Quality control

Why raising the quality bar is the key to unlocking growth in the global avocado market

Why raising the quality bar is the key to unlocking growth in the global avocado market

Is the green gold losing its sheen? For over a decade, avocados have enjoyed relentless growth, their nutritional benefits and versatility making them a darling of uber-cool millennials and health-conscious consumers alike. New plantings have proliferated the world over. But is it reasonable to assume that demand will keep on growing? On what do we base the assumption that consumption rates in Europe and elsewhere will catch up with the US? In fact, there’s growing evidence that supply is catching up with demand. Asian avo growth stalled last year, and while it’s possible this might be a temporary bump in the road driven by logistical and cost issues, it’s a wake-up call for the industry nonetheless. In Europe, too, oversupply has become a key feature at certain points of the year – and will only get worse as output grows. Have we reached a tipping point? It takes four to six years for an avocado tree to reach full production, so any planning decisions necessarily involve some crystal ball gazing. Effective marketing strategies will help drive demand, but they can only do so much. If we want the market to absorb the surge of avocados coming on stream in the coming years we must ensure that consumers keep coming back for more, time after time. And that means getting the quality right. _

As a regional supplier, New Zealand’s avocado industry punches well above its weight. As it throws open its doors for the 2023 World Avocado Congress, Jen Scoular of New Zealand Avocado shares her vision of a sustainable future.

by Maura Maxwell @mauratfruitnet

by Maura Maxwell @mauratfruitnet

Jen, tell us what it means to New Zealand to be the host of this year’s World Avocado Congress and what we can expect from this year’s event.

Jen Scoular: We are incredibly proud to be hosting the 10th World Avocado Congress in Auckland. It is an honour to host such a prestigious event in New Zealand and we are working very hard to ensure the congress provides real value to all delegates, sponsors, partners and presenters. With over 1,000 attendees from 32 countries, we will work hard to provide a platform for real discussion about the avocado sector, including the tough questions about sustainability, global supply and demand, and growing, packing, transporting and marketing the world most nutritious fruit in changing environments.

‘Respectful’ is the theme of this year’s congress, and we know that New Zealand prides itself on the sustainability of its avocado industry. What can other countries learn from your example?

JS: This congress offers the opportunity to share, to learn and to challenge each other to be better for the world. Yes, we are making positive change in New Zealand and we want to share that but we also need to hear about other initiatives so we can improve how we grow, pack, ship and market avocados. Avocados are such an amazingly

healthy product. We must collectively learn how to ensure the production and shipping of our avocados is as healthy for the world as avocados are for our own health.

Can you give us a snapshot of New Zealand’s avocado industry today, and how it has been evolving over the past few years?

JS: We are a small but passionate avocado industry in New Zealand, governed by a grower organisation that wants to ensure the short, medium and long-term commercial sustainability of its members. The industry has seen amazing growth over the past ten years in both value and production.

However, the past two season have been very challenging. Our climate in the most recent season was unbelievably wet – nearly three times wetter than normal, and that poses a whole lot of challenges. Shipping has remained a challenge, and demand across Asia has been a little depressed. The environment

we are growing, packing, shipping and marketing avocados in has changed significantly – we are very aware of the need for the conversations about climate change, global supply and demand and growing avocados in a commercially sustainable way.

In terms of markets, where are the growth opportunities for New Zealand?

JS: Australia remains a very important market for New Zealand, as does our domestic market where

demand has been increasing strongly. We have very good market access across Asia and believe there is very good opportunity to increase demand across many countries in the region.

We are very aware that New Zealand is a small player in terms of volume but we have very efficient systems, we are agile and New Zealand’s reputation for producing high quality, safe, healthy food is an asset to our industry. We are also hungry for new technology, for innovation, for agri-tech being introduced into our supply chain.

As we’ve seen with such devastating impact recently, extreme climatic events are sadly becoming increasingly frequent. How much can the industry do to mitigate against the worst of these events?

JS: New Zealand has certainly suffered some very extreme weather events in the past month, and our thoughts are with the growers and farmers most impacted by the devastation. We must all look at our systems, processes, our rootstocks, our waterways, our shelter and our markets to critically assess how we can mitigate against a wide range of events. If we look at how the world adapted to a global pandemic, we need to seek to extend some of those learnings to improve how we do things in avocados.

I understand Cyclone Gabrielle will have a significant impact on next season’s avocado crop – is this the case?

JS: Avocado trees grow a lot better without cyclones or storms. This will have impacted our future crops. We have just finished our export season, but the cyclone will have reduced the number of late season avocados for the New Zealand market. We won’t know the full impact of this cyclone for another few months but it is yet another challenge for our growers to manage at an already tough time.

During the congress, keynote speaker Eric Imbert will talk about how the “golden age” is over for avocados. And despite the impressive growth in demand, it does seem that this is being outpaced by global supply. What is the best way to ensure the profitable growth of the global avocado industry?

JS: I believe Eric’s message focuses on the importance of investing in increasing demand. He gives the example of the very impressive increase in demand seen in the US, and our Australian neighbours have also invested very strongly to grow their domestic market. We see the opportunity at the 10th World Avocado Congress to discuss how we might collectively work together to increase demand across a number of key markets. Globally the world has a shortfall of nutrition. We have a fruit that contains protein, good fats

and carbohydrates as well as 19 vitamins and minerals. We can be part of a global solution to feed highly nutritious food to our populations. But it won’t happen without new action and thinking.

Finally, are you optimistic for the future of avocados?

JS: There is no horticulture crop that can stay still, we must all navigate the vagaries of climate, environment, global trade and supply and demand. Yes, I believe avocados, as one of the most nutritious fruits in the world have a very important role to play in providing excellent nutrition, versatility and taste to the global population. I believe if that conversation happens more cohesively and collaboratively it will result in mush greater impact and benefit.

“New Zealand’s reputation for producing highquality, safe, heathy food is an asset to our industry”

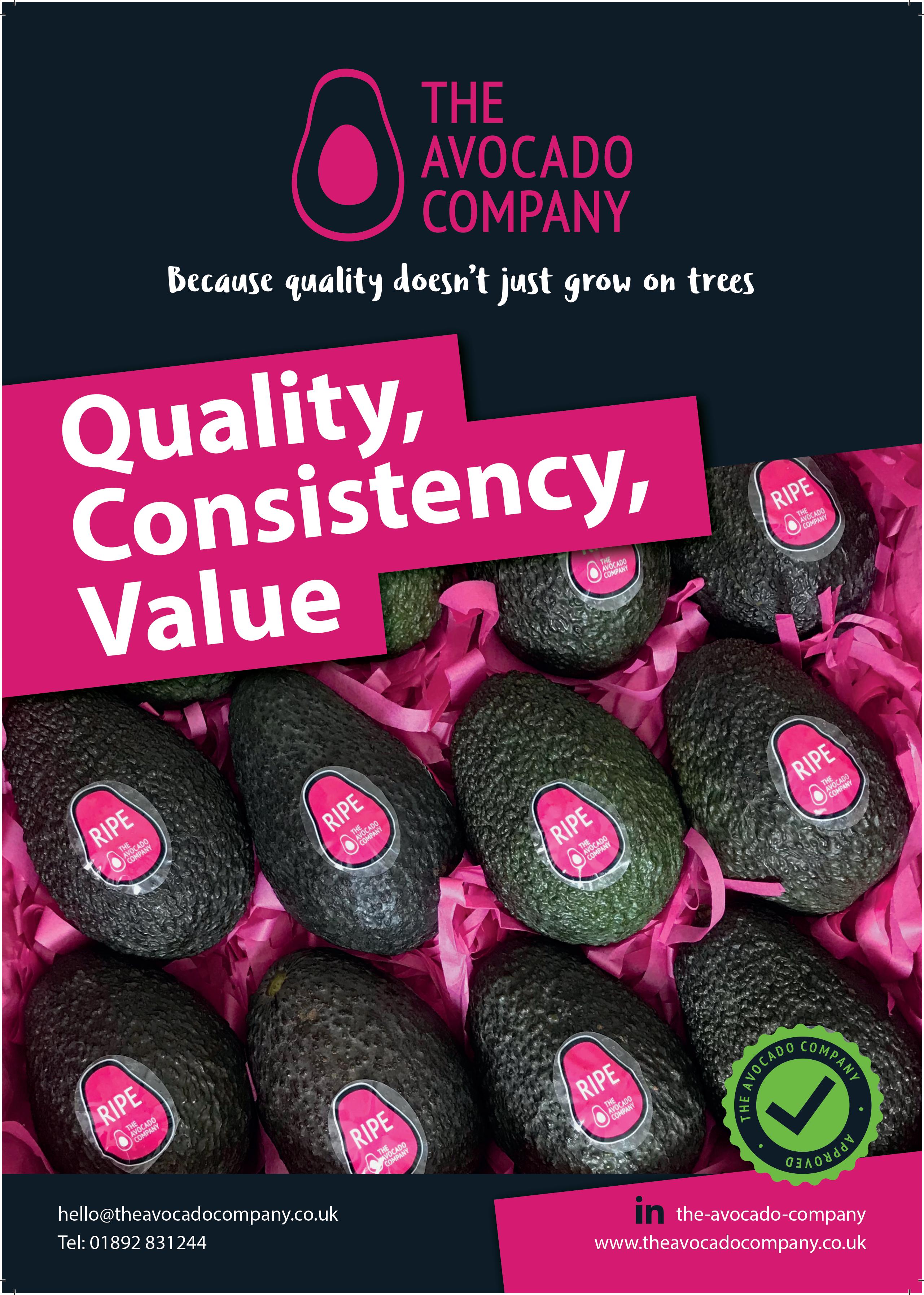

The world’s biggest fruit company has set its sights on driving Europe’s avocado market.

by Maura Maxwell @maurafruitnetWhen Total Produce and Dole Food Company came together to form world’s biggest fresh produce company, Dole plc, in July 2021, the new business was unambiguous in its intent to target the avocado category and to “raise the bar” across the exotics segment in general.

