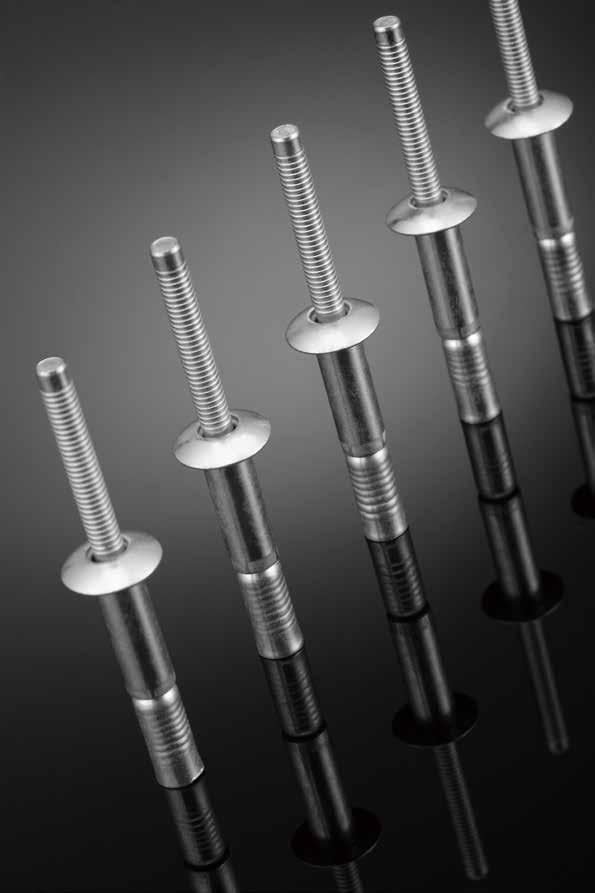

PPG, the world's leading coating supplier, is helping fastener manufacturers break through the bottleneck and meet the international challenges with its leading electrocoating technology.

Renowned as the Kingdom of Fasteners, Taiwan boasts a complete supply chain that caters to global demands with both standard and special products. PPG is a leading global coating supplier and pioneer in application of coatings, dedicated to combining coating expertise with fasteners to enhance their value.

PPG Alltech Engineered Finishes in Kaohsiung, established by PPG in 2006, marked PPG’s first foothold in Asia. It introduced electrocoating technology to Taiwan's fastener market, injecting new vitality into the value of Taiwan's industrial and automotive fasteners. PPG Alltech Engineered Finishes now plays a crucial role in stabilizing the quality of Taiwan's fastener supply chain.

In 1976, PPG successfully developed electrocoating technology using cathodic epoxy, replacing anodic electrocoating and introducing it to the automotive industry. By 2001, PPG had introduced product standards for the fastener industry using this

technology and continuously improved coatings to be compatible with various small components, complying with international regulations. Today, this technology is widely used on construction fasteners and in automotive and industrial markets.

PPG Alltech Engineered Finishes has served Taiwanese clients for nearly 20 years, maintaining close relationships and the highest service levels. “PPG's electrocoating technology uses proprietary technology and allows our team to educate our trusted client base, creating a bond that helps us compete in a crowded fastener coatings market.” The electrocoating film can provide uniform thickness, perfectly covering specially designed fastener recesses and threads, preserving the original appearance

of screws. PPG states, "We excel at coating customized small screws and construction screws because their varied shapes allow us to leverage our strengths of this finish. Other fastening products can also be coated, as we offer the best uniform film build, as well as the best surface protection and maximum product performance."

PPG continues to lead the future with its technology and join hands with the fastener industry to help them survive OEM challenges, and establish a new high value-added image of Taiwan as the Kingdom of Fasteners.

PPG electrocoating technology boasts industry-leading features:

1. Corrosion and Acid Resistance, Doubling Product Lifespan: Salt spray tests (ASTM B117) show increased corrosion resistance to over 2,000 hours. Acid resistance reaches 30 acid rain cycles. Passing the Nordic NORDTEST-method NT MAT 003 C4 and ASTM G85 Annex-5 500 cycles tests.

2. Precise, No Clogging, No Coating Accumulation: The cathodic epoxy electrocoating technology uses the principle of attraction between positive and negative poles, allowing coating particles to be absorbed and evenly deposited on the workpiece surface, forming a continuous thin film that uniformly covers the gaps and corners of the workpiece. The film thickness can be precisely controlled to prevent clogging and coating accumulation.

3. No Hydrogen Embrittlement, Meeting Torque Requirements: PPG’s Electropolyseal® III coating converts phosphate into a base coat, allowing hydrogen ions that cause embrittlement to be released from small pores. It also addresses torque correction issues, ensuring that the workpiece meets the torque requirements for automotive fasteners.

4. Environmentally Friendly, Compliant with Regulations: Extremely low volatile organic compound emissions, with no pollution by hazardous air pollutants or heavy metal contamination from chromium, etc. Compliance with R oHS, REACH, among others, providing a significant advantage for fastener sellers in advanced countries.

PPG notes that many foreign buyers have been actively and strategically seeking low-cost manufacturing, which inevitably compresses profit margins for fasteners. "Enhancing the value of fastener products" is a necessary path for the transformation of the Kingdom of Fasteners, and PPG's electrocoating can be a tool for fastener companies to increase value. By offering better user experiences through the aforementioned four features, PPG helps clients break free from low-price competition. "From a global perspective, the U.S. has the highest demand for electrocoating, while Europe has relatively lower demand. Over the next five years, we will gradually expand into Europe and increase demand there. Additionally, we can collaborate with Taiwanese manufacturers to provide full consulting and coating services for all overseas clients, offering on-site services at the Taiwan International Fastener Show or at clients' facilities."

PPG’s contact: Kayenne Huang, Sales & Service Representative Email: kayenne.huang@ppg.com

Contact: Bill Wang, GM Email: bill@hupao.com.tw

What will you think of first when it comes to the fastener industry? Pollution? Or a sooty workplace? How can an industry that has never been associated with environmental protection go green? Bill Wang, GM of Hu Pao Industries, who has been in the fastener industry for over 20 years, points out that the key lies in “Net Zero”. Net Zero is a process of minimizing carbon emissions and offsetting them with carbon credits or carbon absorption. It sounds simple, but is an important industrial revolution for the fastener industry to enhance the competitiveness, coexist with the environment, and create a circular economy in the future.

In order to reverse the public's stereotype of dirty screw factories, GM Wang, who fully believes that enterprises should not only focus on profits but also bear environmental & social responsibilities, began to promote “net zero” in the fastener industry many years ago, and started with his own factory expansion to create a comfortable and safe workplace with low carbon emissions for all employees. He thinks that the disasters caused by climate change have become more serious than ever, and if people don't do something, they are bound to affect our future generations. “Net zero can’t be just a

lip service and change can only be made by breaking old rules,” says Wang. Such ideas can be implemented in fastener factories through 5S management, lean process management, digital carbon emission management, or improving high carbon emissions through organizations. He thinks that the spirit of net zero is sustainable coexistence, not to comply with regulations, but to demonstrate a company's commitment to environmental protection and find a carbon reduction strategy that best suits its own size in the long run.

The essence of a green enterprise lies on its respect to the environment. Besides eye-catching carbon reduction figures, it should further create a sense of fulfillment for employees, a sense of trust for customers, and a sense of coexistence with the community. Meanwhile, building a company that everyone can be proud of through carbon reduction to enhance the product value is also Wang's top consideration while making decisions. Although the fastener industry is not as large-scale as other industries, each fastener is the key to supporting the global industries. ”CBAM is a challenge, but is also an opportunity for the industry to be transformed and redefined. If we can reduce the carbon emissions of countless fasteners around the world, we can transform ourselves from manufacturers into connectors to sustainability," says Wang.

