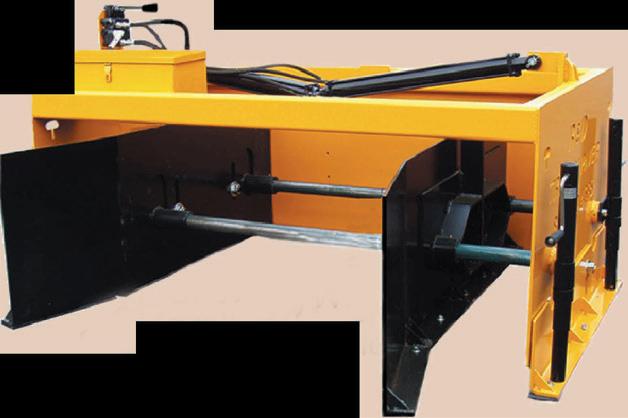

Of the Top 30 products of 2024 there were standout offerings that proved, above and beyond, worthy of recognition.

Weiler Material Transfer Vehicles lead the way with proven innovations to provide the lowest cost per ton of operation.

Innovative and reliable operator friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

Clam shell doors and full width drop down floors provide unmatched access for cleanout and maintenance.

The multiple, incremental improvements to the 4th generation of chains, sprockets and augers are retrofittable to all machines and provide increased wear life.

14 Construction Safety

AI: From the Field to the C-Suite

As AI technology to manage safety onsite and capture incident information comes more broadly to market, Oracle and Newmetrix provide enterprise safety insights and predictive analytics.

The best list of new, innovative, and industry shaping products for the road-building industry.

Taking a closer look at expanded shale, clay, and slate lightweight aggregates.

Jose Hernandez and his brother Pete started their asphalt business from scratch, but discovered an out-of-the-box recruitment method to find quality employees.

40 Building Better Jobsite Safety Strategies

Safety planning for your jobsite can no longer be an afterthought.

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December, with an additional Buyer’s Guide issue published in August by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 600653605. Printed in

Cary Bryant from Caterpillar gives a short talk about all the new features on the company’s highway class tandem rollers at World of Asphalt 2024.

Watch the video at: https://asph.link/catcomp

Nashville was hardly big enough to contain everything that World of Asphalt 2024 had to offer, and whether you were there or not, there are plenty of things you might have missed!

Read more at: https://asph.link/ WOA24

Dynapac showcases its new compaction technology, which is designed to improve ride and efficiency, while reducing emissions.

Read more at: https://asph. link/poxhjg9p

John Anderson, senior sales consultant for Caterpillar, breaks down how the 3D screed works and what sets it apart

Read more at: https://asph. link/7afxpwjv

Astec Introduces ReMix CCPR System

By reusing RAP materials and mixing them at ambient temperatures, the CCPR significantly reduces the need for both virgin aggregate and energy for heating the mix.

Read more at: https://asph. link/0q7mhp0t

Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page: Facebook.com/Asphalt.Contractor

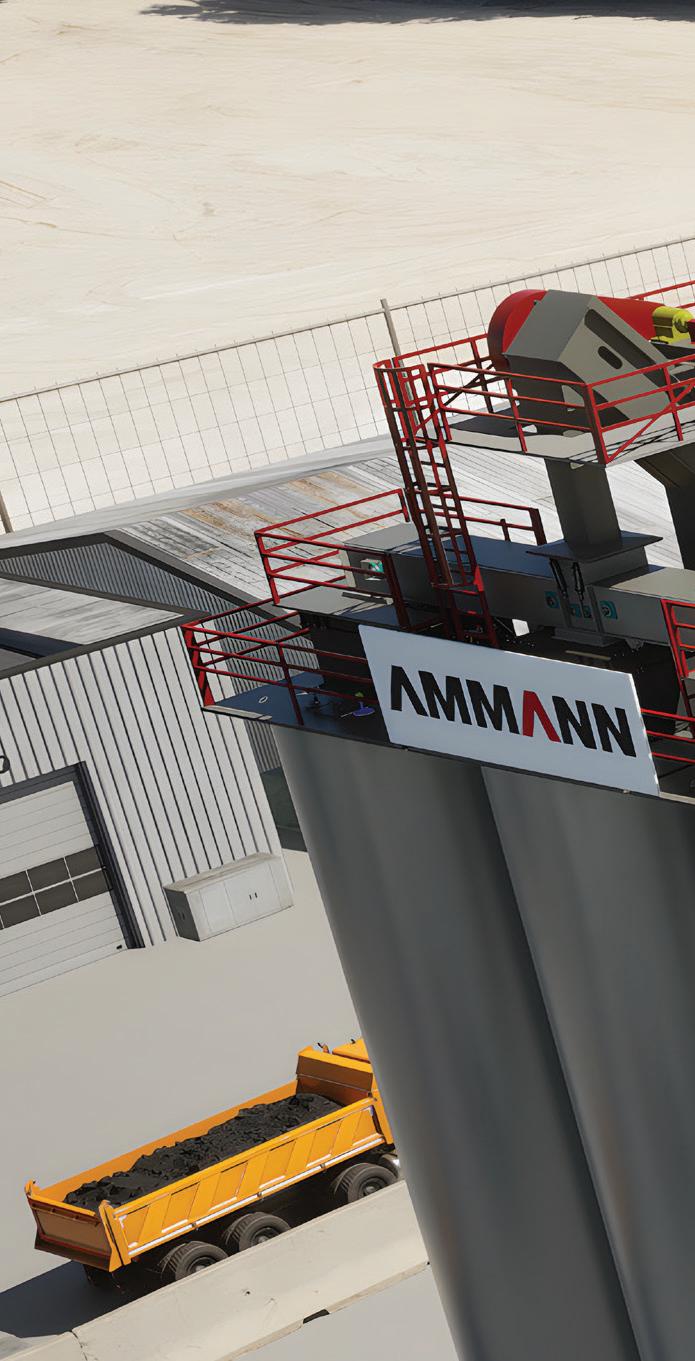

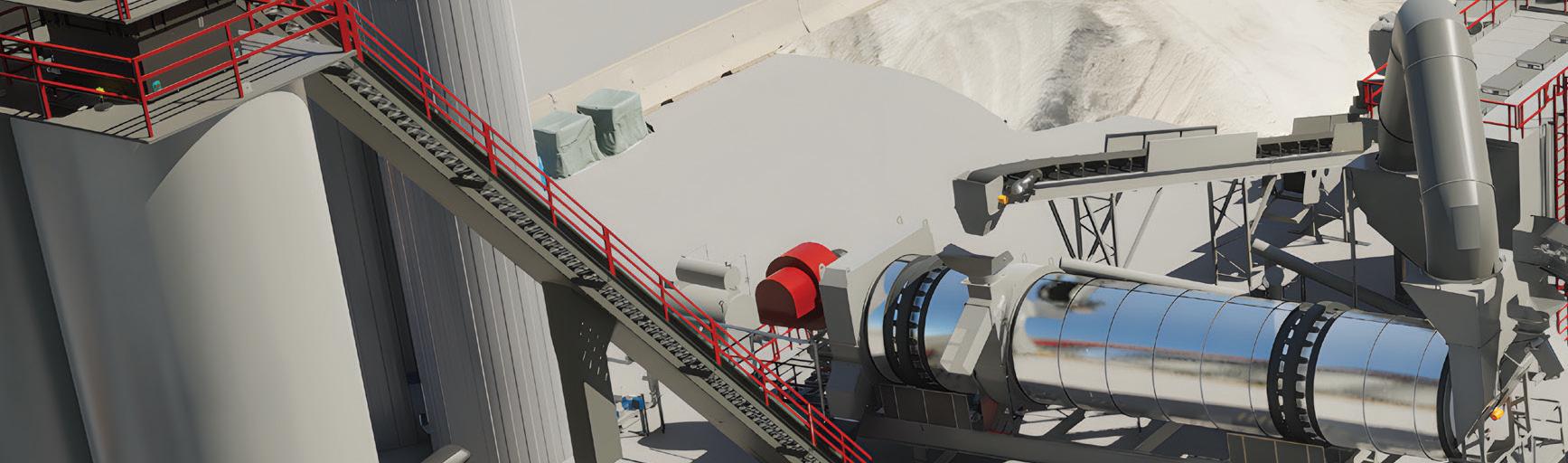

Astec’s commitment to its customers extends beyond making the sale.

From the beginning, our service team has provided construction services for the equipment we build. Astec construction and relocation services for asphalt plants include plant and equipment installs, plant tear-downs and moves, silo repairs, and industrial piping and tank farm installs.

Efficient planning minimizes downtime, local regulations and permits also play a key role. Astec has an extensive history and experience with permitting and regulations. Safety, efficiency, and compliance are paramount throughout the process.

Scan QR code to see Astec’s Asphalt Service & Construction offerings.

Brandon Noel, Editor

Brandon Noel, Editor

bNoel@iron.markets 234-600-8983

World of Asphalt was a huge success, with the highest turnout on record, however, the looming shadow of the Francis Scott Key Bridge disaster impacted everyone in the road building industry.

Since the last issue of the magazine, the industry gathered in Nashville, Tenn., for the 2024 World of Asphalt. By all accounts it was a massive success. It was reported that there was a 38% increase in attendance this year over the record breaking year the show had in 2022.

All said and done there were:

• 440 exhibitors

• 120 educational sessions

• More than 15,800 in attendance

For me, it was my first WOA, and it certainly had a different vibe to it than the other shows I’ve been to so far in my time as editor, which will reach two years when next month’s issue ships out. However, what really caused me to reflect on the past 24 months in this role was what happened between the first and second night of the show.

As everyone knows, the Francis Scott Key Bridge was struck by a disabled cargo container ship, and immediately collapsed into the river. That Tuesday morning, the second day of the show, I came down to get coffee in the lobby of my hotel when one of my coworkers asked me if I had seen the news. I hadn’t, and, like many of you, I was stunned in silence at the footage.