Here, Vincent Dolan, vice president of marketing and sustainability for Dole, outlines the progress made to date and how the company plans to develop its avocado business across Europe and the wider EMEA region in the future.

Vincent, what makes the exotics segment so appealing for the business?

Vincent Dolan: The inherent, untapped potential of the avocado market, coupled with our preexisting in-house strength and capacities, convinced us that, not only is the exotics category worthy of greater focus but that it is also

one to which Dole could add material value and meet an as-yet unsatisfied customer need.

It is well documented that consumption in Europe falls far short of North America – some estimates believe it to be only onethird of the US figure. Given Dole’s extensive on-theground footprint in Europe, our retail relationships and experience and expertise in key markets, there was an obvious opportunity to grow our avocado business here and, by doing so, contribute to promoting consumption.

What is Dole’s strategy in meeting its ambitious targets?

VD: From early on in our planning, we recognised that there are underlying reasons why consumption in Europe is lower. We determined that a ‘me too’ approach to the category would resonate neither with customers nor consumers.

We committed from an early stage to “raising the bar” in the category, bringing to bear the collective reach, resources and expertise and vertically integrated supply chain typically associated with Dole bananas and pineapples to deliver a real point of difference to exotic fruits on the retail shelves of Europe and beyond.

As a consequence, we believe we have fashioned a special proposition in the avocado category built on the

quality of our existing production and our commitment to invest in more; the experience of the global specialists in exotic fruits we have assembled; the technical expertise they bring; our infrastructure – not only across the most fertile global growing regions but also on the ground in key markets, and our capacity to customise.

Complementing group production with third party sourcing, Dole Exotics offers a world-class brand, the security associated with its vertically integrated supply chain, a streamlined route to market and the in-house capacity to assure best agronomic and sustainable practices from farm to fork. It’s a compelling combination.

What does Dole’s avocado footprint look like right now and how are you planning on expanding it in the coming years?

VD: In developing our footprint, we listened first, consulting with supply chain partners and customers to determine the optimal approach, garnering a better understanding of core requirements and potential points of difference in the marketplace. In the short term, we have worked on aligning supply from our own production across South Africa, Chile, Brazil, Peru and Spain with supply from strategic

alliances and long-term agreements we have put in place with best-inclass producers in Colombia and elsewhere to deliver consistently exceptional 52-week supply.

In organisational terms, marketplace operations are focused on five key strategic hubs in Central Europe, France, the UK, Spain and the Nordic markets. Future plans will see these hubs becoming a focal point for embracing new technologies and processes to ensure facilities remain state-ofthe-art and our capacity to cater for local requirements are best-inclass. So we’ll offer the best of both worlds- pan European economies of scale, synergies and efficiencies and localised infrastructure and service provision. Our footprint, of course, continues to evolve. For example, as recently as January, Dole South Africa formed a new partnership agreement with Allesbeste Group in Letaba Pakkers in Tzaneen – a region renowned for the production and export of exceptional avocados from South Africa. This demonstrates, I think our strategic intent to invest in a best-in-class vertically integrated global avocado supply chain and our commitment to becoming Europe’s premier avocado marketer.

Avocado consumption continues to increase globally, but supply is growing at an even faster rate. How will this shape the category over the next few years?

VD: Innovation in the category, and specifically in demand promotion, is key. It is important that as an industry, we are not passive participants when it comes to consumption. This is not something that is out of our hands. There is an onus on us collectively to aggressively promote consumption and reconcile supply.

This can be achieved by the relentless pursuit of ever improving quality and sustainability, constructive collaboration between retail and supplier in creative

OPPOSITE LEFT & ABOVE—Dole says its BE Exotic!-branded avocados and mangoes have been well received

OPPOSITE RIGHT—Vincent Dolan

TOP—Dole’s new avocado packhouse in South Africa

category management and a laser like focus on the consumer, focusing on embracing innovation and imaginative, relevant marketing. In Dole, we’re deeply committed to driving this process.

You launched the new BE Exotic! packaging range at Fruit Logistica. How has it been received by your customers?

VD: We have been hugely encouraged by the response of customers, both current and prospective, at Fruit Logistica, but also since the event. We introduced a comprehensive range of twin-pack, triple-pack and loose solutions for both avocados and mangoes and feedback was overwhelmingly positive.

We were also hearted by how receptive the trade was to the messaging and the marketing communications that accompanied BE Exotic!. We’re trying to do something different with the brand, to speak to the consumer in a contemporary, innovative way and the approach that we’re taking – the imagery, the look and the feel – seemed to resonate.

We were particularly pleased with the response to

our mono-material cardboard twin pack avocado. Enormous effort went into its development, specifically in relation to maximising visibility of product without compromising the protection afforded to the avocados inside, so it was gratifying to see it being so warmly received.

We think that combined, the package that BE Exotic! offers: the supply chain story underpinning it; innovative, striking, sustainable packaging; its fun message, and of course the underlying quality endorsement by Dole, a trusted and recognised name across Europe, is unique in the marketplace so we harbour high ambitions for the brand going forward.

Finally, how are you planning to develop the BE Exotic! brand in the next few years? Can we expect to see new products added going forward?

VD: For now, our focus is on the avocado and mango categories. We will certainly be spending 2023 focusing exclusively on these product lines; promoting the brand in key markets and supporting it at a pan-European level through innovative promotional campaigns. However, the brand lends itself to wider application, and in Dole we are committed to extending its application to a wider suite of products. Should opportunities arise in the future where the quality and sustainability profiles of other products meet the specifications and values of the BE Exotic! brand, there is definitely potential for extension.

Adriëlle Dankier, chief executive of Europe’s largest avocado importer Nature’s Pride, considers the market opportunity in 2023 and the impact of recent cost inflation.

by Mike Knowles @mikefruitnet

by Mike Knowles @mikefruitnet

How do things look for the avocado market in Europe as it heads into spring and summer?

Adriëlle Dankier: Peru will have 10-15 per cent more availability, main increase in the early season which is known for the smaller sizes. South Africa also has 5 per cent more. So, as of May you will see good availability and the price level will go down.

Will we see more marketing activity from Nature’s Pride?

AD: There are lots of promotion possibilities. We will do promotions in different ways with all our customers. In May and June we will also promote through our All Day Avocado campaign to inspire consumption at different times of the day. This will be mainly in the Netherlands, Scandinavia, Germany and Belgium, plus some in Eastern Europe, which is definitely where the consumption growth could be.

What impact has the recent cost inflation had on your business? You have high energy costs, for example to run your ripening and coldstorage facilities. How can you keep those costs under control?

AD: At Nature’s Pride we have worked very hard to make our own

internal process as lean as possible and we have paid careful a ention to our costs and chain efficiencies. Because of our significant higher costs - labour, transport, energy –and inflation, we had to increase our prices last year. What we need to do together is to look at efficiencies in the full value chain, to make sure we don’t have to pass all of that on to the consumer.

What about the impact of higher costs on the international avocado market itself? How significant have those increases been?

AD: Last year saw the highest peak in terms of cost. Consumption of avocados did not drop, but it did stagger a li le bit. It didn’t grow

moment very reliant on the US and on Europe. And Europe can only eat so much.

What about Asia? Do you think markets like China or India can provide more of an outlet and help to balance global supply and demand?

by the 12 per cent that everybody expected it to grow every year. So now there is more production growth than there is consumption growth. We have to pay a ention to that. Peru will look at different possible countries to send their product to, because they are at this

AD: The Chinese market didn’t grow that much. India on the other hand has a lot of people and the potential growth is significant. That makes it a good possibility. And it’s just what we need, a balancing out of avocado consumption throughout the different countries of the world and of course focus on growing European consumption. That’s super important.

