Making Engineers Champions

TURNING & MILLTURN // MACHINE RANGE

TURNING/MILLTURN // MACHINE RANGE

Making Engineers Champions

TURNING/MILLTURN // MACHINE RANGE

AS-200L:

The AS range of machines delivers powerful milling and turning centre at a competitive cost.

• Faster rapid traverse 24m/min for the X-axis and 36m/min for the Z-axis

• Spindle speed 4500min-1

• Driven-tool speed 6000min-1

• Sub Spindle or Tailstock Option

• Linear Guideways on all axes

• +/- 41mm Y-axis

• Bar capacity 65mm standard. 8” Chuck

• All FANUC, CNC control and servo drives.

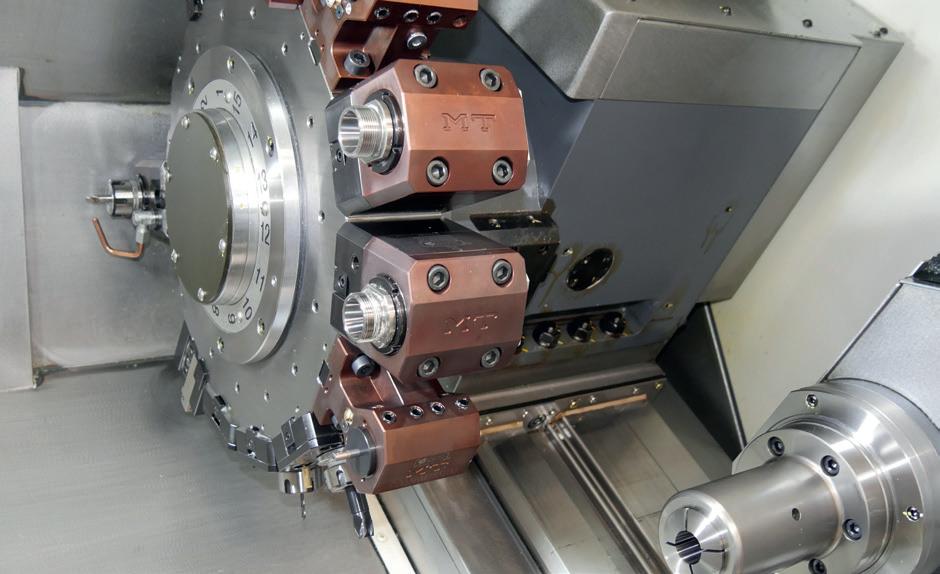

200 – ATC Multi-tasking machine:

Flexible machining with L/R spindles to reduce cycle times

Simultaneous Y axis vertical machining, thanks to its Y-axis travel of ± 105mm on the tool spindle and ± 35mm on the lower turret

Turret centre support on the lower turret is ideal for long workpieces

Max. turning dia. (tool spindle/lower turret)

– compact ATC multi-tasking machine

The Nakamura MX100 is equipped with built-in twin spindles. It is a compact multitasking machine with ATC and Lower turret. Faster cycle times are achieved thanks to simultaneous machining with upper and lower tools on L/R opposed twin-spindles.

The slides, having a vertical column structure, which are mounted on a high rigidity horizontal machine bed with a low gravity design.

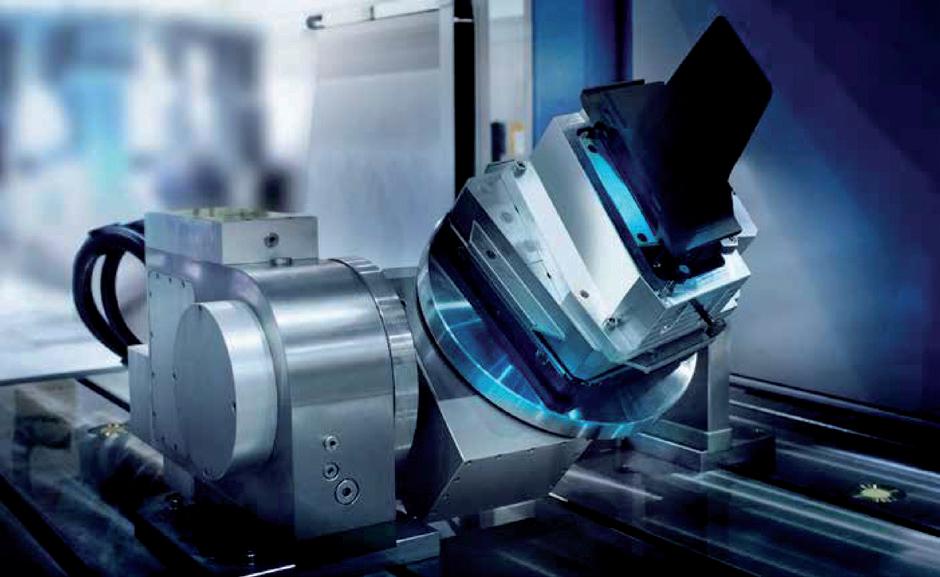

Unique Spindle Technology

Ceramic bearings and Face/ Taper contact as standard Oil cooled Ballscrews, Spindles and housings

