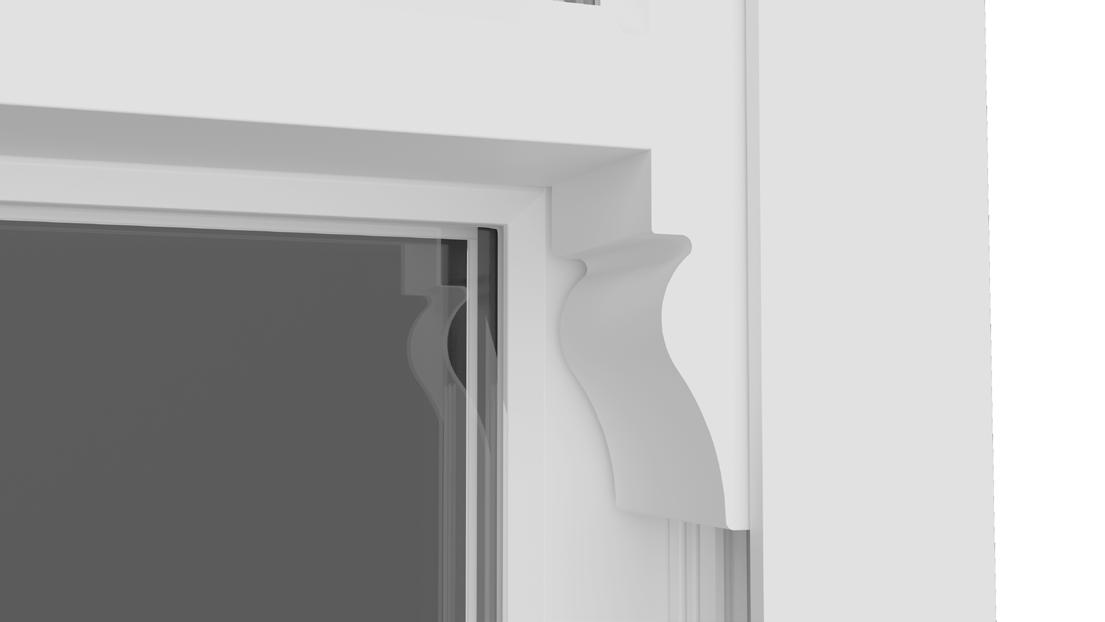

“TRY BEFORE YOU BUY” - MAKEOVERS GO MAINSTREAM IN WINDOW SALES

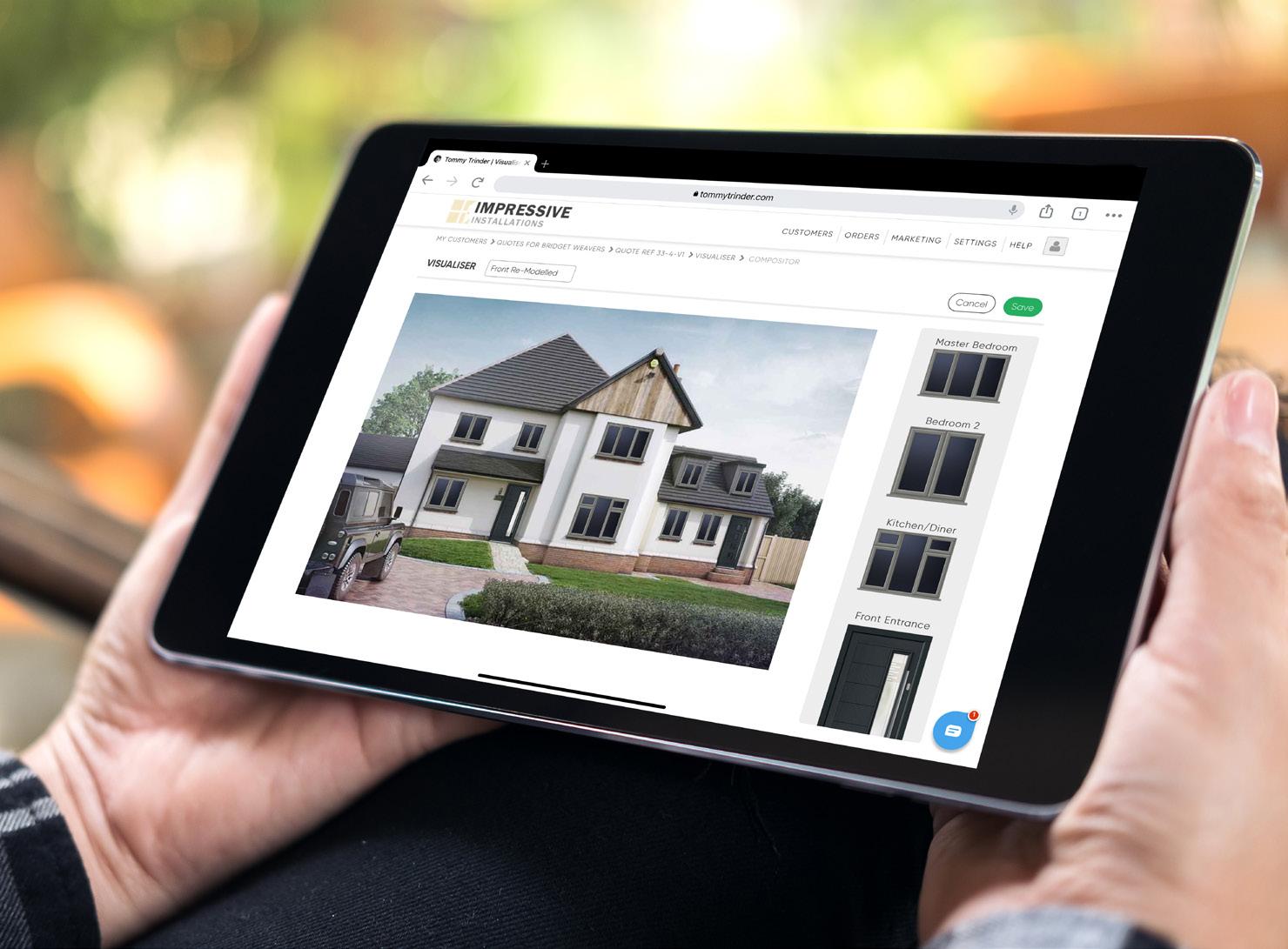

Homeowners are increasingly expecting to visualise their new windows and doors before committing — and installers are rising to the challenge, according to software pioneers Tommy Trinder.

New figures from Tommy Trinder report that just

under 40,000 “makeovers” - photo-realistic renderings of proposed installs - were created via the firm’s platform in the first eight months of 2025, marking a 15% year on year increase. More than half of all quotes submitted to homeowners now include a visual.

“We’re used to seeing how a car or kitchen will look before we buy, and windows and doors are catching up fast,” says CEO Chris Brunsdon. “Makeovers help customers decide quicker, and they give installers clarity and credibility.”

Top uses? Showing colour changes, demonstrating design tweaks like dummy

vents or bar layouts, and highlighting premium upgrades such as flush sashes, deep bottom rails or timber-look cills. Also trending, according to Tommy, is the use of makeovers to show the transformation of a knockout by superimposing bifolds or sliders over windows.

“Installers tell us visuals don’t just wow — they help close deals,” adds Chris. “And crucially they are also a tool for ruling out error; a sure-fire way of avoiding those dreaded ‘that’s not what I ordered’ conversations.’

Read more on page 8...

CAREERS, AI AND HOPES FOR A BETTER FUTURE

If you have children, or grandchildren, about to embark on the careers ladder, what advice do you give them? It’s getting quite confusing and it is difficult to know how to advise them. My inclination is to point them down the road towards a trade as a safe living, although those with the necessary educational qualifications will always have the option of picking the professions such as law, medicine, accountancy and so on. Of course, I’m well out of date with how things are moving in the jobs market and I read recently that by 2035 the UK will require more than 1.9 million professionals in the STEM fields. To further confirm my being out of touch with modern jargon I had to confirm that STEM stood for Science, Technology, Engineering, and Mathematics. Not surprisingly too, green jobs are expanding at about 4 times the pace of the broader jobs market.

So, some of the most in demand and fastest growing job titles include many that, until now, were largely unknown. AI Prompt Engineer, Sustainability Manager, TikTok Strategist, Cybersecurity Analyst, Remote Patient Monitoring Specialist, Climate Data Analyst, Vertical Farming Technician, Virtual Reality Designer, Autonomous Vehicle Engineers and Technology Ethicist.

Hot on the heels of informing us of these new jobs is a report that announces the type of job that AI cannot touch and these include: Healthcare professionals, Creative professionals, Skilled trades (those requiring technical know-how, manual skill, situational judgment), Educators and trainers, Upper-level strategists and analysts, Research scientists and engineers, Customer service representatives (requiring emotional intelligence, listening, problem-solving), Judges and legal professionals, Leadership and management roles, Social workers and mental health professionals, Environmental and sustainability experts, Hospitality and care sector staff. I take it from that that interpersonal skills, empathy, leadership, listening, strategic thinking and communication cannot be replicated by machine or technology, but I’m guessing that’s no surprise to anyone. I find it somewhat reassuring that those skills are recognised and, although new jobs are being added to the list of career options, the skilled trades, those on the creative side and customer service representation, positions so key to our own industry, are accepted to be best operated by real people.

While touching on cybersecurity, this morning I took a test to check my own knowledge of what I should open, delete, or report as phishing, and I was mightily

relieved to find that I’m not a complete donut when spotting dodgy emails, text messages and phone calls! My thanks go to Dave Gomersall, Head of Retail Sales at Nationwide Windows for raising the subject on LinkedIn and pointing us to a fun way to check out our own cyber and scam knowledge. Have a look at https:// bit.ly/4neMFln

Well. It has been fun and games in the political world with resignations and sackings within the government and a host of people biting their nails awaiting revelations from the hundreds of emails gathered by the FBI in conjunction with the Epstein episode. What all this means to the man, or woman, on the street, is anyone’s guess. What is clearer and certainly affects us all is the growth in the economy, or the lack thereof. Add to that the issues of inflation, interest rates, the ever-increasing taxes, unemployment, the cost of the benefits system, a matter of the small boats and immigration, the desperate need for additional housing…. the list seems endless. We’re all in need of some good news. Will the third quarter bring us any relief?

Ryan Johnson, Group Managing Director for the Emplas Group writes in a letter to the press this month” ‘Are we at the cliff edge?’ It is worth a read and describes the issues their group has faced and how they have faced the problems and continued to grow their business. Innovating and investing now will put companies and their customers in pole position as the economy eases. Have a look at what Ryan says.

The success of our industry is highly dependent on the well-being of the UK’s populace and that, regrettably, relies on a government that make the correct decisions concerning taxation and economic growth. That, in turn, translates into whether disposable income is available, or otherwise. Can we expect improvements in the immediate future? I’m guessing the answer will come once the Chancellor presents the budget in the House of Commons on 26th November, outlining the government's plans for taxation and public spending, which are expected to include tax rises and initiatives for growth. Fingers crossed?

Chris

GOT SOMETHING TO SAY?

Email Chris at: chris@glassnews.co.uk

‘TIME OUT’ WINNERS –SEPTEMBER!

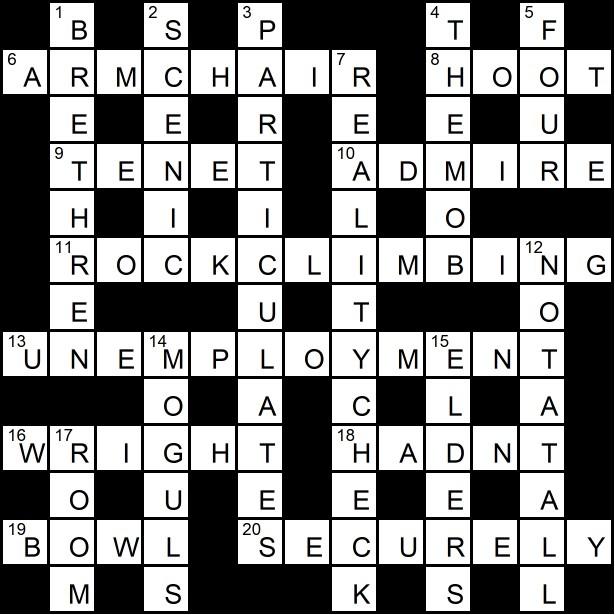

Sudoku:

Mrs E Carter, Bristol

Eye Spy: James O’Neill, Dundee, Scotland

Spot the Difference:

Charlotte Towle, Hurst Doors, Hull

Crossword:

Michele Statham, Sutton Coldfield, Birmingham

Congratulations to all our winners! Good luck in this months Time Out pages!

