of ‘signature’ for the purposes of this legislation.

Electronic signatures

If, having checked its rules/articles and the relevant legislative provisions, a housing association decides to rely exclusively on electronic execution going forward, it must ensure that its internal delegations and approvals line up accordingly and a properly qualified/industry accepted electronic signature platform is used.

There will no doubt be counterparties who take a more traditional approach so, even though there may be no legal prohibition on signing electronically, housing associations should nevertheless be prepared to face questions on this in some transactions. We expect this will become increasingly rare but, practically

speaking, it is worth considering a backup plan for where resistance is met.

It is also important to ensure that any electronic signing protocol is fully compliant with Land Registry guidelines where the signed document will need to be registered with them. There should be no obstacles to registering such documents at the Land Registry so long as the formalities set out in the Land Registry’s practice notes are complied with.

It is understandable that many housing associations want to move to a more efficient protocol of electronically signing all documents. In doing so, it is important that proper consideration is given to the relevant governance issues.

LEGAL UPDATE

22 I LABM MAY/JUNE 2023

Matt Cowen, Senior Associate at Winckworth Sherwood, discusses the electronic signing of documents and the factors housing associations need to consider when adopting this approach.

n Matt Cowen, Winckworth Sherwood Matt Cowen is a Senior Associate at Winckworth Sherwood. Visit www.wslaw.co.uk.

©smolaw11_AdobeStock

“The NHF Model Rules, upon which most housing associations base their own, provide that in the absence of affixing a common seal, the board can “authorise the execution of deeds in any other way permitted by law”.”

InstallerSHOW 2023

Returning to the NEC in June with a packed content programme and an even bigger exhibtion, InstallerSHOW is a key event for installers and specifiers of heat, water, air and energy technology. Here, we explore what’s on offer for local authority and housing association specifiers.

Taking place at the NEC on 2729th June, this year’s event is set to be even bigger — with 400+ exhibitors set to welcome 15,000 industry professionals. Building on the success of its Birmingham debut last year, the 2023 show will feature an expanded offering for visitors to reflect the growing momentum towards net zero solutions.

The event offers a great opportunity to network with industry peers, make new connections, gain insights, debate current challenges and engage in lively discussions on key issues, as well as see the latest sustainable technology innovations and discover new solutions.

The elemental content theatres, BEAMA’s Net Zero by Design, Solar Innovations and the Wates Innovation Zone are just some of the highlights for local authority and housing association specifiers at this year’s show.

elemental content theatres

The speaker line up in the elemental content theatres includes ex-footballer Gary Neville and former Housing Minister Esther McVey, with the discussions taking place in two areas — the Housing Hub and the Decarbonising Buildings Theatre.

Sessions in the Decarbonising Buildings theatre include: The case for mandatory solar; The business case for sustainable buildings; Strategies for achieving net zero

buildings; Energy generation for local authorities; The electrification of heat in buildings; Delivering energy security with low-carbon fuels & hydrogen micro-CHP; The unsung heroes of energy saving; Bristol City Leap: A blueprint for decarbonisation at city-scale; Keynote: Gary Neville; Balancing ventilation, IAQ and energy savings; Improving heat network efficiency; and Sustainable supply chains for building retrofit.

Housing Hub highlights include: National Home Improvement Council (NHIC) Home Upgrades Conference; Who is going to buy a heat pump?; Getting retrofit right first time; The most effective ways to tackle fuel poverty; The future of housing retrofit; ECO funding and decarbonisation; Retrofitting hard-to-treat homes; and Overcoming barriers to low-carbon tech.

Net Zero by Design

BEAMA, the UK trade association for manufacturers and providers of energy infrastructure technologies and systems, will be hosting the Net Zero by Design feature theatre with a full timetable of live events.

Session highlights include: Electric Vehicle Charging; The health risk of poor indoor air quality; Heat pumps and electric heating; Building for Net Zero; What’s next for new-build after the 2025 fossil fuel ‘ban’?; Maximising Efficiency From Gas Central Heating Systems; and Retrofit for Net Zero.

Sustainable technology

Solar Innovations, supported by Solar Energy UK and MCS, will incorporate interactive demo sessions to boost knowledge of solar technology, battery storage, inverters, finance for the market, and upskilling opportunities.

Wates Innovation Zone

Featuring exclusive product demos and an actionable, insights-led speaker schedule, don’t miss the Wates Innovation Zone, which will showcase a host of extensively vetted suppliers who can offer genuine, market-leading sustainable technology to help in the design, construction, maintenance and use of buildings.

Confirmed participants include: Altecnic; Advanced Bacterial Sciences; Veritherm; Eurocell; Lumi Plugin; EVC; Ambion Heating; Cercula; Blygold UK.