Various Spindle speed, power and interface options

Heidenhain, Siemens or Fanuc controls

NT Flex – 2 spindle, 2 turret – multi-tasking lathe:

• High speed indexing

• High speed spindle synchronisation

• Execution of multiple M-codes within the same block

• High speed rigid tapping

• Reduction of PC-G unloading time

• Compact footprint

• Applicable to Oscillation Cutting

• Equip with 3D SmartPro AI

• Applicable to ChronoCut

Please, scan the QR code to search by industry / component.

See this machine in action

Bar capacity 71mm standard

All FANUC, CNC control and servo drives

Dodecagonal 12 station turret

High quality painting, as well as stainless covers 7.1/2.2kW Milling motor / Max. speed 6,000min-1.

Turret Hand Unloading Gripper on Lower Turret.

22/18.5kW Wide-Range motor for powerful cuts

Quicker ‘Non-lift’ turret indexing to cut idle time

Box type slides and rigid turret for high accuracy

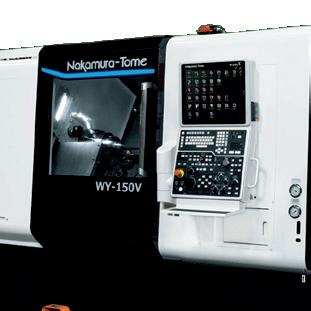

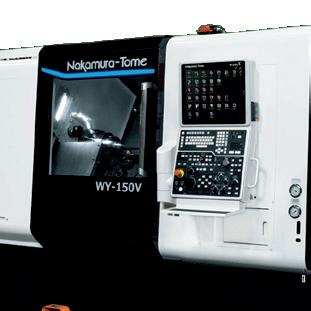

WY-150V:

• A multi-tasking machine with opposed twin spindles and twin turrets, featuring a Y axis on all turrets, as standard

• Reducing cutting oil drastically by applying grease lubrication in all linear axes

DESCRIPTION

Maximum turning diameter 255 mm

Maximum turning length 685 mm

Distance between spindles Max. 970 / Min. 200 mm

Bar capacity L Spindle Ø51 mm Ø65 mm Ø80 mm R Spindle Ø51 mm Ø65

See this machine in action See this machine in action

• High speed indexing

• High speed spindle synchronisation

• Execution of multiple M-codes within the same block

• High speed rigid tapping

High rigidity multi-tasking machine with box-type slides for all axis.

* There is a track record for this specification. Please consult with our sales representatives.