Making net zero a part of his corporate culture, Wang has introduced a digital energy management system, solar panels, equipment upgrade, ISO carbon inventories, and lubricant recycling system into the corporate management. On the other hand, he also planted trees, provided veggie meals for employees, and invited supply chain partners to reduce carbon footprints, putting the concept of net zero into practice in lives and work. “I once visited a cosmetics factory and was surprised at how clearly they showed their carbon footprints on products. The fastener industry must keep pace with the predecessors' advances in digitization and energy efficiency management, and have the spirit of sustainability

internalized. Transparent carbon info is what the fastener industry lacks the most , and understanding CBAM specifications is part of a concerted effort," says Wang.

In response to CBAM and U.S. carbon reduction system, the disclosure of carbon emissions will become a new criterion in addition to price if one wants to compete for orders from large factories. Wang thinks that carbon reduction is a way to reducing costs with quantifiable benefits on one hand, and helping enterprises transform towards branding and innovation on the other hand. Under his leadership, Hu Pao has started to work with customers to design low-carbon products and develop alternative materials. He encourages the industry get to know themselves by carbon inventory, setting up task forces, introducing management systems like ISO14064 and ISO50001, not going it alone, and making good use of associations, industry forums and official/ external consulting platforms to obtain more subsidies or resources. "I hope to build a ‘Low Carbon Smart Factory Demo Base’, and am also developing a more convenient carbon emission statistics system. In the future, I’d like to invite industry partners to set up a ‘Sustainability Alliance’, so as to attract more people (especially young people) to change the fastener industry. Small screws support the world's operation. If you are willing to do so, you can join us to transform the fastener industry into one that thrives with the environment and that you are proud to be a part of,” says Wang.

※Hu Pao's new logo combines the shape of nut threads with the Earth’s curvature, symbolizing the close connection with the world. The inner ringshaped curve symbolizes the company's progress towards the concept of a circular economy. The dark and light green colors represent solid technical expertise as well as innovation, sustainability and hope. They fully reflect the company’s commitment to carbon reduction, sustainability and green coexistence.

Copyright owned by Fastener World / Article by Gang Hao Chang, Vice Editor-in-Chief

Achilles Seibert GmbH, a family-run specialist in fasteners based in HenstedtUlzburg, Germany, continues to strengthen its position as a key partner for distributors worldwide by expanding its services, geographic footprint, and sustainability efforts. With a history dating back to 1951, the company has evolved from a traditional importer and warehouse to a comprehensive service provider, adapting to the challenges of a volatile global market and regulatory environment. Today, it works between distributors and manufacturers, selling to distributors and acting as an importer and a warehouse for distributors such a Bossard, Böllhoff, Würth, from big to small brand names and shops.

At the end of 2023, Achilles Seibert finished its warehouse expansion in Germany. In 2024, it further extended its global reach by establishing warehouses in Vietnam and India, staffed with local employees responsible for sourcing and quality control. This strategic move allows the company to store goods closer to key manufacturing hubs, streamline logistics, and reduce the workload on its German operations. The company is now opening its own office in Ho Chi Minh City, Vietnam, in 2025, signaling a deeper commitment to the Southeast Asian market and enhancing service capabilities for customers in Asia and onto the whole world.

Amid ongoing geopolitical and economic uncertainties, Achilles Seibert has diversified its sourcing strategy to mitigate risks. The company has expanded its supplier base and product range, aiming to meet the demands of a broader customer base. This includes increased business in Eastern Europe, a growing market within the EU, and a strengthened presence in Southeast Asia, supported by the new warehouses in India and Vietnam. These developments enable the company to serve customers more efficiently across multiple regions, including the US and Canada.

The company also plans to enhance its product portfolio in the latter half of 2025, alongside offering sourcing, consultation, and quality control services for customers in India and Vietnam. “We no longer just want to sell fasteners but also offer a service. We want to create added value for customers, including 24-hour fast delivery, delivery directly from their suppliers in 3-6 months, delivery from the Vietnam and India warehouses in 4-8 weeks,” said Timo Scholle, Managing Director. This value-added approach reflects Achilles Seibert’s transition from a pure fastener supplier to a comprehensive service partner, providing 24-hour fast delivery and tailored supply chain solutions.

The company also leverages digital tools to enhance customer experience. Its user-friendly webshop allows customers to check product availability and place orders quickly, reducing administrative burdens and improving supply chain efficiency.

Achilles Seibert values its longstanding relationships with global partners, particularly in Taiwan. The company follows its partners into new production areas, benefiting from their expertise and knowledge. This collaborative approach supports Achilles Seibert’s growth and ability to adapt to changing market conditions.

Achilles Seibert GmbH is successfully navigating the complexities of the global fastener market through strategic warehouse expansion, geographic diversification, enhanced service offerings, and a strong commitment to sustainability and regulatory compliance. With a growing presence in Southeast Asia and Eastern Europe, and plans to broaden its product range and services, the company is well-positioned for continued growth and leadership in the fastener distribution sector.

Contact: Timo Scholle, Managing Director

Email: timo.scholle@achill-fasteners.com

As the European Union continues its phased implementation of the Carbon Border Adjustment Mechanism (CBAM), businesses engaged in importing carbon-intensive goods must prepare for its operational requirements. While previous articles in this series have explored CBAM’s objectives and the industries affected, this article focuses on the procedural aspects—how CBAM works in practice and what steps are involved in compliance. Understanding the key processes will be crucial for companies navigating this evolving regulatory framework.

CBAM is designed to ensure that imported goods are subject to a carbon price equivalent to that imposed on domestic producers under the EU Emissions Trading System (ETS). To achieve this, the mechanism follows a structured process, requiring importers to assess emissions, report them, and ultimately account for their carbon footprint through the purchase of CBAM certificates.

CBAM is being introduced gradually, with a transitional phase allowing businesses to familiarize themselves with reporting obligations before full financial implementation takes effect. The transitional phase, which began in October 2023, will last until the end of 2025, after which the full financial obligations of CBAM will come into force. During this period, importers are required to report emissions data but are not yet required to purchase CBAM certificates.

Importers must determine whether their goods fall within the scope of CBAM. Currently, the regulation applies to high-emission sectors such as steel, aluminum, cement, fertilizers, electricity, and hydrogen. These sectors were chosen due to their significant contribution to global carbon emissions and their exposure to carbon leakage risks.

Each product is classified under specific Combined Nomenclature (CN) codes, which determine its regulatory treatment. Accurately identifying these codes is essential for compliance, as they dictate reporting and carbon pricing requirements. The classification process can be complex, particularly when dealing with composite materials or goods that undergo multiple production stages.

For example, steel products are classified under various CN codes, such as 7208 51 00 for hot-rolled steel and 7210 41 00 for cold-rolled steel. Similarly, aluminum products are classified under codes like 7604 10 00 for aluminum bars and 7606 12 00 for aluminum plates. Importers must ensure that their goods are correctly classified to avoid penalties or delays in customs clearance.

Embedded emissions refer to the greenhouse gases emitted during the production of goods, from raw material extraction to the final product. CBAM requires importers to report these emissions, ensuring that the carbon footprint of imported goods is fully accounted for.

Embedded emissions are classified into different categories:

- Direct emissions: Emissions resulting from the main production process, such as the combustion of fossil fuels in a steel furnace or the electrolysis process in aluminum production.

- Precursor emissions: Emissions associated with the raw materials used in production. For example, in steel manufacturing, the emissions from iron ore processing must be accounted for.

- Indirect emissions (currently excluded but under discussion): Emissions from electricity used during production, such as power sourced from coal-fired plants in a non-EU country.

To comply with CBAM, businesses must accurately track these emissions throughout the supply chain, which can be complex, particularly when dealing with suppliers in regions with limited emissions reporting frameworks.

A critical challenge for importers is ensuring that emissions data is consistent and verifiable. Many suppliers outside the EU may lack

the infrastructure to provide detailed carbon footprint assessments, requiring importers to assist in setting up emissions reporting mechanisms or to seek third-party verification.

The core requirement of CBAM is the calculation of embedded emissions in imported goods. This includes emissions from direct production processes as well as precursor materials used in manufacturing. Importers must work closely with their suppliers to gather accurate emissions data, following methodologies outlined by the European Commission.

