Markets are constantly churning. Add in Trump’s turbulence, and Black Swan events, those 1-in-100-year shocks that are happening more often than predicted. No wonder consumers lack confidence.

It’s harder to grow profitably in a churning market, but quality data reveals trends that help companies follow the money and avoid risk.

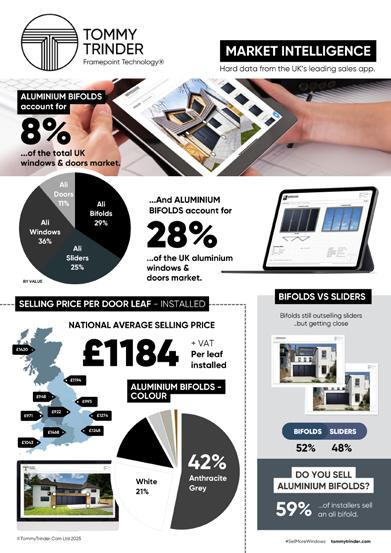

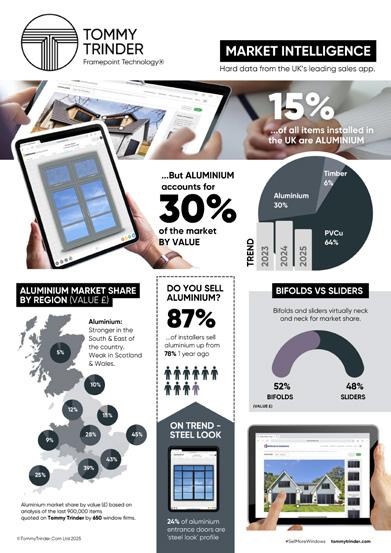

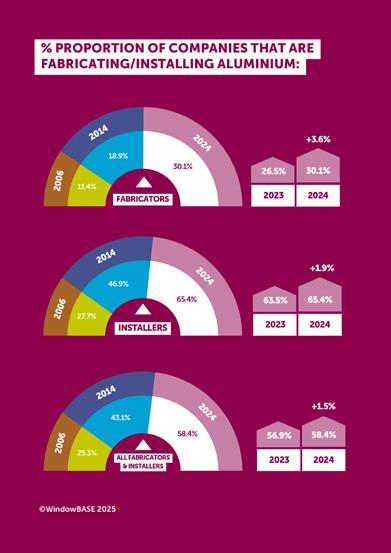

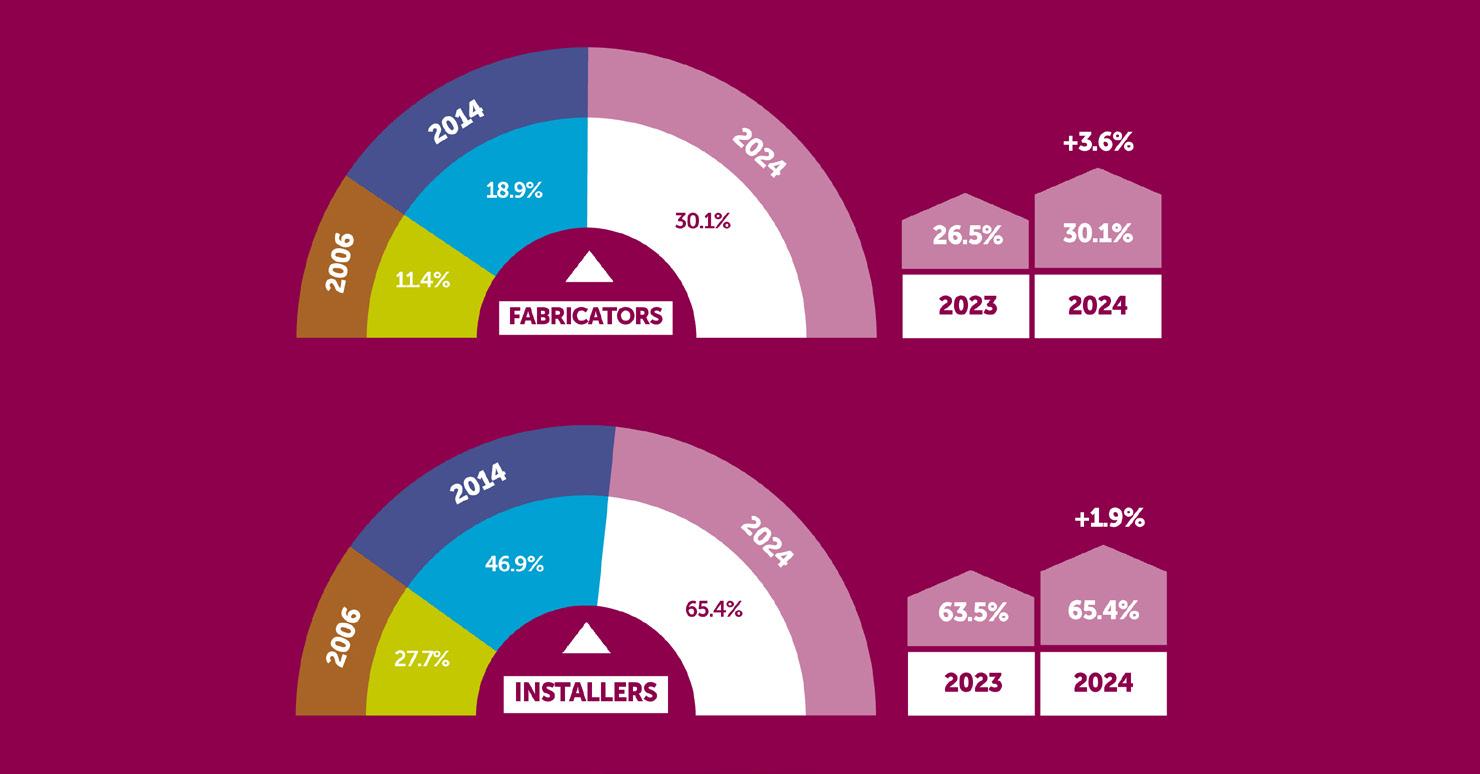

This month, Glass News features ‘Aluminium Market Intelligence’ the first of four excerpts from the 2025 WindowBASE & Tommy Trinder Window & Door report.

“Demand for windows and doors is down,” says Mike Rigby founder of WindowBASE, “and in the last two years some big firms have failed.

“Early this year a few Aluminium Syscos also changed hands. There are lots of them, too many for a healthy retail market so, expect more M&A activity. Putting it in perspective, 35 years ago there were over 80 PVCU Syscos. Now just a handful.

“But this is not a downbeat story about companies disappearing or being sold. It’s a regeneration story of business destruction and creation.

“Big firms hog the headlines, but thousands of changes in small and medium sized firms make the market.

“If you work offline, a list you downloaded some months ago will be significantly unreliable."

“Last year, 884 installers left the industry, but 1,156 new installers set up in business, a net growth of +2.7% in installer firms. Was that in the news?

“Three hundred and eight fabricators shut, while 286 opened their doors, a net drop of -0.6%. Dynamic, or what?

“Who’d start a business today? Larger firms that fail spawn new businesses as ex-staff start afresh.

“If you work offline, a list you downloaded some months ago will be significantly unreliable.

“Using old, incorrect data wastes time and squanders opportunities, even if you’re given a ‘free’ illegal copy. When you’re up against a competitor using up-to-date, quality data, who has a better chance of winning new customers?”

Please see the full industry report on page 48...

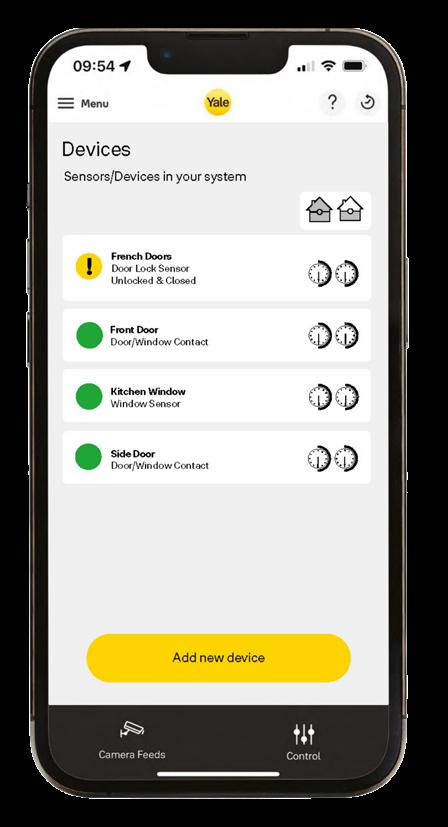

The security system has been Kite Marked for Home security

The Hub is fitted with a 94db intruder / panic alarm

Easy set-up

Wireless connectivity

Geo-fencing security alerts

Real-time notification of status changes

Choice of fully or part armed

Integrates with other technology around your home Scan

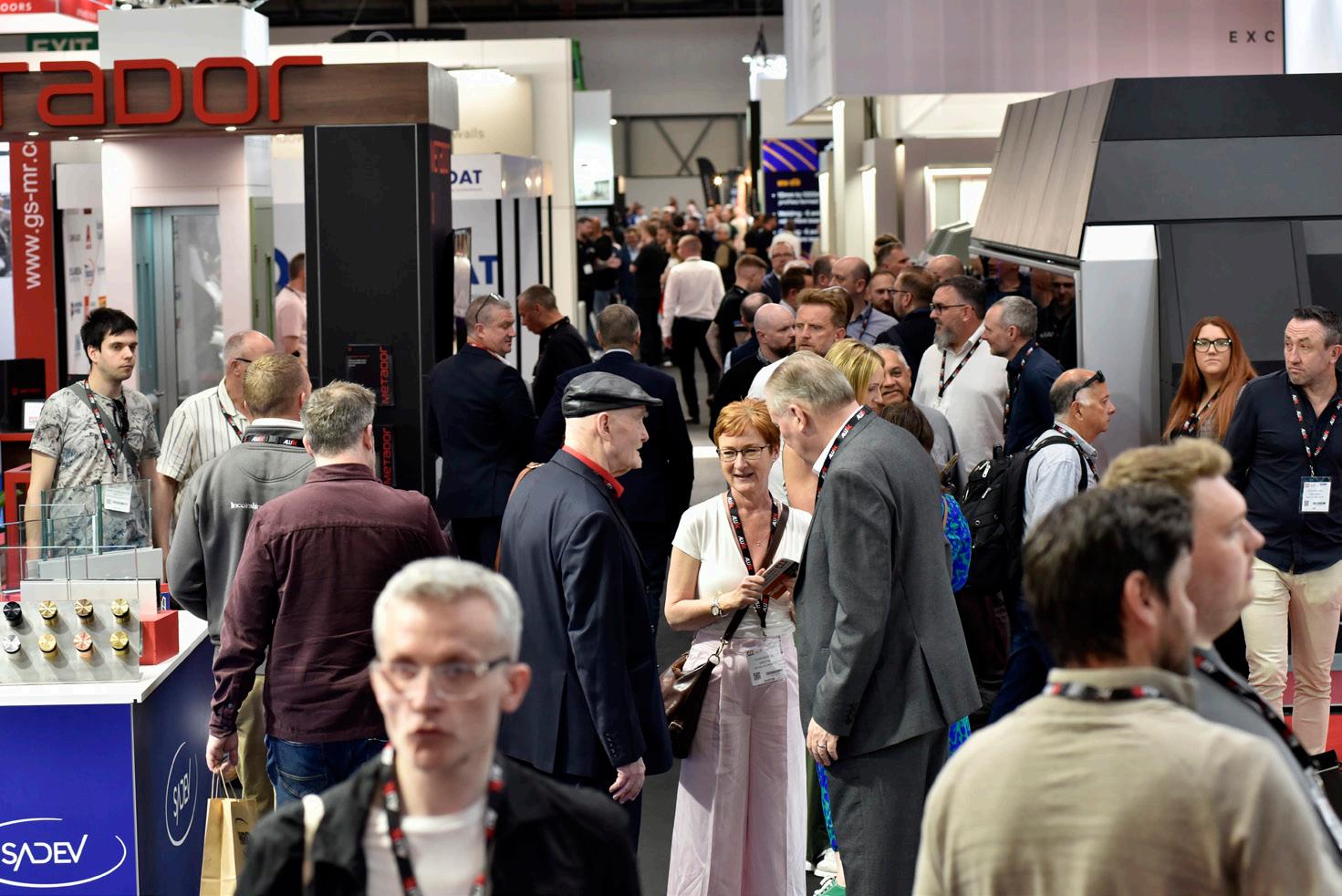

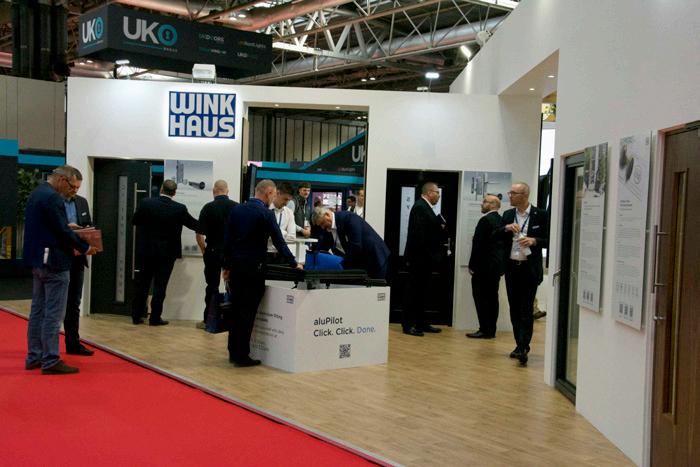

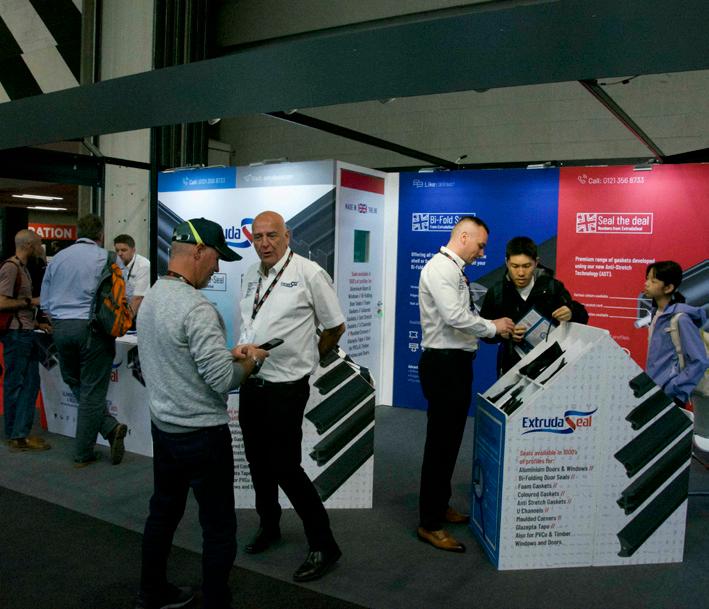

I really think that the 2025 FIT Show was one, if not the best of the shows, to date. The whole layout was inviting to the eye and the wide aisles were needed to accommodate the number of visitors. Some cynics may comment that the wide aisles covered up a lack of stands but I would strongly disagree. The space allowed for relatively easy movement and also meant that one could view the stands without feeling you were cricking your neck in a narrow alleyway! I don’t know whether the number of stands was up or down on 2023’s numbers but, whatever, there really was something for everyone. Nickie West and all her FIT Show team deserve to be applauded for organising a stunning show – as you can tell, I thoroughly enjoyed it while learning a lot, too!