InstallerSHOW

l NEC Birmingham from 27-29th June

l Packed exhibition with 400+ exhibitors

l Comprehensive content programme featuring live debates, panel discussions and hands-on product demos

l Free entry and free parking

n More information about the show here www.rdr.link/lak006

Register for a free visitor pass here www.rdr.link/lak007

MAy/JUNE2023 LABM I 23 SHOW PREVIEW:

Building a concrete future

Concrete bricks are often overlooked in the selection process, with clay bricks usually being favoured, even though they are comparative in many ways. There are also specific benefits of concrete bricks, including their sustainability credentials, which are becoming more important in building project considerations.

A recent project where concrete bricks were extensively used is the North Gate Development in Glasgow. Designed by Architects Page\Park and built by contractor CCG, the North Gate Development in the Gorbals area of Glasgow is among the latest projects for

New Gorbals Housing Association. The aim of the project was to transform a constrained brownfield site into highquality social housing and create a new landmark within the area that also blended with the existing architecture.

A carefully designed series of interconnected towers, the seven-storey North Gate Development, provides a mix of one- and two-bedroomed flats designed to meet the needs of older residents.

The shape of the building means that all 31 flats have dual or triple aspects to maximise natural light and provide views across the city, to create a sense of belonging. With sustainability a core

Here, Fiona Coyle, from Marshalls Bricks & Masonry explains how Marshalls’ concrete facing bricks met with the performance, sustainability and affordability demands of the aesthetically celebrated North Gate Development, a high quality social housing project in Glasgow.

consideration for this development a high-performance building envelope was incorporated, which included a mix of double and triple glazing as well as 72 photovoltaic (PV) panels discretely integrated into the roof. The building’s location and design are also intended to encourage active travel and the use of public transport.

Brick selection process

With brick work featuring prominently, both internally and externally, finding the correct brick for the project was essential. The contractor CCG approached Glasgow Brick Yards (GBY), one of the largest brick stockists and distributers in Scotland, for help finding a suitable product. GBY, CCG, Page/Park and New Gorbals Housing Association were all involved in the selection process. Several Marshalls bricks were identified as possible options.

To help facilitate the final selection, Marshalls and GBY built several test walls at the GBY site nearby. Ultimately, the Marshalls Glencoe Vintage Stock Facing Brick was chosen for its light brown and

The seven-storey North Gate Development is a carefully designed series of interconnected towers

&

HOUSING

REGENERATION

grey tonal variations, which evokes the traditional blonde sandstone used throughout Glasgow.

The Marshalls facing brick lent itself to this project for several reasons. Firstly, the range of colours available meant that the project team was able to select one that met the requirements of the building and reflected the architectural styles and influences of that area of Glasgow.

Sustainable option

Secondly, for a development where sustainability was at its core, the use of concrete bricks became especially advantageous. Marshalls facing bricks are manufactured using raw materials that are generally sourced from suppliers within a 50-mile radius of the manufacturing site, and use minimal cement in the mix design.

The manufacturing of the concrete bricks also creates minimal C02 emissions. The natural exothermic reaction that takes

place is usually sufficient to cure the product. This contrasts with the energy intensive production of clay bricks, which need to be fired in kilns at temperatures between 700 and 1,110˚C.

Further to this, concrete facing bricks can sequestrate carbon once in situ, meaning choosing a concrete brick over a clay brick results in a 49.1% carbon saving. Concrete bricks can also be crushed and recycled at the end of their life, diverting construction waste away from landfill.

Concrete solution

Cost-effectiveness was another important consideration for the New Gorbals Housing Association on this project. There is often a misconception that concrete bricks cannot be laid as quickly as clay bricks, and therefore leading to higher labour costs. However, this persistent belief is not supported by evidence and is the result of a misunderstanding about the

product. For the North Gate Development, the information provided by Marshalls, in addition to CCG’s experience with concrete bricks, reassured the client that the building could be completed on time and to budget.

Despite the numerous similarities to clay and in addition to the lower environmental impact, concrete bricks are still often overlooked. The North Gate Development demonstrates how concrete bricks can be used in a way that supports the aesthetic, environmental and budgetary requirements of a modern social housing development.

MAY/JUNE2023 LABM I 25 n To find out more about the Marshalls’ range of concrete bricks visit www.rdr.link/lak008

Concrete bricks from Marshalls Bricks & Masonry were specified for New Gorbals Housing Association’s North Gate Development in Glasgow

The Marshalls Glencoe Vintage Stock Facing Brick was chosen for its light brown and grey tonal variations

“Concrete bricks can recycled at the end of their life, diverting construction waste away from landfill. ”

Ringing the changes

LHC Procurement Group’s Group Managing Director Clive Feeney and Chair of the Board

1. How much difference will the company structure and new Board make to LHC Procurement Group?

Clive: This is the culmination of an 18month governance review and nine years’ wider work to fully embed our business units across Great Britain, to enable us to better represent our public sector clients’ needs at a local level.