If actual emissions data is unavailable, default values may be used under specific conditions. However, the EU has signaled that default values should only be relied upon as a last resort, and importers must demonstrate efforts to obtain real data from producers.

The process of emissions data collection involves tracking emissions across multiple stages of production. For instance, in steel manufacturing, emissions data must be recorded from raw material extraction, transportation, processing, and final production. Similarly, in the aluminum sector, emissions from bauxite mining, refining, and electrolysis must be captured accurately.

Many companies are now investing in blockchainbased systems to trace carbon emissions throughout their supply chains. Such technologies can improve transparency, reduce fraud, and ensure compliance with CBAM’s stringent reporting requirements.

During the current transitional phase, importers must submit quarterly reports detailing the emissions associated with their imports. These reports serve as a trial period for businesses to adapt to CBAM’s requirements and provide the EU with data to refine its implementation.

Reports must include:

- The quantity and type of imported goods.

- The total embedded emissions for each product.

- Information on any carbon pricing mechanisms applied in the country of origin.

While no financial obligations exist during this phase, compliance with reporting requirements is essential to avoid penalties and to prepare for the next stage.

To ensure accurate reporting, companies should establish internal processes for emissions tracking and verification. This may involve implementing digital tracking systems or hiring sustainability experts to assist with compliance.

Once CBAM is fully implemented, importers will need to buy CBAM certificates corresponding to the emissions embedded in their goods. The price of these certificates will be linked to the EU ETS carbon price, ensuring alignment between domestic and imported carbon costs.

By the end of each compliance period, importers must surrender the appropriate number of certificates to cover their declared emissions. If an importer has paid a carbon price in the country of production, they may be eligible for a reduction in the number of required CBAM certificates, provided that the foreign carbon price is deemed equivalent to the EU standard.

Implementing CBAM will introduce several challenges for businesses:

- Data Collection: Many companies rely on complex international supply chains, making it difficult to gather emissions data from upstream producers.

- Administrative Burden: CBAM requires importers to maintain detailed records and ensure compliance with evolving EU regulations.

- Cost Implications: While CBAM promotes fair competition, it could increase costs for businesses importing goods from countries with high-carbon production methods.

Despite these challenges, CBAM also presents opportunities for companies willing to adapt:

- Supply Chain Optimization: Businesses may explore sourcing from lowercarbon producers or invest in cleaner production methods.

- Competitive Differentiation: Companies that proactively reduce their carbon footprint may gain a competitive advantage as sustainability becomes a key market driver.

- Policy Alignment: Understanding and integrating CBAM into corporate strategy will ensure long-term compliance with EU climate policies.

CBAM is a dynamic policy that will continue evolving. The transitional period, which runs until the end of 2025, serves as a critical phase for refining implementation mechanisms. However, businesses should already be preparing for full compliance, as financial obligations will commence thereafter.

Future developments could include:

-Expansion of CBAM to additional sectors, such as chemicals, plastics, and glass.

-Adjustments to reporting methodologies based on feedback from businesses and regulators.

- Potential agreements with non-EU countries on mutual recognition of carbon pricing schemes.

One of the key discussions surrounding CBAM’s expansion is whether it will encourage other countries to adopt similar carbon pricing mechanisms. If more regions introduce their own CBAM-style measures, global trade patterns could shift toward a new standard for carbon accountability.

CBAM is a major shift in global trade and carbon regulation. As the mechanism progresses, businesses must stay informed about regulatory updates, refine their compliance strategies, and engage proactively with their supply chains.

By understanding the operational steps and integrating CBAM requirements into business processes, companies can not only meet regulatory obligations but also position themselves as leaders in the low-carbon economy. The companies that take proactive measures today will be best positioned to navigate future regulatory changes and benefit from an increasingly carbon-conscious market.

As CBAM continues to evolve, businesses should also consider the following:

- Engaging with Stakeholders: Companies should engage with suppliers, customers, and industry associations to stay informed about CBAM developments and share best practices for compliance.

- Investing in Technology: Investing in digital tools and technologies for emissions tracking and reporting can streamline compliance processes and reduce administrative burdens.

- Monitoring Regulatory Changes: CBAM is still in its early stages, and regulatory changes are likely as the EU refines the mechanism. Businesses should monitor updates from the European Commission and other relevant authorities to stay ahead of new requirements.

By taking these steps, businesses can not only ensure compliance with CBAM but also contribute to the broader goal of reducing global carbon emissions and promoting sustainable trade practices.

Copyright owned by Fastener World / Article by Luigi Villani

The U.S. reciprocal tariffs have come into effect since April 09, causing a significant impact on many products exported to the U.S. from around the world. In addition, pursuant to Section 232, specific steel and aluminum products from all over the world have been subject to a 25% tariff since March 12, which is on top of the basic tariff rates already imposed on exports to the U.S., causing even worse impact on manufacturers and U.S. importers. As a result, some importers have been forced to hold back their shipments or simply abandon their orders. I’d like to remind the suppliers that since President Trump's tax measures have been changing over the past few months, some of the info about the calculation and application of the tax rate on fasteners going to the U.S. may be incorrect. In particular, it should be noted that not all rates are applicable to fasteners. For example, the 32% reciprocal tariff imposed on Taiwan (note: Trump has announced a 90-day moratorium on April 09) is not applicable to fasteners.

Currently, there are two types tariffs applicable to fasteners exported to the U.S. One is the basic tariff rate (e.g., 12.5% for wood screws, 6.2% for self-tapping screws with the diameter less than 6mm, and tariff-free for nuts), and the other one is the tariff rate of 25% pursuant to Section 232 on steel and aluminum products (including derivative products). That is to say, on the basis of non-MFN or non-special countries, a wood screw imported into the U.S. will be subject to a combined tax rate of 37.5% (12.5% + 25%).

Although some countries are entitled to half or exemptions on specific items due to their FTA with the U.S., resulting in a difference of up to 12.5% in the final total tariff rate, there is basically no exception to the 25% tariff increase. This may be good news for companies in Taiwan, China or other Southeast Asian countries as they won’t have to face pressure from higher reciprocal tariffs in the short term, but the conservative market sentiment may still affect customers' willingness to place orders in the near future. According to TFTA Chairman, orders from U.S. customers may temporarily decline by 30% after the implementation of the 25% tariff, and the demand may start to recover only after local inventories bottom out. Other concerns are that fasteners are closely related to many industries and other industries directly slashed by reciprocal tariffs (e.g., precision machinery or CNC machining equipment) may therefore reduce their consumption and lower the demand. Other fastener SMEs that do

not have the capital to set up factories in the U.S. to avoid high tariffs may also shift their focus to the development of non-U.S. markets, indirectly resulting in more fierce competition in these non-U.S. markets.

Some industry players told Fastener World that the reciprocal tariffs imposed by the U.S. on various countries (especially China) may make some orders switched to Taiwanese manufacturers in a short period of time (it is heard that some companies have already had urgent orders recently). It is understood that, in response to the 25% tariff, some Taiwanese companies have reached a tacit agreement with U.S. customers to share tariffs in order to reduce the impact, thus strengthening the force of switching orders to Taiwan. Coupled with the prospect of European market expected to be promising after Fastener Fair Global 2025. the performance of Taiwan's production capacity is very likely to return to normal this year. However, in the long run, it remains to be seen whether the effect of such an order switching can be sustained. In light of the fact that Trump's policies can change from one day to the next, an assessment of the actual impact of these tariffs on the fastener industry may not be clear until the outcome of the negotiations on reciprocal tariffs has been finalized in H2 this year. Before reaching an agreement with the

U.S. administration, maybe the Taiwan government can assist the local fastener industry to tide over the difficult times first by way of tariff subsidies, tax rebates for exports to the U.S., etc., and there should be more resources and units (e.g., the National Development Council or IDA of MOEA) to guide the industry to capitalize on opportunities for digital transformation and smart manufacturing, so as not to let the fastener industry, which has been supporting the development of Taiwan's economy for more than 6 decades, be eliminated in the face of competition, and turn into a situation in which only several large factories can survive and small ones can only close down their factories.

