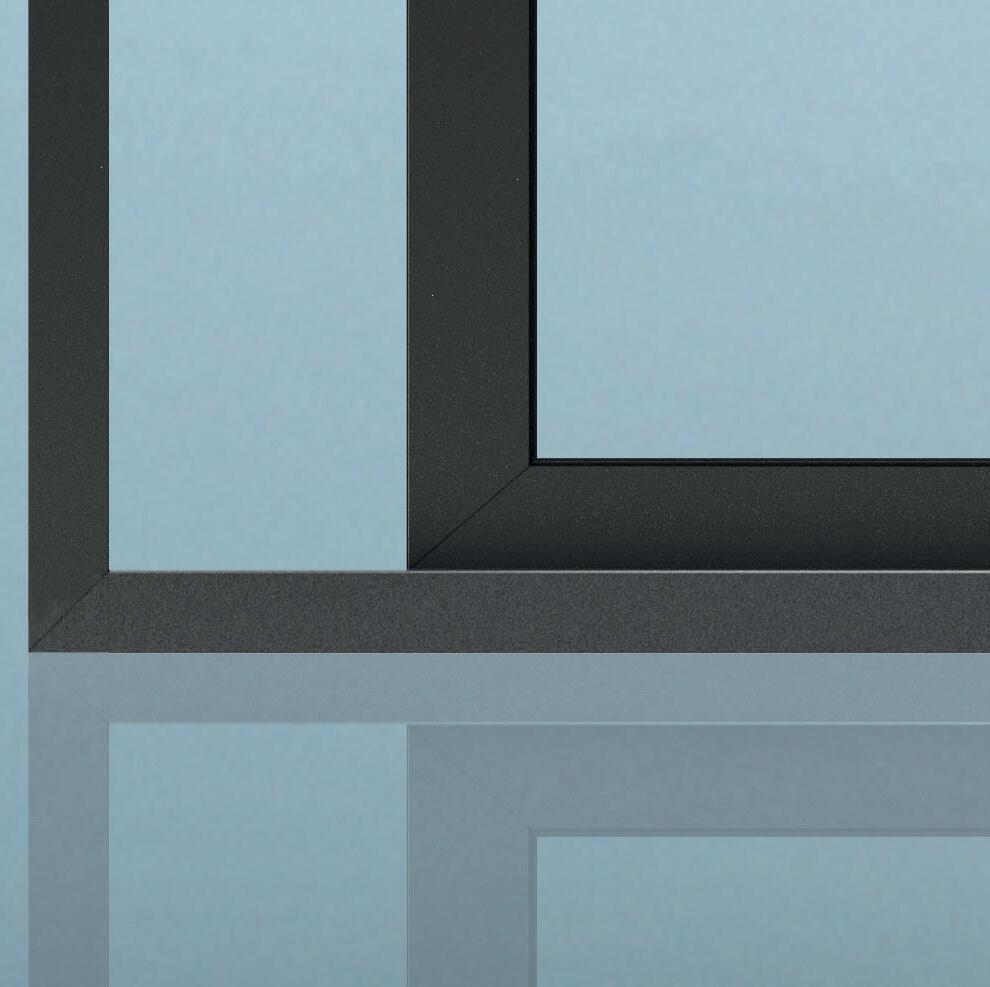

The original gatehouse of Whinney House in Low Fell has received an upgrade thanks to an installation completed by Bison Doors. The project has won Sheerline’s Installation of the Month competition for September as it highlights what can be achieved for heritage properties.

As a listed building, a sensitive renovation that enabled the property to retain its character and charm was key. Although the existing timber windows had to be replaced like for like, permission was granted to install aluminium doors.

Adding the Prestige Bi-fold Door instead of replacing the existing window allowed Bison Doors to create a bright, airy space, flooded with natural sunlight. The existing timber French Doors also weren’t up to standard anymore.

They were replaced with Sheerline’s Prestige French Doors featuring the InvisiHinge from Ingenious, which created a flush finish in keeping with the overall aesthetic of the property. It’s these aesthetic qualities that have made it the hinge of choice for the company.

Bison Doors became a Sheerline fabricator when the Classic Heritage Door was launched as they frequently received enquiries for this style of product. Since then, they’ve added Classic windows, Prestige windows and doors including bifolds, plus the S1 and S2 to their range.

Bryce Morgan, Bison Door’s Manager, said: “We had a discerning customer approach us with a project requiring something a

“It’s

little different, after visiting the property it became clear that the product needed was that of the Sheerline Prestige system and in particular the use of the new InvisiHinge.”

“The old stone-built Gatehouse benefitted from the high-performance Prestige system in both Bifold and French Door options.

It was a great job to be involved with and to top it off we won installer of the month, which is something that is never in the forefront of your mind when undertaking jobs as the focus is always on customer satisfaction, but it does fill you with pride knowing Sheerline also appreciate the final turnout,” he added.

Sheerline’s Area Sales Director (North), Howard Hirst, commented: “It’s great to see Bison Doors win Installation of the Month – and with a stunning project no less! Seeing our products used on heritage and listed properties highlights our versatility, particularly as homeowners are increasingly looking for alternatives when it’s time to replace timber frames.”

To speak to the team at Bison Doors, contact them on 0191 477 6600 or email info@bisondoors.co.uk. New year, new supplier? If you’re thinking of becoming a Sheerline fabricator, get in touch with the team by emailing: info@sheerline.com or call 01332 978 000.

Seeing that bumper sticker on the back of a van professing: “No tools kept in this van overnight” is not an unusual sight and talking to workman from plumbers to joiners and gardeners to window installers, it is amazing how many have suffered from having their vans broken into with thieves making off with a variety of kit. Do they actually want the kit?

Probably not. More likely it is sold off for a fraction of what it’s worth just to get the thief a few ‘readies’. Regrettably the stealing of equipment is very prevalent and is often performed by an opportunist who simply spots a likely van parked up and they are in and off with the goods in a matter of seconds.

I received a press release on behalf of Markel Direct, a specialist insurer providing insurance for a wide range of professionals, consultants, contractors and freelancers and having read it through I was pleased to see the delayed, second reading of the Theft of Tools of Trade (Sentencing) Bill, is now scheduled to take place at the end of this week (31st October), and a recent study has highlighted the need for this bill and the support it has from the trades industry.

Quoting from the release: “Tool theft has affected tradespeople and the construction sector for a long time – however, in recent years, legislation has been passed through parliament to act as a deterrent to would-be thieves. These include the Equipment Theft (Prevention) Act 2023 and - more recently - the Theft of Tools of Trade (Sentencing) Bill, which is now due to receive its second reading on the 31st October 2025, pushed back from the original date which was in July.

The purpose of the Bill is to increase the sentencing category for criminals convicted of the theft of tools of trade. Currently, tool theft is categorised as ‘harm category 3’, because most instances of theft are of a value under £10,000.

The Bill proposes that tool theft should be reclassified as causing ‘significant additional harm’ to the victim of the theft, which would enable magistrates to increase the severity of the offence to ‘harm category 2’ when it comes to the sentencing – even if the value of the theft is under £10,000.

Additionally, the Bill is looking to standardise the calculation of financial loss to include not only the physical cost of the tool itself, but the additional costs that often come with tool theft such as:

• The cost of repairs to any vehicle from which the tools were stolen – such as fixing damage to a van’s locks

• Loss of earnings resulting from the theft – such as being unable to work

• The cost of any interruption of business resulting from the theft – such as being unable to fulfil a contract

A survey was conducted among 500 tradespeople and the results stated that whether it’s a van broken into overnight or equipment stolen from a site, having

your tools stolen can derail work, cost you dearly, and potentially leave lasting stress behind. Tool theft isn’t a rare occurrence; the research revealed that it’s happening on a staggering scale across the nation.

According to the survey, 66% of tradespeople have experienced tool theft. Even amongst those who haven’t had their tools stolen themselves, 27% still knew someone who had, suggesting that the issue is industry wide.

But where exactly are people falling victim to tool theft the most? Well, according to the regional data of the respondents who had been a victim of tool theft, Northern Ireland topped the list with a staggering 85% of tradespeople reporting a theft. It’s followed closely by Greater London (83%) in second place, with Yorkshire and The Humber taking the 3rd spot (67%). The results indicate that this isn’t a localised issue and it’s something that has impacted tradespeople up and down the nation.