CONTENTS

4

6

48

Christina Lazenby

Managing Director / Advertising Enquiries

M: 07805 051322

E: christina@glassnews.co.uk

Emma Champion

Advertising Manager

M: 07508 263262

E: emma@glassnews.co.uk

Justin Lazenby

Finance Director / Press Release Enquiries

M: 07711 828710

E: justin@glassnews.co.uk

Chris Champion

Editor / Editorial Enquiries

M: 07850 267223

E: chris@glassnews.co.uk

Kate Carnall

Graphic Design

E: kate@glassnews.co.uk

Deadline for copy: 16th of each month

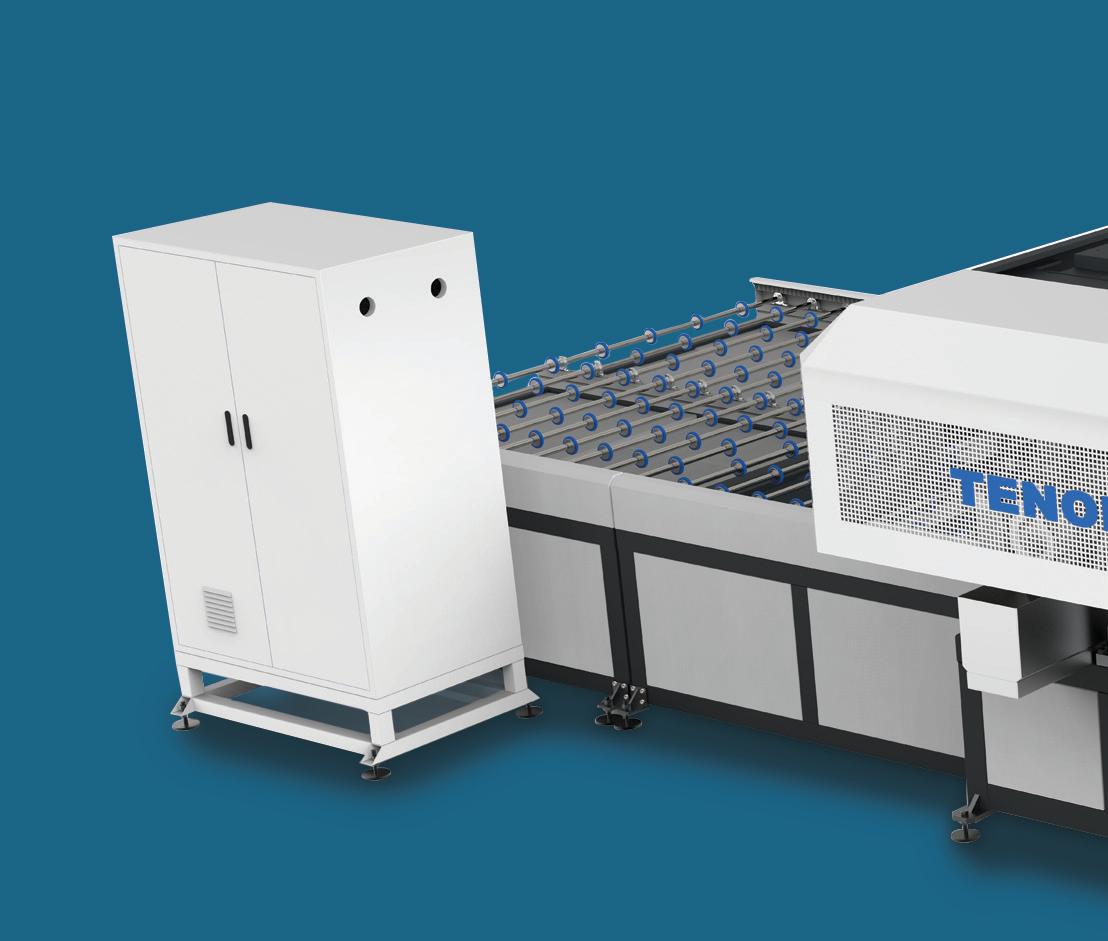

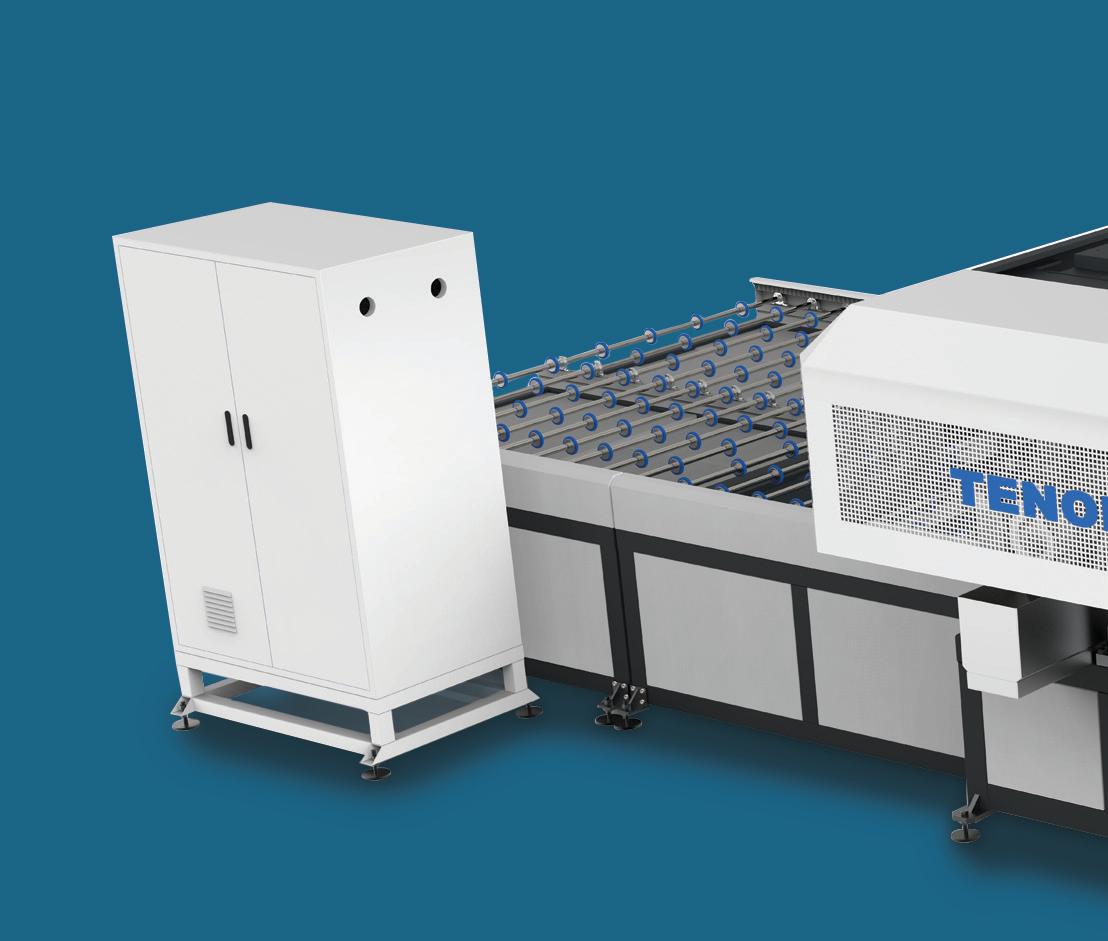

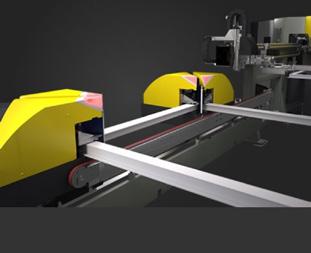

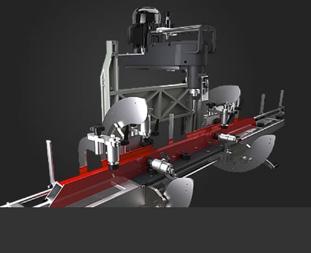

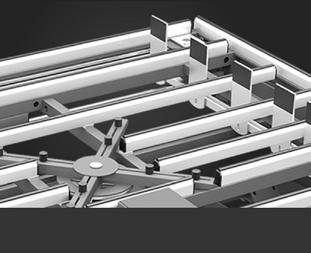

EFFICIENCY, FUNCTIONALITY AND COST EFFECTIVE ROIFLAT GLASS SOLUTIONS EDITOR INTERVIEW

In this interview Chris Champion, Editor of Glass News, speaks with David Cahill, Managing Director of Flat Glass Solutions. David explains how they help businesses face ongoing cost pressures, drive efficiency and offer practical, reliable solutions for customers.

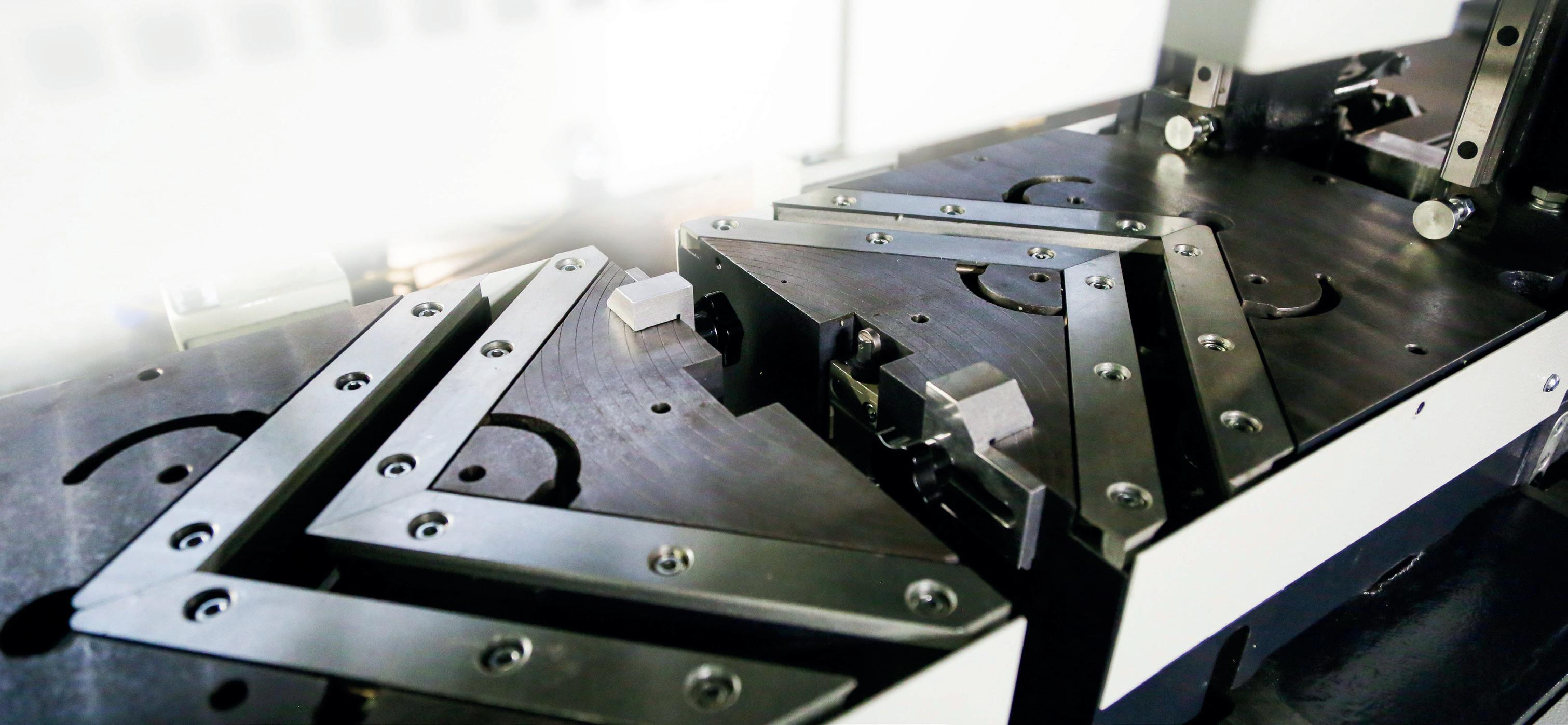

We all know about the cost pressures on businesses and that it’s an ongoing situation, so how can Flat Glass Solutions aid efficiency for your customers in these difficult times?

At Flat Glass Solutions, we recognise and understand the ongoing cost pressures businesses face, and we're committed to helping our customers maintain efficiency without overextending budgets. We offer equipment that delivers core functionality with cost effective ROI. By focusing on what’s essential and avoiding unnecessary extras, we provide machines that are practical, reliable, and often simpler to operate and maintain.

This approach not only reduces initial investment but also supports long-term efficiency. Streamlining operations and reducing operational and maintenance costs are key to helping our customers stay competitive during challenging times.

We’re suddenly hitting a summer of water restrictions and water is an important component in the glass industry – can your products help with the required water efficiency?

Water plays a vital role across many stages of the glass processing industry, and our patented centrifuges are specifically engineered to treat water containing fine glass particles and other processing contaminants. Designed for use in cutting, grinding, and edging operations, the centrifuge enables efficient recycling and purification without the need for flocculants or chemical additives. This environmentally friendly process allows for the safe reuse of clean water and the responsible disposal of solid waste, supporting both sustainability and operational efficiency.

How do you help your customers to operate the equipment they buy from you in the most efficient way?

We help our customers operate their equipment as efficiently as possible by providing comprehensive training programs before handing over any machine. Our fully trained engineers ensure that operators understand both the operation and maintenance of the equipment. Most of our machines can also be remotely accessed by Flat Glass Solutions and the original manufacturers, allowing us to offer quick support and troubleshooting when needed. We recognise that there's often a lot to take in during installation, so we actively encourage customers to schedule a followup visit after several months. This gives us the opportunity to retrain operators, reinforce best practices, and further improve overall efficiency and knowledge. You have invested in new talent in both operations and engineering, people with exceptional experience. What is your policy on expansion within Flat Glass Solutions and your hopes and aims for the future?

We will continue our strategic growth with trusted and industry knowledgeable professionals. Our office in China means we can offer around the clock communication and support. FGS engineers are not only highly trained and versatile, but they are capable of delivering solutions that meet evolving market demands. As automation and semi-automation become industry standards, we are committed to expanding our engineering and aftersales teams to deliver unparalleled customer support.

You partner with companies such as Viprotron and Dieffe and they joined with you at the FIT Show this year. Was this to promote specific products?

At the FIT Show, we highlighted two key innovations that reflect our commitment to sustainable and efficient manufacturing.

Dieffe delivers advanced water treatment and recycling solutions, while Viprotron leads the field in high precision defect detection. Though distinct in purpose and function, both technologies share our goals of reducing waste, streamlining production, and supporting environmentally responsible practices.

Has glass defect detection equipment become a must have for your customers?

When finished products are replaced due to production issues, transport and handling damage, or client rejection, pre-delivery defect detection isn’t just a benefit—it’s a necessity.

How much of an issue is the presence of dirt, scratches and bubbles in the processing of glass? Is the end user becoming more difficult to satisfy than in the past?

Any glass defect—whether it's scratches, dirt, or even something as unexpected as a transport pad trapped inside a unit—can become a serious issue. While the end customer may not be more demanding, they can easily become fixated on even a small, visible imperfection in a double-glazed unit worth £40, especially if it compromises the appearance of a £2,000 front door or a £20,000 conservatory.

Such issues often lead to disputes, delays, and financial repercussions that impact the entire supply chain.

Is there a place for Artificial Intelligence in glass processing and how do you see it being employed, going forward?

Absolutely, there is a place for Artificial Intelligence (AI) in glass processing, and its role is growing rapidly as the industry evolves toward smarter, more efficient, and higher quality production methods. I believe it can be implemented in a number of ways: Automation and Process Control, Quality Control (as noted above), Supply Chain Management

and Stock Control, Improving Efficiency including Energy Usage and Sustainability, Smarter Manufacturing, and Predictive Maintenance, to mention a few.

At Flat Glass Solutions, we have long believed that AI is a key driver of precision, efficiency, and intelligence in glass processing – from raw material handling to final inspection and delivery. As Industry 4.0 practices continue to gain traction, AI is set to play an increasingly vital role in helping companies stay competitive in our ever evolving glass market.

You offer a very wide range of products from partners from all over Europe, and also China, but I have the impression that you are more about being a solution provider for your customers rather than just selling products. Can you talk about your philosophy?

At the heart of our approach is a simple but powerful idea: we are not just here to sell products—we're here to solve problems. It’s in the name – Flat Glass Solutions.

By actively engaging with each customer and sharing a mutual investment in the success of every project—regardless of size—we begin with expert consultation and deliver tailored, high-quality solutions. Rather than offering one-size-fits-all products, we work collaboratively with our clients to understand their unique needs and long-term goals. Our goal is always to help clients streamline operations, minimise waste, and enhance overall productivity through collaborative, results-driven partnerships. This means being proactive, responsive, and adaptable—providing guidance, insight, and support every step of the way. Whether it's improving efficiency, replacing old or worn out equipment, solving a specific challenge such as adapting something to fit in a tight corner of the factory, or future-proofing operations, we deliver more than just products—we deliver outcomes.

David Cahill, Managing Director

S-CLASS BY HURST

Solid, Stylish, A class of its own.

The S-Class Collection brings together the strength of a solid timber core with stylish, well-considered design. It’s a door that not only lasts but looks the part, offering homeowners a premium feel and a finish that enhances any home. With S-Class, you get a door that’s truly in a class of its own.

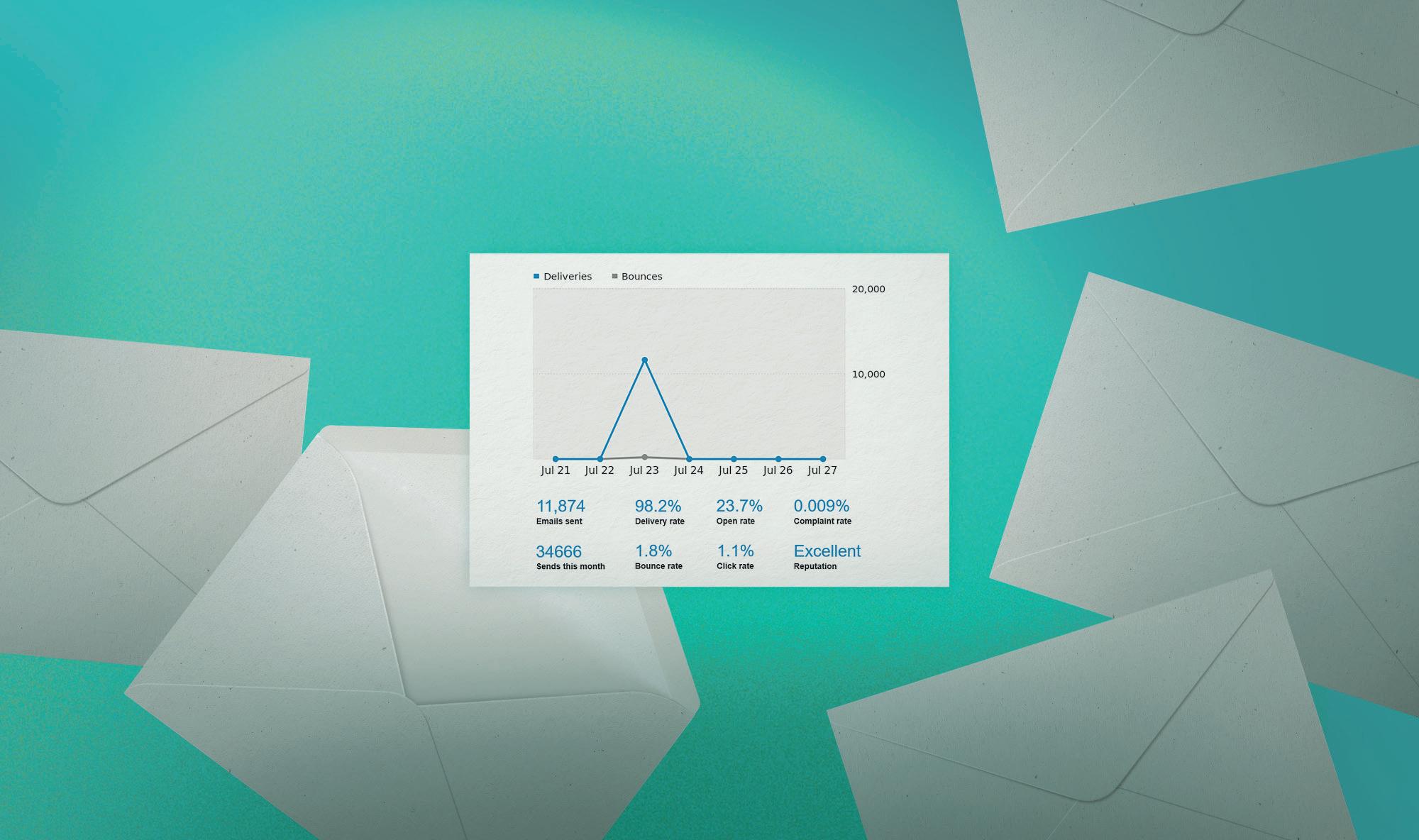

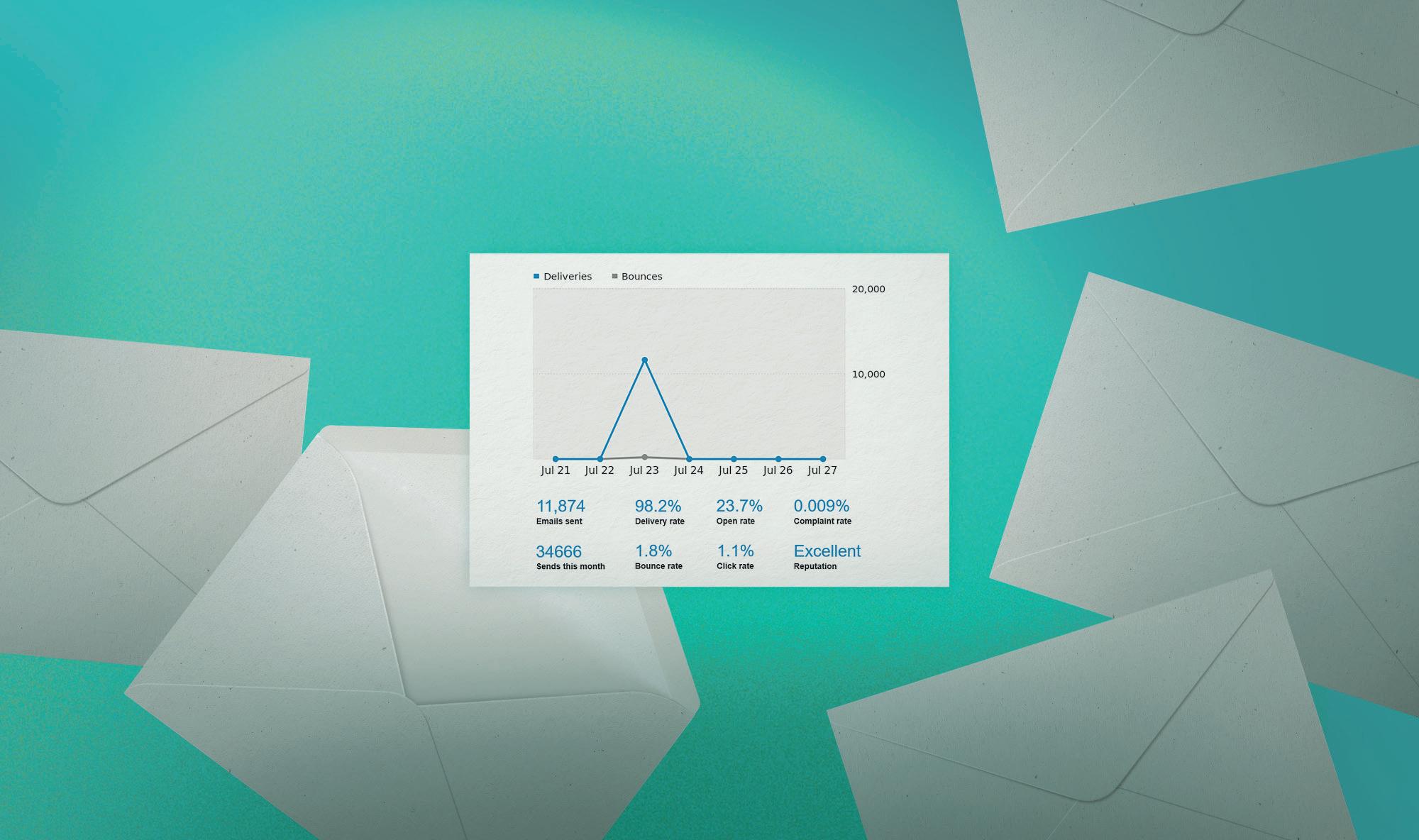

E-MAIL MARKETING IS BETTER THAN EVER – IF YOU DO IT RIGHT

Ab Initio’s managing director

Rhonda Ridge, explores the possibilities for installation businesses looking to keep their name top of mind on a tighter budget, and explains why e-mail marketing is an opportunity not to be missed.