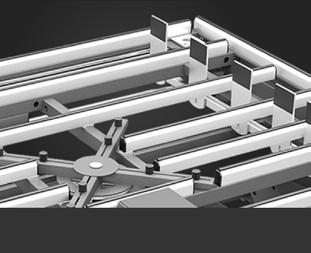

You will find lots of coverage of the show in this edition of Glass News with reports from many companies on the success of the show, and it sounds as if the exhibitors were very happy with both the number of visitors and the quality of the interest shown. It’s always exciting to view new products and even developments of existing products. A good example is Made For Trade’s Korniche lantern which was always quick and easy to construct as can be witnessed from their demonstrations. Now the Mark 2 version is even easier with clever additions such as the formed channelling to direct silicone to specific areas. Neat! The beautiful aluminium conservatory from Sheerline caught the eye and the detailing was stunning. Quickslide was another ‘must see’ stand and their incorporating technology into their slider resulted in a constant stream of visitors looking for a demonstration. Machinery was well represented with Haffner’s Dave Thomas showing the impressive results gained from the Graf Synergy welder. And Gareth Green at Stuga was kept busy with a stream of visitors. Roseview Windows are not ones to sit on their laurels and continue to strive to innovate and now offer three different through horns on their vertical sliders. Dean Bradley was constantly busy at Glazpart and it was difficult to get a word with him! Selecta, too, had a busy stand and a successful show. The GGF stand was also really busy as was AluK. But if you want to talk ‘busy’ DOORCO was right up there and not just showing off 20 different doors but even a new door for the US market. They were serving Korean food – spicy and very good! – but were also running a bar and, arguably, the busiest stand on the extended Tuesday evening punctuated with the constant rumble of Guiness casks being rolled onto the stand!

Talking of that Tuesday night, that has to have been the best late night opening that FIT has staged and it wasn’t just DOORCO who embraced the whole idea of party night. Ian Short on the Morley Glass stand deserves a mention as does Hormann with their Oompah band. But so many exhibitors were offering hospitality that it was difficult to get round and see them all and it seemed

as if the visitors to the show were loathe to leave. If the same spirit and enthusiasm is displayed by both exhibitors and visitors in 2027 then the FIT Show 2027 should be a humdinger!

It's always interesting to note the topics of conversation when the industry gathers together and, naturally, Rachel from Accounts’ efforts to punish most sectors of the economy was high on the list of talking points as was energy, it’s cost, and Milliband’s obsession with getting to Net Zero in the UK while other industrial countries continue to spew CO2 into the atmosphere and keep their economies buoyant. Another topic was Cyber Security and I hadn’t realised how this had affected companies in our sector. While issues with M&S, JD Sports, TMobile, Dropbox and the like are well known, the use of ransomware within fenestration has also caused a variety of companies problems which are both very expensive and time consuming to sort out. The message is that everyone is vulnerable however large or small you may be. Cybernews has been pointing out that apps for mobile phones and even iPhones are a cause for concern. They suggest: Every time you install an app, it asks for access – to your location, your photos, your contacts. Most people just tap “Allow.” Don’t. Head to Settings > Privacy & Security and audit who’s got the keys to your digital house. If an app wants your location, ask yourself why. Spoiler: It likely doesn’t need it.

Update as if your privacy depends on it – because it does. Apple pushes out security updates for a reason. Hackers love old software. Go to Settings > General > Software Update and don’t let those red notification dots linger. The same goes for your apps: update early and often. Lock it down. Still using “123456” or your birthday as a passcode? Time to level up. Use a long, unique passcode and enable Face ID or Touch ID. If someone snatches your phone, you want it to be a brick, not a gold mine. Don’t trust – verify. Treat a new app like a stranger at your door. Check reviews, look up the developer, and think twice before granting permissions. Even the App Store’s walled garden isn’t weed-free. Clean your digital house. Delete apps you don’t use. Every extra app is another potential leak. Before deleting the app, delete the account you created for the service, if they don't have your data, they can’t leak it. Less is more. Stay sceptical. Phishing isn’t just for email. If an app asks you to log in with Facebook or Google, make sure it’s legit. And never, ever tap on sketchy links. Chris

GOT SOMETHING TO SAY?

Email Chris at: chris@glassnews.co.uk

‘TIME OUT’ WINNERS – MAY!

Sudoku:

Karen Jackson, Margate, Kent

Eye Spy:

Duncan Barker, Sherburn-in-Elmet, North Yorkshire

Spot the Difference: T Betts, Blakelands, Milton Keynes

Crossword:

Emma Lewis, Spennymoor, Durham

Congratulations to all our winners! Good luck in this months Time Out pages!

Christina Lazenby

Managing Director / Advertising Enquiries

M: 07805 051322

E: christina@glassnews.co.uk

Emma Champion

Advertising Manager

M: 07508 263262

E: emma@glassnews.co.uk

Justin Lazenby

Finance Director / Press Release Enquiries

M: 07711 828710

E: justin@glassnews.co.uk

Chris Champion

Editor / Editorial Enquiries

M: 07850 267223

E: chris@glassnews.co.uk

Kate Carnall Graphic Design

E: kate@glassnews.co.uk Deadline for copy: 16th of each month

Where were you born and live currently?

I was born and bred in Manchester – I’ve flirted with the idea of leaving, but like any good Mancunian, I always come back. After all, it is the best city in the world, but not always if you’re a Red. Between the rain, the music, and the sarcastic humour, I’d struggle to find anywhere else that feels quite like home.

Your education and the subject or activity in which you excelled?

I studied Biochemistry at the University of Liverpool because, at the time, I thought I was destined for a white coat and a glamourous career in drug development. Turns out, I was really good at explaining complex stuff to people who didn’t ask – a skill that surprisingly comes in handy in sales. Group presentations? Nailed them. Lab reports? Slightly less exciting.

Your favourite sports or interests?

I’m a big fan of pretending I’m sporty without actually committing. I like going to the gym (mainly the idea of it), long walks that accidentally end at a pub, and anything creative – whether it’s painting, photography or trying to frame a day off as ‘wellness’. That said, my English Bull Terrier, Spud, keeps me healthy. She drags me up mountains on the weekends and definitely sets the pace. She has more stamina than I ever will.

Your biggest regret in life?

Spending £750 on Oasis tickets. I love them, don’t get me wrong –but I could’ve had a city break, a spa day and still had change left over for some chips on the way home.

The temptation you can’t resist...?

A double Kraken and coke or some good gossip. Ideally both at the same time, while I pretend I’ve only gone out for ‘one’.

From biochemistry labs to the fast-paced world of decorative glazing, Ella has taken an unconventional path into the fenestration industry. Now a familiar face at RegaLead and across the sector, she brings a unique blend of scientific curiosity, artistic flair, and infectious energy to her role as Area Sales Manager.

Someone or something that inspires you?

I’ve always admired Jane Goodall – a woman who quietly changed the world through sheer passion, patience and an unshakeable belief in the power of nature. Closer to home, my colleagues at Regalead inspire me daily. Their passion and knowledge of the fenestration world is infectious (in the best way, not the lab kind). Being around people who can still keep you laughing when times get hard is rare to come by.

When and how did you join this industry?

I fell into the industry the way most people do – accidentally and then somehow never left. I started at Regalead when I was younger, one of those classic ‘just for now’ jobs. I left to chase the science dream and worked in the Covid diagnostic labs, then found my way back to Regalead. I’ve been here since April 2022 and they can’t get rid of me it seems. Apparently, glass and colour were more exciting than nasal swabs. Who knew?

What is your job?

I’m an Area Sales Manager, with a passion for all things Urban Bar and Engineered Door Components. I get to talk to people all day about decorative glass, colour, and how to make windows and doors look fancy. It’s a lot more difficult than it sounds, and there isn’t a single day that goes by where I don’t learn something new. It’s fast paced, constantly evolving, and weirdly addictive.

Your greatest achievement?

Transitioning from pipettes to panels without a total identity crisis. But to answer the question properly, I’d say its building genuine relationships with customers and being someone they can trust to help them get the job done – and maybe even enjoy it along the way. If I’ve made someone’s day a little bit easier or helped them see a new creative possibility, that’s the real win.

What would you like to do if you weren’t in this industry?

I used to say forensic science or clinical research, but now I think I’d be a travel blogger – jetting off around the world and calling it content. I mean, who wouldn’t want to be paid to drink cocktails in Bali while reviewing suitcase zips?

A particular ambition?

To be that person that walks into an industry event and knows everyone – ideally because I helped them with something useful, not because I fell off my stool at PIGs.

I’d also love to mentor young people coming into the industry – especially those who never imagined themselves in fenestration. If I can show someone that this world is full of creativity, innovation and real career growth, then I’d be pretty proud of myself.

The way you want to be remembered?

As someone who brought energy, humour, and told a few decent stories.

I want people to remember that I cared – about the job, the people, and making even the glassiest of topics a bit more fun. If someone one day says ‘she made a difference’ then I’ll know I at least did something right.

As the UK’s leading PVC-U door panel manufacturer, we offer a high-quality collection with diverse styles, colours, and glazing options. Now featuring seven new contemporary designs, our range is available with Securicore™ reinforcement - a proven PAS 24 compliant option which delivers enhanced security without compromising on style.

Discover the latest styles today.

Kenricks has announced that Window Ware has become a national distributer of AK Touch Secure™, the new high-security Smart door locking system.

Window Ware’s decision to stock AK Touch Secure™ reinforces its commitment to staying at the forefront of smart product innovation. This strategic move opens up significant opportunities for the new and retrofit door market, offering fabricators and installers a smart, secure locking upgrade.

Vaughan, Product Manager at Window Ware, said: “AK Touch Secure™ fits seamlessly into our business providing our customers with a competitive advantage in the smart home space. We were impressed by how easy the product is to install, and we see massive potential in the retrofit door sector.”

AK Touch Secure™ is compatible with any door handle fitted with a Kenrick 3-Star locking cylinder. It offers multiple access options, including intuitive touchsensitive technology, an encrypted key fob, a secure keypad, a traditional key and voice commands via Google Home or Alexa. Via the AK Touch Secure™ app, users can control their doors remotely—lock or unlock them from anywhere, check real-time status updates and view detailed access logs to track who has entered or exited the property. The app also enables temporary, time-restricted access for guests or service providers.

Security is impressive with AK Touch Secure™ and features end-to-end encryption to ensure that all data and access methods are fully protected.

Andy Meakin, Sales and Marketing Manager at Kenricks, said: “We are delighted to partner with Window Ware. Their proactive customer-centric approach makes them the ideal distributor to bring AK Touch Secure™ to market nationwide.”

Since 1987, Window Ware has been a trusted supply partner for fabricators and installers across the UK, offering a vast range of window and door hardware, tools and consumables backed by expert service. This partnership with Kenricks builds on their reputation for delivering industryleading solutions that are both reliable and future-proof.

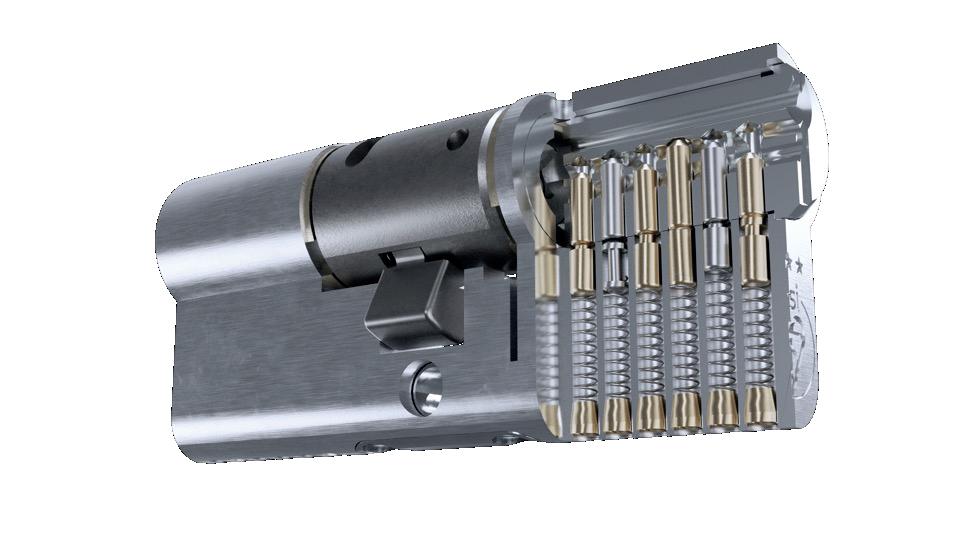

UAP Ltd, the leading Greater Manchesterbased door and window hardware specialist, is today making its groundbreaking Kinetica Freezeguard range commercially available.

UAP is the first manufacturer in the industry to achieve the BSI KITEMARK TS007-1:2024 certification for the range’s 3* euro cylinders, developed in its in-house research and development hub.

The new range is certified according to the newest PAS24:2022+A1:2024 security test standard and accredited by Secured by