Percentage of tradespeople that have experienced tool theft in each UK region:

‘TIME OUT’ WINNERS –NOVEMBER!

Sudoku:

P. Sharma, St. Ives, Cornwall

Eye Spy: Brian Laws, Bracknell, Berkshire Spot the Difference: Lewis Calder, Dundee, Scotland

Crossword: Mrs A Grant, Brighton, East Sussex

Congratulations to all our winners! Good luck in this months Time Out pages!

Christina Lazenby

Managing Director / Advertising Enquiries

M: 07805 051322

E: christina@glassnews.co.uk

Emma Champion

Advertising Manager

M: 07508 263262

E: emma@glassnews.co.uk

Justin Lazenby

Finance Director / Press Release Enquiries

M: 07711 828710

E: justin@glassnews.co.uk

Chris Champion

Editor / Editorial Enquiries

M: 07850 267223

E: chris@glassnews.co.uk

Kate Carnall

Graphic Design

E: kate@glassnews.co.uk

Deadline for copy: 16th of each month

If the bill passes through the house and finally becomes law, that has to be a good thing however it raises other issues. Before you can get compensation for the tools, loss of earnings etc. there’s the little problem of actually catching the thief. Will the police help or will you be left to try and catch them yourself? But be careful: don’t touch the thief or you may be the one to end up in court! I got a shock yesterday when I was leaving a supermarket and set an alarm off and found myself stopped by a security guy demanding to see my receipt. It seems that steaks, in this particular supermarket, are chipped to activate an alarm so they can be checked that it was a bona fide purchase. It was a bit of a shock but perhaps it was a wake-up call to look at my own security measures….

It's early in December but here’s wishing everyone a very Happy Christmas from all at Glass News.

With energy costs rising and homeowners facing more pressure to make meaningful, long-term improvements to their properties, choosing the right windows and doors has never been more important. Beyond appearance, people are increasingly considering thermal efficiency, security, maintenance, and how well a product will preserve or enhance the character of their home.

At the same time, the market has never offered more choice. Dozens of glazing systems compete on aesthetics, performance and price - which can make the decision confusing rather than empowering.

This is where flush systems like Residence 7 have gained attention: offering a way to combine modern performance with a style that works in both heritage and contemporary homes. The Residence 7 collection provides a 75mm flush frame, adaptable glazing options and a full suite of matching doors, enabling homeowners to maintain a cohesive look without sacrificing practicality or efficiency.

To help installers and homeowners understand where Residence 7 fits in today’s market, Jo Trotman, Sales and Marketing Manager at The Residence Collection, highlights 7 reasons why R7 has become a considered choice for new-build, renovation and replacement projects - particularly at a time when long-term value matters more than ever.

1. ENHANCED 75MM FRAME FOR EFFICIENCY AND A SEAMLESS FIT

The Residence 7 system features a 75mm frame depth, which provides both visual and functional benefits. Inside the profile, seven chambers maximise insulation and energy performance, helping to keep heat in during winter and out during summer.

The additional 5mm depth compared to traditional 70mm systems also makes R7 an ideal solution for upgrading existing windows. It helps neatly cover the plaster line, ensuring a clean finish without the need for extra trim work - simplifying installation and enhancing the final appearance.

2. SMARTER GLAZING OPTIONS FOR SUPERIOR PERFORMANCE

R7 has been designed to offer flexible glazing options that improve both thermal efficiency and acoustic insulation. With a simple bead change, installers can update existing R7 windows from 28mm double glazing to 44mm triple glazing. This versatility means homeowners can choose the performance level that suits their property and energy goals.

• U-value of 1.2 with standard double glazing

• U-value as low as 0.8 with triple glazing

These figures have been independently tested, ensuring R7 consistently delivers on its energy efficiency claims.

3. BUILT-IN SECURITY WITH INTERNAL BEADING

Security remains one of the top concerns for homeowners. Unlike many systems that use external beading, Residence 7 features internal beading, significantly improving resistance against forced entry. This design choice is a key security enhancement and delivers peace of mind for homeowners looking for windows that are as secure as they are stylish.

Residence 7 uses a full TPE (thermoplastic elastomer) glazing gasket, ensuring a continuous weather seal around the window. This achieves superior compression, which has been proven through rigorous weather and air-tightness testing. The result is a window solution that performs reliably in all climates, reducing draughts and improving long-term resilience.

R7 offers a fully matching suite of windows and doors - allowing homeowners to achieve a cohesive finish across every elevation of their property.

The collection includes:

• Open-in and open-out doors

• Residential entrance doors

• French doors

• Juliette balcony French door options

• Stable doors

Customisable features such as mid rails, deep bottom rails, and interchangeable door panel designs and a patented* surround trim make it easy to tailor each installation, whether the project is contemporary, traditional, or somewhere in between.

The Residence Entrance Door option means homeowners can now achieve a complete “full house” timber alternative look, where every exterior feature aligns in both style and performance.

The system supports large sash sizes up to 900mm x 2300mm, giving homeowners design freedom without compromising strength or durability.

This expansion in 2025 marked a key development: doors and windows in the same aesthetic language, providing a unified, premium finish.

With 23 colours and finishes available, the Residence 7 collection offers one of the widest colour ranges in the flush window market. Whether homeowners prefer soft heritage tones, deep contemporary shades, or bold design statements, R7 provides extensive customisation choices to suit every property style - from cottages and conservation homes to new builds and high-end renovations.

Commenting on the collection, Jo Trotman said: “We are really proud of the products we have on the market, and we’ve crafted and developed them over time to make them the perfect solution for homeowners. For those looking for superior performance and elegant styling, the Residence 7 range has everything they could ever need.”

If you would like to find out more about the Residence 7 collection, please see here: https://www.residencecollection.co.uk/ collections/r7/

SCALABLE, RELIABLE SUPPLY

SINGLE-SOURCE BUILDING PRODUCT SOLUTIONS

Liniar doesn’t follow, it leads – setting trends and standards! Over 10 groundbreaking industry firsts, including Zero|90 the UK’s first 90mm Passive House certified PVCu casement window.

A PARTNER IN YOUR SUCCESS SMARTER FABRICATION, BETTER MARGINS

SCAN QR TO BECOME A LINIAR CUSTOMER TODAY

THE NEXT GENERATION OF SLIMLINE DESIGN

THE MOST THERMALLY EFFICIENT ALUMINIUM SLIDING DOORACHIEVING U-VALUES AS LOW AS 0.78 W/M 2 K

Hörmann Truedor is supporting its dealer network this winter with the launch of the Clima63 Winter Warmer campaign, offering 20% off its’ Clima63 range of composite doors.

Running from 1st November 2025 to 31st January 2026, the promotion aims to boost winter sales by providing consumers with access to one of the most thermally efficient composite doors currently available - at an even more competitive price.

The Clima63 composite door has been engineered and introduced to meet the increasing demand for energyefficient building products that align with both the Future Homes Standard and homeowner expectations for sustainable, secure, and stylish entrance doors.

In line with the company’s commitment to UK manufacture, Clima63 is produced at the IG Doors facility in South Wales. It features a 63mm insulated GRP door slab combined with a thermally enhanced frame, an advanced triple seal system, and triple glazed units fitted using Hörmann Truedor’s unique cassette system. The range not only offers outstanding thermal performance with U-values as low as 0.80 W/m²K on selected styles but also delivers improved sound insulation and superior weather resistance.

Security is also a key benefit of the Clima63 range. All doors are fitted as standard with Kinetica K4 cylinder locks and multi-point locking systems, and the range has achieved Secured by Design accreditation offering homeowners peace of mind alongside thermal efficiency.

Available in three feature designs - Traditional, Cottage, and Contemporary - the range includes 21 standard styles with options for side lights and fanlights. A wide selection of glazing, hardware and accessories, together with 20 standard colours and a choice of RAL colours allows homeowners to fully customise their door to suit their property.

With rising energy costs and a growing awareness of building performance standards, the Winter Warmer campaign is perfectly timed to help installers meet seasonal demand while offering added value to their customers.