TURNING/MILLTURN // MACHINE RANGE

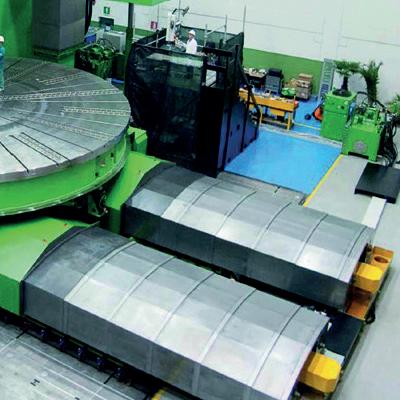

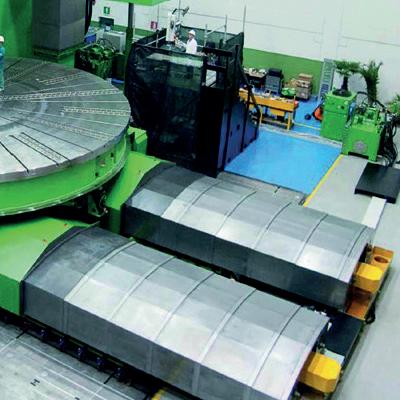

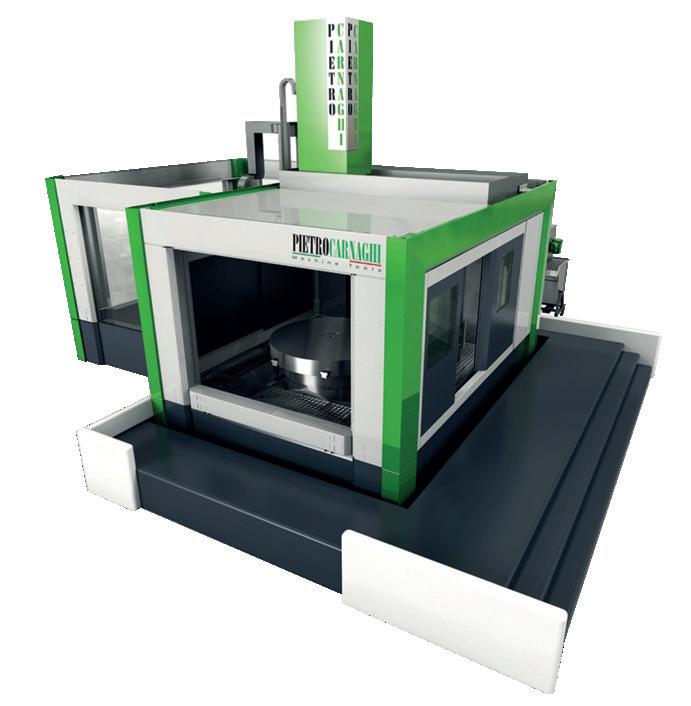

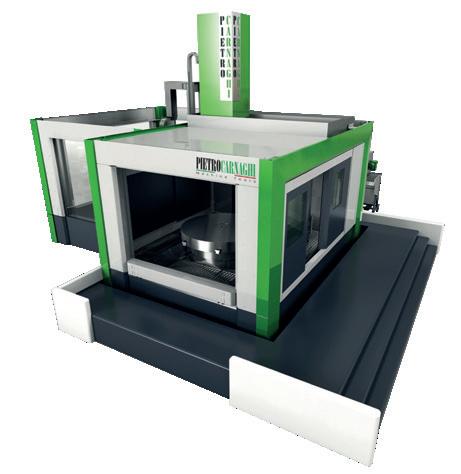

The AC series of vertical turning centre is designed and built with a compact, extremely rigid, thermo-symmetrical structure, featuring either a single or double column mounted to the table base. All structural elements are assembled to create a robust framework that ensures maximum stability and rigidity.

• Dynamicity (40 m/min)

• Precision (up to mm 0,007)

Massive vertical lathes, designed with provision of movable table (Y axis)

Extremely rigid cutting with power up to 300 kW

Hydrostatic axial bearing table for table loads up to 500 ton

Wide range of milling accessories and capability to interpolate up to 5 axes

• High rigidity, perfect thermos-symmetry and high damping capability, using the last temp-controlled systems.

• All the machines are made with cellular construction and evaluated using FEM and Structural optimisation software (Siemens NX CAE).

ETG brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, fabrication machines, automation, laser cutting, wire EDM, workholding systems and industry 4.0 advancements to deliver highly productive and effective metal cutting solutions.

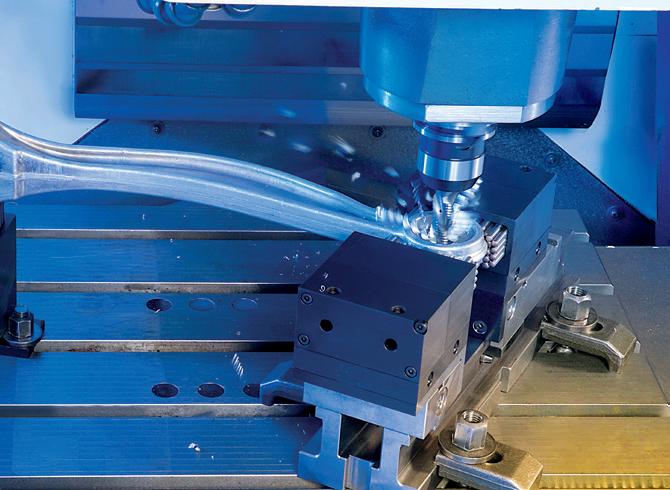

Turning and mill-turn machines play a crucial role in modern manufacturing, offering high precision, efficiency, and flexibility in machining complex parts. Traditional turning machines specialise in rotational operations, while mill-turn machines combine turning and milling capabilities in a single setup.

One of the key advantages of mill-turn machines from ETG, is their multi-tasking functionality, allowing manufacturers to perform milling, drilling, and turning in a single operation. Equipped with Automatic Tool Changers (ATC), these machines can seamlessly switch between different cutting tools without manual intervention, reducing downtime and increasing productivity.

By consolidating multiple processes into one machine, mill-turn technology enhances accuracy, minimises material handling, and significantly shortens lead times. This makes it an ideal solution for manufacturing sectors requiring high-precision components, such as aerospace, automotive, and medical manufacturing.