At first, there wasn’t a lot of information, but by that evening, contractors were sharing in the commiseration that six road crew repair workers had likely perished in the disaster. They were out there, in the middle of the night, patching potholes on the bridge surface. A couple times since I started this job, I’ve applied the phrase “invisible work” to an aspect of what our industry does, and this is maybe the paramount example.

Dorlian Ronial Castillo Cabrera, Alejandro Hernandez, Fuentes Carlos Hernandez, Miguel Luna, José Mynor López, and Maynor Suazo Sandoval were truly doing the invisible work that so many in our world do. They were out there working to support themselves and their families, and making the daily commute for thousands of others just a little better and safer. Everyone on a road crew knows that it comes with dangers on the job, but not one of them that night could have ever imagined something like this when they set out for work.

Road crews across the nation are vital to the quality of transportation and infrastructure we all enjoy. I just wanted to take a moment to honor, not just those who’ve lost their lives on the job, but to all of you who continue to show up each day.

I consider it an honor to get to do what I do, and I look forward to continuing to serve the awesome men and women of this industry.

See you on the road.

EDITORIAL

Editor ............................................................................. Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Gigi Wood gwood@iron.markets

Senior Editor, Equipment & Workwear, IRONPROS .......................................... Michael Cheng mcheng@iron.markets

Junior Editor Merina Shriver mshriver@iron.markets

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manager ...................................... Cindy Rusch crusch@iron.markets

Art Director ............................................................... April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Audience Development .................................. Ronda Hughes VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan

Corporate Director of Sales Jason DeSarle Brand Director, Construction, OEM & IRONPROS .....................................................Sean Dunphy

Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.asphaltcontractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

@ASPHALTCONTRACTOR @ASPHALTCONTRACTOR @ASPHALT-CONTRACTOR-MAGAZINE

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher. Published by IRONMARKETS 201 N. Main St. Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 • WWW.IRON.MARKETS @ASPHALTCONTRCTR

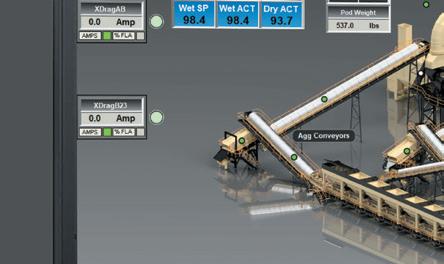

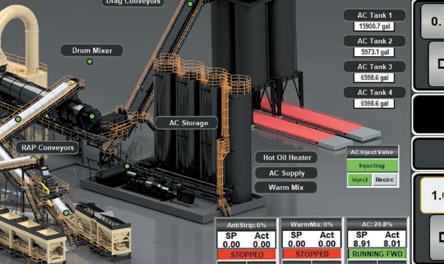

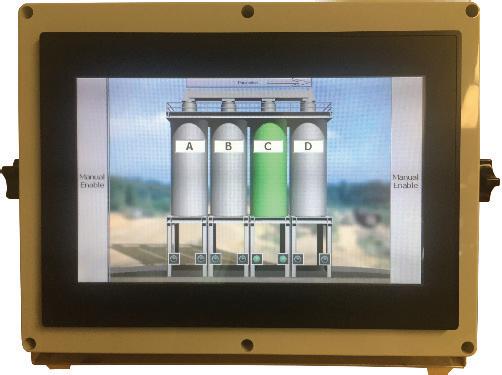

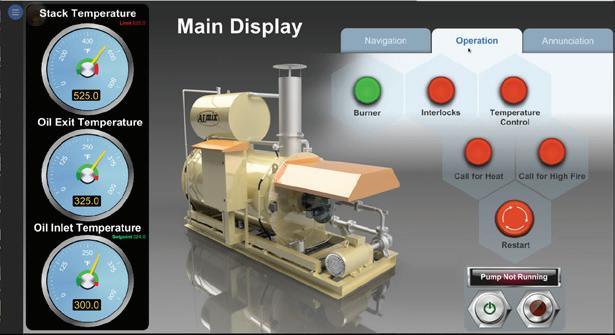

The future is connected. That’s why we’ve designed the ALmix Insignia Control System (ICS) around the power of high-speed Ethernet communication. An ethernetconnected facility means our team of programmers have complete visibility into your plant equipment and motor control center for diagnostics and remote troubleshooting. View and control data from your asphalt plants like never before. The Insignia Cloud Platform provides access while you are at the plant, in the office, or on the go. Critical, real-time, plant information is at your fingertips when you need it.

DON’T LET YOUR EXISTING ASPHALT PLANT CONTROLS KEEP YOU GUESSING:

The Insignia Control System is available on all new ALmix Asphalt Plants and is also available for existing plant control upgrades.

SCAN HERE TO LEARN MORE OR TO SCHEDULE A DEMO

The Trimble TDC6 Handheld Data Collector is a lightweight, handheld GNSS data collector for performance construction surveying. The TDC6 allows contractors to work with complex data sets in the field, connect to the office and communicate changes to field crews. The device offers integrated Wi-Fi and Bluetooth, built-in cameras and 5G compatibility in a shock-, dust- and water-resistant package. The data collector works with Trimble Siteworks Software for construction surveying and can be used to visualize the jobsite with Trimble SiteVision Software, an augmented reality solution.

Bridgestone Americas (Bridgestone) will officially debut its new V-STEEL Z TRACTION (VZT) construction tire. The 25-in. tire is for loader and grader applications and tread compounds are engineered to help improve heat, cut and tear and increase total tire life by up to 15% compared to previous generation product, based on internal estimation related to tread design elements. The new tire includes a tread pattern design with 9% improved traction (optimized casing structure only in 23.5R25 and 26.5R25 compared with Bridgestone VJT based on the actual operating condition of loader/ grader. Actual results may vary.

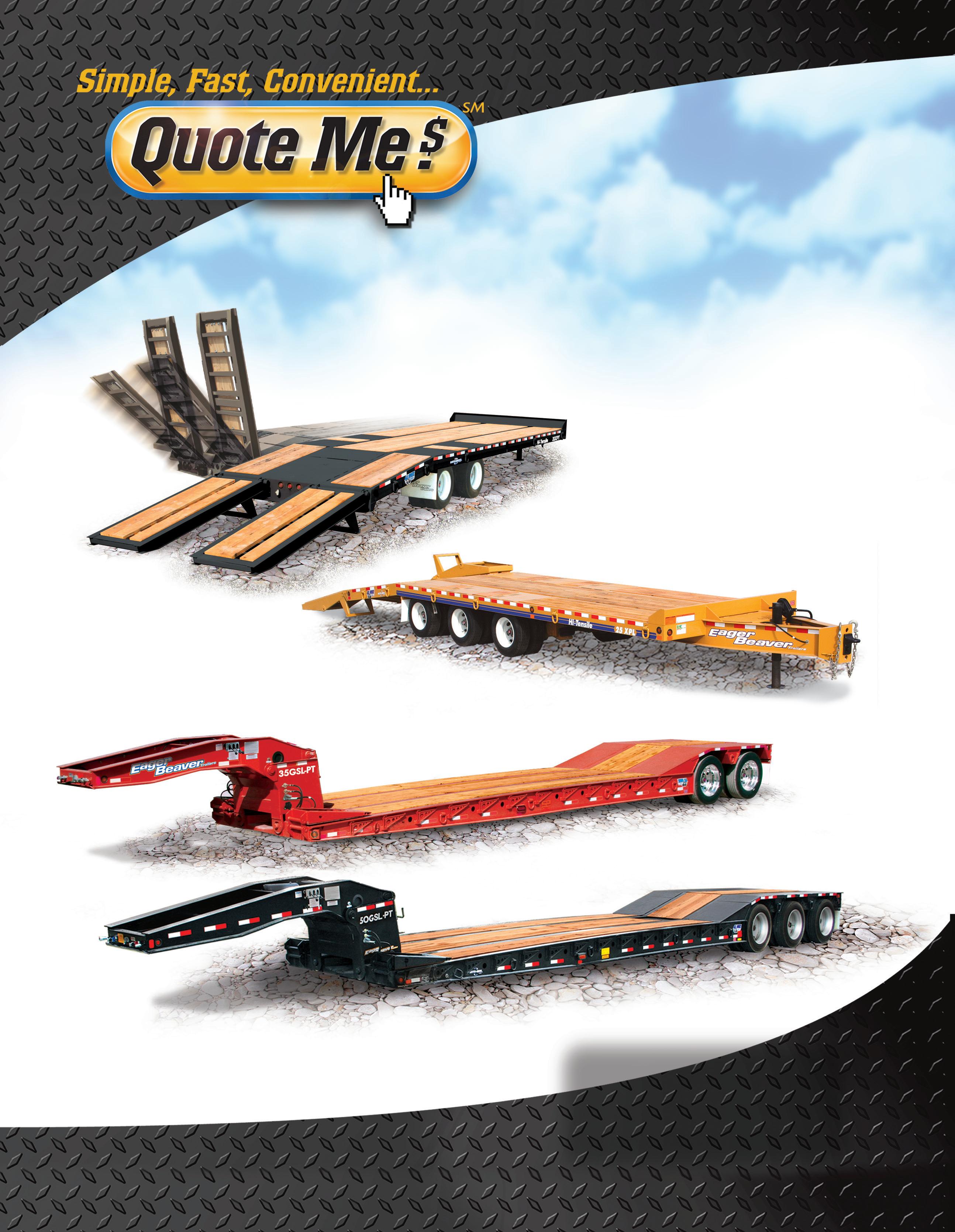

The XL Knight 80 MFG has an updated mechanical, full-width gooseneck trailer design. The 48ft. long detachable gooseneck lowboy has an overall capacity of 80,000lbs. and a concentrated capacity of 70,000lbs. in 16ft. The trailer offers 29ft. of main deck loading space and a loaded deck height of 18in. for versatile hauling. The mechanical, full-width gooseneck is also known as the double drop. The detachable gooseneck features front connection plates with three height settings for adaptability over various terrains. The front of the main deck can go up or down 1.5in., for a total of a 3 in. variance.

Komatsu has introduced the new GD955-7 motor grader to the North American market. The GD955-7 provides operators with the ability to build and maintain haul roads for truck fleets of 100 tons and up. This new machine generates blade downforce pressure for grading performance. With faster working travel speeds compared to the previous model, Komatsu engineered the GD955-7 to increase grading performance while helping reduce maintenance requirements. Despite its large size, the GD955-7 offers maneuverability on the jobsite.

Tenna has announced the launch of TennaCAM 2.0 Heavy Equipment for the construction industry. This dual facing heavy equipment dash camera is fully integrated with TennaCANbus, which allows it to deliver ECU data alongside video telematics. The TennaCAM 2.0 Heavy Equipment is intended for use within the closed cabin of a piece of heavy construction equipment. Paired with a monitor and additional auxiliary cameras around the sides and rear of the machine, this product provides footage and live visibility around the operation and surrounding area of heavy equipment on active jobsites.

Lincoln Electric offers the Velion DC Fast Charger for Electric Vehicles, a Level 3 DC fast-charger platform. DC output voltage is 200-1.000V DC, DC output current is up to 150A, DC output power is up to 150 kW and input voltage is: 460V AC +/- 10% (60 Hz), 3-Phase, Protective Earth (UL Model).

The 150kW Velion DC fast charger exceeds 75% domestic content and is engineered to exceed 97% uptime with an output of up to 1,000V at 150 amps and 500V at 300 amps. It operates within the temperature range of -31° F to 122° F (-35° C to 50° C). It is backed by Lincoln Electric’s multi-point service network.

New Holland Construction introduced three new compact wheel loaders: W60C, W70C and W80C LR. The W60C shares the same frame as the W50C but with enhanced horsepower to elevate output. Upgrades to horsepower and the Z-Bar boom design tailor the W60C for applications like material handling and more. With a light operating weight of 12,000 lbs. and 74 hp, the W70C is designed for a range of tasks. Designed for the agricultural market, the W80C LR model is a high-speed option that employs a lift capacity of 10,600 lbs. and an operating weight of 13,000 lbs.

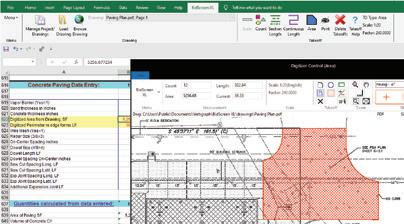

Serves as a takeoff and estimating software solution for businesses in the construction industry. The product is an add-in to Microsoft Excel, enabling contractors to manage their projects. With BidScreen XL, the on-screen quantity takeoff is now part of Excel with an audit trail where the colorcoded takeoff, drawing and value are all automatically recorded and saved to the cell and workbook. BidScreen XL works with most drawings including vector PDF, raster PDF and AutoCAD. Customizable takeoff and estimating templates for concrete estimating are also included.

The FleetWatcher platform now integrates with Oman Systems Field Manager PRO. Data from FleetWatcher equipped assets flows through to populate in Field Manager PRO, thus eliminating the manual input of this information. Contractors

Thunder Creek Equipment has announced the expansion of its truck upfit line of fuel and service solutions with the addition of the Class 5 Isuzu NRR truck chassis. This expansion includes both the No HAZMAT Fuel and Service Upfit model, as well as the Service and Lube Truck Upfit for daily fluids and preventive maintenance. The Isuzu NRR truck chassis features a GVWR of 19,500 lbs. and is built sturdy to handle bulk fluid delivery to jobsites. Thunder Creek upfit platforms offer the ability to get in and out of more compact or crowded sites, minimized disturbance and low ground pressure and the ability to deliver critical fluids ßwithout requiring a HAZMAT endorsement or a CDL.

The 275-hp (205-kW) crawler loader has an operating weight of 65,901 lbs. (29,892 kg) and replaces the 973K worldwide. It joins the 953 (160 hp/119 kW) and 963 (202 hp/151 kW) in the Cat track loader line. An updated cab features a suspension seat and adjustable armrests and controls. A 10-in. (254 mm) touchscreen dash display features a standard High Definition rearview camera. Slope Indicate shows machine mainfall and cross slope right on the display. The 973 is powered by a Cat C9.3B engine. Fuel consumption is reduced up to 10 percent with Auto Mode that will adapt the engine speed to the load. Eco Mode uses even lower speed for further reduction in fuel consumption.

using Oman Systems software to manage operations and equipment maintenance can use FleetWatcher telematics to complete the data transfer chain.

Hitachi Construction Machinery Americas offers the ZW310-7 wheel loader for transporting, loading and transferring materials around jobsites. The ZW310-7 wheel loader will be offered in a base model and a premium model. Both the base model and the premium model include a standard fully adjustable, heated air ride seat that incorporates a seat-mounted armrest with electric over hydraulic controls. The armrest and controls adjust forward or reverse to accommodate operators of varying sizes. Both models have Approach Speed Control which gives the operator control of the top speed selected during v-loading. A Payload Checker allows the operator to weigh and log material moved and a power up feature anticipates power requirements.

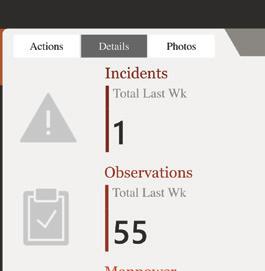

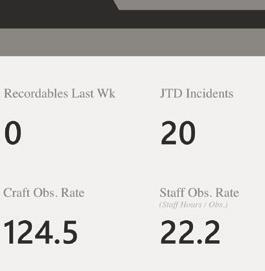

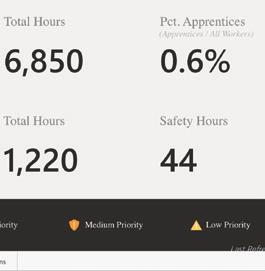

Manage safety onsite and capture incident information using AI.

When contractors think about construction safety technology and systems, they may primarily envision software and devices deployed on site.

Contractors may use software systems to record and report on safety incidents to support their own management decisions and for regulatory reporting. This safety reporting is often supported directly in construction operations software, including field productivity solutions like Raken, Assignar, HCSS Safety or project management tools like Procore, InEight or Autodesk Build.

They may also deploy cameras or Internet of Things (IoT) devices to capture activity on the site and deploy machine vision to document whether safety practices are being followed. Wearable IoT devices from companies including Triax and Eyrus may assist in coordinating workers and crews on a site and capture safety incidents using manual entry, accelerometers, and other tech.

Applications that capture imagery for other purposes — like Earthcam’s robotic cameras, which are primarily used to document time-lapse progress imagery — are also now delivering AI safety functionality. Earthcam used its archive of images across decades to train their artificial intelligence (AI) to spot and send notifications of unsafe work.

On construction equipment, technologies ranging from intelligent radar motion detection to machine-learningdriven pedestrian detection help prevent safety incidents and may capture data on incidents and near misses.

Technologies are also coming to market that use AI to identify, not just pedestrians, but objects, berms, voids and other pieces of equipment.

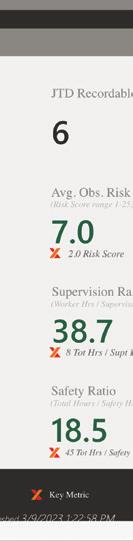

While these AI-driven applications often capture data that can be used to look back at what happened, AI is also coming to market that can apply predictive analytics to safety data, helping contractors report and prevent them before they happen.

In the case of Oracle, which acquired safety AI vendor Newmetrix in late 2022, these predictive insights can increasingly be shared across a broader construction analytics platform in Oracle Construction Intelligence Cloud.

Newmetrix was a middle-market sized startup at the time of the acquisition, founded in 2015 as Smartvid.io. Postacquisition, Newmetrix is a standard Oracle SKU that can be sold by any Oracle Construction and Engineering sales representative and channel partners.

“We are a part of the broader Oracle Construction Intelligence Cloud

Newmetrix is exposing safety data to predictive analytics to actively prevent incidents.

analytics and AI team,” Kanner said. “The vision at Oracle is to provide AI and analytics across the key areas of construction delivery risk, from safety to schedule to cost to quality, helping contractors and owners reduce risk and improve their overall project portfolio performance.”

Kanner founded other companies acquired by IBM and Autodesk and appreciates the added breadth of an enterprise organization. Customers get enterprise-level customer success, support organization, and stable, secure provisioning on the Oracle Cloud Infrastructure.

“We trained up the Oracle customer success team,” Kanner said. “It’s great to be a part of that bigger team.”

Becoming part of Oracle increased the total number of customers that the

Newmetrix technology can reach, and deep integrations are designed to make it into a core benefit. While the full scope of Oracle’s plan for its new construction safety AI analytics technology is yet to be made public, we are able to share some insights.

“Most recently, the Newmetrix platform, as it exists today, went through an Oracle Security, audit, and update process,” Kanner said. “As a result, it’s now available as of October through Oracle Systems as a formal Oracle product. That was a big milestone for us, to now be formal Oracle SKU for sales and acquisition and management through all the normal Oracle processes. The next big milestone is going to be where the Newmetrix product is relaunched within Oracle Cloud Infrastructure (OCI) as a part of the broader Construction Intelligence Cloud.”

In September at Oracle Cloudworld in Las Vegas, Oracle announced that Oracle Database 23c will support AI vector search. According to an Oracle release, this will, “Enable the Oracle Database to store the semantic content of documents, images, and other unstructured data as vectors, and use these to run fast similarity queries. These new capabilities also support Retrieval Augmented Generation (RAG), a breakthrough generative AI technique that combines large language models (LLMs) and private business data to deliver responses to natural language questions.”

RAG was praised for increasing the security of LLMs, reducing, “hallucinations,” or made-up responses. Extending an enterprise database for AI rather than relying on a stand-alone application with its own cloud database, brings additional benefits.

“The combination of business data and semantic data is what enterprises need to implement AI solutions,” Oracle Executive Vice president, MissionCritical Database Technologies Juan Loaiza said in the release. “By adding AI Vector Search to Oracle Database, we enable customers to quickly and easily get the benefits of AI without sacrificing security, data integrity, or performance. Using Oracle AI Vector search does not require machine learning expertise. All database users, including developers and administrators, can learn to use it in less than 30 minutes.”

This move will bring benefits to existing Oracle construction customers who gain the Newmetrix safety AI toolset.

“We integrate directly with Oracle products like ACONEX, as well as other

construction management products— wherever safety related data might lie,” Kanner said. “And we pull that in through our pre-built integrations that can include safety observation data, safety checklist data — all kinds of structured data.”

While Newmetrix can ingest and produce insights from photogrammetry and regular photographs, it is agnostic with respect to what hardware generates the images — which distinguishes it from camera system-based machine vision that may be able to identify safety issues.

Rather, Newmetrix can access a broad spectrum of project documents, both inside and outside the Oracle product set, to extract predictive safety insights.

“If you have a project list, and you have observation data, and you’ve got incidents and near misses, that’s a great

starting place for the journey to use data to help measure and manage safety in a predictive way,” Kanner said. “One of our core philosophies is that we go get the data where it exists. You might have schedule data with activities in it. You might have manpower data in your field reporting system, that tells you different types of manpower on site and the hours they’re there. We’ll go get it and we’ll try and make it work. That’s actually a part of our service — something we call a predictive data assessment, which is a way we go in and work with a customer to assess their data. In essence, we look at what ingredients they have in the pantry, their data pantry, and see what of those ingredients we can use to build either a benchmarking or predictive analytics approach for safety for them.”

The software automatically transforms the project data into the standard Newmetrix data model for predictive

analytics. This requires, according to Kanner, 18 to 24 months’ worth of data. Customers can harvest these insights from within a web interface, and use the Computer Vision API to port them into other business intelligence applications. When used to send data out through APIs to other systems, Newmetrix is more akin to an AI-as-a-service tool than a system of record because it accesses data, transforms it, and then relays it to other systems to be actioned.

Newmetrix customers will find pre-built integrations with Autodesk; Procore; SharePoint and; for 360-degree imagery, DroneDeploy. And as part of Oracle, Newmetrix can harness the power of OIC, an integration platformas-a-service technology.

By Charles Rathmann, technology editor.For more information visit https://asph.link/b5xdw5

By Brandon Noel, Editor

By Brandon Noel, Editor

dominate the market, your competitors, are also the places you have to go to buy your asphalt, then it’s definitely going to limit your ability to grow. It means you’re always going to be paying more for your asphalt than the companies buying it from themselves, and it also means that you’re going to have to wait in line, because their day-to-day projects are going to take priority over yours.

However, there are still some contractors out there finding a way to be a growing mid-size asphalt, paving, and road work company despite these types of market conditions. They’re doing it by buying their own asphalt plant, one that produces enough mix for themselves to start, and has room to grow in the future to sell to others like they were previously doing.

Growing a family company over a century means learning from the lessons of the past.

In the state of Ohio, there are a few large companies that carve up a majority of the Department of Transportation road projects every year. From talking to contractors from other states, this is not too uncommon. The state DOTs have a handful of companies that they are familiar with, have good track records, and, yearafter-year they take on more of those

projects. The result of this trend can be that the market starts to look somewhat bifurcated.

Asphalt and pavement contractors are often a small-to-medium sized operation, doing commercial paving work, buying asphalt from the larger companies that make up the other half of the state’s industry. This can make it difficult to continue to grow if you’re a commercial pavement professional who wants to break into DOT, municipal, or other types of larger scale local or state work. The challenges get as sticky as tar pretty wuick, and for a number of reasons.

If the large-scale companies who

Henry W. Bergman Inc., and the Bergman family’s history in the area concerning road building goes back far enough to predate modern techniques.

“Great grandpa started in 1912. He did roadwork, commercial, blacktop, and culvert work in the winter,” said Paul Bergman, vice president of the company. The Bergman family literally built up the Genoa area. “I think we actually laid lumber down to start route to a sectional.”

Lumber isn’t the type of base we would use today, but Bergman’s paving division has been involved with every facet of the asphalt industry. Paul got his start shaking striping paint cans in a Taco Bell parking lot when he was seven years old, but the company has done crack sealing, sealcoat, and anything in-between. If it has to do with asphalt, they’ve been there.

Where they’ve really grown their business over the last decade or so has been getting involved with DOT work as well as rural road repair with a form of chip seal and paving.

“Anytime they mill out a street -- it’s called an inner layer,” explained Bergman. “We’ll do a chip seal and then pave on top of it. That helps with reflective cracking so it doesn’t come up through as fast. It’s kind of like a glue interlining layer.”

At a certain point it was clear that if they wanted to continue to grow, and deliver at the pace and quality they desired, a plant would be the best option. After considering several manufacturers, they decided to go with an Asphalt Drum Mix ers (ADM) EX 8844.

Around 2019, just prior to the COVID-19 pandemic, the company began to finalize the details, and then in early first quarter of 2020, they set the plans in motion. Footers were laid around February, and then the unthinkable happened when a huge portion of the country shutdown in an unprecedented way. Work and health restrictions at the time made the construction a challenge, but they forged ahead as best they could.

them for six-to-eight years before it was sold off. It’s not completely clear what happened, but Paul has a hunch it had to do with the logistics of the time.

“My first thought is logistics, right,” Bergman said. “You have to be near projects to pave them out of the plant. Back then you didn’t have big dump trucks, yet. Just single single axle trucks, and possibly some horseand-buggy still.” Unfortunately, Oak Harbor wasn’t the most ideal location for an asphalt plant at that time. This generation of Bergmans wanted to ensure they didn’t repeat history, and make the same error.

The selection of a good location for a new plant is essential.

“We found our quarry in Perrysburg (OH), it’s near Toledo and the surrounding area. Logistically, for us, it was a good move. To be able to control your schedule more, as well as the pricing on the material.”

After a short delay, they placed a call to ADM that the site was ready, and trucks arrived quickly thereafter. A little more than a week later, they had their plant, although it didn’t come online fully until later that year in July.

Interestingly, while this is the only plant that Bergman has, this wasn’t the first time in the company’s long history that it was producing asphalt in the area.

“In the early 1950s. My grandpa decided to build a plant in Oak Harbor,” Bergman said, and showed me a picture of an old half-ton batch plant that still hangs on the walls of their offices. The plant operated with

Every new step of growth has its own new challenges that it brings with it, however, and once they overcame a pandemic, shutdowns, delays, and everything else, they had to figure out what to do next.

“Just to be able to read the job mix formulas, and all the testing that goes behind one of those was a learning curve,” said Bergman. “You just want to make sure your plant is always producing the same thing. Once you have the right ingredients and how to run these basics tests, making sure it meets the right criteria, you’re good to go.”

It wasn’t without one or two hiccups at the start. Their first few batches came out brown, due to a mixup with the wrong type of sand. However, with each challenge they’ve faced, they pull back, examine the situation, and, sometimes with extra help from ADM, then

make the proper adjustments.

This is where I met the namesake of the company Henry W Bergman III, who was out at the plant when we caught up with him. The day I visited the location, he was working through an issue they were having in production.

He explained that the aggregates weren’t hitting the exact optimal position for their asphalt veil. To help me understand he took out a marker and drew on the side of a metal panel to illustrate the issue. The arrangement and type of drum flightings, in this case those that were bucket shaped, was such that it dropped the material just beyond the center line of the burner.

When this happens, it can take longer for material to reach the desired temperatures, and result in losses of efficiency. Through trial and error, they’d figured out where the adjustments needed to be made, and were making sure everything was set for the upcoming season, a few weeks away.

I asked if there were any regrets or things they’d wished they knew at the start, which they would do differently in hindsight. Going ahead with a new plant for the first time, were there any lessons they’d want themselves to know?

“We only wish we’d gone with ADM for the RAP [recycled asphalt pavement] system too,” said Bergman III. They bought a used system, and saved some money on the costs, but there were complexities involved with the setup that could have likely been avoided otherwise. “Getting the insertion exactly right was a bit of a struggle, and I think it might have been better to just go all in on everything from the start.”

For more information visit https://asph.link/wmjikv

Every year there are a great number of new products that come to market for the asphalt and road building industry. They make the work we do fast, more efficient, cleaner, cheaper, and sometimes they completely change the game. The Asphalt Contractor Top 30 list is meant to reflect what we felt were the best of those new-to-market items, but we don’t stop there. Some products have been so longstanding and made such a huge impact on the way things are done, that we want to recognize them for the legacy of innovation they represent. Here we present our selections for the 2024 Top 30 products in the asphalt and road building industry.

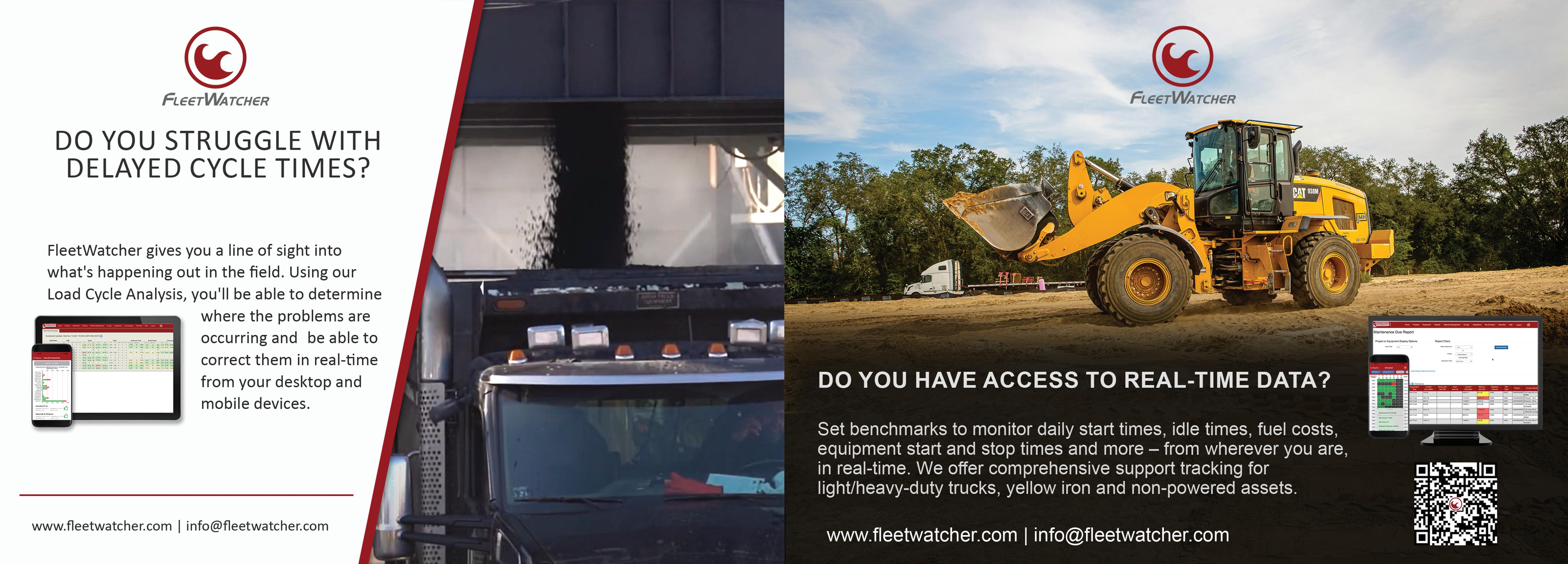

Foamed asphalt is manufactured by the introduction of precisely metered water into the flow of liquid asphalt between the A.C. pump, meter and the plants mixing zone. The water, when introduced into the A.C. immediately turns into steam gas which expands the volume of the liquids. The shear unit and the mixing action that takes place with the application of horsepower are similar to an emulsion process. The foamed asphalt more completely coats all aggregates, RAP, RAS, -200 or other materials. By positively blending the additives with the liquid asphalt, the foaming action is DRAMATICALLY INCREASED. More importantly, the fusion is maintained for a longer period. The Custom Engineered Accu-Shear Multiple Purpose Additive Blending System consists of the following components which emphasize performance, accuracy, ease of installation, operation and adaptability.

The intelligent SEISMIC system improves compaction performance significantly compared to conventional compaction carried out at fixed frequency. SEISMIC automatically detects the optimum compaction frequency and continuously adjust accordingly. Thanks to the SEISMIC system we can offer an increase of efficiency and lowering running costs due to savings in fuel consumption. SEISMIC technology is designed to further optimize compaction efficiency, reduce fuel consumption, and enhance operator comfort. Automatically detects the optimum compaction frequency. Continuously adjusts drum vibration frequency according to the resonance frequency of the drum / asphalt mat. Less noise, and less vibrations transmitted to the cab due to lower frequencies.

Bobcat super-flow planers are high-powered attachments capable of milling concrete and asphalt up to 7 in. thick. The super-flow planers are available in 24-in. and 48-in. cutting widths. These versatile attachments utilize the extra hydraulic power available in the Bobcat T86 compact track loader and S86 skid-steer loader equipped with super flow generating up to 42 gpm and 4,061 psi. Bobcat also offers a 40-in. planer compatible with both super-flow and high-flow hydraulics. In all, Bobcat offers six planer attachments that accommodate standard, high-flow and super-flow hydraulics.

Process Heating Company (PHCo)

Lo-Density Rigid Tubular Drywell Tank Heaters provide a more efficient and safe form of heat for asphalt and emulsion distributor truck tanks than fossil-fuel-fired systems. With the Lo-Density heating system, the operator simply plugs the heater in at the end of the day, and it maintains the emulsion at the correct temperature overnight or over a weekend. With no open flame, these heaters eliminate concerns about the ever-present dangers associated with lighting and operation of burners. Lo-Density electric heat also can reduce operating costs for distributor trucks.

Equipped with an efficient narrow conveyor management system, the machine is ideal for heavy commercial paving and large volume jobsites. The LeeBoy 8608 is powered by a 125hp Kubota Tier 4 engine and 14.4 kW belt driven generator. With an operating width of up to 15 ft., 6 in., this versatile machine will be easy to maneuver in tight spaces. The new 8608 asphalt paver takes operator comfort to another level with the addition of the Oscillating Bogie Style Track System. It also includes a lowered SCR, exhaust and flat hood for enhanced operator visibility.

With new features on all models, such as Custom Flow Balance, customizable joystick function buttons, new work modes, and Trimble-Ready components, the new X4S captures improved efficiency and up to 5% improved cycle times. Additional options such as HD arms, WAVES +, reversible engine fans, and Precision Grade on select models add to the perks of owning and operating a Link-Belt excavator. Dynamic Stability Control, Payload, Height and Depth Alarm, and even a digital level, are all standard equipment on our Premium 220 X4S machine. An all-new 190 X4S excavator features a 120-horsepower Yanmar Tier 4 final-compliant engine. Boasting an upsized undercarriage compared to its little sibling, the 170 X4S, the 190 X4S offers superior lift performance, improved stability, and productivity.

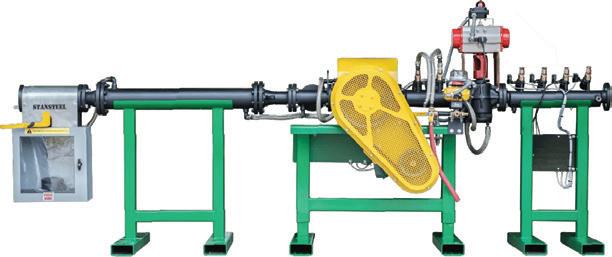

Guards against the most dangerous and expensive accident that can occur at an asphalt plant – inadvertently opening the wrong silo. Equipment damage, personal injury, litigation and lost production are all consequences of a silo accident. Infrared sensors enable each silo, if and only if, the truck is in the proper position. Touch screen display indicates sensor and silo gate activation to the operator. Auto-alerts for potentially defective sensors.

VÖGELE is taking two steps into the future at once: new operator ergonomics, more automated processes and faster set-up times, together with reduced noise and exhaust emissions. Highway Class pavers are perfectly at home whether on highways or handling other demanding large-scale projects.

The SUPER 2100-5(i) has a mighty power pack from John Deere with an output of 187 kW at 2,000 rpm. This engine is characterized by economical consumption and comparatively low noise emissions. The ErgoPlus 5 operating system makes the SUPER 2100-5(i) simple and intuitive to operate. ErgoPlus 5 is characterized by a good overview, great convenience and perfect ergonomics.

Designed to make longitudinal joint sealing easy for any paving crew to perform and enables paving crews to invest in longitudinal joint sealant freeing them of expensive alternatives. First and only towable VRAM (Void Reducing Asphalt Membrane) applicator that does not require a CDL. Saves money by enabling you to take control of longitudinal joint sealing. Faster and simpler logistics on every project when you control this step of the paving process. Control the pace. Only seal what is needed for the day so motorists are not exposed to slick centerlines. Works well with bulk material and material in solid block form. Basic set up and easy operation with Cimline automated controls. Application bar can be set to specified width and material application rate in seconds. Indicator lights tell the driver when the system is active and speed is within rate application range.

The new Caterpillar RM600 and RM800 reclaimer/stabilizers compete at the high end of the reclaimer/stabilizer size class with an all-new adjustable height design capable of cross-slope cutting. Their turbocharged Cat C18 engine gives the RM600 up to 17% more power than the RM500B. The RM800 delivers up to 42% more power than the RM500B and up to 23% more power than the RM600. These reclaimer/ stabilizer models adopt rotor system components from Cat cold planers for cutting and mixing. Featuring a belt driven rotor drive system, the machine is capable of flushcutting on the right side. The new System K rotor uses the same cold planer fastenerfree, dual-taper toolholder and base block components to deliver material quality on a range of projects.

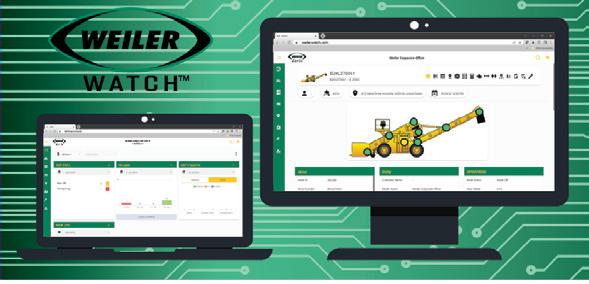

Weiler Watch is currently available for Weiler material transfer vehicles and offered with a one, three or five year initial subscription. Access from a computer, tablet or phone with real-time location, hours, status and fluid levels. Analyze fleet utilization with runtime performance including working hours, idle hours and fuel burn rates with the ability to establish target runtimes, compare daily working hours and fuel consumption. Machine specific wear life calculations based on wear component measurements allows for maximum life of wear components and the ability to schedule maintenance for minimal downtime. View machine fault codes with status, source, description and type at last reported time or utilize Rapid Report to access real-time diagnostics for the engine, drivetrain, feeder system, sensors and CAN system. Receive notification of next scheduled maintenance requirements and log activities to a service history for each asset.

When using Invigorate at a 1% dosage rate, a 50 degree decrease in temperature at 40% RAP achieves similar or better results in both Hamburg and Ideal TC testing. In Ideal CT testing, Invigorate at 270 degrees Fahrenheit received a test score of 174.9, besting test samples heated to 320 degrees by more than 45 points. In Hamburg testing, Invigorate reached the -12.5 limit after more than 18,500 passes. These two scores together demonstrate an impressive relationship of resistance to cracking and pliability in the 270 degree test. Lower your mix temperature while also including up to 40% RAP; preferable to save costs. This warm mix solution is an all-natural additive, which contains 100% bio-based content and attacks aged binder at the molecular level to transform recycled material from the inside out. This product is also EPD verified.

Wirtgen’s W 150 F(i) compact milling machine features a milling width of 1.80 m (6 ft.) and is designed for use on major construction sites with restricted space. The intuitive operating design, digital assistance systems and the LEVEL PRO ACTIVE leveling system allow for one-man operation. The agile front loader with a standard working

width of 1.50 m (5 ft.) features ecofriendly engine technology compliant with EU Stage 5/U.S. Tier 4 Final exhaust emission standards. The 9L John Deere engine offers a maximum rated output of 315 kW and has been specially adapted to meet the needs of cold milling applications. It offers high torque and simultaneously low noise emissions under various load conditions.

A new 50-ton crawler excavator for tough applications. It’s a partner for the Volvo A25G to A35G hauler and a successor to the Volvo EC480E. A notable change can be seen in the cabin design and styling, with new layout and features including highdefinition co-pilot screen, keyless engine start, wired and wireless smart phone charging and new work mode switch. This next generation excavator is set up to access a range of machine options to help operators complete their tasks. These include the operator coaching app, Volvo Dig Assist - designed to eliminate the need to manually mark out a site.

Tenna’s new new hardware product for heavy equipment allows for tracking third-party powered accessories. Tenna also released a new add-on product: Custom Inspections. Tenna’s new TennaCANbus tracker is an updated way to track heavy equipment. By installing the TennaCANbus on heavy equipment, users can now track and monitor idle time, fuel consumption, asset information, engine information, battery level, fault codes and decoded messages, environmental data and tracker analytics. TennaCANbus enables managers to make decisions about rentals, replacements, preventative maintenance and resource management.

EccoFab’s heat resistant asphalt drum flighting is forged from Hardox HiTemp – a unique blend of heat resistant and wear resistant steel. This innovative material selection ensures maximum durability, allowing the flighting to outperform and outlast typical OEM flights. In fact, while an average OEM flight often needs to be replaced within just two years, our heat resistant flighting has demonstrated remarkable longevity.

It also offers unparalleled heat resistance, capable of withstanding temperatures of up to 903 degrees Fahrenheit. This high heat tolerance not only ensures the flighting’s longevity in harsh operational conditions but also enhances safety and reduces the risk of equipment damage caused by overheating.

The flighting’s impressive wear resistance ensures that your equipment will spend less time out of operation for part replacement, potentially reducing costs and increasing profitability. Additionally, the exceptional heat resistance enhances the safety and stability of your operations, providing you with peace of mind.

JCB has developed a single-machine pothole and patching repair solution to fix potholes permanently, the Pothole Pro. This solution helps minimize labor intensive repair methods or additional machinery. The Pothole Pro can repair a pothole in less than eight minutes. With a 25-mph travel speed, the machine can relocate between sites without additional transport costs. The JCB Pothole Pro is equipped with a planer, mounted on the machine’s rear skid steer hitch. The planer is 24 in. wide, with up to 4.26 ft. of side-shift adjustment. This allows the operator to plane a full roadway lane from the curb, without repositioning the machine. Hydraulic tilt and depth control provide a consistent depth for large patches.

Crafco has unveiled the EZ Patcher skid steer attachment for pavement repairs. Designed by Crafco’s Equipment Engineering department from the ground up, this patented technology offers safe application of repair material. The EZ Patcher provides roadwork agencies and contractors with a method for repairing long, linear cracks such as deteriorated longitudinal joints or utility cuts, using a repair material known as mastic – a binder and aggregate mix that is heated and applied to distressed pavement for a durable, weight-bearing repair without extended road closures. The new EZ Patcher joins the Crafco family of mastic melter/applicators, including the trailer-mounted Patcher II and Patcher 4, as well as the 10-gal. Hot Mastic Applicator cart.

Running on an Android operating system and enables operators to control cutting depth according to project design. The intuitive system allows operators to meet demanding specs for complex projects, minimizing over-cutting and creating a smooth surface on airport runways, highways, racetracks and other projects that require smoothness. The 3D design is displayed to the machine operator showing areas on, above or below grade, comparing the actual drum position and slope with the digital design. The platform automatically guides the milling drum to cut the depth and slope without string lines or manual adjustments.

By providing operators with the ability to make informed decisions and adjustments in real time, the system contributes to a more efficient and cost-effective asphalt production process. The visibility it offers into moisture levels not only enhances the quality of the final product but also transforms the way asphalt production is managed, ultimately leading to substantial savings and increased operational excellence.

A sustainable approach to road construction that minimizes the environmental impact.Reuses RAP materials and mixes them at ambient temperatures, significantly reducing the need for both virgin aggregate and energy for heating the mix.

• RAP Stockpile Utilization: Reduces the environmental footprint.

• Modular Configurations: able meet diverse requirements.

• Efficient and Cost-Effective: Reduces RAP disposal costs, etc.

• User-Friendly Interface: Enhances productivity, reduces training time.

New ALmix Hot Oil Heaters are supplied with the ALmix “Reign of Fire” (ROF), PLC-based, total heater control and alert system. The ROF system utilizes a 15.6” touchscreen HMI setup for easy local and remote control. ROF can use either an ethernet connection or a cellular-based setup allowing for remote access, monitoring, and custom alerts from any internet-connected device. Whether you are at the plant or on the road, you can control your heater schedule, monitor key temperatures, view the heater operation log, or even reset your burner. Existing heater control retrofits are available.

Road Widener offers the Curb Backfiller accessory for the FH-R material placement attachment. The accessory extends to the left or right of the FH-R and dispenses material over the curb to backfill with dirt or aggregate. Paired with the FH-R, the Curb Backfiller supports safety by replacing a backfilling method typically done manually by workers with shovels. Crew members can operate it with the original FH-R remote, reducing the number of needed laborers to just one. The Curb Backfiller attaches to the FH-R and can fill on the righthand side by default, or the left, with dual configuration. It provides a clean process by backfilling curbs and keeping debris off the roadway.

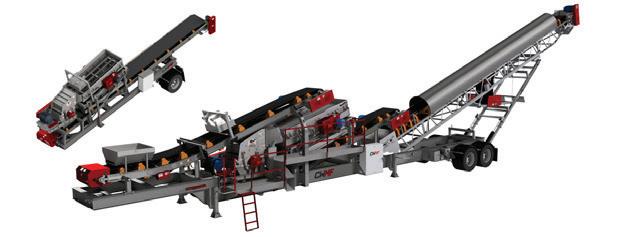

The RAP Boss and RAP Boss Jr. allow hot mix and crushed asphalt producers to minimize material handling, reduce or eliminate RAP crushing costs, and reduce RAP product moisture. The result is significant time and cost savings. This RAP crushing machine brings together top equipment like the Honey Badger crusher and Tremor Shaker scalping screen. The RAP Boss lets you take your crushed asphalt show on the road. The portable crusher and scale systems leverage the Honey Badger hammer mill 40 and a 4×10 Tremor Shaker single deck. For more cost savings, the RAP Boss Jr. offers a slightly scaled-down version that eliminates the feed conveyors and the tandem axle chassis.

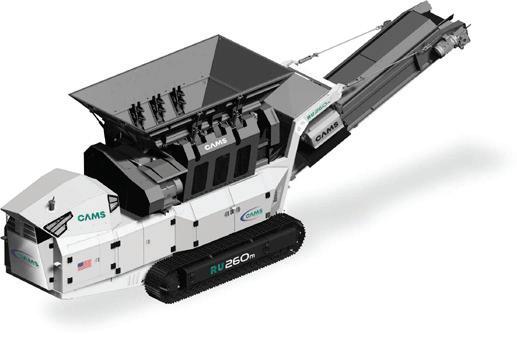

The slow and gentle shredding technology results in fewer fines, low acoustic and dust emissions, and guarantees 100% of original bitumen content reuse, giving back recycled products with the same grading curve as the original asphalt pavementation. A patented system allows to easily replace the components without disassembling the machine

FEATURES

• Built-in specific shredding programs depending on the type of material

• Ability to process wet material

• Low fuel consumption

• Compact transport dimension

• Low wearing

• Ability to provide electrical power on site

It’s time to unleash your team’s productivity because…

Astec Digital is the leader in plant automation, telematics, and data management from Rock to Road and beyond. We are creating a platform to connect every piece of your operation and tear down the silos so that you can have the visibility and insights to improve efficiencies and reduce costs. Real-time data, increased control, and higher profits start here. The future is connected: AstecDigital.com

Designed for high-volume production at a low cost per ton, these plants continue to stand the test of time. Revolutionary dual-drum counterflow technology utilizes separate drying and mixing zones for maximum heat transfer and fuel efficiency.

Available in portable, skid mounted and relocatable versions, meets all federal and state specifications and consistently produces quality asphalt to help protect operators against out-of-spec-damages.

Capable of processing high percentages of RAP, these plants produce hot mix containing up to 50% recycled material. The MileMaker virtually eliminates blue smoke and emissions by separating the burner from the mixer. Any gases that are created are captured and reintroduced to the combustion zone. Produces 160 to 425 tons per hour. Can introduce water or chemicals into liquid asphalt entering plant, appropriately lowering temperature to warm-mix specifications.

Powered by a proprietary Rapid Digestion Process (RDP), SigmaBond is an innovative asphalt modifier that enables hot mix contractors to use more upcycled materials while extending the life of pavements. Polyco reengineered the way rubber modified asphalt is formulated. Their proprietary RDP completely digests recycled tire rubber and asphalt into a liquefied, homogeneous state — resulting in upcycled performance.

BENEFITS:

• Safety: Makes roads safer with darker, smoother pavements

• Cost Savings: Removes the need for any specialty equipment

• Versatility: Can be used in any application, up to 10% rubber loading

• Resiliency: Superior resistance to cracking, UV oxidation and aging

• Sustainability: Reduces tire waste

The electric tandem roller introduces sustainable, low-noise and zeroemissions operation to the 2.5-ton class commercial roller market. With its 39.4-in (1,000 mm) rolling width, this powerful and versatile machine makes short work of parking lot, driveway, and asphalt repair.

Equipped with two electric motors, one dedicated to travel and the other for steering and vibration. With no warm-up necessary, the roller is quickly ready for work at the push of the ignition button. Allows for individual vibration control to both drums, and vibration actuation is conveniently controlled through the soft-response travel lever. Intelligent vibration control (IVC) helps operators to know when compaction has been optimized to save on passes.

Foamix Eco represents an evolution within the Foamix cold-lay asphalt solution, achieving carbon neutrality through the integration of carbon negative aggregates and biogenic binders. Using mobile plant on-site recycling, Foamix Eco reduces the associated vehicle movements and therefore the associated carbon footprint. Providing a truly sustainable approach to pavement solutions.

APPLICATIONS:

• Major & Minor Roads

• Haunch Repairs

• Trench Reinstatement

• Parking Areas

• Cycle Tracks & Footpaths

• Local Housing Estates

Hydraulically actuated diverter chutework allows multi-feature deck selection, blending and by pass. Calibration chute for sampling verifies that the mix-design spec requirement is correct. Screen service platforms are positioned on both sides of the screens for ease of maintenance. Available side-discharge conveyor from crusher may be used for stockpiling or returned to another conveyor for re-circulating back to the plant screen for resizing. Ability to utilize system for screening only, all material is conveyed to stockpile. Easily allows you to switch from top to base material production from control house. Service friendly design: Screening process can continue while crusher is removed from circuit.

A closer look at expanded shale, clay, and slate lightweight aggregates.

Mountaire Farms’ agricultural food production and processing facilities near Lumber Bridge, N.C., has its share of heavy, 18-wheeler traffic. The number of vehicles entering and exiting the facilities along with the location’s rainy climate has led to a higher degree of skid accidents when compared to other, similar locations.

When it came time for the North Carolina Department of Transportation (NCDOT) to revitalize the road surface, it was apparent the project needed to address this safety concern in addition to routine maintenance.

NCDOT knew that these roads needed a high friction surface to help trucks and other vehicles stop safely. However, calcined bauxite, the typical material used for high friction surface treatment (HFST) was cost-prohibitive.

NCDOT had a chip seal operation working nearby that was using expanded shale, clay and slate (ESCS) lightweight aggregate on secondary roads. This material was used in other parts of North Carolina due to its high retention rate and ability to reduce the amount of emulsion necessary to reseal a road, and also improved wet road traction. The Asphalt Surface Treatment Supervisor suggested to the Division Engineer that ESCS aggregate would be a viable alternative for a high friction surface treatment (HFST).

The justification is that ESCS has a network of internal pores that contribute

to a higher surface friction that resists polish. The question is did it work? To understand the answer, it’s important to know the requirements around skid resistance and how ESCS works as a premium asphalt chip seal material.

Skid resistance measures the force that resists relative motion between a tire and the pavement. It’s dependent on both the macro- and microtexture of a pavement surface — both of which work together, especially in wet conditions.

The macrotexture of a pavement refers to the larger scale (0.5mm to 50mm) surface characteristics formed by individual aggregates or by grooves cut into the pavement. Macrotexture is the result of mixture design as well as methods of finishing. This aspect of pavement surfaces provides drainage channels for water to be expelled, allowing better contact between the tire and the pavement. Macrotexture is predominantly responsible for skid resistance at speeds over 56 miles per hour (mph).

Microtexture, on the other hand, refers to the surface quality under

The voids within ESCS aggregates create better adhesion and promote long-term skid resistance.

0.5mm. At this level, the paving surface and tire interact directly. This characteristic of a paving surface is largely dependent on the materials used and is responsible for skid resistance at lower speeds.

Macro- and microtextures come together to form a pavement’s overall skid resistance, which is often described in three-zones. Zone 1 refers to the space where a tire initially meets the pavement. The macrotexture allows fluid to drain and the tire to contact the pavement. Zone 2 is the space where the tire and pavement begin to fully connect—in this zone, a thin film drains through the microtexture of the paved surface. In Zone 3, the tire has dry contact with the pavement. In this understanding, both textures are necessary for determining a pavement’s ability to provide adequate friction in wet or dry conditions.

According to the U.S. Department of Transportation (USDOT), pavement friction is one of several factors that influences road safety. In the introduction to a 2023 primer of friction measurement and management methods, USDOT states that skid resistance is, “explicitly considered in certain aspects of highway geometric design,” and that pavement friction’s characteristics will vary over time, so it should be, “managed throughout a pavement lifecycle, up until the very end-of-life.”

The Federal Highway Administration (FHWA) pavement policy within the Code of Federal Regulations indicates that pavements shall be designed to accommodate current and future predicted traffic needs in a safe, durable and cost-effective manner. Research conducted by the National Transportation Safety Board and FHWA indicates that about 70% of wet pavement crashes can be prevented or minimized by improved pavement friction. Thus, skid resistance is an inherent component of pavement safety, so state DOTs often have their own recommendations for skid resistance based on the details of specific projects. These recommendations include monitoring pavements through a variety of tests and repairing them when pavement friction data dips below

recommended values. The ability to maintain a consistently high level of skid resistance over time is one of the biggest challenges of designing safer pavements. Often, creating roads with long-term skid resistance comes down to the materials they are made of.

Skid resistance is reduced over a road’s lifecycle in several ways. However, polishing is perhaps the most seemingly inevitable. Polishing occurs as traffic, dust, and debris smooth a pavement, specifically the aggregates that make up the road’s surface. While polishing most directly impacts the microtexture of a paving surface, it also affects the peaks and valleys of the macrotexture to contribute to the overall reduction of a pavement’s skid resistance.

In locations with horizontal curves, steep grades, or intersection approaches, there is a higher friction demand. This often leads to premature polishing. Reduced pavement friction contributes to increased crash rates and less safe infrastructure. Because polishing is an evitable part of the wear and tear of a road’s surface, it is recommended that DOTs monitor its progression and take appropriate action when a pavement has been polished such that it’s unsafe. DOTs typically have two methods

of combating polishing. The first is to resurface pavements on a regular basis, paying particular attention to locations that may experience premature polishing. The second is to use a HFST that resists polishing for longer than traditional limestone aggregates.

Resurfacing pavements to mitigate polishing can be both cost-inefficient and inconvenient to constituents — especially in areas that commonly experience both heavy traffic and premature polishing. The other option can be equally expensive with some HFST materials. However, ESCS lightweight aggregate can provide a cost-effective high-friction pavement surface that also has a longterm resistance to polishing, due in part to its physical characteristics.

It’s produced by heating shale, clay, and slate in a rotary kiln to temperatures around 2000° F. During this process, air bubbles form within the expanding material. These air bubbles remain as a network of unconnected voids throughout the cooled aggregate. The material can then be crushed and sorted into highly regulated particle sizes. As such, ESCS can achieve a highly predictable amount of friction compared to natural aggregates.

The voids within create a surface with a skid resistance that is significantly above limestone aggregate, approximately 65 for chip seal (compared to limestone’s 50) and 44 for hot mix (22 for limestone). Further, these aggregates do not readily polish, creating a relatively stable amount of skid resistance over the service life. While some degree of polishing is inevitable in application, ESCS resists polishing to extend the level of safety an asphalt can provide.

Lightweight aggregates also support cost-effective and safer roads with retention rates up to 99% and less damage to passing vehicles.

As stated above, ESCS resists polishing for longer than conventional aggregates. This translates to asphalts that can provide an adequate amount of friction for safe driving for a longer period. Roads that stay safer longer not only reduce the amount of maintenance a DOT will need to plan for, but they also reduce the risk of liability if an accident occurs and the pavement’s skid resistance is deemed inadequate. Both contribute to more costeffective pavements, allowing DOTs to allocate resources elsewhere.

While ESCS can extend the safety a road provides, its network of voids also mean other benefits for longer lasting infrastructure. These voids increase the adhesion between the aggregate and the emulsion, which translates to less chipping and aggregate loss over the course of the pavement’s life. When used in asphalt chip seal, it contributes to approximately a 40% longer service life than chip seals using conventional aggregates.In residential areas, the service life may extend up to 14 years.

This material can provide retention rates of 99%, compared to the average 60% retention rate for natural aggregates, which contributes to a lower cost for resurfacing (as well as damage caused to vehicles from dislodged aggregates, due to lower density). Through the combination of immediate and long-term performance and resilience, it can help roads stay safe and viable for longer. This not only decreases DOT long-term spending, but it also contributes to better road conditions for constituents.

The ability for ESCS to lengthen the amount of time a pavement is safe and useable is not just theoretical. It has been proven in several states, from Utah to Kansas, from Louisiana to North Carolina and more. Bolstering this data, the use of ESCS lightweight aggregates at Mountaire Farms contributed to a decrease in accident rates, demonstrating the material is an economical and practical alternative for HFST.

Long-term skid resistance numbers and retention rates are not the only ways this material contributes to more economically efficient asphalt resurfacing. The NCDOT performed a return on investment (ROI) analysis, and the results found that fine grade ESCS substantially increased the amount of area able to be covered by a similar amount of heavier aggregate while also using less oil. Further, the overall weight contributed to reduced transportation costs. Finally, its consistent quality gradation decreased blockages in spreaders for a more efficient use of labor. All of these reduced the overall cost of pavement maintenance while also contributing to a longer lasting and safer road surface.

Whether or not an asphalt pavement needs a high degree of skid resistance, asphalt chip seal that uses ESCS lightweight aggregate can be a cost-effective option and is worth consideration as DOTs look for ways to extend the service life of their pavements.

byJim Thompson, lead road material sales and technical services at Stalite and is a member of the ESCSI.

For more information visit hhttps://asph.link/background

Oftentimes, we hire someone based on what that person can do for us, but in reality the employer is just as much in need of the employee. Especially in today’s world! So how can we attract good employees? By simply removing barriers.

The hiring process can be an arduous task for any manager, you don’t know them and they don’t know you. You put an ad out for a job opening and they inquire about it, and now an interview

is set up. The potential employee comes in with a resume and you start the process by asking questions about their experiences and their skills, their positives and negatives. You explain what the job requires and if they feel they can meet them. You tell them what the job pays and ask if they are ok with that and then finally you ask if they have any questions of you. Then you say you will review everything and get back to them.

Guess what? The moment that employee leaves, they’re gone and you’re back to square one.

This was me in 2016, my brother Pete and I decided to start a small paving company after five years of him selling his other paving company to Hubbard Construction named TPC, where I held the position of QC manager. After selling TPC he founded BlackRock Milling and, in the following five years, grew it to 15 milling machines!

So, going into business with him was a no brainer!

Just after deciding to do this he was diagnosed with stage four colon cancer and had a golf ball-sized tumor removed. I wanted to call off starting BlackRock Asphalt but he insisted we continue as planned, because he’s going to fight it!

We go forward. We start buying equipment and put an ad on Indeed for crew members and called on people we knew in the industry to see if they had anyone interested. We did anything and everything we could do to get someone to come work for us! Interview after interview and nothing!

Through all of this my brother was in chemotherapy.

It was a really tough time for everyone to find employees and especially for a small paving company. I mean what did we have to offer? No 401K or insurance, so if the bigger contractors were struggling to hire, how were we going to do it? To make matters worse, we had been awarded three jobs and still had no crew!

One of the many things I learned from my brother was that you will always hit walls in life, it’s just a matter of whether or not you will hit it so hard you go through it. He went through a lot of them.

We had to find a way to get these jobs done. So I reached out to Lane Construction and asked if they would sub out one of their crews to us, just the crew, I had all the equipment needed and, of course, I was buying their asphalt. They said, “Yes.”

Phew!! Ok, that crisis was averted, but we still had no crew of our own, and then three jobs turned into four!

I was beyond freaking out. “Keep bidding on work! Don’t worry, we’ll figure it out,” Pete always tested and pushed me to my limits, but because of him I love challenges!

I get a phone call from Ricardo, a crew member at TPC who had a buddy named Miguel flying in from Puerto Rico to Orlando where his wife just got a job with Disney and was looking for work.

“Great give me his number!” I said. Miguel and I talk and this guy sounds amazing. He can operate a paver, roller, screw, lute, skidsteer, milling machine, tack

truck, and he’s a mechanic!! Wow, if only we could manage with one person. It all sounds good, but proof is in the pudding, right?

How the heck am I going to get this guy to show me he can do all these things? I tell my brother about him and that we should offer to pay him $300 cash and reimburse his travel to come to the jobsite and show us everything he can do. Pete says, “Do it!”

I called Miguel, gave him the deal, and he took it. We told him to meet at the shop at 5:30 a.m. and we’d take him to the jobsite, but when I got there at 5:00 a.m. he was already there. I liked him already!

We get to the jobsite and the Lane crew shows up, preps, and begins working. Miguel starts off with the lute, rakes, then runs the screw, jumps on the paver, and the super for Lane is looking at me like, “Who is this guy? He does it all!”

We finished the day and I gave Miguel the money, and offered him $17 an hour (remember this is 2016), which was $10 more than what he was making in Puerto Rico, and guaranteed him 40 hours a week, if he came to work for us. He took the job!

We had Miguel work on one of the milling and paving crews with Lane, while I continued to look for more workers. Again we found nothing! I spoke with Miguel and asked if he knew anyone else who would come to Florida and work. He made some phone calls on a Thursday, and on that Saturday I received 12 phone calls!

These guys couldn’t just get up to come on their own to interview, so we had to get creative. My brother said, “You know what you have to do.” And I sure did. Miguel and I went to Puerto Rico and spoke to all 12 guys who called me.

On the flight to PR, all I could think was, “How the heck am I going to go about this?”

We met with the first candidate the following morning. A young man in his early 20s with a wife and two kids. How am I going to convince this guy to pack up and leave his family for a paving job in Florida? I told him about our company and about our experience. The great thing about having

Miguel with me was he could verify that we were not just some fly-by-night company. Miguel told him about all the work we had, and the better pay in Florida rather than in Puerto Rico. It all sounded good to the gentleman, but he had a problem, “How am I going to get there?” Even if he got a flight there, then what? He would have no where to live. You guessed it!

I had to make a phone call. I told my brother that we were going to have to make it a no-brainer for these guys. This was the deal we offered:

• Pay for the flight

• 3 months full-time work at $17 an hour

• 3 months rent for an apartment

• 3 month car rental

If it did not work after that period, we would fly them back. I told him, “Give

me an opportunity to show you a better way of life, and if it doesn’t work, I’ll fly you back home. But if it does work, I’ll fly your family to Florida, what do you say?”

He says he’ll do it, and six total of the people we met with agreed.

I got back to Florida and began booking flights, rented two apartments and transportation. Done, done, done.

We got them to Florida and began working our jobs with our own crew! Our first job was a Winn-Dixie parking lot mill and pave in Lakeland, Fla.

Less than two years later, we had two and a half crews.

We succeeded because we were not just in the paving business but the people business.

Now, I know my story is an anomaly in the way we went about it, but there is still a difficulty in hiring employees. What is your current approach to

hiring? What are you offering? What is your culture? How involved are you with your employees, your community, your industry? What does your website and social media say about your company? Look within your company first, and then ask yourself and your management team, “What are WE offering THEM? Why would anyone want to work for us?”

Forever in honor of my brother, business partner, mentor, hero

Pete M. Hernandez 2/23/1972 – 7/26/2018

I promise you, as long as I’m standing I will run through any wall put in front of me!

For more information visit https://asph.link/tech

Safety planning can’t be an afterthought.

Proper training, awareness, and planning all go in to ensuring the safety of your crews. In every work zone there are individual, equipment, and external safety factors. There will always be unexpected and uncontrollable elements at play, of course, but if you take the necessary steps you can reduce the chances of permanent or serious harm. It’s important to note that avoiding such scenarios also means avoiding negative liabilities and financial risks.

The statistics on work zone safety have been trending in the wrong direction when motor vehicles are involved, and since the end of 2020 it’s gotten worse. By the very nature of what our industry does, we work everyday in the primary environment of cars. The safety measures you take are meant to protect your people, your employees, but they are designed to communicate to drivers. The problem is that many of today’s drivers are distracted, not paying

attention to signage, lights, or flaggers.

According to the National Work Zone Safety Information Clearinghouse:1

“Over the past 10 years, work zone fatalities have increased from 619 in 2012 to 956 in 2021. This equates to nearly three persons per day being killed in work zones in 2021. Approximately four out of every five work zone fatalities involve a driver or passenger of a vehicle. Meanwhile, estimated injuries in work zones have also increased, from 31,000 in 2012 to 42,000 in 2021. In 2021, this equates to approximately 112 injuries per day in work zones. (Source: NHTSA FARS, GES, and CRSS).”

According to a report by The Center for Construction Research and Training, road maintenance workers died on the job four times more often than the average American worker, and nearly 20 times more than administrative, engineering, or office workers.2

Sharing a workspace with drivers is dangerous, but there are important steps that can be taken.

Whether or not you already have a safety plan in place, taking the time to review your policies and their effectiveness on a regular basis, is just as important as getting one on the books.

“One of the things we talk about the most is situational awareness,” said Justin Baskin, national safety and environmental director for Rose Paving LLC. “You need to know what’s going on around, you so you don’t get yourself hurt. You have to be aware of the hazards and potential hazards around you. Take inventory of what you can see around you. This goes for everyone, top-to-bottom, from the shovel guy to the project manager. Situational awareness is where it starts.”

Baskin included that one of the biggest hurdles to a positive situational awareness is the level and number of distractions. Removing different kinds of distractions, can foster a better environment for workers. Albeit, distractions are a much bigger issue when it comes to external factors, like distracted drivers. To simplify the steps to safety for their employees, Baskin instituted a four-step process he called S.T.A.R. in order to help workers on the job easily remember what to do:

• Stop

• Think

• Act

• Review

“When I came here, there wasn’t anybody that was head of safety, so we’ve been focused on developing a safety culture,” said Baskin. “Our mantra has become: stop, think, act, and review. The main thing for me is getting out there and empowering our workers to speak up if they recognize that something isn’t safe.”

The central tenet of Baskin’s methodology is that the people doing the work are the literal frontline of safety, because they are in the thick of it. They are on the site, using the tools, and are the first line of defense when it comes to improving things.

Not every company has the available resources to hire a full-time position dedicated solely to jobsite safety management. In many cases it’s a role being filled by someone who is pulling doubleduty or wearing multiple hats. If that sounds familiar, then you are probably aware of hard it can be to try to:

• Create new safety policies

• Daily managet multiple jobsites

• Execute permitting requirements

• Implement new safety technologies This can especially be the case when you are in a situation where you’re trying to either overhaul or establish a new company culture of safety.

“Our goal is to ensure every team member, their safety and well-being every day, in addition we also try to maintain a strong and trusting customer partnership,” said Seth Walpole, vice president, integration and transformation at AWP Safety. “We want to bring innovative tools to contractors through our fleet monitoring and analytics, where a driver’s habits aren’t just recorded, but predictive software can offer guidance on ways to prevent unsafe situations.”

Additionally, AWP Safety has automated flaggers and signaling trailers that can safely direct the flow of traffic while communicating with each other, and trigger GPS systems to notify drivers using the system that they will encounter construction on the road. The integration of new technologies is a great next step for contractors who’ve made improvements to their company culture, but would welcome high tech tools to

One of the biggest hurdles is navigating and filing for the proper permits. This is a huge deal, and it can be an even bigger headache if not taken care of.