We all know marketing is about getting your company in front of the right people at the right time. So, the more you do, the more likely you are to strike gold. But of course, it’s not that easy in a contracting market when budgets are tight. E-mail marketing has always been a strong contender in the

customer outreach marketing mix because it is so cost effective to deploy. In recent years though, with new technology entering the space, e-mail marketing has taken it up a notch. Data can be managed more cleverly, it’s easier to personalise campaigns for a higher success rate, and the process of sending e-mail campaigns out is stressfree. Companies that are embracing a more strategic approach are reaping the rewards. In an age of social media, some companies have moved away from e-mail marketing because they think it’s old fashioned but in its next generation form it is unrivalled for its ability to be personalised and relevant. Companies that can identify and zoom in on carefully selected demographics and target them with pertinent messages are more likely to get their e-mails read and get a response.

WHEN THE CHIPS ARE DOWN BUILD TRUST IN YOUR BRAND

When done well e-mail marketing is a low-cost and highly effective customer outreach marketing strategy that can build trust and familiarity despite a difficult economic climate. It allows installation companies to stay in touch with prospects and be top of mind as soon as they are ready to buy. AdminBase, the all-encompassing installation management system has a built-in e-mail campaigns feature, AdminBase Campaigns, to give customers the automated support they need to get the most of out of this marketing tactic.

Prospects will always be more likely to open an e-mail and read on if it is personal to them. Installation businesses that use AdminBase will already have their prospects in a central system with useful notes attached regarding the products they

Rhonda Ridge

special offer if they recommend a friend or if they place an order for some followon work. Or a voucher specifically for prospects that have shown an interest in a particular product in the past. As a result of this high level of targeting AdminBase users are regularly achieving delivery rates of 98.2 per cent, and open rates averaging at nearly 24 per cent. A good open rate is considered to be anything above 17 percent – though many prove to be significantly less than this. AdminBase Campaigns also eliminates the need to export data out of the central system and import it into third party mailing software. Sometimes when e-mail campaigns are conducted via third party mailing software, information can be lost in the export and import of data. AdminBase offers installation companies the ability to send e-mails directly from the system to make sure it’s easy and no data is lost. Maximising efficiencies in all areas of the business is critical as the economy bites, and AdminBase is helping installation businesses tighten up across the board, including in the realm of marketing. AdminBase Campaigns is proving to be a failsafe way of maintaining invaluable communication with potential clients in a difficult market. It allows home improvement companies to be proactive without taking up too much time or costing too much money and most importantly, is a hassle-free way of generating and converting those much-coveted leads.

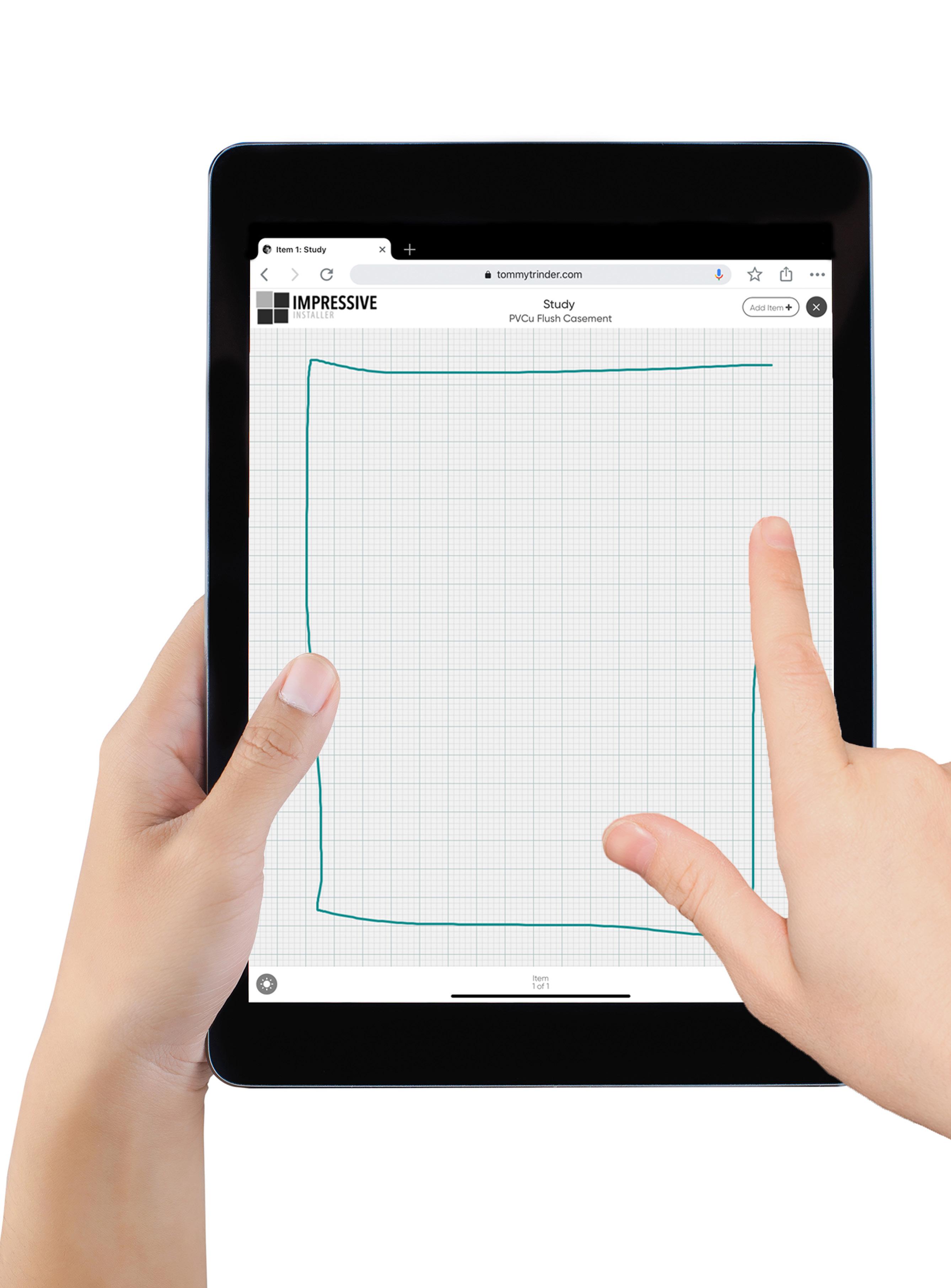

"Our sales have risen 20% in six weeks with Tommy Trinder."

book a

- www.tommytrinder.com ...and it’s as simple as sketching on a pad.

Chris N el s o n West Corn w a ll P l a s tic s

“TRY

BEFORE YOU BUY”MAKEOVERS GO MAINSTREAM

IN WINDOW SALES

Homeowners are increasingly expecting to visualise their new windows and doors before committing — and installers are rising to the challenge, according to software pioneers Tommy Trinder.

New figures from Tommy Trinder report that just under 40,000 “makeovers” - photorealistic renderings of proposed installs - were created via the firm’s platform in the first eight months of 2025, marking a 15% year on year increase. More than half of all quotes submitted to homeowners now include a visual.

“We’re used to seeing how a car or kitchen will look before we buy, and windows and doors are catching up fast,” says CEO Chris Brunsdon. “Makeovers help customers decide quicker, and they give installers clarity and credibility.”

Top uses? Showing colour changes, demonstrating design tweaks like dummy vents or bar layouts, and highlighting premium upgrades such as flush sashes,

deep bottom rails or timber-look cills. Also trending, according to Tommy, is the use of makeovers to show the transformation of a knock-out by superimposing bifolds or sliders over windows.

“Installers tell us visuals don’t just wow — they help close deals,” adds Chris. “And crucially they are also a tool for ruling out error; a sure-fire way of avoiding those dreaded ‘that’s not what I ordered’ conversations.’

Installers interested in finding out more about Tommy Trinder’s platform can book a free demo at www.tommytrinder.com/demo.

PST TURNS 35 –CELEBRATE WITH A MONTH OF VSHOME FREE

This November, Production Software Technology (PST) will celebrate its 35th birthday and to mark the occasion, the company is giving new vsHome users their first month free!

The offer is available to anyone who starts a vsHome trial during November 2025 and goes on to subscribe, giving them an additional free month on top of the standard 14-day trial. This extended access gives businesses more time to get set up and integrate vsHome into their sales process.

vsHome is PST’s all-in-one design, quoting and sales platform for the glazing and home improvement industry. From windows and doors to garden rooms, orangeries and conservatories, vsHome lets businesses produce detailed and professional designs in minutes, complete with advanced 3D visualisation to help close deals faster.

When paired with VisiRoom, PST’s augmented reality app, vsHome brings projects to life in real scale. Customers

can “walk through” their future conservatory or extension on-site using just a phone or tablet, making decisions with complete confidence.

“vsHome was developed to give businesses everything they need in one place, from design and pricing to immersive visualisation,” says Neil Travers, Managing Director at PST. “To celebrate our 35th year, we want to make it easier than ever for companies to see the difference it can make.”

This offer is available exclusively for trials that start during November 2025 and applies to users accounts as credit once a full months subscription of vsHome has been paid for.

To learn more or register for your free trial, visit pstonline.co.uk or contact the team directly on info@pstonline.co.uk or 0114 221 7070.

QUALITY BREACH DETECTED: QFLOW NEUTRALISES RISK AT THE GATE

Qflow (Qualis Flow),a leading construction data capture and analysis tool, focused on real-time tracking of materials, waste, and carbon data, launches Advanced Alerts. The first tool on the market that gives project teams a point of intervention before non-specified or non-compliant materials are installed.

This is a breakthrough moment for the construction sector, solving a common and costly challenge that has long plagued project teams: knowing what actually arrives on site, in time to act.

While the industry has made strides in improving quality and compliance, material verification remains a persistent weak spot. Recent data shows that up to 95% of deliveries arrive with incomplete or poorquality documentation, leaving room for error, rework, and in some cases, real safety and performance risks for end users.

With Advanced Alerts, Qflow empowers construction teams with live notifications, via app and email, that flag any risks linked to incoming materials, based on site-specific rules. For the first time, teams can intervene before faulty, substandard, or incorrect materials are installed. Fewer delays, reduced rework, and greater peace of mind.

Critically, this also protects the long-term performance of the building itself. When wrong materials are installed, the result isn’t just wasted budget; it can lead to fire safety risks, structural failures, or reduced thermal comfort for the people who live and work in those buildings. Easy to deploy and integrate with existing tools, Advanced Alerts provides immediate, actionable insights that put project teams back in control.

In a fast-moving, high-risk environment like construction, this real-time visibility is a game-changer, giving teams the confidence to deliver to spec, to budget, and to the highest safety standards.

Commenting on this latest innovation, Jade Cohen, Co-founder at Qflow, says: "On site, it is natural that substituted materials, unapproved suppliers, or incorrect fuel use, can go identified and, often, these issues aren’t picked up until it’s too late.

Advanced Alerts, has been developed in consultation with Project and Site Managers, Environmental, Finance, Quality and Compliance Teams, and is available in Beta to existing customers at no additional cost until the end of October 2025.

To learn more about Qflow and Advanced Alerts, visit: https://www.qualisflow.com/

GRM WINDOWS: A FABRICATOR PARTNERSHIP SPANNING THREE DECADES OF GROWTH

Pontyclun, South Wales is the home of fabricator GRM Windows. At just a 30-minute drive from Cardiff, it makes the perfect place for an SME to serve the capital, while still benefitting from the tranquillity of the countryside.

This year, GRM is celebrating its 45th anniversary, having also spent 30 of those years as a REHAU partner. This three decadelong partnership is a tale of longevity, trust and constant innovation. After all, there must be more than one reason why GRM and REHAU have stuck together for so long.

A FIRST MOVER: TAKING THE INITIATIVE

REHAU is constantly looking for new ways to innovate its product range. But for fabricators, taking on any new product or switching supplier can always feel daunting. However, GRM are proof that taking the plunge can deliver long-term benefits. The company has always been among the first of REHAU’s fabricators to take on new products, testament to the level of trust that 30 years of working together has established.

Richard Gambling, Managing Director of GRM Windows says, “I’ve been working with REHAU since 1994 when we switched from another profile supplier. During this time, we’ve worked on lots of different projects with a wide range of REHAU products.”

GRM have taken on many new REHAU products over the past 30 years, but some recent examples include SLINOVA, ARTEVO and Window.ID. In fact, GRM was one of the first fabricators to take on SLINOVA and the very first to take on Window.ID. This has allowed GRM to reap the traceability benefits of the unique add-on for quite some time.

“The SLINOVA sliding door is a real improvement on the previous generation of product. It works beautifully, it’s costeffective and our customers really enjoy it,” says Richard.

“I can say the same about ARTEVO,” says Richard. “The reception among GRM customers has been fantastic, especially those in our commercial markets. It has allowed us to tee up many large business projects, including with

housing associations, who are excited about the product’s 100% recyclable properties and sustainability credentials.

“It’s not only sustainability that our commercial customers welcome with REHAU products, but also the traceability that they get with add-ons like Window.ID,” says Richard. “Assigning a unique ID to each window allows us to monitor the status of installations via a digital dashboard. This allows us to continually deliver excellent customer service, while also having total control over what information is made visible.

“REHAU’s innovation and dedication to improving product offerings has meant we can tick all the boxes that matter to us and our customers. Thanks to REHAU’s constant innovation, we’ve been able to continue reaping all the benefits.”

THE SECRET TO A LONG RELATIONSHIP

A thirty-year partnership is no mean feat. It requires hard work and dedication from both sides, but most of all, it relies on fabricators feeling more than satisfied with the service they receive and the products they produce.

Richard says, “We’ve never had any reason to change from REHAU, and any issues we’ve had have always been solved quickly. The service has always been excellent, and the onboarding process was easy and filled us with confidence about the journey ahead of us. I’ve switched supplier before and it’s not to be taken lightly, but the support and longterm value that REHAU provides is more than enough to make up for any short-term inconvenience.

“The REHAU authorised partner scheme is also really great for our business. It means we can bring our customers into the fold, and they become part of our relationship with REHAU. It is a great point of differentiation between us and other suppliers and is one of the reasons why we’ve experienced such huge growth over the past three decades.”

And it’s not only GRM who have noticed the benefits of such an evergreen partnership, as Gareth Thomas, Area Sales Manager at REHAU explains, “the relationship with GRM is fascinating. They’ve been very innovative and have taken on lots of new products which have brought their business success.

“Over three decades of introducing a variety of new products, we always work closely with GRM to answer their questions and give guidance. REHAU have provided technical support for the company in a variety of different

ways. We have introduced the team to different types of software when onboarding new products and have helped with their tooling, sending one of our technical team to GRM’s site whenever they need extra support or training. We’ve also supported GRM directly on commercial projects with things such as drawings and specification. I also like to drop by to the site frequently– it’s always nice to see our fabricators’ friendly faces.

“But above all, one of the key reasons for the success of this partnership is the relationship GRM have with our Trade Sales Manager. This strong line of communication has led to the specification of many projects which has helped get both REHAU and GRM into the marketplace. James McLauchlan, Trade Sales Manager for REHAU, targets specific installers and funnels appropriate leads toward the business. It’s a winwin for everyone involved.”

KEEPING IT FRESH AFTER THIRTY YEARS

After such a long length of time working together, everyone who works at GRM has come to know the REHAU team, and the products, very well. Abi Osborne, Office Manager at GRM Windows, says, “REHAU is a well-known, quality profile and it’s liked by both homeowners and tradespeople. We’ve been dealing with REHAU for some time now, and we love working with them.

Their marketing support is also great. REHAU has helped us with all our branding, providing us with samples and brochures that we offer to our customers. The company website is also packed with information that we refer to if we need.

“My personal relationship with the REHAU team is great. Gareth always checks in to see that we’re all okay and our Sales Coordinator, Sue Sanderson, is always at the end of an email or phone if we need help, we know we can get in touch with REHAU straight away. They’re just a friendly bunch and are always happy to help!”

The GRM relationship with REHAU has not fizzled out or lost its spark after thirty years. If anything, the excitement for what the future holds and opportunities for growth have made the partnership even stronger. Here’s to the next three decades!

For more information on switching to REHAU window profiles, visit: https://window.rehau.com/uk-en/window-of-opportunity.