See the full Nakamura-Tome range of machines available from ETG

ETG’s Turning & Millturn Principals and Associates include: HERE

See the full Pietro Carnaghi range of machines available from ETG TURNING/MILLTURN // MACHINE RANGE

Making Engineers Champions

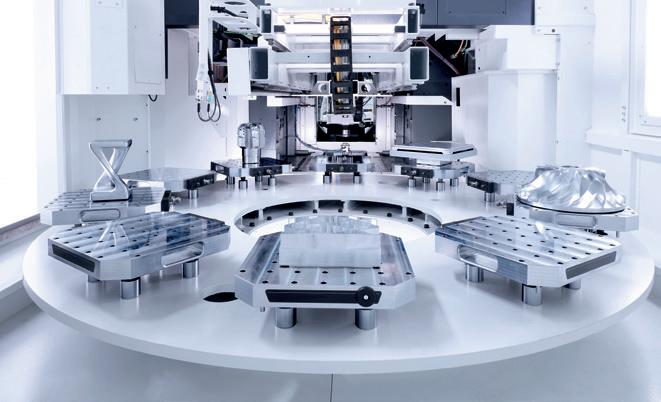

PRISMATIC // MACHINE RANGE

Advantages of the G Series include:

• Perfect U-shape closed-gantry design

• Linear scales in all guideways

• High-performance built-in spindle

• Table moved by swivelling-rotary axes

• Single table and integrated automation options available

• Ultra dynamic A/C axis movement based on torque motor technology

• Large tool magazine as a standard feature

• Up to 1,200mm diameter maximum component size

Advantages of the MF700 Flex include:

• Unique dual table design

• Multi-face or fully functional simultaneous 5 axis capability

• Fanuc, Siemens or Heidenhain control systems available

• 700mm x 700mm VMC table

• Large standard tool magazine with various options

• High specification standard equipment

• Multiple flexible operating configurations

• Proven MF design structure

Advantages of the DC Series include:

Massive bridge supported on a one-piece base casting

Machine body made of high-quality cast iron

3-guided Y-axis carriage to ensure speed and stability

Extremely rigid 4-guided Z-axis Box-in-Box designed RAM

Torque motor driven B (spindle) and C (table) axis

Large tool magazines as standard

Various pallet change solutions

HSK-A63 & HSK-A100 spindle variations available

Advantages of the MV1-3 Series include:

Unique spindle technology

Ceramic bearings and face/taper contact as standard

Oil cooled ballscrews, spindles and housings

Various spindle speed, power and interface options

30 tool magazine positions as standard, can be upgraded to 48 or 60

Heidenhain, Siemens or Fanuc controls

Ergonomic design for easy access

Proven, stable machine structure

PRISMATIC // MACHINE RANGE

Advantages of the Series 19 include:

• Precise, flexible and high-performance machining

• Mobile gantry design for high static and dynamic rigidity

• Best thermal stability thanks to actively cooled drive components

• Gantry round axes with direct torque drive

• Many tools in the machining centre for extensive processing operations

• Easy access to the working area for set-up, automation and crane loading

• Tool change during machine operation for maximum output

• Intuitive operation via TouchLine

Advantages of the Micro 5 include:

Advantages of the Series 16 include:

Highly flexible – due to the modular building block principle: Mobile gantry design

Small footprint even with a large number of tools

Mineral casting machine bed, inherently stiff and vibration-damping

High static and dynamic stiffness

Excellent thermal stability

Highly productive motor spindles

Rotary axes with torque direct drive

A new string to the Chiron bow whilst keeping with traditional values of speed and accuracy. The result of a smart revolution whose exceptional technical performance is made possible by High-Speed Machining (HSM) technology.

Performance:

• Very low measurement dispersion

• Ultra compact machine

• Very Low degree of thermal influence

• Total weight of the axis base: 35kg

Precision:

• Fastnesses < 1 [µm]

• Straightness < 4 [µm]

• Parallelism < 3 [µm]

• Cylinder diameter < 3 [µm]

Advantages of the high-speed Eagle V-Line include:

• True high speed machining technology

• Various spindle configurations available up to 42,000rpm

• Thermo symmetric gantry design

• Optimum performance of footprint to axis travel

• ‘Multitool’ and ‘Multichange’ offer various tooling and automation options and can be combined

• Torque motors on all rotary axis

• Twin ‘Y’ axis drive system

• Fully sealed for dusty materials as well as non-ferrous and hardened ferrous materials

The HBZ® Aerocell ® series is designed for maximum material removal rates, the machining of large aerospace aluminium structural parts. These 5-axis CNC machining centres offer precise cutting with high material removal rates, ensuring optimal productivity in a compact footprint.