We have made our own internal process as lean as possible and we have paid a ention to our costs and efficiencies

What’s in store for Europe’s biggest avocado producer? Fresh Focus Avocado catches up with Enrique Colilles,

by Maura Maxwell @maurafruitnet

by Maura Maxwell @maurafruitnet

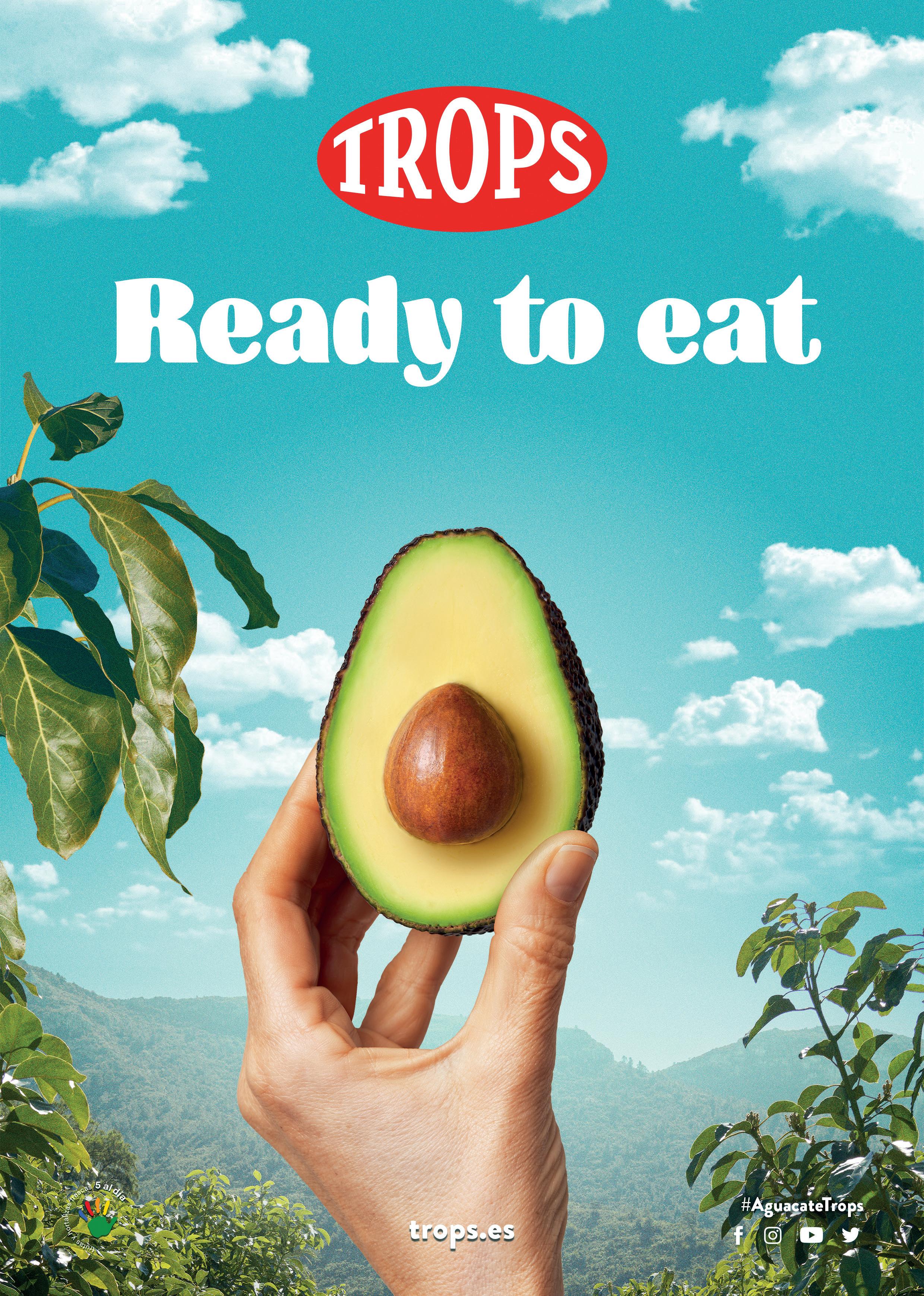

Last year, Trops signed collaboration agreements with two Spanish companies, Cooperativa Agrícola de Callosa d’en Sarrià y Única. Why do you see it as important to consolidate your coverage of the Iberian Peninsula?

Enrique Colilles: Trops is Europe’s biggest avocado and mango company. We have farmers all over the Iberian Peninsula, as well as in South America. Our commitment to quality means having the best fruit available to enjoy at the optimal moment of consumption. We can only do that across 12 months of the year if we have the breadth and scale of growers within the group, all working under the same quality parameters, and with our full oversight of the agricultural and post-harvest process.

There has been a sharp drop in avocado production in Spain, Morocco and Portugal this season. Does that mean that we’re seeing good prices in Europe at the moment? Has the cost-of-living crisis dampened demand?

EC: The drop in production is normal given that this was an off-year. But the drought has undoubtedly affected production in some

areas. There is an expectation that the economic crisis will impact consumption. However, as a wellestablished brand, even in this scenario we’re unable to meet demand.

Oversupply is becoming an increasingly common feature of the European avocado market at certain times of the year. As the continent’s largest supplier, how do you think this situation will play out over the coming years?

EC: At Trops we’re investing very intensively in research and innovation to improve our harvest and post-harvest processes. We also carry out extensive marketing campaigns that help to li demand for our avocados throughout the year and generate brand loyalty. Consumers know they can trust our brand, while retailers know they will have fewer losses, higher turnover and see more repeat purchases.

Avocado consumption is growing in Europe, but the global supply is growing faster. What is the best way to stimulate demand so that the market can absorb all this additional volume?

EC: In two ways: firstly, by investing in more promotional activities to increase consumption and secondly is by ensuring that the avocado that the consumer buys is always good. Trops has prioritised both these elements for more than 15 years and

we’re achieving great results with this strategy.

What about processed avocado products, like IQF, guacamole or avocado oil? Is this a growing part of the business?

EC: Absolutely, it is a complementary and necessary part of the business. Lots of people consume avocados in the form of pastas, sauces, guacamole – and we can make the job easier for them! Sales of processed avocado products like guacamole are growing year a er. But I don’t see a great future in the frozen sector as this is a commodity that moves exclusively by price and there is no margin in it.

Are there any factors holding back the development of Spain’s avocado sector?

EC: It’s true to say that up to now we have not built an adequate water infrastructure, we simply collect rainwater and what we do not use we throw into the sea. But that is starting to change and in a few years, as water availability improves, we will see an exponential rise in avocado plantings. Being able to grow more fruit in the same geographic market will bring unbeatable competitive advantages.

company’s avocado output is on an impressive growth trajectory.

To handle its ever-growing output, Global Avocados has embarked on a major expansion programme at its state-of-the-art packhouse in Tavira. Equipped with a six-line calibrating machine able to process 200 tonnes of avocados a day, the facility will soon count on four new ripening rooms, new flow pack and bagging machines and extra coldstorage capacity.

by Maura Maxwell @maurafruitnetGlobal Avocados is a company with big ambitions. Set up in 2020 by three avocado growers from the Algarve in Portugal who wanted to start exporting directly rather than selling their fruit through a third party, the company is scaling up its production and investing in new ripening and packing infrastructure in response to

strong demand from its European customers.

The group has 850ha of own production extending from the Spanish border right across the Algarve to Lagos city, in addition to which it counts on 150ha of production from strategic partners in the region. With plans to increase its acreage to up to 1,400ha in the next few years, the

“This season we’ll reach a volume of 4,000 tonnes, climbing to 6,000 tonnes next year and 12,000 tonnes within three years,” says Hugo Melita, one of the partners behind the venture. “Around 70 per cent of our fields are young trees so there’s plenty of potential to increase production.”

The bulk of the company’s sales go to European markets like France, Switzerland, the Netherlands, Italy, Spain, Germany and the UK among others, where it has already built up a strong customer base. Melita also sees excellent potential to develop the Portuguese market where he hopes to establish Global Avocados as one of the country’s main suppliers.

“Conditions in Portugal are well suited to growing avocados sustainably. The trees are very well adapted to our climate and don’t require much water, and fruit can be on the supermarket shelf within four or five days of harvesting,” he says.

The favourable climate also means the company can limit its use of chemical inputs. It has stopped applying herbicides altogether, instead opting to remove weeds mechanically. And since it only needs to apply pesticides once or twice a year, it has decided to begin certifying its production under the Zerya zero residue accreditation system.

“We follow high sustainability standards and as such take agri-tech very seriously,” says Melita. “For example, all our fields are equipped with humidity and nutrient probes which allows us to make be er decisions about when to water and feed the trees.”

The company is also in the process of obtaining GlobalGAP’s Spring and BioDiversity add-ons and has started to convert one of the fields to organic production.

“When we see the climate change that is happening all over the world and particularly in the Málaga region, where the growers are being affected by a severe drought, it is clear that governments need to take action to protect food supply, such as building new water reservoirs and desalinisation plants, and promoting agri-tech farming,” Melita says. “A growing company like Global Avocados is always the first to be concern about being sustainable because our future depends on it.”

Sustainable production with a strong focus on quality and consistency underpin the company’s philosophy.

