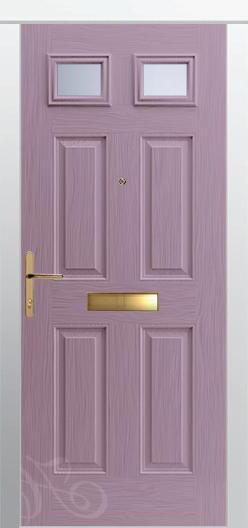

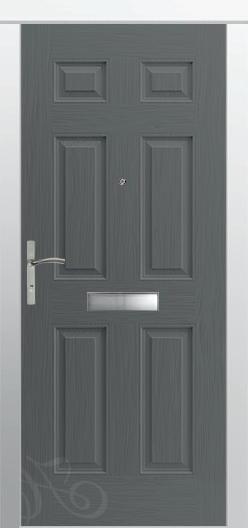

• UKAS Accredited: BS EN 1634-1 – internal and external use.

• Exceeds FD30: Average 52 mins, up to 70+ mins fire resistance.

• Building Safety Act Ready: Traceable, verifiable performance.

• Agrifiber Core: Renewable, stable and consistent.

• Long-life Durability: PAS 24 security, 2mm GRP skins, 25-year guarantee.

In Person GQA Accredited Courses:

Fire Door Inspection Course

Fire Door Installation Course

Fire Door Repair and Maintenance

Fire Door Awareness

Procurement Course

GQA Accredited Short Online CPD Courses:

Navigating FD Documentation

Identification Marks and Labels

Fire and Acoustic Seals

Regulated Vocational Qualification:

FD Inspector Diploma Level 3 – GQA

Installation Diploma qualification Level 3

Further regulated qualifications coming soon..

View our website

We would like to welcome you to this, the first edition of the Fire Door Journal.

You may be asking yourself why this new publication has suddenly appeared, bearing in mind the multitude of trade magazines that proliferate the building, housing, glass and fenestration industries? The simple answer is that this has not been an instant fix to talk about the issues of fire safety and, as publishers, we were approached to consider taking on the responsibility of bringing this title to market – and after much research we discovered that although there are lots of fire safety publications, there are none which focus on fire door safety as the main focal point.

As it says on the front cover, this is all about making buildings safer and it will come as no surprise that Grenfell was the catalyst that brought all these companies together in a determination to ensure such a tragedy is prevented in future. Importantly, many of the leading players within the industry have volunteered their services to form a panel of experts - fire door safety professionals, who can offer advice and support to our readers.

We want this journal to help the industry as a whole, individual companies and, indeed, individuals themselves, to understand the importance of education and training in ensuring that Fire Doors are correctly constructed, tested, and also fitted. It is one thing to ensure a Fire Door set passes the necessary tests and another thing altogether for it to be installed correctly. And once fitted

there are all the issues around the maintenance of that product. We are fortunate that there are companies that offer Fire Door Maintenance and Training and it is essential that companies involved in supplying fire doors understand the regulations and standards and are able to be appraised of any changes and additions that will inevitably come in future.

The Panel of Experts are key to helping everyone in the industry – we have experienced, professional people prepared to help and answer anyone’s queries or concerns. And that panel will expand over time. This your chance to ask for their advice and assistance.

We would encourage everyone to read the host of important articles in this first edition of the Fire Door Journal and either start or continue their education. Everyone involved with this publication is committed to helping the industry understand the complexities involved with producing and installing of fire doors and their ongoing maintenance, and to encourage and help those wishing to add fire products to their offering, to do so correctly and safely.

Chris Champion Editor

Christina

Lazenby Publisher / All Enquiries

M: 07805 051322 christina@firedoor-journal.co.uk

Kate Carnall Graphic Design / Ad Specifications kate@hook-a-duck.co.uk

Get

acquainted with our Expert Panel,

here to answer your questions and discuss the topics that matter, value your opinions and listen to your ideas.

You are invited to submit technical questions, requests for general advice and comments. This will provide the panel with the opportunity to share their perspectives and respond where appropriate, share their thoughts and offer guidance where they can.

Please send your questions and comments to: christina@firedoor-journal.co.uk

Nicola John Managing Director, Fire Door Maintenance Training and Development (FDM by UAP Ltd)

An experienced and professional journalist and Editor with significant experience across a wide variety of businesses including the composite door and fire door industry, the window, door and glass industry in general, landscaping products and manufacturing. Experienced presenter and speaker at seminars, conferences and exhibitions with many television and radio appearances. Skilled interviewer and writer of editorial material, articles and press releases. 60 years of work experience with 35 years at Director level.

As the Managing Director of the Fire Door Training Academy, Nicola is passionate about elevating fire safety standards. The award winning academy, housed in a stateof-the-art training centre, is dedicated to equipping professionals with the knowledge and skills needed to ensure fire doors are installed, inspected, and maintained correctly. Their mission statement is to significantly improve safety and standards in the fire door industry. The recent legislative changes underscore the critical importance of fire safety in buildings. The demand for specialised training in fire door inspection, installation and maintenance is unprecedented. Nicola’s team comprises fire safety experts, educators and support staff, committed to elevating fire safety standards.

FDM was established to address the growing need for high-quality fire door training after the Grenfell tragedy, ensuring professionals across the industry have the skills and confidence to meet evolving fire safety regulations. Since launch, FDM has partnered with over 50 industry

Christina is the Managing Director of the window, door and conservatory newspaper, Glass News (Glass People Ltd) which distributes monthly to manufacturers, fabricators and installers, established 15 years. Christina has worked within the window/ door industry, including fire doors, in some way or another for 30 years and is an experienced publisher of a number of B2B titles, within niche sectors and construction.

leaders and top suppliers of door sets and components, including Falcon Timber, GGF, Mann McGowan, Lorient, PDS, IG Doors, Sentry, Strongdor, NorDan, and many more.

A round table was recently hosted at FDM head quarters, composing of an indomitable team of fire safety experts, including the esteemed Dame Judith Hackett, resulting in The Fire Door Maintenance Report.

You can obtain a free copy of this report.

Please email the publisher of Fire Door Journal to receive your electronic copy.

Raising Standards in the Fire Door Industry

fdmltd.co.uk

Bryan Bultema Managing Director, ODL Europe

Bryan Bultema is Managing Director of ODL Europe, part of the global ODL corporate group with over 80 years of experience in developing high-performance building products. Based in Bootle, Liverpool, ODL Europe is focused on building value into building products and setting higher standards for safety, performance and sustainability.

As a panelist for the Fire Doors Journal, Bryan shares insight into how the

leadership, ODL Europe has invested in advanced solutions that provide consistent performance and assurance across the supply chain.

Central to this approach is the Guardsman FD30 Fire Door slab. Developed in collaboration with Capstone Engineering and leading fire door fabricators, the Guardsman is a nextgeneration GRP composite fire door designed to deliver dependable performance every time.

Tested under UKASaccredited conditions, it consistently exceeds its FD30 classification, achieving burn times of up to 70 minutes. Constructed with Agrifiber cores, FSC® certified timber and durable GRP skins, it combines safety with sustainability and long-term resilience.

Bryan continues to drive ODL Europe’s commitment to delivering proven, accredited composite door solutions that give specifiers, contractors and building owners complete confidence in performance.

Owen Jones brings over 30 years of experience in the construction products industry, having begun his career with IG Limited in 1990. He later joined IG Doors Ltd as Technical Development Manager, contributing significantly to its growth into one of the UK’s largest composite door set manufacturers.