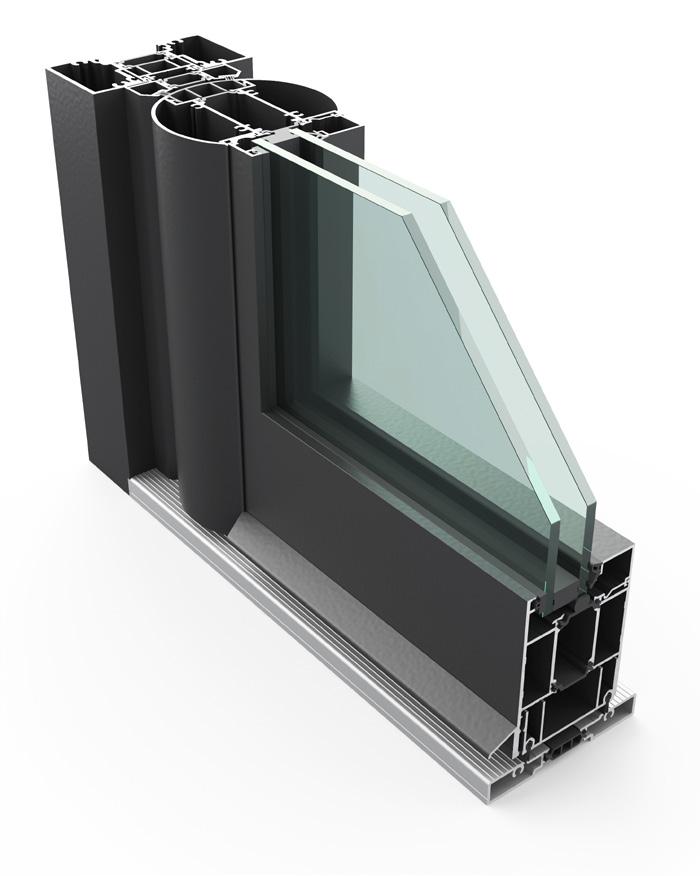

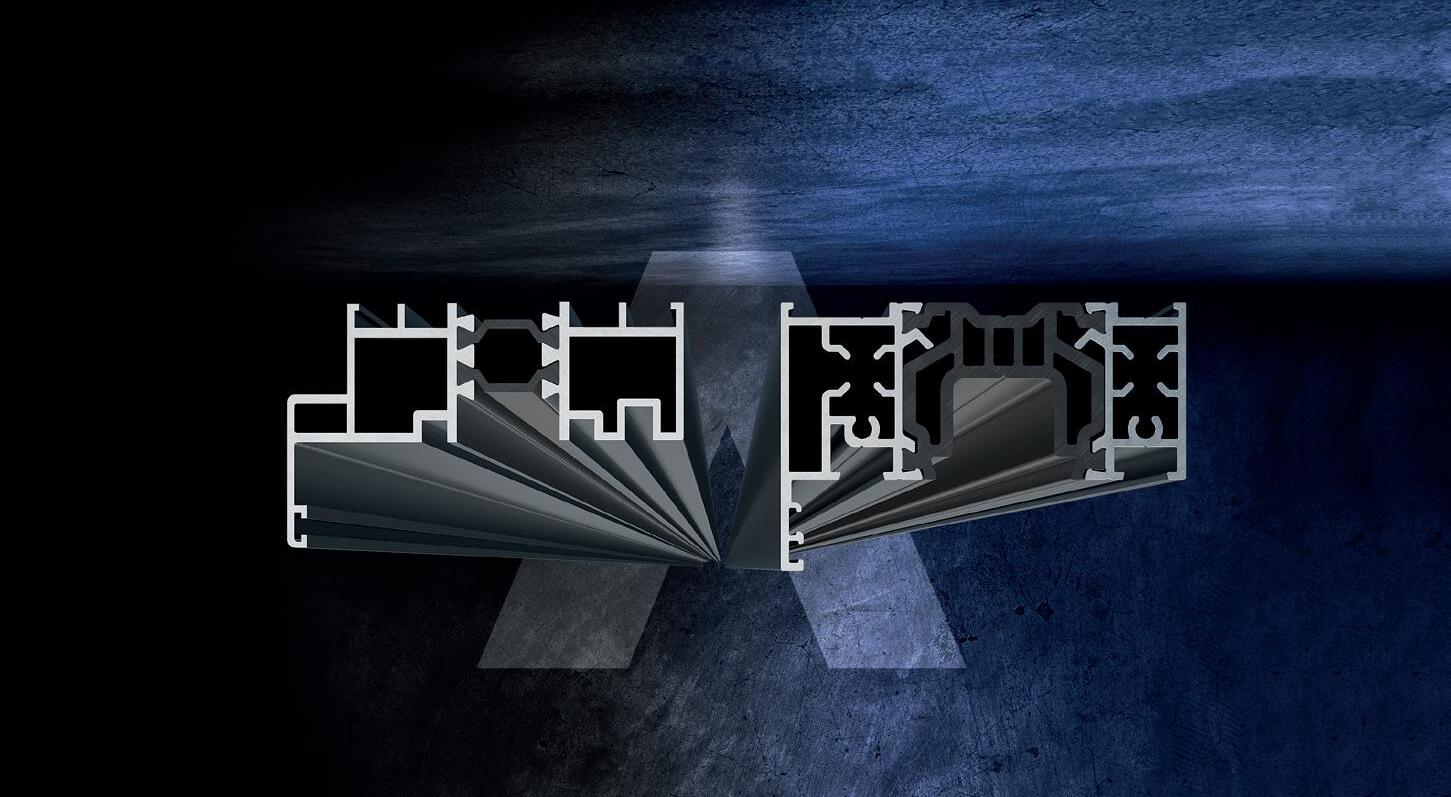

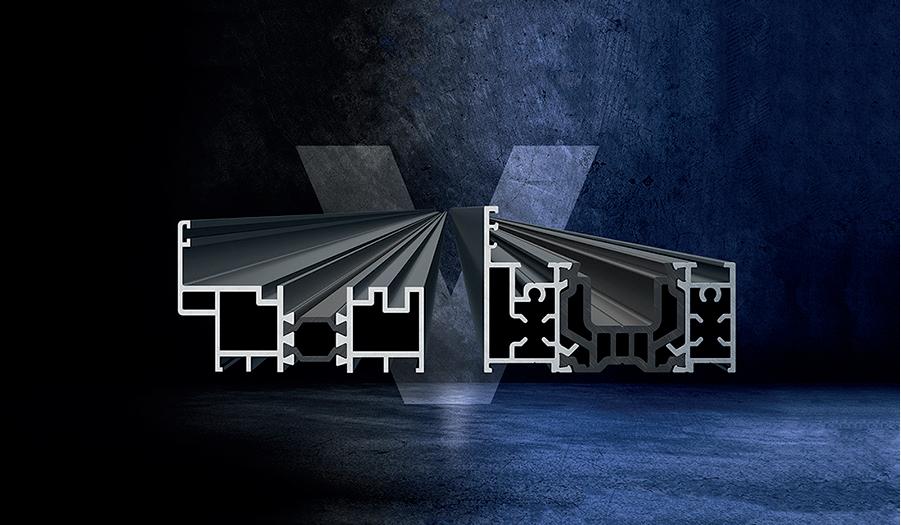

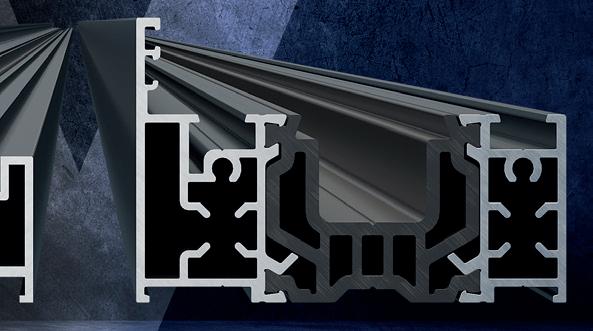

VBH, the hardware manufacturer, has advised that sales of one of its star products for aluminium window production is ‘on the up.’

The greenteQ Securitas Offset Security Espagnolette is a specialist product for users of slim aluminium casement windows from three of what VBH describe as the ‘most popular’ aluminium systems, including Sheerline.

These slim profiles have no Eurogroove to accept the locking system. Securitas Offset’s 16mm wide U-rail stainless steel faceplate is designed to be surface fit to account for this, and its offset gearbox ensures that the glazing area is not broached when fitted.

"2025 has seen sales continue to rise as we penetrate further into the aluminium sector. It really is one of our products that is “on the up."

Up to four pairs of bi-directional adjustable mushroom headed cams provide compression and security when in the locked position. The cam pairs locate into both sides of a greenteQ night vent striker plate to firmly hold the sash secure even in the face of a determined attempt at forced entry.

Nine lengths, starting at 320mm going all the way up to 1320mm, mean that even the smallest and largest casements can benefit from Securitas Offset

Gary Gleeson, marketing manager at VBH, says, “Securitas Offset is a major strand of our range of locking systems for outward opening single and double sash casements. We now offer thirteen different solutions across the greenteQ, Roto and Yale brands.

“We launched this product eighteen months ago and it proved so popular that the industry voted it Window Component of the Year last autumn. 2025 has seen sales continue to rise as we penetrate further into the aluminium sector. It really is one of our products that is “on the up.”

As well as being very quick to fit, VBH advise that Securitas Offset is approved for use on Q-secure

Design. These updated standards ensure locks can withstand extreme tampering, protecting against increasingly sophisticated break-in techniques including freezing, gluing, snapping, drilling, picking, and bumping.

While the industry continues to adjust to new requirements, UAP has already delivered fully compliant products that fabricators and installers can rely on.

Adam Dixon, Senior Technical Manager at UAP Ltd, said: “Our status as the first in the industry to achieve the new BSI Kitemark is testament to our team, who work tirelessly to develop products that meet and exceed security standards. The new Kinetica Freezeguard range shows our commitment to leading the way with proactive security innovation, giving our clients a competitive edge.”

PREMIUM installations, offering consumers the peace of mind that the popular hardware security guarantee brings.

As with all greenteQ products, Securitas Offset is supplied with a long guarantee; ten years in this case.

To find out more about Securitas Offset, or any other hardware in the VBH range, contact the company on 01634 263263 or via email at sales@vbhgb.com.

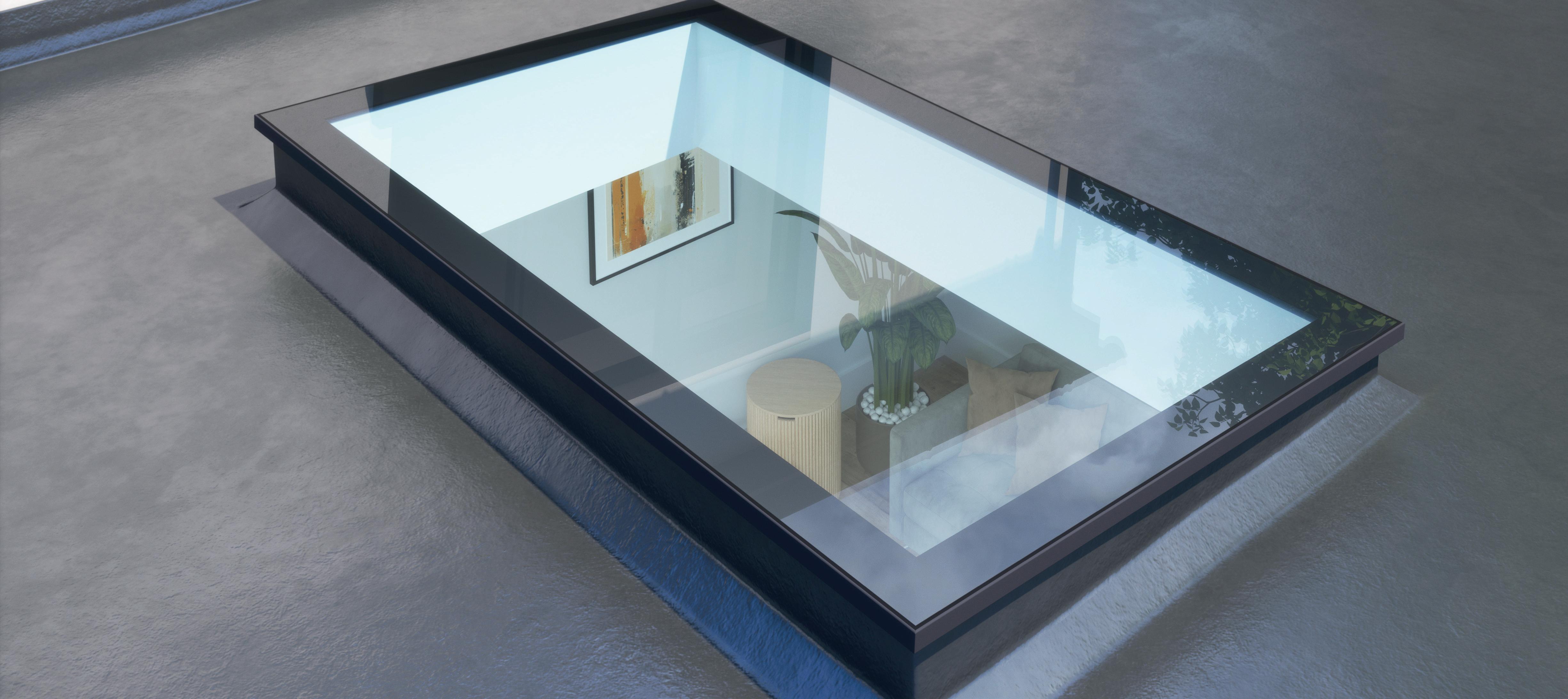

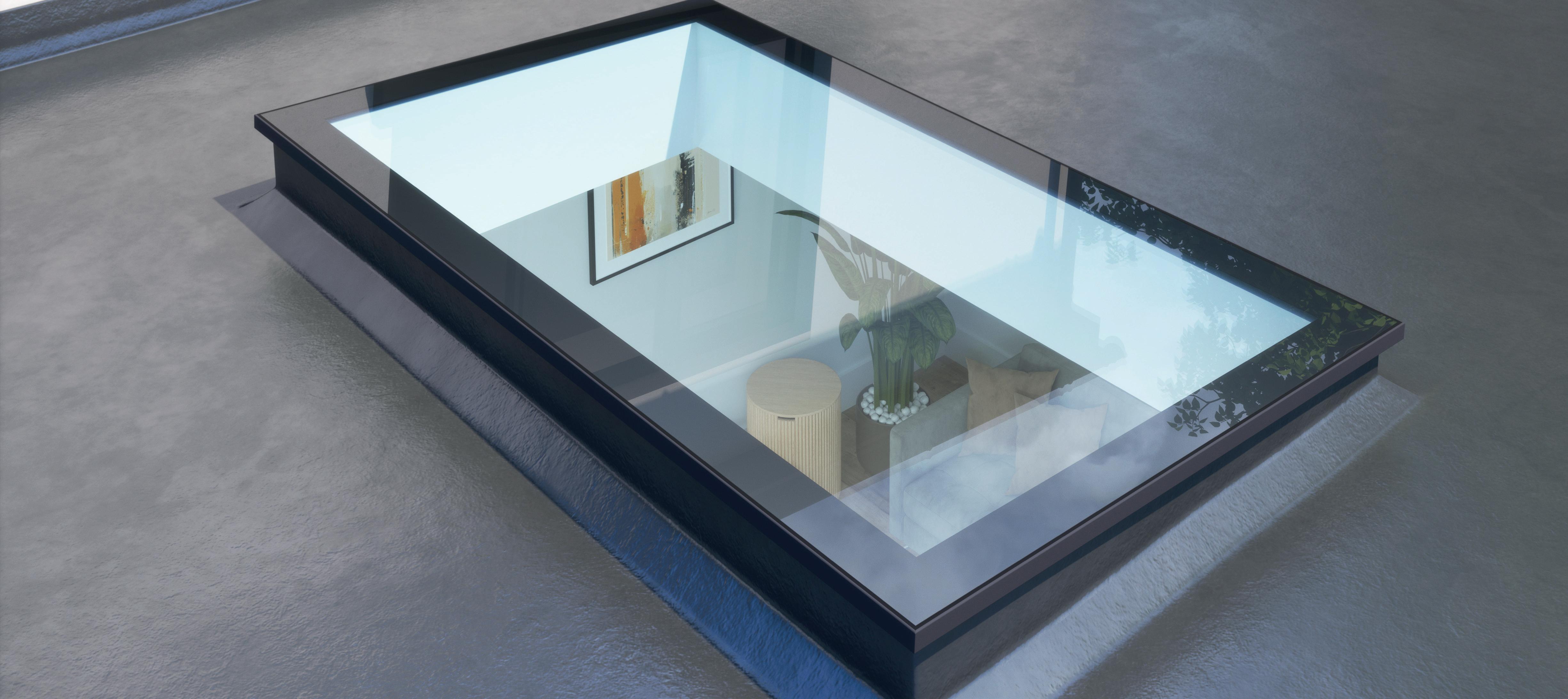

Specialist daylight solutions manufacturer Brett Martin has introduced a new addition to its glass rooflight range, the Pyramid Roof Lantern. This square, four-pane solution is available in both standard and bespoke sizes, providing additional design options for projects where maximising natural light is a priority.

With an attractive slimline profile, the new Pyramid Roof Lantern allows focused even light to penetrate buildings, creating a striking focal point in any desired space. The Pyramid Roof Lantern’s four standard sizes range from 1000mm x 1000mm, up to 2500mm x 2500mm, with a lead time of just three to five days.

The new addition adds to the existing range of four and six-pane rectangular roof lanterns as well as square, rectangular and circular flat glass rooflights, all of which are available with combinations of white, black or grey frames, inside and out. The glass can also be specified, with the options for clear or solar-control blue glass available for reduced solar gain and decreased internal temperature spikes.

As with the other products in the Brett Martin range, the Pyramid Roof Lantern is double glazed and complies with the guidance from the Rooflight Association which recommends that a laminated inner pane should be the first

choice for safety when specifying overhead glazing.

Tony Isaac, Sales Director at Brett Martin commented, “The launch of the new Pyramid Roof Lantern better enables us to help specifiers and installers to select the ideal roof lantern for their projects. Easy to install, it can be fitted from the roof and requires minimal silicon use – only at the kerb. As such it provides a fast and stress-free daylighting solution to transform living areas.”

For more information about Brett Martin’s glass rooflight range, visit: www.brettmartin.com/daylightsystems/our-products/glassrooflights.

The team at Sheerline are delighted to share they have been shortlisted for eight National Fenestration Awards. This is just the latest good news announcement on the back of the system being recognised with a coveted King’s Award for Innovation 2025.

