ALLIED ASSOCIATIONS

Power and Precision: Installing the Rootzone Mix in a USGA Putting Green Installing the rootzone mix during construction of a USGA putting green requires both power and precision. Hundreds of tons of material must be brought into the putting green cavity using heavy equipment. At the same time, the rootzone mix must be carefully installed to avoid disrupting the gravel layer and drainage system. The mix must also be spread with precision to a uniform 12-inch depth, plus or minus 1 inch. The first step is ensuring that any equipment involved in handling or spreading the rootzone mix has been thoroughly cleaned. This will prevent soil and other contaminants from being introduced into the rootzone mix. Tracked equipment is typically the best option for spreading the rootzone mix. The larger surface area of the tracks reduces the risk of creating ruts and helps compact the rootzone mix. Rubber-tired equipment can be used to spread the mix, but there is a higher risk of it sinking into loose material and potentially disturbing the underlying layers. Determining how much rootzone mix will be required for a given putting green cavity can be challenging. Calculating the total volume of sand required based on the putting green’s square footage is a good starting point, but the degree to which the mix settles will always cause some variability in the actual quantity needed. Some accredited labs can test the compression characteristics of a rootzone mix, but basic estimates can also be made in the field. Fill a 5-gallon bucket with dry rootzone mix and place a weight on top of the mix. Set the bucket on a running piece of equipment that will apply strong vibrations. After a few minutes, measure the amount of settling for a rough estimate of how much extra mix will be needed to fill a putting green cavity. Throughout the installation process, the rootzone mix should be kept moist to encourage compaction. Repeatedly driving over the rootzone mix in multiple directions with heavy equipment will also help firm up the material. Pay particular attention to compacting the rootzone mix along the edges of the putting green. These areas receive less traffic during the installation process and may require additional compaction with a plate compactor or other piece of smaller equipment. A mechanical bunker rake is an excellent tool for smoothing the final surface. Working in a continuous circular motion, the rake should pass over the entire surface many times to smooth and compact it. Be sure to monitor the depth of the rootzone mix by checking grade stakes and using a probe throughout the installation process. Surveying equipment should also be used to ensure that the desired contours are created. Once the rootzone mix is smoothed and the final contours are approved, the putting green is ready for planting. The USGA is currently updating its Recommendations for a Method of Putting Green Construction and the associated “Tips for Success” materials. The revised Recommendations account for current scientific research, modern construction techniques and technology, and current material testing methods. The revised USGA Recommendations will be released in early 2018.

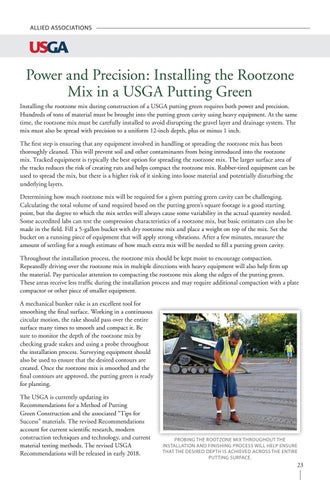

PROBING THE ROOTZONE MIX THROUGHOUT THE INSTALLATION AND FINISHING PROCESS WILL HELP ENSURE THAT THE DESIRED DEPTH IS ACHIEVED ACROSS THE ENTIRE PUTTING SURFACE.

23