• 5-axis HSC horizontal machining

• 5-sided machining in one setup

• Highly dynamic machining of aluminium

• High material removal rate and productivity

• Integrated pallet changing system as standard

• Very high path velocities

• Significant reduction in machining times and costs per piece

• Compact machine design with low space requirement

• Fully enclosed workzone

• Numerous options for automation available

• Reduced downtime with dual workpiece loading

• Proprietary bavius milling head: robust, dynamic, and versatile

• Effective chip and coolant removal via horizontal machining

• Compact design with no special foundation required

• 5-axis HSC horizontal machining for optimum chip management and disposal

• 5-sided machining in one setup

• Highly dynamic machining of aluminium

• High material removal rate and productivity

• High productivity due to Integrated pallet changing system, as standard

• Very high path velocities

• Significant reduction in machining times and costs per piece

High speed milling

When producing large aluminium structural parts the AeroCell horizontal machining centre ensures optimum results from start to finish. High chip removal rates are the result of a machine concept designed for high performance: the synergy between high travel speeds, accelerations, jerk values and high spindle power and speed.

Integrated pallet change

The swivel and rotation function of the space-saving pallet changer with two pallets on the AeroCell allows loading and unloading while production is in progress. This proven bavius concept keeps non-productive time to a minimum!

• Fully enclosed workzone

• Numerous options for automation available

• Reduced downtime with dual workpiece loading

• Proprietary bavius milling head: robust, dynamic, and versatile

• Effective chip and coolant removal via horizontal machining

• Compact design with no special foundation required

• Siemens SINUMERIK ONE control with all its advantages like Digital Twin

ETG brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, fabrication machines, automation, laser cutting, wire EDM, workholding systems and industry 4.0 advancements to deliver highly productive and effective metal cutting solutions.

In the world of advanced manufacturing, prismatic multi-axis machines redefine precision metal cutting by enabling complex geometries, high efficiency, and superior surface finishes. These state-of-the-art CNC systems utilise multiple axes of motion to execute intricate cuts with unmatched accuracy, reducing setup times and enhancing production flexibility. Whether for aerospace, automotive, medical, or industrial applications, multi-axis machining ensures optimal material utilisation and high repeatability, meeting the most demanding industry standards. With innovative tooling and intelligent programming, these machines push the boundaries of modern metal cutting technology, delivering components with exceptional precision, quality and surface finish.

Making Engineers Champions

The MV-S series is made for high cutting speeds with a combination of tight tolerances and low power consumption. With its non-contact Tubular drive and modern technologies, it optimises wire and power consumption. Therefore, these machines ensure economic benefits which pay off, year after year. They are ideal for a reliable man-free operation due to “Intelligent AT” wire threading.

MV-R Series – Power for Precision:

The MV-R Connect delivers <Ra 0.2 * and the perfect blend of performance, precision and ergonomics. Set-up, programming, maintenance etc. – all the key elements are directly accessible at the front of the machine. The entire wire feed, automatic wire threading and wire guide heads plus the whole workspace are readily accessible – not least thanks to the open design and automatic vertical sliding door. *1200 & 2400 size

The MP Series has the highest precision of water wire erosion from Mitsubishi electric with a pitch accuracy of +/- 0.001µm. The high frequency digital fine surface generator produces the best surface finishes available. Ease of access with the 3-sided work tank and all-round casting cooling backed up with the Tubular drive technology with 12-year positional warranty delivers the highest quality and results.

The MX900 is Mitsubishi Electric’s cutting-edge solution for high-performance wire EDM machining in oil to <Ra0.1. Designed to meet the most demanding requirements, the MX900 delivers exceptional precision, smoother surfaces, and enhanced efficiency in every cut. With groundbreaking technology and superior control, it’s the ultimate machine for industries that require flawless precision. The future of precision machining!

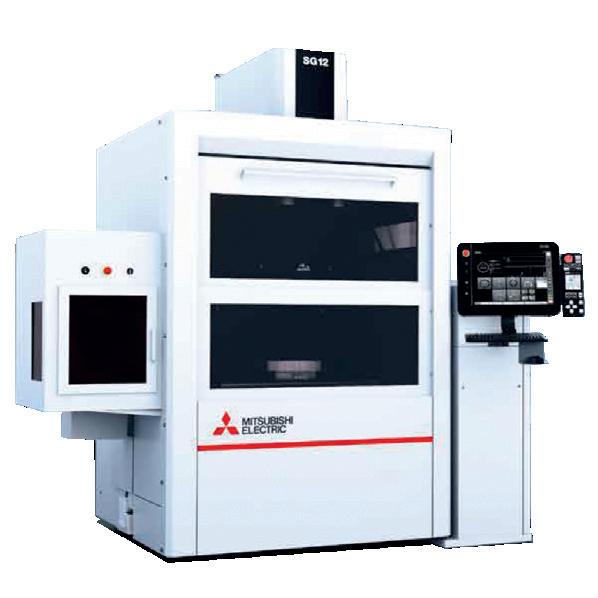

The rock-solid machine base of the SG-Series is your assurance of precision and durability. The choice of high-class components ensures the long-term reliability of the machine system. The simplicity of the control and the programming itself is a hallmark of EDM machines by Mitsubishi Electric. Allowing the operator to focus on the essential, i.e., the proper planning of the various eroding tasks.