To find out more information about the Clima63 promotion contact Colin Grey. Email: c.grey.lei@hormann.co.uk or call: 07973 735182.

Leading trade fabricator Modplan has announced a significant increase in production capacity for its VEKA OMNIA range, moving from a three-day to a five-day shift pattern in response to surging customer demand.

Liam Isaac, Head of Sales and Marketing at Modplan, said:“Since launching OMNIA earlier this year, the response from our customers has been exceptional. The system’s versatility, aesthetics and performance have truly struck a chord in the market. To ensure we continue meeting this growing demand, we’ve increased our OMNIA production to a five-day operation. This investment reinforces our commitment to delivering the quality and service our customers expect from Modplan.”

The OMNIA suite of double flush windows and doors has quickly established itself in the market. At the heart of its design is a zero sight-line mullion, creating a clean and expansive appearance. For consumers seeking an even more refined aesthetic, windows can also be manufactured with invisible mullions, preserving the pure simplicity of the profile.

Liam said: “Combining sleek sightlines, exceptional design flexibility and outstanding thermal performance, OMNIA has become a standout choice for our customers across both contemporary developments and heritage restoration projects”.

By expanding to a fiveday shift, Modplan is

ODL EUROPE OPENS NEW IN-HOUSE PAINT FACILITY TO ENHANCE QUALITY AND COLOUR CHOICE

enhancing manufacturing efficiency, shortening lead times and strengthening its ability to support installers with reliable supply. The change is part of Modplan’s wider growth strategy, which continues to focus on investing in people, technology and product innovation.

Liam added: “The increased shift pattern reflects not only the strength and success of OMNIA, but also the confidence our customers place in Modplan as their trusted supply partner. This development follows a series of significant investments, including the purchase of a new Supercut 6 Machining Centre from Avantek, to further support our growth and ongoing manufacturing expansion.”

Modplan manufactures the full OMNIA suite including casement windows, tilt & turn windows, French doors and residential doors from its stateof-the-art Newport fabrication facilities.

The company also offers a comprehensive range of VEKA, Profile 22 and LEKA Systems products, making it a comprehensive trade supplier for installers across the UK.

ODL Europe has announced the opening of a new inhouse paint facility as part of its continued investment strategy. The dedicated paint plant will now handle all composite door painting in-house, ensuring the highest levels of quality, consistency and colour accuracy across the company’s GRP door range.

Suzanne Nicholl, Head of Sales and Marketing at ODL Europe, said: “This latest investment reflects our commitment to delivering exceptional product quality and choice for our customers. By bringing painting in-house, we have complete control over every stage of the process, ensuring every door that leaves our factory meets our exacting standards.”

The new facility uses a hard-wearing polyurethane paint system, similar to that used in the yacht industry, to provide a superior finish that combines durability with long-lasting visual appeal. Each painted door has a 10-year guarantee against fade, loss of gloss and adhesion, while stained doors carry a 5-year warranty, giving customers lasting confidence in the product’s finish.

Doors are available in any RAL colour, as well as a wide selection of pre-finished colour options and TrueGrain woodeffect finishes. The range includes popular standard colours including White, Green, Red, Blue, Black and Anthracite Grey, along with foil-matched finishes, woodgrain colours and premium shades including Duck Egg and Bastille Blue. Suzanne added: “This new paint facility gives us complete flexibility to meet the growing demand for bespoke and premium colour door options. It means our customers can offer more choice, faster turnaround times and the same high level of quality ODL Europe is known for.”

She continued: “Paint is an essential part of our fully prepped process, and we know our customers appreciate the quality of our painted products. By increasing the efficiency of our paint offer, we can meet customer demands more effectively and deliver a complete prepped, painted and glazed solution from a single source.”

Crucially, this investment also means that the colour warranty on ODL Europe’s doors will now come directly from the company rather than through a third party. This strengthens the company’s commitment to accountability, quality assurance and customer confidence.

This latest development follows a series of significant investments across ODL Europe’s operations as part of its strategic growth strategy. The new paint facility follows the company’s recent six-figure investment to double the footprint of its in-house door prep facility, further enhancing its ability to meet growing customer demand with quality, precision and efficiency.

Suzanne concluded: “At ODL Europe, our strategy is built on continuous improvement and long-term partnership. Every investment we make is focused on supporting our customers with reliable quality, consistency and innovation and our new paint facility is another important step in that journey.”

Pre-assembled doors Slim interlock PAS24 Security* 10 year warranty featuring KORNICHE

Fast & simple glazing with the unique patented KORNICHE SpeedBead

Delivery with glass & doorSash up to 2.5m direct to site

Double & triple glazing

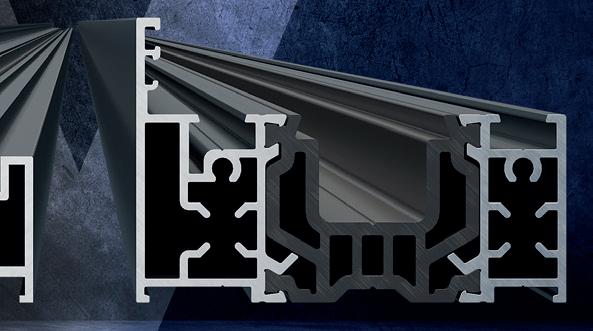

After successfully previewing the S3 Architectural Glazed Roof at FIT Show 2025, Sheerline is pleased to announce it is now available to order. In addition, it is on permanent display at the National Self Build & Renovation Centre (NSBRC) in Swindon.

Sharing a similar design ethos to the awardwinning S1 Roof Lantern, the S3 is set to shake up the glazed roof market. Aside from the launch of the S2 (an evolution of the well-known K2 system) at FIT Show 2023, it is fair to say there has been little innovation in the glazed roof market, until now.

The S3 has been developed from the ground up and reflects the needs and wants, not only of homeowners, but of fabricators and installers too. As with all Sheerline products, it combines a refined sleek aesthetic with performance and ease of installation.

For example, there are fewer components required for the S3 when compared to

KEYSTONE CELEBRATES TWO YEARS OF CONSUMER INSIGHTS WITH FREE AUTUMN FENESTRATION REPORT

Keystone Market Research is pleased to announce the publication of its Autumn 2025 Consumer Fenestration Trends Report, marking two years of continuous insight into UK homeowner attitudes, preferences and spending behaviour across the fenestration market.

Drawing on feedback from more than 5,300 homeowners throughout 2025, this report consolidates findings from all four quarterly surveys, providing the most complete view yet of how consumer choices around materials, glazing types and investment intentions have evolved over the past year - and how they compare to trends first identified in 2024.

This edition was made possible through the continued support of our sponsors: Endurance Doors, Epwin Window Systems, the GGF, Liniar and VEKA; whose backing has helped Keystone deliver independent, high-quality consumer research to the fenestration industry.

Charlotte Hawkes, Director of Keystone Market Research, commented: “We’re proud to celebrate two full years of publishing the Consumer Fenestration Trends Report and thanks to the support of our sponsors, we’re able to share this report for free, allowing more fabricators, installers and system companies than ever to access this important resource.”

Charlotte also joined an expert panel at this year’s Glazing Summit, where she shared highlights from the Autumn report -

traditional ‘lean-to’ systems, which is a benefit to installers as it simplifies on-site assembly. Plus, the pitch is set in the factory during fabrication, which reduces the time required on site.

A standout feature that gained attention during FIT Show 2025 was the gutter and downpipe system, which are fully aluminium so there’s no warping or fading over time. The S3 on the stand featured the contemporary square gutter, but there’s also a traditional Ogee option too.

Homeowners will appreciate the sleek aesthetic of the S3 as it perfectly matches with Sheerline’s aluminium windows and doors, creating beautiful fully glazed extensions for the ultimate in luxurious living.

Aside from the aesthetic appeal, there are other benefits for homeowners including thermal efficiency. Sheerline recognises that while this is important to those in

including key insights into shifting material preferences, consumer priorities and longterm spending confidence. The discussion drew attention to how young homeowners are set to be the largest market for home improvement projects next year and they are setting aside higher budgets to meet their requirements for superior quality, aesthetics and efficiency.