One of the reasons the NFAs are so important to Sheerline is the fact they’re peer-voted and speak volumes within the industry. This year’s awards look to be the most competitive yet, with Sheerline nominated in several sought-after categories.

This includes the title of Aluminium Systems Company of the Year, which Sheerline was thrilled to receive last year, particularly as 12 other well-known systems houses were in the running for the award. This year it will be even more hotly contested with 14 systems houses shortlisted.

Sheerline has been nominated in a broad range of categories covering

its products, services, and people reflecting its continued impact within the industry. The S1 Roof Lantern is in the running for Conservatory Product of the Year while the Fast Connect Hybrid Bead is up for New Product.

Other categories featuring Sheerline include Colour Specialists and Systems Company. The ‘U-values You Can Trust’ campaign is up for Digital Marketing Campaign, While Martin Hepburn is up for Sales Executive of the Year and Felicity Theaker is up for Social Networker.

Tony Basile, Sheerline’s National

Leading trade fabricator John Fredericks Plastics has invested in a new Graf Synergy SLS – Single Head CNC Cill Welder from machinery experts Haffner. The new machine delivers seamless, high quality welds reinforcing John Fredericks’ commitment to product excellence. Alan Barnard, Factory Director for John Fredericks, said: “We are delighted to introduce this advanced machine to our production line up. Its precision and efficiency perfectly support our drive for continuous improvement and ensure we can consistently deliver the superior product quality our customers expect.”

The team at John Fredericks wanted to invest in machinery that would help them increase output, save time and increase the quality for which they are renowned. After carefully researching the market, they contacted Haffner as the machinery supplier best placed to meet their needs on this project.

The Haffner team recommended the Graf Synergy SLS – Single Head CNC Cill Welder, the first and only single head CNC welding machine designed for the welding of bay cills. To finalise the details, Alan visited Graf Synergy’s headquarters near Modena, Italy, where the deal was agreed.

Like all Graf Synergy machines, the Cill Welder produces a perfect seamless weld which is free of excess sprue. This eliminates the need for post-weld cleaning or touch-ups, saving valuable production time and improving fabrication efficiencies. Further, only one operator is needed, boosting productivity. All profile tolerances are measured and recalibrated before welding, helping to reduce wastage.

The compact machine has a small footprint to save space on the factory floor. It can be used on profiles coated with any film or foil including painted PVC.

Alan commented: “The Graf Synergy Cill Welder will increase our production output and eliminate the need for sanding and polishing plain white cills and remove the need for penning in. It delivers a seamless, high-quality weld that will complement our Ultimate Collection™ product range.”

Sales Director, commented: “We’re not even halfway through the year and we’ve already won Best Technical Innovation at the GGP Installer awards (for the third time), received a King’s Award for Innovation 2025, and now we’ve been shortlisted for eight NFAs.” “2025 is shaping up to be the most successful year for Sheerline in terms of award wins and this is all while announcing our ambitious expansion plans and celebrating the 5th anniversary of our launch. If the previous five years are anything to go by, we’ve got a bright and busy future ahead,” he added.

A firm favourite within the industry, The NFAs are scheduled to take place on Saturday 25 October at Doncaster Racecourse. Voting opened at the beginning of May and will remain open until September 19, giving plenty of time to break last year’s voting record.

Find out more about the awards and vote for Sheerline here: www.fenestrationawards.co.uk/nfa25

This latest investment reflects John Fredericks’ ongoing strategy to drive manufacturing efficiency and product quality through advanced automation. By embracing the latest machinery innovation, the company will continue to reinforce its position as a leading name in UK fabrication.

The collaborative approach and technical insight provided by Haffner have been instrumental in shaping this next phase of investment. Both companies are also exploring further opportunities to partner on future machinery developments.

INNOVATION TO ELEVATE YOUR OFFERING

STEEL-STYLE MEETS UNPARALLELED THERMAL PERFORMANCE POWDERCOATED IN-HOUSE

MANUFACTURED IN THE UK HIGHLY DESIRABLE INDUSTRIAL DESIGN

Keystone Market Research is pleased to announce the release of its Spring 2025 Consumer Fenestration Trends Report - an indepth analysis of the evolving behaviour, preferences, and frustrations of UK homeowners in the windows and doors market.

Key findings from the Spring 2025 Report include:

• Sliding Patio Doors Now Firmly Lead: Sliding doors have cemented their position as the UK’s most popular patio door style, overtaking bifold doors by a significant margin. This trend is consistent across all 12 UK regions, making sliding doors an essential offering nationwide.

Building on the momentum of previous editions, this latest report reveals subtle shifts in consumer priorities and offers an expanded regional analysis across 12 UK areas. This edition is once again made possible through the sponsorship of Endurance Doors, Epwin Window Systems, the GGF, Liniar, and VEKA, whose support helps ensure this essential resource remains accessible throughout the fenestration industry. Customers of these companies gain free access to the series that delivers consumerdriven insights that can shape sales, marketing, and product development strategies.

• Tilt & Turn Windows Gaining Momentum: While casement windows remain the dominant choice, tilt & turn styles continue to gain traction, with particularly strong interest in Northern Ireland where they ranked as the top preference. This suggests the UK market may be aligning more closely with European style trends.

• Homeowner Frustrations Are Growing: Satisfaction with current windows and doors has declined sharply—from 23% last year to just 11% today, signalling a ripe market for replacements. Find out which areas are impacting homeowners most in the report.

• Smart Home Technology Still Not a Priority: Despite the wider growth of connected tech, smart

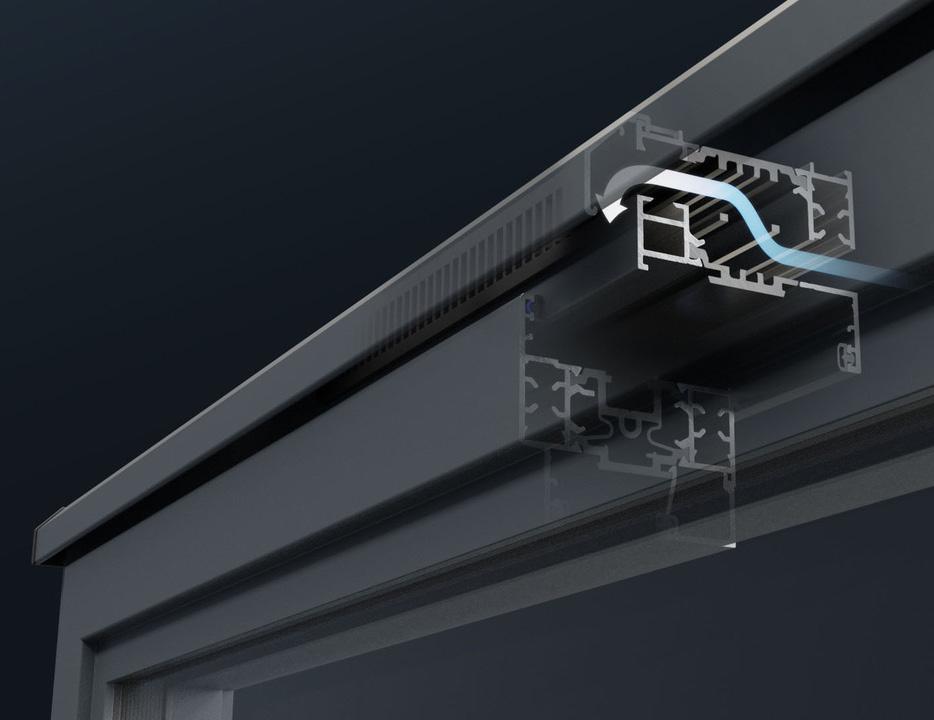

Sheerline’s Prestige Grille Shroud offers a host of benefits for fabricators and homeowners. It’s the ideal alternative to unsightly exterior plastic trickle vents that can warp over time and fade in the sun.

home compatibility continues to rank low among homeowner considerations for windows and doors – we will explore further in next quarter’s report.

Charlotte Hawkes, Director of Keystone Market Research, commented: “This report is about more than preferencesit’s about understanding the motivations behind homeowner decisions and recognising the subtle changes that can impact the

market to arm businesses throughout the supply chain with the knowledge to make informed decisions on everything from new product development through to marketing. Our regional breakdowns help businesses see the variations that exist across the UK and installers tailor their messaging more effectively for their unique area. I’m also delighted that access to the report continues to grow with the support of our sponsors, who share our commitment to equipping

Charlotte Hawkes

the industry with powerful, actionable data.”

Keystone invites industry professionals and companies across the supply chain to explore the findings and use the insights to strengthen their engagement with today’s homeowners. Businesses interested in supporting their customers, and the wider fenestration industry, with Keystone’s trusted consumer insights are encouraged to reach out as a limited number of sponsorship opportunities remain available.

For more information about the Spring 2025 Consumer report and Keystone’s research services, visit: www.keystonemr.co.uk.

employers who want to ensure their staff can live with dignity and security.

Perfectly colour matched with the frames, it blends in seamlessly with the rest of the window. It’s available in the full Sheerline colour range.

The Prestige Grille Shroud differs from traditional trickle vents as it runs the full width of the window, enabling its integral head drip to protect the edge of the sash that sits below. It also means they’re less likely to be damaged or cause damage to other frames whilst in transit. As well as being less obtrusive, Sheerline’s Prestige Grille Shroud is more aesthetically pleasing than standard options. It provides an architecturally refined yet practical solution, hiding the flat aluminium grille that sits under the shroud.

Jon Crohill, Sheerline’s Design Project Manager, said: “We’ve developed a discreet solution to a

divisive topic within the industry. Regardless of how you feel about trickle vents, many properties need them for Part F compliance, so why not choose the most stylish one.”

Find out more about Sheerline’s Prestige Grille Shroud by calling 01332 978 000 or emailing info@sheerline.com.

Leading West Lothian based window and door manufacturers Window Supply Company (WSC) has demonstrated its commitment to employees by becoming Living Wage accredited. With over 190 members of staff throughout the business’s head office, manufacturing, and trade counter operations, WSC joins over 15,000 businesses across the UK paying the real Living Wage.

The real Living Wage is a voluntary wage rate independently calculated by economists at the Resolution Foundation on behalf of the Living Wage Foundation. The real Living Wage is based solely on the cost of living to account for essentials like housing, food, and travel but also small discretionary expenses that allow for a decent standard of living. The real Living wage is paid by employers who voluntarily commit to go further than the government national living wage to make sure all staff can earn enough to live on.

The real Living Wage is paid to all employees over 18 and currently stands at £12.60 per hour across the UK and £13.85 per hour in London to reflect the city's higher living costs. It is paid by over 15,000

Duncan Murray, CEO WSC says “As a responsible employer, we want to demonstrate our commitment to our excellent team who are the driving force behind this business. This commitment applies not only to directly employed staff, but also our third party contracted staff. By becoming a member of the National Living Wage Foundation, our team can earn a wage that they can live on - because their wages are kept at pace with the cost of living. It is extremely important to us to achieve this accreditation, not only showing our support for the initiative, but perhaps encourage others in our sector to follow suit’ WSC employee benefits package also includes life insurance, pension contribution, shopping perks, Health and wellness and access to 24/7 Employee Assistance Program.

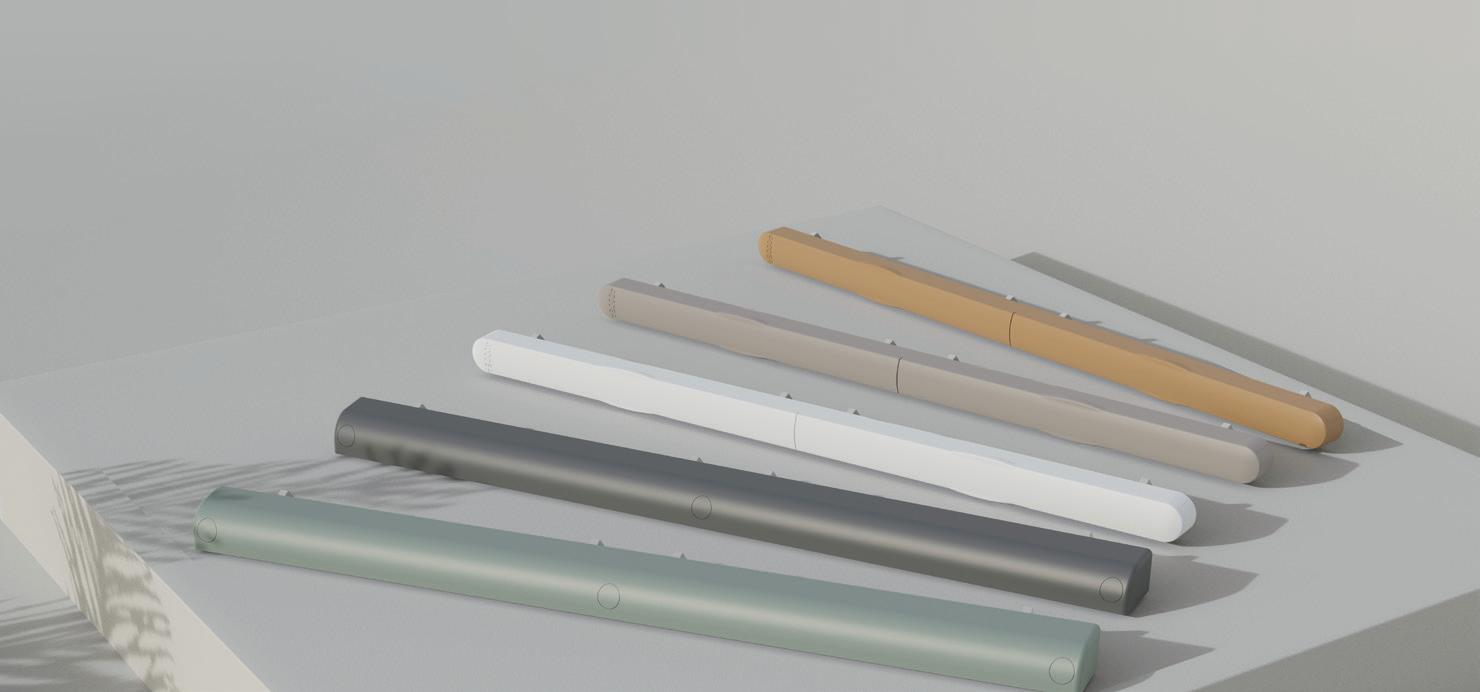

VEKA plc, an innovative leader of PVCu window profile systems, is proud to introduce Feinstruktur – a premium new range of fine-textured, matt finish decorative foils to the market. Delivering aluminium-inspired aesthetic in a PVCu solution.

Responding to consumer trends and rising sustainability demands, Feinstruktur emulates the aesthetic appeal of powder-coated aluminium whilst providing exceptional durability and thermal performance of a PVCu profile.

According to the Keystone Market Research (Autumn 2024), the aluminium window market is increasingly on the rise as homeowners are looking to achieve a striking, modern aesthetic for their property. However, aluminium can prove to be costly both in the initial investment and subsequent maintenance costs, as well as the risk of corrosion and environmental wear. In recent years, aluminium prices have also been driven up by international tariffs and global supply chain pressures. PVCu provides consistent value, superior thermal performance and long-term durability without corrosion.

VEKA Feinstruktur delivers a contemporary, industrial look of aluminium with a PVCu profile. The surface effortlessly aligns with modern trends in colour and texture whilst maintaining VEKA’s signature reliability and performance, serving as a cost-effective, energy-efficient alternative to aluminium window systems.

Feinstruktur is available in eight elegant trend-led coloursanthracite grey, slate grey, basalt grey, umber, black, quartz grey, silver grey and traffic white - each carefully selected to complement modern architecture. The textured matt foil is weather-resistant and scratchproof, whilst the easy-to-clean, anti-fingerprint finish, ensures the windows maintain their visual appeal with minimal effort.