The heart of the SG-R is the GV80 generator with 80 A peak power as standard –optionally upgradeable to 120 A. The GV generator is the strong all-rounder; whether maximum performance with minimum wear with graphite electrodes is required in mould making, whether carbide must be economically machined, or even unusual tasks such as the machining of titanium or PCD, the GV generator is ideally equipped for all tasks.

OPS-INGERSOLL are pleased to announce its new range of COMPETITION machines derived from the success of the Gantry Eagle series of EDM die sinkers. Top of the range models included the new fine finishing generator POWERSPARK, together with G5 PRECISION, this technology is now included in the COMPETITION series which also includes the new PowerSpark ONE control.

(depending on model)

The EAGLE G80 Competition is the symbiosis of a large working area and small footprint combined with incredible performance - guaranteeing market success. The successful portal design is the basis for maximum dynamics and demanding requirements with the groundbreaking EAGLE PowerSPARK technology.

The potential of the GANTRY EAGLE 1200 is unique. Thanks to a high traversing speed and EAGLE POWERJUMP it remains dynamic in complex workpieces, while it is designed for efficient machining in the making of large moulds. Despite the different machining capabilities, the GANTRY EAGLE 1200 operates with full precision at an impressive speed.

* Note: The indicated values are maximum values, which may vary according to the clamping system used, standard version. **plus version

The requirements for larger components and precise machining details are met by the new gantry EAGLE 1400. The high traversing speed (EAGLE POWER JUMP) and the EAGLE POWER TEC generator technology enable dynamic and efficient machining of both large moulds and complex workpieces with the GANTRY EAGLE 1400.

(depending on

Travel (X / Y / Z)

Worktank (W x D x H)

Worktable load

Distance electrode clamping chuck to worktable

/ 2350 / 700 mm

/ 2590 / 790 (1015**) mm

* Note: The indicated values are maximum values, which may vary according to the clamping system used, standard version. **plus version

ETG brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, fabrication machines, automation, laser cutting, wire EDM, workholding systems and industry 4.0 advancements to deliver highly productive and effective metal cutting solutions.

Mitsubishi Electric and OPS Ingersoll are industry leaders in Wire EDM (Electrical Discharge Machining) and EDM Sinker technologies, providing precision machining solutions to a wide range of industries. These state-of-the-art machines are trusted by manufacturers worldwide.

With unmatched accuracy, efficiency, and versatility for high-precision manufacturing, some key advantages of EDM include:

• Unparalleled Precision – Achieve tolerances down to the micron level for intricate and delicate components.

• No Mechanical Stress – Non-contact machining eliminates material distortion and ensures superior surface finishes.

• Complex Geometries – Easily create intricate shapes, fine details, and sharp internal corners with extreme accuracy.

• Hard Material Processing – Effortlessly cut tough materials like titanium, carbide, and hardened steels.

• Reduced Waste & Costs – Optimise material usage and minimise secondary finishing processes, improving overall efficiency and electrode usage.

Mitsubishi and OPS Ingersoll EDM solutions empower manufacturers with cutting-edge technology to enhance productivity, quality, and innovation across most business sectors. Call ETG on 01926 818 418 to find out more about wire and die sinker EDM sales, spares, consumables, service and maintenance.

Making Engineers Champions

FABRICATION // MACHINE RANGE

The Durma PB Bending Centre offers maximum speed and safety with fully automatic tool change and minimum set-up time. With the PB Bending Centre, you achieve excellent bending results and increase your production efficiency.

HRB-4 Cylinder Bending machine range:

Durma HRB-4 is developed to give the plates mostly a cylindrical and conical shape. These bending machines are renowned for transforming flat sheet metal into a spherical body. Moreover, it can produce a cone tube body and other various shapes. HRB-4 Roll Bending Machines are productive. They are precise, safer and versatile.

SBT Swing Beam Guillotine Shear machine range:

Equipped with cutting-edge technology, Durma SBT Series Guillotine Shears give excellent results in every type of manufacturing. You can enter all your cutting information with the user-friendly SBT Series interface and achieve perfect cuts.