Since 2021, Owen has served as Technical Director at Distinction Doors Ltd, where he leads the technical development and supply of composite door blanks and components, including

a fully tested fire door system. His expertise spans the manufacture of GRP, ABS, and steel composite doors within timber and PVC-U frames.

A Chartered Engineer and BFRC-accredited thermal simulator, Owen is committed to advancing product standards and safety. He was instrumental in founding the Association of Composite Door Manufacturers (ACDM), serving as Technical Director and Vice Chairman, and currently chairs the ACDM group within the GGF.

Owen has contributed to key industry initiatives, including post-Grenfell discussions with MHCLG, and has held roles on several BSI committees, notably chairing the latest revision of BS 8529 for composite doors. His collaborative approach and technical insight make him a respected figure in the sector and a trusted voice in regulatory development.

Mike Rigby Managing Director, MRA Research and the MRA Team Members

Mike Rigby Founded Michael Rigby Associates (now MRA Research, MRA Building Markets Reports, and MRA Data Services) in 1991 to bring new insight and direction to the building materials, construction and home improvements sector. With a background in both consumer and trade markets, including 10 years in marketing and research at Dulux paints, time as head of marketing at a national builder’s merchant, and as marketing director of a national home improvement company, he understands the challenges facing the home-improvement and construction industries.

Mike’s experience of fire safety: Mike was involved in PR for the Passive Fire Protection Federation for several years in the 2000’s. Exova, the Fire Service, ASFP, the Government and other bodies were PFPF members, so he heard the inside stories and went to Westminster with the chair and deputy chair when the Government tasked the PFPF with leading one of its task forces. The Lakanal House fire, a prequel to Grenfell, and a fire in the Channel Tunnel occupied the team for a

long time. The PFPF was eventually merged with the ASFP. Mike also worked on PR for a leading group of passive fire protection products. MRA produced the ‘Fire Door Quarterly Trends’ survey for the BWF and its fire door scheme for 10 years, which appeared in BMN magazine. When Grenfell occurred, the Government knew so little about fire doors and fire safety that they sent a bunch of officials to one of Mike’s clients to learn about fire doors. After the Grenfell Inquiry, Judith Hackitt tasked the CPA to consult the industry on it’s Marketing (loose and unsubstantiated claims), and the CPA asked MRA Research to consult the industry on the new code (which is now run by the CCPI - Code for Construction Product Information). Since then MRA Research has worked on a research project on specifiers and fire products for a large international, and has just conducted fire safety research for another large group.

Mike is a member of the Market Research Society, a liveryman of Worshipful Company of Builders’ Merchants, and Worshipful Company of Marketors.

With over 25 years of industry experience, Jason is a recognised authority on fire door performance and compliance. His expertise spans product testing, certification and design innovation, with a specialist focus on innovative fire safety solutions.

Within Robust, Jason is responsible for leading product development, driving improvements and standardisation in design and processes, overseeing testing and certification, and ensuring compliance with the latest standards. A strong advocate for third-party testing and certification, Jason champions its role in providing customers with confidence that products not only meet legislation but also deliver proven, reliable performance in real-world applications.

As the FPA’s Technical Director George oversees the strategic direction and delivery of the FPA’s technical services, supporting its mission to reduce fire risk and improve safety standards across the built environment. The FPA is deeply involved in the assessment, testing and training related to fire doors, providing:

• Specialist training courses to ensure fire doors are installed, maintained and inspected by competent professionals

• Fire risk assessments and compartmentation surveys to ensure fire doors are installed and maintained correctly

• Full scale fire testing at our laboratory to both British and European furnace test standards.

George and the FPA continue to support industry, insurers, and regulators with evidencebased guidance and technical expertise, helping to ensure that fire doors fulfil their critical role in protecting lives and property.

Steve Goodburn is Business Development Director at Pyroguard, a leading global manufacturer of fire-safety glazing solutions. With extensive experience in Business Development, Key Account Management and manufacturing operations, Steve brings both commercial insight and technical expertise to the sector. He is a strong advocate of a systembased approach to passive fire protection, recognising the need for fire doors to be tested and certified as complete assemblies.

A regular contributor to industry debate, Steve has authored RIBA-approved CPD materials and delivered presentations to architects, specifiers and manufacturers on the correct specification of fire-resistant glazing. He has also driven product innovation, including the launch of Pyroguard Advance for timber and steel fire-door systems. Passionate about safety and design, Steve views the fire-door industry as a unique responsibility: safeguarding lives while supporting architectural creativity.

Ian Glenister Technical and Sales Manager, DoorCo

Ian Glenister has worked across a range of sectors within the fenestration industry over the last 40 years including Production, Quality, Operations, Sales Management and Certification. With knowledge across commercial, retail and trade sectors, Ian’s knowledge of fenestration as a whole is vast, making him the perfect candidate to spearhead DoorCo’s fire door operation.

Since the Grenfell tragedy and the subsequent MHCLG investigation, DoorCo have actively been working towards a fire door solution to meet the needs of the supply chain in the changing world of fire doors and with an emphasis on consistency. Working closely with key suppliers including their slab manufacturing partner, DoorCo Korea, Ian has been the project lead for one of the largest and most successful type testing fire door projects in the UK.

Gareth Jeffries is the Commercial Sales Director of Permadoor and Wrekin, part of the Epwin Group. Permadoor, the UK’s original composite door manufacturer, is an industry leader in the design and supply of highperformance composite fire doors for the social housing and affordable homes sector. Renowned for innovation, the business is committed to compliance, sustainability and product performance.

With more than seven years at Permadoor and extensive experience in the building materials sector, Gareth plays a pivotal role in driving strategic growth. He ensures the business remains ahead of evolving Building Safety Act requirements and stricter regulations, while aligning the needs of specifiers, contractors and building managers with innovation in compliance and performance. Passionate about raising standards, Gareth provides invaluable insight into how regulation, sustainability and safety can be translated into practical solutions that deliver safer, more sustainable homes and genuine peace of mind for all stakeholders.

Karen started her journey in the architectural ironmongery sector in 1994 and has built an established career grounded in technical expertise and customerfocused service. Drawing upon 30 years of industry experience, Karen supports architects, contractors, door manufacturers and end users with expert guidance on fire door hardware specification and performance and remains committed to raising awareness on key themes such as fire safety, building regulations and testing standards.

Since joining Allegion UK in 2017, Karen has advised local authorities, architectural ironmongers and manufacturers on all aspects of fire safety and door hardware, ensuring projects are equipped with the most suitable, effective and compliant fire door hardware solutions.

Karen is also a strong advocate for continued education and professional development, holding qualifications such as DipGAI and DipFD that complement her extensive industry knowledge. Her passion for fire safety performance makes her a trusted voice for those committed to delivering safe, secure and accessible buildings.

Wojciech Brożyna is Managing Director of Aluprof UK, a leading supplier of aluminium systems for windows, doors, and façades. With more than 20 years’ experience in the fenestration and construction industry, he has played a key role in delivering safe, sustainable, and high-performance solutions across the UK and Ireland.

Wojciech, one of the directors of the Council for Aluminium in Building (CAB), has been actively engaged with industry institutions and trade bodies, strengthening collaboration across the sector. He promotes compliance, innovation, and education to ensure Aluprof’s systems meet the highest technical and fire safety standards.

Wojciech works closely with architects, contractors, and specifiers to raise awareness of fire door performance, certification, and regulatory requirements, supporting safer building design. His focus lies in combining technical expertise with practical guidance to help the industry meet Gateway 2 obligations and wider responsibilities under the Building Safety Act.