Designed with sustainability and cost-efficiency in mind, Feinstruktur is fully recyclable and manufactured using sustainable raw materials to minimise environmental impact, and can be processed using standard lamination machinery, requiring no additional investment or downtime.

Feinstruktur is ideally suited for OMNIA, VEKA’s awardwinning suite of PVCu double flush windows and doors. Presenting a truly flush appearance inside and out, enhanced by the aluminium look, while also giving optimal thermal efficiency, security, weather protection, and acoustic performance.

“As the aluminium aesthetic is growing increasingly popular with homeowners, Feinstruktur offers more than a contemporary visual appeal,” said Loredana Emmerson, Customer Marketing Manager at VEKA plc.

“It allows our partners to meet demand for aluminiuminspired design and performance benefits of PVCu systems, whilst staying true to VEKA’s commitment to sustainable innovation. Feinstruktur benefits architects, fabricators, installers, and homeowners alike, serving as a future-ready alternative to aluminium.”

Level up to the next era of window aesthetics with the Feinstruktur range, discover more at www.vekauk.com/feinstruktur.

Aluminium fabricator Fentrade has been announced as a finalist in two categories at the National Fenestration Awards 2025: Aluminium Fabricator of the Year and BiFolding Door Manufacturer Of The Year.

Chris Reeks, Director of Fentrade, commented: “The National Fenestration Awards are decided completely by the participation of the industry, so it’s a real honour to be announced as finalists. Thank you to everyone who nominated us.” The fast-growing aluminium fabricator brings a wealth of experience and a deep understanding of the it’s customers’ needs, qualities that’s reflected in its finalist status.

Chris said: “The vision for Fentrade has always been to be a leading name in high-quality, expertly manufactured aluminium products, underpinned by an exceptional service ethos. It’s a mantra that guides everything we do, from fabricated products to customer support. Being recognised as a finalist is testament to the dedication and hard work of the Fentrade team.”

The National Fenestration Awards is the industry’s fastestgrowing and most inclusive awards event. Now into its 12th year, the awards aim to be the fairest, most inclusive fenestration event, rewarding the very best of the sector.

Each year there is a nominations phase where people put forward the names of people and companies they believe deserve to be recognised. The industry then votes on shortlists in each category based on the nominations submitted, making it the only fenestration industry award built upon the industry itself.

Voting for this year’s awards is open now at www.fenestrationawards.co.uk/nfa25/ and closes on 19 September 2025. The winners will be announced at the awards ceremony on 25 October 2025.

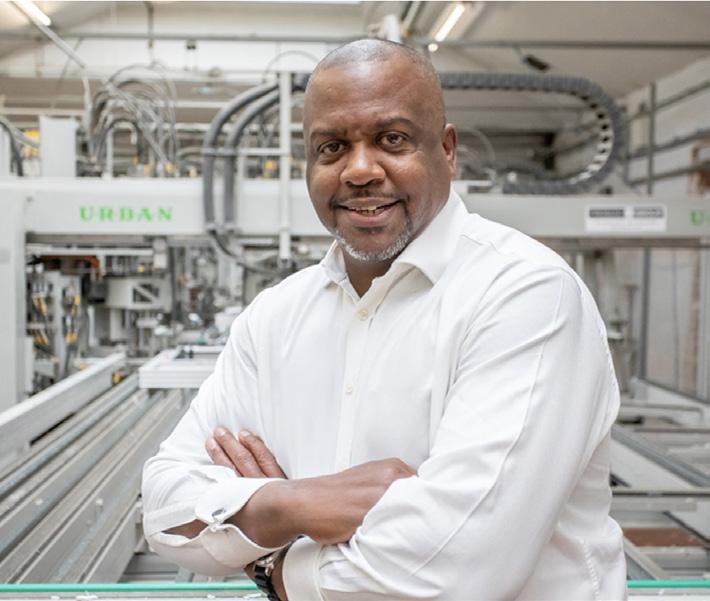

Garnalex can officially announce it has received a coveted King’s Award for Innovation 2025 for its groundbreaking Sheerline aluminium windows and door range. With only 46 businesses being recognised in the innovation category this year it is testament to how game changing the Sheerline system has been.

This award reflects the significant contribution and advances the company has made within the fenestration industry.

Although Sheerline was launched during the global pandemic, the challenging external landscape has not stopped it from achieving success.

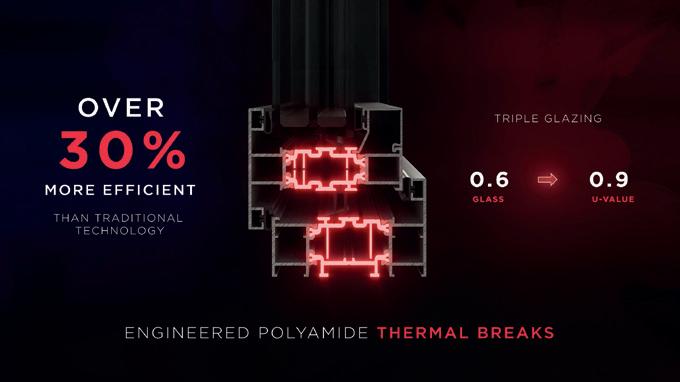

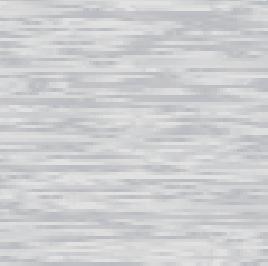

Two innovative aspects in particular were highlighted by the awards process. Firstly, Sheerline’s patented construction method, which not only reduces waste and locks in quality, but also results in better looking windows with less misalignment in frames for improved aesthetic appeal.

In addition, Thermlock®, Sheerline’s proven proprietary thermal technology was highlighted. Aside from offering greater thermal efficiency than legacy polyamide systems, easily achieving Part L compliance with competitive U-values, it also allows installers to fix through the optimum area profiles as it’s less brittle than polyamide.

Its Newport factory manufactures a full range of fenestration products, including bi-folding doors, from respected industry names including Aluk, VBH, Kestrel and Jack Aluminium. Customers can expect reassuring reliability, with on time in full deliveries every time. Service is similarly impressive, with quotes returned within 24 hours, phone calls that are always returned and technical assistance always available. Quality is also at the heart of everything from incoming materials to finished goods.

Thermlock® is also a key ingredient in Garnalex’s market leading agility and ability to deliver consistently on its 5-day lead-time promise, as it allows finished profiles to be assembled close to dispatch.

It has differentiated itself in a competitive industry by focusing on product innovation, its customers and first-class service, and delivering on its

promises. This approach has enabled it to blaze a trail where others have lost momentum.

Roger Hartshorn, Garnalex’s CEO, said: “It is a privilege and an honour to be able to share the news that Garnalex has won the prestigious King’s Award for Innovation. The fenestration industry has always been a competitive industry, where accolades such as this make a real difference.”

“Not only will it enable us to continue to stand out in an increasingly crowded space, but it highlights the far-reaching impact we’re having as a company. We look forward to celebrating and bringing even more industry-changing innovations to market,” he added.

The King’s Awards for Enterprise, previously known as The Queen’s Awards for Enterprise, were renamed in 2023 to reflect His Majesty The King’s desire to continue the legacy of HM Queen Elizabeth II’s by recognising outstanding UK businesses. The Award programme, now in its 59th year, is the most prestigious business award in the country, with successful businesses able to use the esteemed King’s Awards Emblem for the next five years.

To find out more about Garnalex and its innovative Sheerline aluminium range of windows and doors, visit the website here: www.sheerline.com. VEKA FEINSTRUKTUR DELIVERS ALUMINIUM-INSPIRED

Door manufacturer Apeer Doors recently welcomed Blinds in Glass Group to its Ballymena based factory site for in-depth product training and strategy talks concerning the growing distribution of Apeer doors across the UK. As part of the partnership deal between the two companies, BIGG will help drive sales through its own network of window companies and facilitate the delivery of the product to areas within England and Wales which are still undeveloped by Apeer. Since establishing the partnership, BIGG managing director, Ian Woolley, along with son Ben, have worked closely with Apeer to ensure the positioning and marketing of the Apeer range of doors meets their mutual high standards in terms of performance and service. Their visit to Apeer’s factory highlighted how dedicated and committed the company and its workforce are, on a daily basis, to those very concepts.

“The market is tough at the moment, but that only gives companies such as BIGG, and Apeer, the opportunity to truly showcase a ‘best in class’ type approach,” commented BIGG’s Ian Woolley. “I was bowled over by what Apeer has achieved over the last 30 years, and as a relatively new kid on the block, we have set ourselves some BIGG targets. Apeer is the level of partnership we are constantly seeking to help us achieve those targets.”

“The BIGG mindset and approach to doing business is what we are constantly seeking to instil across our trade installer network, and we are already seeing the energy levels increasing across the market,” added

Apeer’s CEO Asa McGillian. “In tougher economic conditions it is the strength of the supply chain that will help any business overcome adversity. Working with BIGG gives us confidence that the foundation we are building today will bear even more prosperous fruit in the future.”

Ian Woolley established BIGG during the height of covid in 2020, and has grown it into a solid £1.6m turnover business focusing primarily on integral blinds and composite doors. The company has created a solid operational framework for growth, and sees this partnership as a primary focus for growth, continuing high levels of service with minimal investment.

Carl F Groupco has been announced as a finalist in the Hardware Company of the Year in this year’s National Fenestration Awards. Owen Coop, CEO of Carl F Groupco, said: “The National Fenestration Awards are voted for by the industry, so being shortlisted is recognition of the hard work and dedication of our entire team.”

Carl F Groupco is one of the industry’s only independently-owned hardware distributors. The company supplies a complete range of premium quality window and door hardware from 57 brands including Roto, Siegenia, Fuhr, Maco and Yale. Its independent status means it can objectively offer the best technical hardware solutions without the constraints of prioritising commercial gain.

In addition to the strength of its hardware offer, Carl F Groupco is widely recognised for its exceptional customer support. For example, its testing service goes beyond advising on compliant hardware. The team provides end-to-end support, from hardware selection advice to onsite visits to support fit-ups and pre-test preparation, ensuring a smooth and successful process for its customers.

The company holds up to £5 million in stock at any one time and operates with a stringent ‘On Time In Full’ (OTIF) target of 98%. Notably this metric is measured by orders rather than by component part, setting a higher standard of performance. With distribution centres in Peterborough and Cumbernauld, Carl F Groupco offers daily, next-day deliveries, including to

Conservatory Outlet has again been recognised for its success in training and developing staff at the West Yorkshire Apprenticeship Awards.

Held in Bradford for 2025, the annual event shines a light on those businesses and people who demonstrate excellence in vocational education. The company was singled out for the success of its apprenticeship programme, which has recently expanded to include degree-level qualifications and is also creating a manufacturing-specific course. As well as being singled out for praise for its industry-leading apprenticeship programme and constant elevation of staff through training, it was a night of success for three staff members who were recognised as amongst the best and highest-achieving learners in the region.

Those were Beth Cain (Advanced Apprentice, Level 3), Sarah Fox (Higher Apprentice, Level 4-5) and Joe Davis (Engineering & Manufacturing Apprentice).

Sarah, one of Conservatory Outlet’s key Account Managers, said: “Conservatory Outlet has been incredibly supportive.

The time was right for me to progress, and I’ve been able to do that personally and professionally by studying for and obtaining a Higher National Diploma. It’s an honour to be named as one of the apprentices of the year”

These fantastic achievements underscore Conservatory Outlet’s continued investment in career development and our strong support for vocational pathways within the fenestration and manufacturing industries.

The company operates a thriving in-house apprenticeship programme that spans various departments, including finance, marketing, operations, customer service and production.

This initiative is designed to nurture the next generation of talent, offering structured development plans, professional mentoring, and opportunities for long-term career progression within the business.

Scotland and the Scottish Highlands. This helps customers keep their stock holding low, reducing risk and improving cash flow.

Owen commented: “In a competitive market, we know it takes more than great products to earn long-term loyalty. That is why we focus on delivering exceptional service, technical expertise and reliability, giving our customers complete confidence in choosing us.”

The National Fenestration Awards are the industry’s most inclusive awards programme. Now in their 12th year, the awards are designed to celebrate excellence across the entire fenestration sector, recognising achievement through a transparent and industry-led voting process.

Voting for this year’s awards is open now at www.fenestrationawards.co.uk/nfa25/ and closes on 19 September 2025. The winners will be announced at an awards ceremony on 25 October 2025.

Joe Davis, one of the company’s lead Maintenance Engineers, says, “Conservatory Outlet has backed me, even when I wasn’t sure about myself. I never thought I’d achieve what I have. I’m blown away by the support I’ve received and the progress I’ve made over the years.”

The programme has received praise from local education providers and industry partners for its comprehensive approach and consistent results.

Apprentices are supported throughout their journey with tailored learning experiences and the chance to make meaningful contributions from day one.

As the company grows, its commitment to developing skills and creating career opportunities through apprenticeships remains at the heart of its long-term strategy.

“Apprenticeships are key to Conservatory Outlet’s success,” explains Conservatory Outlet’s Managing Director, Mick Giscombe.

“We have an established apprenticeship scheme that we’ve expanded recently to include degree-level qualifications. This means that we can provide tailored apprenticeships to everyone, from those leaving school or entering the industry for the first time to those who want to obtain degrees in fields such as Marketing, Engineering or Finance.

“That three of our apprentices were celebrated in this prestigious awards ceremony shows the value and success of our approach to training and development. And, of course, congratulations to Beth, Joe and Sarah. They should be very proud of their achievements.”

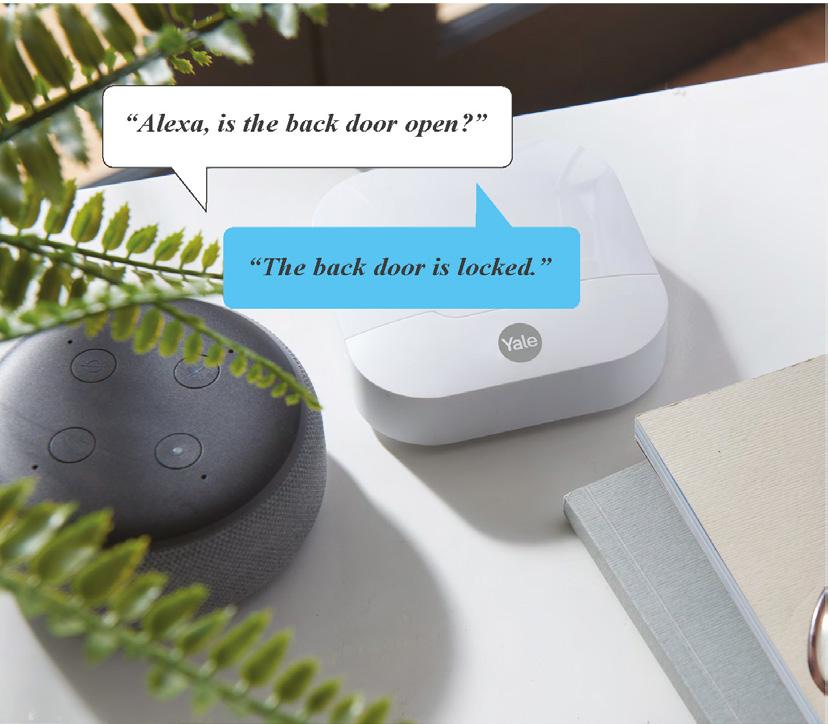

Consumers are becoming increasingly aware of the benefits of smart home technology—such as the convenience of automation, advanced energy management, and enhanced safety and security. With 25% of potential home movers considering smart technology a “must have” and sharing that they would pay an average of 7.7% more (up from 6.5% in 2023) for a fully equipped smart home, we should be looking at ways we can assist this when it comes to building and renovating homes.