Whether or not a manufacturer has circumvented customs duties via a third country has been the focus of the U.S. Customs in recent years and the U.S. Customs also have guidelines for determining a product's place of origin. It is also heard that in the past some manufacturers from other countries once exported semi-finished products to third countries subject to lower tax rates for simple processing and packaging, faking them to be products produced in third countries, which, if detected, may affect the image of the same products from other counterparts in the international market. The high reciprocal tariffs previously announced by the U.S. against specific countries in Southeast Asia were more or less a sign to speculators warning them not to circumvent via third countries. The industry should still comply with the relevant international regulations and should not jeopardize the industry's long-established good image for selfish reasons.

Before the U.S. levied a 25% steel and aluminum tax on the whole world, the profit margins of Taiwanese standard fasteners had not been too much in the face of competition from their Chinese or other countries’ counterparts. In the current U.S. tax algorithm for fasteners, Taiwan's profit margin has been further reduced by 25%. If the wire costs of China and other Southeast Asian countries which have been 15-30% lower than that of Taiwan are also taken into account, Taiwanese fastener companies bearing up to 60% of their manufacturing cost from wire will go into a tougher situation. The prices of wire rod and coil are definitely the most important factor that affects the profitability of manufacturers and the competitiveness of their quotations. In Q2 this year, Taiwan CSC raised NT$600 per ton for wire rod (it is understood that the average price of domestic wire rod this April was about NT$24,900 per ton), so the production costs of manufacturers definitely have increased again. In June, Taiwan CSC will hold the Q3 production and sales meeting with the industry again, and the price adjustment of wire rod will definitely become the most important concern of the industry. Some manufacturers have privately revealed that it would be best if Taiwan CSC could reduce its wire coil price per ton by NT$1,000-1,500. If Taiwan CSC can take the impact of U.S. tariffs on the domestic industry into consideration and make more concessions on the price adjustment for Q3, coupled with the exchange rate of USD against NTD coming to 1:31, and the active introduction of innovative wire processing processes by Taiwanese manufacturers to reduce their production costs by 10-20%, the pressure on businesses should be greatly relieved and the reduction in profit margins due to the tariff increase can be compensated.

Copyright owned by Fastener World

Article by Gang Hao Chang, Vice Editor-in-Chief

At the end of April this year, the exchange rate of the Taiwan dollar against the US dollar averaged around 32.5 TWD per USD. However, within less than a week, it rapidly appreciated, even breaking through the 30 TWD mark, reaching the highest level in nearly three years. Table 1 summarizes the trajectory of the Taiwan dollar's appreciation from late April to the time of writing this article (May 6). This article analyzes the impact on Taiwan's fastener industry and the existing countermeasures during this period.

Table 1. USD to TWD Exchange Rates from Late April to May 6, 2025 (Source: cnYES)

Trading Volume SMA 1 2.331B

Exchange Rate Analysis:

• At the end of April, the USD to TWD exchange rate was around 32.5, indicating a relatively strong Taiwan dollar.

• On May 2, the Taiwan dollar sharply strengthened to about 31, marking nearly a 3% appreciation.

• By May 5, it further appreciated to 30.1, gaining another nearly 3%, reaching the peak appreciation during this period. During the trading hours of that day, it even broke the 30 mark, hitting 29.5, showing a significant Taiwan dollar appreciation and relative weakening of the US dollar.

• On May 6, the rate slightly returned to around 30.2, with minimal change.

• Overall, during this period, the USD to TWD exchange rate exhibited a dramatic appreciation trend, moving from approximately 32.2 to as far as 29.5. The difference between the highest peak and lowest trough exceeded 9%, indicating a rapid and steep appreciation of the Taiwan dollar.

Figure 1. Daily USD to Taiwan Dollar Exchange Rate from April to May 6, 2025 (Source: cnYES)

• Figure 1 illustrates that the Taiwan dollar’s appreciation speed between April and early May resembled a runaway train, breaking through many Taiwanese manufacturers’ profit defense lines. Media outlets have already warned that this could lead to very low-performing corporate financial reports.

Mr. Yung-Yu Tsai, Chairman of Taiwan Industrial Fasteners Institute, stated that the average gross profit margin in the fastener sector is only about 15%. The recent rapid appreciation of the Taiwan dollar has eroded profit margins to zero or even pushed them into negative territory within a short period. If the Taiwan dollar continues to strengthen, the industry could face a large wave of business closures. According to industry insights, if the USD-to-TWD exchange rate appreciates to 28, only companies capable of maintaining a gross margin above 30% might survive, but such high-margin fastener manufacturers are rare in Taiwan.

From the perspective of Chun Yu Works, a major screw manufacturer, an exchange rate shift from 32.5 to 30.0 represents about an 8% loss in competitiveness for Taiwanese fasteners. A Taiwanese fastener company generates an average 15% gross margin. The exchange rate shift translates to losing over half of the profit margin.

The average gross profit margin in the fastener sector is only about 15%. The recent rapid appreciation of the New Taiwan dollar has eroded profit margins to zero or even pushed them into negative territory within a short period.

Moreover, about 80% of Taiwan’s screw manufacturers are small and medium-sized enterprises with even lower profit margins. Taiwan fastener industry is already facing intense competition from low-cost products from China and Southeast Asia. The loss of exchange rate advantage will further weaken the price competitiveness of Taiwanese fasteners in the international market.

Barry Tsai, Manager at Sheh Kai Precision, a manufacturer of stainless steel and alloy steel bi-metal screws, noted that the strengthening Taiwan dollar has already led to at least an additional 10% in exchange rate losses based on the May 5 exchange rate. “We quote our products in USD with our overseas buyers, so to cope with this exchange rate impact, we must raise prices in the short term,” said Barry.

“Sheh Kai Precision has about 10% of its orders from the United States, and we are closely watching whether the strong appreciation of the Taiwan dollar will lead to a decline in demand from U.S. buyers, impacting order volume. For Europe, where we receive over 50% of our orders, we anticipate that the impact of our price increase will be minimal for European buyers due to the weakening US dollar and strengthening Euro for the time being. Looking ahead, we will continue to update our certifications annually and are developing new anchor products expected to be launched next year,” he continued. Overall, while the appreciation of the Taiwan dollar poses significant challenges to the industry, Sheh Kai Precision believes it has a sufficient foundation to overcome this challenge and suggests that the government provide tax cuts or preferential loan interest rates.

In the field of fastener inspection machinery, General Manager Mr. Hsu of Ching Chan Optical Technology stated that the rapid appreciation of the Taiwan dollar in early May was unexpected and had a comprehensive impact, catching many domestic exporters trading in US dollars off guard and creating considerable challenges in mitigating losses.

Ching Chan Optical Technology is responding to the exchange rate changes by raising prices in the short term. Looking ahead, the company assesses that these dramatic exchange rate changes will not have a significant impact on its overall operations, and it will continue to provide robust supply support for fastener inspection needs both domestically and internationally. In recent years, it has continuously invested in development of new and upgraded AI technologies for its inspection machine products and will continue to delve into potential industries such as semiconductors, electric vehicles, automation, robotics, medical care, and food safety.

Chairman Mr. Zhuang of Taiwan Association of Machinery Industry stated that the global economic downturn, combined with pressures from domestic competitors as well as international competitors such as Japan and South Korea, has made running machinery businesses in Taiwan very difficult. He urged the government to support export-oriented industries and requested that banks avoid tightening loans during poor economic conditions. He also called for relaxed loan-tovalue ratios on loans secured by land or factory buildings to ensure companies have sufficient working capital to overcome the current challenges.