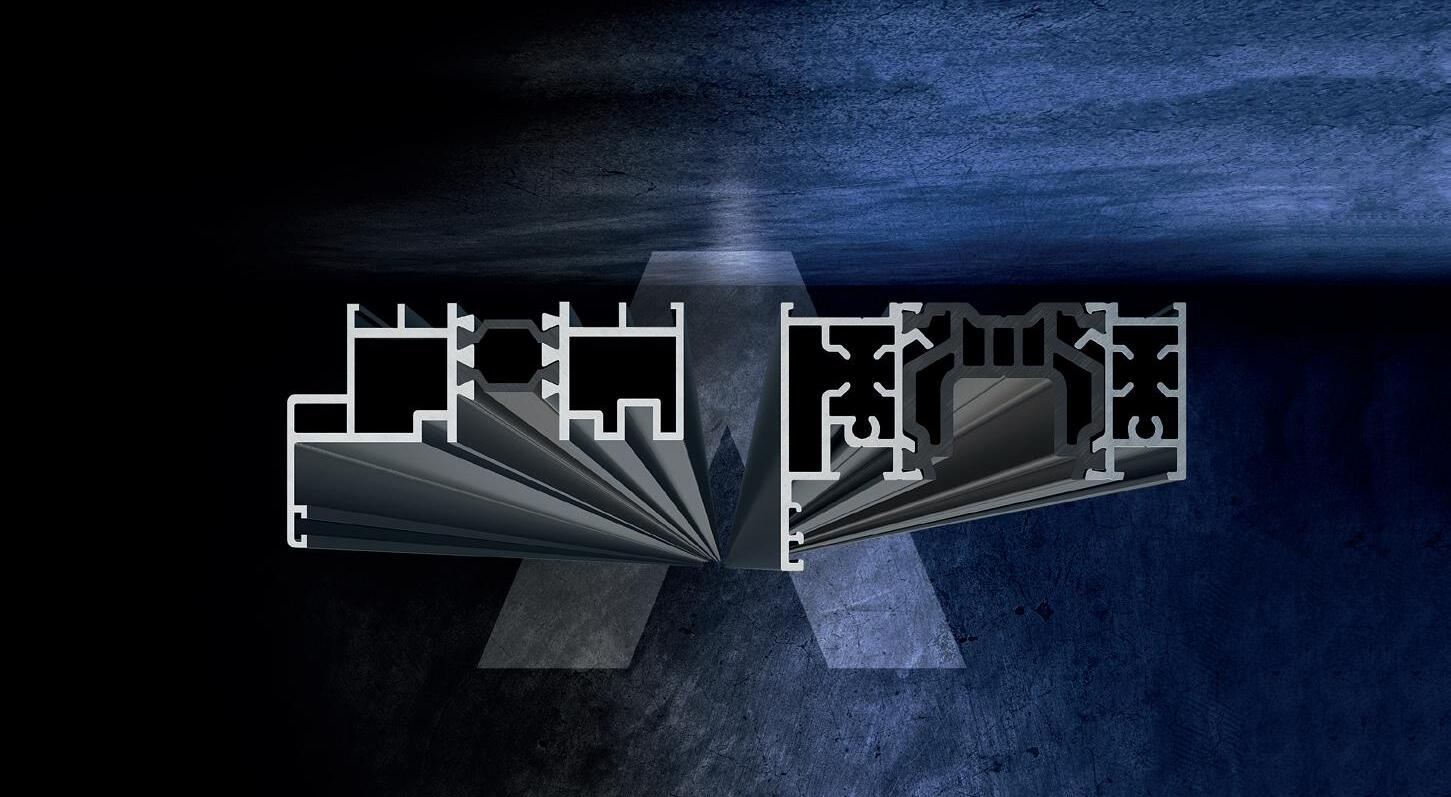

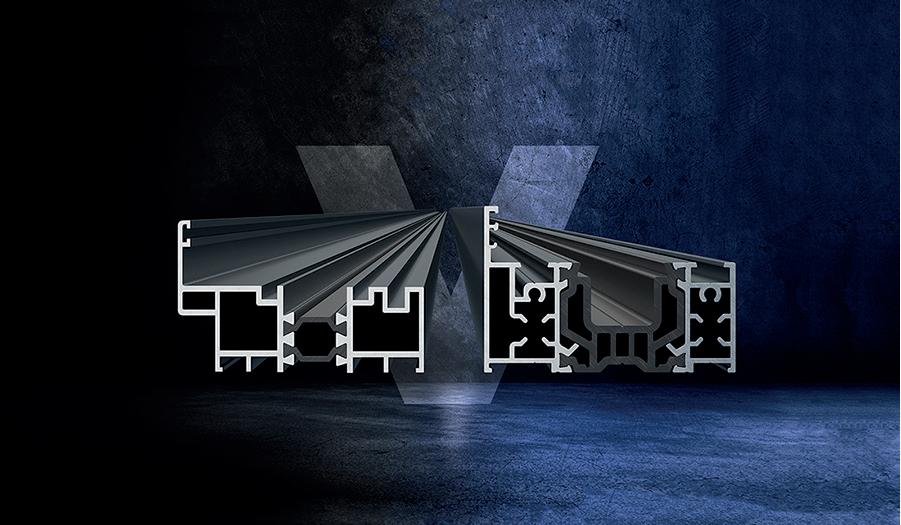

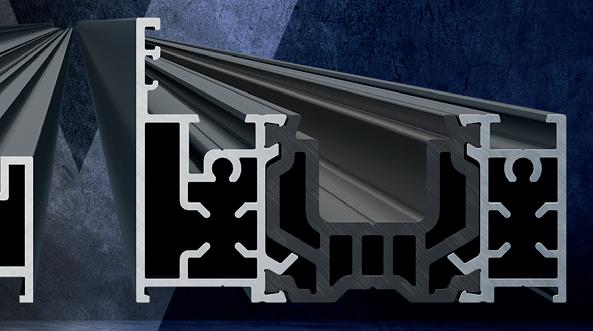

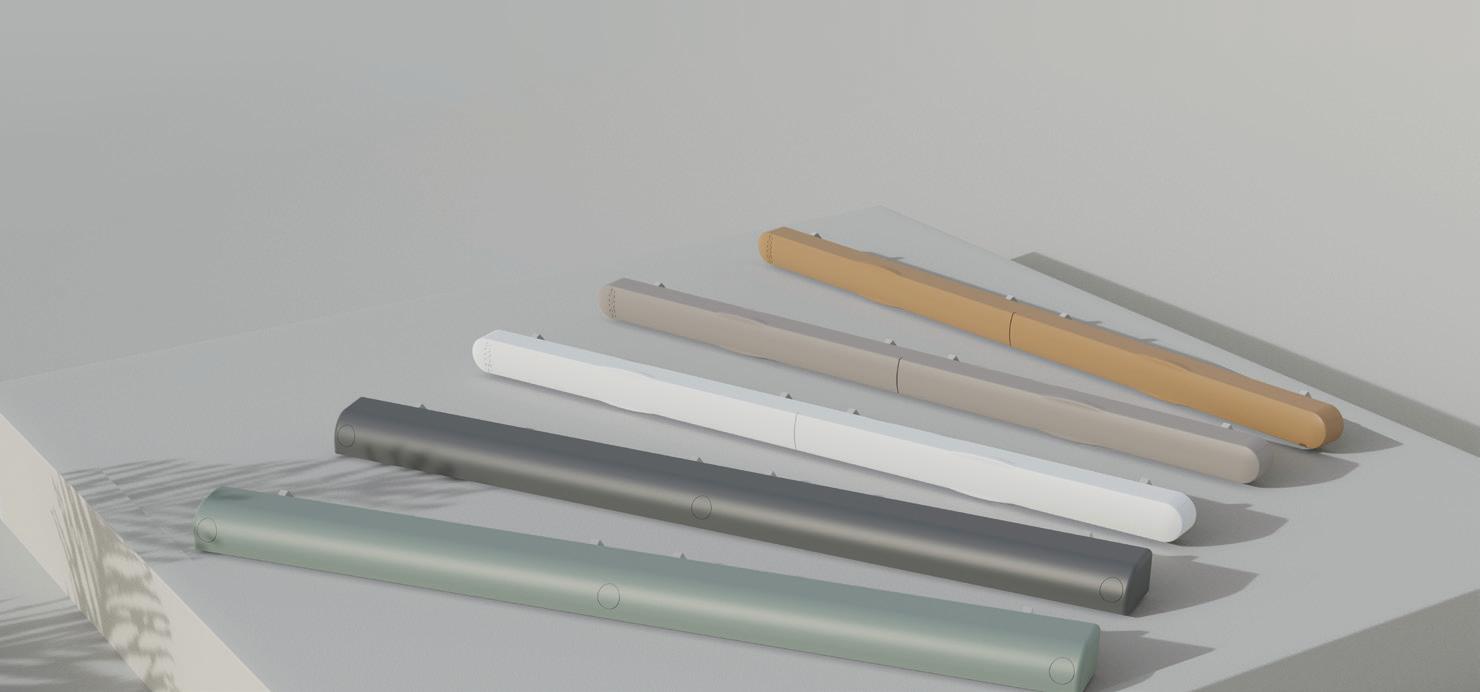

ULTRA-SLIM SIGHTLINES OF JUST 29MM THE NEXT GENERATION OF SLIMLINE DESIGN

THE MOST THERMALLY EFFICIENT ALUMINIUM SLIDING DOORACHIEVING U-VALUES AS LOW AS 0.78 W/M 2 K

OPTIONAL FLUSH STACKING

EXCLUSIVE SIGNATURE KNURLED HANDLE

UNPARALLELED THERMAL EFFICIENCY POWDERCOATED IN-HOUSE MANUFACTURED IN THE UK

CONCEALED RUNNING GEAR FOR SEAMLESS AESTHETICS

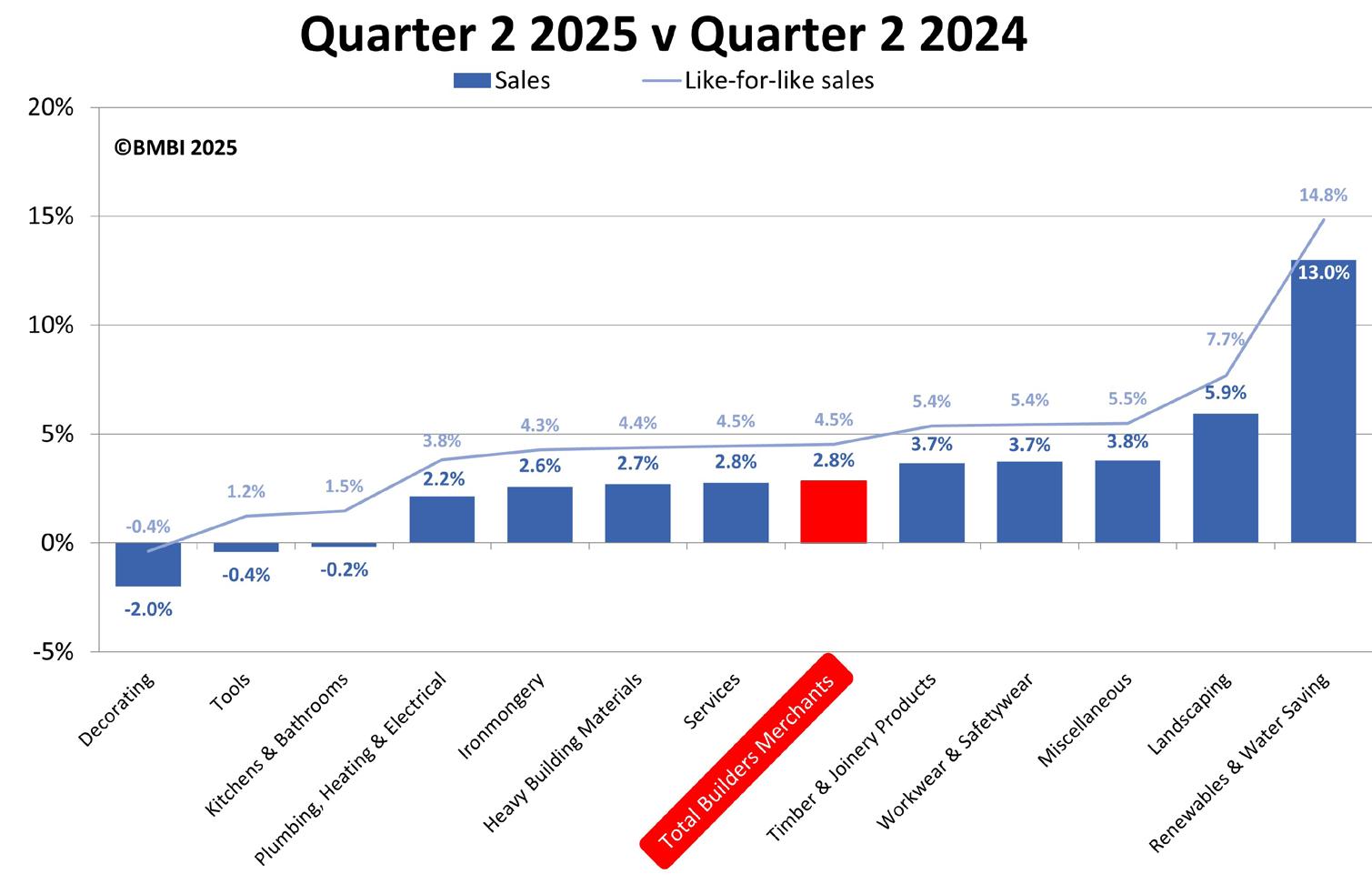

BUILDERS MERCHANT BUILDING INDEX

BUILDERS’ MERCHANT VALUE SALES VIRTUALLY FLAT IN JULY (+0.1%) YEAR-ON-YEAR BUT VOLUMES UP +0.6%

The latest Builders Merchant Building Index (BMBI) report, published in September, shows builders’ merchants’ value sales in July 2025 were virtually flat (+0.1%) compared to July 2024. Year-on-year volumes increased +0.6% while prices fell -0.6%. There was no difference in trading days.

Eight of the twelve categories sold more in terms of value compared to July last year. Renewables & Water Saving (+3.7%),

Timber & Joinery Products (+2.6%), Kitchens & Bathrooms (+1.8%) and Services (+1.7%) were the best performing categories. Heavy Building Materials (-1.1%) Decorating (-3.9%) and Workwear & Safetywear (-5.3%) were the weakest.

LATEST THREE MONTHS

In the three months from May to July 2025, total value sales were +1.8% higher

than the same three-month period a year before. Volume sales were up +3.0% while prices were down -1.2%. Ten categories sold more in terms of value with Renewables & Water Saving (+13.3%), Timber & Joinery Products (+4.0%), Plumbing, Heating & Electrical (+3.9%) and Services (+2.8%) up the most. The biggest category, Heavy Building Materials (+1.0%) grew less than Total Builders Merchants, while Workwear & Safetywear (-1.2%) and Decorating (-2.5%) were the weakest categories.

MONTH-ON-MONTH

Value sales in July were +5.8% higher than in June. Month-on-month, volume sales were up +5.4% and prices were up +0.4%. All categories’ value sales increased with Miscellaneous (+11.3%), Services (+9.0%), Tools (+8.9%), Decorating (+7.4%), Timber & Joinery Products (+6.9%), Heavy Building Materials (+6.3%) and Ironmongery (+6.0%) ahead the most. Landscaping (+0.6%) grew more slowly. With two extra trading days in July, like-

FIRE DOOR JOURNAL

New Launch | Print & Digital | Bi-monthly Magazine

for-like value sales (which take trading day differences into account) were -3.4% lower.

LATEST 12 MONTHS

Total value sales in the 12 months from August 2024 – July 2025 were flat (0.0%) compared to the previous 12-month period (August 2023 – July 2024). Volume sales increased +1.7% but prices decreased -1.7%. Seven categories sold more by value, with Services (+3.7%), Tools (+3.3%) and Landscaping (+2.6%) doing best. Of the two biggest categories, Heavy Building Materials’ (0.0%) performance was on a par with Total Builders Merchants, while Timber & Joinery Products (-1.1%) fell behind. Renewables & Water Saving (-3.9%) was the weakest category. With one less trading day this year, like-for-like value sales were +0.4% higher.

For the full report, including comments from the BMBI’s panel of leading industry Experts, please visit www.bmbi.co.uk.

Fire Door Journal is the go-to resource for industry professionals, contractors, inspectors, and facility managers who want expert knowledge delivered straight to their inbox, along with a printed edition of the bi-monthly journal. Join a growing community of professionals who prioritise safety, performance and compliance in every project.

As a subscriber, you'll get:

• Updates on fire door regulations and standards.

• Installation and maintenance best practices.

• Expert interviews, case studies, technical advice and product reviews.

• Upcoming industry events and training opportunities.

• A Panel of Experts available to answer all of your fire door related questions.

• Digital Edition direct to your inbox bi-monthly, six editions per year.

• Print Edition posted to your chosen address, six editions per year.

• Digital Newsletter direct to your inbox, monthly, twelve editions per year.

Exclusive giveaway’s, competitions and discounts in each edition.

£49 +VAT (one invoice to cover all of the above). First Edition FREE OF CHARGE. Subsequent Editions You will need to SUBSCRIBE. First Edition: September/ October 2025

To subscribe please send your full name, position, company name and invoice address to: christina@firedoor-journal.co.uk.

DOORS

SHOWROOMWORTHY STYLE

From bold colours to minimalist details, Signature Doors make an unforgettable first impression with limitless possibilities to match your project’s design vision.

FIT AND FORGET

Say goodbye to costly and time consuming call backs. Signature doors are designed with durability and reliability in mind, allowing you to Fit and Forget

NO BOW GUARANTEE

Setting a new standard for composite doors, DAWS offers an allaluminium door that’s unshakeably secure and comes with a No Bow Guarantee.

ROCK-SOLID SECURITY

Rock-Solid Security

Reinforced aluminium, a £4,000 guarantee on the locks, and PAS24 compliance, your customers will sleep easy.