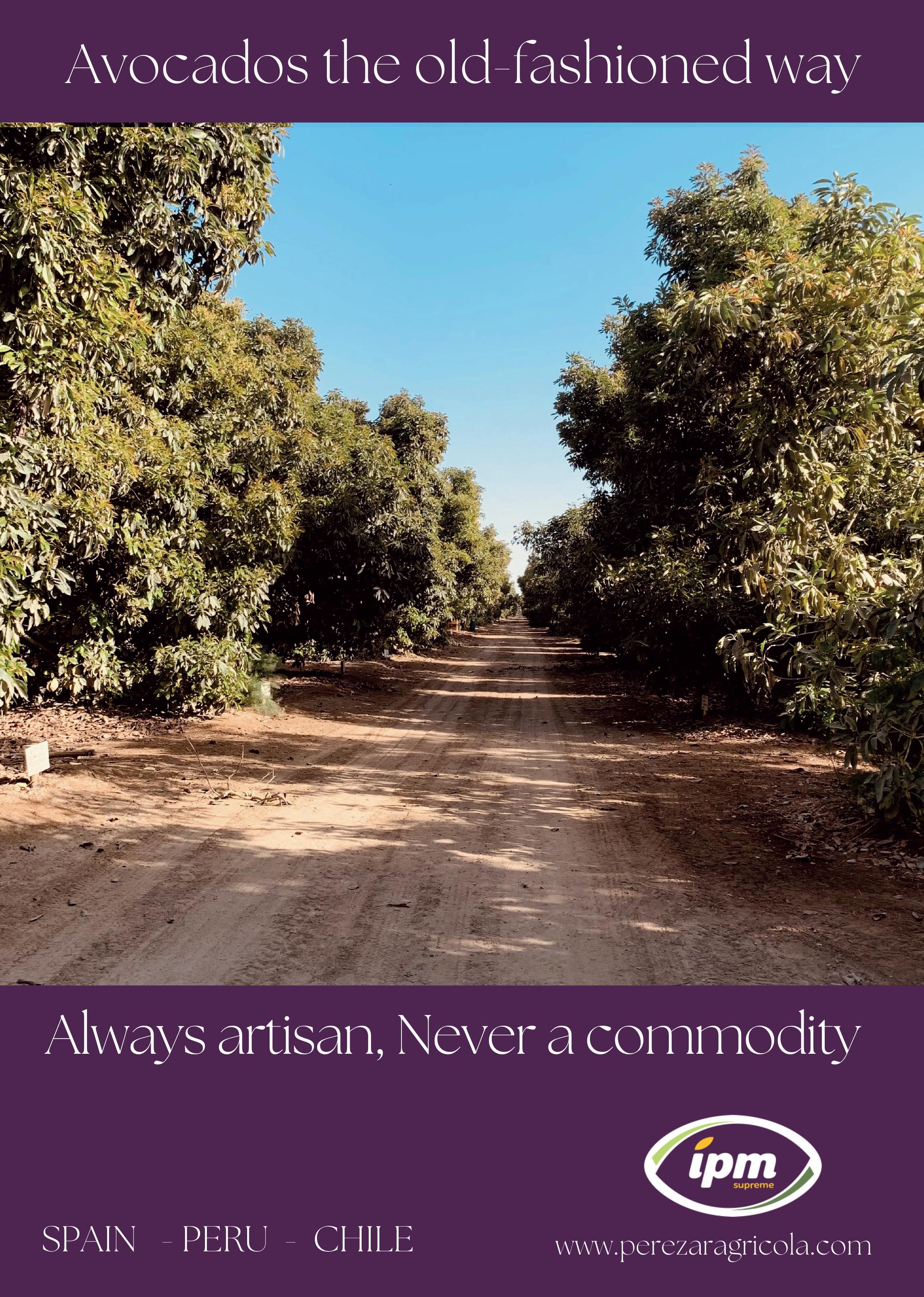

by Maura Maxwell @maurafruitnetLocated in the Guadiaro Valley in the Spanish province of Cádiz – an area blessed with fertile limestone soil and an abundant supply of water, familyrun Pérez Zara Agrícola started out as a citrus producer before moving into avocados as Spanish production spread steadily along the Andalusian and Mediterranean coastlines. Today it has built a year-round Hass programme, supplementing its own production with locally sourced fruit from third party growers and imports from Peru and Chile.

“We handle around 5,000 tonnes of avocados a year and our distribution is strictly private label, mainly pre-ripened and focused on southern Europe and small companies who share a similar philosophy of quality, rather than quantity,” says partner Hugo Steeds. “In an overcrowded market with

a cacophony of mediocre supply, our objective is to deliver a truly superior eating avocado, sourced and delivered sustainably.”

Over the past decade avocado demand has consistently outstripped supply, causing strong retail prices and a ractive returns for producers. But Steeds acknowledges that as supply catches up – and eventually overtakes – demand, price volatility and instability will become more common features of the market.

“To stimulate demand, a product needs to offer stability in price and be consistent in quality. The danger is that as producing avocados becomes less profitable and the cost of inputs such as fertiliser and labour rise with inflation, producer margins will shrink and force growers to seek out efficiencies, cut corners, and cause a further downturn in quality,” he warns.

BELOW LEFT— The company handles around 5,000 tonnes of avocados a year

BELOW—The team at Pérez Zara Agrícola

Instead, he believes the supply chain must become even more efficient in delivering a more consistent quality product. “As a vertically-integrated company with a strong focus on quality and sustainability, we are able to offer all of this, guaranteeing exceptional fruit, week a er week.”

Over the short to medium-term, Steeds anticipates a bumpy ride in the European market, especially in the spring and summer window, noting that “price volatility is indicative of an industry entering a boom-and-bust cycle”.

He also points out that while Europe’s per capita consumption is relatively low at an average of 1.6kg, it is wrong to assume that it will continue to increase to US levels of 3.9kg per capita.

“Recent years have seen a marked slowdown in growth, which suggests a different story,” he says. “Mexico, with nearly 270,000ha under production, represents a fortress-like 90 per cent of US avocado purchases. This dynamic forces Southern Hemisphere sources to divert volumes to Europe with li le or no other diversification on offer.”

Steeds would like to see a slowdown in the proliferation of uncontrolled planting worldwide so that global supply can be properly regulated.

As well as aiming for price stability and improved quality, he says the industry must become more sustainable, radically reducing waste and cu ing its water footprint. “If this is supported with the right promotions and marketing and a renewed focus on quality, then consumers will regain the confidence they have lost in our product,” he concludes.

Avocados From Mexico (AFM) has achieved what very few fresh produce brands manage to accomplish. In the ten years since its launch it has become one of America’s bestknown consumer brands, picking up numerous accolades and awards for its innovative marketing campaigns along the way and helping to lift US avocado consumption to over 9lb per capita.

The figures are staggering: US imports of Mexican avocados doubled from 544,000 tonnes in 2014 to 1.09m tonnes in 2021 and today more than 80 per cent of all the avocados sold in the US carry the AFM label.

“Since we began in 2013, we have worked hard to inspire good taste, good health and good times,” says AFM’s CEO Alvaro Luque. “We are charged with the dual responsibility of building a brand for Mexican avocados and driving avocado consumption in the US. As a result of our efforts and our marketing programme, we have increased brand preference for AFM from 20 per cent to 60 per cent and have continued to grow

the demand for avocados.”

Luque puts the rise in US avocado sales down to a number of factors, including the growth of the Hispanic population, increased use of avocados by restaurants, consumer trends toward ethnic and healthpromoting foods and increased awareness of the fruit’s health benefits.

Increased availability is also helping to fuel the expansion of the US market. Until recently, all of the Mexican avocados sold in the US came from Michoacán. However, in 2021 the state of Jalisco was authorised to export north of the border, with the first delivery arriving in August of last year.

“The recent addition of avocados from Jalisco strengthens supply during the summer and further enhances the industry’s ability to meet year-round demand,” says Luque. “Our Mexican avocado import programme now integrates more than 600 growers and 11 packers from Jalisco and depending on the crop, the state represents roughly 8 per cent of Mexico’s total import volume.”

As well as its consumer

programmes, a key strand of AFM’s work is to develop avocado sales in other channels like foodservice. Thanks to the fruit’s versatility, avocado menu usage is increasing all the time. According to Luque, over 54 per cent of menus in the US now feature avocados, with further potential to expand this channel.

ABOVE—Alvaro Luque has been at the helm of AFM for 10 years OPPOSITE—AFM’s Avocado Glow home and kitchen accessories line

“With the recent emphasis on SKU rationalisation, restaurants want to ensure multiple uses for every ingredient they keep back of house, and avocados are no different. The good news is they are extremely versatile,” he says.

AFM has a foodservice team on

“The recent addition of Jalisco strengthens summer supply and enhances the industry’s abililty to meet year-round demand”CEO Alvaro Luque tells Fresh Focus Avocado how Avocados From Mexico became one of the most successful consumer brands in the US.

hand to highlight the benefits of fresh avocados and make it easy for foodservice operators to add them to their menus. It offers a wide range of educational resources, from collateral and virtual training on its website to personalised, in-person Avocado University sessions hosted at AFMs state-of-the-art culinary centre or on-site at its foodservice partners’ locations.

custom marketing programmes for our top operator partners and unique customer experiences in the food service space to drive inspiration and innovation including Made in Mexico tours, Trend Tours and our concession programmes. And we’ve developed leading research for the industry to establish ourselves as a go-to information source.”