Do you think you have the expertise to join our panel?

We are looking for fire door safety professionals who can offer advice and support to our readers.

It’s free to take part, all we ask is that you are available to answer any relevant questions you feel qualified to do so and that you send us a brief biography of your experience within the fire door industry (and related industries) so we can assess your suitability to: christina@firedoor-journal.co.uk

We will respond to your email as soon as possible.

When it comes to fire safety compliance, the traceability of fire doors and their hardware is critical. And in an era where information is more accessible than ever before, the industry is presented with a transformative opportunity, explains Karen Trigg of Allegion UK.

Building safety has always been an ever-evolving landscape of legislation and regulatory frameworks. The industry strives for stronger construction safety practice and in doing so, the need for reliable, transparent and accessible product information is clear - especially when fire door safety compliance is on the line. It was in response to the Grenfell Tower fire and Dame Judith Hackitt’s review that the Building Safety Act 2022 was passed, which has since looked to introduce a number of ground-breaking reforms to improve fire safety standards and facilitate greater accountability across the board. A key component of the regulation has been the requirement for duty holders to retain fire and structural safety information, making it necessary to manage an accessible digital record of decisions and updates throughout a building’s lifecycle.

This ’Golden Thread of Information’, as it’s known, has placed a renewed focus on the presentation and management of construction product information and ensures the right people have the right information at the right time. From a single source, building owners, developers, regulators and residents are given a greater

understanding of the materials and assets used during the construction process, as a way of driving standards and saving lives. With emphasis shifting from product performance claims to verified, traceable assurances, there has never been a better time to assure peace of mind when it comes to fire door safety.

The Building Safety Act recognises the importance of fire safety systems and mandates that the Golden Thread of Information must include comprehensive data on all fire detection and prevention systems in high-risk buildings, including fire doors.

As a vital element of passive fire protection, fire doors and their hardware are often the first line of defence against fire and smoke, and as such are a legal requirement in all non-domestic properties and houses in multiple occupation. To operate as intended, fire doors will call on their various hardware components, including hinges, latches, seals, door closers and opening mechanisms, meaning they are only as effective as the weakest link in their assembly. As

such, the correct specification, installation and maintenance of fire door hardware is considered crucial if a building is to meet both its functional and safety standards. With that, decision makers must be confident they can identify the necessary hardware for their building, and in doing so, must also ensure components are fit for purpose and comply with UK Construction Products Regulations.

To assist duty holders in meeting these expectations, conscious manufacturers have stepped up, and as part of the Golden Thread regulatory framework are providing more detailed information in the form of product datasheets, installation guides and training portals. From a compliance standpoint, decision makers can instantly check a product’s associated Declaration of Performance (DOPs) to show

hardware conforms to the correct testing standards and UKCA and CE certifications, as well as Environmental Product Declarations (EPDs) when looking to conform to the latest environmental benchmarks. With this information, those involved in product selection can assure their installed fire door hardware will perform when it is called upon.

Transparent product information is also useful when it comes to maintenance periods and conforming to Approved Document B, with amendments made as recently as March 2025 focusing on Regulation 38, which states that “the person carrying out the work shall give fire safety information to the responsible person no later than the date of the completion of the work, or the date of occupation”. By providing this material, manufacturers are offering improved traceability on products and their performance, empowering duty holders to comply with legal obligations and keeping occupants safe in the process.

Data is a critical resource in decision making and with several schemes evolving such as the Golden Thread and the Code for Construction Product Information, a real strategy is forming. Where information is accessible and no longer ambiguous, the industry is fostering a proactive culture of collaboration, further transitioning from reactive compliance-driven tasks to a more effective method for tackling fire door safety and building design as a whole.

Outside of duty holders being able to demonstrate compliance by showing how they are managing risks throughout their buildings, there is perhaps a greater opportunity presented with clear communication amongst stakeholders. Where it’s imperative for industry professionals to remain informed on the latest standards and hardware options, a collaborative approach can lead to better and more informed design choices that continue to deliver post-project delivery and improve fire safety outcomes. Furthermore, with information readily available, there is an opportunity for early identification of potential hazards and vulnerabilities. For existing projects, decision makers can check what hardware product has been used and where, deciding if

it has been suitable and further reducing the use of ineffective options and avoiding costly retrofits when the time has come to repair or replace products.

From an operational perspective, when reliable product information can be accessed and assessed instantaneously, duty holders are able to streamline their decisions - assuring any changes or issues with fire door safety products are rectified quickly and actioned efficiently. With this holistic approach to information sharing, building and fire safety management becomes a shared duty. The Golden Thread is setting the standard and protecting all stakeholders in the processhelping to build trust in an area it is most needed.

The use of traceable and transparent product information means the approach to fire door safety and building management is changing and the industry is urged to continue building upon this culture whilst navigating the latest standards. Traceability is no longer a burden of best practice - it’s an industry expectation and equally, a golden opportunity that must not be missed.

Allegion UK is committed to supporting transparency and traceability in construction and has a wealth of product information resources to help professionals undertake product selection, installation and maintenance checks on fire doors and hardware. For information on product selection and installation, please speak to our experts or head to our download centre for technical fitting instructions and product certifications. Allegion UK also proactively participates in the EPD programme, with full EPD documentation available for download on Briton products, based on ISO 14025 and EN 15804 environmental declarations, from the Allegion and Briton websites. For more, visit www.allegion.com

As London’s skyline continues its rapid transformation, developers and contractors are under increasing pressure to balance innovation, design efficiency, and – above all – safety. With Glenigan reporting a surge in highrise office tower projects across the capital, the need for highspecification building components has never been more critical.

One such product answering this call is the Duplex 120 Riser Door – 2hr Fire Rated Both Sides, exclusively from Panelcraft Access Panels. Designed specifically for environments where uncompromising fire performance is required on both sides of a partition wall, this riser door is rapidly becoming a go-to solution for modern high-rise developments.

In tall structures, vertical service risers present a potential pathway for fire and smoke to travel rapidly between floors. As regulations grow stricter and awareness of passive fire protection increases, developers must ensure that every component meets the highest standards of safety and compliance.

The Duplex 120 doesn’t just meet these standards – it exceeds them.

Here’s why the Duplex 120 stands out in a competitive market:

• 2-Hour Fire Rating –Both Sides

Unlike many access panels that offer fire resistance on only one side, the Duplex 120 is firerated for 120 minutes on both sides. This is essential in highrise settings, where compartmentation integrity must be maintained regardless of the direction of fire spread.

• Sound Tested to BS EN ISO 10140-2 : 2010 with a 36dB Sound Reduction

• Smoke Tested to BS EN 1026

• Ideal for High-Rise Risers and Shaft Walls

With a focus on riser doors, this product is tailor-made for service voids common in multi-storey buildings. It integrates seamlessly into shaftwall systems and is engineered to work with non-standard dimensions — making it perfect for bespoke installations in commercial towers.

• Custom Built for Your Specification

The Duplex 120 is available in bespoke sizes — ensuring a precise fit for your riser openings. This flexibility is invaluable in projects where space efficiency and modular construction are priorities.

• Concealed Frame for a Flush Finish

High-rise office developments are not only judged on performance, but also on aesthetic and design consistency. The Duplex 120’s concealed frame design supports a minimalist, flush finish that aligns with

modern architectural trends.

• Tested to EN1634-1 Standards

Peace of mind comes standard. The Duplex 120 is rigorously tested to BS EN 1634-1 fire resistance standards, giving specifiers confidence in its compliance and performance.