One of those ways is with smart window and door sensors. In the past smart window and door sensors have been complex and difficult to set up, providing little benefit to the homeowner, but all that is about to change.

Imagine coming in from a long day at work, on a cold, dark winter evening, you open your front door and in an instant your hallway light comes on, the smart speaker greets you with your favourite songs, and the heating is boosted for 30 minutes to get the chill out of your bones. Convenience, automated. Alternatively, your child arrives home from school, hot and flustered from their walk home, opens the window in their bedroom and the radiator automatically stops heating the room. Energy saving, automated. Or maybe you are a carer for a venerable person, wouldn’t it be great if you could set up a routine that alerts you if a door is unexpectedly opened during the

“Before Matter, each smart home device had its own “language,” but with Matter, all these devices can now “speak” the same language, making it much easier to set up, control, and integrate smart home devices.”

night, meaning you can check on things before a real emergency occurs. Safety, automated.

A restricting factor on the uptake and implementation of smart products to enable this sort of automation was the requirement to have an additional gateway hub to allow products to work in harmony within the network of the building. Anyone who wanted to create a fully integrated smart home with multiple smart devices, from a variety of brands would need several gateway hubs which then becomes costly, confusing and inconvenient. Thankfully the powers that be at corporations such as Apple, Amazon, Google, Samsung and others have come together to bring us the Matter Protocol.

The Matter Protocol is a mutual language that all devices can understand, that will simplify and streamline our experience, making the benefits of a Smart Home accessible to all. Before Matter, each smart home device had its own "language," but with Matter, all these devices can now "speak" the same language, making it much

easier to set up, control, and integrate smart home devices. This means you can mix and match devices from different brands without worrying about compatibility issues, leading to a more seamless and integrated smart home experience. It also removes the requirement for the additional gateway hub, and now this technology is available to you.

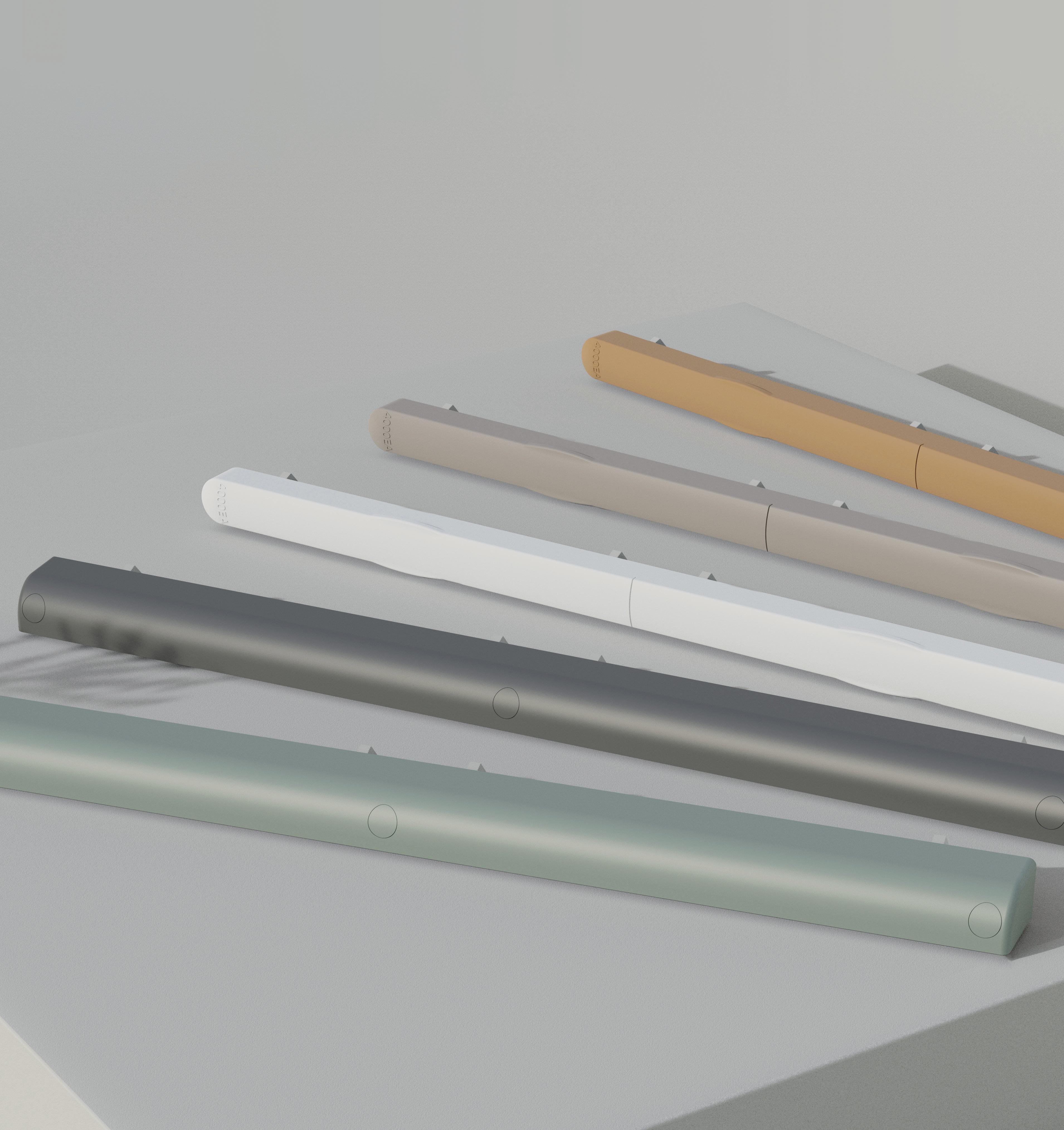

Introducing, ‘Sense by MACO’, the first integrated smart window and door sensors available in the UK to utilise the Matter Protocol. Available from MACO Door & Window Hardware (U.K.) Ltd and their network of suppliers, they can not only be fitted to new windows and doors during the manufacturing process, they can also be retrofitted seamlessly to existing MACO window and door hardware. ‘Sense by MACO’ removes the barriers of complexity and enables the benefits of smart security systems that can automate family life,

enhance standards of living, and offer additional safety measures, to be adopted by everyone.

It’s no longer about simply knowing if your doors and windows are open or closed, it’s about what this technology can enable in the challenging and stressful environments of the modern world. Technology, when implemented correctly, really does make Sense. The only ‘matter’ now is what you will do with it.

Find out more about ‘Sense by MACO’ by visiting www.maco.eu/sense

“‘Sense by MACO’ removes the barriers of complexity and enables the benefits of smart security systems that can automate family life, enhance standards of living, and offer additional safety measures, to be adopted by everyone.”

With Sense by MACO wireless sensors you install the future. Make your windows and doors intelligent and smart home-capable in no time at all. The sensors reliably recognise the status – open or closed – and transmit it in the new, multi-sector Matter standard for smart home solutions. This makes them the basis for the automated control of other smart home products. For more convenience, more security and a bright future: Sense by MACO wireless sensors

Talk to your MACO sales partner and find out more directly at www.maco.eu/sense

The DoorCo team have scored a UK Manufacturing Awards hat-trick, recently being named Best Family Business – their third consecutive triumph at these awards.

Founded by Dan and Jayne Sullivan in December 2007, DoorCo has been operating as a family run business for nearly 20 years and the values within this set up have been identified as some of the strongest in the industry in their recent win.

Speaking on the win, DoorCo Managing Director Dan Sullivan, says, “it’s always a great feeling to be acknowledged with an

award but we particularly look forward to the UK Manufacturing Awards as an opportunity to measure ourselves against the wider manufacturing industry, opposed to just our fenestration counterparts.

“We have previously won Fastest Growing Team and Most Innovative business at these awards, so we’re really pleased to add Best Family Business to that list.

“The fact we are a family run business from day one is part of our DNA. It shapes our morals and values as a company and paves the way for how our culture operates day to day. It felt natural to share our story as part of these awards and we’re really proud the judges have seen credit in how we work.”.

Talking further on the reason for choosing the Best Family Business award as their

nomination this year, Marketing Manager Ellie Pool, tells us: “We’re passionate about ensuring the awards we enter are a fair representation of what we’re focused on as a business.

“Our attention is always equally split between our products and our people. We’re proud of the awards we’ve won over the years that draw attention to our product development or manufacturing set up but

it’s equally important to us to celebrate our culture and values.

“Being a family business with Dan and Jayne very much still at the helm is a massive part of who we are. We’re proud of our roots and how it has shaped the dynamic of the business. To be recognised as the best in class for manufacturing businesses operating in this way is a real honour.”

DoorCo add the title to their growing list of accolades including other people awards such as UK Manufacturing Awards’ Fastest Growing Team and the Health & Wellbeing Award at the 2023 North Cheshire Business Awards.

For more information, visit: www.door-co.com.

There’s a buzz of activity at Senior Architectural Systems’ Rotherham manufacturing facility – and it’s not just from the factory floor. The leading manufacturer of aluminium doors, windows and curtain walling has installed its first on-site beehive, marking another step forward in its commitment to sustainability and biodiversity.

The hive is the latest initiative to take flight as part of Senior’s comprehensive sustainability strategy, which has seen the company make significant investment in the use of low-

carbon aluminium, operational efficiencies across its two main UK manufacturing facilities, and the development of an extensive range of Part L compliant fenestration products. Located at Senior’s dedicated Thermal Improvement Facility in Rotherham, which has boosted the production capacity

of Senior’s patented PURe® range of low U-value aluminium windows and doors, the beehive is also helping Senior support local biodiversity and national environmental goals set out under the Environment Act 2021.

Bees play a vital role in global food production and the maintenance of healthy ecosystems, with a significant number of UK crops relying on pollinators. By providing a protected, managed habitat onsite, Senior is taking a proactive step to help counter the rapid decline of bee populations and protect the local environment.

The initiative forms part of a wider Biodiversity Policy being rolled out across Senior’s UK sites under the guidance of the company’s newly appointed UK Sustainability Lead, Luke Osborne.

Commenting on the new beehive initiative, Luke said: “Helping nature thrive is essential for a more sustainable future, and we’re proud to be playing our part. The new beehive at our Rotherham site may seem like a small step, but it reflects our wider ambition to support the recovery of nature and embed biodiversity

Freefoam Building Products is excited to announce the launch of its newly updated Product Training Module, designed to provide essential knowledge on PVC building products for industry professionals, stockists and merchant suppliers.

Whether you’re looking to expand your expertise or need a refresher on key products, the updated module offers an engaging and user-friendly learning experience.

With a fresh new look and additional product insights, the module covers a wide range of PVC home improvement products, including fascia, soffit, cladding, window trims, and skirting boards.

Key features of the training module include:

• Product Overviews – A deep dive into Freefoam’s core product range.

• Colour Options Guide – Learn about the variety of finishes available.

• Fitting Information – Essential tips for correct installation and fixing distance.

• Product Guarantees – Understand the guarantees and benefits Freefoam offers.

• Self-Assessment Quiz – A short quiz to test your knowledge.

Designed for maximum convenience, the entire training module can be completed in just 15 minutes, making it an ideal tool for merchants, installers, and sales teams looking to boost their product knowledge quickly and efficiently.

into how we use and manage our land. Sustainability isn’t just about carbon – it’s about ecosystems, communities, and resilience.”

For more information, please visit www.seniorarchitectural. co.uk or search for Senior Architectural Systems on LinkedIn andFacebook.

Freefoam UK Sales Director Richard Jackson recognizes the value of the updated Freefoam Training Module to help suppliers stay ahead in the market.

“We understand the importance of having the right knowledge when it comes to recommending and installing PVC building products. This updated module makes it easier than ever for merchants and independent PVC Suppliers to build product knowledge for their whole trade counter team and offer the best solutions to their customers.”

The Freefoam Training Module is now available. Visit: qrco.de/bftUQQ.

One of the key claims made by exhibitors at shows is that what they are showing is innovative.

Not a surprise, given the fact that often exhibitions like the FIT Show are often the first-time installers and fabricators will have had a chance to ‘kick the tyres’ of many products. It’s the ideal place for systems houses and manufacturers to showcase their newest ranges and ideas.

But is it possible the word ‘innovation’ is being bandied around too much? In an increasingly competitive marketplace, it’s worth asking: what does true innovation look like? And what are the markers of real innovators?

Simply saying you’re announcing the latest innovation or labelling yourself an innovator isn’t enough – anyone can say whatever they like. But true innovators will be able to provide tangible evidence to support their claims.

For example, third party recognition in the form of awards are a great indicator of what the industry really thinks of a product, initiative, or training programme. We recently received a King’s Award for Innovation 2025 for our Sheerline system. This is unarguably one of the most

prestigious awards a business can receive. But that’s not all.

Did you know Sheerline has won Best Technical Innovation at the GGP Installer Awards three times now? And we’re finalists in eight NFA categories for 2025, on the back of winning Aluminium Systems Company of the Year 2024.

These awards not only reflect the work that goes into our products, but the whole Sheerline experience. We’re committed to achieving excellence in aluminium by redefining the expectations of our customers.

Companies genuinely innovating regularly launch new products and updates. For us, this is what a commitment to continuous improvement means. Sheerline was the first to introduce a pre-gasketed bead – and we’ve followed that up with the introduction of our Fast Connect Hybrid Bead recently. We pioneered straight forward Part L compliance across all our products, allowing our customers to comply from day one. No fuss, no foam. Backed up by publicly available proof in the form of our freely available U-value reports.

Another way to decipher between what’s just marketing spiel and what’s real innovation is patents. Or rather, the number of patents a company holds is a clear indication of how much time it is investing in research and development.

From our modular cills and ancillaries, which were introduced to reduce stockholding and waste, to our patented corner construction and the Thermlock® technology that sits at the heart of every Sheerline product – every innovation offers tangible improvements over legacy aluminium systems. Backed up and protected by patents to maintain the advantage our customers have in choosing Sheerline as a business partner.

Finally, the way to gauge what’s real innovation is to assess how the market has changed since its launch. We’d argue that before Sheerline, the aluminium sector was stagnating, with little innovation and limited focus on improving customer experience.

The way Sheerline operates now and how the business was initially set up was intentionally with growth in mind. That’s how Roger turned his vision for a vertically integrated sustainable UK manufacturing business into a reality.

What we’ve proven in the five years since the Sheerline system was launched is that

there is plenty of scope for improvement within the aluminium sector. It’s not just about the awards we’ve won, but the feedback we’ve received from fabricators who’ve switched to us.

Another sign we’re doing something right is the number of products imitating our designs – the S1 Roof Lantern in particular has gained competitor attention. But claiming you’re innovating when in truth you’ve just copied someone else’s idea is either dishonest or delusional.

There are lots of ways to tell the difference between an innovator and an imitator. It’s less about what a company says and more about what they do and what trusted thirdparty sources think. In the (not too far away) past, companies could say whatever they wanted.

Although some still take this approach, it’s becoming less of an option. Not just because of legislation such as the Future Homes Standard (FHS), but because customers expect honesty. Telling the truth isn’t just good business, it’s about having integrity and principles.

Being a genuine innovator means pushing the boundaries, which in turn forces the industry to change how they do things, which ultimately makes things better for installers, fabricators, and consumers.

Want to discover true innovation? Contact Sheerline by emailing info@sheerline.com or calling 01332 978 000.

By Dave Wigley, Sheerline’s Head of Marketing

“We

“We

Recent manufacturing data from polymer solutions leader REHAU reveals an ongoing trend in the rise of flush fit windows, highlighting their continued appeal for residential and commercial projects.