One of the highlights of AFM’s marketing programme is its Big Game TV advert – and this year’s didn’t disappoint. Around 113,000 tonnes of avocados are shipped from Mexico to the US every year during the four weeks leading up to the Big Game in February, or, as Luque puts it, “enough avocados to cover a football field with more than 75 feet of guacamole!”.

This year’s ad featured comedy actress Anna Faris as Eve in a twist on the biblical story of original sin. In the 30-second spot, Faris takes an avocado from the garden of Eden after the apple, triggering a vision of a future avocado-based utopia where New York City is nicknamed the “Big Avocado” and an Apple-like tech giant named Avocado.

The ad was part of a 360 multisensory marketing campaign featuring shopper promotions, a new AFM Pantone colour and the release of an Avocado Glow home and kitchen accessories line (pictured left).

“The Big Game represents a great opportunity for AFM. We are not only the dominant player, with more than 95 per cent of the market in January and February, but we are also one of the few brands that are on the consumers’ tables at the time they are watching the game – because there’s not football without guac,” says Luque.

Plus, it provides free guides on how to select the right avocados, how to store them to ensure peak ripeness, how to handle them back of house, and much more.

The AFM team also hosts customised ideation sessions to identify and validate new concepts that will work best in restaurants.

“There are so many factors eating away at restaurants’ bottom lines, including inflation and labour challenges, so one of our key focus areas right now is highlighting the profitability that fresh avocados can add to the menu,” explains Luque.

“For example, a recent Datassential study found that consumers are willing to pay US$2.50 more on average to add fresh avocado to a hot sandwich.

“Additionally, we have developed

Few marketing organisations can match the scale and breadth of AFM’s activities, and these do not come cheap. Fortunately, the Mexican Hass Avocado Importers Association (MHAIA), and Association of Avocado Exporting Producers & Packers of Mexico (APEAM), the two bodies behind the brand, have the resources to fund these activities thanks to year after year of profitable growth that AFM helps deliver, not just for the Mexican avocado industry but for the economies of both countries.

According to a study carried out by Texas A&M University for the 2021/22 growing season, imports of Mexican Hass avocados to the US generated US$11.2bn in economic output, including US$6.1bn to US GDP, US$3.9bn in labour income and

US$1.3bn in taxes. In that year, the industry accounted for 58,299 US jobs and approximately 78,000 direct and permanent jobs and more than 300,000 indirect and seasonal jobs in Mexico. And Luque is confident that the US imports of Mexican avocados will keep on growing in the coming years. “AFM is prepared to meet these needs. In fact, Michoacan is the only place in the world where avocados bloom year-round making it the perfect fit for meeting growing US demand,” he says.

With US per capita consumption projected to hit almost 5kg by 2026, Latin American suppliers are jostling for position to grab a slice of the action.

by Jeff LongFew produce categories have seen as great an increase in consumption over the last two decades as avocados. Driven by the fruit’s outstanding health attributes, avocados are projected to become within a few years the world’s second-most-traded tropical fruit for volume, trailing only bananas. As of 2022, the Hass variety reportedly comprised 80 per cent of the US$14bn global avocado production.

One of the largest markets for Hass is the US. Since the turn of the century, Americans have had a budding love affair with the pebbly fruit. The USDA’s Economic Research Service (ERS) currently measures US per capita consumption at more than 4kg – up from 0.81kg in 1999. America’s appetite for Hass is expected to continue unabated and could reach almost 5kg per capita by 2026, according to a recent Rabobank report. And the fact that about 40 per cent of US households have yet to purchase avocados leads Rabobank to conclude that “there is still room for growth.”

The growth of the US market can be directly traced to the USDA’s decision to readmit Mexicangrown fruit in 1997 after 83 years of prohibition due to pest issues.

Since then, imports of Mexican Hass have grown from roughly 4,100 tonnes to more than 946,500 tonnes as of 2022. Barring interruption of production from weather or international politics, Mexico’s Hass exports to the US will likely top the 1m-tonne mark in 2023.

Prior to 1997, California was America’s primary source for Hass, supplemented by seasonal imports from Chile. Since then, California’s production has been limited by climatic conditions as well as rising costs for water, labour and energy, while more Chilean fruit remains at home every year due to rising domestic demand.

If avocado consumption is going to continue to grow in the US, however, additional sources

will need to be found. The Mexican state of Michoacán currently accounts for 75 per cent of Hass production, with more acreage steadily added every year despite concerns over loss of habitat for endangered species, such as the monarch butterfly.

After years of delay, Jalisco-grown avocados also finally gained access to the US market. Although far smaller in production than Michoacan, Jalisco represents a significant new source for Hass-hungry America that will continue to expand as additional acreage is certified. The fact that Jalisco’s season happens to fall when Michoacan production is at a low ebb makes it all the more lucrative for its growers.

First permitted market access in 2010, Peru has since emerged as the second-leading source of Hass avocados to the US with exports of nearly 122,000 tonnes last year. Spurred by booming global consumption and advantageous agricultural laws, the Peruvian industry had been on a planting binge during the last decade, adding between 4,000-5,000ha of new acreage annually. A recent repeal of the ag-friendly legislation has caused the Peruvian growers to all but

cease planting additional acreage and look to neighbouring Colombia and Ecuador for expansion. Although as much as 10,000ha are expected to come into bearing during 2023, unless the favourable laws are reinstated Peru’s avocado production may level off in future seasons.

Colombia is the newest player in the US Hass avocado supply picture. First granted market access in 2018, the South American nation upped its exports by more than 500 per cent in 2022 to 19,500 tonnes. Colombia is an intriguing region for Hass production as it offers multiple growing zones that allow for nearly year-round harvests. However, there are obstacles to developing the kind of large-scale operations that characterise the Peruvian and Chilean industries.

Much of the initial acreage planted across Colombia was on quite steep terrain rendering relatively small holdings managed by farmers generally unfamiliar with cultural practices for the Hass variety. Nevertheless, USDA-certified acreage continues to expand with every season, leading the Colombia Avocado Board to predict that exports to the US market will likely double in 2023.

So it would appear that there is likely to be ample production becoming available within the Western Hemisphere through the balance of the decade to feed America’s growing avocado habit. Could there be too much fruit in US distribution channels to the point where supply outpaces demand? If that turns out to be the case, it may not be a bad thing.

Waiting in the wings for US access are Ecuador and Guatemala – both of which are expected to receive USDA approval soon. While Ecuador’s avocado production is relatively small, Guatemala’s industry is well established, with acreage reportedly of around 15,000ha, placing not far below California.

“More and more (Hass) avocados are being grown worldwide every year, which means even more fruit will be coming to the US in the future,” says an executive with a major California avocado marketer who preferred to speak off the record. “The question is: Will prices go down substantially or not as much (as it has historically) due to the increased demand?”

Peru, which gained market access in 2010, has emerged as the second-biggest supplier of Hass to the US after Mexico

Thanks to its ability to supply the market year-round, the company is seeing strong sales growth in Europe and the US.

by Maura Maxwell @maurafruitnetCartama has been at the forefront of Colombia’s avocado export boom since its establishment in 2000. Today, the fully vertically-integrated company supplies Hass avocados to customers worldwide through 52 weeks a year. Last year alone the company’s saw a 51 per cent jump in exports – despite Colombia’s overall shipment volume contracting by 8 per cent due to excessive rainfall. And with plans to add another 2,000ha of new acreage, the company is set to smash its shipment record in 2023.

“We’re seeing strong demand in the European market, which we serve through our sales office in the Netherlands, as supply from other origins is quite low,” says CEO Ricardo Uribe. “Peru is beginning to load, but there’s a new requirement there for fruit to have a minimum of 21.5 per cent dry ma er and this has delayed the start of their season. We therefore expect to have a good window with strong prices until around week 19.”

However, Uribe foresees a much more complicated scenario in Europe as we head towards summer. Peru is on course to ship around 640,000 tonnes this year, a considerable jump on last year’s 550,000-tonne total. At the same time, there’s a big question mark over the extent to which the cost-of-living crisis will affect consumer spending. “This is where our partnerships are going

to really come into their own,” he says. “If you have fixed programmes I think you will do much be er than on the spot market. That’s going to be a blood bath.”

Conditions at home are equally challenging. With Colombia’s inflation currently running at almost 14 per cent and interest rates at 18-19 per cent, producers are feeling the squeeze. Fortunately, the recent 20 per cent devaluation in the Colombian peso, is compensating somewhat for the inflation. And while Cartama is forging ahead with its expansion plans, Uribe says he is keeping a watchful eye on every dollar of investment. Right now the company is in the process of building a new US$22m packhouse, which will be ready by the end of 2024, as well as expanding its nursery operation.

“You can see some companies in Colombia beginning to slow down,” Uribe says. “Our strategy reinforces the vision we had to be a fully vertically-integrated business from producing the seed right through to marketing. This is going to be a big plus for Cartama.”

Going forward, he foresees a greater focus on the US market, both for Cartama and Colombia as a whole. Until recently, around 90 per cent of Colombian Hass avocados used to end up in Europe but now the figure has dropped to around 70 per cent, with most of the remainder going to the US.