• Supporting London's Office Tower Boom

As Glenigan reports, the London office sector is bouncing back with a pipeline of sophisticated, highdensity towers. From flexible workspaces to sustainable smart buildings, the demand is growing for building products that perform under pressure — in safety, scalability, and design.

The Duplex 120 is ready to support that growth.

Whether you’re working on a 30-storey tower in the City or a new commercial hub in Canary Wharf, Panelcraft’s Duplex 120 riser door ensures your project is protected from the inside out.

To learn more about how the Duplex 120 can be integrated into your next high-rise project, or to request a quote for a bespoke size, visit the product page here: https://www.panelcraftaccesspanels.com/Riser-Doors.php

Doorset manufacturers are being reminded about their responsibilities regarding thirdparty certification for emergency exit and external panic doorsets, as the Office for Product Safety and Standards (OPSS) clamps down on non-compliance.

The callout comes from Warringtonfire, a leading provider of testing, inspection, and certification services. It warns that many doorset manufacturers are not adhering to the correct procedures for thirdparty certification of their external doorsets, resulting in non-compliance. This follows recent scrutiny from industry bodies such as the Door & Hardware Federation (DHF) and the Guild of Architectural Ironmongers (GAI), who have been informed of the situation by the Office for Product Safety and Standards (OPSS).

It is the responsibility of manufacturers to

ensure their products are correctly certified and have a Certificate of Constancy of Performance (CoCoP), which then allows the product to then obtain a conformity marking (CE or UKCA). Without this, doors cannot be legally sold on the market, posing significant financial and reputational risks to manufacturers, as well as putting people at risk.

“Simply having third-party certification for individual elements and hardware of the panic or emergency exit doors is insufficient,” warns Michael Skelding, DHF’s General Manager & Secretary. “It is the responsibility of doorset manufacturers to ensure that the entire doorset, once assembled, is certified to meet compliance standards. Without this, manufacturers risk having their products pulled from the market by the OPSS, along with severe reputational damage.

“While the DHF and GAI have noted that many doorsets are noncompliant, we recognise that manufacturers are not deliberately breaking the law – it is more an issue of lack of awareness. It is now essential that

“Ensuring that your doorsets are fully certified is not only a legal obligation but also a commitment to safety and quality.”

the word is spread so that manufacturers can obtain third-party certification and prevent any repercussions.”

Obtaining third-party certification is a straightforward process. It requires a factory production control (FPC) audit from a UKASaccredited laboratory, or an EU notified body, both of which Warringtonfire is qualified to conduct. The process includes witnessing the entire doorset in operation, with no additional testing required. This service can often be completed within a day by Warringtonfire, with the issuing of the CoCoP

following shortly after.

Mark West, Principal Product Assessor at Warringtonfire, states: “Ensuring that your doorsets are fully certified is not only a legal obligation but also a commitment to safety and quality. The certification process is designed to be quick and efficient, providing peace of mind for manufacturers and end-users alike.

“Here at Warringtonfire, we can offer third-party doorset certification at the same time as other services, enabling clients to ensure this important box is ticked on the same day that they receive other audits.”

For more information on third-party certification with Warringtonfire or to schedule an audit, please visit: https://www.warringtonfire.com/certification-services/fire-certification/ce-marking

2 HOUR FIRE RATED BOTH DIRECTIONS

DOORS

120 Minute UKAS fire tested to BS EN1634-1:2018 Fully compliant 36dB acoustic rating BS EN ISO 10140-2:2010 Part B compliant Smoke tested to BS EN 1026 Insulated with a U Value of 0.55W/2mK

Nicola John, Managing Director at Fire Door Maintenance (FDM by UAP Ltd), explores why fire door competency must become the cornerstone of building safety — and how FDM is setting a new industry benchmark with practical training, innovative digital tools, and a first-of-its-kind platform that supports accountability and access for all.

Fire safety doesn’t always look heroic. Sometimes, it’s simply a door. Fire doors are one of the most effective forms of passive fire protection we have — and one of the most misunderstood. They sit in buildings across the UK, largely unnoticed, until something goes wrong. When they work, they save lives. But far too often, they don’t.

We know this because the data is telling us. And we know this because Grenfell made it impossible to ignore.

Around three million new fire doors are installed in the UK every year, but the problem isn’t how many doors we’re fitting — it’s how few are being maintained, checked and signed off by people with the right training.

An estimated 600,000 fire doors in the UK need remediation. In housing, healthcare, education, and commercial properties, doors are damaged, misaligned, incorrectly fitted, or simply not compliant. These are the kinds of issues that compromise their performance in seconds.

Since the Fire Safety (England) Regulations 2022 came into force, buildings over 11 metres tall are now required to have quarterly checks on communal fire doors and annual checks on flat entrance doors. Across the UK’s housing stock, that means an estimated 3.5 billion inspections every year — and that’s before factoring in care homes, hospitals, schools, and offices.

Yet the industry isn’t ready. We don’t have enough trained people to meet that demand. In many cases, we don’t even have consistent standards for what a ‘trained’ professional looks like.

The 2017 fire at Grenfell Tower exposed systemic failures in building safety, from cladding to communication. But fire doors played a role, too.

Many of the flat entrance doors failed far earlier than expected. Some lasted just 15 minutes in conditions they were rated to withstand for 30. Some didn’t selfclose. Others lacked the appropriate seals. It all meant that smoke poured into common areas and escape routes were compromised.

Subsequent inquiry reports confirmed that several doors installed didn’t match the versions tested by the manufacturer. There were installation errors, design flaws, and oversight gaps.

The tragedy prompted 15 specific recommendations related to fire doors. These included tighter inspection protocols, clearer lines of accountability, and better information for residents. The government accepted them; but, years later, many of these changes remain in consultation.

Doors fail when they’re poorly installed. When gaps aren’t measured, seals aren’t replaced, or closers aren’t tested. When installers are rushed, or undertrained, or under pressure to move on to the next job. When checks become tick-box exercises.

Many of the people responsible for inspecting, installing, and maintaining fire doors don’t have specialist training. Some are general contractors, caretakers, facilities staff, or even volunteers. And without the right knowledge, the risk remains.

Fire door safety is being regulated like never before. But unless we close the competency gap, enforcement alone won’t solve this. We need a trained, qualified, and confident workforce that knows what to look for, how to fix it, and when to escalate concerns. And we need to value that knowledge as the frontline safety role it truly is.

isn’t there yet

The uncomfortable truth is this: the UK does not currently have the training capacity to meet its fire door inspection and maintenance obligations.

And this isn’t just a resourcing issue. It’s about approach. In too many cases, fire door qualifications are basic, fragmented, or outdated. Training is theoretical rather than practical. Courses are focused on awareness rather than hands-on understanding. And when people do complete training, there’s little accountability for how that knowledge is applied in the field.

We need to build a pipeline of fire door professionals — not just paper-qualified inspectors, installers, and maintainers, but skilled individuals who understand why each element of a fire door matters, and how it performs in real conditions.

That means raising the standard of qualifications and designing training that reflects real-world risk. It means shifting from compliance culture to competence culture, where understanding isn’t just assumed but demonstrated.

Competency in fire door maintenance needs to be seen as essential, not optional, starting with the way we talk about passive fire protection and shifting mindsets. Fire doors are lifesaving systems and should be treated with the same seriousness as any other emergency measure. That means clear guidance, adequate funding, and appropriate training backed by accountability.