The new structure really recognises our commitment to improving lives in local communities. not only is this baked into our procurement solutions but is delivered through our Community Benefit Fund, which provided almost £275,000 in grants to local community causes across the country in 2022/23.

Simon: The fact that this year LHC has had one of its strongest financial performances is testament to this work. It also illustrates that these fundamental structural changes are right to prepare us for future growth.

2. How important is it that LHC has directly sought board representation from public sector organisations it works with?

Clive: We’ve been clear since the start of this process that having senior representatives from public sector

organisations across Great Britain on the Board is essential for directing and shaping the future of LHC, ensuring its continued growth and success.

To understand what is happening out there in the communities in which our frameworks operate, we need to work closely with those organisations that are truly embedded in these areas.

Simon: In my experience, the organisations that really manage to hone their services to meet clients’ and customers’ needs are those that are integrating these views and challenges at board level. This was certainly key in attracting me to the chair position at LHC.

3. What are the challenges and opportunities for the next 12 months?

Simon: Building an effective board that provides appropriate oversight, and both supports and guides the executive in delivering our core services, presents an immediate challenge and opportunity.

Clive: It’s going to be a very exciting, busy 12 months embedding our fantastic new Board and CLG structure, working to deliver what the public sector needs in terms of social housing, education, and the

maintenance and refurbishment of the built environment. We are using the changes to further sharpen our services and drive excellence in public sector procurement.

4. Why is good practice procurement so important for the future of the construction sector?

Clive: Procurement is vital for the construction sector in driving jobs creation, pushing for higher standards against legislation and guidance, and encouraging collaboration.

There has never been such a concerted focus on procurement, frameworks and alliancing as key mechanisms for achieving excellence in the built environment, and this will continue with the Procurement Bill.

Simon: One of the ways the uK can speed up our transition to carbon net zero is by expanding our low-carbon housebuilding and major retrofit programmes. Value-led public sector construction frameworks have an important part to play in this.

n For more information on LHC and its services visit www.lhcprocure.org.uk

Simon Wilson discuss positive changes at the organisation, and what its new CLG structure and Board mean for public sector clients.

ADVERTISEMENT FEATURE 26 I LABMMAy/june2023

Simon Wilson, Chair of the Board at LHC

Clive Feeney, Group Managing Director at LHC

Digital transition

Gavin Bashar, UK Managing Director at Tunstall Healthcare, discusses the role of technology in making social housing more affordable from a health and care perspective.

Around 4.2 million people live in the social rented sector1, yet housing is often forgotten when it comes to integrating services that support vulnerable people. However, it has a significant role to play in improving health outcomes and supporting health and community care services, and making these services as efficient as possible.

While social housing is often cheaper than privately rented accommodation, and can offer greater security from eviction, local councils and the social housing sector must be included in developing strategies to offer more integrated and cost-effective support to those that are most in need, and the duty of care reaches far beyond simply providing shelter.

How to implement technology

Understanding how to adopt the right technology is important if we are to transform our services. This ranges from reducing costs and inequalities, to

increasing inclusion and engagement amongst those needing social housing.

With so many solutions currently on the market and every individual requiring different levels of care, it can be challenging to procure and integrate the correct technology. However, there are some practical steps that can be taken.

Working in partnership with providers will support the delivery of effective technology enabled care services (TECS) and data led practice. A collaborative approach, including co-production with tenants, means any investment in technology is maximised and service delivery models are designed around improving service user experience and delivering organisational goals.

Outcomes and financial savings should be defined at the outset and tracked effectively. Good measurement is based on making sure goals are well defined and measurable, and that any financial savings are applied at the beginning so that the whole service can be evaluated, rather than

smaller elements. The importance of outcomes does, however, go beyond financial savings. Providing more preventative and personalised care in social housing by using technology, also gives people more choice and control, which in turn can help to maintain independence and thereby prolong tenancies.

Integrating the right devices

There is massive potential in how infrastructure improvements will allow technology to enhance services. With the UK’s Public Switch Telephone Network (PSTN) ceasing in 2025 and switching to voice over internet protocol (VoIP), social housing providers need to audit existing technology estates and develop strategies for upgrading equipment to digital where necessary.

This will ensure that vulnerable people are not put at risk when we reach the cut off point for the transition, and that providers take advantage of the opportunity to use technology to offer tenants better support.

mAy/jUNE2023 LABm I 27 HOUSING & REGENERATION

HOUSING & REGENERATION

By educating themselves on how the upgrade might impact services, providers will be able to plan accordingly and ensure they are able to get the right devices working in the homes of their tenants. However, it’s important to remember that technology can’t and shouldn’t be used to replace human interaction, but it can be used to target care where and when it is needed most. This will ultimately make housing services more efficient.