“Colombia is in a great position to serve the US market as we’re only three days away from the East Coast, giving us a big competitive advantage over Mexico,” Uribe explains. “We currently do about 10 loads per week to the US and this will keep on growing. Europe will continue to be our main market but the ratio will be around 60:40 in the long term.”

For now, the company’s focus remains on sustainability and growth. Cartama was the fi rst Colombian avocado producer to achieve BCorp certification, and this year it will be increasing its investment into solar panels.

“In everything we do it’s important for us to have a positive impact on our community and environment and we want to continue along that path,” Uribe says.

The company is exploring new markets as its avocado output continues to grow.

by Maura Maxwell @maurafruitnetPeru is on course to export 624,000 tonnes of Hass avocados in 2023, according to ProHass. This is an increase of 12.5 per cent increase on last year’s total and almost double the 338,549 tonnes shipped in 2018.

ProHass’s president, Carlos Paredes, says supply will have to be managed in a responsible way to ensure a profitable campaign. “What is important is that this volume is shipped at an orderly pace and that we avoid supply peaks concentrated in a few weeks,” he said.

Paredes notes that 2023 is different from previous campaigns as the past couple of months has seen lower volumes from Spain, South Africa, Israel and other African countries, ensuring a relatively undersupplied market where Peruvian shipments get underway.

Peru is set for a big increase in avocado volumes in 2023, ushering in what is shaping up to be a challenging European market in the spring/ summer window, according to Sergio Torres, senior vice president of Camposol.

“Mexico is back up to full production – and with Jalisco now also able to supply the US market, Peruvian shippers will have very limited options in North America so we can expect to see heavy volumes in Europe,” he tells Fresh Focus Avocado. “We’ll also see an earlier start to the Peruvian deal, with sustained volumes expected from April through to August.”

This means, Torres says, that European retailers will likely have to fall back on regular promotions throughout the summer.

This upcoming season Camposol anticipates a 25 per cent increase in its avocado production.

In addition to its farms in Peru the company has its own Hass production base in Colombia and sources from producers in Spain, Portugal and Morocco to complete its year-round supply.

According to Torres, production at the company’s Colombian farms is expected to be in full swing by 2025. “As Colombia’s avocado output grows this will put extra pressure on Peru,” he notes. “Peru has around 30,000ha of avocado production, and more and more of these are reaching full maturity each year,

Moreover, he says the focus should be on achieving a better spread of shipments between the different markets, with less volume concentrated on the European market and more to the US and Asia.

which means even bigger volumes will come on stream in the next few years.

“Yes, demand is increasing, but in Europe this is being outpaced by supply in specific windows, namely Peru’s, so more will have to be done to boost consumption.”

To ease pressure on traditional markets, Camposol is working hard to develop new outlets for its avocados. Latin America, the Middle East and North Africa are all within its sights, while in Europe, the company sees good potential in countries like Italy and Poland where consumption is increasing steadily.

At the same time, Camposol says it is looking at new options in the processed sector such as IQF.

ABOVE LEFT— Camposol has its own avocado farms in Peru and Colombia

“Peru will have limited options in North America so we can expect to see heavy volumes heading to Europe”

Eurofruit app is available for download, try it for free now!

Fred Searle talks to Paul Devlin and Ayanda Kanana of South African avocado grower and global marketer Halls to hear how they think the industry should respond to the likelihood of an oversupplied global market in 2023.

by Fred Searle @fredfruitnet

by Fred Searle @fredfruitnet

Green gold: that is the media tag given to avocados thanks to the huge global demand for the fruit and the relatively high margins (in fresh produce terms) that can be made by producers.

Generally speaking, the past decade has been a story of runaway success for the avocado sector, and over that period, sales have rocketed in Europe and the US thanks to highly effective marketing and media exposure around the fruit’s health benefits and versatility. In the UK alone, retail sales of avocado have leaped from 22.5m kg in the year to 24 May 2015 to 59m kg in the year to 12 June 2022.

Attracted by this exponential sales growth, producers across the world – both old and new – have been getting in on the act by planting vast orchards of Hass avocado for export to lucrative global markets.

Until recently, the general feeling was that demand would not stop growing any time soon. And in some respects, this seemed a fair assumption given the relatively low per capita consumption of avocados. Even in more mature markets like France, Germany, the Netherlands and Scandinavia, the headroom for consumption and penetration growth remains significant.

The avocado industry now appears to have reached a crunch point, however, and this season is going to be a “big test” for the sector, according to Paul Devlin, managing director of Halls International – a major avocado supplier headquartered in South Africa with operations across Europe and China.

At certain points last year, avocado prices fell sharply due to oversupply, not least in Europe. And a more intense scenario looks likely in 2023, with global avocado production forecast to rise again. Global avocado exports could potentially grow by another 10-12 per cent this year, from 2.75m tonnes to a record 3m tonnes. This represents an additional 275,000300,000 tonnes to be marketed globally since all the major producing origins are up this year.

To put that into context, the 2023 export crop from South Africa will be 70,000 tonnes, so substantial extra volume needs to be absorbed.

Peru alone, which has expanded plantings more than any other country in recent years, is on course to export 624,000 tonnes of Hass avocado in 2023, according to ProHass. This is an increase of 12.5 per cent on last year’s total and almost double the 338,549 tonnes shipped in 2018. South Africa, meanwhile, expects to ship around 18m cartons of avocado this year –almost 2m more than in 2022.

“There needs to be a slight recalibration of the narrative to make sure everybody is aware that planting needs to be responsible,” says Devlin. “We’ve got to make sure everybody understands the realities of the industry and is balancing plantings with actual sales. It’s about having accurate data and information for the

industry as a whole. We all require the avocado category to grow, but it must be at sustainable prices, unlike in many periods in the summer of 2022.

“There are a lot of new places around the globe looking to plant, which is great, but I think the ‘green gold’ tag has actually been one of the most damaging things for the fruit. Let’s focus on more data-based factual information rather than making emotional decisions.”

For the past five years, global demand for avocados has exceeded supply, but this year Devlin believes the international avocado industry has reached a “real balancing point of whether supply will outstrip demand”. In a flooded market, the need to produce consistent, highquality avocado is paramount, to ensure repeat purchases. And CEO of Halls Fresh Produce, Ayanda

Kanana, stresses the need for suppliers to “level up” in 2023.

“We believe that even in a flooded market, if the fruit is good quality, we will be able to sell it. We’re not seeing it as a doom and gloom story; we’re seeing it as an opportunity to sharpen our delivery.

“We all have to go back to basics and make sure our farming practices

and the quality we deliver are excellent. If we fault on quality, reliability, or consistency, we will be taken out because there is so much fruit coming. Nobody has time for mistakes.”

As well as offering a more consistent product, there is a growing need to evolve the way avocados are marketed, Devlin adds. “There’s still a lot of work to be done to promote avocados,” he says. “And something we all need to talk about more and take responsibility for – across the industry – is the taste experience for the consumer.”

Most consumers are now aware of avocados’ health benefits, but there is far less marketing focus on the fruit’s flavour profile, Devlin points out. Issues persist around variable product quality, internal defects, and unripe avocados being sent to market.

“Some producers have tried to second-guess the market and

send their fruit when it’s not ready,” he says – and this has put off some consumers from making a repeat purchase. “We can’t just rest on our laurels and say: ‘The market is growing; volumes are growing’. The sector will not continue to grow longer term unless the consumer has that great experience.”

Despite this caveat, Devlin remains bullish that over the next seven years, avocado demand will continue to grow in Europe, the US and other emerging markets in Asia. The world’s most populous country, China, has so far failed to live up to expectations in avocados. In fact, last year it was only the 10th largest import market with per capita consumption reported to be only a fraction of the 4.1kg eaten by the average American. That said, Devlin predicts that China will become the third-biggest market globally by 2030.

When it comes to the UK market, one of the biggest challenges will be negotiating a price point that fairly rewards growers at a time when supply is high and supermarkets are keen to keep down prices as much as possible amid record inflation.

With this in mind, the versatility of avocados could work in the industry’s favour. The fruit’s use in cooking oil, yoghurts, smoothies, cosmetics and a range of other products will allow the sector to absorb some of the extra volume and hopefully go some way to balancing supply and demand.

“With so many avocado products now available, the retail sector could improve cross-selling,” says Devlin, “and that may be an area the sector looks at in more depth to drive sales performance.”

Every little will help as the global avocado trade enters what might prove to be its most challenging year to date.

Mission Produce has announced a joint venture with South African farming company ZZ2 Boerdery (ZZ2) private equity firm Criterion Africa Partners (CAP) to develop avocado production in South Africa. The joint venture company, Selokwe Agri (Selokwe), is expected to expand to over 1,000ha of avocado orchards in the premium growing region of Limpopo, South Africa.

“As global demand for avocados continues to grow, establishing additional sources of owned production through vertical integration is a key element of our sourcing strategy to promote increased supply reliability,” says Steve Barnard, founder and chief executive of Mission Produce.

“South Africa is the second largest exporter of avocados to the European Union and the UK during the summer season. So, our new investment in the region is expected to support our expansion in export markets, especially in

conjunction with the anticipated March opening of our newest forward distribution centre in the UK.”