Competency should never be an afterthought. It should be the first question asked when a new door is fitted, or an existing one is inspected and maintained.

FDM is leading this change. Not content with ticking boxes, the team has developed training that goes beyond industry standards — combining theory with hands-on practice to ensure professionals leave not just qualified, but genuinely competent.

To support those already in the field, FDM is developing an easy-to-use app that puts vital information at professionals’ fingertips, bridging the gap between classroom learning and on-site application. And in a first for the industry, it has created a universal platform where individuals can demonstrate their competency on site. This isn’t just a one-off solution, it’s an end-to-end system of support, accountability, and access that the sector has needed for far too long.

FDM recently launched a new Level 3 Diploma in the Inspection of Fire Resistant Doorsets — the most comprehensive qualification of its kind in the UK. Developed in partnership with GQA Qualifications and the National Skills Centre, the diploma blends legislative understanding with real-world application, offering 313 guided learning hours across 12 units.

Crucially, it includes onsite assessments featuring different types of doorsets, carried out by FDM assessors based at the specialist facility — the UK’s first practical training centre. It’s a step towards professionalising the industry, giving learners the time, tools, and environment they need to build confidence and competence that goes with them beyond the classroom, to the sites they work on. It marks another chapter in FDM’s work to close the competency gap, with more to come.

Competency in fire door safety isn’t just technical — it’s behavioural.

It’s knowing the difference between a minor defect and a critical failure, or when to raise a flag. And it’s having the confidence to challenge decisions that compromise safety.

That takes more than a one-day course.

It takes structured, experiential training, delivered by people who understand the risks, the regulations, and the realities of managing buildings day to day.

It also takes consistency. Not every site is the same, but the standard we work to should be.

The post-Grenfell regulatory landscape has brought longoverdue attention to the role of fire doors in protecting life and property. But while new legislation has set out clear expectations, turning those into everyday reality on the ground is a different challenge altogether. Too many buildings still fall through the cracks, and too many professionals lack the clarity, training, or accountability needed to get it right.

If we’re serious about change, it’s time to move beyond good intentions. To meet the expectations set out by recent legislation, and to do right by the lessons of Grenfell, we need action on five fronts:

1 Mandatory minimum qualifications for anyone installing, inspecting, and maintaining fire doors. It’s no longer enough to rely on experience alone. The complexities of fire door design, installation, and compliance demand a recognised level of technical knowledge. Minimum qualifications would provide a clear benchmark, reassuring residents and regulators alike that work has been carried out to a consistent, high standard. Without that, we’re gambling with safety.

2 A centralised register of competent fire door professionals, accessible and transparent. Right now, it’s hard to know who is truly qualified to carry out fire door work. A single, up-to-date register that is independently verified and publicly accessible would help housing providers, building owners, and residents identify professionals they can trust. It would also help to drive up standards across the industry by rewarding those who invest in their training and accreditation.

3 Standardised training frameworks recognised across the UK. We can’t build a safer industry on a patchwork of inconsistent training routes. Clear, nationally recognised frameworks are essential in ensuring everyone is working to the same level, and that qualifications mean the same thing and carry the same weight wherever you are in the UK. Whether we’re talking about inspectors in Lanarkshire or installers in Leeds, the baseline of knowledge should be consistent.

4 Investment in training capacity — particularly for housing providers and social landlords. There’s no point mandating qualifications and training without giving people the means to access them. That’s especially true for stretched teams in housing associations and local authorities, where capacity and cost are often barriers to upskilling. If we’re serious about raising standards, we need to make sure the training is there — and that it’s affordable, accessible, and scalable.

5 Clear enforcement structures so that failure to meet inspection, installation, and maintenance duties carries real consequences. The postGrenfell landscape has seen new rules and responsibilities introduced, but too often, enforcement is vague or inconsistent. We need clear lines of accountability and a willingness to act when things go wrong. Without robust enforcement, legislation risks becoming a box-ticking exercise — and residents remain at risk.

The longer we wait, the greater the risk. We can’t afford a situation where lives depend on doors, and no one knows who signed them off. These five areas aren’t optional upgrades: they’re essential foundations for a culture of competence and accountability. And they need to happen now.

The sector has made progress. But progress is not enough.

We’ve seen what happens when standards slip. We’ve heard the stories, read the reports, seen the footage. We know how quickly smoke spreads; how many minutes matter. So, there’s no going backward: only forward.

That means building an industry where competence is the norm, and where people are trusted because they’re trained — not just because they’ve been doing the job for years. Where fire doors are recognised for what they are: the last line of defence between a fire and the people inside. And where those responsible for safety are never left to guess. The stakes are too high for ambiguity, shortcuts, or silence.

We owe it to every resident, every building user, and every family affected by fire to get this right. That starts with people who know what they’re doing — and have been given the tools, training, and time to do it properly.

Gavin Skelly, CEO of growing fire safety industry body Fire Aware, spoke of the moral and behavioural changes in culture needed to improve standards at the Scotland Housing Leaders’ Summit.

He called for unity of all of those working across the entire fire safety supply chain to consider

their moral responsibility including national and local housing associations, local councils and developers across the UK.

To change the culture of the built environment, he outlined the actions being taken by Fire Aware in introducing a moral code of conduct via a series of charters designed to influence how member companies behave in upholding their duty of care.

Gavin Skelly said: “Of course we understand

the need for competence. But when dealing with an industry that the public relies on to keep them safe, there has to be more. There has to be a tangible recognisable commitment to safety. There must be unity in the message all duty holders send to the public if they are to relate to its meaning.

“As with a number of other sectors and professions, the fire sector has a wide array of duty holders, but they all share one common requirement, which is to

Gavin Skelly

understand they are there primarily to keep the public safe.

“We are appealing to the fire safety industry and those with responsibility for making decisions to think about their moral duty from the outset of any project. We know from the feedback we receive from our members that the industry is keen to make this work. We believe in going above and beyond legislation and minimum standards and test regimes.

“Members of the Fire Aware community are taking a stand. They have told us they care and want to commit to best practice. Working together, members can contribute to the wider cause of safety in the interests of those people using inhabiting the buildings and spaces we create.”

Fire Aware is a recognised membership body serving the built environment and related sectors with a common aim to work and trade responsibly to all best practice standards in the interests of the safety of the general public.

• UKAS Accredited:

BS EN 1634-1 – internal and external use.

• Exceeds FD30: Average 52 mins, up to 70+ mins fire resistance.

• Building Safety Act Ready: Traceable, verifiable performance.

• Agrifiber Core: Renewable, stable and consistent.

• Long-life Durability: PAS 24 security, 2mm GRP skins, 25-year guarantee.

Gateway 2 Compliance, introduced under the Building Safety Act 2022, is creating significant disruption across the Construction Industry.

At this stage of the approval process, a complete and fully coordinated design must be submitted and approved before any building work can begin. This requirement represents a major shift from established practices where design and construction traditionally overlapped, allowing issues to be resolved on-site. The result has been widespread project delays, increased costs and logistical difficulties as developers and contractors adjust to the stricter regulatory environment.

Much of the challenge lies in the scale of information now required. Gateway 2 places a strong emphasis on

detailed documentation and maintaining the ‘golden thread’ of information, ensuring that design intent, safety measures, and materials are all fully recorded. Many organisations, particularly smaller firms, are struggling with the resources and digital systems needed to meet these demands, added to this is a lack of clarity in how regulators will assess submissions, which has created uncertainty and hesitancy in moving projects forward. For an industry already under pressure to deliver more housing quickly, these bottlenecks are proving difficult to manage.