Rick Wang, president of Masterpiece Hardware Industrial, a major fastener manufacturer in Changhua County (central Taiwan), pointed out that although exchange rate fluctuation itself is a normal phenomenon, the sudden and sharp appreciation in early May caught many manufacturers by surprise, leaving them little time to hedge or mitigate the impact. “In the short term, we must adjust prices and communicate well with clients. If the strengthening Taiwan dollar continues for more than a month, it could become persistent, significantly weakening the pricing advantage of Taiwanese fasteners and severely impacting the industry. Besides the tariffs imposed during the Trump administration, the current exchange rate losses are like rubbing salt into the wound. Moreover, the Trump tariffs caused China to increase exports to Southeast Asia and countries other than the U.S., while Taiwan, which has yet to be an RCEP member, faces intensified competition from low-priced Chinese products.” Rick hopes the government will assist by providing

preferential interest rates, financing loans, and specialized machinery financing programs to help the industry navigate this challenge and prepare for future industrial upgrades.

Masterpiece Hardware Industrial believes the ultimate solution lies in strengthening product differentiation and core competitiveness, optimizing cost structures, and precisely positioning products and target markets. Only by reinforcing the fundamentals can companies withstand the overwhelming challenges ahead.

Now it is critical for Taiwanese fastener companies to establish robust exchange rate risk management during Trump's second term.

The appreciation of the Taiwan dollar has increased working capital risks for Taiwanese fastener manufacturers. That is, export revenues (in USD) decrease in value when converted into the stronger Taiwan dollars. While production costs remain unchanged, many Taiwanese companies face cash flow tightness. Taiwanese industry players have already been aware of Trump’s ambition of a weaker US dollar and a stronger Taiwan dollar, which now comes true in the way that Trump had hoped for. Now it is critical for Taiwanese fastener companies to establish robust exchange rate risk management during Trump’s second term. They might consider adopting practices from the Taiwanese textile industry—another victim to the Trump tariffs— such as adjusting contract terms to include exchange rate adjustment clauses. When exchange rate fluctuations exceed a certain threshold, prices can be renegotiated to share the exchange rate risk with clients.

Although many firms have raised product prices, they must also strengthen their financial risk controls to survive the economic turmoil of 2025.

“Overall, I figure the recent Taiwan dollar appreciation has only a shortterm impact on Masterpiece Hardware Industrial, but a long and sustaining development requires continuous effort and improvement. We are still expanding our factory near our headquarters to meet growing future overseas demands,” said Rick.

Larger fastener manufacturers, such as Chun Yu Works, have adopted exchange rate hedging strategies to mitigate the impact of currency fluctuations. Chun Yu Works stated that they generally lock in exchange rates when taking orders, so companies that hedge actively will experience minimal impact on already confirmed orders. However, this hedging approach is difficult for small and medium-sized enterprises with weaker financial strength to implement. Currently, Taiwan’s financial regulators impose strict controls to prevent speculative currency trading. These measures set high barriers for companies wishing to use lockin exchange rates or pre-selling methods, increasing the difficulty for businesses to hedge exchange rates effectively. As a result, some industry players have called for a relaxation of these restrictions to facilitate better risk management.

Additionally, some companies reportedly delay converting received US dollar payments into Taiwan dollars to avoid unfavorable exchange rate periods. This means they hold onto US dollars after payment and wait for the Taiwan dollar to return to a more favorable rate before converting. However, this strategy requires sufficient cash flow to sustain operations during the waiting period.

The rapid appreciation of the Taiwan dollar in early May 2025 has posed a severe challenge to Taiwan fastener industry, especially for exporters heavily reliant on foreign markets.

The sharp currency strengthening has pushed many companies to the brink of survival that leaves them facing zero gross margins and declining competitiveness. This exchange rate shock serves as a wake-up call, prompting the companies to focus more on exchange rate risk management amid an increasingly volatile global economic environment. The Trump administration wields its tariffs like a wild blade, relentlessly slashing into the profit margins of foreign competitors, as its dominance over the global market economy becomes an entrenched norm. Large Taiwanese fastener companies, with relatively stronger cash flow, can weather the short- to medium-term currency impact, but small manufacturers and OEMs urgently face foreign exchange losses that threaten their viability. Although many firms have raised product prices, they must also strengthen their financial risk controls to survive the economic turmoil of 2025.

The Taiwan dollar sharp appreciation delivered a significant shock to Taiwan’s exportoriented manufacturing sectors, including fasteners, plumbing hardware, and electronics. These industries had already faced tariff pressures from the Trump tariffs in the first four months of 2025, and now the strengthening Taiwan dollar adds further operational strain. An anonymous CFO from a major Taiwanese electronics firm revealed to the press that if the appreciation does not ease, gross margin losses could conservatively start at 10%, and in reality, could be several times higher. Plumbing hardware companies typically have gross margins of only 10% to 15%, and fastener manufacturers around 15%. The exchange rate shift from 32 to 30 TWD per US dollar has already eroded most of their profit margins. Should the Taiwan dollar continue to strengthen past the 30, 29, or even 27 levels without intervention, it could trigger a widespread wave of business closures.

Tariff wars, carbon reduction, regional conflicts and developments in international relations will continue to shape the global industry in 2025. Policies and attitudes of the U.S. new administration on whether to raise tariffs on specific products from certain countries, whether the EU CBAM’s emissions calculation will be significantly adjusted in H2 this year, the Russia-Ukraine and Israel-Hamas wars with still no end in sight, or the subtle changes in competition or alliances between economic powers (such as the US, China, and the EU) will continue to bring more uncertainties to the global market, further heightening the concerns of many business owners about the future of their industries.

“The level of uncertainty in the global economic and political landscape has continued to increase beyond what we have experienced in the past. Rapid geopolitical shifts and evolving policy priorities are reshaping the economic environment, requiring both society and businesses to adapt swiftly to a constantly changing reality. This volatility presents significant challenges, particularly in terms of strategic planning, as recent political developments have demonstrated how unpredictable the global stage has become,” said EFDA President Andreas Bertaggia.

▲ EFDA President Andreas Bertaggia

In order to survive in a market full of uncertainties and create greater competitive strengths to face future challenges, not only leading companies but also many SMEs with a forward-looking vision have begun to speed up the pace of their regional market layout and make more appropriate adjustments in response to more rapid policy changes. For example, some Taiwanese fastener manufacturers have recently set up new factories in Vietnam, large car manufacturers are planning factory expansions in the U.S., or Japanese and South Korean companies have set up large-scale industrial clusters in Southeast Asian countries, etc.

“In such an environment, agility and adaptability remain crucial for businesses to navigate ongoing disruptions. However, it is also important to recognize that change can bring opportunities. While some market segments face significant headwinds, others stand to benefit from emerging economic realities and evolving policy frameworks,” noted President Bertaggia.

Promoting the economic recovery of the EU and enhancing the external competitiveness of industries within the region are important directions in the current policy making for many European governments. In the past, bureaucratic systems have often resulted in inefficient implementation and excessive burden on industries. Therefore, the EU has begun to make some improvements in the promotion of various programs and policies in order to respond to external political or economic challenges.

“At the European level, we observe a shift in political priorities, particularly in light of the changing dynamics in EU-U.S. relations. There is now a stronger focus on revitalizing the economy and reducing bureaucratic burdens, as seen in the introduction of initiatives such as the Clean Industrial Deal released in February this year. Notably, the proposed improvements in the Carbon Border Adjustment Mechanism (CBAM) reporting process represent a step in the right direction, easing some of the administrative challenges faced by our industry. However, until significant changes are made to CBAM, EFDA continues to advocate for the exclusion of downstream products such as fasteners made from CBAM, as we believe the application of CBAM to these products places an unnecessary burden on our sector,” added President Bertaggia. “In terms of policy focus, we note that while sustainability remains an important long-term objective, immediate priorities have shifted towards economic resilience and strengthening Europe’ s self-defense capabilities. The increasing emphasis on reducing bureaucratic complexity is a welcome development, as excessive regulatory burdens can hinder competitiveness, especially for European companies operating in a globalized market. While the core objectives of many regulatory initiatives are well-founded, their implementation often results in reporting obligations that exceed the practical capacities of our industry. It is crucial to strike the right balance between regulation and competitiveness to ensure European businesses can thrive in the international arena.”