Now in its second year, the Consumer Fenestration Trends series has established itself as a trusted benchmark for the industry, helping businesses anticipate demand and tailor their strategies accordingly.

Keystone also announced that sponsorship opportunities for the 2026 series are now open. Sponsors receive early access to each quarterly edition and the ability to share the content directly with their customers, ensuring that their networks are armed with the latest consumer insights.

Companies can also subscribe to receive all 2026 reports annually, providing an ongoing source of market intelligence throughout the year.

You can register to receive your free copy of the Autumn edition until 19th December at: www.keystonemr.co.uk/sign-up.

For more information about the Autumn 2025 Consumer Fenestration Trends Report, sponsorship opportunities, or annual subscriptions, visit www.keystonemr.co.uk.

the industry, it is even more important for homeowners who live with the products. And not just in terms of keeping heat in during winter but also letting heat out during the summer to prevent overheating. Sheerline has the ideal solution for these concerns in the form of SheerVent®. This intelligent ventilation solution utilises powered actuators and can be enhanced with a discreet rain sensor.

In addition, to ensure the highest possible thermal efficiency, the S3’s rafter bars are 230% better insulated when compared to traditional conservatory roofs. This is thanks to the inclusion of Sheerline’s awardwinning Thermlock® technology.

Jon Crohill, Sheerline’s Technical and Design Office Manager, said: “In typical Sheerline fashion, we’ve spent a lot of time working on the detail, ensuring that this premium product sits perfectly alongside our existing range.”

“Designed from the ground up, the S3 is aimed at those consumers who want to transform their homes. But it’s not about simply adding space, it’s about extending the luxurious setting they have already created within their home,” he added.

To get a quote contact Sheerline on 01332 978 000 or email info@sheerline.com.

CRL has extended the design possibilities of its shower systems, including the multi award-winning Quadrato, with the launch of new, co-ordinating Shower Door Thresholds.

Infinitely practical, the new snap-in thresholds measure 2.4m and are designed for use with SDCD38 U Channels. They can be installed under and above fixed panels, allowing the U Channel to be used as a frame, and continue

“The new Shower Door Thresholds are made from premium materials to ensure long-lasting durability.”

across door openings to create a watertight barrier and ensure no water leaks out of the shower area.

Available in six chic and sophisticated colours of Matte Black, Brite Anodised, Polished Nickel, Brushed Nickel, Satin Brass and Brite Gold Anodised, CRL’s new Shower Door Thresholds will seamlessly complement all of its bespoke frameless shower screens to create a truly cohesive look.

Providing customers with even more creative

freedom, the new Shower Door Thresholds are made from premium materials to ensure long-lasting durability. The perfect partner to its popular, award-winning Quadrato Shower System, pictured, which combines style, versatility and ease of installation, the new aluminium thresholds provide CRL customers with a complete showering solution.

For further information call 01706 863600, email crl@crlaurence.co.uk, or visit www.crlaurence.co.uk.

Brett Martin’s Marvault rooflights have been installed as part of a multi-awardwinning refurbishment at Center Parcs’ Whinfell Forest holiday village in Penrith, Cumbria. The customer required a solution that would increase the thermal efficiency of the large, subtropical space in order to reduce heating costs and the sites carbon emissions. Brett Martin’s vaulted multiwall polycarbonate rooflight system, which covers an area of approximately 2,785m2, provided the ultimate solution, enabling the existing roof to be kept whilst reducing heating usage by 11.14%.

Part of a 400-acre site, Whinfell Forest in Cumbria has accommodation for nearly 5,000 guests. At its centre is the Subtropical Swimming Paradise, with pools and tropical plants all enclosed under a widespan roof. However, Center Parcs found that there were increasing heat loss problems with the old roof. This meant that maintaining the level of heating required to create a comfortable environment for both guests and plants was generating significant costs, as well as effecting the park’s overall environmental impact.

To address the issue of heat loss through the roof, the team from Center Parcs, led by Project Manager Marc Preite, reached out to Brett Martin in the hope of finding

a solution that would continue to allow the maximum amount of natural light into the space, whilst improving environmental and cost efficiency.

Brett Martin put forward its Marvault rooflight system which utilises aluminium and polycarbonate to create a barrel-vaulted shape. This shape increases light penetration and enables spans of up to seven metres to be bridged with no restriction on length. This suited the requirements of Center Parcs as the existing roof utilised long unbroken rooflights that spanned four metres and ran from 30m to 61m in length.

Unlike the old, single layered polycarbonate rooflights installed at Center Parcs, Marvault is glazed with two layers of Brett Martin’s 16mm Marlon ST Longlife polycarbonate. This lightweight, multiwall insulated panel provides increased efficiency by reducing heat loss through its seven layers, as well as providing UV protection. These attributes combine to make a strong, lightweight rooflight that maximises light penetration whilst minimising harmful UV and costly heat loss. As a result, Marvault has a U-value of 1.09W/ m2K, balancing excellent light penetration with improved thermal performance.

Brett Martin worked closely with the roofing contractor Central Roofing to

ensure that the Marvault rooflights could be incorporated into the complex curved roof that defines the striking project. Rising from 6 metres to 27 metres, with a 24-degree incline, the saddle roof posed multiple challenges for the team from Brett Martin who designed and detailed the Marvault glazing to curve with the roof’s striking form. The installers then had to grapple with the Cumbrian weather and night installations in order to complete the project.

Marc from Center Parcs commented “We are really impressed by the performance of the product Brett Martin was able to offer, as the roof refurbishment has enabled us to reduce our gas heating usage by 11.14%. This has not only enabled us to lower operational costs, it has also facilitated a reduction in the amount of CO2 the site produces. Decreasing our emissions is one of our key environmental pledges, and this new roof is helping us to deliver our commitment to cut our emissions by 30% from 2020 to 2030.”

Brett Martin was able to demonstrate the aesthetic and technical benefits of its Marvault system by taking the team from Center Parcs to see the product in situ on another project. Recently completed, Porsche’s new High Wycombe showroom

utilises Marvault to bring light into the deep plan building. This helped to demonstrate the benefits to the team from Center Parcs and played a vital role in securing the contract.

Adrian Lukic, Sales & Commercial Director at Brett Martin noted that “This was an exciting project to be involved with, and it is great to have it recognised nationally with awards from the LWRA and the NFRC, and internationally at the IFD International Roofing Awards. Efficiently heating such a large space to a degree that makes it comfortable for guests is a difficult feat, but our Marvault has demonstrated what a crucial role new and efficient rooflights play in achieving great thermal and environmental efficiency.”

To find out more about Brett Martin’s Marvault rooflights, as well as the other products in its polycarbonate and glass rooflight ranges, go to www.brettmartin.com.

The UK fenestration landscape is undergoing a vibrant transformation. While white and classic neutrals will always have their place, a distinct and growing trend for bold colours and expressive finishes on doors and windows is sweeping the nation, driven by homeowners' desire for unique personality and enhanced kerb appeal.

“It’s a trend that’s creating exciting growth opportunities,” explains Richard Bryant, Commercial Director for UK fenestration hardware provider, Window Ware, “... and we've made sure we’ve got the right hardware solutions to help fabricators to meet this evolving demand.”

COLOUR REVOLUTION

This shift towards a more distinctive exterior is particularly evident in the expanding array of choices now available. With more materials, colours, styles, and finishes than ever before, homeowners are truly empowered to make a statement, transforming their front façade into a unique focal point.

This desire for individuality is manifesting in several key colour trends. Deep, rich tones like forest green and deep navy are gaining immense popularity, injecting luxury and drama into main entrances. Earthy tones such as terracotta, clay, and chocolate browns are connecting homes to more natural aesthetics, while the enduring power of matte black continues its ascent as a dominant choice for aluminium frames. Beyond just colour, natural wood finishes, timber replacement and matte textures are popular for a sleek, contemporary look. Crucially, dual-colour options (different colours inside and out) are essential, enabling homeowners to express boldness externally while maintaining a versatile, neutral interior.

Echoing this sentiment, The Residence Collection has observed a similar evolution in customer preferences for its timber replacement systems. Jo Trotman, Marketing Manager, notes, “We’re seeing a real shift in consumer confidence when it comes to colour. More homeowners are embracing individuality through bold window and door finishes, moving beyond traditional whites and greys. At the premium end, especially within heritage and high-end new-build properties, colours like deep green and rich burgundy combined with textured finishes are becoming defining features.”

She adds, “Natural tones like soft, earthy greens are continuing to grow in popularity too, particularly within our timber-effect ranges, which allow customers to blend character with contemporary appeal. As these colour palettes become more

adventurous, the role of hardware becomes increasingly more important. It’s not just about adding in the functionality but instead completing the look.”

Guy Hubble, Joint Managing Director at Regalead couldn’t agree more. He explains, “As a business focused on the aesthetics of glass and doors, we've seen a significant shift in the market. Homeowners are moving away from the conventional and embracing expressive design, whether it's the sleek, architectural appeal of a premium matt finish or the timeless charm of a heritage-inspired door with decorative glass panels.

“The resurgence of stained glass is further proof that people are looking to inject personality into their homes. Our focus, therefore, is on providing solutions that make an impact, and distinctive door furniture, like Window Ware’s Regal Hardware, can support us in that mission.”

Window Ware’s Richard Bryant argues, “We understand that a stunning door or window isn't just about the frame colour; it's about the complete aesthetic, and hardware plays a pivotal role in that. As a leading supplier, we're focused on providing the perfect components to bring these bold, beautiful designs to life for fabricators across the UK.”

Window Ware's extensive range is curated to support these trends. The hardware specialist’s on-trend black range, from sleek espagnolette handles and period casement

stays to slimline letterplates, and knurled door handles, ensures fabricators can provide the cohesive, contemporary look that complements or contrasts with any frame finish.

Beyond black, the company offers door and window furniture in a full spectrum of styles and finishes – including increasingly popular Antique Bronze (as seen with their new Regal Hardware Knurled range) and various metallic tones – that can either blend seamlessly or provide a striking contrast to any chosen bold frame colour.

When it comes to essential Part F-compliant trickle vents, a wide choice of stocked finishes is essential for ensuring they blend seamlessly with today’s expanding colour palette of window and door profiles.

Richard emphasises, “Crucially, our hardware isn't just about looks. It's about delivering the durability, security, and performance that homeowners expect, ensuring that these bold design choices stand the test of time.”

The shift towards bold and expressive fenestration is an exciting one, offering incredible opportunities for fabricators.

Window Ware is proud to be at the forefront of supplying the diverse, high-quality hardware solutions they need to transform these colourful visions into reality and fully capitalise on this growth market.

For more information, call 01234 242724, email sales@windowware.co.uk or visit www.windowware.co.uk.

Following its acquisition by Aluminium Vision Limited earlier this year, independent trade fabricator Fentrade is reporting a period of continued stability, strategic investment and sustained sales growth as the business prepares for its next phase of expansion.

Since the sale of shareholdings in April 2025, it has very much been business as usual for the Newport-based fabricator, but with significant planning for the future taking place behind the scenes. The new ownership has already brought tangible investment into the workforce, including additional estimating staff and the appointment of a new Technical Manager to further strengthen customer support. Recruitment is also underway on the shopfloor to increase manufacturing capacity.

Chris Reeks, Managing Director and co-founder of Fentrade, commented: “Whenever a business changes ownership, there can be concern that standards may slip. But with Aluminium Vision, this was never in doubt. The new team shares the same values of service, quality and reliability that have always defined Fentrade. Retaining my position as Managing Director has ensured continuity for our staff and

our customers, while giving me the opportunity to oversee the growth of the business in the way I could not previously realise.”

Despite wider economic uncertainty, Fentrade has delivered consistent sales growth throughout 2025, acquiring new trade customers and securing several large, high-profile commercial projects. With further investment planned and relocation options being actively explored, the company is forecasting continued momentum into 2026 and beyond.

The strengthened partnership with Aluminium Vision has also reinforced Fentrade’s long-term manufacturing strategy. The business continues to operate from its modern Newport facility, fabricating an extensive aluminium product range using systems from leading industry names including Aluk, VBH, Kestrel and Jack Aluminium.

Chris added: “We’ve built a reputation as a dependable fabricator that delivers on time, in full and with exceptional attention to detail. With the backing of Aluminium Vision and the additional resources now in place, we are in a stronger position than ever to support our customers and grow our presence in both the trade and commercial sectors.”

Fentrade’s commitment to service, quality and technical expertise remains unchanged, and the company’s ongoing investment ensures it is well-positioned to support partners with both current and future project demands.

Chris Reeks – MD at Fentrade

“Retaining my position as Managing Director has ensured continuity for our staff and our customers, while giving me the opportunity to oversee the growth of the business in the way I could not previously realise.”

One of the UK’s leading home improvement specialists is marking its 20th birthday in style by setting out a four-year growth plan to achieve £100m in sales.

Conservatory Outlet, which is headed up by CEO Greg Kane and Managing Director Mick Giscombe, has unveiled an exciting strategy that will see it invest heavily in diversifying its manufacturing operations and further expansion of its hugely successful home improvement offering.

The Wakefield-based company is also marking the major anniversary by introducing a new corporate structure that will involve the introduction of Conservatory Outlet Group as the holding business, with CO Manufacturing and CO Home Improvements reflecting its two main areas of operation.

New websites and branding have been introduced to support the name change, kickstarting a £1m investment drive that will involve the installation of state-of-theart CNC machining at its Cutting Room facility, a fleet of commercial vehicles, new IT infrastructure and the creation of 20 new apprenticeships.

“We’ve had a fantastic two decades in business, enjoying significant growth across both our manufacturing and retail arms - so much so that we are now generating £62m of annual revenues and employing more than 400 people,” explained Greg Kane, CEO of Conservatory Outlet Group.

“This is just the start. You can’t stand still in our world, and we want to continue to meet customer expectations when it comes to new home improvement products and improving their experience.”

The firm has developed a specialist collection of windows and doors for both areas and is investing £1m in 4-axis CNC machines to give it greater capacity and repeatable quality across its production facility.

Similar levels of investment are being channelled into boosting the skills of its workforce, with 10 apprentices currently being recruited and the launch of its tailored Manufacturing Degree pathway that aims to create the production leaders of the future.

Greg went on to add: “We’re currently generating over £30m of revenues across manufacturing and we believe, with the right backing and diversification, we can take this figure up to £50m.

He continued: “That’s why we’ve outlined a new four-year growth plan that will look to accelerate us towards £100m and, to do this, we required a clear business structure that clearly celebrated our history but also paved the way for the future.

“Our group will now comprise CO Home Improvements (covering the six retail businesses we own – Clearview, Orion, Planet, Trent Valley Windows, West Yorkshire Windows and Yorkshire Windows) and CO Manufacturing.

“The latter reflects our commitment to delivering the highest quality windows, doors and living spaces to our vitally important Premium retailers, but also the growth opportunities we see in other markets.”

CO Manufacturing has identified strong expansion possibilities in its fledgling trade products business in the North West and Yorkshire, as well as with housing companies through its dedicated new build offer.

“The market is changing and we’re helping push the boundaries of innovation when it comes to thermally efficient products and utilising new materials for achieving different aesthetics.”

CO Home Improvements will work closely with the company’s network of 22 independently owned retailers, which span all of England and Scotland.

These firms have worked with the business for many years and share its values of excellent customer service and trust, with an appetite to embrace the latest technology to improve the client journey.

The network complements the firm’s six retail brands that operate predominantly in the East Midlands, North West and Yorkshire.

Greg concluded: “We are expecting similar growth in retail as we are in manufacturing and, together, we’ll hopefully hit the £100m target by 2029.

“Our aim is to enhance the support we give to our network even further so they can collectively achieve great things, as well as looking at the opening of four new showrooms in Derbyshire, South Yorkshire, the Lakes and one in either Liverpool or Manchester.”

For further information, please visit www.comanufacturing.co.uk or follow the company across its social media channels.

Leicester-based IGU manufacturer Cleartherm Glass Sealed Units Ltd is calling on others in the industry to embrace automation – or risk falling behind.

With more than 37 years in business, Cleartherm has seen first-hand how the power of automation has boosted capacity, improved consistency and driven long-term growth.

Cleartherm has significantly expanded production in recent years thanks to the decision to automate its insulated glass unit manufacturing process using Super Spacer® from Edgetech, and it’s a move that has been made possible through its long-standing partnership with the Quanex company.

“We’ve worked with Edgetech for approaching 25 years now and they bring both a truly great product and a wealth of automation expertise as a partner,” says David Laing, Managing Director of Cleartherm.

“And automation has been the real game-changer. It has allowed us to produce a consistent high standard, every

day, every shift. We used to produce 300–400 units a week manually. Today, we’re consistently hitting over 4,000 units per week, all in a standard 8.5-hour shift, and we are always able to pick up the phone and speak to Edgetech’s technical team if we need to.”

With labour challenges continuing to affect the manufacturing sector, automation also offers a more sustainable way forward.

“It’s difficult to find consistent, skilled labour today,” David continues. “Automation eases that pressure. You still need a team that understands how to work with the technology, and once you’ve got that in place, it makes growth far more achievable. You have to be prepared to adapt and work with automation, as opposed to counter it and say it's not going to work for us.”

Gareth Laing, Clearthem’s Sales Director, agrees: “If I were talking to any IGU manufacturer not using automation, I’d say: automate, automate, automate!

“Without automation and making that investment I don’t think we’d be where we are today as it offers you so much more capacity against manual production and I think most IGU manufacturers that are in the same position as us would echo that.”

Tony Palmer, Head of Sales at Edgetech, said: “Cleartherm has always been at the forefront of embracing new technology and they are a great example of what can be achieved when you combine forward-thinking leadership with reliable automation and proven spacer technology. We’re proud to be part of their journey and to support more manufacturers making the same transition.”

Cleartherm's message is clear: automation isn’t just an option, it’s the future and a necessity for growth, efficiency, and long-term success in the IGU sector.

To learn more, you can watch the full interview with Managing Director David Laing and Sales Director Gareth Laing here: https://www.youtube.com/watch?v=JTM8Cu1SHmc

PVCu window and door

systems supplier VEKA plc has launched a new website designed to deliver greater accessibility, transparency, and efficiency for its partners across the fenestration industry.

The new site represents the latest stage in VEKA’s ongoing digital evolution and forms part of a wider focus on helping fabricators, installers, and specifiers access accurate information and expert support more easily.

Usability is at the core of the site, with product and technical content carefully structured for easy navigation, enabling users to locate data sheets, performance information, and specification guidance in just a few clicks.

Beyond its improved product resources, the website also showcases the full breadth

of support VEKA offers across the supply chain. Users can now more easily tap into technical and commercial guidance, explore marketing support, and access installer programmes.

The streamlined experience reflects feedback from research undertaken with VEKA customers, installers, and industry professionals who called for faster, more intuitive access to essential technical information, to help them work more efficiently and with greater confidence.

“We’ve responded to those challenges with this significant investment into our digital services, providing fabricators, installers, and specifiers with a more practical, accessible solution which makes it easier for them to work more effectively, and more collaboratively with us."

Launching alongside the website, the VEKA Edge partner portal has also been enhanced, further strengthening customer support by consolidating technical documents, manuals, ordering tools, marketing materials, and digital design platforms such as WinDoPlan into one secure, integrated hub.

Set to celebrate its 40th year of British operation in 2026, VEKA says the investment into its digital offering shows it is evolving in line with the needs of its partners and the wider industry.

Jessica Brooks, Brand and Insight Manager at VEKA, said: “We know our partners face complex and changing demands, from compliance and sustainability to customer expectations. We’ve responded to those challenges with this significant investment into our digital services, providing fabricators, installers, and specifiers with a more practical, accessible solution which makes it easier for them to work more effectively, and more collaboratively with us.

“This milestone is proof of our commitment to continuous improvement – not just in our product systems, but in how we support the people who use them. The new website looks firmly to the future but is also built on the solid foundation that has defined VEKA for decades: reliability, consistency, and partnership.”

Operating from its Burnley site since 1986, VEKA plc is part of the VEKA Group, a family-owned company established in Germany in 1969. With more than five decades of experience and operations in over 40 countries, the group provides a stable platform that enables VEKA to continue investing in the people, processes, and systems that strengthen its partners’ businesses.

Consort Ltd, one of the UK’s most established fabricators of PVCu and aluminium windows and doors, has unveiled its new brand identity.

CONSORT – BUILT AROUND YOU.

This marks the beginning of an ambitious new chapter for the Nottinghamshirebased manufacturer, as it evolves to meet

the needs of modern installers across the country - focusing not just on product, but on the people, partnerships, and trade-first service that set Consort apart.

“At Consort, we’ve been delivering more than windows and doors since 1981 - we’ve been delivering confidence,” says Simon Holt, Managing Director at Consort.

“For over four decades, installers across the UK have counted on us for quality they can trust, products that perform, and service that delivers - on time, every time. We’ve built Consort around our installers. That’s what the Built Around You message is all about.”

The refreshed brand identity is part of a strategic shift that puts installers firmly at the heart of everything Consort doesfrom production and logistics to technical support and quality products.

More than just a new look, Built Around You reflects Consort’s renewed focus on:

• Unrivalled customer service

• Hands-on trade support

• Seamless digital quoting and ordering tools

• And a commitment to helping installers win work, grow their business and stay ahead

Consort is part of the JBS Group, a UK manufacturing group that includes industry innovators Nico Manufacturing Ltd and Coburn Sliding Systems. That backing brings scale, technical strength, and exclusive access to component solutions that give Consort’s customers a competitive edge.

“At Consort, we don’t compete with our partners - we support them every step of the way,” says Aled Davies, Sales Director at Consort.

“Everything we do is designed to make life easier for our installers - from seamless online quoting and ordering tools to dependable technical support and precision manufacturing. Our dedicated team works craftsmanship with purpose.”

“We’re not just trade focused. We’re tradebuilt. Everything we do is designed to make life easier for our installers - from seamless online quoting and ordering tools to dependable technical support and precision manufacturing. Our dedicated team works craftsmanship with purpose. Every product is built with meticulous attention to detail, ensuring smooth installation and a finish that helps our installers stand out and impress their customer — the homeowner.”

Consort manufactures using systems from two of the industry’s leading suppliers: VEKA for PVCu and Smart Systems for aluminium. With a strong supply chain, deep technical knowledge, and a nononsense approach to service, the company is perfectly positioned to deliver what the modern installer needs - not just now, but into the future.

With the Built Around You identity now in place, Consort is launching a bold new wave of marketing activity. The campaign will shine a spotlight on what makes Consort different: the people, the industry knowledge, and the genuine, reliable tradefirst approach that installers value.

Expect to see social storytelling, video content, product spotlights and nationwide outreach designed to inspire pride in existing customers, while attracting a new generation of installers looking for a supplier that truly understands their world.

“We’re not distracted by anything else,” adds Simon. “We’re here for one reason - to support our installers. Built Around You isn’t just a slogan. It’s how we operate.”

For more information visit their new website: www.consortwindows.com.

At the time of writing, the Budget is looming and the glazing industry faces mounting pressures. Insight Data’s Commercial Director, Alex Tremlett, explores how firms can use market intelligence to drive growth.

As the Chancellor prepares to unveil the next Budget later this month, to jitters all round, business confidence across the home improvement and construction sectors hangs in the balance. The glazing industry is facing one of its most complex periods in years, and while inflation may be easing, energy costs, material prices and labour shortages continue to apply pressure. Add to that cautious homeowners and a slower housing market, and it becomes clear why so many companies are tightening their belts.

At Insight Data, our live market intelligence platform, Salestracker, monitors more than 50,000 companies across the glazing and construction supply chain. That gives us a clear view of how the market is shifting in real time. Our most recent figures show there are now just under 13,500 active firms

across the glass and glazing industry. The number of UPVC fabricators has fallen to around 1,100 from roughly 4,000 two decades ago, while aluminium continues to gain share. This shift reflects the move towards higher-value, more sustainable products; a trend that shows no sign of slowing.

But behind these structural changes lie deeper challenges. In the run-up to this year’s Glazing Summit, we surveyed more than 2,000 installers. A third told us that while order values have risen, it is now harder than ever to win new work.

Competition for fewer, higher-value projects is intensifying, leaving many firms fighting for visibility.

Meanwhile, digital advertising spend in the glazing sector has hit record levels. The industry is now investing close to £100 million a year in Google Ads alone – an astonishing figure that, in many cases, delivers diminishing returns. The pandemic triggered a rush to online advertising when traditional sales routes were cut off, doubling the cost per click almost overnight. Many companies have since found themselves hooked on paid ads, while brand-building and local reputation have taken a back seat.

This is where the fundamentals of marketing matter most. As our Managing

Director Andrew Scott reminded delegates at the Glazing Summit, sustainable growth is about building trust, reputation and longterm visibility. Installers and suppliers must refocus on what makes customers choose them in the first place: expertise, reliability and value. The businesses that understand their market, communicate their strengths clearly and nurture customer loyalty will be the ones that thrive.

Diversification is another crucial ingredient. Our data shows that companies exploring renewables and energy-efficient home technologies are weathering the downturn more effectively. Similarly, trade suppliers moving into both commercial and retail markets are spreading their risk and finding new opportunities. The message is clear: agility and awareness are now competitive advantages.

The upcoming Budget may bring modest relief for businesses, with expected measures to support growth and investment, but it is unlikely to reverse the fundamental pressures on the industry. Companies cannot afford to wait for market conditions to improve; they must act on the information available now.

That is where live, accurate data becomes invaluable. Knowing which firms are growing, which are scaling back and which are entering new markets helps suppliers

and manufacturers make confident decisions. It means targeting the right customers, at the right time, with the right message. It also avoids the waste and frustration that come from working with outdated or inaccurate information.

At Insight Data, our team makes more than 20,000 live verification calls every month, speaking directly to fabricators, installers and suppliers across the UK. This ensures that Salestracker users always have access to the most current and reliable intelligence available. The system allows businesses to segment prospects, track performance and strengthen relationships, giving them a genuine competitive edge.

Behind the scenes, we are working on a new of version of Salestracker that will make accessing and interpreting data even faster and more intuitive. As the glazing industry continues to evolve, we are evolving with it, providing the insight and clarity companies need to stay one step ahead.

In challenging times, knowledge is more than power. It is the difference between reacting and leading. Those who understand their market best will not just survive this period of uncertainty; they will emerge stronger, more focused and ready for the opportunities that lie ahead.

www.insightdata.co.uk

Purplex Marketing founder and MD

Andrew Scott argues that in an age dominated by AI and data, creativity and emotional storytelling remain the true drivers of lasting brand value.

There is a belief that modern marketing has become a science. Everywhere you look there are dashboards, algorithms, and now artificial intelligence, all analysing behaviour, predicting trends and optimising campaigns. Science makes marketing accountable and measurable, telling us what works and what does not.

However, data and AI alone do not move people. The reason for this is because marketing, at its heart, is still an art. It is about understanding what makes people feel something. It is about ideas that stir emotions, build trust and make someone choose you and your brand. Somewhere along the line, in our obsession with analytics and instant results, that human part is being lost.

The most powerful brands have always known that logic and emotion must work together. Coca-Cola’s Christmas campaigns do not sell a drink; they sell belonging. Cadbury’s Glass and a half of milk campaign, created nearly a century ago, still endures because it taps into something timeless and familiar. These ideas live on precisely because they were crafted with imagination and feeling. They are art as much as marketing.

Truly great marketing hinges on making a connection. The big idea is what cuts through the static of everyday life and lodges itself in memory, yet too many agencies have become trapped in the pursuit of short-term gains. They chase clicks and conversions, mistaking movement for progress. True

brand value takes time, and the brands that endure are built through creative stories and experiences that people remember long after the ad spend runs out.

My own belief in creativity was shaped long before I entered marketing. My uncle, William Scott CBE RA, was one of the great British abstract artists of the twentieth century. His paintings hang in the Tate, the Guggenheim and the Met, and sell for staggering sums. But to me, he was simply Uncle William. I can still remember him arriving at our small council house in Belfast in his Rolls Royce, a surreal sight against the backdrop of coal fires and Formica tables. He and my Aunt Mary would spend much of their time in Italy, yet when they visited us they brought with them a sense of another world entirely — one filled with imagination and possibility.

As a child, I did not understand his work. It looked so simple; bowls, bottles and shapes, rendered with restraint. Only later did I understand that he was reducing life to its essence, removing everything unnecessary until what remained carried real power. That principle of simplicity has stayed with me ever since.

At Purplex, I often think about that lesson. Great marketing, like great art, is about clarity. Knowing what to leave out is as important as knowing what to include. In an industry filled with noise, the clean line and the pure idea always stand out.

“Great marketing, like great art, is about clarity. Knowing what to leave out is as important as knowing what to include. In an industry filled with noise, the clean line and the pure idea always stand out.”

When I founded the agency, my goal was to bring that balance of art and science into everything we do. Data can make a campaign more efficient, AI can make it faster and more targeted, but neither can make it meaningful. Only creativity can do that. Data wins the short-term game, but creativity wins the long one.

The influence of my family, and of my uncle in particular, reminds me that creativity is not a luxury in marketing. In fact, it is the foundation. It is what transforms information into inspiration, and customers into believers.

In a world that worships algorithms and AI, let us never forget that imagination is the most valuable asset of all.

Discover how creativity can transform your brand. Talk to Purplex Marketing and see what great marketing looks like when art meets science. www.purplexmarketing.com.

Coastal Group has strengthened its commitment to showcasing innovation in external door and window hardware with the addition of a new feature installation at its Brand Centre in Cornwall.

Inspiration Doors has generously donated a striking entrance door finished in liquid metal oxidised iron, delivering a distinctive patina effect that highlights the growing market demand for texture and cutting edge design.

The handcrafted door provides a new focal point within the Brand Centre, giving visitors the opportunity to experience the relationship between premium front doors and high-performance door furniture.

The installation also demonstrates how even the heaviest doors can be lifted and operated with precision-engineered hardware, reinforcing the importance of pairing specialist entranceways with robust, marine-grade components.

Loren Jenner, Managing Director at Coastal Group, emphasised the increasing role of sensory experience in product

selection: “People love texture – materials that invite interaction and spark curiosity. Our industry is no longer just about performance; it’s about how products feel and how they contribute to an experience. When customers visit the Brand Centre, they don’t just see the hardware; they touch it and feel the engineering. This new door allows us to showcase that connection in a way that is both compelling and meaningful.”

The partnership between Coastal Group and Inspiration Doors reflects a shared ambition to continuously raise standards across the door and window sector. As design expectations rise and customers demand more, collaboration between manufacturers is increasingly important.

Bruce Dudman of Inspiration Doors highlighted this shift in homeowner expectations.

“Years ago a door handle was a door handle; it was functional. But people now want something a little bit better – more inspirational and tactile. People demand more. They want a door that makes a

statement and hardware that enhances the design rather than just operating it.”

The oxidised iron finish used on the new door is created through a highly specialised liquid metal application process that results in a varied, natural patina. This approach has grown in popularity among architects and high-end joiners seeking unique, characterful surfaces that cannot be replicated through standard coatings.

Mathew Jones, Managing Director at Inspiration Doors, noted the natural fit between the two companies’ product portfolios: “We are both at the pinnacle of our product ranges so it makes sense to work together. Our doors rely on exceptional hardware to perform at their best, and Coastal’s engineered solutions complement what we build perfectly.”

The new installation at the Cornwall-based showroom serves as a tangible example of how manufacturers can combine expertise to influence the future of the industry.

As sustainability, durability and design-led thinking continue to guide development

Following on from the publication of its new Environmental Product Declaration (EPD) for its SF52 aluminium curtain wall system, Senior Architectural Systems is encouraging contractors to challenge manufacturers to provide the proof behind their sustainability claims.

Overseen by Senior’s dedicated UK sustainability lead Luke Osborne, the development of the company’s new EPD document has been done in a deliberately different way and sets a new benchmark for transparency in the fenestration industry. Unlike many EPDs that include insulated glass units, which are typically not supplied by system houses, Senior has chosen to omit glazing from its calculations on the environmental credentials of its SF52 aluminium system. This is because the heavy weight of glass, combined with its relatively low carbon per kg, can make the overall figures for the aluminium

system look lower than they really are after conversion. By omitting the glazing from its EPD, Senior ensures that the carbon figure per square metre reflects only the aluminium system itself, giving a more accurate and honest assessment.

The SF52 EPD also introduces non-linear scaling, which is a first for the sector. Instead of relying on a single reference size, Senior has verified three different system sizes and consolidated them into one publication. This allows for more precise calculations across a range of project

configurations and removes the guesswork from environmental assessments.

Senior’s approach goes further still by including the environmental impacts of profile extrusion and non-aluminium components such as thermal breaks, gaskets, and fixings. These elements are often overlooked but can significantly affect the overall footprint of a system. By accounting for them, Senior provides a more complete picture of what specifiers are actually choosing.

in external door and window systems, the relationship between structural components and hardware is becoming more integrated than ever.

Coastal Group expressed its appreciation. “We want to thank Mathew, Bruce and their team for this stunning piece,” continued Loren. “The addition of the statement door supports the Brand Centre’s mission to give joiners, installers and architects a space where they can interact with products in a real-world context. It also helps home owners make informed decisions and is sure to inspire future projects.”

The new installation is available to view at the Coastal Group Brand Centre in Cornwall.

Senior’s UK sustainability lead Luke Osborne explains: “Our new EPD offers a holistic overview that spans from manufacture to delivery and fabrication. It reflects the real-world journey of the SF52 system through our UK-wide fabricator network, but most importantly, it includes the depth of relevant detail that is needed for a more accurate assessment of a product’s performance. We are proud to be setting a new standard for how environmental data should be presented in the fenestration industry and we are set to build on this with the development of further EPDs across our product range, including our patented PURe® aluminium system.”

Download the SF52 EPD via Senior’s NBS Source profile or request a copy from UK sustainability lead Luke Osborne at lukeo@sasmail.co.uk. For more information, visit www.seniorarchitecturalsystems.co.uk.

In a market where efficiency and reliability are crucial, fabricators and installers are facing growing pressure to deliver more - faster and without compromise! With fluctuating demand, material challenges, and an evertightening labour market, the need for dependable supply chains and consistent quality has never been greater.

Peter Grundy, Vice President Operations at Quanex brand, Liniar, believes success in today’s fenestration sector depends on “building strong, transparent partnerships that give fabricators the confidence to plan ahead, knowing their systems supplier will deliver - literally and figuratively.”

Few things disrupt production schedules more than a supplier who can’t deliver on time or in full. Missed deadlines and incomplete orders ripple through fabrication, installation, and customer satisfaction.

“At Liniar, we’ve made reliability our foundation,” says Pete. “Our On Time, In Full rate consistently exceeds 99%, which means customers can plan production with confidence.”

Operating from an impressive 375,000 ft2 facility in Derbyshire, Liniar maintains nearly 10,000 SKUs, holding over £10 million of stock ready for immediate dispatch! Supported by a 175,000 ft2 warehouse and a dedicated UK-wide transport fleet, the company’s logistics network ensures fabricators receive the right products exactly when they’re needed.

“This operational efficiency not only minimises downtime but supports sustainable growth for customers scaling their businesses,” Pete adds.

Quality inconsistencies create issues on the shop floor and, potentially, costly callbacks on site. Liniar’s reputation as the UK’s most invested PVCu systems house comes from its commitment to world-class manufacturing standards and smart design principles.

“Our customers expect profiles that perform flawlessly,” Pete explains. “That’s why we continually invest in advanced extrusion technology, precision tooling, and rigorous quality checks at every stage.”

Each Liniar profile is engineered with fabricators in mind - optimised for ease of

“Our On Time, In Full rate consistently exceeds 99%, which means customers can plan production with confidence.”

machining, minimal waste, and maximum performance. The result? Fewer production headaches and greater profitability for Liniar fabricators and installers alike.

Coordinating multiple suppliers often leads to inconsistencies, colour variations, and administrative strain for fabricators. Liniar removes that complexity by providing a complete, single-source solution across both PVCu and aluminium systems - giving customers one trusted partner for every requirement.

With all products colour-matched, fully compatible, and manufactured to the same exacting standards, fabricators gain a seamless, reliable supply chain that saves time and reduces risk.

“By taking multiple moving parts and bringing them under one roof, we make life easier for our customers,” Pete explains. “It’s about giving them simplicity, consistency, and confidence in every order from a single point of contact.”

AS

As the fenestration sector continues to evolve, Pete believes collaboration will define the next decade of growth. “At Liniar, we’re not just supplying profiles - we’re partnering with customers to help them adapt, innovate, and thrive. Continuous improvement is part of our DNA, and our focus remains on supporting the people who want to drive this industry forward.”

With that forward-thinking approach, Liniar continues to set the standard for reliability, quality, and partnership in UK fenestration.

Force 8 has launched a completely new composite door system designed to give homeowners a more authentic timber door appearance, while offering all the performance benefits associated with modern composites.

For the first time, the company has developed a method of manufacturing raised panels on to the door slab, creating a true joinerystyle finish. Until now, the detail on composite doors has typically been in-bossed into the surface. While effective at suggesting panel depth, this approach has often fallen short of replicating the definition and character of traditional timber joinery.

By introducing raised panels, Force 8 has achieved a closer resemblance to handcrafted timber doors. The result is a system that combines the appearance of period joinery with the durability, energy efficiency and security that installers and homeowners expect from a composite door.

The new Heritage Range is available in a broad selection of colours and designs and can be tailored further with a wide choice of glazing options. This flexibility allows installers to offer styles to suit both contemporary and

traditional properties. The raised panel detailing could be particularly relevant for homes in conservation areas, where planning requirements often want a more faithful reproduction of original features.

In addition to its design qualities, the Heritage Range incorporates Force 8’s well-established “No Bowing” system, which ensures structural stability in varying weather conditions. This feature addresses a common issue in composite doors, giving both installers and homeowners confidence in the product’s long-term performance.

From a technical perspective, the Heritage Range retains all the expected benefits of composite construction. High levels of thermal insulation help to reduce heat loss, while advanced locking systems provide enhanced security. For installers, the system offers a new opportunity to meet growing demand for doors that balance authenticity with practicality.

Commenting on the launch, Force 8’s Founder, Dennis Sumner, explained: "The raised panel design represents a significant step forward for composite doors. For years, the market has sought an option that combines the aesthetic qualities of timber with the performance advantages of composite materials. This development allows us to bridge that gap and offer a solution that is both practical and looks authentic."

With its blend of style, strength and practicality, Force 8’s new Heritage Range marks a significant step forward for the composite door sector, giving trade installers an exciting new product to present to their customers.

To find out more, visit their website at: https:// force8.uk/force8-products/ heritage-door/

With the UK continuing to experience some of the driest and hottest weather on record, Endurance® Doors is issuing a timely reminder of the benefits of its industry leading bowing guarantee.

The process of bowing can affect all composite doors and normally happens in the first twelve months of their use. Its occurrence should be temporary however and leave little to no lasting consequences

Bowing is caused by the natural expansion and contraction of the door and its component materials due to changes in the ambient temperatures both inside and outside of the property.

It is most common in the summer and winter because these seasons experience extremes of hot and cold weather.

After bowing, and as temperatures normalise, the door should return to its original flat plane.

Endurance is so confident this will happen with its products that it guarantees to replace any of its doors that stay bowed by 3mm or more, free of charge and using its own field-based service engineers.

In comparison, most other composite door manufacturers only guarantee to replace doors that stayed bowed by upwards of 7mm - a tolerance that is more than double.

Scott Foster, group marketing director, at Endurance® Doors comments: “A bowed composite door can cause serious issues for the homeowner, reducing customer satisfaction and harming the reputation of both the installer and manufacturer. It can also result in call backs creating remedial work for the installer and damaging profit margins.”

“A bowed composite door can cause serious issues for the homeowner, reducing customer satisfaction and harming the

reputation of both the installer and manufacturer.”

He continues: “Most people would struggle to open and close a door that’s bowed by 7mm let alone lock it. We believe 3mm is more acceptable and provides far greater peace of mind.

“We are able to offer this unrivalled level of reassurance because our doors are premium products with an innovative design and high quality construction.”