However, despite the frustrations, Gateway 2 is an essential step towards raising safety and quality standards in construction. The system was introduced to prevent unsafe compromises and poor record-keeping, lessons tragically underscored by the Grenfell Tower fire. By ensuring that critical safety measures are embedded in the design before work begins, Gateway 2 helps protect

residents and provides greater accountability throughout the building’s lifecycle. Over time, the requirement for earlier collaboration, better coordination, and improved transparency has the potential to transform industry culture, leading to fewer defects, safer buildings, and stronger public confidence. Whilst the transition is undoubtedly challenging, Gateway 2 should be seen as an investment in a safer, more professional built environment.

Aluprof UK has demonstrated a strong commitment to aligning with the Building Safety Act 2022 requirements, particularly regarding Gateway 2 approvals. Their broad range of high-performance façade solutions, all 3rd party tested to relevant standards, with over 1,500 third party certificates of compliance, makes Aluprof the ideal partner. Their major projects team collaborates closely with specialist façade contractors to ensure that all

necessary supporting documentation and compliance measures are meticulously prepared for submission to the Building Safety Regulator (BSR). This proactive approach is crucial, especially considering recent challenges faced by the BSR, such as delays in processing Gateway 2 applications due to an outsourced delivery model and a shortage of in-house technical expertise.

Choosing Aluprof fireresistant screens together with Glassprof glass provides a reliable and fully tested solution for safeguarding buildings while maintaining design flexibility. Aluprof’s systems are engineered to deliver high levels of fire resistance, compartmentation, and smoke control without compromising on aesthetics, while Glassprof glass complements these systems with certified fire-rated glazing that ensures transparency, natural light, and architectural freedom. Together, they offer architects, contractors, sub-contractors and building owners a trusted combination of safety, compliance,

and performance for all construction projects.

Aluprof’s vertical integration benefits specifiers by ensuring consistent product quality, streamlined supply chains, and enhanced technical support. With inhouse system design, manufacturing, and testing, Aluprof delivers high-performance aluminium systems that meet stringent UK and EU building regulations, including Gateway 2 requirements under the Building Safety Act 2022. This integrated approach allows for greater customisation, faster lead times and improved cost efficiency, giving specifiers confidence in project timelines and compliance. Additionally, direct collaboration with Aluprof’s experts ensures tailored solutions that align with architectural intent whilst enhancing sustainability and energy efficiency.

Current statistics show that Gateway 2 compliance remains a major challenge for the Construction Industry. Approval rates are very low, with only around 10–14% of applications being approved. For example, as of mid2025, just 20 out of 187 new higher-risk building

applications had received approval. Across all new build and remedial submissions between late 2023 and 2024, the success rate was similar at 146 approvals from 1,018 applications. The vast majority of applications—up to 75%—are being rejected due to incomplete or poor-quality submissions, while a further 20% are ruled invalid because they fail to meet statutory requirements or lack essential documentation.

Delays are also a serious issue, with the average approval taking around 22 weeks, far exceeding the statutory 8–12 week timeframe. In some cases, projects have been delayed by 40 weeks or more waiting for Gateway 2 clearance. Freedom of Information data shows that by early 2025, over 700 applications were still pending, adding to a significant backlog. These statistics highlight both the complexity of the new regime and the ongoing difficulties applicants face in providing the detailed fire and structural safety information required by the Building Safety Regulator.

Speeding up Gateway 2 approvals requires both improved application

quality from Industry and greater efficiency within the BSR. Many delays stem from incomplete or poorly prepared submissions, so design teams must ensure that all structural and fire safety details are fully coordinated and documented before applying. Investing in specialist consultants, carrying out thorough pre-application checks, and engaging earlier with the regulator can reduce the risk of rejection. Better training for architects, contractors, and consultants on Gateway 2 requirements would also help raise standards and cut down on the high percentage of invalid or incomplete applications currently being submitted.

On the regulator’s side, resourcing and process improvements are key. The BSR could speed up approvals by expanding its review teams, streamlining the multidisciplinary assessment process, and introducing clearer guidance on what constitutes a compliant application. Phased or staged approvals, already being trialled in some cases, may also help by allowing work to progress whilst certain technical details are finalised.

Ultimately, a combination of better-prepared applications and more efficient regulatory handling will be needed to reduce backlogs, shorten determination times, and give the construction sector greater confidence in navigating Gateway 2. Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about the wide range of systems and specification support is available through the company website at www.aluprof.co.uk or for home improvement at www.aluprofliving.com and direct from their UK head office in Altrincham by phoning 0161 941 4005

By Tom CherowbrierMajor Projects Manager at

Aluprof UK

Growing fire safety industry organisation Fire Aware is driving the move for cultural change by raising moral and ethical standards across the built environment sector through a code of conduct and series of charters.

By raising the consideration of responsible behaviour in all of those working in the supply chain, and in doing so helping to support technical knowledge wherever possible, it believes it can make a difference in delivering the cultural change in the construction industry demanded by Dame Judith Hackitt in 2018.

Gavin Skelly, CEO of Fire Aware, said: “We’re already seeing a lot of interest in our organisation and what we stand for. Membership is growing quickly and the organisations joining us want to adhere to all best practice. We are seeking to shift the culture of the built environment sector both morally and technically. We believe in setting standards.

“Importantly, the visible moral position of member companies can also be

performance tested, ensuring the services they provide are in line with their moral undertakings. Under performance can be monitored by the Fire Aware organisation and agreed action taken in the event of consistent disregard for the safety of those who inhabit the buildings we create and manage.”

The 2018 Hackitt Review into building regulations and fire safety found that the industry had a tendency to focus on cost-saving rather than building safety, and it demanded that the onus for safety be placed on the entire industry, from design to completion and maintenance.

The Fire Aware Charter Conditions do not seek to override any legal obligations as specifically imposed

by those of sectorspecific professions. All members must abide and comply with the law and regulations that are relevant within their specialism in addition to the Fire Aware Code of Conduct, and relevant charter.

Supporting the code, Fire Aware’s series of charters apply to main contractors, property developers, building management, designers, local councils, specialist contractors and subcontractors.

The charters ask the member business to consider the safety of the end user, and to go above and beyond minimum standards to promote an enthusiasm within the member business to identify itself as a business that cares. It also recognises those

outside of the fire sector, who, while holding a duty of care are not specifically part of the fire sector.

Gavin Skelly added: “We and our members are addressing the wider issues of safety in the interests of those people using the buildings and spaces we create. We are asking any organisation considering how to improve their moral and technical standards of operating in the built environment to talk to us.”

Fire Aware is a growing, recognised membership body serving the built environment and related sectors with a common aim to work and trade responsibly to all best practice standards in the interests of the safety of the general public.

When it comes to fire safety, there is no room for compromise. That’s why building managers, housing providers, and specifiers across the UK continue to put their trust in Permadoor; the original manufacturer of specialist composite fire doors and one of the most respected names in the industry.

Permadoor has consistently set the standard for quality and safety, pioneering solutions that place compliance and performance above all else. Today, as part of the Epwin Group, Permadoor continues to strengthen its position as a trusted industry expert, delivering not only exceptional fire doorsets but also a full-service contract management solution that takes the risk out of fire door specification, installation and lifecycle management.

Permadoor’s legacy is built on a simple but vital principle: fire doors save lives. The company has long been recognised as a trailblazer in designing and manufacturing third-party certified composite fire doorsets for the social housing and affordable homes sector. With over 35 years of specialist experience and Group-wide investment in research, development and testing, Permadoor offers building managers, housing providers and tenants complete confidence in door performance.