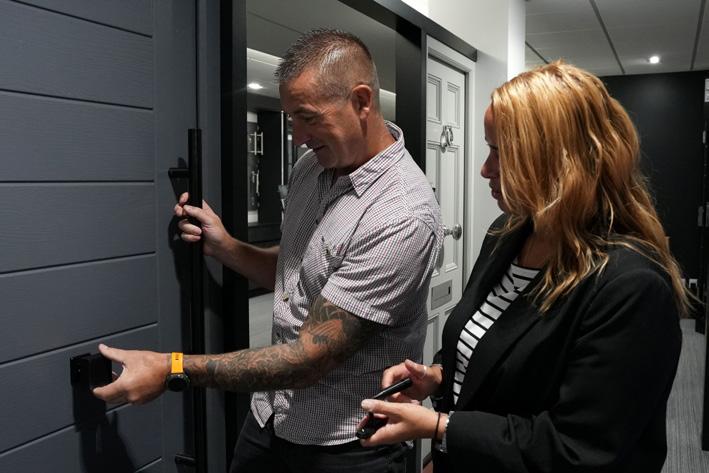

ASK THE EXPERT HARDWARE

In this month’s Glass News interview, we sit down with Phil Walklett, Design & Engineering Manager at Coastal Group, to explore how the company’s innovative research and development process is shaping the future of door and window hardware.

PUSHING THE BOUNDARIES OF HARDWARE DESIGN: AN INTERVIEW WITH COASTAL GROUP’S DESIGN & ENGINEERING MANAGER, PHIL WALKLETT

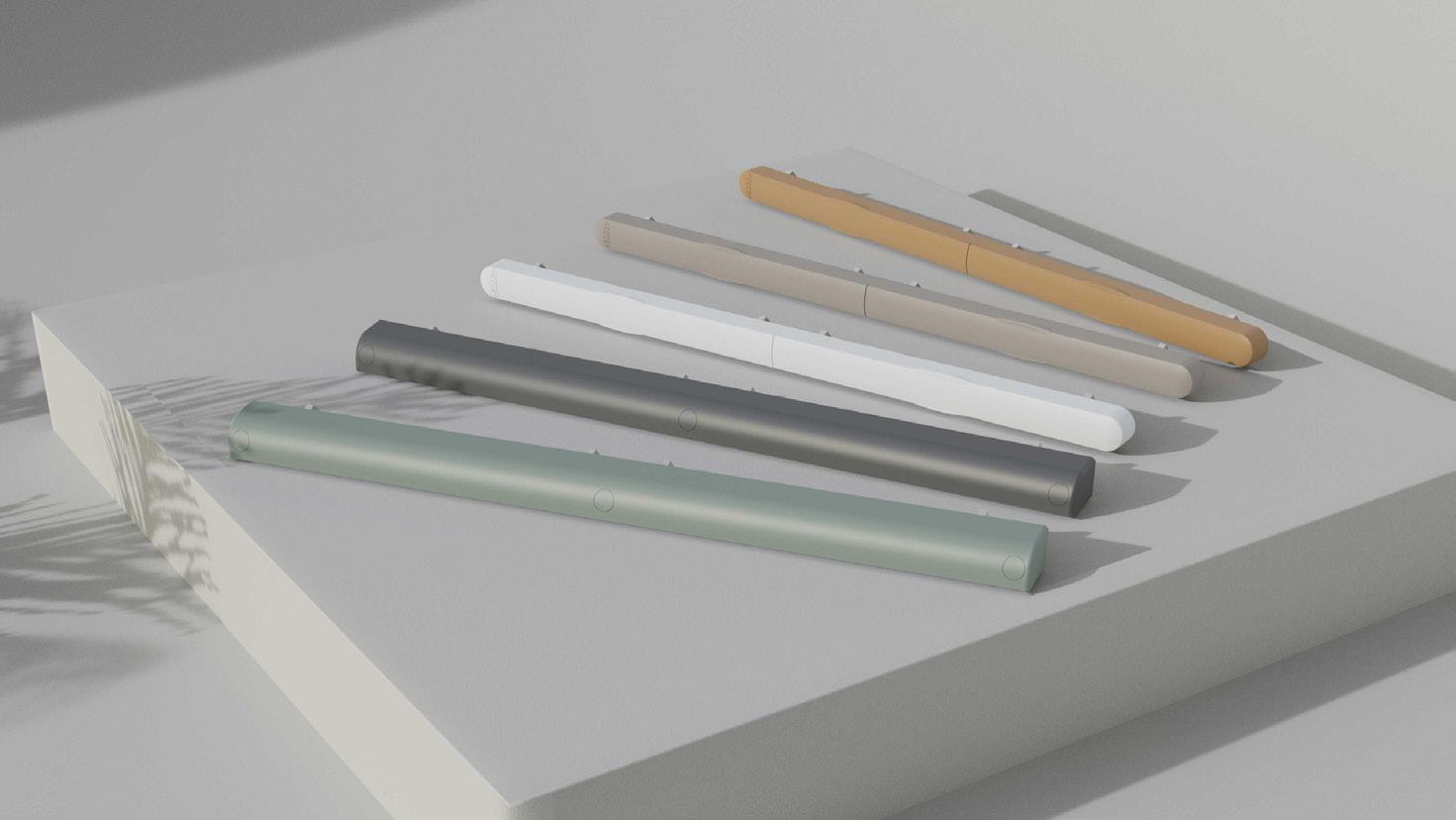

Phil, tell us a bit about your role at Coastal and what a typical day looks like. My day revolves around new product development. Right now, we’ve got around 60 projects in the pipeline. That means a lot of CAD drawings, renders and prototypes to bring ideas to life. I also work closely with our Research and Development coordinator, Michelle. She passes new product ideas to me, I turn them into designs and then we refine them together with the customer. On top of that, I support engineering and IT within the business.

With so many projects on the go, how does Coastal’s approach to product development differ from others in the market?

We’ve invested heavily in the full design cycle. We create lifelike renders, move quickly into 3D printing and get working prototypes into the hands of customers for testing. In some cases, we can take an idea from a sketch to a 3D-printed model in as little as 48 hours. That speed and accuracy give us – and our customers –real confidence before committing to full production.

And how do customers respond to that? They love it. Holding a prototype, fitting it to a door and seeing how it feels is so much more valuable than looking at a 2D drawing. From our perspective, 3D printing lets us validate the design early and make sure it works. Customers tell us this is something our competitors just don’t offer.

Can you share some recent projects?

We’ve been working on a spring cassette system for lever handles, which ensures the handle always returns smoothly. We prototyped and tested it in-house before sending it to the supplier, who told us it was an “outstanding design.” That was great feedback. We’re also developing new lever handles, door furniture and backplates tailored to both timber and aluminium markets, as well as a product that’s completely new to us; but we can’t talk about it yet!

You mentioned different markets. How do customer insights feed into development?

A lot comes directly from our business development team, who are out with joiners, manufacturers and installers every day. In the aluminium sector, for example, there’s huge demand for slimmer styles of hardware to suit narrow-framed doors. Timber markets, by contrast, lean toward more traditional looks. We listen to both and adapt accordingly.

Coastal is well known for 316 marinegrade stainless steel. How does engineering ensure products can withstand tough environments?

We’ve got the advantage of being based in Cornwall – one of the harshest environments in the UK. We carry out inhouse and outdoor testing here, monitoring products over six months or more in real weather conditions. Alongside that, we work with suppliers and test houses on cycle

testing, salt spray, UV resistance and scratch resistance. All that data feeds back into refining finishes and performance.

Coastal recently launched interchangeable handles and back plates. What challenges did you face in bringing that innovation to market?

A few years back we launched our Regent and Opera ranges of door handles. They did well and gave us valuable feedback. We went back to the drawing board, added a spring cassette system, standardised back plates, and made everything interchangeable. That means if a spring fails, you just replace the cassette, not the whole handle. It also gives customers endless design flexibility. Early feedback has been excellent, and we’re already expanding the range.

Can you give an example of a product that went through major refinement during development?

Our TS008-certified letter plate is a great example. Creating something traditionallooking that also meets stringent modern security standards has been a real challenge. We’ve used 3D printing and rapid prototyping extensively, and we’re currently about 85% there. We’re continuing to fine-tune the design with input from external partners as well, but we’re close to finalising this new product.

Sustainability is a big topic in product design. How do you address this?

We factor it in from the start. We minimise waste by getting designs right on screen

before prototyping. We also look at whether we can make components smaller, more cost-effective, and longer lasting. Stainless steel is naturally sustainable because of its longevity, and most of our products carry a lifetime guarantee. For our new brass range, we’re working with a supplier that uses fully recycled brass – mostly recovered from old gas taps – which is a big step forward.

Finally, what excites you most about the projects in the pipeline and where do you see the market heading?

For me, it’s the satisfaction of taking something from a customer’s idea, developing it, and seeing it come to life. That’s the best part of the job. Looking ahead, I think hardware will increasingly move towards electronic solutions – things like fingerprint or keyless entry. We’re already working with Winkhaus on the EAV4+ electronic locking system and developing furniture to complement it. At the same time, slimline designs and flexible, customisable ranges are going to be key trends.

And where do you gather inspiration for new ideas?

Trade shows are important, but so are our own teams. Our business development staff are boots on the ground, bringing back real insights from customers, and that shapes what we do. Whether it’s slimline door furniture or recycled brass hardware, it all comes back to listening to the market and innovating with purpose.

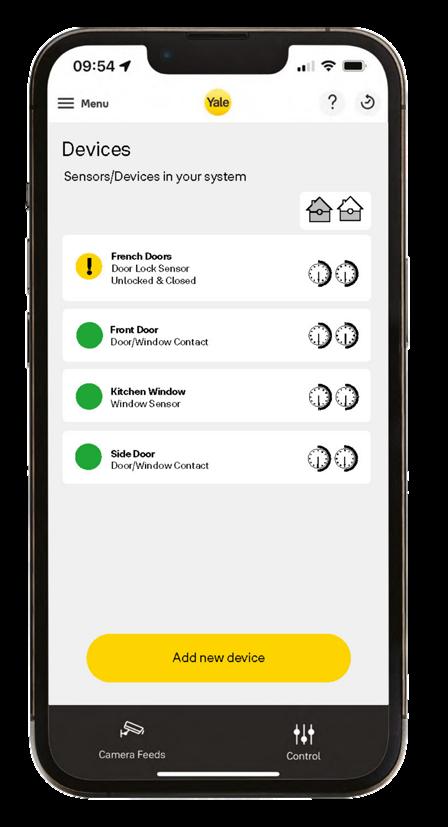

KENRICKS EXTENDS SMART LOCKING RANGE WITH AK SAFE

SECURE SMART LOCK BOX

Kenricks has expanded its smart locking range with the launch of the new AK Safe Secure Smart Lock Box. The new smart box offers a robust and intelligent solution designed to keep keys and access cards safe, secure and always within control.

The new lock box combines Kenricks’ renowned strength and reliability with cutting-edge smart technology, making it an ideal choice for locksmiths, property managers, rental operators and commercial businesses that need to manage access securely and efficiently.

Andy Meakin, Sales and Marketing Manager at Kenricks, said: “The AK Safe Secure Smart Lock Box provides a simple and secure way to manage shared access. Whether you’re a locksmith supplying customers, a facilities manager overseeing multiple buildings, or a commercial operator needing secure key storage, this product delivers unmatched convenience and peace of mind.”

The AK Safe Secure Smart Lock Box has been designed to offer significantly greater storage than standard lock boxes,

Experience Exceptional Service

Discover service that goes beyond hardware supply. Our team of experts are on hand to advise, source and deliver the hardware you need, when you need it.

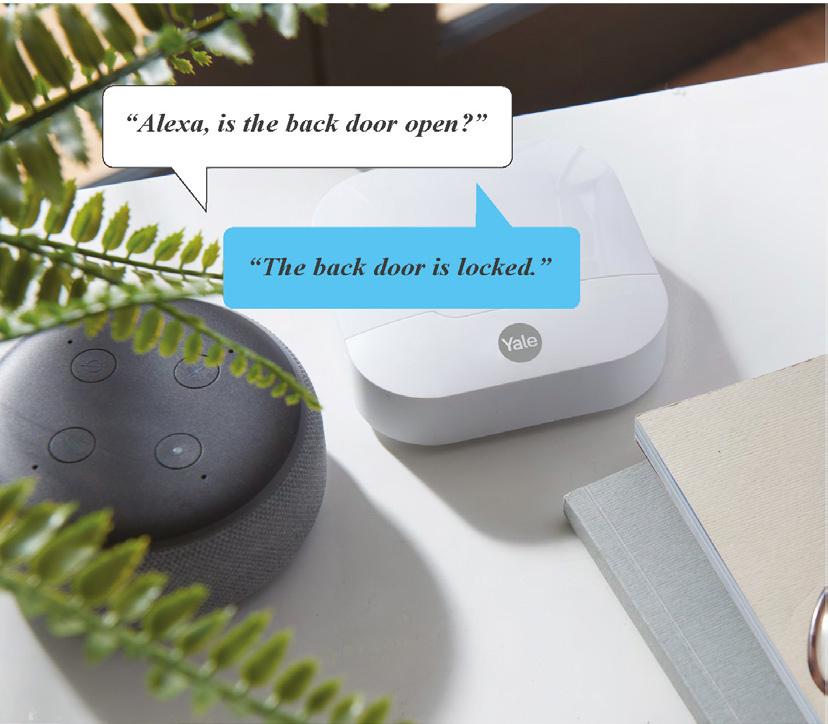

holding at least six keys, two cards and one car key. It can be managed and monitored remotely through the AK Secure™ smartphone app, which provides real-time notifications and integrates seamlessly with Google Home and Alexa for easy, hands-free control.

Designed to withstand the toughest conditions, the lock box features a zinc die-cast body that is weatherproof to IP55, while the advanced digital keypad has been rigorously tested to resist up to 150 lbs of force and 250 lbs of pulling pressure. Available in both wall-mounted and portable versions, it provides the flexibility needed across residential, commercial and industrial settings.

“The AK Safe Secure Smart Lock Box provides a simple and secure way to manage shared access. Whether you’re a locksmith supplying customers, a facilities manager overseeing multiple buildings, or a commercial operator needing secure key storage, this product delivers unmatched convenience and peace of mind.”

Installation is straightforward, making the lock box a strong retrofit option as well as a valuable upsell opportunity for locksmiths and trade professionals. It joins the acclaimed Kenrick AK Touch Secure™ smart locking system, which has already earned praise for its ability to be fitted quickly without major hardware modifications.

Like the AK Touch Secure™, the AK Safe Secure Smart Lock Box reflects Kenricks’ intelligent application of smart technologies. With its combination of innovative design and uncompromising durability, it delivers everything expected from a company with Kenricks’ extraordinary history and exceptional track record.

MILA BOOSTS DOOR HANDLES’

SECURITY ACCREDITATION

Mila’s SUPASecure™ 220mm and Harbour Collection high-security TS007 2 Star door handles have achieved Sold Secure certification, joining the already accredited SUPASecure™ 240mm model. This means all three handles now carry Sold Secure Silver Grade, Secured by Design, and TS007 2-star approval – a triple badge of trust.

The new accreditations further strengthen Mila’s security credentials, providing door and window fabricators with greater assurance that Mila handles can deliver the highest level of protection available.

When paired with a 1-star cylinder – all three door handles now achieve the maximum 3-star TS007 rating. The highest standard attainable anywhere, the TS 007 3-Star Kitemark testifies that a product offers elite protection against common forced-entry techniques such as snapping, bumping, drilling, and manual attack.

Straff Cooke, Technical Director at Mila, is proud of what this means for customers: “We’re delighted with these latest accreditations. They confirm that our door handles meet the very highest industry standards for security, reinforcing our position as a trusted leader in security hardware for the window and door industry.”

With the handles part of wider product ranges, SUPASecure™ and Harbour, fabricators and installers can specify fully coordinated door and window hardware solutions that not only offer unrivalled protection but have a consistent look and feel.

Moreover, each handle is backed by Mila’s 25-year mechanical and finish guarantee, underlining the company’s confidence in long-term performance and durability. Straff Cooke adds: “We’re absolutely committed to offering product ranges that meet the most rigorous standards for burglary resistance, long-term durability, and style. These new accreditations underline that there is no better option for fabricators in search of door handles that tick every box.”

To find out more about Mila and its marketleading range of door handles, please visit https://www.milasecure.com/uk/en.

UAP LAUNCHES NEW BULLET DOOR CHAIN: SLIMMER, STRONGER SECURITY WITH A SLEEK, STYLISH FINISH

UAP Ltd, a leading UKbased supplier of highquality door hardware and security solutions, has launched an innovative new Bullet Door Chain: a next-generation door security chain engineered for strength, style, and effortless installation.

Designed with a thinner yet more durable profile, the new Bullet Door Chain meets and exceeds the latest TS003 security requirements and is fully PAS 24-compliant, delivering robust protection without compromising aesthetics. Featuring a

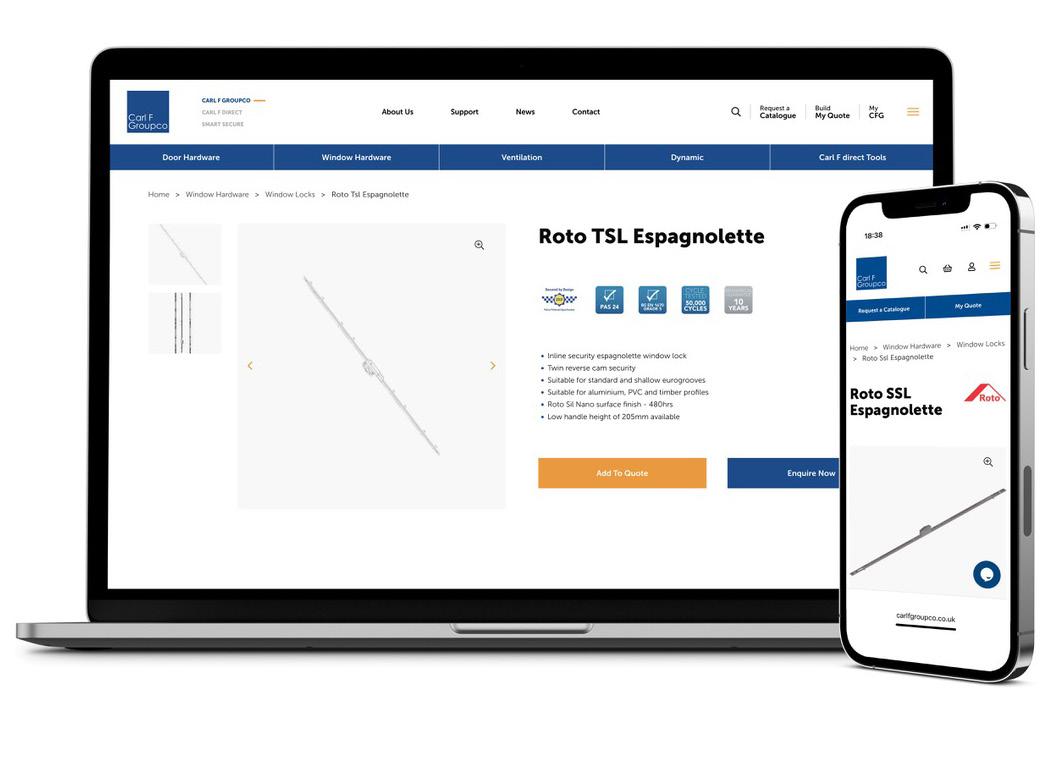

CARL F GROUPCO SELLS ONE MILLIONTH

ROTO

Independent

hardware supplier Carl F Groupco has sold its one millionth Roto Espagnolette Window Lock, underlining both the popularity of the product and the strength of its partnership with Roto.