REHAU sold over 358,000 meters of Rio sash in 2024 – a 14% increase on 2023 –while demand for the Rio door launched in 2023 grew by 70% in 2024.

“Rio’s success can be put down to two complementary factors,” says Clare Higgins, Senior Product Manager for REHAU UK. “Firstly, that well-designed frames will always find their place in the market, especially when they offer outstanding aesthetic and energy-efficiency benefits and have plenty of accessories and customisation options.

“But beyond this, Rio’s success demonstrates the enduring popularity of flush fit windows among homeowners and commercial specifiers alike, who are prioritising clean lines to ensure minimal impact on a property’s exterior.”

The new data demonstrates both a continued and recent rise in the number of Rio frames supplied and fitted. Since its launch five years ago, the number of Rio window frames manufactured has grown from 11,666 in 2019 to 89,657 in 2024 – an almost eight-fold increase.

“Demand for the Rio flush fit window frame continues to soar and it is great to see its door counterpart experience similar success,” Clare concludes. “The aesthetic versatility of the Rio range and its ease-ofmanufacture have helped facilitate this rise, and we’re confident that both the window and door frame will be similarly successful this year and beyond.”

https://shorturl.at/dZByM

Freefoam is proud to announce that we have successfully retained our Ecovadis Silver Medal for 2025, placing us in the 94th percentile of all companies assessed globally. This recognition reaffirms our unwavering commitment to sustainability and responsible business practices.

Ecovadis is a globally recognised sustainability ratings platform that evaluates companies on their environmental, ethical, labour and human rights practices, as well as sustainable procurement. Freefoam’s achievement places us among the top 6% of all companies assessed, reflecting significant progress since our first evaluation in 2023, when we ranked in the 78th percentile.

“We’re thrilled with our performance this year,” said Kevin Cronin Chief Operating Officer. “Achieving a 75/100 overall score – a six-point improvement from last year – and increasing our scores across all four assessment themes is a testament to our team’s hard work and dedication to continuous improvement.”

Highlights of Freefoam’s 2025 Ecovadis results include:

• Increased scores in Environment, Ethics, Labour & Human Rights, and Sustainable Procurement

• A 6-point overall score increase, reaching 75/100

• Above-average performance in both general manufacturing and plastic product manufacturing sectors

With the gold medal threshold just one percentile away, Freefoam remains committed to further enhancing our sustainability efforts and advancing toward even higher standards in the years ahead.

“We would like to thank everyone across the organisation for their contributions to this achievement,” added Kevin Cronin. “Sustainability is a collective effort, and this recognition is something we can all be proud of.”

Spot three differences. Fill in your answer and your contact details below and send your competition entry to: FAO: Christina Lazenby, Glass News Competitions, 19 Heather Close, Tickhill, Doncaster, DN11 9UU or Email: christina@glassnews.co.uk. Entry deadline: 20/06/25.

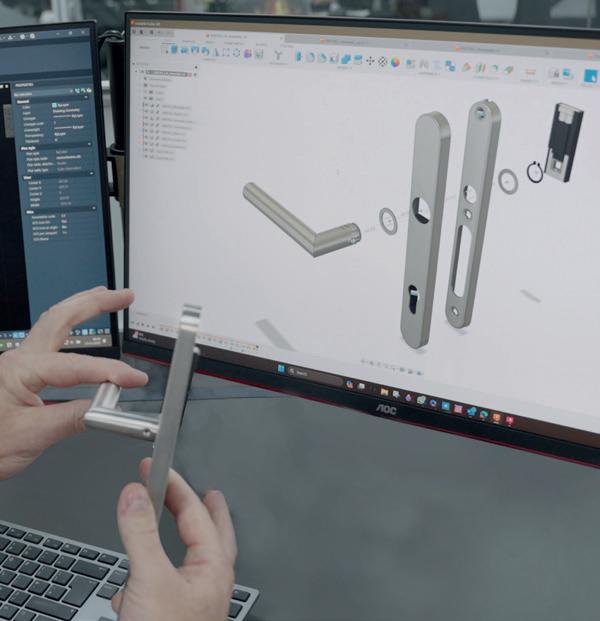

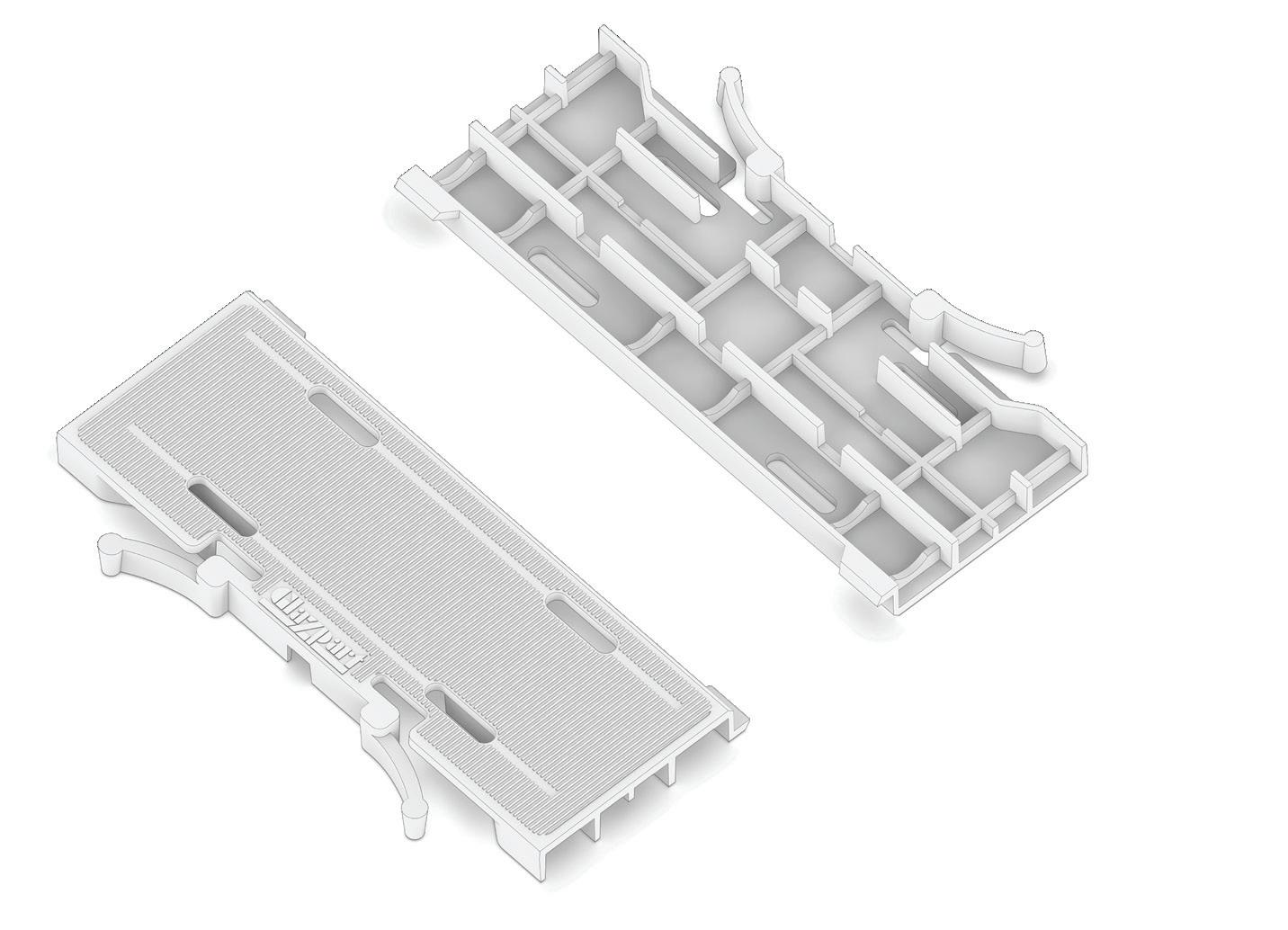

At Coastal Group, we don’t just supply hardware – we engineer solutions. Our in-house Research & Development team works side-by-side with door and window manufacturers to turn ideas into fully realised, precision-engineered products.

Bespoke

If you can imagine it, we can design, prototype, and manufacture it. Every challenge is an opportunity – and our team is ready to make your vision a reality.

Let’s create something together.

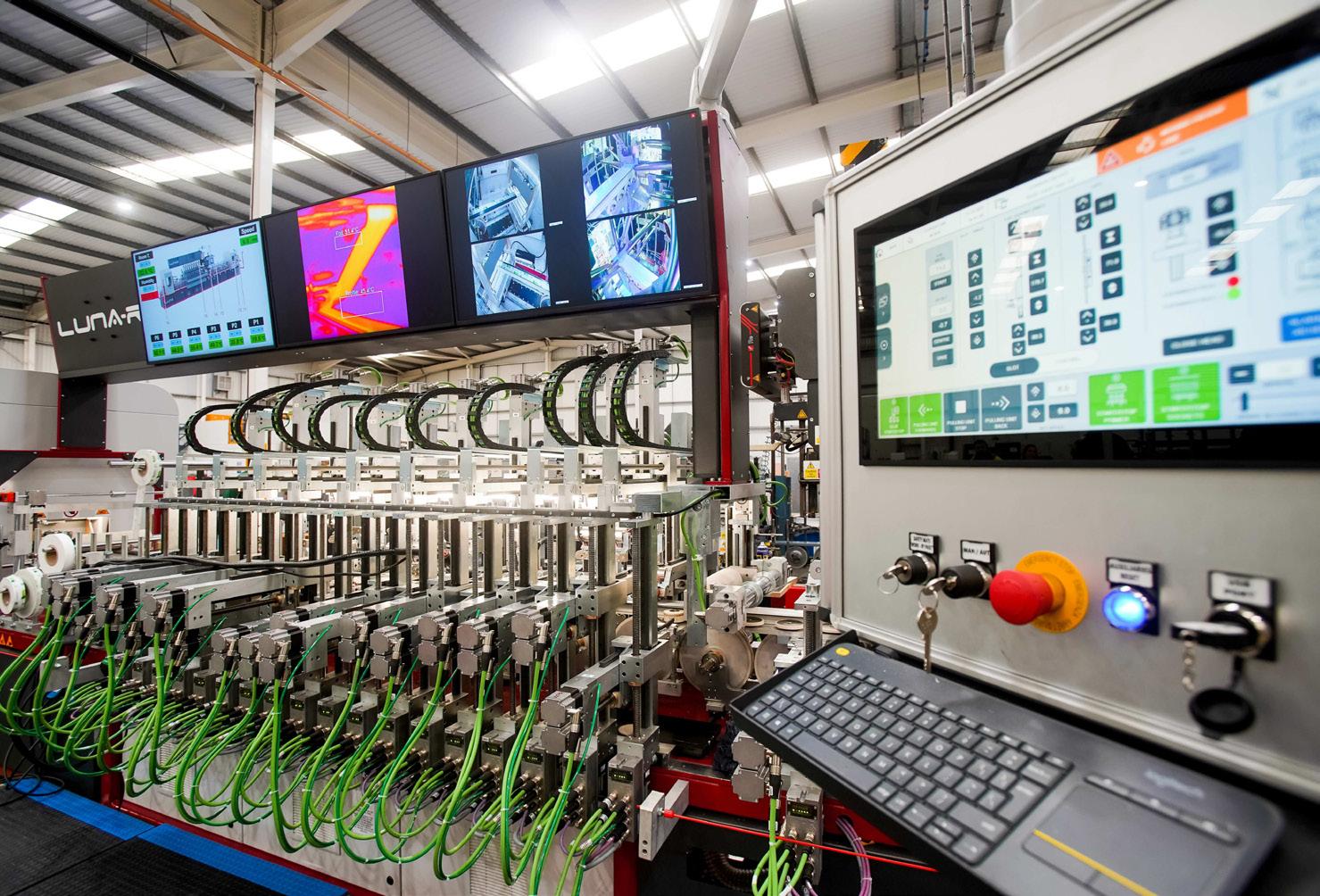

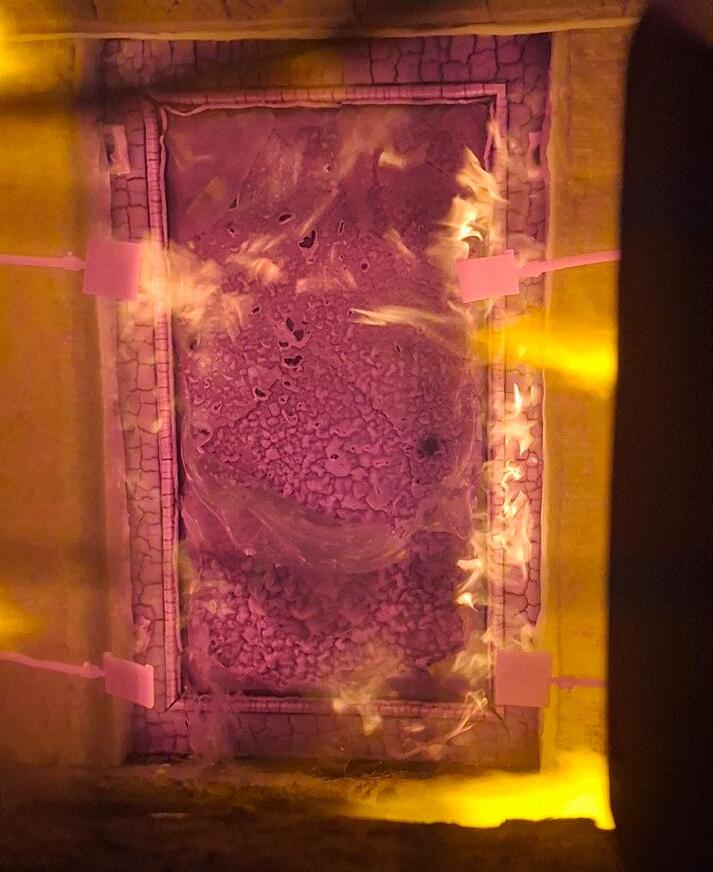

John Stark, Liniar Lamination Production Manager, works closely with profile wrapping technology and adhesive specialist WPR-TAKA and is currently coordinating a bespoke training programme as part of Liniar’s continuous improvement culture.

John discusses how environmental conditions at Liniar’s Lamination Hall are meticulously controlled to help ensure every foiled product meets exacting British Standards Institute (BSI) standards, and how he is excited to work with members of the WPR-TAKA team for their upcoming collaboration – the Academy sessions.

Leveraging the financial strength of parent company, Quanex, Liniar consistently invests in its facilities. This commitment ensures their manufacturing equipment remains at the forefront of technological advancements.

John explains, “Two crucial factors in creating optimal conditions for laminating are humidity and temperature. After consulting with Humidity Solutions back in 2022 we invested in a high-end system which allows precision control of humidity. To my knowledge, Liniar was the first systems house in the UK to install this technology.

“Our humidity and temperature-controlled environment means we can guarantee consistent adhesive application and bonding quality all year round,” explains John.

“It’s this investment in process stability that underpins our 99.94% conformity rate. But we’re not stopping there — we’re always looking for incremental improvements, which is why we signed up for WPR-TAKA’s Academy sessions.”

Discussing the WPR-TAKA Academy, Area Manager Davide Viero says, “The programme offers structured modules including plant audits, operator training, and advanced sessions for supervisors and quality engineers.

“It’s not just about showing teams how best to run a foiling line, it’s about empowering team members to understand the ‘why’ behind each step.

“In our experience, when people have a better understanding of the science behind our specifications for applying and curing adhesives, best practices become easier to follow,” he adds.