Housing providers can also ensure they are well prepared by partnering with a range of stakeholders involved in the

digital transition. Whether this is communications providers or technology partners, collaboration is required to develop an effective solution that mitigates the risk of disruption in service delivery. It’s also important to seek advice to ensure any investment can deliver longer as well as shorter term benefits, i.e. choosing technology solutions that will evolve over time.

Implementing tech to drive cost efficiency in practice

Tunstall Healthcare has worked closely with Lincolnshire Housing Partnership (LHP), not only on a day-to-day basis, but have also collaborated to prepare a strategy for the UK’s transition to a digital communications network and adapting its services to become more resilient and agile during and post pandemic.

LHP and Tunstall have worked to audit existing schemes and equipment and scope a potential footprint for new technology and service delivery models. The relationship with the healthcare provider is multi-layered — as well as working together to improve services to LHP customers, Tunstall has supported LHP’s successful bids to provide TECS to

other organisations, and enable initiatives with partners in health and social care.

Embedding the change

With implementation of the current reform agenda already underway, as well as the significant pressures on existing services, it is understandable that the bandwidth for addressing yet another issue such as technological change may feel peripheral when compared to the scale of charging reform or current workforce challenges.

However, it’s widely understood that technology needs to be front and centre of any strategy to drive true change. It is likely to provide the best route over time to enhancing the capacity of housing services whilst at the same time reducing pressure on the workforce and maintaining high quality services. Housing providers should be thinking now about where technologies could reduce expected pressures in the future.

28 I LABM MAY/JUNE2023

1. Housing, England and Wales: Census 2021

Tunstall Healthcare’s Comunicall is a scalable communications system for group living environments

n

“Providing more preventative and personalised care in social housing by using technology, also gives people more choice and control, which in turn can help to maintain independence and thereby prolong tenancies.”

More information on Tunstall Healthcare, its services and the digital transition here www.rdr.link/lak009

Easing the pressure

Against a backdrop of high inflation and soaring energy costs, housing associations and tenants are facing numerous challenges. The topic of energy and water efficiency is front of mind for many. Here, Martyn Brown, Technical and Contracts Manager at Triton Showers, explores key considerations for shower specification and why going electric can help ease financial pressure for property owners and occupants alike.

The cost-of-living crisis appears to show no sign of subsiding anytime soon. Statistics released in April reinforce this, showing that the Consumer Price Index (CPI) inflation rate is almost a full percentage point higher compared to those projected in the Bank of England’s February report.

In the context of social housing, last year’s Sector Risk Profile highlighted numerous challenges posed by inflation, centring around financial pressures such as rising cost of debt, a proposed rent cap, and a weak housing market. Simultaneously, tenants face their own difficulties, with some households having to default on rent and/or go without necessities such as food, gas and electricity1

With these challenges front of mind, the conversation comes back to how properties can be made more efficient. Whether upgrading insulation, adding double-glazing or making homes more airtight, the reality is these options are not always easy to implement at scale. Add the varying age, condition and design of the UK housing stock into the equation,

along with a shortage of tradespeople, and changes become increasingly difficult to roll out at speed.

Certainly, wide-scale home improvement strategies should be the end goal. Yet, in the interim, there are alternative ways to implement energy and water saving measures. One such solution is efficient electric showers. Deliverable in a much shorter timescale, installing this technology can provide immediate, tangible effects that can be seen year-round.

Efficiency with electric

When it comes to bathroom specification, there are many reasons to opt for electric models, but one core benefit is that they draw on domestic cold mains supplies and only heat water on demand. Warming flow only when needed is deemed the best way to safeguard energy and financial savings over time.

In real terms, showering with an electric unit could cost nearly a third less to run each year when compared to a mixer option. This is according to our recent research, with findings based on a five-

minute shower and comparing an 8.5 kW electric model to a mixer fed by an Arated combi boiler outputting 12 l/min.

Our analysis also reveals that users could see a reduction in energy usage of up to 76% and save more than 40 litres of water per shower. Plus, carbon footprint could be reduced by up to 70%. All in all, an electric shower could save up to 52,000 litres of water for an average three-person household when compared to alternative shower types.

At a time when cutting costs is a priority, any energy and water saving goes a long way, therefore it’s clear that choosing an electric model can make a big difference. Not only this, as people become more mindful of their consumption of resources in terms of environmental impact, installing electric showers can help tenants make their lifestyle more sustainable.

Installation considerations

When potentially faced with hundreds, if not thousands, of homes to look after, efficiency in terms of installation rollout is an equally important consideration. This is

30 I LABM MAY/JUNE2023