Julie Warner, Roto Product Manager at Carl F Groupco, said: “Our customers consistently value the combination of quality, reliability and functionality that Roto delivers. Reaching the one million milestone is clear evidence of this.”

The Roto Twin-Cam Security Lock Espagnolette has been designed to provide a high level of security for outward opening windows.

The espagnolette features up to four pairs of dual reverse locking points. When the handle is operated, it drives the double-

sided strikers from opposite directions, ensuring maximum burglary protection.

The Roto SSL Espagnolette is suited for both top and side hung outward opening casement windows, accommodating sash rebates between 240mm and 1,800mm. Profile-related

unique bullet-shaped chain end, the force of impact is distributed evenly across the bracket and receiver, reducing stress and enhancing long-term durability.

The chain’s sleek magnetic park system keeps it securely and neatly in place on the wall when not in use, elevating the look of any door with a polished, design-led finish. Thicker chain links increase overall strength and tamper resistance while maintaining a slim, modern profile that complements contemporary interiors. Available in a range of premium finishes, the Bullet Door Chain comes with pre-fitted fixings, providing the fastest installation experience on the market and saving valuable time on site.

Adam Dixon, Senior Technical Manager at UAP Ltd, commented: “The all-new Bullet Door Chain is a perfect example of

how innovative design and engineering can redefine everyday hardware. Slimmer, stronger, and smarter, it delivers uncompromised security while enhancing the door’s aesthetic appeal.

“Backed by patent applications and protected design rights, it reflects UAP’s commitment to driving progress in door hardware innovation — combining strength, style, and functionality in one elegant solution. Whether for residential or commercial use, the Bullet Door Chain raises the standard for door hardware security across the board.”

For more information or to speak with the UAP sales team, visit www.uaplimited. com/products/bullet-doorchain/ or contact sales@uaplimited.com.

ESPAGNOLETTE WINDOW LOCK

keeps are available and the espagnolette is compatible with all leading profile extruders.

Both espagnolette options feature RotoSil surface protection, providing a Grade 5 finish that is particularly important for coastal applications.

Carl F Groupco is a longstanding Roto partner and one of the UK’s largest stockists of its hardware. Its portfolio includes espagnolettes, hinges, sliding door systems, tilt & slide hardware and reversible gearing. The company holds around £5.5 million of stock across all product ranges, enabling it to fulfil over 98% of orders within 24 hours.

Julie commented: “The strength of our partnership with Roto supports the service reliability that customers expect from us. The one millionth sale demonstrates not only the quality of Roto’s products, but also the trust fabricators place in Carl F Groupco to deliver consistently.”

Reaching one million sales is a clear endorsement of both the product and the partnership behind it. For fabricators, it underlines why Carl F Groupco is trusted as a leading hardware supply partner: proven product quality, reliable availability and service levels that ensure orders are delivered on time, every time.

PROFILE RELATED CATALOGUES FROM VBH

Hardware supplier VBH has introduced a range of profile related catalogues to help their customers quickly find products from the vast VBH range.

The selection covers what VBH describes as the most popular PVCu and aluminium systems currently in use in the UK. Each catalogue is tailored to the individual system, meaning that everything listed is suitable to the reader’s needs.

As well as products from VBH’s own hardware and furniture brand, greenteQ, each catalogue also includes relevant hardware from VBH’s key supply partners including AGB, Cotswold, Roto, Securistyle, Weiss-Chemie and Yale amongst others.

Gary Gleeson from VBH says “We initially produced a profile related catalogue to suit Deceuninck’s PVCu systems to support our joint customers.

“The catalogue proved so popular that it made sense to roll out the idea further to other widely used PVCu and aluminium systems. We basically strip out all the irrelevant products and variants and add more detail on the profile related parts, making it easier to navigate. Who wants a catalogue showing window handles with 11 different spindle lengths when you’re only going to use one length? Nobody!”

The very latest VBH catalogues are available to view and download from the company’s website at www.vbhgb.com and Customer Portal at www.vbhgb24.com.

Gary adds “The benefit of having our catalogues online is that we can always ensure that they are 100% up to date. Our range is constantly evolving, therefore so is our literature.”

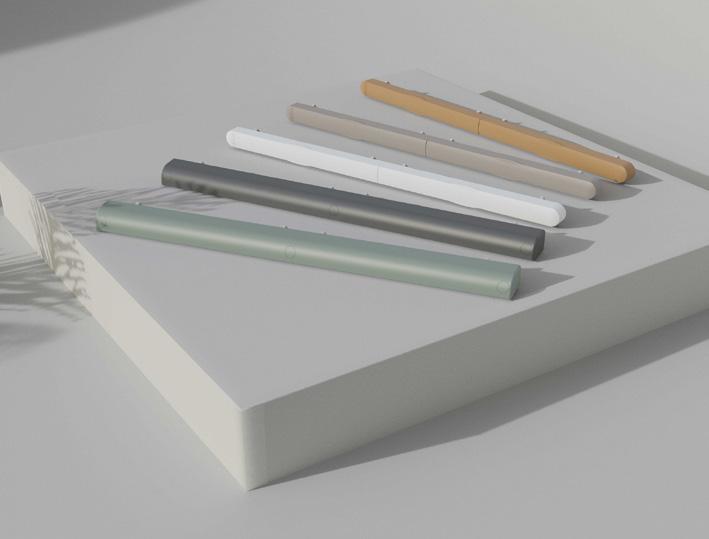

The Perfect Handle for Slim Aluminium Doors

Give your customers the upgrade they’ve been looking for with Coastal Group’s new slimline lever door handles, the AML096 and EGC096.

Key Features:

y 26mm width backplate – perfect for narrow profiles

y Solid 316 marine grade stainless steel – maximum corrosion resistance, and durability

y Spring cassette – smooth, solid operation

y Lifetime guarantee

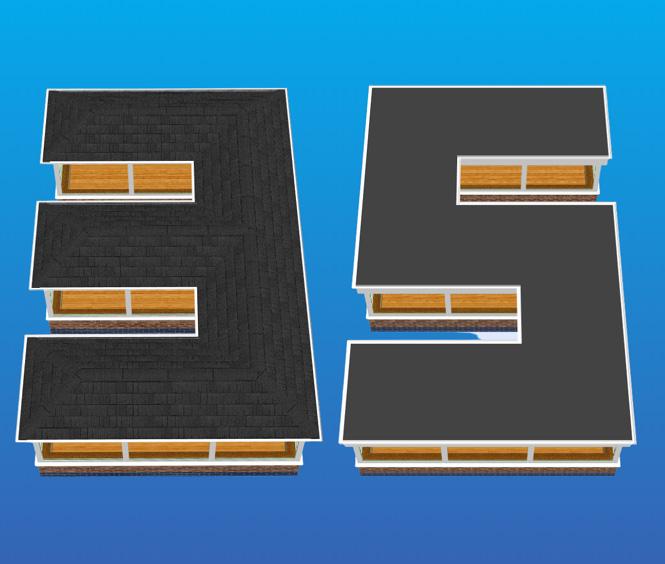

Spot three differences. Fill in your answer and your contact details below and send your competition entry to: FAO: Christina Lazenby, Glass News Competitions, 27 Langdale Drive, Tickhill, Doncaster, DN11 9UX or Email: christina@glassnews.co.uk. Entry deadline: 20/10/25.

Name: Tel:

Address:

y Single plate system – no cover plates, just a clean, seamless finish

y Designed & assembled in the UK

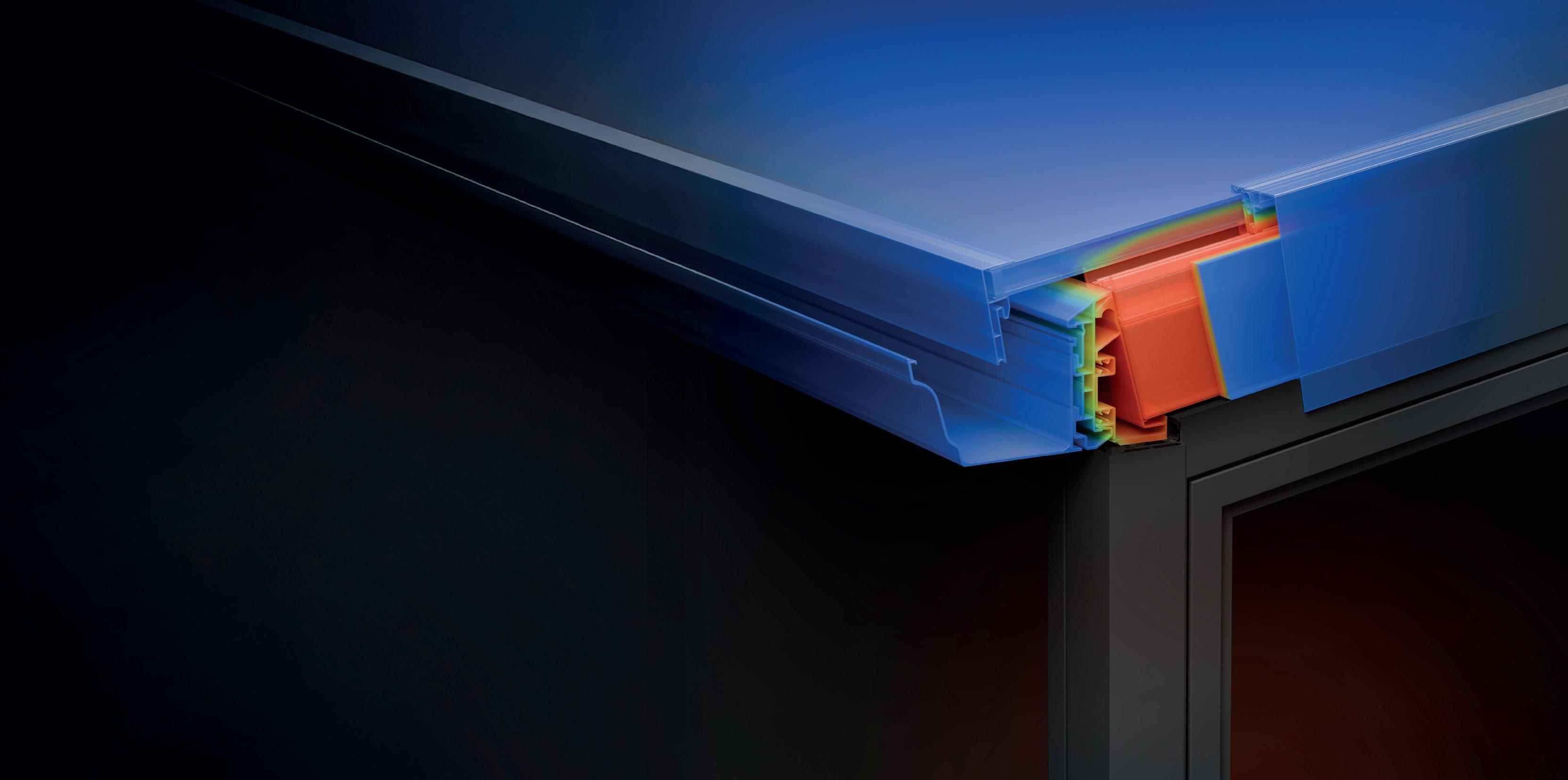

ASK THE EXPERT SUSTAINABILITY

In this month’s Glass News interview, we sit down with Luke Osborne, Senior Architectural Systems’ UK sustainability lead. Luke gives fabricators and installers the clarity they need to stay ahead in a competitive market.

SIMPLIFYING SUSTAINABILITY WITH ACCURATE PRODUCT INFORMATION

With sustainability targets rising across the fenestration sector, Luke Osborne, Senior Architectural Systems’ UK sustainability lead, discusses how product manufacturers, and specifically the technical documents they provide, can give fabricators and installers the clarity they need to stay ahead in a competitive market.

When it comes to making claims about the performance of a product, Environmental Product Declarations, or EPDs, are a vital part of cutting through the noise and proving how ‘environmentally-friendly’ a product really is. For installers and fabricators, understanding what an EPD is, and what makes one truly useful, is key to being able to have more informed discussions with main contractors and specifiers. As regulations and sustainability targets tighten and carbon reporting becomes more project-specific, this ability to interpret and apply environmental data is no longer just a technical concern but can also be a commercial advantage.

WHAT IS AN EPD?

Put simply, an EPD is a third-party verified document that outlines the environmental impact of a product across its entire life cycle. This includes everything from raw material extraction and manufacturing to transportation, installation

and end-of-life disposal. It doesn’t make value judgments about whether a product is sustainable, but it does provide the facts needed to make meaningful comparisons and informed decisions.

NOT ALL EPDS ARE EQUAL

Senior Architectural Systems has recently published a new EPD for its SF52 mullion drained aluminium curtain wall system, and by doing so we hope to have set a new benchmark for transparency in the fenestration industry. Developed in accordance with EN 15804+A2 and independently verified to ISO 14025:2011, our SF52 EPD includes data on global warming potential, energy consumption and water usage but crucially, it covers the full system—not just the aluminium billet. That means thermal breaks, gaskets, fixings, fabrication and delivery to site are all accounted for, along with the energy-intensive extrusion process.

This level of detail is often missing from comparable EPDs, which typically report carbon figures for 1kg of aluminium and exclude key stages of the product’s journey. By contrast, we have created an EPD that offers project-relevant data which actually reflects the reality of what installers and fabricators are working with on site.

THE DEVIL IS IN THE DETAIL

Curtain walling is inherently bespoke, with individual project requirements introducing design changes which makes like-for-like comparisons of different systems very difficult. That’s why we have aligned our EPD with the latest BS EN 18001:2024 Product Category Rules for curtain

walling, using the recommended reference sizes for the system. Importantly, this means that glazing is left out, as it is not normally supplied by system houses. If glazing is included, it can distort results when divided down to 1m² declared unit. The heavy weight of glass, combined with its relatively low carbon per kg, makes the overall figures for the aluminium system look lower than they really are after conversion. That’s why for complete accuracy, glazing should always be reported separately through its own EPD. By taking this approach, we believe our SF52 EPD gives a true and transparent figure per m² of aluminium system. In addition, multiple system sizes have been verified and scaling tables developed to ensure precise data is available across the full SF52 range, and we are proud that we are currently the only UK system house to take this comprehensive approach.

WHY IT MATTERS TO YOU

Reliable environmental data has become a vital part of the construction process. Whether you’re quoting for a BREEAM-certified build or advising on Passivhaus compliance, having access to clear, project-specific data helps you build trust with main contractors, support sustainable specification, and stand out in competitive tenders. Our SF52 curtain wall system is one of our most popular product solutions so it made sense to us to lead with this EPD but we are in the progress of developing further EPDs for our aluminium system portfolio, including our patented PURe® range of windows and doors. It’s all part of our commitment to raising standards and helping to drive continuous improvement in environmental performance across the aluminium fenestration industry,

The EPD for the SF52 curtain wall system is available to download now from Senior’s website or by contacting the team directly. For more information, visit www.seniorarchitectural.co.uk call 01709 772600 or email enquiries@sasmail.co.uk.

SHEERLINE SELECTED FOR TRANSFORMATIVE EXTENSION IN WINTERBOURNE, BRISTOL

A bungalow in the idyllic setting of Winterbourne, Bristol, has undergone a huge transformation thanks to a large extension and the installation of Sheerline’s aluminium windows and doors. As a result of the impressive transformation, the project has won Installation of the Month for July.

The fabricator on the project was Master Plastics, the long-term supplier of Bristolbased installer, Maynard Windows. The companies previously won Sheerline’s competition last year for the work they completed on an exclusive development in the Frenchay area of Bristol.

As part of the Winterbourne project, Maynard Windows installed multiple products from Sheerline’s Prestige range in Anthracite Grey (RAL 7016) inside and out to achieve consistent styling throughout. This includes a Prestige Door with an aluminium panel along the bottom.

Prestige windows were installed to the side of the property. In the main living area, two large picture windows and an impressive double pane Prestige Lift & Slide Patio measuring approximately 5.8m in length were installed.

This combination of products offers a minimal frame to glass ratio and was selected for its ability to provide unrestricted views of the surrounding countryside. Maynard Windows also made use of Sheerline Bespoke’s in-house arched frame service.

In the kitchen there had originally been a bi-fold door with an arch above it, however, due to the new layout, this product no longer worked. Instead, the homeowners opted to maintain the existing shape with an arched Prestige frame.

Underneath it, there are two standard casement Prestige windows that push open

to allow for ventilation as required. As well as providing views to the fields behind the house, the arched frame is a standout design feature of the new kitchen.

Matt Maynard, Director at Maynard Windows, said: “Everything was spot on, I’ve had no issues with Sheerline, I like everything about it – it’s the best system on the market without a doubt. But more importantly, the customers are happy, and the house looks lovely.”

Martin Hepburn, Sheerline’s Area Sales Director - South West, commented: “Well done to Master Plastics and Maynard Windows – what a stunning installation! This project shows precisely what can be achieved with the Prestige range and how easy it is to create a consistent aesthetic throughout the home with Sheerline.”