Their extensive range includes both internal and external fire doorset solutions, all precision-engineered to meet the highest standards of fire safety, security and compliance. By combining robust certification with a commitment to continuous improvement, Permadoor has earned an enviable reputation as a reliable and innovative partner.

One of the most pressing challenges in fire safety is ensuring that doors are not only manufactured to the highest standards but also installed correctly. A compliant door poorly fitted is a compromised door. Recognising this, Permadoor has developed a comprehensive contract management solution; a full manufacture, supply and install service designed to eliminate risk for building managers.

From the earliest site survey and tenant liaison through to quotation, manufacture, installation, and aftercare, this full lifecycle solution delivers peace of mind at every stage. By entrusting the process to Permadoor’s proven network of nationwide installers, stakeholders can be confident that every fire door will perform as intended, safeguarding both lives and properties.

In the post-Grenfell landscape, the concept of the “golden thread” has become central to building safety. This golden thread of information ensures that critical safety details are captured, preserved and accessible throughout the lifecycle of a building. For fire doors, where ongoing performance and maintenance are essential, this digital record is particularly important.

Permadoor has embraced this requirement with the introduction of its innovative digital data pin solution. Small in size but powerful in capability, each data pin is embedded within the doorset, linking to a secure cloud database. Here, vital details are stored, including manufacturing specifications, hardware lists, installation records, inspection dates, maintenance logs and compliance certification.

This system not only ensures that every Permadoor fire doorset can be uniquely identified and tracked throughout its lifecycle, but it also provides building managers with the reassurance that they are meeting their legal and regulatory obligations. The data pin is a

practical, future-ready tool that supports full golden thread compliance, strengthening collaboration across the door industry and setting a new benchmark for transparency.

For Permadoor, compliance is never optional, it is the cornerstone of every decision. All fire doorsets undergo rigorous third-party testing and certification to ensure performance can be relied upon in the most demanding circumstances. By partnering with accredited certification bodies, Permadoor guarantees that its products consistently meet and exceed regulatory requirements.

This dedication extends beyond safety to aesthetics. Permadoor’s fire doors don’t just protect, they also enhance buildings. A wide variety of design options, including newly introduced sidelights, toplights and fanlight specification options, offer building managers the flexibility to combine compliance with style. This commitment to continuous improvement demonstrates Permadoor’s ability to innovate in ways that meet the evolving needs of both specifiers and residents.

Permadoor’s commitment to innovation and industry collaboration will be on full display at London Build in November. The company will showcase

its comprehensive range of solid timber core and GRP composite fire door solutions, alongside its groundbreaking contract management service. Visitors will have the opportunity to learn more about how Permadoor is redefining best practice and delivering total peace of mind to stakeholders across the social housing and affordable homes sectors.

Fire doors remain one of the most critical elements of building safety. Their ability to contain fire, protect escape routes, and ultimately save lives depends not only on how they are made but also on how they are installed, maintained, and monitored. Permadoor’s comprehensive approach - blending innovation, compliance and customer care - ensures that every stakeholder, from building managers to tenants, can trust in the integrity of their fire doors.

When it comes to compliance, performance, and trust, Permadoor doesn’t just follow industry best practiceit helps define it.

Kirk Smith of Allegion UK outlines why fire door closers are central to maintaining fire safety standards in buildings and advises decision makers on how to select the right hardware for their project.

Fire doors are designed to save lives. When closed, they form a crucial barrier against smoke and fire and provide vital time for occupants to escape in an emergency situation. An open fire door on the other hand is rendered useless in the event of a fire, and for this reason, fire door closers are equally recognised for their lifesaving capabilities.

The relationship between fire doors and fire door closers is synergetic in fact, with both considered key elements of a building’s passive fire protection system. When a fire door must close to completion during a fire incident, it will always rely on its mechanical closing device to do so effectively. Door closers are an essential operational component and must be capable of closing the door leaf from any angle of opening and strong enough to overcome the resistance of any latch seal, ensuring the door is held firmly in place by its frame.

Whilst all fire door closers serve this same function, decision makers are reminded that an incorrectly specified door closer can compromise the integrity of an entire fire door assembly. With different project requirements and hardware options available, specifiers and decision makers alike must be confident in their

door closer selection. Where occupant safety is on the line, what should specification teams look out for?

Kirk Smith of Allegion UK explains: “Fire door closers are paramount to the success of fire door safety and specification should be a structured process to ensure appropriate closers are chosen at each touchpoint. There are various types of door closers available on the market, but whether concealed or surface-mounted, all controlled door closer models use spring hydraulics to close and engage fire doors onto their latch, allowing buildings to compartmentalise areas and provide occupants with vital escape routes. To perform this task, fire door closers call upon a number of elements including: the door closer mechanism, mounting hardware, arms and links.

“There are often a number of considerations to make when choosing between door closer products. In any instance, specifiers must first establish whether their door is a fire door or a non-fire door, for example. To

ensure a closer is fit for purpose and meets fire safety compliance, all door closers installed on fire-rated doors must be tested to EN 1634 and UKCA and CE marked. Mechanical variants must also conform to EN 1154 and electromagnetic hold-open devices to EN 1155, which test and classify hardware over its category of use, number of test cycles, power size, fire behaviour, safety and corrosion resistance. A Declaration of Performance (DoP) must also be reviewed to ensure a door closer is certified when fitted with backcheck or delayed action.

“From an operational viewpoint, it’s important that a chosen door closer meets the needs of a building and its users too. Buildings with high footfall will often benefit from an electromagnetic holdopen device, which keep certain fire doors open until a fire alarm is activated, in which the system will automatically release and close

doors to completion. The size of a door can sometimes be a key factor when selecting a door closer too. Unusually tall or heavy doors may often require a door closer with a higher power size, in accordance with EN 1154 - it’s key to remember that fire doors require a minimum Power Size EN 3 to conform to this standard. Should a specification team be unsure about the size of the door, it is often best practice to choose a door closer unit that can be adjusted during the installation stage.”

Regardless of where a fire door may be positioned, its size or how it may be used, operation must always be controlled, as this will prevent future damage to the door and its frame - which can be a crucial step towards retaining fire safety performance.

Kirk Smith continues: “Surface mounted closers are the most durable and common type of door closer, with units mounted to the surface of the door or frame with a quick and simple installation process. Comparably, concealed door closers are fitted within the door leaf and frame and whilst providing the functionality of a surface mounted closer are hidden from view as a way of enhancing aesthetics. When reviewing the mounting requirements, it’s important to consider door closers can be installed in different ways, often depending on the application. The four most common ways to fit a door closer are:

• Figure 1 door mount fixing: where the closer body is mounted on the pull face of the door.

• Figure 61 transom mount push side: where the closer body is mounted on the transom, on the push side of the door.

• Figure 66 parallel mount push side: where the closer body is mounted on the push side of the door.

• Slide track fixing: where the closer with slide arm and track is door or transom mounted, on either the pull or push side of the door.

“Specifiers must also evaluate whether backcheck control is necessary. Door closers with adjustable backcheck can better control the speed of the door, slowing it down prior to making contact with a door stop or before reaching the fully open position. This function prevents or minimises

damage to the door, hardware and adjacent walls, which would otherwise be caused by the door being forcefully open or caught by a gust of wind.