Mission has partnered with ZZ2 and CAP to vertically integrate its operations in South Africa and leverage the expertise of each shareholder to maximise the production and distribution potential of the region.

CAP established Selokwe as part of its higher and be er use investment strategy, which creates value through the improved utilisation of land, water and labour resources in South Africa and increases employment opportunities in its regional communities.

In addition, ZZ2 brings its expertise in avocado cultivation and environmentally conscious farming to maintain compliance with CAP’s environmental, social and governance standards, including the maintenance of the Global GAP and Sustainability Initiative of South Africa (SIZA) certifications.

“We look forward to deepening our relationships with some of the most well-established, reputable partners in South Africa, the world’s eighth largest exporter of avocados,” said Keith Barnard, senior vice president of sourcing of Mission Produce.

“The avocado seasonality of South Africa extends our supply availability by approximately two-to-three months before Peru’s peak season and is expected to bring a long-term benefit in our ability to offer a yearround supply of ripe Hass avocados.”

ZZ2 has currently developed more than 250ha of avocados at Selokwe, which are expected to be harvested for the first time this 2023 season. Mission has engaged Core Fruit to manage its logistics and transportation to the European market, where the majority of volume from South Africa is planned for distribution.

“The opportunity to grow the avocado market in Europe is significant – in 2022, the EU’s per capita consumption was 3.3lb, compared to the US’ 8.5lb,” added Barnard.

“The addition of a high-quality source to our existing network strengthens Mission Produce’s position as a global market leader and enhances our ability to drive avocado market growth in the EU.”

Avocado demand is growing, albeit at a somewhat slower pace than we’ve seen over the past decade. Where do you see the best opportunities to increase sales in Europe?

Alk Brand: I believe demand will continue to grow in our traditional European markets of the UK, France and so on. But we also see tremendous growth in Italy and Germany. Penetration is still incredibly low in these markets – and avocado consumption per capita is still under 1kg per person per year in Italy – however we see growth of between 10 and 20 per cent in these two countries.

We are also seeing strong growth in Eastern European countries like Poland. Eastern Europe was a relatively late adopter of avocados, but we really see avocados taking their place there and doing very well. I would say there’s especially strong potential in Poland because it’s such a big country, but most Eastern European countries have the ability to take part in this avocado growth.

The UK market had a tough time in the last couple of years but now we’re seeing it in recovery mode. The reasons for the difficult period in Britain are hard to put your finger on. It could be partly Brexit, partly the UK economy being more depressed than in certain other countries – and during Covid, supply chains struggled.

It was sort of a collective thing, but I think we’ve seen the end of that now. Demand has recovered to pre-Covid levels and we’re expecting growth of seven to eight per cent this year. The UK has super retailers; they know their stuff and are putting those tough times behind them.

Despite concerns around oversupply, Alk Brand is full of optimism for the future of the European avocado market. The group CEO at Westfalia Fruit tells Fred Searle where he sees the greatest potential for production and consumption growth.

by Fred Searle @fredfruitnetHow worried are you about the cumulative effect of skyhigh production, energy and logistics costs, as well as squeezed household incomes, given the bigger avocado volumes coming onto the market this year?

AB: From a grower perspective, I am worried because it has been very tough on farms, with very high input costs and incredibly disrupted supply chains – like nobody’s ever seen before. But we’re not only increasing production because we need the product; we’re growing because we care about the communities in our production regions, and we see an enormous responsibility to look after them. Having said that, you can only do that if you get a decent price for your avocados, which was more difficult than normal last year.

Meanwhile, from a consumer point of view, I am worried that not all shoppers can afford the product. But in terms of there being too much supply and not enough demand, I think that’s a temporary thing. As an industry, we have a responsibility to promote the product more.

Without a doubt, consumers are moving to a healthier, more plantbased diet, and avocados are really well suited to that. Most foods are allocated to a specific time of day, whereas avocados are consumed

right through the day and sit well in any diet – be it vegan, vegetarian or meat reduction.

Avocado sourcing regions have never been so diverse. How is that playing out in Westfalia’s own business?

AB: We want to be a supplier for 52 weeks a year. We don’t want to have a break in our supply calendar because consumers want avocados every day, so we have to source from regions that can help us always have that availability.

For climatic reasons things sometimes go wrong in a country –due to droughts, floods or whatever – so we always need to have at least two or three areas that can supply the same supply window.

I think there is huge potential for production growth in Latin America and Africa. And Africa is very understated still in terms of its supply of avocados to the European market.

Westfalia still focuses a lot on Africa, and South Africa in particular supplies large volumes – not only in the middle of the year but also in the early and late windows. We also plant a lot in other parts of Africa, especially Kenya and Tanzania.

When it comes to Latin America, we believe that Colombia will help us fill a window where supply is

lower than at other times of the year. Colombia has been a huge investment for Westfalia since we began growing avocados there in 2016, and we are very focused on developing production.

In addition, we are trialling production in Guatemala and the Dominican Republic. We are testing the water at the moment in these countries to make sure the supply chains are adequate in terms of product quality and logistics.

Then there are the traditional sources of Israel, Spain and Morocco. Morocco is in early development for us. We are developing our grower relationships there and this will help us to ensure 52-week avocado supply.

Westfalia’s research division is the largest privately funded subtropical fruit R&D operation in the world. What advances is it making in tackling the effects of climate change on avocado production?

AB: We are very proud of our research division, Westfalia Technological Services (WTS). The main base is in South Africa in an area called Tzaneen, however we have hubs all over the world, Chile and Colombia being two of them.

We have invested a lot of money in WTS, and a lot of the things it does are very long term – like developing sustainable rootstocks geared to all the different climates we grow in; using less water (30-40 per cent less) through high-level drip irrigation methods; replacing pesticides and herbicides with more environmentally friendly methods; and developing higher-yielding varieties like Gem, which require fewer trees and less growing area.

These things can take up to 20-30 years to commercialise, but they are crucial to the long-term sustainability of the avocado sector.

AB: Our company is very much focused on growth, and to have growth you need the right facilities. At the end of last year, we opened up a beautiful new packhouse in Peru, close to Lima. And I’m very excited that we’re opening another unbelievable new packhouse in Graveson in the south of France. It’s spectacular and has the latest ripening IP. It will help us develop our business in France and enter other markets like Italy and certain parts of Spain. We’re really excited about that.

We are already well established in France – we have the largest avocado market share in the country – but we felt that we needed a second facility that would cover the south of France and enable us to go into Italy and Spain as well. From a business continuity perspective, Graveson will help us take pressure off our facility in Rungis, Paris.

The Graveson site is environmentally well designed, it’s modern, and has been developed with food safety and health and safety in mind. It’s also very convenient because it’s close to the harbour of Marseille, so imports from East Africa will arrive there earlier than if they went through Paris.

OPPOSITE—Alk Brand says having a good spread of sourcing regions is key

TOP—Westfalia has nurseries in Peru as well as South Africa

MIDDLE—Westfalia’s packhouse in Cañete, south of Peru’s capital Lima

BOTTOM—The new packhouse in Graveson will improve links to southern Europe

Following a disappointing 2022 season, the industry expects a rise in volumes this year.

The South African avocado export industry has released its first estimate of the new season, predicting that the country will export around 18m cartons this year. This would mark an increase of nearly 2m cartons, up ten per cent on last year’s 16.3m cartons.

Not only is there a bigger crop, but marketing prospects are also reported to be much better than last year, particularly in the early season. Growers were reportedly keen to get their fruit to market early, with the first containers destined for Europe and the UK leaving South Africa in mid- to late February.

by Fred Meintjes”Our growers are in a confident mood and we are also continuing our efforts to get access to China, Japan and India,” Donkin confirmed. ”We are realistic about these processes and even if we have success this year, we are not likely to ship much fruit.”

10

per cent increase in volumes this year

Derek Donkin, Subtrop CEO, said the estimate was laid out at the first exporter marketing meeting, having earlier been pegged at 17m cartons.

“Growing conditions are very good, recent rains have not affected the fruit and we look forward to a good season,” he said, noting that supplies from Spain, Israel and Morocco were likely to finish early due to shorter crops.

“Peruvian supplies are expected end April and early May, so that leaves the early season for us,” he said.

A good season is required to boost avocado growers, who by all accounts had one of their worst seasons in decades last year.

South Africa has also been boosted further by growth in its domestic market, he outlined.

“We have managed to expand early and late season production by utilising special climatic conditions in certain growing regions,” Donkin added. ”Except for a couple of weeks in January, we are self sufficient un terms of our local market. Novel sales methods, such as the avocado bags, are really taking off.”

TOP—Growing conditions have been good with volumes forecast to climb

A new probe in the distribution and marketing of fresh produce in South Africa will focus attention on the reasons for steep increases in fresh produce prices, while also focusing on the behaviour of growers and retailers.

South Africa’s competition watchdog is set to investigate farmers and retailers in the country as food prices continue to rise at the fastest rate since 2009.

The investigation will include the possibility of uncompetitive behaviour and collusion in the supply chain, including the role of farmers, retailers, and exporters, and how this affects prices.

The focus will reportedly be on avocados, apples, bananas, oranges and other citrus, stonefruit, pears, grapes and nuts, along with vegetables such as potatoes, onions, tomatoes, sweetcorn, carrots and cabbage.