The retaliatory tariff increases between the U.S. and Canada, the escalating trade war between the U.S. and China, and even the recent war of words between the U.S. and Europe over whether or not to increase taxes on specific products of the other side are all adding to the tension in the global trade situation. Many of the major players in these markets are concerned that if these tensions continue to spiral out of control, consumers may face higher prices and inflation, which could have a knock-on effect in the marketplace.

“ The escalating trade tensions pose another significant challenge, with potential ramifications for the broader economy. Rising prices, driven by trade restrictions, are likely to contribute to inflationary pressures. As inflation increases, interest rates may follow, which in turn raises financing and investment costs—factors that have historically led to slower economic growth, particularly in already fragile market conditions,” noted President Bertaggia.

Trade between countries should be based on the principle of fairness. However, if one party competes on an unequal basis (e.g., large subsidies or tax rebates from the government), it may cause an imbalance in the supply chain of the market, resulting in unfair competition.

“At EFDA, we remain committed to advocating for fair trade policies, sustainable business practices, and an open market that fosters long-term industrial growth. In these challenging times, close cooperation between industries and policymakers will be essential to overcoming obstacles and identifying opportunities that support Europe’s economic future,” concluded President Bertaggia.

With such a wide variety of construction screws available in the market, customers often face a time-consuming process when trying to find the right solution. Even after identifying a potential match, the product may still fail to meet the actual fastening requirements - offering quick installation but lacking sufficient holding power, or providing strong fastening strength while failing to meet the latest environmental standards. To solve this problem, it is important to choose the supplier carefully. Fong Prean Industrial, with nearly 4 decades of experience in developing customized construction fasteners, is specialized in solving customers' fastening problems. Under the efforts of the strong and experienced R&D team, in recent years, it has been assisting customers in Europe, the U.S., Japan, and other 25 countries to develop many creative and functional fastening solutions. The MS series, in particular, has repeatedly made a splash in many important international exhibitions.

Fong Prean mainly produces stainless/carbon steel customized construction screws with sizes ranging from 9 to 400mm. Its monthly production capacity is up to 2,500 tons, with flexibility to meet specific customer requirements. The G2 drywall screw is engineered to significantly reduce camout and installation errors, ensuring a faster and more reliable fastening process. Another signature product line is the MS wood screw series, which is designed based on the hardness and structure of different wood and can be used without pre-drilling. Common problems found with conventional screws- such as edge splitting, burrs, and insufficient holding power- can be effectively resolved with this practical and efficient fastening solution.

“The MS series is particularly well-suited for composite materials, hardwood flooring and outdoor decking. The MS Twister, designed for wood-towood applications, MS Reamer for hardwood-towood, and MSword for hardwood-to-hardwood all require no pre-drilling, which significantly reduces installation steps and minimizes the risk of edge splitting. Their specially engineered head design ensures a flush finish with no surface burrs, and a variety of thread and point designs enhance holding strength, resulting in safer and more reliable fastening,” said Fong Prean Manager Chia-Ling Wu.

In view of the fact that customers are paying more attention to “faster installation”, “less splitting”, “improved holding power” and “environmental protection and compatibility with new tools”, Fong Prean continues to develop products in cooperation with customers in order to gain a greater competitive edge. The recently launched MS Sharp-Drill Point Screw is designed for fastening MDF to wood, light gauge steel, aluminum and other substrates. Its uniquely engineered sharp drill tip allows for easy penetration into composite materials, while the MS head delivers a clean countersink without pre-drilling- achieving high fastening efficiency while minimizing the risk of cam-out and edge splitting in composite panels and interior finishing applications.

“With a highly integrated, agile and flexible custom development process- including independent inhouse tooling design, product forming, heat treatment, and quality control- we are able to quickly transform customer ideas into production-ready, highperformance solutions,” said Wu.

From raw material to final shipment, Fong Prean's automated and modularized process follows the ISO 9001, ISO 14001, CE, ETA and other quality management certifications. Its data-based tracking system and regular annual internal audits and third-party inspections allow it to assure customers of consistently high product quality. As part of its commitment to sustainability, Fong Prean is actively promoting ISO 14064 GHG inventory implementation and has equipped its facilities with real-time energy monitoring systems. These efforts support green manufacturing through material reduction, energy optimization, and enhanced employee awareness—further aligning its production practices with global environmental goals.

“We live for solving problems.” More than just a motto, this statement reflects Fong Prean’s core philosophy. In the face of rising raw material costs, unstable supply chains, CBAM regulations and U.S. tariff adjustments, Wu emphasized, “We will continue to support our customers with strong adaptability and product development capabilities— helping them stand out amid increasing ESG carbon-reduction requirements across Europe, the U.S., and beyond. Our goal is to collaborate with forward-thinking customers to design solutions that meet real market needs, maximize product value, and together lead the fastener industry into a new era of efficiency, innovation, and sustainability.”

Fong Prean contact: Chia-Ling Wu, Manager Email: ling@ms.fongprean.com.tw

On March 12, 2025, the U.S. government announced a 25% tariff on a broad spectrum of EU imports, targeting products like steel, aluminium, and derivatives, including fasteners. This move aimed to address trade imbalances and protect domestic industries from foreign competition. The tariffs affected approximately €26 billion worth of EU exports, representing about 5% of the EU's total goods exports to the U.S.1

The tariffs' impact extends beyond the industry, affecting the broader EU economy. European Central Bank President Christine Lagarde warned that a 25% U.S. tariff on European imports could reduce eurozone growth by 0.3 percentage points in the first year. If the EU were to implement retaliatory measures, this reduction could deepen to about 0.5 percentage points. Additionally, these measures, coupled with a weaker euro economic structure, could raise inflation by around 0.5 percentage points in the short term.2

The EU fastener industry is a significant sector, comprising numerous SMEs that manufacture a wide range of products, from simple screws to specialized components for high-tech applications. In 2023, the EU exported approximately US$16.6 billion worth of fasteners, with the United States being the second largest country importer, accounting for 7.4% of these exports (approximately US$1.23 billion). In 2024, these exports exceeded US$1.5 billion. This data underscores the critical importance of the U.S. market to the EU's fastener industry, highlighting the potential impact of any trade policies affecting this sector.

The Guardian indicates that the threatened 25% tariffs on EU imports could lead to a significant reduction in EU exports to the U.S., potentially decreasing them by 15-17% and contracting the EU economy by 0.4% 3 Based on this trend, it is predicted that the fastener market could experience an immediate 15% decline in EU fastener exports to the U.S. within the first quarter following the imposition of the 25% tariff, resulting in a loss of approximately €46 million.

The automotive industry, a major consumer of fasteners, faces significant challenges due to the tariffs. European carmakers, particularly in Germany, have experienced a substantial decline in exports, estimated at nearly 20%. This downturn not only affects manufacturers but also reverberates through the supply chain, impacting suppliers and related industries.4

1https://luxembourg.representation.ec.europa.eu/actualites-et-evenements/actualites/eu-countermeasures-us-steel-and-aluminium-tariffsexplained-2025-03-12_en

2https://www.reuters.com/markets/europe/euro-zone-inflation-could-jump-growth-sink-trade-war-with-us-lagarde-says-2025-03-20/

3https://www.theguardian.com/business/2025/feb/27/donald-trump-tariffs-on-eu-imports-could-trigger-economic-turmoil

German automotive manufacturers such as BMW and Daimler have reported significant financial impacts due to the tariffs. BMW anticipates a €1 billion reduction in profits this year, attributing this decline to U.S. tariffs and European Union duties on China-made electric vehicles. This profit reduction represents a 36% decrease from the previous year, with earnings before taxes falling to €11 billion from €17 billion.5

Similarly, Daimler Truck has reported disruptions from tariffs, leading to the implementation of a €1.1 billion cost-cutting program. 6

The decline in automotive exports has a cascading effect on the supply chain. Suppliers of components, including fasteners, face reduced demand, leading to decreased production and potential layoffs. Industries related to automotive manufacturing, such as steel and aluminum producers, logistics providers, and dealerships, also experience negative impacts due to the reduced output of vehicles.

The German economy, heavily reliant on its automotive sector, faces broader economic challenges due to the tariffs. The resulting production and sentiment disruptions could significantly affect the German economy.7

The construction sector, another significant user of fasteners, is grappling with increased costs. Projects that rely on imported fasteners from the EU are experiencing budget overruns, leading to delays and, in some cases, cancellations. This situation hampers infrastructure development and affects employment within the sector

SMEs, which constitute a large portion of the EU's fastener industry, are particularly vulnerable. The decline in exports has led to reduced revenues, forcing some companies to downsize or cease operations. Consequently, there has been a notable increase in unemployment rates in regions heavily dependent on fastener manufacturing.

In response to the U.S. tariffs, the EU announced a series of countermeasures. On April 1, 2025, the EU reinstated previously suspended tariffs on U.S. products, including motorcycles, whiskey, and jeans, affecting approximately €8 billion worth of goods. Additionally, the EU plans to implement new tariffs targeting around €18 billion worth of U.S. exports, with products ranging from agricultural goods to industrial equipment.8

The tariffs have disrupted global supply chains, compelling companies to seek alternative suppliers or relocate production facilities. This realignment has led to increased operational costs and inefficiencies, affecting the competitiveness of both EU and U.S. manufacturers on the global stage.

Analysts predict that if the tariffs remain in place, the EU could face a contraction of 0.4% in its economy, while the U.S. economy might shrink by 0.17%. These projections underscore the detrimental effects of prolonged trade disputes on economic growth and stability.9

Both the EU and the U.S. have expressed willingness to engage in negotiations to resolve the trade dispute. However, reaching a consensus requires addressing underlying issues such as trade imbalances and market access. The outcome of these negotiations will significantly influence the future of transatlantic trade relations and the stability of global markets.

The U.S. 25% tariff on EU fastener exports has significantly disrupted trade, impacting industries such as automotive, construction, and manufacturing. European fastener producers, especially SMEs, face declining revenues and competitiveness in the U.S. market, leading to potential job losses and economic strain. Meanwhile, American importers and manufacturers are grappling with higher costs and supply shortages, which could contribute to inflation and reduced industrial output. These economic pressures highlight the broader consequences of protectionist policies, which often result in unintended harm to both exporters and importers.

To mitigate these challenges, policymakers must engage in constructive dialogue and explore collaborative solutions that promote fair trade. Instead of prolonged tariffs that strain global supply chains, efforts should focus on revising trade agreements, offering exemptions for critical industries, or fostering joint manufacturing initiatives. A cooperative approach would help restore balance to transatlantic trade, ensuring long-term stability, protecting jobs, and supporting sustainable economic growth for both the U.S. and the EU.

4https://www.theguardian.com/business/2025/feb/27/donald-trump-tariffs-on-eu-imports-could-trigger-economic-turmoil

5https://www.ft.com/content/8b733479-d7a5-4c88-97a1-60c3f3846e7c

6https://www.thetimes.com/business-money/companies/article/bmw-says-trumps-tariffs-will-cost-it-1bn-this-year-38nvcfdjb

7https://www.forbes.com/sites/neilwinton/2019/02/18/u-s-tariff-action-could-cost-german-carmakers-more-than-7-billion-report/

8https://luxembourg.representation.ec.europa.eu/actualites-et-evenements/actualites/eu-countermeasures-us-steel-and-aluminium-tariffsexplained-2025-03-12_en

9https://www.theguardian.com/business/2025/feb/27/donald-trump-tariffs-on-eu-imports-could-trigger-economic-turmoil

A-Stainless International, which has more than 30 years of experience in the field of stainless steel fasteners and wire, held a simple opening ceremony for its new factory in Vietnam on April 25th this year. This modern and well-planned factory is not only the first attempt of A-Stainless' overseas investment, but also a very important milestone for it to respond to the current changes in the international situation and strengthen its services to the customers in Southeast Asia, Europe and the U.S. which are its major export destinations.

The new 5,000 sq m factory is located in Thai Ha Industrial Park, Ha Nam Province, in the northern region of Vietnam, less than 100 km from the capital “Hanoi”, the eastern port city “Hai Phong”, and the airport. Convenient land, air, and sea transportation allows A-Stainless to serve local and overseas customers more efficiently. The factory is dedicated to the manufacturing of stainless steel screws and is expected to be staffed with 80 employees and equipped with 100 sets of heading, thread rolling, thread cutting and saw slotting machines as well as 1 passivation line to satisfy more customers' demand for stainless steel screws.

“The new production line has launched its trial run since this April, and if everything goes well, we expect the monthly production to reach 120 tons. We’ll also gradually work towards the goal of reaching 200 tons by 2026 and the max. capacity of 300 tons in due course,” said A-Stainless.

The delicate and sensitive political tug-of-war between the U.S., China, and Taiwan has always been

an essential factor affecting the long-term stability of the cross-strait supply chains. In view of the regional tension caused by China's military drills in the Taiwan Straits during the visit of U.S. House of Representatives Speaker Nancy Pelosi to Taiwan about 2 years ago, and based on customers' concerns about whether there would be disruptions in Taiwan’s supply chains and the consideration of reducing geopolitical risks, A-Stainless after evaluating various aspects chose to set up a factory in Vietnam, where there are sufficient land, labor force, favorable policies, and enjoys preferential tariff rates from EVFTA.

“In addition to avoiding geopolitical risks, our Vietnam factory also enjoys the benefits of lower tax rates to Europe, abundant labor force, and proximity to the emerging electronics market in the northern region of Vietnam, thus making us more competitive. Coupled with the operational management and technical support from the Taiwan headquarters, the Vietnam factory certainly will be complementary to A-Stainless' business expansion and market development,” said A-Stainless.

Over the past 2 years, the fastener industry has been hit by Covid, supply chain disruptions, geopolitics and destocking, etc., resulting in a significant slump in revenue. The industrial recovery has become even more uncertain due to U.S. President Trump's drastic tax increase in 2025 after he took office. However, A-Stainless is not worried about this situation at all. “In order to survive in a competitive environment, it is very important to improve the management and technology R&D capabilities of the company. In the future, we hope to strengthen the training of local management and technical personnel in the Vietnam factory, deepen localization, and more importantly, create a more flexible and reliable supply chain for customers,” added A-Stainless.

Copyright

owned by Fastener World / Article by Gang

Hao Chang, Vice Editor-in-Chief

A-Stainless contact: Mr. Asser Liu Email: astainless@hibox.hinet.net

In 1841, the English engineer and inventor Joseph Whitworth presented his paper, “ A Uniform System of Screw Threads” to Great Britain’s Institution of Civil Engineers. This paper was a proposed solution to an Industrial Revolution problem vexing Great Britain and other western countries. Although it started with the burgeoning railroads, this problem was being experienced globally throughout all industries relying on newly developed mechanization. Specifically, when threaded fasteners failed or needed to be replaced, there was no uniformity among manufacturers. Without any confidence in interchangeability, replacing a broken part required going back to the original manufacturer, which often was inconvenient and sometimes impossible. Whitworth’s uniform thread design solved this problem and was quickly adopted as a national standard, propelling it into the history books as the world’s first industrial standard.

Today, there are thousands of fastener standards, including global standards like ISO, regional standards like JIS, ANSI, and DIN, and individual user standards like Boeing, Honda, and Bosch. Standards fall into one of two categories, Consensus Standards and Nonconsensus Standards. Consensus Standards are generated by Consensus Standard’ s organizations, which means they are developed by a diverse and multi-talented group of experts using a formal set of procedures and rules that guarantee they reach consensus regarding the contents of the final standard. Non-consensus Standards are developed by individuals and individual organizations to best represent their specific interests.

Standards related to fasteners can be divided into several categories:

1. Product Standards: These standards provide all the requisite information to be able to produce a part or family of parts. Foremost they provide dimensional information but may have other information required to make or control the proper manufacture of parts as well.

2. Material Standards: This is a slightly broader range of standards, as it includes standards related to raw materials, performance (specifically mechanical performance), heat treating, plating and coatings, and testing.

3. Testing Standards: This is a small group of standards that are specifically written to detail one or more fastener test methods.

4. Procurement Standards: These are generally unique to aerospace and defense fasteners and provide requirements related to quality, performance, and procurement.

5. System Standards: These are broad standards that detail qualityrelated, business management systems, some are intended to encompass all industries and others are specific to fasteners.

In North America, there are several Consensus Standard’s organizations that generate fastener standards. The primary ones include:

• American Society of Mechanical Engineering (ASME), predominantly providing product standards. Fastener-related standards come from two different technical committees, B18 (fasteners) and B1 (threads).

• American Society of Testing and Materials (ASTM), predominantly providing material and testing standards. Fastener-related standards come mostly from the Fastener Committee F16 although a number of them are derived from the steel committee A01.

• Society of Automotive Engineers (SAE), providing mostly material and a few product standards. Fastenerrelated standards come primarily from their Fastener Committee, although aerospace fastener material standards come from their Aerospace Material Division.

• National Aerospace Standards Committee (NASC), providing product, material, testing, and procurement standards for aerospace fasteners.

• International Organization for Standardization (ISO), providing product, material, and system standards. ISO is unique because it is a world organization and, thus, delegates to the fastener committee, TC2, represent different countries or regions.

• Research Council on Structural Connections (RCSC), exclusively focused on structural bolting.

• National Association of Corrosion Engineers (NACE), with several fastener standards, mostly focused on the oil and gas industry.

• American Petroleum Institute (API), with several material standards exclusively for oil and gas industry fasteners.

There is always debate over which standards, Consensus or Non-consensus are better. Good arguments can be made for both sides and, the best answer is, most likely, “ it depends” For example, if you are an automotive OEM and have some specific requirements that you wish to maintain, a company proprietary, Nonconsensus Standard is probably a better choice. One of the big advantages, however, of most of the Consensus Standards is that one of the rules of the Consensus Standard’ s organization is that standards must be kept up to date. Each organization has its own rules, but most require that the standard be reviewed and either updated or reapproved every five to seven years. This is good practice because it doesn’t allow these standards to fall too far behind the state of the industry. Although this is really a necessity, it can often be frustrating because it means that these standards are continuously changing, and users must be continually attentive to recent and upcoming additions and revisions.

The following are some of the current activities of these fastener committees:

The ASME fastener committee B18 meets twice a year. The last meeting was in September 2024 and the next meeting was held in April 2025 at the IFI headquarters in Cleveland Ohio. The following are highlights of some of the recent revisions and work of this committee.

• ASME B18.6.3: “Machine Screws, Tapping Screws, and Metallic Drive Screws (Inch Series)”. A new revision of this standard was published in the first half of 2024. Although it was a significant editorial update from the 2013 revision, technical changes include a reduction of the core hardness to not exceed HRC36 for case hardened tapping screws, revised guidance regarding the Hydrogen Embrittlement Test, and revised underhead thread rolling parameters on tapping screws to reduce the risk of rolling threads into the fillet radius.

• ASME B1.1: “Unified Inch Screw Threads”. This standard was revised and published in May of 2024. It corrected and revised several issues from the 2019 revision.

• ASME B18.3: “Socket Cap, Shoulder, Set Screws, and Hex Keys (Inch Series)”. The Subcommittee that is responsible for this standard is working on a major revision. Currently the only allowable material choice is to use ASTM A574. This ASTM standard provides only one strength grade, equivalent to 180,000 psi. Unfortunately, this strength level makes these specific parts susceptible to hydrogen embrittlement, especially when they receive a zinc electroplated surface finish. Although the standard recommends avoiding this practice, it does not outright disallow it, and thus, it gets commonly applied. Metric socket parts can also experience this issue, but the metric standard includes option for property classes lower than 12.9 (the metric equivalent of a 180,000 psi strength fastener). To correct this, a task group in this ASME subcommittee has been working on a revision that will include Grade 5 and 8 inch socket products. Work is proceeding but likely will not be completed until the latter half of 2025 or sometime in 2026.

The ASTM fastener committee F16 meets twice a year. The last meeting was in November 2024 and the next meeting is held in Toronto Canada in May 2025.

The following ASTM Standards were revised in 2024:

• ASTM A193/A193M: “Alloy Steel and Stainless-Steel Bolting for HighTemperature or High-Pressure Service and Other Special Purpose Applications”

• ASTM A320/A320M: “Alloy Steel and Stainless-Steel Bolting for LowTemperature Service”

• ASTM A394: “Steel Transmission Tower Bolts, Zinc-Coated and Bare”. This standard was not changed but was reaffirmed to the last revision in 2008.

• ASTM A540/A540M: “Alloy Steel Bolting for Special Applications”

• ASTM A962/A962M: “Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to the Creep Range”

• ASTM F880: “Stainless Steel Socket, Square Head, and Slotted Headless Set Screws”

• ASTM F593: “Stainless Steel Bolts, Hex Cap Screws, and Studs”

• ASTM F3148: “High Strength Structural Bolt Assemblies, Steel and Alloy Steel, Heat Treated, 144KSI Minimum Tensile Strength, Inch Dimensions” This standard was not changed but was reaffirmed to the last revision in 2017.

• ASTM A194/A194M: “Carbon Steel, Alloy Steel, and Stainless-Steel Nuts for High Pressure or High Temperature Service or Both”

• ASTM A563/A563M: “Carbon and Alloy Steel Nuts (Inch and Metric)”

• ASTM F467: “Nonferrous Nuts for General Use”

• ASTM C1513: “Steel Tapping Screws for Cold-Formed Steel Framing Connections”

• ASTM F436/F436M: “Hardened Steel Washers Inch and Metric Dimensions”

• ASTM F3393: “Zinc Flake Coating Systems for Fasteners”

• ASTM F606/606M: “Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets”

So far, only the following ASTM Standard has been revised in 2025:

• ASTM F3125/F3125M: “High Strength Structural Bolts and Assemblies, Steel and Alloy Steel, Heat Treated, Inch Dimensions 120KSI, 144KSI,and 150 KSI Minimum Tensile Strength, and Metric Dimensions 830 MPa and 1040 MPa Minimum Tensile Strength”. This was a significant revision as it added the 144KSI strength grade for all styles and types of structural bolts.

Highlights of future activity include:

• Currently there are almost seventy work items open in the F16 Committee, impacting forty different fastener standards. Many of these are relatively simple, minor changes, but having so many open work items signifies that this committee is currently very busy, and many standards are likely to be revised in 2025 and 2026.

• A proposal is underway to provide a galvanizing option for A490 (high strength) structural bolts.

• A guideline for best practices regarding fastener test reporting has been in development for several years and may see completion in 2025 or 2026.

The SAE Fastener Committee met in September 2024 and will have its next meeting in September 2025.

Highlights of recent activity include:

• Combination of SAE J1701 and 1701M- These standards are the inch and metric versions of “Torque-Tension Tightening for Inch Series (J1701) and Metric Series (J1701M) Fasteners”. These have been combined into one standard that is expected to publish in early 2025.

• SAE J995 - “Mechanical and Material Requirements for Steel Nuts”- There is currently a work project on this standard to clarify the usage of screw machining materials.

• SAE J58- “Flanged 12-Point Screws”. There is currently a work project to revise and update this standard.

• SAE J429: “Mechanical and Material Requirements for Externally threaded Fasteners”. There is a significant revision of this document currently being worked on by a task group. It was balloted in early 2024 but is currently on-hold pending the proposed addition of Grade 5 and 8 versions to ASME B18.3 Socket Products.

The ISO Fastener Committee, TC2, is not a regional Consensus Standard organization, but rather the global activity of many regional fastener organizations. In the U.S., ISO fastener activities are primarily hosted by the ASME Fastener Committee B18, Subcommittee 4. As most metric fasteners worldwide are governed by the standards under the jurisdiction of this committee, it is a very important one.

Highlights of recent activity include revisions to the following standards:

• ISO 15330 : “Preloading Test for the Detection of Hydrogen Embrittlement- Parallel Bearing Surface Method”

• ISO 10684: “ Hot Dip Galvanized Coatings”