To speak to Master Plastics directly, contact the team on 0117 971 4433 or visit the

website: https://www.masterplastics.co.uk. Maynard Windows can be contacted on 07977 490777 or via the website: https://www.maynardwindows.co.uk.

Alternatively, find out more about Sheerline’s Prestige range here: https://www.sheerline.com.

NOVUM STRUCTURES AND PYROGUARD DELIVER INNOVATIVE FAÇADE GLAZING SYSTEM FOR LUXURY CRUISE LINERS

Novum Structures, a globally recognised specialist marine contractor in glass, steel and ETFE, and Pyroguard, the world’s leading independent provider of fire safety glass, have worked in partnership to design a fire-rated, clear-view façade glazing system that is fully tested and accredited to meet A30 and A60 fire resistance criteria for use on cruise liners. The innovative solution was developed for the Royal Caribbean Group and first used as part of its latest ‘Wonder of the Seas’ liner. Novum Structures approached Pyroguard to support the company in meeting the challenges and specific requirements of the project. The requirement was to produce glazed wall panels and a clear-view façade which complied with fire safety standards, whilst meeting aesthetic requirements and achieving a lightweight design.

One of the main challenges of supplying glass solutions was ensuring the system did not exceed stringent weight recommendations. In shipbuilding and the marine sector, weight is a crucial factor as it can impact overall efficiency, fuel consumption, stability, balance and performance.

Novum’s design aimed to achieve the maximum glazed area, with minimised steel frame, offering an unimpaired vision for the passengers. Pyroguard’s glazing system had to deliver exceptional fire resistance while maintaining a clear-view façade glazing system without obstructing frame elements. Specifically, it had to meet A30 and A60 fire-resistance criteria.

The Pyroguard and Novum glazing solution achieved IMO MED (International Maritime Organisation Marine Equipment

Directive) certifications, which ensure the system meets strict fire and safety performance for marine applications.

Steve Goodburn, Business Development Director, at Pyroguard, said: “We are delighted to have worked closely with Novum to develop fully tested and certified fire-rated, clear-view façade glazing systems for cruise liners. This was a complex project that involved the expertise of our technical teams and it was great to partner with Novum from an early stage on the project. Once the system was fully tested and certified, it was delivered on schedule to meet the client’s exacting requirements.”

A key engineering challenge was the curved configuration of the glazing system. Traditional curtain wall systems would have required extensive use of steel supports, significantly increasing the overall weight and obstructing passenger vision.

To address the design and weight challenges of the project, Pyroguard, in collaboration with Novum, proposed the use of a buttjointed glazing system. This provided a structurally efficient and lightweight solution that offers the necessary flexibility. This approach also enhances visual clarity, light transmission and UV stability without compromising safety. The design of the system minimised the use of additional steel reinforcement, meeting the unique design requirements and significantly reducing the overall structural load.

Pyroguard’s toughened fire-rated glass is designed to withstand fire exposure for up to 60 minutes. The installation consists of 280 m2 of 32 mm thick glass

comprising three layers of toughened safety glass with two active gel interlayers. The internal cavities of the profiles are filled with non-combustible insulating materials to minimise heat transfer, resist high temperatures and provide excellent insulation, effectively preventing the spread of flames, smoke and heat.

The glazing system is supported by a robust stainless steel profile structure, made from 1.4401 grade steel, which was selected for its superior corrosion resistance in marine environments.

The system was tested to ensure that it met the required fire safety standards for the marine environment and it successfully achieved an A60 class rating for straight walls and an A30 class rating for facetted walls.

Richard Mattocks, Managing Director, Novum Structures said: “We are excited to offer the cruise market a fully tested and certified fire-glazed system and it was fantastic that its first use was on such a prestigious cruise liner.

“The project had its challenges and complexities but by working closely with Pyroguard, we were able to meet all the fire safety and performance requirements of the glazing system. Together we have pushed the boundaries of design and innovation with this newly developed curved glazing façade that complements the aesthetic requirements with maximum light transmission and minimum weight.”

For more information visit www.pyroguard.eu.

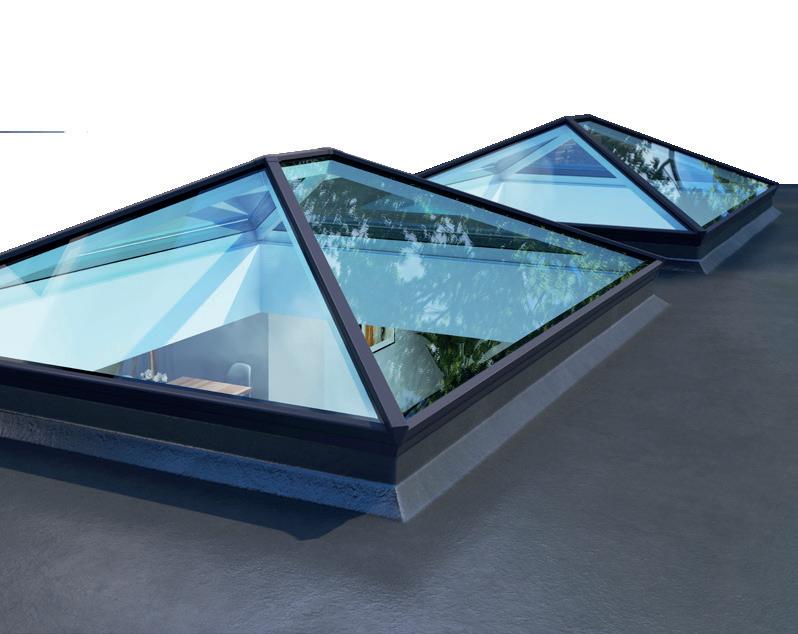

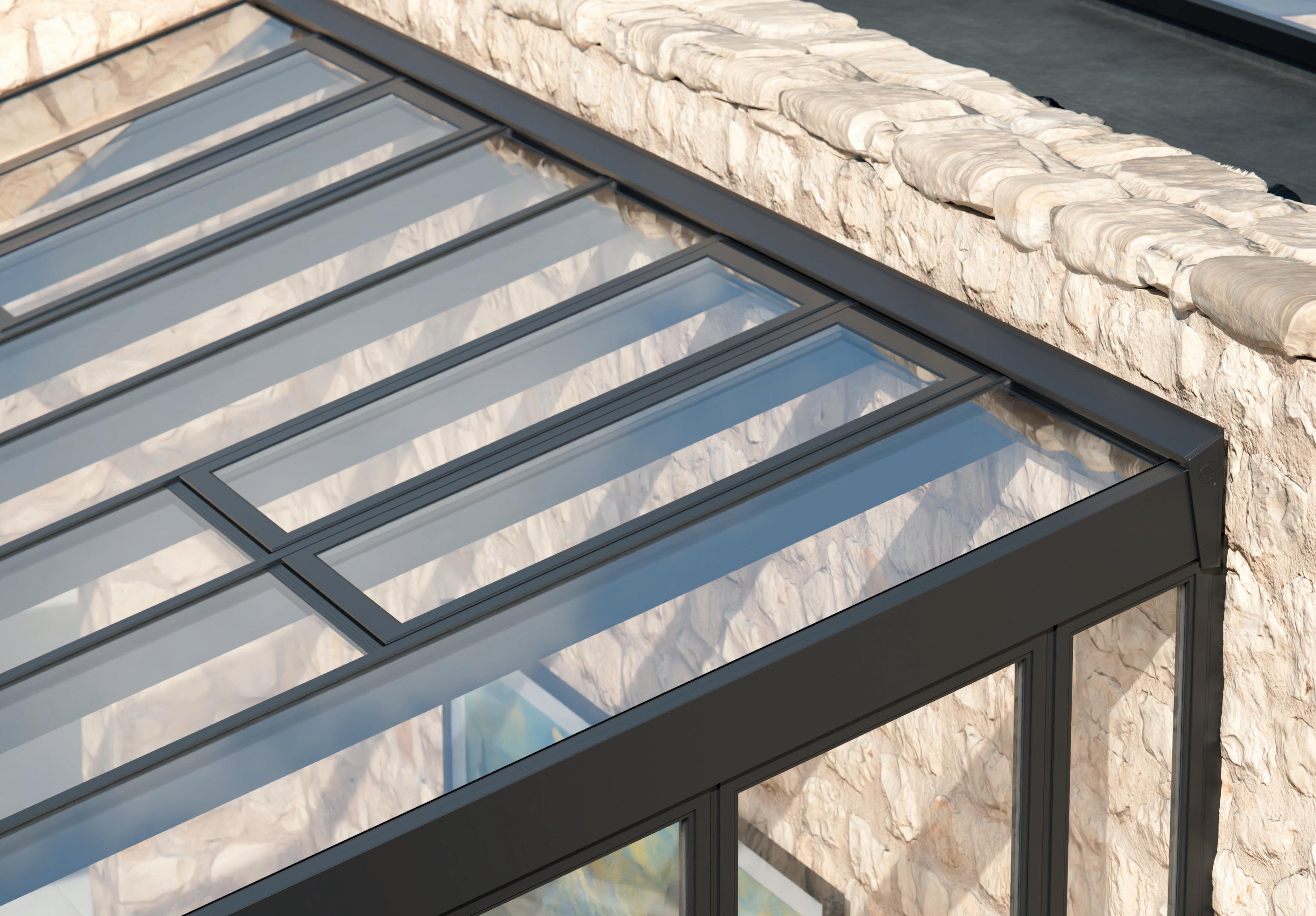

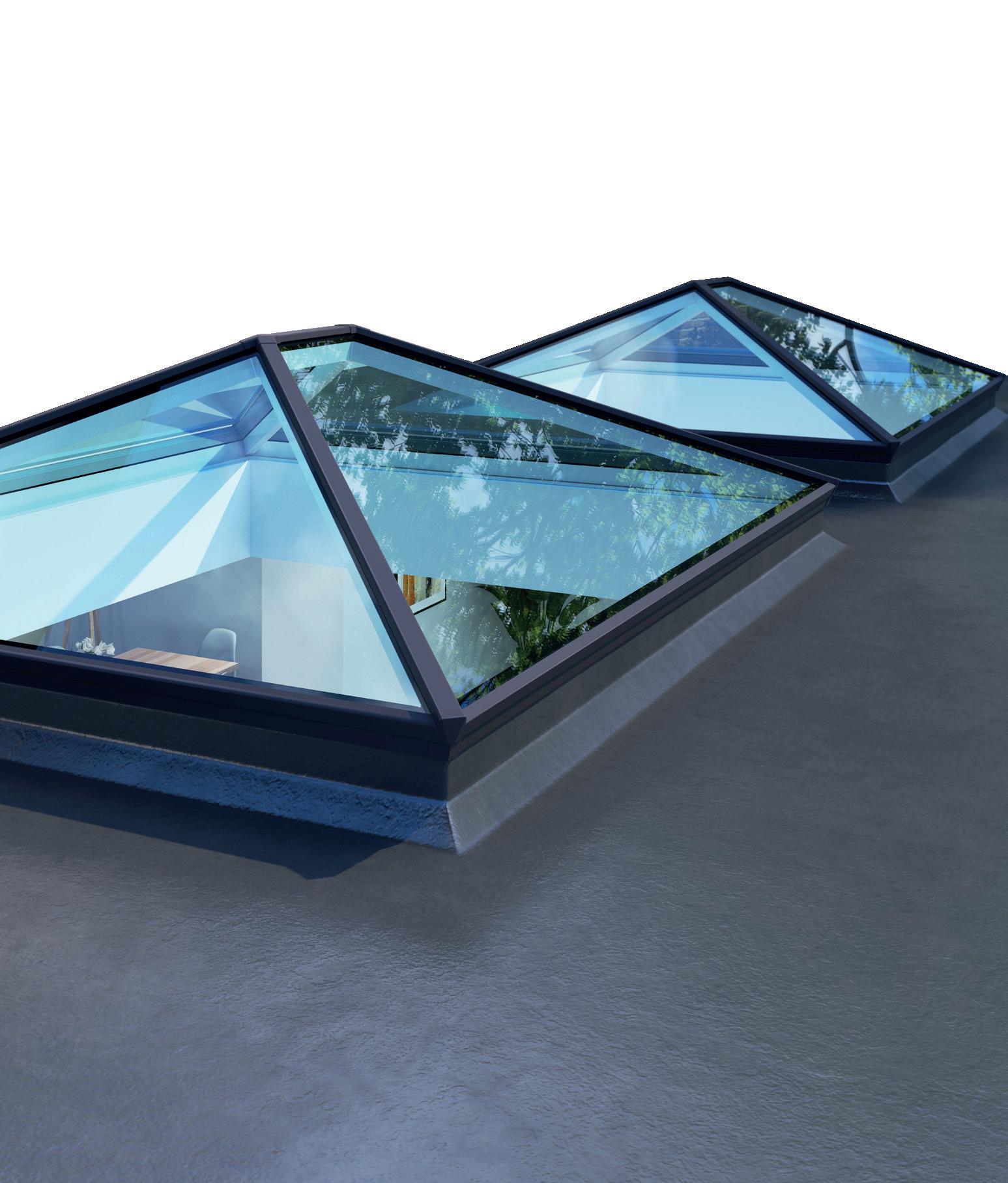

NEW - MSBP (Multi

System Bridge

Packer)

Fitted in minutes, glazed in seconds

Strongest lantern in class

Available up to 3x2.5m in four glass panels and a maximum size of 6x4m Black, White and Anthracite Grey. Single and dual colours with no extra cost

WEST LEIGH’S EXPERTISE AT LEN HOUSE LEADS TO A WIN FOR COMMERCIAL PROJECT OF THE YEAR AT SWA AWARDS 2025

West Leigh has won the Commercial Project category at the Steel Window Association (SWA) Awards 2025 for its work on the Len House project in Maidstone, Kent.

THE PROJECT

West Leigh was tasked with the like-for-like replacement of the existing steel framed windows and doors, matching the originals as closely as possible, along with the replacement of the existing box mullion wind posts to the windows to the rear elevation, and the refurbishment of the existing box mullion wind posts to the River Len Elevation.

Drawings of two proposed W20 windows were issued to the planning department and the architect and a sample window was manufactured and installed on site alongside the existing windows to show the planning department and the architect how closely they could replicate the original windows.

West Leigh installed approximately 130 W20 section steel windows in total, including numerous curved on plan frames and glazing units, utilising single glazed units, Low E double glazed units, and louvre panels, along with numerous steel door sets with W20 fixed frame inserts, to match the sightline sizes of the glazing bars to the adjacent windows. To aid in the replacement of the large wind posts, a structural engineer was engaged by West Leigh to determine the correct sizes required for each post, to suit the correct design wind pressures and structural requirements of the building. The existing box mullion wind posts to the River Len Elevation were refurbished by needle gunning each post to remove surface rust, primed and painted with a rust inhibitor and overclad with channel pressings, polyester powder coated to match the new W20 window frames. Many of the W20 windows to the first floor, known as

“The Winter Garden”, provide an enclosed balcony space for the residential units, providing views out over the River Len. The large W20 windows to the ground floor, along the River Len Elevation, provide a light and airy avenue for the retail area, where numerous retail units, bars and restaurants will be located. The upper top hung casements to the windows to this elevation are fitted with mechanical window actuators to allow ventilation to the public spaces.

Andy Bawn, West Leigh Managing Director, commented, “I am very proud of the whole team who delivered a complex project within programme”.

John Ranshaw, Judge of the awards comments, “West Leigh has brought its extensive knowledge and light-touch approach to bear on an architecturally significant building, helping to preserve it for future generations, while also ensuring

it meets modern performance standards. The company’s superior technical ability and rigour is not only evidenced in the breadth and variety of the window and door specification, but also in its approach to refurbishing the wind posts on the River Len elevation. The result is a highly convincing project that seamlessly knits both new and old elements together. A deserving winner.”

The ironmongery for this project was supplied by SWA associate member Steel Window Fittings.

For further information on the Steel Window Association or if you’re interested in becoming a member, please visit www.steel-window-association.co.uk.

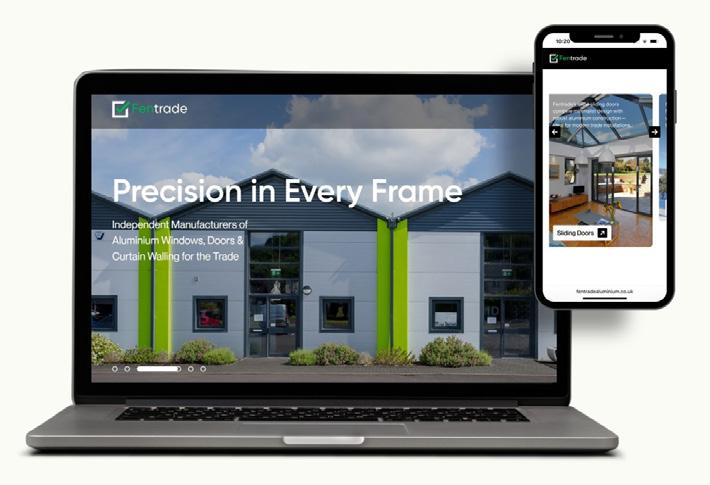

FENTRADE LAUNCHES NEW WEBSITE TO STRENGTHEN TRADE ENGAGEMENT

Independent trade fabricator

Fentrade has launched its new website designed to give trade installers, contractors and architects an improved online experience and streamlined access to product information.

Chris Reeks, Director at Fentrade, said: “The new site has been developed with the needs of installers, contractors and architects in mind. With intuitive navigation and a clean, modern layout, it

allows visitors to quickly explore our full range of aluminium products, including windows, doors, bi-folds, inline sliders, curtain walling and internal screens. Brochures and technical details can also be downloaded instantly, making it easier for

our trade partners to prepare quotes and plan projects efficiently.”

The new website reflects Fentrade’s core values of reliability, service and quality. Customers benefit from quotes returned within 24 hours, technical support delivered by an experienced team and a commitment to delivering every order on time and in full. By streamlining access to information, the website reinforces Fentrade’s commitment to making it easier for trade professionals to work with the company.

