the future electrical machines manufacturing hub putting uK manufacturing at the forefront of the electrification revolution

the future electrical machines manufacturing hub putting uK manufacturing at the forefront of the electrification revolution

The past year has seen a real shift in momentum in our dissemination and external engagement as much of our initial research comes to fruition in publications and external engagement events get back to normal. The Hub has been prominent at several technical conferences, exhibitions and panel discussions. Of the many research achievements in the past year, the growing profile and presence that the Hub has attracted in research associated with the circular economy of electrical machines under the leadership of Jill Miscandlon at Strathclyde has been a real highlight.

question! We continue to seek out opportunities to deliver sessions in schools and, within reason, have no geographical limits, so please do get in touch if you would like to suggest a school visit.

A particularly welcome development in the past year has been the ability re-engage with schools through both science fairs and direct visits. As will be seen in later in this report, we have received a very positive response from schools, particularly the opportunity for pupils to build their own electrical motor. A particularly vivid memory for me was being asked whether I knew Brunel during a question-and-answer session at a primary school in Coventry. In 30+ years of giving presentations all over the world I can’t recall a more disarming

As we passed into the second half of our 7-year programme, we undertook and in-depth review of future research opportunities and with invaluable input from our Industry and Scientific Advisory Boards set out a revised and refreshed research programme for the remainder of our grant period. This has included drawing in additional expertise into the Hub, notably the team from Bristol on additive manufacturing of coils, colleagues in Sheffield on blanking and punching of laminations. Further details of the outcome of our programme refresh is on page 60 of this report. Alongside the refresh of the research programme, Michael Ward from Strathclyde has a led a major activity to draw together a comprehensive technical roadmap for electrical machines. This has

been a major endeavour with significant input from our Industry and Scientific Advisory Boards, including a dedicated road-mapping workshop. The roadmapping activity is described on page 68 and a copy of the resulting report can be downloaded from the Hub website from April 2023.

acquaint team members from the various disparate disciplines with each other’s technologies and terminologies, but has grown into a real highlight of our activities and a valued contribution by our industry partners.

We were particularly grateful for an additional award from EPSRC for capital expenditure in support of the Hub activities at the end of 2022 and have put this to good use with instrumented facilities for termination of coils and lamination stamping.

Overall, we have entered the second half of our Hub programme with some notable highlights and much still to do.

Training sessions covering a broad spectrum of topics in both electrical machine technology and manufacturing continue to generate a deal of interest amongst our research team, researchers from Universities beyond the Hub consortium and many engineers from within our industry partners. It was particularly pleasing this year to see the breadth of contributors, including from our industry partners. This aspect of the Hub’s activities grew from an initial short-term desire to

professor gerAint Je Well FEMM Hub Director

1 2 3 4 5 6 7 8

the hub Will Address key MAnufACturing ChAllenges in the produCtion of high integrity And high vAlue eleCtriCAl MAChines in the folloWing seCtors: AerospACe, energy, high vAlue AutoMotive, preMier ConsuMer

To establish electrical machine manufacturing as a recognised research discipline in the UK with a critical mass of activity which is internationally leading.

To develop innovative manufacturing processes and technologies to improve the integrity and in-service reliability of high performance electrical machines.

To bring rigorous leading-edge manufacturing systems and digital manufacturing research into high value electrical machine manufacture with ultimate control and flexibility.

To embody the research findings in an array of hardware demonstrators and modelling tools to support Technology Readiness Level (TRL) scale up and wider industry/academic engagement.

To rapidly transition emerging technology through to industrial application by pulling proof of principle/concept manufacturing systems through to manufacturing research demonstrators prototypes for industry to work on alongside Hub researchers and develop for application.

To create an open and inclusive academic, innovation and industry communities around the Hub that provides supported access to the research outputs we develop and stimulates new collaborations.

To improve the UK skills base, including within partner companies, in the field of electrical machines and their manufacture.

To support UK manufacturing industry as electrical machines increasingly become core products in new sectors.

exeCutive te AM

Our Executive Team is made up of the Director, Deputy Director, Hub Manager, representatives from each of our academic partners and an Early Career Representative.

Dr Xiao Chen The University of Sheffield LECTURER in ELECTRICAL MACHINES Early Career Representative

hub direCtor

Professor Geraint Jewell The University of Sheffield

deputy direCtor

Professor Ash Tiwari The University of Sheffield

Professor Michael Ward University of Strathclyde/NMIS DIRECTOR OF INDUSTRIAL STRATEGY & CHIEF TECHNOLOGY OFFICER

Dr Glynn Atkinson Newcastle University READER IN ELECTRICAL MACHINES GC 1.1 Lead

Dr Xiao Chen The University of Sheffield LECTURER in ELECTRICAL MACHINES Early Career Representative

hub direCtor

Professor Geraint Jewell The University of Sheffield

deputy direCtor

Professor Ash Tiwari The University of Sheffield

Professor Michael Ward University of Strathclyde/NMIS DIRECTOR OF INDUSTRIAL STRATEGY & CHIEF TECHNOLOGY OFFICER

Dr Glynn Atkinson Newcastle University READER IN ELECTRICAL MACHINES GC 1.1 Lead

our pArtners help us Work toWArds our vision of putting uk MAnufACturing At the forefront of the eleCtriCAl revoultion And hAve helped shApe our Current And future rese ArCh progrAMMe. We Are interested in the full speCtruM of industry pArtners froM l Arge oeM’s through to sMe’s in the supply ChAin.

if you Are interested in beCoMing A hub pArtner, ple Ase eMAil hub MAnAger: lAurA .okeefe@sheffield. AC.uk.

Our board brings together senior figures from the FEMM Hub’s industry partners. They appraise and advise on the impact activities to maximise the opportunities for knowledge exchange and ensure the Hub delivers impact for UK industry. We would like to thank our industry board for all their input this year.

gAreth edWArds Programme Director AMPI NATIONAL PHYSICAL LABORATORY

sAM turner Chief Technology Officer, HVM CATAPULT

ruArAidh MCdonAld-WAlker Technical Director MCLAREN Applied

kirAn hArish Lead Technologist ATI

ChuAnli ZhAo Principle Research Specialist GKN AEROSPACE

ZiAd AZAr Generator Technology Development Manager SIEMENS Energy

gAreth edWArds Programme Director AMPI NATIONAL PHYSICAL LABORATORY

sAM turner Chief Technology Officer, HVM CATAPULT

ruArAidh MCdonAld-WAlker Technical Director MCLAREN Applied

kirAn hArish Lead Technologist ATI

ChuAnli ZhAo Principle Research Specialist GKN AEROSPACE

ZiAd AZAr Generator Technology Development Manager SIEMENS Energy

our boArd brings together le Ading ACAdeMiCs froM ACross eleCtriCAl MAChine And MAnufACturing rese ArCh. they Advise on And help support the developMent And groW th of the hub, inCluding its le Adership role Within the nAtionAl rese ArCh And innovAton l AndsCApe. We Would like to thAnk theM for their support over the pAst ye Ar

Duc Trouong Pham is Chance Professor of Engineering and Director of Research with the Department of Mechanical Engineering at the University of Birmingham. He has made wideranging contributions to the theory and practice of mechanical, manufacturing and systems engineering. He is a Fellow of the Royal Academy of Engineering, Learned Society of Wales, Society of Manufacturing Engineers, IET and IMechE.

duC trouong phAM University of Birmingham

Manoj Shah is an internationally recognized expert in the area of advanced design and analysis of electrical machines. He has co-authored 88 U.S. patents, 21 Institute of Electrical and Electronics Engineers (IEEE) journal papers, and over 25 conference papers. He was recently elected to the National Academy of Engineering for his technical advancements in design, analysis and alpplications of electrical machines.

Peter Tavner is an Emeritus Professor of the School of Engineering and Computing Sciences at Durham University. He then held senior research, development and technical positions in manufacturing industry, most recently as Group Technical Director of FKI Energy Technology, an international business manufacturing electrical machines, drives and wind turbines in the UK, Holland, Italy, Germany and the Czech Republic.

Professor Tetsuo Tomiyama is Vice-President and Dean of the Faculty of Technology at the International Professional University of Technology in Tokyo. He is an internationally wellknown expert in design theory and methodology, function modeling, systems architecting, maintenance engineering, and service engineering. He was awarded Royal Society–Wolfson Research Merit Award Holder, Fellow of ASME, CIRP, and JSME.

EPSRC published their 3 year EDI action plan in December 2022, within it they aim to “ensure fairness, accessibility and inclusivity in our activities and investments”. As a hub, we actively promote a culture where the diversity of the staff involved in the Hub is positively valued and celebrated. We believe that diversity in all its forms delivers a greater impact to our research and enhances the experience of our staff, students and partners.

The FEMM Hub ED&I committee was formed early 2022 and comprises of 6 volunteers representatives from each of our 3 constituent institutions.

Our aim is to create a fully inclusive culture that is proactive in initiating change and driving forward best practice in equality and diversity matters. We have developed an EDI policy which can be found on our website, within it we commit to the following goals:

• To increase the female participation and representation within FEMM to above 20% across all levels Hub overall striving to achieve this by the end of 2025.

• To maintain greater than 30% BAME representation within the FEMM Hub overall striving to achieve this at all levels by the end of 2025.

In December 2022, we invited Dr Vi Parker, EDI Training Lead – University of Newcastle to deliver a session on “white privilege”. The training introduced our team to the concepts of “privilege”, “whiteness” and the intersectionality of these two constructs. Dr Vi Parker discussed specifically what being white and privilege means and how it impacts on our environment and our responsibilities to challenge this to ensure under-represented members of our community can benefit from the powerful white privilege position some of us hold. The group engaged in important conversations around difficult concepts of “whiteness” and “white privilege”. Our next EDI training session will take place at our next Quarterly Meeting, taking place in Glasgow June 2023.

the rese ArCh ACtivities enCoMpAssed by the hub ContAin A CoMbinAtion of A-priori defined rese ArCh proJeCts delivered through t Wo grAnd ChAllenge (gC) theMes And ACCoMpAnying hub phd studentships, And An ArrAy of More flexible ACtivities Where the speCifiCs of the rese ArCh Will eMerge throughout the lifetiMe of the hub.

gC theMe 1: proCess innovAtion, Monitoring And siMul Ation

gC 1.1. re Alising novel MAChine designs froM innovAtive MAnufACture.

Work-package lead: Dr Glynn Atkinson (Newcastle)

gC 1.2. MAnufACturing of fe Atures for in-serviCe perforMAnCe.

Work-package lead: Professor Jiabin Wang (Sheffield)

gC 1.3. MAnufACture of light-Weight And MultifunCtionAl CoMponents.

Work-package lead: Dr Jill Miscandlon (AFRC)

pl AtforM rese ArCh

1st fe Asibility CAll

Hub PhD studentships

Externally funded research

- Manufacturing of lightweight structural components for high performance electrical machines by electromagnetic pulse technology (EMPT).

- HiPPES – High Performing and Processible Electrical Steels.

- Industrial Manufacture of Marinised Coils – IMMCoil.

- Additive Manufacturing for Next Generation Functional Integration of Windings and Thermal Management in Future Electrical Machines.

Industry funded PhD studentship

gC theMe 2: MAnufACturing-led innovAtion in eM

gC 2.1. forM noMinAl Core properties to in-serviCe perforMAnCe.

Work-package lead: Professor Geraint Jewell (EEE, Sheffield)

gC 2.2. MAnufACturing high perforMAnCe Coils With ultiMAte Control.

Work-package lead: Dr Steve Forrest (EEE, Sheffield)

gC 2.3. MAnufACturing teChnologies for flexibility And CustoMisAtion.

Work-package lead: Dr Lloyd Tinkler (AMRC)

- Next Generation Composite Air-gap Windings of Future Lightweight Electrical Machines.

- Feasibility study for a flexible, modular pilot line to accelerate innovative soft magnetic material development for electric machines.

- A critical evaluation of large scale direct drive wind turbine electrical machines manufacturing techniques considering sustainability aspects and recyclability issues ‘CEDEMSARI’.

By 2035 the Advanced Propulsion Centre (APC) is projecting the need for a step change in electrical machine performance, with power density rising from 2.5kw/kg to 9kW/kg and cost reduction from to more than half from 10$/kg to 4.50$/kg. The aerospace industry seeks greater changes with power densities reaching 40kW/kg. To enable this the fundamentals can be assessed:

Torque = Magnetic load × Volume × Electrical Load

Power density increase with speed; as is a growing trend in electrical machines but mechanical and loss limitations abound. Improved magnetic materials; there is no imminent step change here. Increased volume reduces power density, so is not desirable. Increased electric load means more current; more power loss and more heat generated. Electrical machines are designed close to their thermal limit, more heat necessitates improved thermal management if thermal limits are to be maintained. GC1.1 addresses this in two ways.

• Denser coils (a higher fill factor) greatly improve bulk thermal conductivity through the coil; then the electric load can increase within the thermal limit. Traditional winding methods preclude a higher fill factor. A modular stator however, where individual teeth can be bobbin wound, or preferably the coil created separately in a controlled manner, will give the higher fill factor and improved thermal capacity required.

• Advanced thermal management; Phase change heat transfer and new thermal materials allow the increased heat generated to be more efficiently removed; again maintaining the thermal limit at a higher load and power density.

As a basis for experimental comparison of modular and non-modular machines we have designed two machines to the Freedom Car specification: 50kW peak and 30kW continuous, up to 14,000rpm and at efficiencies exceeding 95%.

A distributed wound machine sets the benchmark as the “common manufacturing method” machine. A concentrated wound version allows direct comparison and is the intermediate step toward modularisation of the stator by a variety of methods. Experimental data will allow direct performance comparison between the various methods of construction.

Following workshops and discussions with our industrial partners we have highlighted four modular stator topologies for further investigation. In each case easier access for winding the coil winding is offered; giving the higher fill factor, lower bulk thermal resistivity and improved thermal contact between coil and tooth to allow the higher electric load, within the thermal limit, to enable increased power density.

Axial interlock: Packs of several aligned laminations arranged in an alternating fashion, giving axial and radial stability. The manufacturing challenge is to maintain the mechanical integrity of the glued stack.

2½D Topologies: A hybrid structure of a traditional laminations plus 3D features in SMC or variable profile laminations. Rounded surfaces reduce end winding length and improve the thermal interface between coil and tooth and reduce potential coil abrasion with sharp corners and edges no longer present. The coil can be would directly with three-sided access, or preferably separately for placement during assembly. The manufacturing challenge is to lock the separate tooth components reliably onto the core-back.

3D Topologies: Either SMC or variable profile laminations. Harnessing the full 3D design space enables; new topologies (axial flux machines,

Circumferential interlock: A complete laminated stack, segmented circumferentially with the scope for a more mechanically stable interlock design. Segmentation allows a bobbin wound coil to be placed with two-side access. The manufacturing challenge is to ensure a module interface with minimal magnetic gap, minimal sensitivity to manufactured tolerance variation, yet sufficient mechanical stability and vibration resistance.

transverse flux machines and YASA), variable slot shape - to take advantage of additive-manufactured variable profile coils, integrated features and cooling channels. The manufacturing challenges centre around new or unfamiliar materials, new production methods and a more limited supply chain and manufacturing expertise.

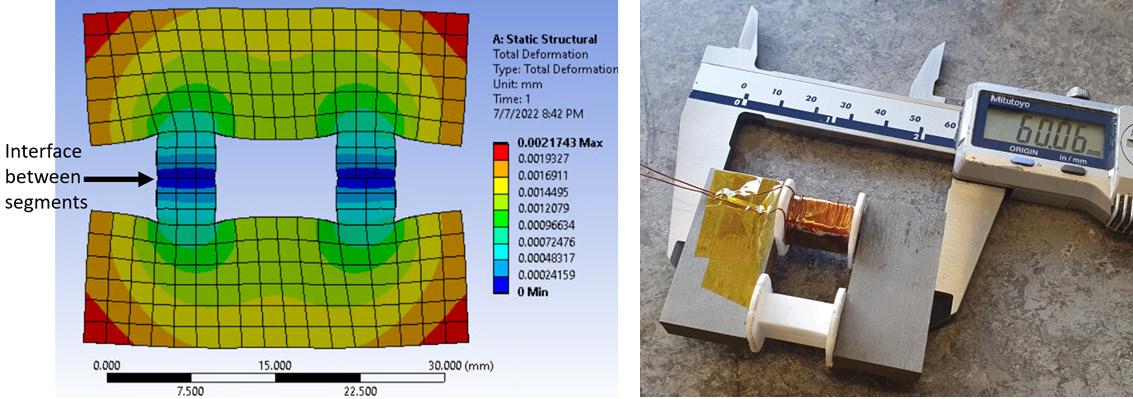

The interface between segments will influence the

electromagnetic, thermal, mechanical, and acoustic performance of the electrical machine. In the next phase GC1.1 will explore this in much more detail; we are currently recruiting PhD students and research staff with mechanical and manufacturing design and analysis skills to accelerate this work. Initial work carried out by Yan Zhu, a visiting researcher, has explored the effects of surface finish at the interface between segments and when under compression.

A rectangular core design is used to give a uniform stress distribution under compression. Four cores have been constructed; solid (non-segmented) for an experimental benchmark, plus three segmented cores with increasingly polished surfaces at the interface between halves; analogous to the interface between stator modules.

BH Loops have been obtained at 500Hz and 1kHz for the solid and four segmented cores. From the data the average segment airgap is calculated (derived from the reluctance and compared to the solid core). Inspection using the Optimax visualiser measures the gap between segments which confirms the magnetic measurements.

Looking in detail along the edge of the interface, an incremental misalignment between laminations builds. The left most edge is aligned, the rightmost is more than ½ lamination out, a potential cause of localised eddy currents. Initial testing at 1kHz has not yet isolated this, but we plan to test up to 5kHz.

Measurements were carried out under compression in steps up to 87.5MPa, the variation in hysteresis loss and reluctance derived magnetic gap was obtained.

As expected, hysteresis loss did increase with pressure, a result seen in many other studies. Of interest here is the effect of the surface finish at the segment interface; the more highly polished surfaces exhibit less loss - in addition the application of pressure did not have a significant effect on the interface gap length. These early results suggest the stator modules will require interface edge processing to minimise loss, and core compression will not reduce the interface gap length.

The Thermal Management work package has focused on advanced phase-change solutions for the next generation of high-specific output electrical machines. Initial exploratory work has shown a good promise when employing more conventional heat pipe-based concepts for thermal management of electrical machines, with up to 30% improvement in the output torque/power. However, the work has also highlighted several compatibility issues, electromagnetic, thermal, and mechanical, which need to be addressed for successful commercial deployment of the technology.

Both design and manufacturing processes require further developments to aid design of the phase-change solutions for close integration within the machine body, e.g., stator-winding or rotor assembly. More specifically, a set of theoretical, experimental, and manufacturing techniques has been in development, as a part the work package activities.

The additive manufacturing (AM) of phase-change solutions have already shown the performance and cost benefits and is the preferred manufacturing methods for developing custom integrated phase-change thermal management for the next generation of high-specific output electrical machines. Manufacturing of integrated AM phase-change components have been successfully demonstrated.

The figure above presents the technology demonstrators, which have been developed as part of GC 1.1 activities, where:

1. The use of off-the-shelf heat pipes in thermal management of high-specific-output electrical machines has a limited scope due to relatively low heat transport capability and high additional power loss when considering close heat pipe to winding integration.

2. Custom additively manufactured heat guides allow for a significant 85% increase in dissipative heat transfer from the windings with low additional power loss and relatively simple subsystem integration. Further improvements would require a phase change element.

3. Custom build heat pipes allow for a significant increase of heat transport (×7) and reduction of additional power losses (×60).

4. A heat pipe to heat guide solution utilising high thermal conductivity ceramics to provide an improved heat transport into the heat pipe body without additional power losses. A phase change solution fully utilising available space between windings would be a step change in heat transport capability.

5. A custom additively manufactured vapor chamber with an integrated liquid-cooled heat exchanger. The concept proves feasibility of manufacturing and processing advanced phase change components. To fully utilise the additively enabled solutions a compatible high purity set of materials need to be used.

6. A custom stator core segment with an embedded vapour chamber and liquid cooled heat exchanger. This solution requires further developments in both materials and manufacturing of such components, e.g. magnetic core and heat transport part. Alternative embedded systems are possible subject to a specific electrical machine design and application.

7. A testing/ benchmarking platform for a repeatable thermal and power losses characterisation of advanced phase change components/subassemblies. A motorette (a sector of stator-winding assembly) of 80kW, 8000rpm traction motor used as a baseline for the study.

The work on GC1.2 by the core team of researchers in the Hub has been scaled down over the past year with a decision to focus the outcomes and expertise gained from prior work on their implementation in case studies, in other GC projects, other projects aligned with the Hub and PhD studentships. The research reported in the 2022 Annual Report on the experimental testing of the utility of Fibre-Bragg-Grating (FBG) for vibration monitoring has been taken forward to demonstrate fault-detection in a permanent magnet machine via a PhD studentship. Research has been focussed on understanding the nature of the change in vibration magnitudes and frequencies at key locations within the machine stator under both healthy conditions and under a range of different electrical faults within the winding. This in turn provides a means of optimising sensor number and location to provide a robust and reliable means of detecting faults and discriminating between different types of faults so that the most appropriate remedial action can be taken. This is a coupled mechanical and electromagnetic problem since faults such as inter-turn short-circuits within a single coil can introduce unbalanced conditions into the machine and so introduce additional frequency components of force and hence strain into to the machine structure. By way of example, the three-dimensional finite element predicted stator core strain distribution shown (see bottom left) illustrates the regions that exhibit the greatest strains for the particular electromagnetic force distribution imposed. Finite element modelling allow strain spectra to be predicted for both healthy and faulted conditions. By way of an example, the spectrum below shows the additional frequency components of strain at 3 points in the stator which are introduced by an inter-turn fault with a single coil. A comprehensive investigation of the predicted frequency spectra allows the faults to be categorised in terms of the change in the spectrum of the strain components. This research has now progressed to the build and testing phase of an FBG instrumented machine to demonstrate reliable detection of a range of faults.

One of the main streams of work for GC1.3 in the past two years has been the development of a methodology to fully integrate manufacturing constraints and opportunities with the machine design considerations. The novelty in this work includes material data specific to individual manufacturing process in the design of components. Not only does this reduce the risk of over-engineering components, it also allows for an assessment of when and where expensive materials and processing routes can be put to best use.

In 2022, the team working on GC1.3 published the paper “A Manufacturing Driven Design Methodology to Lightweighting of the Structural Elements of a Permanent Magnet Electrical Machine Rotor," in IEEE Access [1]. This paper was the culmination of over a year’s work with contributions from across the consortium, optimising how the manufacturing requirements can be optimally integrated into the design stage of electrical machines components. Typically, electrical machines are designed with little or no input from a manufacturing production viewpoint, and this can often lead to cost increases and time delays as designs are iterated to accommodate for manufacturing limitations. This paper proposed a methodology to fully integrate the mechanical design and manufacturing process routes into electrical machine design, and illustrated the benefits of such a process within the context of lightweighting a permanent magnet rotor for an aerospace electrical machine.

Within the methodology proposed in this paper, several alternative configurations of rotor design were considered with appropriate manufacturing routes identified at the initial concept design. Different material and manufacturing constraints

were identified in this paper, as well as the impact that the manufacturing process can have on the final component. These impacts were then embedded into the initial design procedures. The final section of the paper demonstrated an application of this methodology, and discussed the features which offer opportunities for achieving economically lighter weight design through the integration of manufacturing into the design procedure.

The case study in this paper presented three designs of a rotor hub and shaft, shown in Figure 2, and considered the effect on weight when manufacturing specific material data is used. The choice of manufacturing route can greatly affect the yield stress of the final component, and this was included in the modelling to highlight potential lightweighting potential by selecting an optimal method of manufacture, as shown in Figure 3. Work is now ongoing for the follow up to this paper, where a second paper will focus on more detailed

modelling which will further highlight the benefits of introducing manufacturing considerations into the design of electrical machine components.

Last year a new stream of work was also launched, in conjunction with GC2.3, on understanding what a manufacturing system for small batch electrical machines would look like. The approach developed for the type and volume of machines considered in the FEMM builds on several manufacturing system ideas that have already been developed. Examples can be found in academia and industry of Dedicated Manufacturing Systems (DMS), Reconfigurable Manufacturing Systems (RMS), and Flexible Manufacturing Systems (FMS). A Flexible Manufacturing System is a manufacturing system in which there is some amount of flexibility built in that allows the system to react to a certain degree of change. Reconfigurable Manufacturing Systems

(RMS) are designed for rapid changes in structure, hardware, and software, in order to quickly adjust its production capacity and functionality within a series of part families.

Manufacturing processes were generated for each of the four key elements of the machine: rotor, stator, coils, and non-actives. They were then ranked against each other based on a variety of drivers including process speed, process and tooling flexibility, and cost. The highest ranked manufacturing methods were then combined to produce a flexible factory option. , which is shown in Figure 1.3:4.

The net zero 2050 targets which have been set out by many countries across the globe will rely on the electrification of transport and energy sectors, which in turn will require an increase in the power density and volume of electrical machines. The key

aim of this work is to understand how we ensure manufacturing solutions are flexible enough for future production challenges. This includes not only the ability to handle different machine topologies currently being manufactured, but also the ability to deal with radical design changes that might come with the need for ever increasing power density requirements.

In 2022, the team working on GC1.3 also designing and delivered a training course for FEMM hub members “Manufacturing Opportunities for Future Electrical Machines”. This course was delivered by colleagues at the Advanced Forming Research Centre (AFRC) and the Advanced Manufacturing Research Centre (AMRC), and introduced novel manufacturing routes which could be utilised for the manufacture of non-active components in electrical machines. This course was well attended, with over 75 participants, and will be run again in future.

With a focus on the wind energy sector, Dr Abbas Mehrad Kazemi Amiri led a team of researchers to deliver the technology white paper “Design and Manufacturing Challenges and Opportunities for Offshore Wind Turbine Electrical Generators”. The main objective of this Technology White Paper, in which the existing and future challenges in costeffective design and manufacturing of the next generation of direct-drive electrical generators in offshore wind turbine generator systems are

identified, and corresponding opportunities to address those challenges are discussed. It has tried to contribute to finding answers to the following questions: a) what are the current manufacturing methods? b) what are the challenges with scaleup in size and number? c) what are the major differences between the direct-drive generator and the conventional ones for wind turbines that influence the manufacturing process?

Direct-drive permanent magnet generators are now dominating the offshore supply chain. In offshore wind farms, the overall cost of energy is pushing the turbine design to be larger in power and slower in rotational speed. Due to the high demands on wind energy as the major low carbon source of energy, significantly more wind turbines (particularly offshore) need to be designed, manufactured and installed. This white paper relies on the literature review, existing information in the public domain as well as interviews with experts, as the two former sources have been found to be quite limited. More information on this white paper can be obtained by contacting Dr Amiri or Dr Jill Miscandlon (both University of Strathclyde).

[1] Miscandlon et al., A Manufacturing Driven Design Methodology to Lightweighting of the Structural Elements of a Permanent Magnet Electrical Machine Rotor,” IEEE Access, vol. 10, pp. 117449-117468, 2022

[2] Global Wind Energy Council. Gwec - global wind report 2022. Technical report, Global Wind Energy Council, 2022

edge dAMAge Modelling due to l Aser Cutting

Research into the representation of edge damage from manufacturing processes has continued over the past year with a focus on material characterisation and improved mathematical models for representing the observed behaviour in finite element models of complete machines. To model the effect of edge damage on magnetic properties of Cobalt irons caused by laser cutting, a series of test samples of Hiperco 50 shown below were produced with a progressively increasing number of laser cuts along the lengths. The samples were cut by Tannlin UK Ltd using a 400W rated laser operating at average power of 56W average power with nitrogen gas assist and a 180mm/s cutting rate. In each case, the cuts extended only over the central 290mm of the strips leaving 5mm uncut at each end. This joined section at each end was well outside the region whose properties contributed to the measured magnetic characteristics. The widths of the cuts were measured using a Keyence VHX-100K digital microscope and the proportion of material removed was accounted for in the cross-section and mass used in the processing of the measured flux linkage and current data into B-H data.

The quasi-static magnetisation curves measured with the single-strip tester for rolling direction samples with between 1 and 4 cuts are shown alongside the corresponding magnetisation curves for an un-cut sample (designated as 0-slit). As would be expected, there is a progressive deterioration in the magnetisation curve as more cuts are introduced in a sample of a given width. This data is useful in establishing the extent to which the damage is cumulative within these samples. It is worth noting that these 4 characteristics are for four samples, albeit from the same batch, and not for a single sample into which the introduction of individual cuts is interspersed with measurements. The relative permeability curves were derived based on the measured quasi-static magnetisation curves, and as expected, the relative permeability diminishes markedly with an increasing number of slits.

Measured quasi-static magnetisation curves and the corresponding relative permeability curves with between 0 and 4 cuts for RS (rolling direction) samples. (l) Quasi-static magnetisation curves. (r) Relative permeability curves.

The core losses at various flux densities (0.5T, 1.0T, 1.5T and 2.0T) and various frequencies (200Hz, 400Hz and 1kHz) were measured for all RS (rolling direction) and TS (transverse rolling direction) samples. By way of example, the 4-slit hysteresis loops need more field strength excitation to reach the same flux densities as the those of the 0-slit sample, which is consistent with the trend in the quasi-static magnetisation curves. Moreover, it can be observed that the enclosed areas of the hysteresis loops increase after laser cutting, indicating an increase in the hysteresis losses whose trend is consistent with the core loss comparison between 0-slit and 4-slit samples particularly at high flux densities.

Measured hysteresis loops for RS (rolling direction) samples with 0 and 4 cuts at 400Hz.

Measured core losses for RS (rolling direction) samples with 0 and 4 cuts.

To account for the deterioration in the magnetisation curve in the regions around the laser cut, a twoterm exponential function was employed to represent the relative permeability reduction variation with the distance to the cut edge, as shown in μ_r (x,H)=[1(ae^bx+ce^dx )] μ_r (H), where a, b, c, and d are coefficients of the relative permeability reduction function. x is the distance from the cut edge. μ_r (H) is the original permeability at a given value of magnetic field strength H. However, any laser cut within the strip will generate damage in both directions away from the cut. Hence, the above equation must be applied in both directions away from the strip. As a representative example, the figure below shows the normalised variation of permeability across one slit along the mid-line of the strip for a = 0.5, b = -600, c = 0.2 and d = -1000.

Variation in normalised permeability across one strip due to a single cut along the mid-line of the strip (a = 0.5, b = -600, c = 0.2 and d = -1000)

As further slits are added into a strip is important to establish a consistent representation of the cumulative damage done to the material. The representation adopted in this model is straightforward and represented by the product of the individual functions for degradation associated with each cut. By way of example, the figure below shows the individual functions for two cuts at 10mm and 20mm across the width of a 30mm strip and a combined variation which is simply the product of the two individual variations with the same set of parameters.

The spatial variation in the permeability will give rise to a corresponding spatial flux density variation across the width of the strip when a given magnetic field strength is applied. However, the variation in the flux density across the width of the strip cannot be directly measured and the sole measurement available is the total flux in the sample, which in turn provides a means of inferring an average flux density in the sample. It is necessary to integrate the flux density contributions from across the strip: B_mean (w)=1/w

Hμ_r0 (x)dx〖, where w is the strip width, and μ_0 is the permeability of free space.

Variation in normalised permeability across one strip due to two slits (a = 0.5, b = -600, c = 0.2 and d = -1000)

Then, the measured quasi-static magnetisation curves of the test-pieces are used to establish a set of parameters for the model which fits a specific combination of material and cutting conditions at a given value of magnetic field strength. The least square error method was employed to determine a, b, c and d coefficients at various magnetic field strengths, by minimising the mean error between the predicted and measured permeabilities for all the slitted samples. Subsequently, by substituting the derived load dependent a, b, c and d coefficients into the twoterm exponential edge damage function, the normalised permeability distribution across each strip can be modelled accordingly. The figure above shows the normalised permeability comparison between the curved fitted measured results and the model calculated results at various load conditions. A good agreement between the curve fitted measurement results and the model calculated results shows that the proposed model can represent the measured edge damage effect on the DC magnetisation curves of the Cobalt iron material.

To account for the edge damage effect in a finite element model of an electrical machine, the derived edge damage function is used to generate a series of magnetisation curves in which the distance to the edge is set at mean distance of the inner and outer profiles of the layer for a layered geometry. Note that this process must account for all the laser cuts which might impact on the net magnetisation characteristics, recognising that the effects of cuts close to the layer may well dominate over more distance cuts.

Normalised permeability comparison between the curved fitted measured results and the model calculated results at various load conditions

To investigate the impact of mechanical stress on the magnetic properties of Cobalt iron, a test rig comprising single strip tester and universal mechanical tester with strip supports and PTFE spacers was built as shown below. The strip supports are particularly important for compressive stress load conditions where the buckling can easily occur given that the strip thickness is only ~0.15mm. However, the strip supports, on the other hand, will give rise to a friction between the strip and its supports if the strip is tightly clamped, which will further lead to the difference between the force measured by the load cell and the localised force to which the strip is exposed. Therefore, the PTFE spacers are inserted between the strip and the strip supports to reduce the friction between them.

Prior to the loss density measurements a strip was placed under increasing tension and then the tension removed and a loss density measurement taken at 0MPa. As can be seen, irrevserisble increases in the 0MPa loss are observed when the strip has been exposed to stress in excess of ~160MPa, which is around half of the manufacturer quoted 0.2% yield stress of 310MPa.

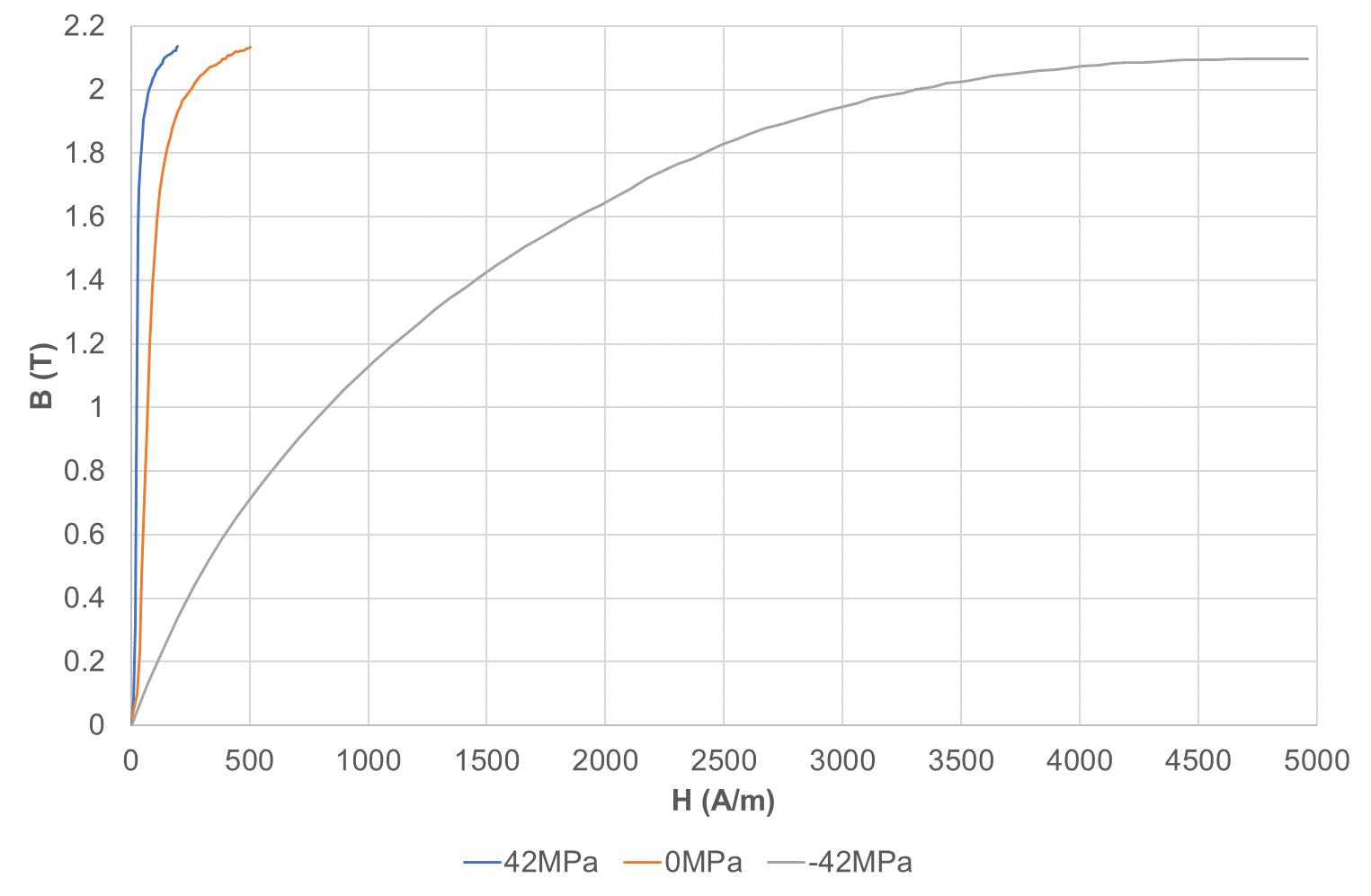

The measured BH loops under various tensile/ compressive stresses at 1.75T and 200Hz are shown in the figure below. Positive stress corresponds to tension while negative stress corresponds to compression. It can be seen that the impact of the tensile stress on the BH loops is much smaller than that of the compressive stress. When the compressive stress magnitude increases, the required magnetic field strength for a given flux density increases remarkably. The same trend can be observed in the measured DC magnetisation curves below. The required magnetic field strength for 2T at -40MPa is ~55 times that at 40MPa. This leads to a significant challenge in the attempt of higher compressive stresses, which is further compounded by a more severe buckling.

The measured loss densities under various tensile/ compressive stresses at 1.75T and 200Hz are shown in the next figure for both transverse rolled strips. With increasing tensile stress, the core loss initially reduces to a minimal point before increasing, a trend which is consistent with literature. However, in compression, the measured core loss although increasing initially, levels off with increasing compressive stress. As can be seen the curves are very similar until the compressive forces start increasing.

Change in loss density at 0MPa for transverse rolled strip after exposure to increasing stress

Measured BH loops for transvers rolled strips in tension/compression at 1.75T and 200Hz

Measured DC magnetisation curves for transverse rolls strip at 40MPa, 0MPa and -40MPa

This Grand Challenge is concerned with the precision manufacture of electrical machine coils, with a particular focus on solid bar section conductors and hollow conductors. Bar section conductors can significantly improve slot utilisation and improve inter-conductor heat transfer within winding. As detailed in the 2021 and 2022 Annual Reports, hollow conductors, where a fluid passes through a small duct in the centre of the conductor, transfer heat directly to the fluid and therefore reduces the dependency on heat transfer across the slot and through layers of insulation. For both variants of bar type conductor there is scope to increase current densities and hence power density of the electrical machine. Moreover, with hollow conductors, a more robust insulation system could be applied to meet electrical and mechanical requirements, rather than a compromise to manage thermal conduction within the winding.

The current focus of this work package has been on gaining an understanding of the challenges in producing form wound coils in square conductors, in particular in-plane bend forming. Several hundreds of metres of solid and hollow 4mm x 4mm copper conductor have been procured to facilitate experimental activities (see right). Each conductor type has 0.5mm corner radii and are covered with a 1x50% sintered Kapton insulation, with a 240°C temperature rating. The hollow conductor variant has a 2mm diameter circular duct at its centre.

Coils formed in bar-type conductor are constrained by the minimum bend radius of the conductor when forming the end windings and terminations. Consequently, the tooth width or coil span will define

the minimum conductor size. When producing bends in the conductor during the coil forming process, it is imperative that the integrity of the insulation is maintained, and the profile of the conductor cross-section is preserved. In the case of the hollow conductor, deformation in the duct will result in greater pressure drop in the coolant through the narrowed section of duct. Furthermore, the roundness and position of the duct, and an altered profile of the conductor cross-section due to bend forming, will affect heat distribution and losses within the conductor, as well as thermal resistances across the conductor. Thus, an investigation into the impact of bend forming on the hollow conductor duct and the insulation on both conductor types

is ongoing. A strip bending device, from Rigon Instruments, has been used to produce 180° bends in 4x4mm conductor samples. The device is a manual strip bending tester, for strip enamelled wire and tape wrapped wires, according to IEC 60851-3.5.1.2.

A straight wire sample of wire approximately 200 mm in length is bent through 180° round a polished mandrel of the appropriate diameter. A typical sample is shown below.

The change in conductor and duct profile, attributable to bend forming, is viewed by slicing the experimental conductor samples through the conductor crosssection, as shown in figure 5. The use of a wire EDM machine was deemed the least damaging method of slicing the conductor from the methods readily available. The EDM machine is able to determine the mid-point of the 180° arc by measuring the position of the inside edges along the straight part of the U-shaped conductor. The formed conductor sample is aligned parallel to the y-axis of the cutting wire and mid arc position measurement is taken at the start and the end of the 180° bend arc. Measurements of the sliced conductor profile and duct have been performed using a Keyence VHX Digital Microscope. Images of the cross-sectional view through the conductors, for the unformed conductor and the 5 bend radii, are shown in below.

The conductor is clamped between a plastic ring and collar, to maintain the conductor in the horizontal plane, and rolling bearings produce the bend in the wire sample. Customised plastic rings and collars have been produced to suit the 4x4mm conductor samples. The rings and collars are sized such that 3.5mm of the conductor width is clamped, with the remainder exposed to contact with the rolling bearing. This is in line with the manufacturer recommendation that the clamp should cover at least 60% of the sample. Literature suggests minimum bend radii for a bar type conductor of 1x conductor width for the solid variant and 3x conductor width for hollow conductors, the increase being required to preserve the duct geometry. Initial tests have been performed using mandrel diameters of 6, 12, 18, 24 and 30mm. This range represents 0.25x, 0.5x, 0.75x 1x and 1.25x the recommended minimum bend radius of the 4x4mm hollow conductor and 0.75x, 1.5x, 2.25x, 3x and 3.75x the recommended minimum bend radius of equivalent solid bar conductor. Manufacture of a second set of mandrels, rings and collars with diameters 8mm and 10mm, which represent 1x and 1.25x the recommended minimum bend radius of the solid bar conductor, is in progress.

The use of image recognition techniques, to analyse the conductor and duct profiles, is under consideration with other FEMM researchers. The progressive departure from of the original conductor and duct profiles can be seen as the forming bend radii are reduced.

Models of bend forming were developed previously as part of an ongoing investigation into potential support mechanisms for the conductor and duct during bending. The models provide predictions of conductor and duct deformation and are discussed in the 2021 Annual Report.

Removal of the polyimide insulation is required in certain sections of the conductor, to achieve an electrical contact in the wire EDM machine. For the initial samples, the polyimide insulation was removed

with abrasives. The use of an oven to breakdown the insulation would require temperatures in the region of 360-380C, which is likely to provide a degree of stress relief in the sample. For copper this occurs between 150-275°C, which could ultimately alter the stress effects created in the conductor sample through the forming of each bend and invalidate this investigation. A procedure is currently under development to remove the polyimide insulation by exposing all or part of the sample to concentrated sulphuric acid, using fume cupboards. The sulphuric acid is likely to require heating, which adds a significant level of complexity to the procedure.

To create standardised wire samples and for future coil winding activities, a two-plane wire straightening device has been manufactured by procuring of a pair of commercial wire straightening rollers and wire guides. The straightening roller assemblies are sized for a nominal 4mm diameter conductor, however the upper limit of the adjustment range extends to 5.5mm. The rollers are non-grooved to allow flexibility in wire profiles. Instead, a two-plane wire guide at each end keeps the conductor within the rollers. The wire straightening assembly is shown in below.

A simple former has been produced for initial coil winding trials, shown below. The conductor is wound around 4 pillars, which can be removed to release the coil, post forming. It is anticipated that initially, the effects of spring-back can be removed by controlled pressing of the sides of the coil post forming.

Progress has been made towards establishing an automated process to form multiple layers coils, in bar type conductor, for electrical machine windings. The coil is formed in incremental layers in terms of coil height and width. The proposed strategy is to wind a series of turns around a former, representative of the stator tooth, introducing a layer change feature per turn into the wire feed at a separation that results in the nesting of the layers changes in the end-winding region as illustrated to the right.

This activity will make use of a Winding Technology WT500 coil winding machine, once installation is complete. The shaft mounted on the former will be installed into a chuck mounted on the faceplate of the geared main spindle. Due to the cross-sectional area of the bar type wire, tension control cannot be applied directly to the conductor, and is instead achieved by applying a braking force to the reel. The wire straightener and equipment for producing the layer change feature will sit in line with the wire feed. The wire guide, tensioner/de-spooler and spindle of the winding machine are controlled through a common PC.

change feature into the conductor feed, as discussed in the 2022 Annual Report. This will allow layers to be established incrementally in the end-winding region, while keeping the conductors in the active region of the coil running parallel along the slots. This feature is produced in the feed by pressing the conductor between two forms, which creates two 45 degree bends and and a resulting one layer increment in conductor position. The hardware has since been manufactured and trial bending is ongoing to quantify spring-back in the conductor and assess the repeatability and effect on the insulation, when the layer change feature is produced. Springback compensation methods are currently being explored. Examples from the initial bending trials, with no springback compensation, are shown below.

coil design is 2 conductor layers in height and 4 layers in width. Due consideration has been given to ensure the minimum bend radii is within the constraints of the conductor. Due to extended lead-times on 4x4mm hollow and solid bar conductors, initial trails were carried out using insulated 4mm round copper wire. The wire was manually manipulated onto the former, as intended, and the resultant coil is shown below. As predicted, the effect of spring-back within the coil is clearly evident as the conductor transitions from the end winding region.

A hydraulic press has been used to apply the necessary force to the punch / die arrangement, however it is proposed that this force would be applied by an actuator in the coil winding process. Thus, some simple FEA analysis has been carried out to determine the required force. This model also forms part of an ongoing investigation into springback compensation.

The concept of winding a spiral type coil arrangement using a stepped former, then compressing to a final geometry, was reported in the Annual Report of 2022. A CAD image showing the intended formed coil, prior to compression, is shown below. The coil design was determined through a case study where the increased thermal performance of hollow conductor coils is exploited to reduce the volume and weight of the original air-cooled machine. Further details of the case study can be found in the 2021 Annual Report. The

A further iteration of former to produce a spiral coil, improved for automation, is shown below. The placement of the conductor during the winding process is controlled using fin guides. The coil, once formed, is then removed and compressed to its final geometry. In this case, spring-back can be managed by controlled pressing of the coil sides (active region), prior to removing the from the former. Development of further iterations to the coil former geometry to compensate for spring-back are ongoing and allow the overbending of the conductor at the transition from the end winding to the active region.

The existing hollow conductor thermal model, which estimates average conductor temperature for a given coolant flow rate, current density and coolant inlet temperature, has been improved to include more detailed fluid characteristics. This enhancement allows instantaneous determination of the fluid density, viscosity, heat capacity and

Peak average copper and fluid temperature and pressure drop for 4x4mm, Ø2mm duct conductor. Current density = 40A/mm2, inlet coolant temperature = 57.2°C. Length of conductor = 1m.

thermal conductivity, for a given estimation of fluid temperature, in each axial element along the length of the conductor. The conductor and fluid are modelled as a series of discrete elements, which represent a length of fluid or conductor. Manufacturer data for the fluid is interpolated in each element to provide properties for any predicted fluid temperature, within the range of the data supplied. Furthermore, alternative fluids, for which comprehensive property data is available, can easily be incorporated into the model. The current fluid models are Midel7131 and Eastman2839. Predicted average copper temperature, fluid temperature and pressure loss, across a 1m 4x4mm hollow conductor with a 2mm diameter duct, is shown in the graph above as a function of flow rate, for Midel 7131 and Eastman 2389 coolants. The temperature values represent

the peak of the average copper temperature, along the length of the conductor. The predicted pressure drop is across the 1m conductor.

Thermal characterisation of a 3x2.3mm PEEK insulated hollow conductor, with a 1.3mm duct has also been carried out using the existing hollow conductor test rig. Further details of the experimental test rig can be found in the FEMM Hub 2022 Annual Report. The current density was set at 40A/mm2 and the coolant flow rate was limited to 1.2 l/min in a 220mm long section due to the pressure drop of 4.1bar being at the limit of the available pump. Measured temperatures at a series of point along the conductor, fluid inlet and outlet temperature for these conditions are shown in below.

Measured copper and fluid steady state temperature for 3x2.3mm, Ø1.3mm duct conductor operating at a current density of 40A/mm2 at a flow-rate of 0.55l/min for 7 thermocouples spaced at 30mm along the 220mm long sample and at inlet, outlet and connection cables

Grand Challenge 2.3 focuses on opportunities and enabling technologies for flexible manufacture, bringing the benefits of automation, such as improved quality and traceability to low volume production of high value electrical machines.

Remote laser cutting is being explored in this grand challenge as an alternative to conventional fusion laser cutting of electrical steel laminations. This technique which relies on high-brilliance lasers to achieve power densities of 107– 1010 W/cm2 and scan speeds on the order of several meters per second whereupon material partially vaporised. The expanding plume of the vaporised fraction pushes molten material from the kerf to a depth of tens of microns, cutting through the full sheet over multiple scans, achieving effective cutting speeds several times faster than conventional systems. The technology is therefore explored as an opportunity to extend the

viability of laser cutting beyond prototyping, and exploit the additional design freedom of customising each layer with a laminated stack.

Work has continued to investigate the range of workable cutting parameters for silicon (SiFe) and cobalt (CoFe) electrical steels using a mixture of microscopy on cleaved and polish samples (as shown in Figure 2.3:1) and focus-variation microscopy to obtain the cut profiles. The material removal rates in SiFe and CoFe was evaluated at various scan speeds and laser powers, showing more effective cutting in CoFe and which was observed to be accompanied by less thermal damage. The difference between these materials will be studied in greater depth over the next year. The results on CoFe steel were presented as a poster at PEMD 2022 by Dr Alexei Winter and published in the conference proceedings.

Samples of SiFe were also prepared for mechanical testing as part of a feasibility study funded by the

FEMM Hub with Dr Hassan Ghadbeigi and Luke Jones from the University of Sheffield, Department of Mechanical Engineering. The objective of this work was to characterise any knock-down in mechanical performance and correlate this with cutting parameters which could then inform the design of features such as the thin bridges found in synchronous reluctance machine rotors. This study included nanoindentation hardness testing to identify the extent of thermal damage and microCT measurement of the failure mechanism under tensile testing (see Figure 2.3:3). The results of this feasibility study are expected to be published in the coming months.

After developing a recipe for cutting SiFe, attention was turned to cutting laminations for a complete stator with tailored laminations to approximate threedimensional features, a so called 2.5D geometry. This stator shown in Figure 2.3:4 was produced in collaboration with a High-Value Manufacturing Catapult-funded project on lightweight electrical machines. This production run has highlighted key technical challenges to address in the Hub to enhance the manufacturing readiness level of this technology. In particular, whilst a short focal length objective lens may be used to achieve the required power density without dramatically increasing the laser power, greater care must be taken to avoid contamination of the optics. Additionally, consideration must be given to the tool path to avoid the build-up of heat in an area over successive scans.

Following completion of the 2.5D stator in March, attention will return to drafting a journal article on process optimisation in remote laser cutting of

electrical steels whilst the drives for the linear axes are sent for repair.

Industrial robot manipulators can be adapted to a wide range of tasks applicable to electrical machines and have been demonstrated in magnet placement, coils insertion and lamination stacking. Such robots are therefore proposed as the basis of a flexible manufacturing system that can switch between these various tasks, affording the benefits of automation, such as improved quality and throughput, without the inherent inflexibility of dedicated automation.

Over the last year, work has continued in developing robotic needle winding using a KUKA KR 60 HA robot equipped with a bespoke end-effector (see Figure 2.3:5). Previous studies have demonstrated robotic needle winding using parallel kinematic and SCARA but have suggested that six-axis industrial robotic manipulators are not sufficiently stiff to counteract the tension on the wire. Under static trials in which the wire was drawn under various tensions up to 45 N from the end-effector the robot deflected by up to 1.6 mm suggesting compliance of 32 μm/N, an order of magnitude greater than that reported for comparable robots in literature.

During winding the robot’s deviation from the planned trajectory was measured using a laser tracker which uses a combination of encoders and laser distance measurement by time of flight. An extract of these results is shown in Figure 2.3:6. The planned trajectory was assumed to be that followed by the robot without the perturbation of the wire at low speed. It was found that the wire did indeed deflect the robot from the planned trajectory but for the wire tension used, this deviation was not much larger than that expected when the robot runs at high speed. Therefore, it was concluded that such sixaxis robots are capable of needle winding with the wire tensions considered.

It was then observed that the exit angle of the wire from the needle has a significant influence on the resulting tension on the wire due to friction. It was found that the wire tension at the output of the needle could double at large angles. Work is currently underway to use this calibration data to compensate for the additional variation in wire tension due to the varying exit angle from the needle. The efficacy of this compensation will be evaluated using a

multi-axis load cell to which the stator tooth will be mounted to allow the magnitude and direction of the force imparted to be measured. This can similarly be expected of standard needle winding machines and in the wire guides of linear winding machines.

A manuscript describing work is currently being prepared for a journal article.

A desktop study was conducted into flexible manufacturing processes for slinky stators, a technology highlighted on the Advanced Propulsion Centre’s Electrical Machines Roadmap to reduce wastage in stator and rotor production. In this study

the material utilisation for stators with different internal diameters. It was found material utilisation can be several times higher when cutting a slinky compared to a stator alone provided the internal diameter is above 36% of of the outer diameter. However, if the rotor lamination is also required, cutting the stator as a slinky at best only offers savings of 3.8%, but is generally less efficient than nesting the rotor within the stator. Several options for cutting slinky stators were evaluated in terms of productivity and the flexibility offered. A manuscript describing the result of the study is currently being prepared.

Collaboration has continued with Dr Jill Miscandlon on a general assessment of manufacturing processes

which might enable flexible or highly customised production of electrical machines, with a journal article now close to submission.

For detailed information about the FEMM Hub Grand Challenge 2.3 contact Lloyd Tinkler, Senior Technical Fellow in Electrical Machines: l.tinkler@amrc.co.uk

In January 2021, a new work package was launched within the FEMM hub focused on the sustainable manufacture of electrical machine components, with a view to implementing circular economy strategies. Sustainability is a key component of any future machine design, and as such, this Grand Challenge was updated to be a cross-cutting theme of all FEMM hub work packages. This will ensure that a clear focus is given to the sustainability of future electrical machines. This work package aims to:

• Reduce use of finite materials in next generation of machines and enable recapture cycles to reuse materials

• Give consideration to energy efficient manufacturing

• Implement Design for Disassembly strategies for future electrical machines, including opportunities for reuse, recycle, remanufacture etc.

• Develop a circular economy approach for an electrical machine supply chain that uses data driven intelligence based on product data

To achieve many of these goals, the FEMM hub are collaborating with the wider community on key strategic areas. Discussions are ongoing about joint projects with the Offshore Renewable Energy Catapult, and the wider High Value Manufacturing Catapult, of which two FEMM hub groups are already a part of (NMIS and AMRC).

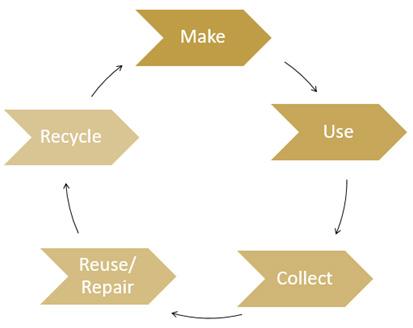

Current electrical machines are manufactured using a linear economy model- the “take-make-waste” model as shown below - which takes raw material, transforms it into products, and then discards them to waste without considering the environmental consequences.

The circular economy (CE), shown below, is a systemic approach to economic development designed to benefit businesses, society, and the environment. Adopting circular economy approach does not dictate one solution to solve all the issues, but is an alternative way of approaching the problem, and provides many solutions that can be adopted.

Often, when “sustainability” is mentioned within the engineering community, the first response is often linked to recycling material. Although recycling of materials will be an important factor in the drive towards circularity, it should not be considered the first or only solution. The circular economy hierarchy (see right) is a ranked order with the most favourable solutions at the top, i.e. those that require less energy consumption and material usages, and the least favourable solutions at the bottom. This hierarchy doesn’t imply that activities such as recycling or remanufacture should not be included in a comprehensive circular economy strategy, but other strategies, such as redesigning components in order to reduce material waste and design for disassembly and repair, should be prioritised.

Due to the diverse range of topics included in GC X1, a series of small feasibility projects have been undertaken in the previous two years investigating multiple areas of interest. In 2021, projects were concluded on “Removal of coil resins in high value electrical machines”, “End of life strategies for electrical steels”, and “Strategy workshop for circular economy of electrical machines”. The project “Life Cycle Assessment (LCA) of an electrical machine” was also conducted with a FEMM hub partner, and discussions are ongoing on the best method of publication for the project outcomes. Further information on these topics can be found in the FEMM hub 2022 annual report. In 2022, additional projects were launched to fill in knowledge gaps, and these will now be summarised.

A project was conducted on collecting information on the certification requirements for electrical machines within the wind, aerospace, and automotive sectors. Information will be gathered on both newly manufactured and remanufactured components in order to aid GC X1 with developing a comprehensive end-of-life strategy for high value electrical machines.

A short project was also launched looking at the potential for replacing virgin materials with recycled stock in electrical machines. This focused on the key materials within an electrical machine, including titanium, steel, aluminium, and copper, and started the research stream into understanding the main differences in performance and life span of recycled materials versus virgin stock. Another project summarised the state-of-the-art in sustainable composites and potential recycling strategies, as well as highlighting potential areas of implementation

within future electrical machines. ‘Green’ composites are receiving a lot of attention, with these materials manufactured using biomass rather than the traditional sources. Crucial research is also progressing into recycling of composite materials, with current estimates of 40-90% of composite material (dependent on material type) ending up in landfill.

The FEMM hub team at NMIS hosted a masters student from June to December 2022 in the area of electrical machine sustainability. Eilidh Pearce, who is studying for a MEng in Mechanical Engineering at Glasgow University, completed her masters thesis on “Sustainable Design of Generators for Offshore Wind: Life Cycle Comparison of Lightweight Rotor Structures” under the supervisions of GC X1 leader Dr Jill Miscandlon. Eilidh applied the principles of the circular economy to the IEA 15 MW Reference Wind Turbine [1], and optimised a lightweight design to meet the minimum air-gap deformation and modal requirements. She found that a conical rotor design showed a large advantage over other rotor designs, with a 29.9% mass reduction and a subsequent 32.5% reduction in carbon footprint compared to the original design. In addition, designing the rotor for reuse offers even larger environmental benefits overall. This work was also supported by Dr Pablo Sola at Edinburgh Napier University, who previously received funding from the FEMM hub for a feasibility study “CEDEMSARI- A critical evaluation of large scale direct drive wind turbine electrical machines manufacturing techniques considering sustainability aspects and recyclability issues”. The aim for GC X1 is to take these two streams of work forward into a future joint project between FEMM hub and Dr Sola.

The tracking and traceability of manufacturing processes allow for improved quality and cost savings within many industrial activities. These have recently been driven by digitalisation through sensors and other data capture means, and the integration of this data into high-fidelity models or ‘Digital Twins’. The manufacture of electric machines is itself a complex task, involving the synthesis of many traditional machining/forming and cutting processes interspersed with assembly, integration and test. This year our work has focused on the theme of digital twins, looking into the capture and modelling of manufacturing and assembly processes and their subsequent characterisation and optimisation.

The coil winding / forming process within electric machine manufacture includes several variable methods, from simple bobbin wound linear coil winding and needle fed winding, to the more common random wound and insertion techniques used in the automotive industry. In all instances, it is important to know the state of the wound coil, either for in-process monitoring or post-process assessment and characterisation. This work has focused on establishing a methodology for the in-process monitoring of linear coil winding and coupled digital twin of the wound coil. Through the use of deep neural network (DNN) semantic object

detection, we can extract individual wires that make up a coil and use this information to build a spline representation that can be fit to a digital model of the coil. This allows us to track the overall shape and placement of individual wires as it is being wound.

In this work, we focus DNN models for semantic instance segmentation (YOLACT++) to provide realtime data as the coil is being wound. Over time as more and more wires are extracted, we can use this information to update a parallel digital twin model of the winding process. The ability to characterise in near real-time could allow us to undertake corrective measures if errors or defects seem likely or are predicted. Figure X2-1 highlights this process, showing data capture, wire segmentation and coil model (wire count / lead wire angle).

One of the challenges in this type of activity is the accurate capture of image data of the coil as it is being wound at high speed. Though high-speed cameras can be utilised to extract this information, an alternative source of data has begun to enter the fray of industrial process monitoring. Event based cameras work on a completely different paradigm, capturing per-pixel data only when a sufficient threshold has been met. This provides some benefits, such as an extreme capture rate of around 10,000fps, a high dynamic range (120dB) and low light capture (0.08 lux). Supporting both DNN machine vision

architectures and more biologically inspired spiking neural networks (SNN), the EVK4 camera provides new opportunities for tracking and traceability of high-speed processes. In support of the linear coil winding work and other high-speed processes in EM manufacture, we have incorporated an event camera into our data capture pipeline and are currently investigating the benefits such a system can bring for monitoring of these EM processes as shown in figure X2-2.

According to a recent survey [doi: 10.1177/09544054211016675], up to 10% of Litz wires have failed connections due to incomplete stripping of some strands inside the connector. Figure X2-3 shows the CT scan of a Litz wire termination showing the wires that had incomplete enamel

removal did not allow a soldered connection (darker region). Individual processes of stripping and joining will often increase the handling effort, production times and costs required. These are inevitable in Litz wires that are required to operate effectively at higher temperatures, for example in aerospace applications. Some processes for quantification of enamel removal have been reported in the literature,

however, non-destructive testing processes for inspection of enamel removal are lacking. This work attempts to address this gap by utilising infrared thermal imaging and machine learning techniques

for the inspection of the enamel removal process on Litz wires commonly used for aerospace and automotive applications. The temperature profiles of the wires with or without enamel were recorded using infrared thermal imaging and data obtained during the heating and cooling profiles of the wires was used to train the machine learning techniques for automated inspection of enamel removal on Litz wire bundles. Several classifier models such as Support Vector Machines (SVM), K-means and Gaussian Mixture Model with Expectation Maximisation (GMM) were investigated for automated inspection of enamel removal for identifying the remaining enamel on a set of enameled copper wires. After comparing the performance of the classifier models in terms of classification accuracy, the GMM was found to be the best with a training accuracy of 85% and enamel classification accuracy of 100%, and the fastest evaluation time of 1.05 seconds. Figure X2-4 shows the average training and enamel classification accuracy for each trained model for two classes (enamel and non-enamel). The SVMs were also trained using a bagging classifier. For the four-class model (enamel, copper, background, and tape), the Support Vector Classification (SVC) with bagging classifier achieves an accuracy of 82% when the 2nd derivative of the cooling period is used, however, the evaluation time of 134 seconds makes it difficult to use for live systems. A future study currently being undertaken will involve building a demonstrator utilising the current findings and applying the Gaussian Mixture Model for real-time in-process monitoring.

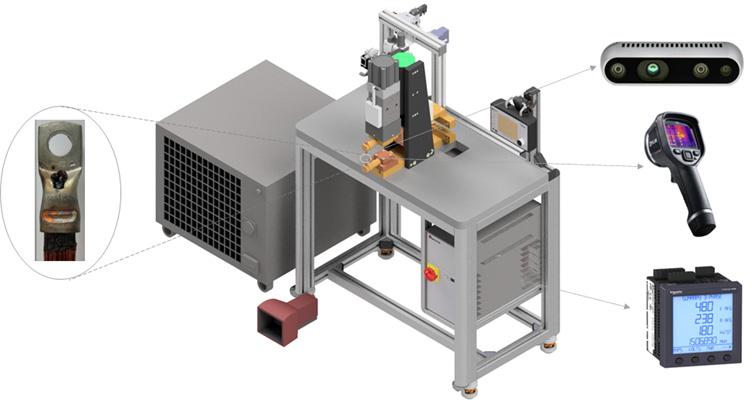

In another area of high interest in terminations, technologies that combine both the process steps of stripping and joining are being investigated due to their cost-effectiveness and efficiency. The thermal or hotcrimping technique combines high process stability with short tact times, however, this process is prone to generation of defects such as improper insulation melting and burnt wires resulting in requirement for frequent setup processes (and corresponding costs). Research being undertaken in our lab is currently developing a lab-based sensorised hot-crimping system to investigate the process parameters that impact the quality of the hot-crimped termination. The hot-crimping system will be instrumented with various sensors such as vision sensors for monitoring the tool’s wear, infrared sensors to capture the thermal profile of the joint while it is being made, and a power monitoring device that can monitor the power drawn by the system, as shown in Figure X25. Data acquired from the sensors can be analysed and sensor fusion techniques can identify the most useful sensors and meaningful data. Supporting the work flow and digitalisation of the terminations process, the manipulation and assembly of cable and wires has also been investigated building upon past work.

In this instance, the manual assembly of deformable linear objects (DLOs) and the supporting algorithms for their detection continues in a use case built around the challenge of cable routing and manipulation. The need to track the correct placement of DLOs internally within a wind turbine and keep record of the current state (cable length) from one work area to the next is a challenge. Here we are investigating methods for DLO detection in environments where

incomplete detection leads to gaps and missing data which then needs to be ‘fixed’ in order to correctly model the DLO in the scene. State of the art DLO detection algorithms such as FastDLO are capable of modelling fully detected DLOs but struggle with partial detections as seen in the figure X2-6. Though the individual components that make up a DLO can be modelled, their full connectivity often fails. Exploiting additional information (direction and ‘flow estimation’) of the individual cables, we are looking to develop better detection and DLO modelling algorithms for processes such as these.

Figure X2-6: Cable routing and assembly is another activity that requires the detailed capture and modelling of deformable linear objects (DLOs). Obscured and discontinuous cables pose a challenge when trying to construct and measure the total length of laid cables and wires during assembly.