John explains, “The initial intake of Liniar team members is already underway, with plans for a 2026 intake too. I have over 35 years’ experience of managing wrapping processes, however, passing on this knowledge to the next wave of lamination operatives is a crucial part of Liniar’s futureproofing strategy for ensuring expertise stays within the business for the long term.”

Davide adds, “John and his team have a huge amount of expertise, and still tell us they learn from our collaborations. It’s great to see Liniar has a plan for protecting the continuity of collective industry knowledge and experience present in its current team.”

Lamination Manager John concludes, “We’re extremely proud of the standards we’re upholding in our Lamination Hall, but never rest on our laurels. We test to BSI 7722 for adhesive bond strength, and by continuing to seek out incremental gains our goal is always to improve consistency and eliminate any potential for quality concerns.

“This enables us deliver products that perform perfectly from fabrication and installation, to standing the test of time as stylish finished products in buildingsproviding customer satisfaction along the entire supply chain.”

To find out more about Liniar’s full range visit: https://www.liniar.co.uk/

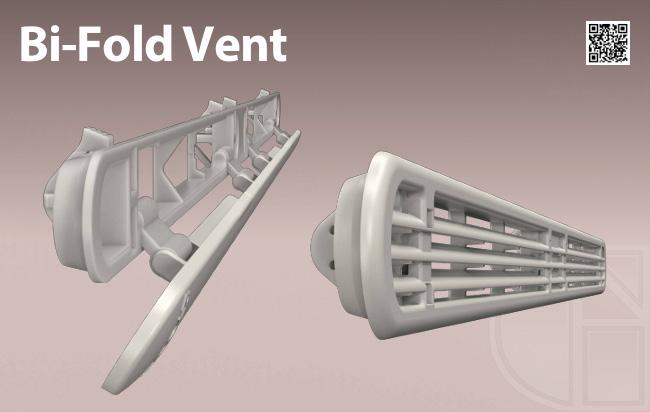

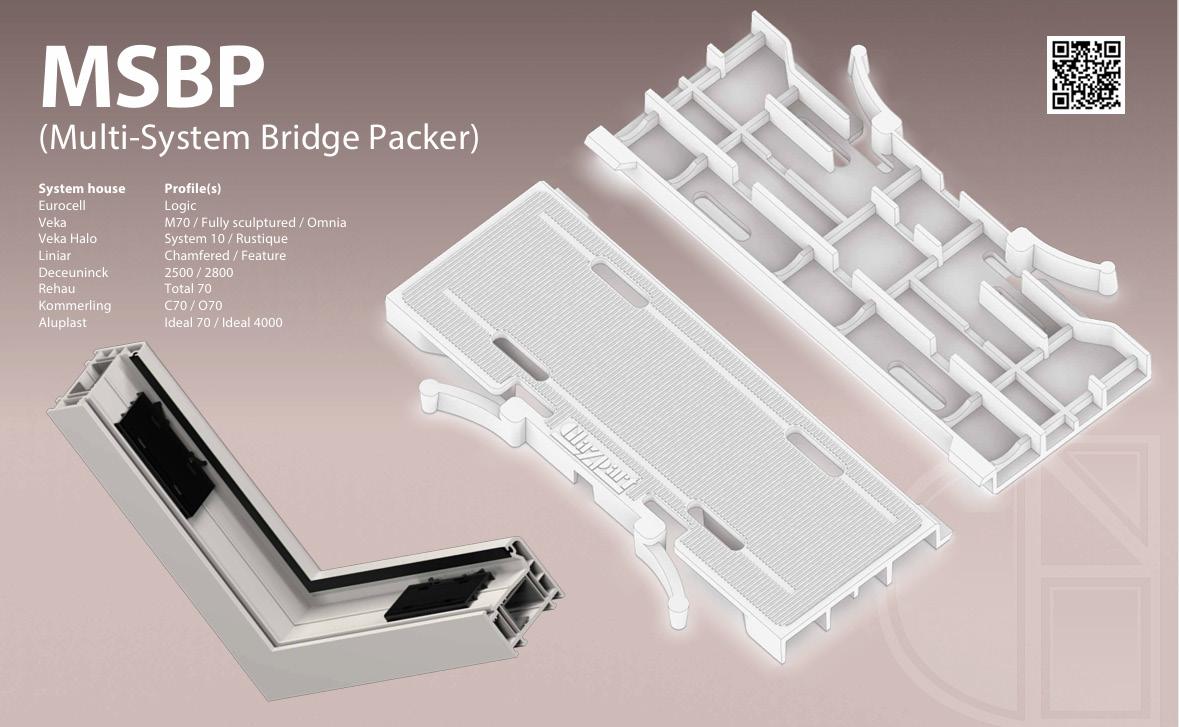

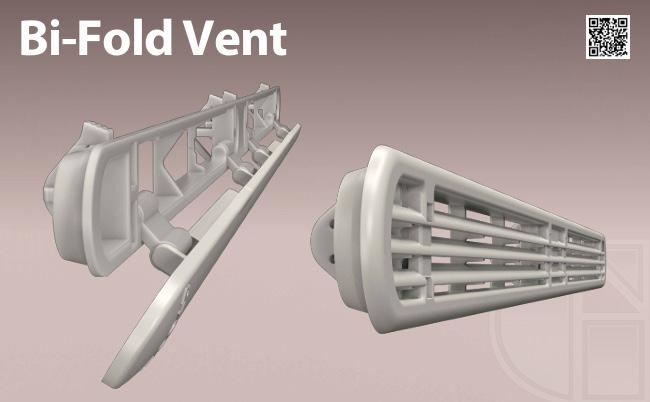

Glazpart’s award winning range of trickle vents

Premium and woodgrain finishes now in packs of 10 vents or canopies

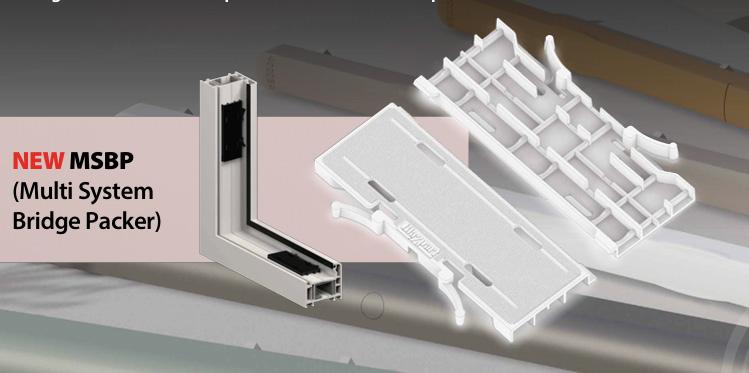

MSBP (Multi System Bridge Packer)

For more information and to find your local stockist visit: glazpart.com/trickle-ventilation | 01295 264533 or call to speak with one of the team.

Available to order from 16th June

Quick & Easy Installation

PAS24: 2022 Security

Triple Weather Seals – Provides superior weather protection

Available in Set Sizes:

From 400x700mm to 1000x2700mm

28mm double or 44mm triple glazed options

Engineered for Affordability

UK Manufactured & UK Warranty

Free site delivery*

FIT Show 2025 has firmly established itself as the UK fenestration industry’s mustattend event, delivering its biggest and most vibrant edition yet at Birmingham’s NEC. Spanning four halls and drawing thousands of visitors, this year’s show has not only set new records for attendance but also raised the bar for innovation, networking, and sector collaboration.

FIT Show director Nickie West comments: “FIT Show 2025 performed strongly compared to 2023, with pre and onsite registrations increasing by 7% - no mean feat given the challenging backdrop the industry has, and continues to face. Overall attendance grew by 7.5%, with day one showing the most significant improvement at 13% more visitors than in 2023. We also experienced a notable rise in repeat visits on days two and three, reflecting that there’s now so much more to explore at the show. It’s clear that one day simply isn’t enough to take in everything FIT Show has to offer.”

UNPRECEDENTED SCALE AND ENERGY

With close to 300 leading brands and a significant number of first-time exhibitors from more than 20 countries, FIT Show 2025

“The show floor was alive with product launches, from new door and window systems to the latest in software, hardware, and service innovations.”

offered a truly international showcase. Visitor registrations surpassed all previous editions, with the opening day alone exceeding 2023’s numbers and the halls buzzing with energy and anticipation. The event’s expanded footprint meant professionals from every corner of the supply chain could see, touch, and compare thousands of products and solutions under one roof.

Nickie adds: “We worked incredibly hard to expand both the footprint of the show, as well as broadening out the show proposition. This included an increased representation of machinery, with the Haffner Machinery Village occupying a significant footprint, as well as securing support from more glass brands than 2023

including the likes of Pilkington Glass and Clayton Glass to strengthen our offering for IGUs and fabricators.

“The introduction of the timber trail, led by FIT Show newcomer, the Timber Joinery Network, saw 50 of its members put on a fantastic display for both fabricators and installers looking to broaden their portfolios by incorporating this material.

“Similarly, a huge objective for 2025 was to meet the demand from 2023 visitors to see more systems houses represented on the show floor.

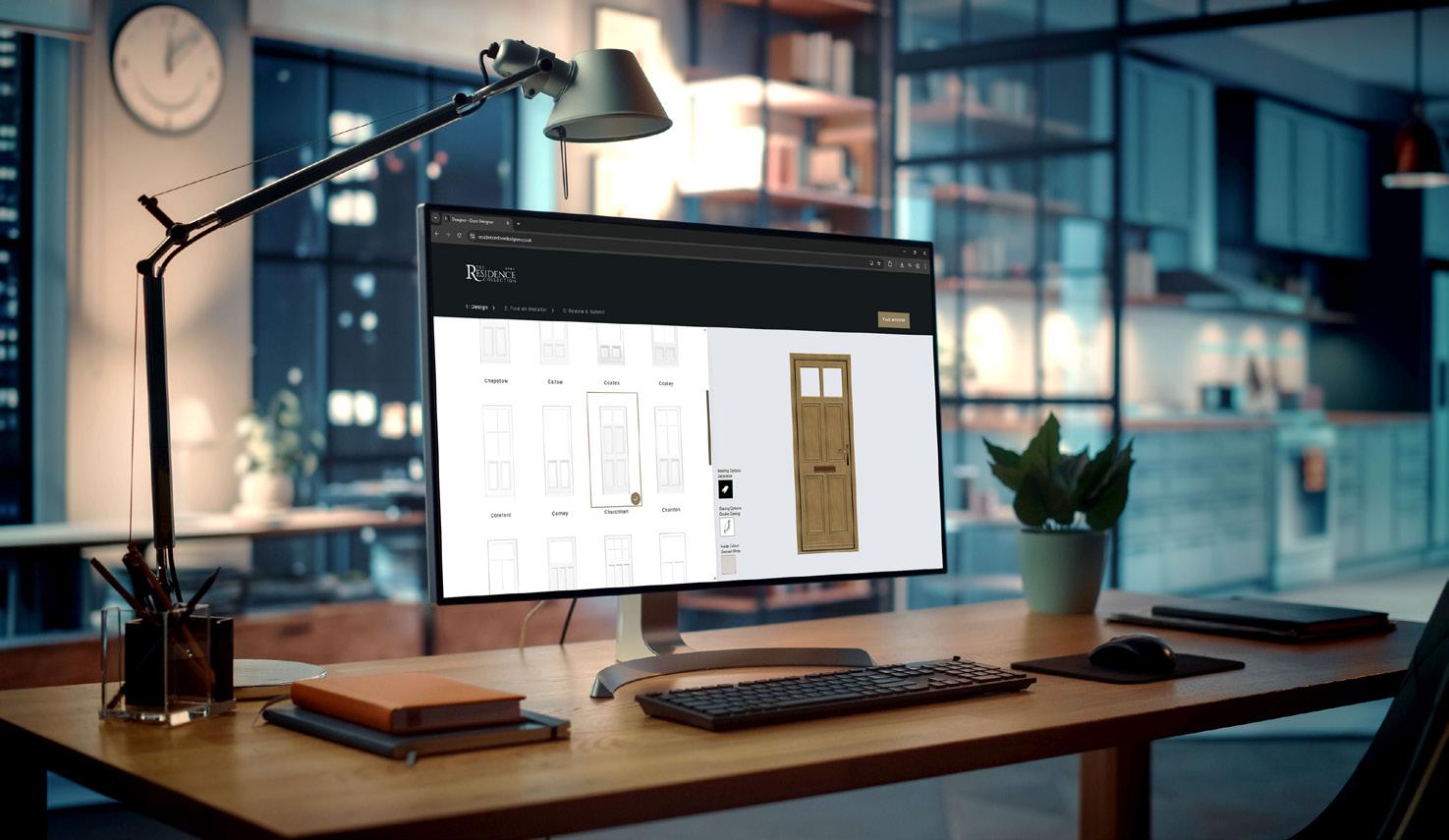

“We took this number from three in 2023 to seven for this edition, which included Selecta Systems, ALUK, Cortizo, Residence Collection, Aluplast, Smart Systems, Exlabesa - this was incredibly well received by visitors!”

The show floor was alive with product launches, from new door and window systems to the latest in software, hardware, and service innovations. Many brands timed their launches to coincide with FIT Show, giving visitors exclusive first access to cutting-edge solutions.

The Installer Demo Zone, sponsored by Smart Systems and back by popular demand, provided handson demonstrations of machinery and installation techniques, allowing attendees to experience products in action and gain

practical insights from participating brands including ALUK, Soudal, Bereco, Brett Martin, Kenricks, Keylite Roof Windows and the Timber Joinery Network.

Nickie adds: “Attracting roofing and construction professionals was a big objective for our 2025 campaign. Features such as the Installer Demo Zone and Marketplace allowed us to incorporate new brands and product offerings, with the likes of Gutterplus delivering handson demonstrations for people looking for new and innovative ways to not only install roof lights and lanterns, but the ancillary products to support these.”

A standout new feature for 2025 was the Marketplace, where visitors could purchase tools, services and ancillaries directly on the show floor.

Located alongside the Installer Demo Zone, this area gave tradespeople immediate access to the latest innovations, making FIT Show not just a place to discover but also to equip and upgrade in real time. Participants included Blakeley Construction, ER Certification, CT1, Camel Clamp and Xpert Tools who created a starter bundle for glaziers.

FIT Show 2025 also cemented its reputation as the industry’s leading learning platform. The CPD-accredited seminar programme, delivered in partnership with GGF & FENSA, drew impressive crowds with sessions covering everything from new building regulations and sustainability to AI, security, and future homes standards. This content was free to all visitors and designed to keep the industry up to speed with the latest technical and legislative developments.

Ben Wallace, GGF managing director comments: “I’ve attended many FIT Shows during my time at the GGF, and this one was by far the best for us. The GGF stand was absolutely packed for the majority of the show. It gave me a moment to step back and appreciate the progress we’ve made. We were able to showcase a lot of the hard work and various workstreams the team has been focused on over the past couple of years, and we received some really strong feedback.”

Beyond the stands, FIT Show’s networking opportunities were second to none. On-stand entertainment, exclusive giveaways, and the much-anticipated Late Night Wednesdaywith its live music, themed food and drink, and relaxed atmosphere-fostered meaningful connections and a real sense of industry community. For many, these after-hours events were as valuable as the show itself, enabling business relationships to flourish in a more informal setting.

Feedback from exhibitors and visitors alike has been overwhelmingly positive. “I’m absolutely thrilled with the energy and attendance on day one of FIT Show 2025, which has already surpassed our 2023 edition in terms of visitor numbers,” said FIT Show director Nickie West.

“The halls at NEC were absolutely buzzing with thousands of visitors discovering the very latest in windows, doors, glass, hardware and roofing products from close to 300 leading brands and exciting new exhibitors.

“Our expanded Installer Demo Zone was a real highlight, giving visitors hands-on access to live product installations and the brand-new Marketplace area.

“A big thank you to the FIT Show team for delivering such a well-run event.”