The new website comes during a period of growth for the award-winning business. Earlier this year, Fentrade was acquired by Aluminium Vision Limited, a move that further strengthens its market position and

manufacturing capacity. The Newportbased fabricator continues to invest in products, people and production to meet rising demand for its high-performance aluminium products.

With over 30 years of inhouse fenestration expertise and membership of the Council for Aluminium in Building, Fentrade has established itself as a trusted independent fabricator in both the trade and commercial sectors. Its new website brings together the company’s product portfolio, technical expertise and service offering in one easily accessible platform

To explore the new site visit www.fentradealuminium.co.uk.

THE AWARDS KEEP COMING: SHEERLINE NAMED WIRED TRAILBLAZER 2025

Sheerline can reveal it has been named a 2025 WIRED Trailblazer. The awards, which were launched by HSBC UK and WIRED Consulting, recognise mid-sized scaleups that are growing quickly and using innovation to tackle social, economic, and environmental challenges.

Receiving this award highlights what Sheerline has achieved in a relatively

short space of time thanks to the right strategy, investment, people, and products. The result has been a range of perfectly matched, fully-suited products, an OTIF consistently above 99%, and multiple award wins.

A special event was held at Cleaver & Wake in Nottingham to celebrate the East Midlands-based recipients of this year’s awards. It provided an opportunity to meet with likeminded business leaders from the region who share the same values and growth mindset.

Ross Hartshorn, Sheerline’s Technical Production Director, attended the event and said: “It was fantastic to meet so many likeminded and inspiring business professionals from across the East

Midlands who are driving real change in multiple industries.”

“Being named a 2025 Trailblazer is rewarding for everyone at Sheerline – it reflects our commitment to innovation, continuous improvement, and strategic, sustainable development. Thank you to WIRED Consulting and HSBC UK,” he added.

Now in its fourth year, the WIRED Trailblazer awards have built a community comprising of inspiring entrepreneurs and business leaders. This year, a total of 17 companies in the East Midlands region were recognised for their commitment to innovation.

2025 is shaping up to be a fantastic awardwinning year for Sheerline, having received Best Technical Innovation for the third time at the GGP Installer Awards earlier in the year and a King’s Award for Innovation 2025, which recognises unique benefits of the Sheerline system.

To find out what makes Sheerline standout, visit the website: www.sheerline.com, call 01332 978 000, or email info@sheerline.com.

TRUST PIONEERS WITH AN ESTABLISHED LEGACY

CONSERVATORY OUTLET’S DEGREE APPRENTICESHIP PROGRAMME SEES FURTHER SUCCESS

Conservatory Outlet’s apprenticeship programme continues to go from strength to strength, with Warehouse Manager Adeoye Adedayo becoming the latest employee to complete a Level 5 Apprenticeship in Operations Management.

Adeoye, who has been with the Wakefield-based fabricator for four years, successfully concluded the course –

equivalent to a foundation degree - after building an extensive portfolio of on-the-job and off-the-job projects. Alongside practical and academic work, Adeoye also received one-to-one mentoring from his tutor and support from the company itself.

“The apprenticeship has equipped me with the skills and knowledge to lead and motivate my team,” Adeoye said.

“I’ve gained new insight into teambuilding, conflict resolution and strategic planning. It’s had a positive effect on everything, and I can’t believe that I’ve achieved a foundation degree. This qualification gives me a strong

platform for the future, and I’m committed to taking on new challenges and opportunities for growth within the organisation.”

As part of his final project, he had to propose and implement new warehouse processes, which were then measured by and discussed by a panel of independent assessors.

These changes, including the adoption of 5S principles, have already delivered operational improvements, with Conservatory Outlet’s transport and warehousing departments achieving their highest-ever scores in the company’s quarterly Customer Journey Survey – a key metric the manufacturer uses to monitor performance.

Reflecting on Adeoye’s achievements, Greg Kane, Conservatory Outlet’s CEO, said: “I’m incredibly proud of Adeoye. He has worked very hard to reach this point and has grown both personally and professionally throughout his apprenticeship. His development has been a joy to see as he’s progressed through the company to his current position in our management team.”

“His success is a clear example of how investing in people drives tangible business benefits. Our apprenticeships aren’t just a training programme, they’re a route to better processes, stronger leadership and a more resilient business.

Adeoye’s accomplishment sits within a broader training programme that the business continues to scale. Conservatory Outlet has invested a significant sixfigure sum over the past few years to embed and provide opportunities for development across all departments, from the office to the shopfloor.

This sustained, long-term investment has seen nearly 75% of its employees benefit from either an apprenticeship or job-specific training courses. At the moment, the fabricator has a further 11 people working towards degree-level qualifications and an additional 9 people on undergraduate apprenticeships.

And this comes at a time when the fabricator is also rolling out free training courses for sales professionals working across its Network of Premium Retailers.

Greg adds: “The dedication shown by Adeoye and all our apprentices, plus the willingness of colleagues to support them, sums up who we are as a business. We’re always moving forward, looking to be better and provide a truly leading service.

“We view these programmes as part of a long-term talent strategy that benefits both our team and our customers.”

“I’ve gained new insight into teambuilding, conflict resolution and strategic planning. It’s had a positive effect on everything, and I can’t believe that I’ve achieved a foundation degree.”

Greg Kane presents Adeoye Adedayo, the latest graduate of Conservatory Outlet’s Degree Apprenticeship, with his Foundation Degree certificate.

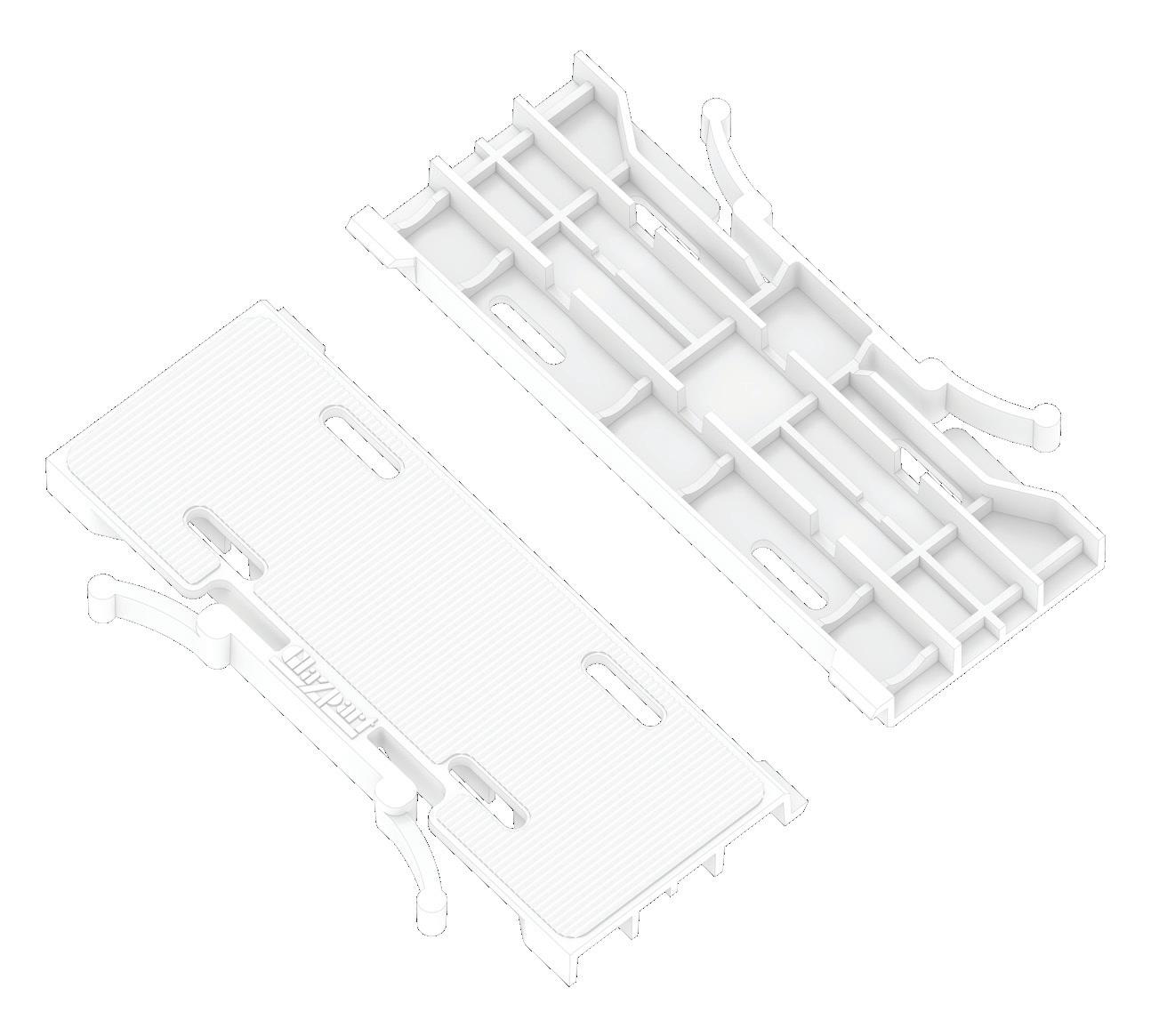

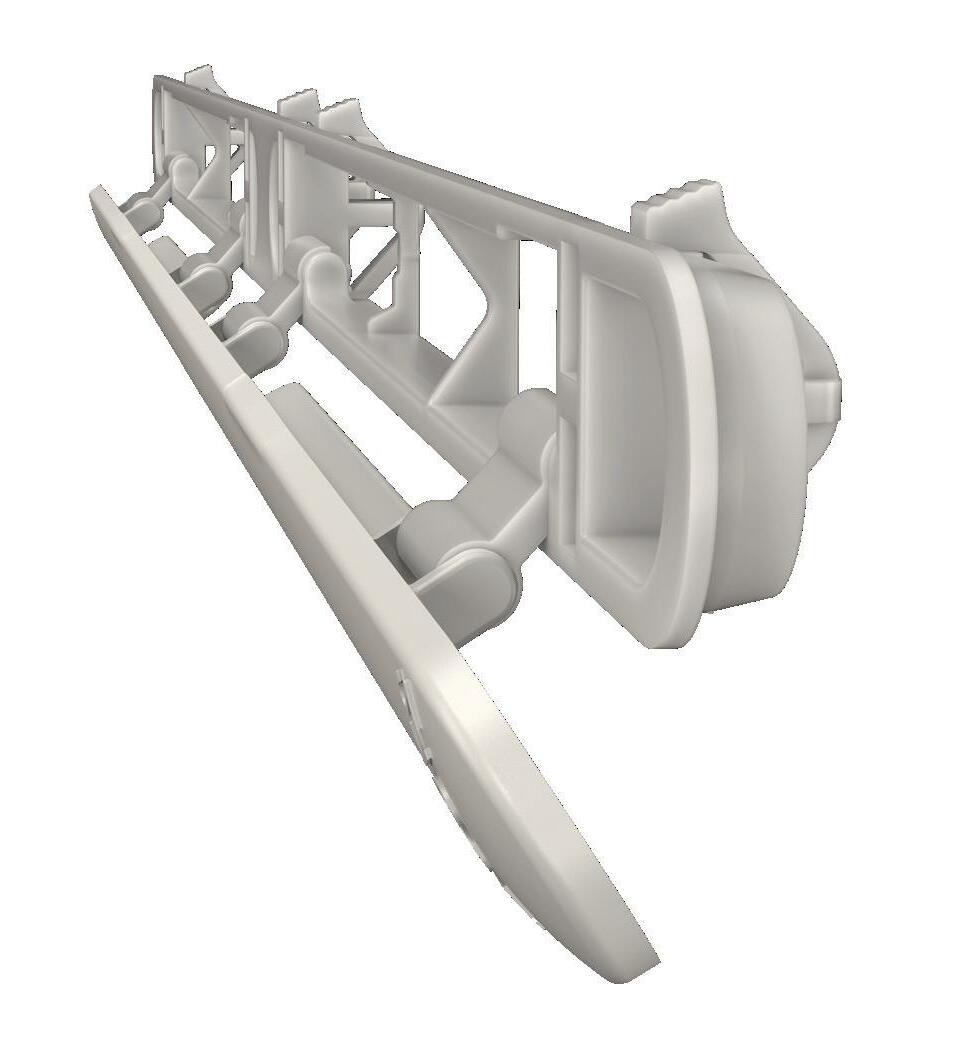

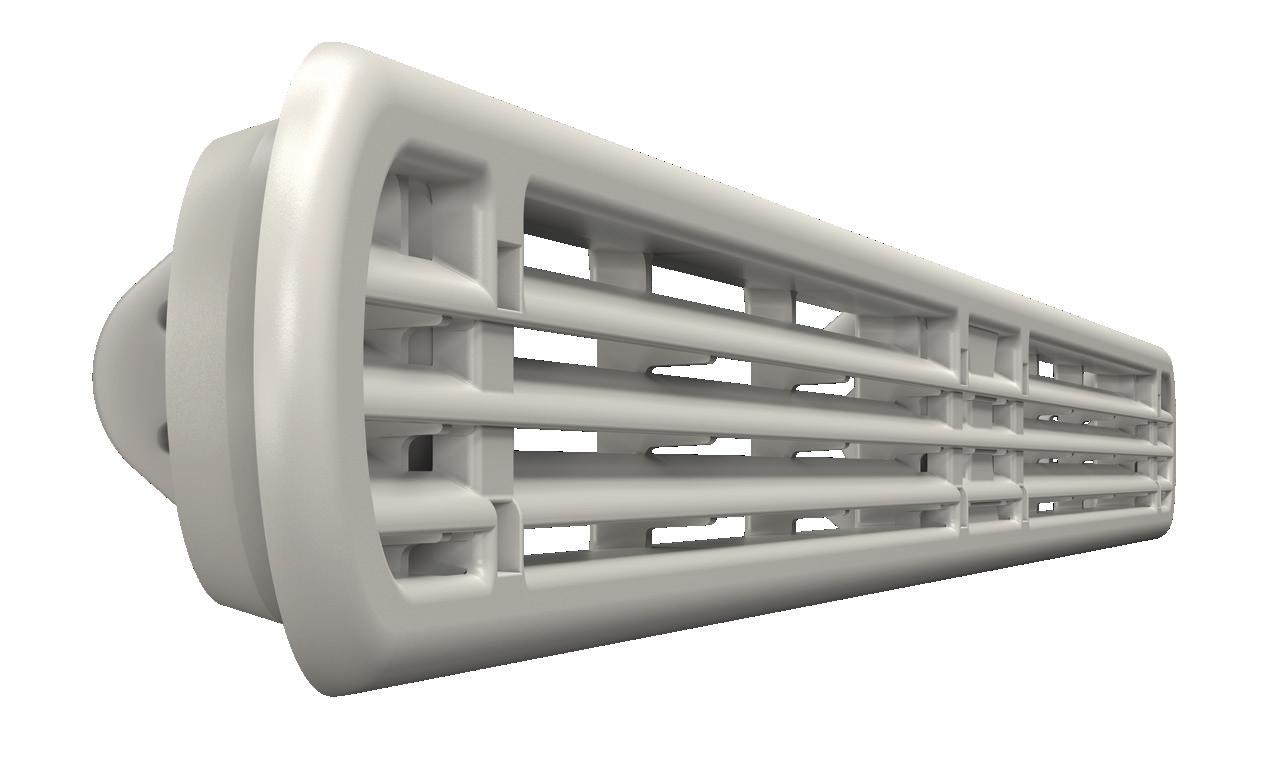

GLAZERITE JOIN GLAZPARTNERS

Glazpart is pleased to announce that Glazerite have become Glazpartners.

With over 25 years in the window and door fabrication industry, Glazerite has grown through a steadfast commitment to quality, innovation, and strong partnerships.

Glazerite’s success is built on the dedication of their experienced team, the trust of our customers, and close collaboration with our suppliers – all working together to deliver UK-wide exceptional product solutions for windows, doors and conservatories.

From their humble beginnings to becoming one of the UK’s leading trade fabricators, their journey is marked by growth and adaptability to meet their customers’ evolving needs.

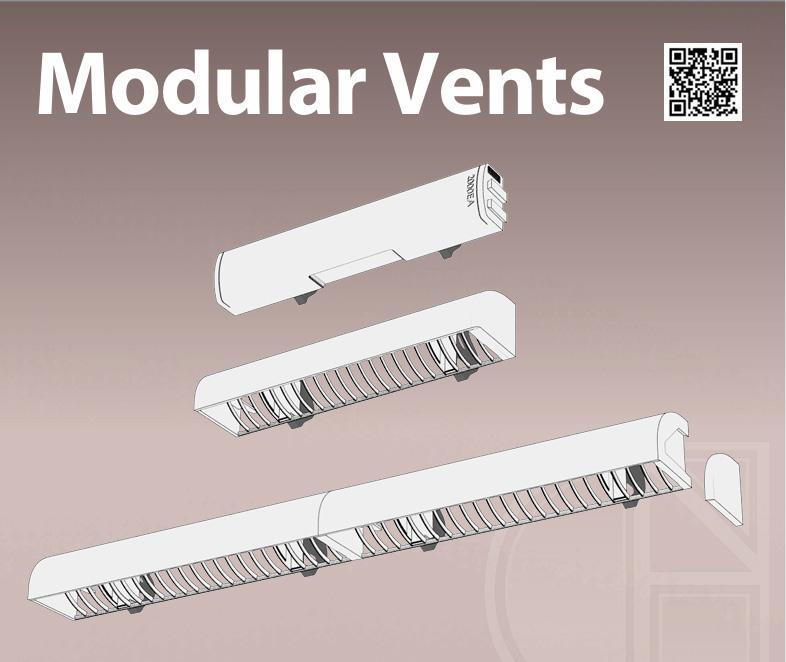

On becoming a Glazpartner, Jeff Dunn, Glazerite Sales and Commercial Director commented, “We’ve worked with Glazpart for over 20 years and more recently we’ve used their Link Vents to meet the compliance requirements for background ventilation for our windows. We’re therefore delighted to be Glazpartners which fits perfectly with our own mission and ethos.