Kenyan avocado producer and exporter Kakuzi enjoyed a successful trading season in 2022, which included important inroads into the Chinese market. In December, the company scooped a number of awards at the annual Avocado Industry Excellence Awards in Nairobi, including the Avocado Person of the Year award, which went to managing director Christopher Flowers for his invaluable contribution to the

Kenyan avocado industry, his commitment to quality, traceable and sustainable production and his role in bringing Kenyan fruit to China.

“Every fruit we export carries the Kenya quality reputation,” says Flowers. “Both the European and Chinese markets are demanding high-quality fruit, and that’s got to be our enduring objective; giving our customers a fruit they want more of while sustaining Kenya’s market and brand positioning.”

The company also emerged victorious in the grower category, winning the Large-Scale Orchards over 100 Acres award. The company currently boasts 928ha of Hass avocado production, having started planting in 1996.

From January 2022, Kakuzi undertook all the necessary preparatory frameworks ahead of its China market entry, including audits by the Kenya Plant Health Inspectorate Services (Kephis) and the Chinese National Plant

ABOVE—China’s NPPO approved nine packhouses for avocado exports to China »

Protection Organisation (NPPO). NPPO approved 15 orchards, nine packhouses and one fumigation facility, including Kakuzi’s orchards and packhouses for exporting fresh avocados to China.

Flowers says shipments to China are providing much-needed growth leverage for Kenyan produce and for Kakuzi as it seeks to expand its markets.

The first Kakuzi avocados were dispatched from Mombasa to China, where they were stocked at the Shanghai Huizhan Fruit and Vegetable Wholesale Market, making Kakuzi the first African firm to officially undertake commercial sales of avocados on Chinese soil.

“Discerning Chinese consumers have woken up to the market availability of the freshest Kakuzi Hass avocado,” says Flowers. “This development officially marks the entry of Kenya as an exporter of quality avocado fruits to China.”

Following the first airfreighted shipment to China in June 2022, Lifan Yu of Halls Fresh Produce, the market agent for Kakuzi in China, predicted an enhancement

of bilateral trade and social relations between the Chinese and Kenyan people. Shipments for the rest of the year were due to travel by sea.

“The Chinese community has been a true friend to the people of Kenya, and this inaugural shipment of fresh avocado fruits will cement these relations,” he said. “At Halls Fresh Produce China, we have been promoting ready-to-eat avocados for several years. Chinese consumers are now more familiar with our quality and premium products as quality, sustainability, and traceability are at the heart of what we do.”

Yu said that the Chinese market required greater supplies of high-quality fruit and more options to enable consumers to

Top executives from Chinese fresh fruit and vegetable importer Dalian Yidu Group toured Kakuzi’s operations in mid-February, according to a report from Capital News. MD Chris Flowers said Kakuzi had invested heavily to ensure compliance with the stringent Chinese market demands, including tree-to-plate traceability protocols.

Kakuzi has also expanded its production to meet the appetite of the China market, adding another 60ha to its existing 927ha of orchards.

“Kakuzi is strategically positioned to provide quality superfoods for the local and export markets,” Flowers said.

“The visit by the team from Dalian Yidu underscores the importance of quality management systems, as such buyers undertake rigorous evaluations to enable them to deliver nothing but the best to their discerning customers.”

Dalian Yidu Group business executive Laura Xu said Dalian Yidu was looking forward to working with Kakuzi, noting the Kenyan exporter aligned with the Chinese company’s supply chain standards.

“Dalian Yidu is proud to be associated with a qualityconscious Kenyan grower such as Kakuzi, producing quality Hass avocados which are in very high demand in China,” Lu said. “Dalian Yidu has been in the Chinese fresh fruit and vegetable import business since 1988 and has developed formidable international sourcing, cold-chain, and related logistical management structures for its fruit and vegetable business.”

purchase avocados all year round at affordable prices. “More consistent availability of quality fruit with the correct dry matter content is essential to ensure we encourage repeat purchases because they have a great taste experience,” he added.

“Both the European and Chinese markets are demanding highquality fruit, and that’s got to be our enduring objective”

In February of 2023 the East African nation began exporting Hass avocados for the very first time. The aim: to establish the country as a trusted supplier and lift small-scale farmers out of poverty.

by Fred Searle @fredfruitnetWith Hass avocado plantings booming across the world – not least in Peru, Colombia and Kenya –you would be forgiven for thinking there wasn’t much need for another country to get in on the act. But outside the summer peak, from May to October, avocado supply to Europe is lower, and buyers are continually looking for new sources in a bid to ensure continuity of supply. This is becoming increasingly important as climate change takes hold, making growing conditions harder to predict.

One country that has just embarked on its own Hass avocado journey is Uganda – and hopes are high that the East African nation can one day become a major player in exports to Europe and beyond. Producers will be looking to emulate the success of neighbouring countries Kenya and Tanzania. Indeed, following rapid expansion in the past decade, Kenya became the world’s sixthlargest producer of avocados in 2020, reaching a volume of 322,000 tonnes, according to The Food and Agriculture Organisation of the UN.

For Uganda, its’s still very early days, and the beginning of 2023 marked the start of its commercial Hass production. Up until now, growers have instead produced local, green-skinned varieties, predominantly for the domestic market and the Middle East. But now there is a government push

in Uganda to boost exports in various fruits and vegetables, and Hass avocado has been identified as a priority crop. It is the avocado variety with the greatest export potential thanks to its longer shelflife, fast tree maturity, and high yields.

Post-Covid, the Ugandan government wants to ramp up exports across a wide range of industries to drive economic growth and recover the 300,000 jobs that are estimated to have been lost during the Covid pandemic.

The stated aim of Uganda’s Presidential Advisory Committee on Exports and Industrial Development (PACEID) is to overcome bottlenecks that prevent the country from “fully harnessing its industrial and export potential”. The body wants to help Uganda double its total national exports from US$6.6bn to US$12bn by 2027. And the fruit and vegetable sector is where PACEID is targeting some of the fastest growth, with ambitions to boost shipments by 60 per cent in that period.

Agricado Farms, an up-andcoming producer and exporter in Uganda’s Central Region, hopes to lead this charge. The supplier, which has GlobalGAP and GRASP certification, is part of a larger group of companies involved in printing and packaging, manufacturing, IT services, and coffee processing.

Its 400-acre farm was set up in 2019 with the aim of producing Hass avocado and macadamia nuts for export to Europe and the Middle East. Having planted its first orchard, the business expects harvesting to begin towards the end of 2024. And in February, Agricado sent its first exports of Hass, grown by a number of smaller growers that supply its packhouse in the capital, Kampala. In addition, the company has started a project to grow, certify and sell its own highquality Hass seedlings.

“Right now, our main market for avocados is the Middle East [mainly Dubai] but we want to try to get them into Europe and potentially the UK,” says company director Aliya Hajee. “We’re already starting to see enquiries from Spain and other parts of Europe, so excitement is growing – both in Uganda and abroad.”

ABOVE—Agricado expects to harvest its very first Hass avocados in late 2024

LEFT—The supplier has already started exporting Hass grown by other producers

OPPOSITE—Aliya Hajee would like to see government support for Ugandan Hass growers

Between 2021 and 2022 Agricado planted 20ha of Hass, with plans to add a further 40ha in 2023 and another 40ha in 2024. And while Hajee waits for these trees to come into production, her business is also growing approximately 14ha of red, green and habanero chillies, for export to the Netherlands and other EU countries.

The limited volume of avocado that the supplier currently receives from external growers means shipping full containers – via the Port of Mobasa in Kenya – isn’t yet possible. But as previously

mentioned, Agricado already airfreights smaller volumes of Hass, as well as local green-skin varieties, to Middle Eastern markets.

“We are currently in the process of mapping our supply,” says Hajee. “A lot of farmers are starting to approach us and say ‘I have 20ha here’ or ‘I have 40ha there’. We’re trying to piece it all together and understand how quickly we can start building up containers. We intend to start shipping containers in 2023.”

When it comes to production, Agricado’s managing director Harald van Aubel believes Uganda is well placed to establish itself on the global market. “Thanks to the diversity of altitudes and seasons in Uganda, we will have avocado all year round, which is quite exceptional from a global point of view,” he says. And given avocado trees’ high water requirement, the country’s two rainy seasons – from March to May and

from September to December –should work in growers’ favour so long as their orchards have proper drainage (to avoid root rot).

With a view to bringing more growers into the fold and delivering agronomy training, Agricado has plans to launch its own ‘outgrowers scheme’ for the other farms that supply it. Hajee says the first steps will be to raise awareness, train growers, grow seedlings, and sell subsidised seedlings to farmers, “so they start to understand the potential around Hass production and how to do it well”.

Asked whether she is concerned by the potential for a flooded international market, both this year and in future, Hajee says the concept of ‘green gold’ is “something we have to monitor”. Nevertheless, she sees clear potential for Uganda, especially in the February-March window when global supply is lower. “I think it will be about finding the right marketing channels and trying to tap into the right supply windows based on the seasonality of Uganda’s different growing regions,” she says.