TP – Hydraulic Punch Press machine range:

Durma TP Hydraulic Punch Presses provide cutting-edge technology and precision in shaping. With features like its precise and fast turret, improved hydraulics and automatic index stations, Durma TP Hydraulic Punch Press produce perfect results.

FABRICATION // MACHINE RANGE

Durma HD-F Laser Cutting Machines stand out due to their fast-cutting technology. They are energy efficient, and thanks to its superior Fiber Laser Cutting technology, easy-to-use products. They have low maintenance costs, and they provide easier manufacturing processes. Durma adds value to your business by providing quality, performance and efficiency. With servo motor driven rack gears motors, Durma HD-F Laser Cutting Machines can reach high acceleration. Durma Lasers are unrivalled with their rigid and modular body structure, excellent filtration system, compact design, efficient and user-friendly structure.

(depending on model)

Durma HD-FO Laser Cutting Machines, stand out with efficiency in manufacturing, as well as their high-quality material construction and industrial design. Loading and unloading of the material that needs to be cut will require less effort when the shuttle table is not necessary. The ease of use, low operating costs, quick-opening top cover, easy access to the cutting area, the compact bridge design and easy transportation of HD-FO Laser Cutting Machine will increase your work efficiency in all areas.

The HD-FN Fibre Laser cutting machine features dual tables that switch automatically, allowing for simultaneous cutting and loading/unloading. Its shuttle table is arranged longitudinally, ensuring optimal accessibility for optional loading and unloading systems. The machine integrates control, laser source, and cooling, while the cutting head includes automatic focus adjustment.

PL-C Plasma Cutting machine range:

FABRICATION // MACHINE RANGE

The Durma PL-C (Compact) Series Plasma Cutting Machine has a modular frame. Modular frames are welded, and stress relief is performed after welding to ensure quality and accuracy. High-quality and precise plasma cutting is possible with double-sided synchronised gap-free planetary reducers that offer high precision.

AD-S Ad Servo Press Brake Machine

With Durma’s AD-S Hydraulic Press Brake your part bending will be precise and accurate. Durma offers the world’s best press brake due to its easily programmable control unit, stable frame structure, excellent design, low operating costs, different options and maximum safety standards. Durma press brakes are manufactured by using quality-proven components.

(depending on model)

EB-CNC Series machine range:

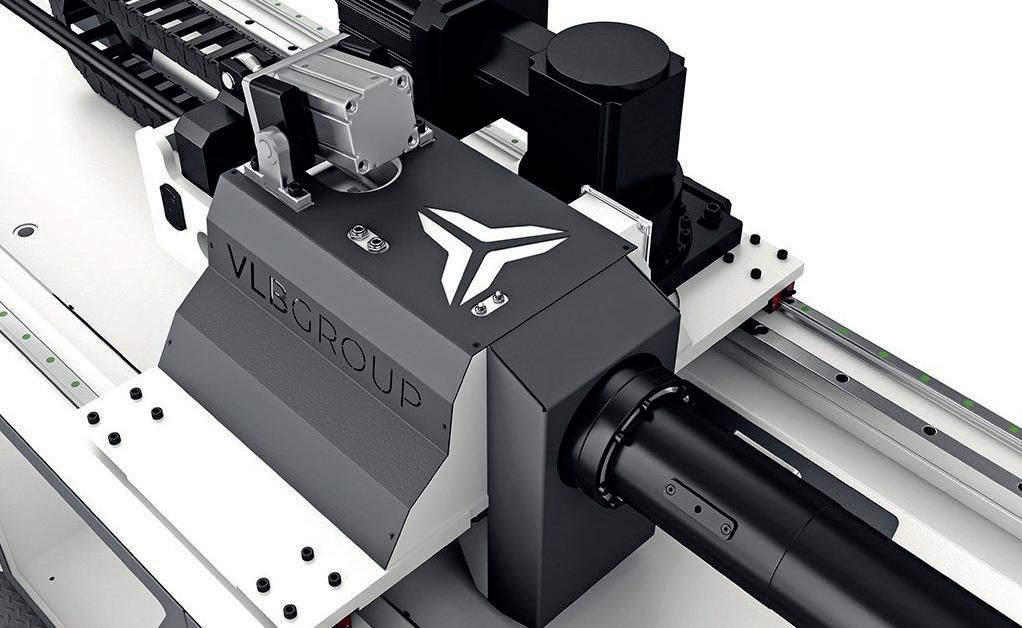

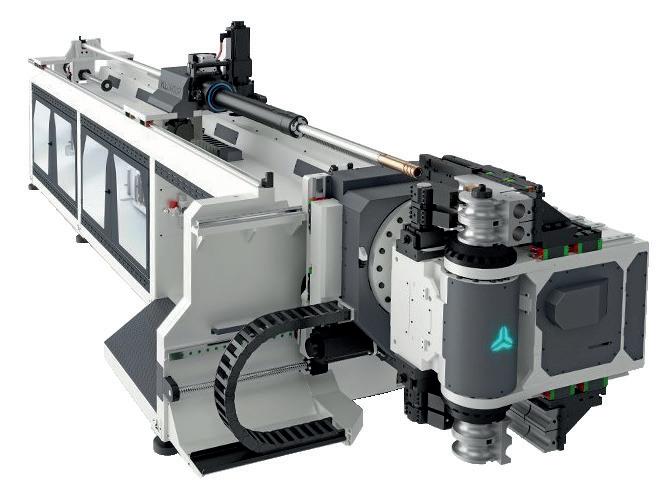

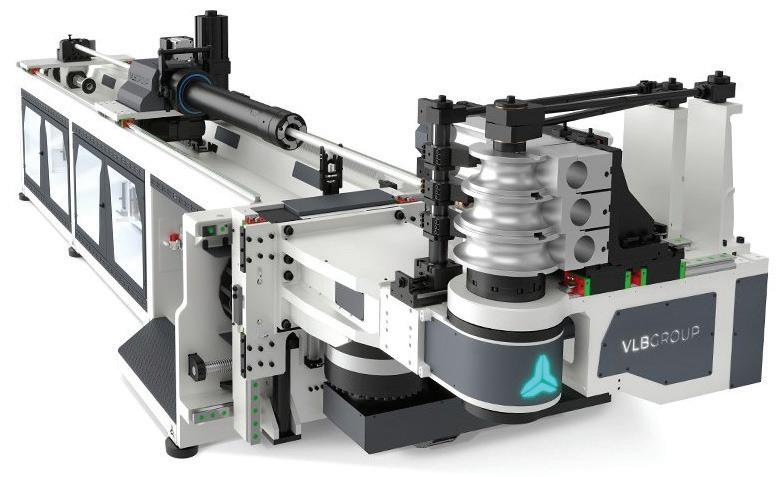

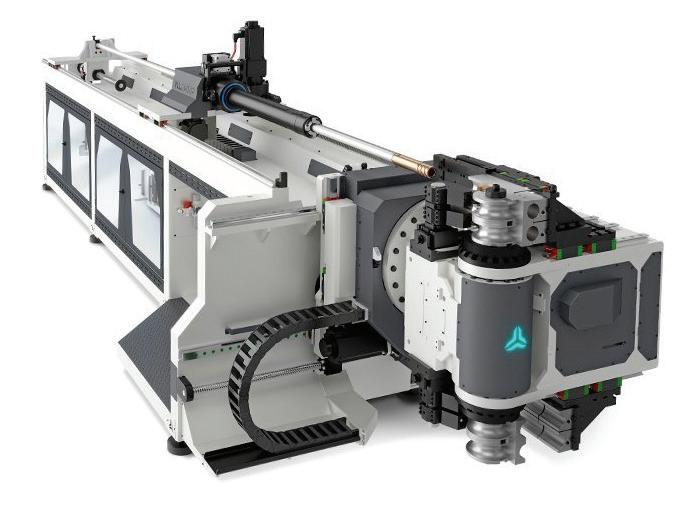

The EB-CNC series electric VLB pipe bending machines are equipped with the latest Electric Motion technology. With up to 9 fully electric drive axis, pipes with a diameter of 6mm -150mm can be bent. Equipped with a Booster system, it is possible to achieve radii up to 1D with reduced marks in the inner bend.

The EB Rotary Head CNC series of electric tube bending machines from the VLB Group are equipped with the latest Electric Motion technology. With up to 9 fully electric drive axis, pipes with a diameter of 6mm - 150mm can be bent. Ideal sectors that this machine can serve include oil and gas, furniture and automotive.

ETG brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, fabrication machines, automation, laser cutting, wire EDM, workholding systems and industry 4.0 advancements to deliver highly productive and effective metal cutting solutions.

ETG specialises in providing manufacturing machinery for every sector—spanning aviation, engineering, medical, automotive and more, and now they have moved into the fabrication space with new fabrication machinery. The ETG Fabrication Division has been created to continue ETG’s expansion into every manufacturing sector, delivering a comprehensive solution to the purchase and lifelong maintenance of heavy-duty production machinery.

Partnering with leading brands Durma and VLB Group, ETG has ensured the Fabrication Division’s success by offering an incredible array of machinery and equipment, a snapshot of which, is shown in this brochure, ready for delivery across the UK and Ireland. The ETG Fabrication Division also offers comprehensive service support and spares to brands it champions, please ask your local representative for further information.