“Equally, specifiers must consider whether a door closer requires delayed action. A delayed action closer offers a period of delay from when the door is opened to closed, which is usually set to be a maximum of 25 seconds (recommended for fire doors). This functionality makes delayed action closers ideal for environments that require easy passage, such as doors used by children, the elderly or wheelchair users, for example. With this in mind, decision makers should always check the Declaration of Performance (DoPs) and certification on fire door closers, ensuring they will remain certified and perform in usekeeping fire doors closed when it matters most.”

For more, visit www.allegion.com

UK reviews the critical nature of escape routes in school buildings and how fire door hardware plays a role in keeping students safe and emergency exits functional.

Whether it’s the end of the day or end of term, when schools close, it’s not unusual to see children and staff alike scrambling out the doors as they head for a much needed period of relaxation. Though, more vital than finding an exit for a break is the need to safely and swiftly evacuate school premises when an emergency situation arises. When fire breaks out in a school building, every second counts. Panic and emergency escape routes provide a direct path to safety and are critical in minimising risk and the time spent evacuating, and as a result, are highly regulated in educational facilities as per the Regulatory Reform (Fire Safety) Order 2005 and the Building Bulletin 100 (BB100). Accordingly, designated panic and emergency routes must be highlighted with concise signage, remain clear at all times and contain fully compliant and operational fire exit doors -

which are recognised as the final point of escape.

During term time, when a school is at its busiest, staff, students and visitors must be confident in locating and traversing their nearest emergency exit route at any given time. Regular fire drills, evacuation plans and staff training can play a critical part in ensuring the effective use of escape routes in schools, though, often overlooked is the important detail of exit hardware. Where neglected routes can turn a manageable emergency into a potentially dangerous situation, duty holders are urged to recognise the importance of functional fire exits and how exit hardware keeps them operational.

School buildings are often more complex than they first appear. Between sprawling corridors, high-traffic communal areas and frequent transitions between classrooms, halls and outdoor areas, there are various challenges and vulnerabilities to consider when it comes to fire safety and the accessibility of escape routes.

Fire is an unpredictable danger for any facility, made more apparent

in school buildings by the presence of flammable materials - such as art supplies, paper and chemical substances in science labs, for example. In some schools, arson also remains a real concern, further elevating the chance of fire and reinforcing the need for effective emergency escape routes and operational fire exit doors. In any case, escape routes must not only be compliant but robust enough to support an orderly evacuation under duress, and for that, correctly specified, installed and maintained fire exit hardware is key.

In panic situations, particularly where children are involved, ease of use and reliability are fundamental. For schools, where there are usually more than 60 occupants present, panic exit hardware is a typical installation on fire exit doors, with horizontal push bars and pads used for intuitive egress at the end of escape routes. These panic devices are designed to provide safe and effective escape through doorways with

minimum effort and without prior knowledge of operation. Horizontal push bars for example, are often utilised on external outward opening doors, with panic hardware required to cover at least 60% of the door width, ensuring devices are easy to find and operate in an emergency. All panic exit devices must also be fitted to comply with the harmonised version of EN 1125 Panic and EN 179 Emergency standards and ensure UKCA and CE markings are present.

Far too often, escape routes are compromised in school buildings as a result of poor planning and a lack of fire exit maintenance. Where insufficient signage, blocked exit routes and untrained staff are common oversights that can severely impact the effectiveness of emergency exits, poorly maintained exit hardware could be the difference between safe escape and disaster.

The durability of exit hardware is regularly put to the test in school buildings, with wear caused by high footfall, heavy usage and vandalism. With this in mind, a duty holder or responsible person (often the headteacher or facility manager) is required to perform regular fire risk assessments to ensure appropriate precautions are in place to safeguard pupils and staff. As part of their duties, it is recommended that maintenance checks are conducted on a regular basis on escape routes and that all fire door hardware is in

correct working order, ensuring all components are present, in satisfactory working condition and operate as follows:

1) When the horizontal bar is pushed, it should unlatch the door immediately without requiring a key, knob or other tools. The mechanism should be intuitive and require minimal force to open. Once operated, the door should also return to its original position.

2) Pushing the bar should release the latch and or bolts, allowing the door to swing open freely, facilitating rapid evacuation.

3) The hardware should normally be latched to prevent unauthorized entry from the outside. A door may be locked from the outside with a key or locking device, but from the inside should always be operable without a key.

4) Some panic bar models may include alarms or signals when the door is opened in an emergency or may have an optional dogging feature to keep the door open temporarily.

5) Hardware must meet local building and fire safety codes. Typically, it should be rated for a certain number of cycles and withstand specific forces. When on fire doors, hardware should also hold a fire rating.

Worn or faulty panic hardware can delay an exit door from opening or may simply cause the door to fail entirely, rendering a carefully planned and clear escape route useless in the event of a fire. In any case, should a fire door not be operating as intended, it’s imperative that a school’s responsible person seek out professional advice to ensure maintenance is carried out quickly and professionally, especially when children are present.

Schools will always be thought of as places of learning, care and responsibility, and with that there is an ongoing duty to protect the lives of our next generation and those who nurture them. To truly mitigate the risk of fire, responsible parties must work together to guarantee safe egress is possible at all emergency exits by specifying, installing and maintaining appropriate hardware fit to meet the demands of school settings. After all, an escape route is only as reliable as the exit hardware found throughout it.

For more, visit www.allegion.com

A lack of clarity about what it means to be “competent” to install a fire door has been a longstanding issue for the construction sector – but a new Competence Framework for specialist fire door installers now promises to set that straight. Richard Kowalski, Technical Manager for Doors at Stairways Midlands, who was among the industry voices behind the framework, explores this vital turning point.

What does it mean to be competent to install a fire door? For years, regulations have

been clear that only competent individuals should undertake this safety-critical work – but what “competent” actually looks has never been properly defined. The result has been inconsistency, uncertainty, and in some cases dangerous practice.

That confusion is now on its way out. A new Competence Framework for Site Carpenters and Specialist Timber Fire Door Installers, developed by the Construction Industry Training Board (CITB) under the Industry Competence Steering Group (ICSG) – Sector Led Group 10 (SLG10), is providing long-awaited clarity.

Richard Kowalski, Technical Manager for Doors at Stairways Midlands, one of the experts involved in its creation, believes this marks a turning point. With more than 25 years’ experience and seats on both the Fire Door Alliance and British Woodworking Federation committees, he has long

argued for meaningful standards and believes that this is “long overdue recognition of the crucial role fire door installers play in keeping people safe – and the standards of knowledge, skills and professionalism that must therefore apply.”

Fire doors are life-saving devices, required by law in many buildings to help stop the spread of fire and smoke. The Regulatory Reform (Fire Safety) Order 2005 states they must be installed by a “competent person,” but the bar has been left open to interpretation.

Some installers have pursued third-party certifications such as FIRAS, BM TRADA Q-Mark, or Certifire; others have relied on little more than short online courses. “We’ve seen projects revisited years later under new inspection regimes, only to find doors that were never compliant from the start,” explains Richard. “Sometimes the most basic safety-critical details were missed. We’ve seen inspectors pull off architraves to discover there was no mastic at all between the frame and the structural opening. Examples like that underline why a clear benchmark has been so urgently needed.”

Published in July for consultation, the Specialist Timber Fire Door Installer Competence Framework

sets out the essential skills, knowledge, experience, and behaviours (SKEB) required for Site Carpenters and Specialist Timber Fire Door Installers.

The framework is the result of collaboration across the sector, involving manufacturers such as Stairways, the British Woodworking Federation, training organisations, and on-site professionals. That collective input helped shape a flexible model, says Richard: