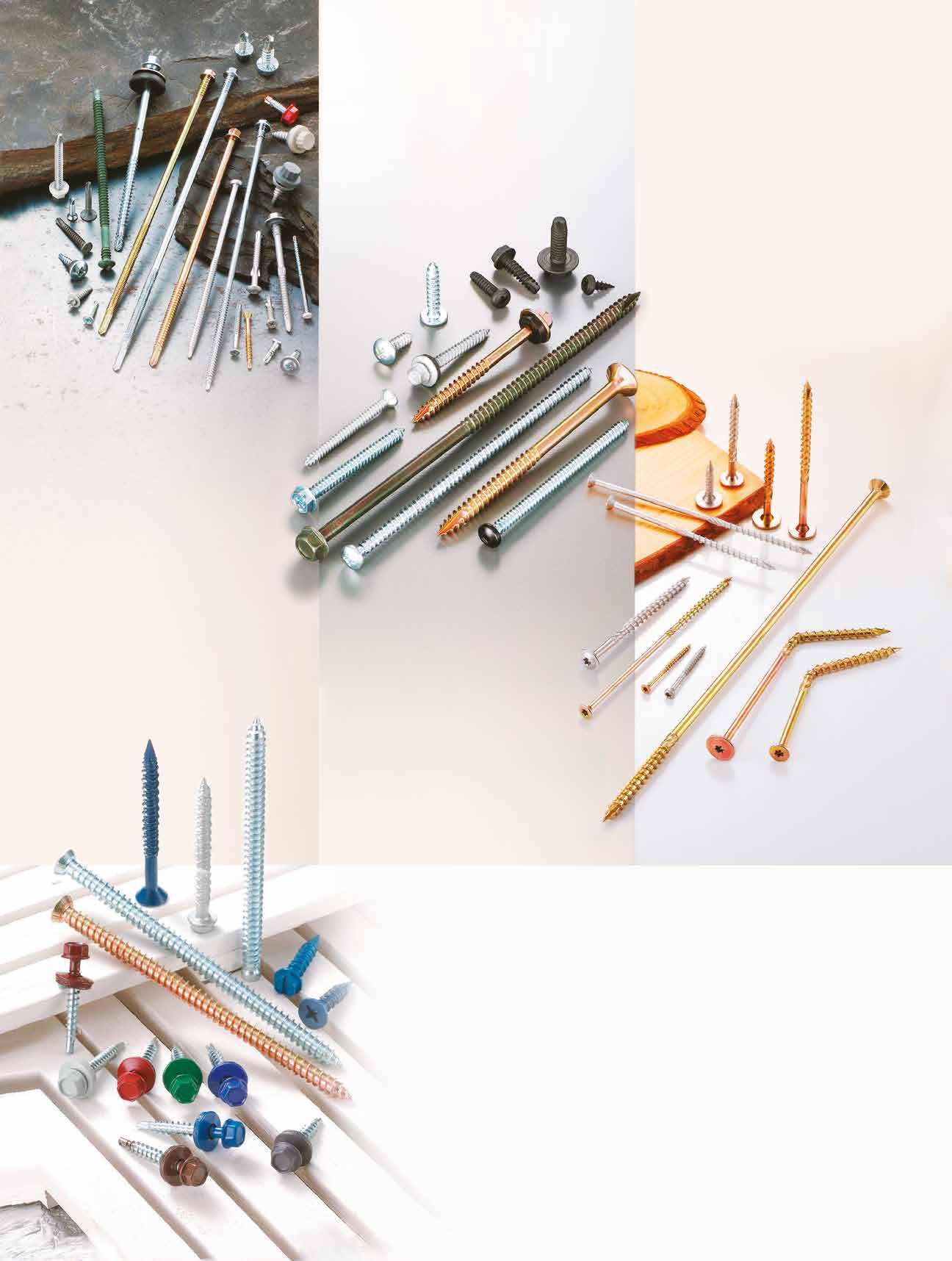

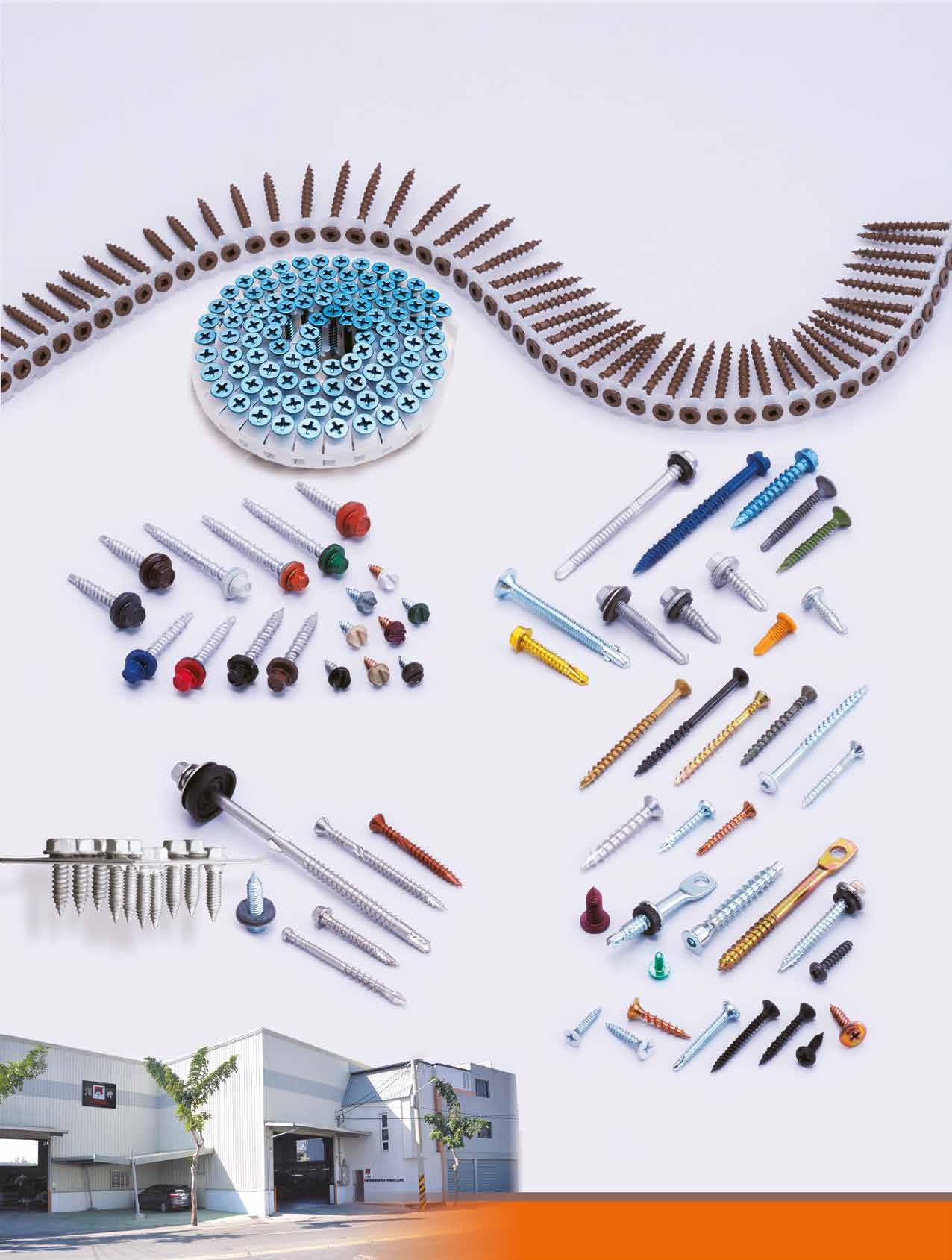

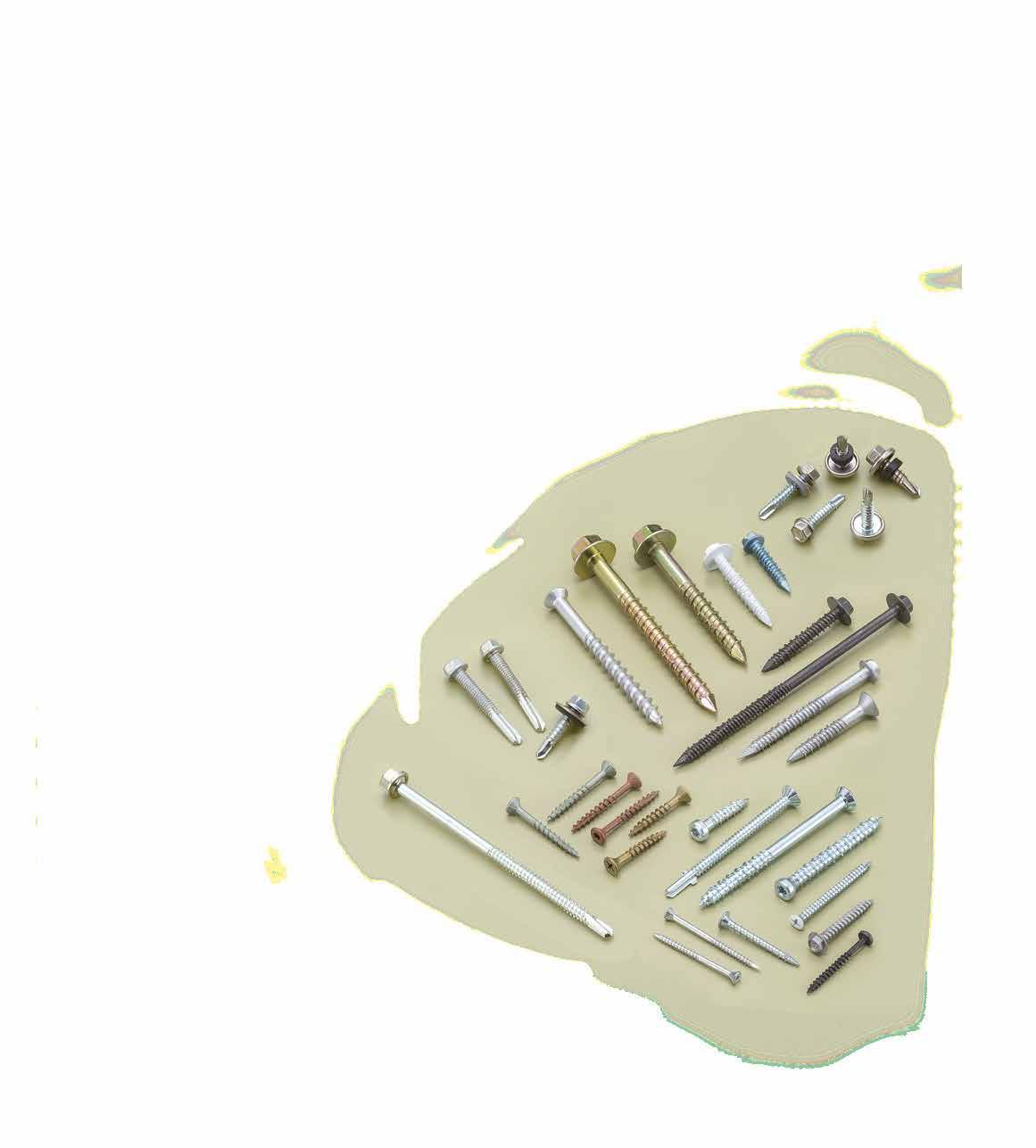

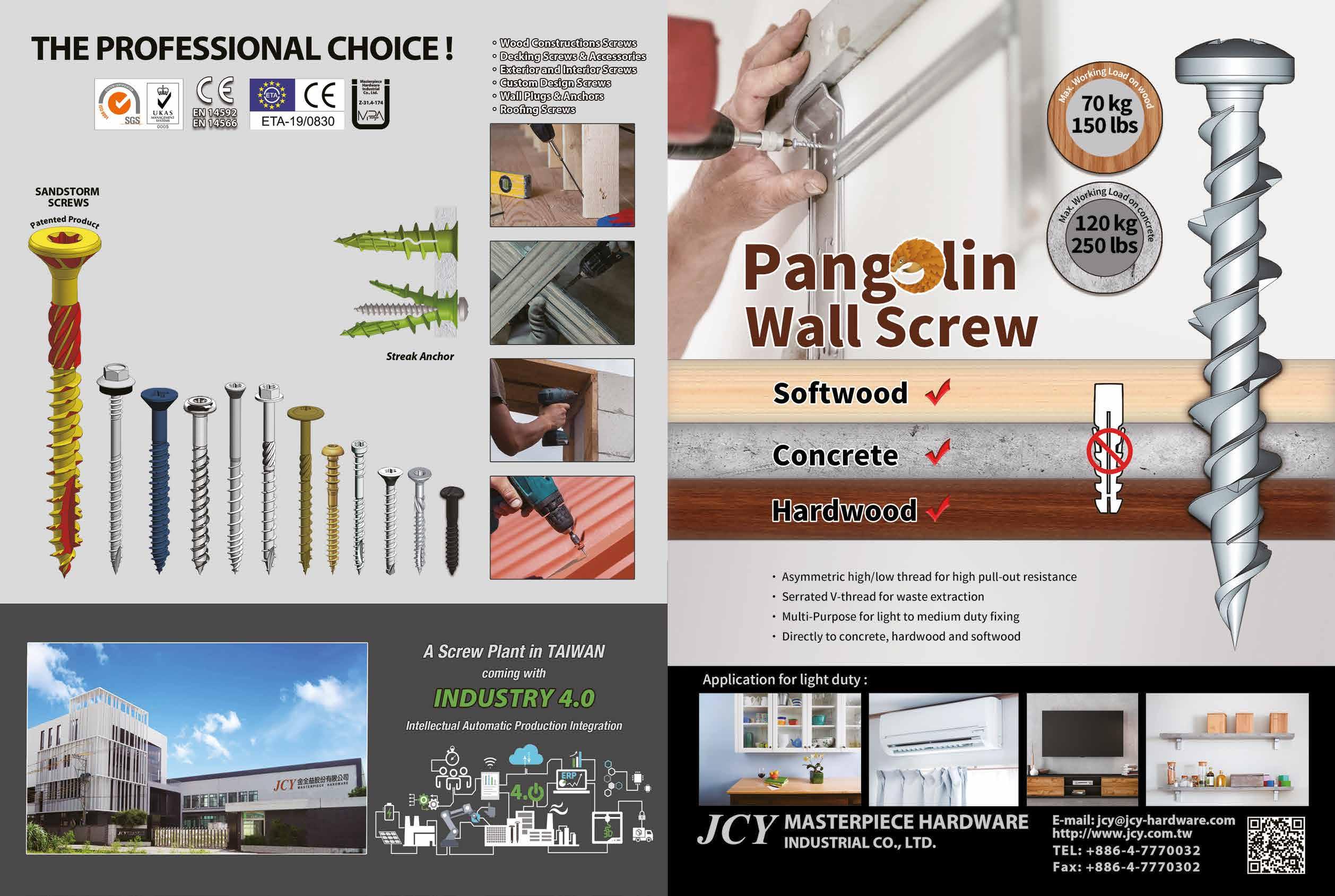

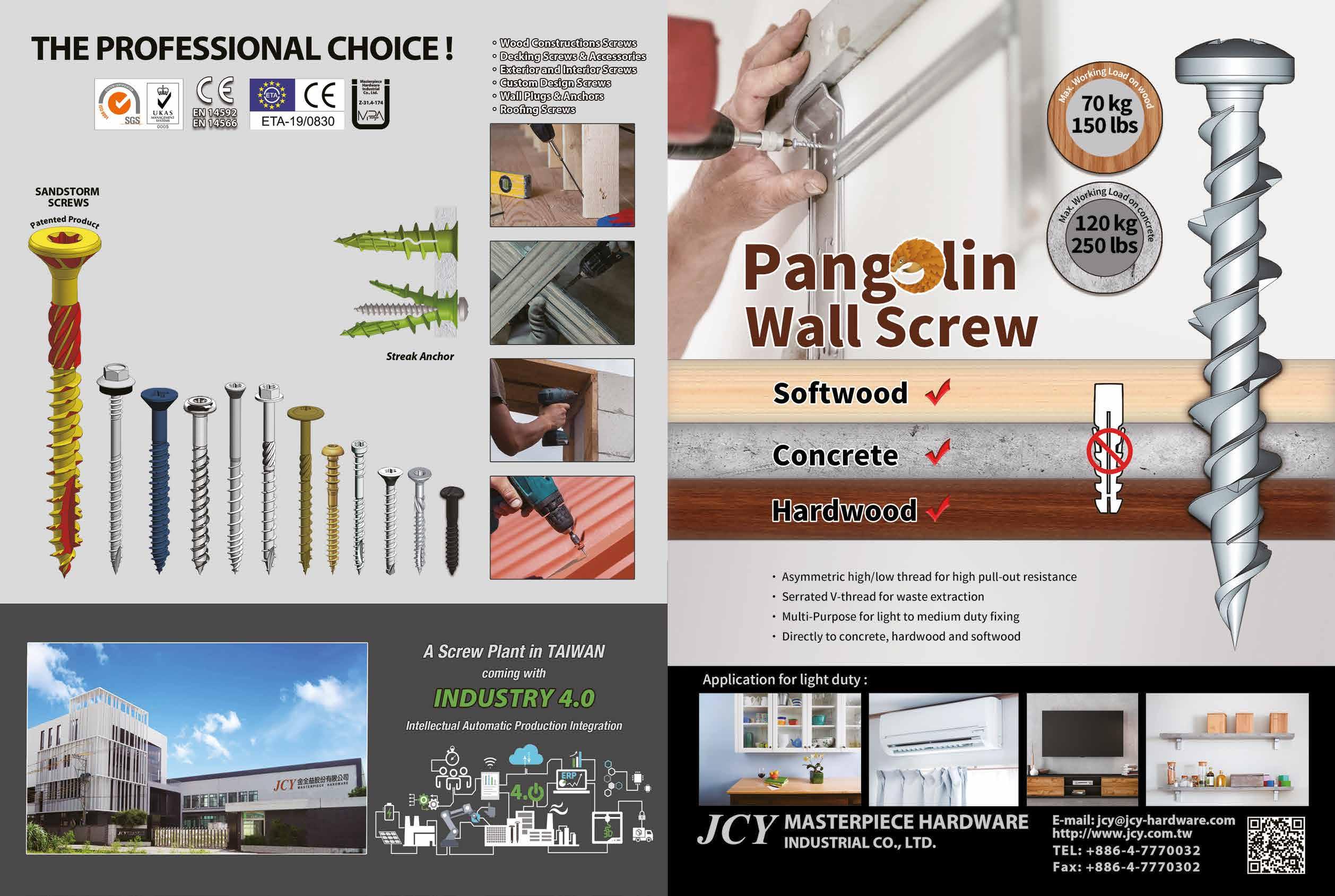

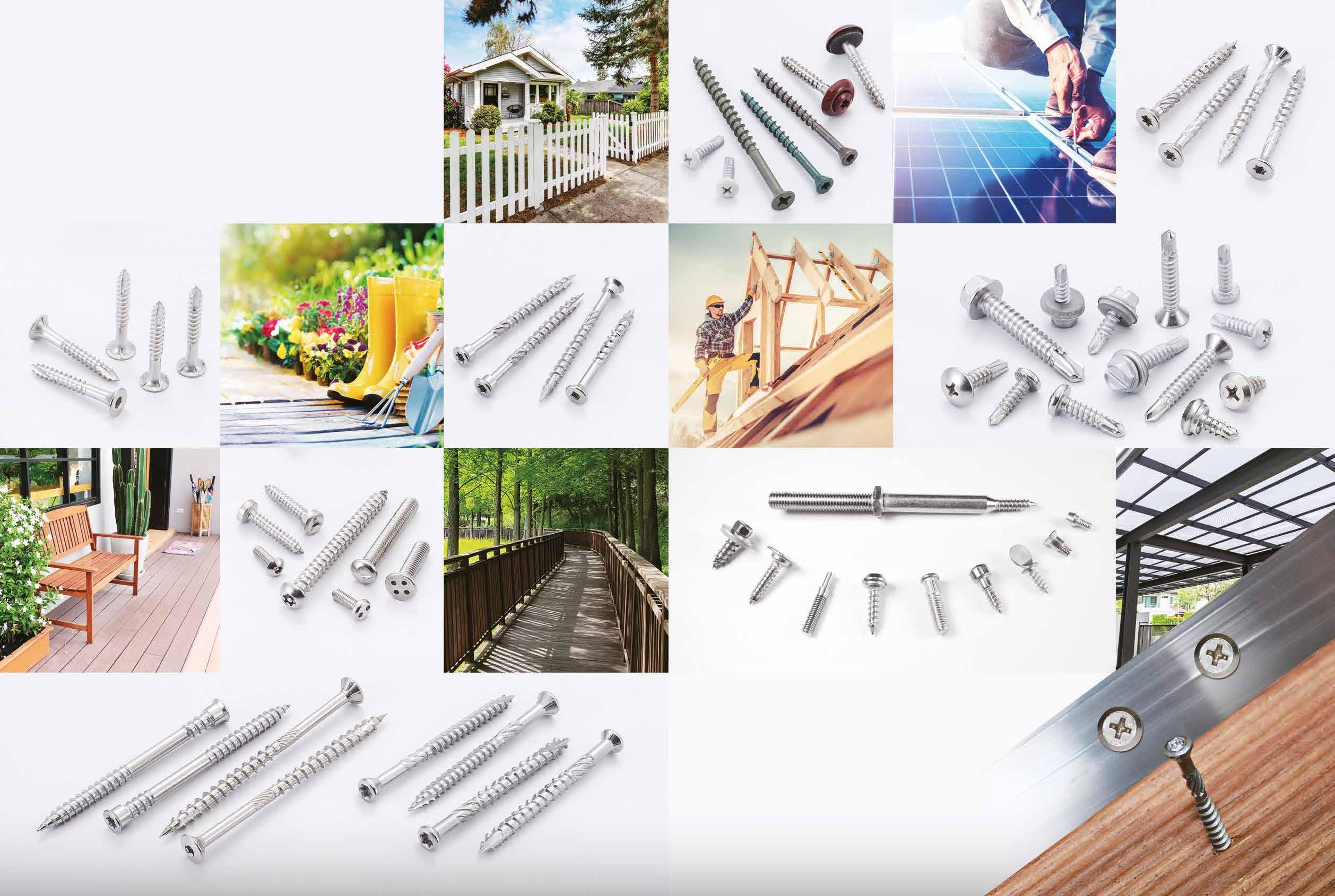

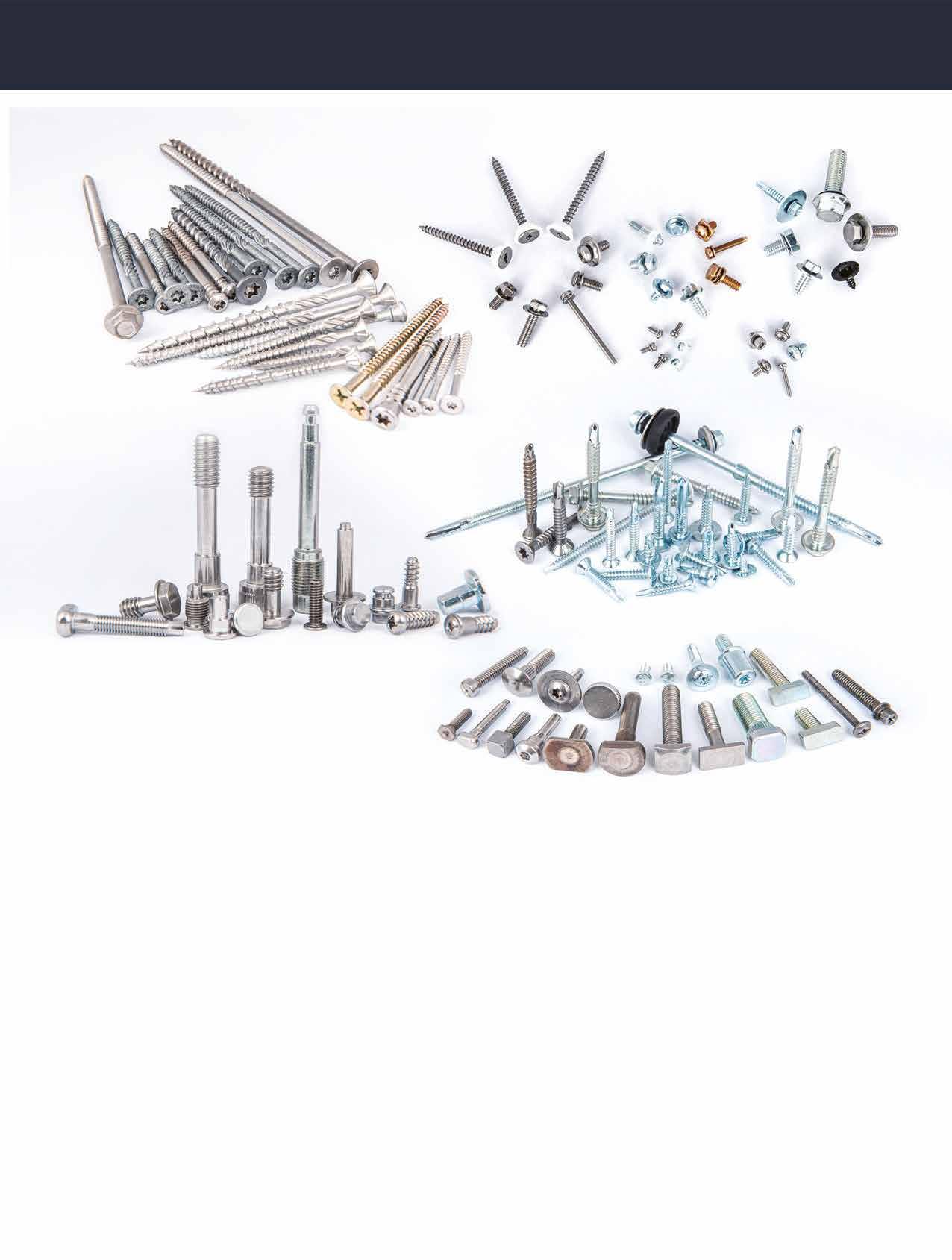

ABi-Mirth specializes in the R&D, production and export of structural wood and concrete fasteners, of which 25% are exported to the U.S., 70% to Europe and 5% to other countries including Brazil and Japan. Soon after they announced an update on their U.S. ICC certificate, electroplating line, electroplating liquids and coatings last September, they are now featuring three special products this spring and will embark on a full-range sale promotion in the upcoming Fastener Fair Global and Taiwan International Fastener Show. This cover story takes a dive in the features of BiMirth hardwood screws, timber-concrete connector screws, and A2/A4 stainless steel wood screws, and ends with a scoop on Bi-Mirth’s carbon reduction arrangements in response to the EU carbon tax.

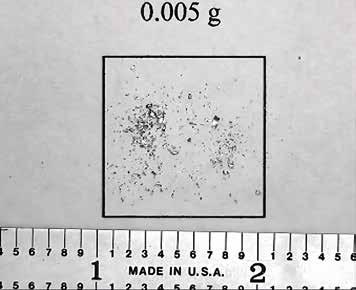

Traditionally, timber constructions usually use softwoods, but recently more and more countries are using hardwood as a building material. Hardwood uses less surface area to achieve equal or higher performance than softwood. Regular screws could break when drilling into hardwood due to its high density. Bi-Mirth did intensive research on hardwood and rolled out a screw made with a specific material and heat treatment technology to cope with the high density in hardwood. This special screw is characterized by low insertion torque and no breakage during installation.

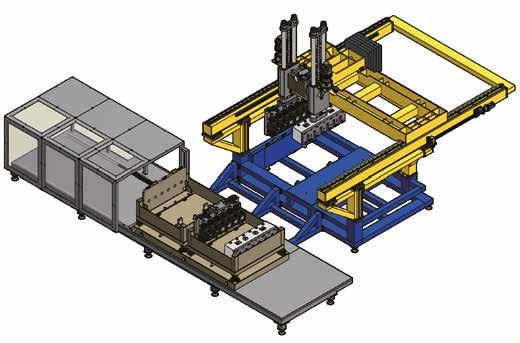

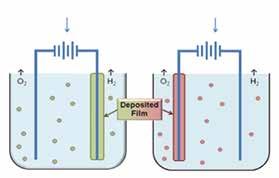

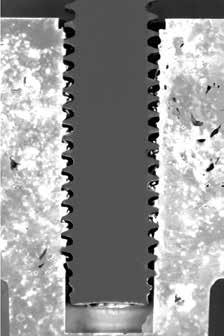

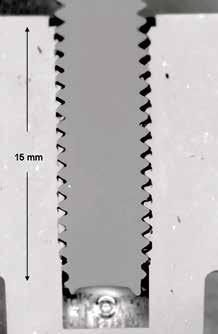

There are many old houses in various countries that are in high demand for renovation. Wood is resilient (very flexible) and delivers good shear resistance (not easy to break); concrete performs better in resisting pressure. The use of both concrete and timber in the renovation process can bring out the advantages of both materials. In addition, this solution creates better acoustic effect in the building. Bi-Mirth has developed a suitable solution for timber-concrete connection that prevents displacement between the two materials and provides excellent shear resistance.

>>Contact: Bi-Mirth Sales Team Email: sales@bimirth.com.tw

The BM Quickdrill wood screw series now adds stainless steel as a material option. A2 304/305 and A4 316 stainless steel deliver extraordinary resistance against high salinity and acidic environment. High rust and corrosion resistance makes it ideal for use in harsh environments near the sea to maximize the combined effect.

All these three screws are available for customized production and Bi-Mirth has already applied for ETA certification. The certificate for A2/A4 stainless steel wood screws will be obtained this March or April at the earliest.

The EU carbon border tax has spurred a lot of discussion in the fastener industry in Taiwan. With a focus on the European market, Bi-Mirth devotes a lot of attention and preparation to carbon reduction and green manufacturing. They have installed solar panels on the roof of their own electroplating factory and are planning to make green electricity in the future. Bi-Mirth’s forming, coating, and packaging plant will also be planning to build solar power in the near future. In addition, they have introduced electrostatic oil-filtering devices in their screw manufacturing plant to significantly reduce fume emissions in the plant.

At present, the common ways to reduce carbon include planting trees, installing solar panels, or converting heat into electricity in the production process of machines. However, in the face of the carbon tax which will be imposed by the European Union by 2027, will the existing practices be able to respond? In this regard, Bi-Mirth calls on the Taiwanese fastener industry to pool their ideas and develop innovative ways to reduce carbon in the fastener industry. For example, study how to reduce carbon emissions in material selection, manufacturing process, outsourcing, cleaning, inspection, packaging, logistics and other aspects. Or, think about how to pull out vertical collaboration through Taiwan’s unique strong screw supply chain, or how to learn horizontally and introduce carbon reduction technology from other different industries. These are the issues we can think about immediately.

In addition, there are still a lot of details up in the air regarding the current carbon tax. When the tax starts to be levied, Taiwan fastener traders will need a set of benchmarks to determine whether their partner suppliers meet the carbon emission standards. Bi-Mirth points out this aspect also deserves the industry’s attention.

Bi-Mirth believes that the next focus on carbon reduction is timber buildings. Steel and concrete building creates more carbon from raw material to the construction of the building comparing to timber building. Traditionally, people have a misconception about the safety of the timber building; however, new technologies for timber constructions make timber buildings safer. Timber buildings can bear both horizontal and vertical shock waves, and are more resistant to earthquakes than steel buildings. In addition, fire safety is greatly improved in timber constructions. Bi-Mirth will continue on its path of wood screw development and continue to make innovative products.

by

Dean Tseng, Fastener World

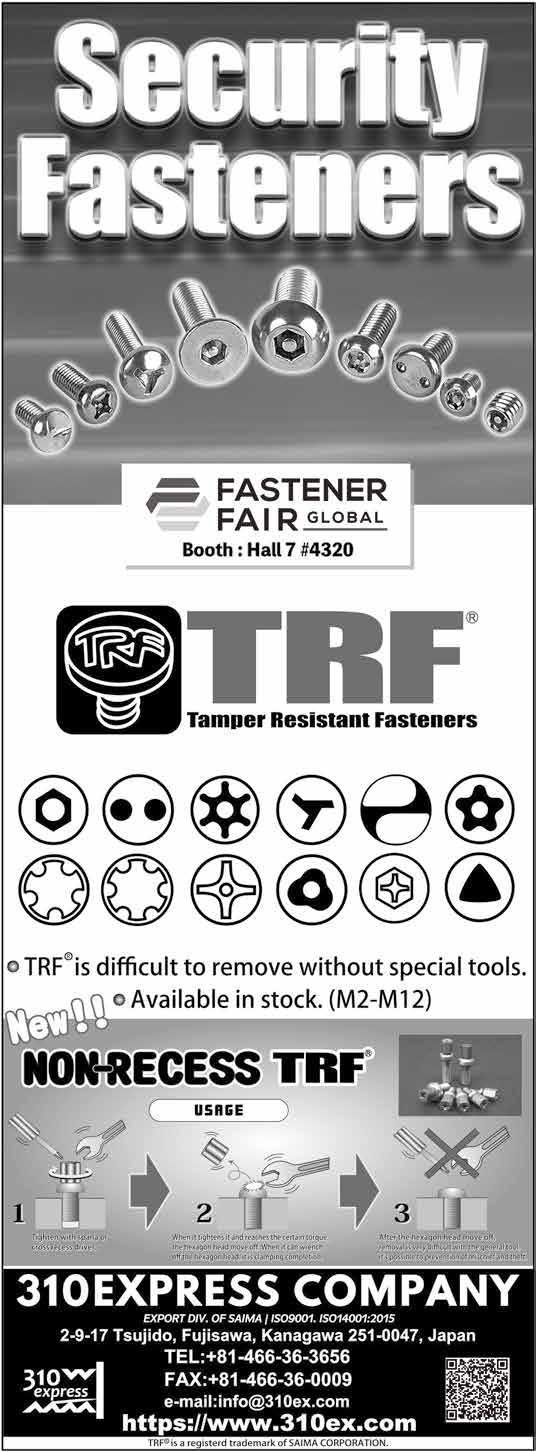

271 310EXPRESS COMPANY (Japan)

Security, Tamper Proof, Anti-theft Screws...

242 A-PLUS SCREWS INC.

Chipboard Screws, Customized Special Screws / Bolts...

186 A & M PRODUCTS CO., LTD.

Fasteners...

330 ABC FASTENERS CO., LTD.

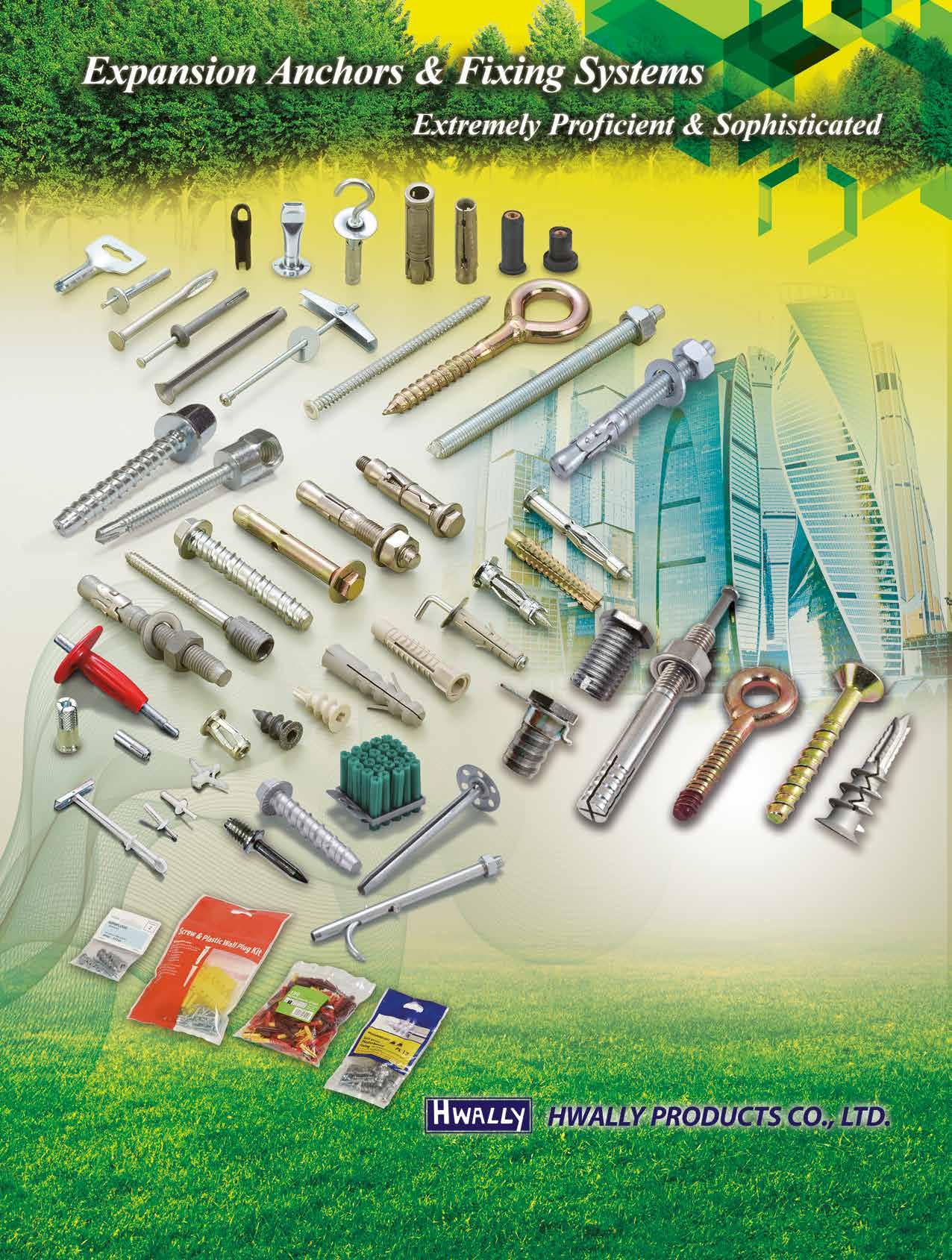

Drop-in Anchors, Expansion Anchors, Wire Anchors...

153 ABS METAL INDUSTRY CORP.

Elevator Bolts, Flanged Head Bolts, Floorboard Screws...

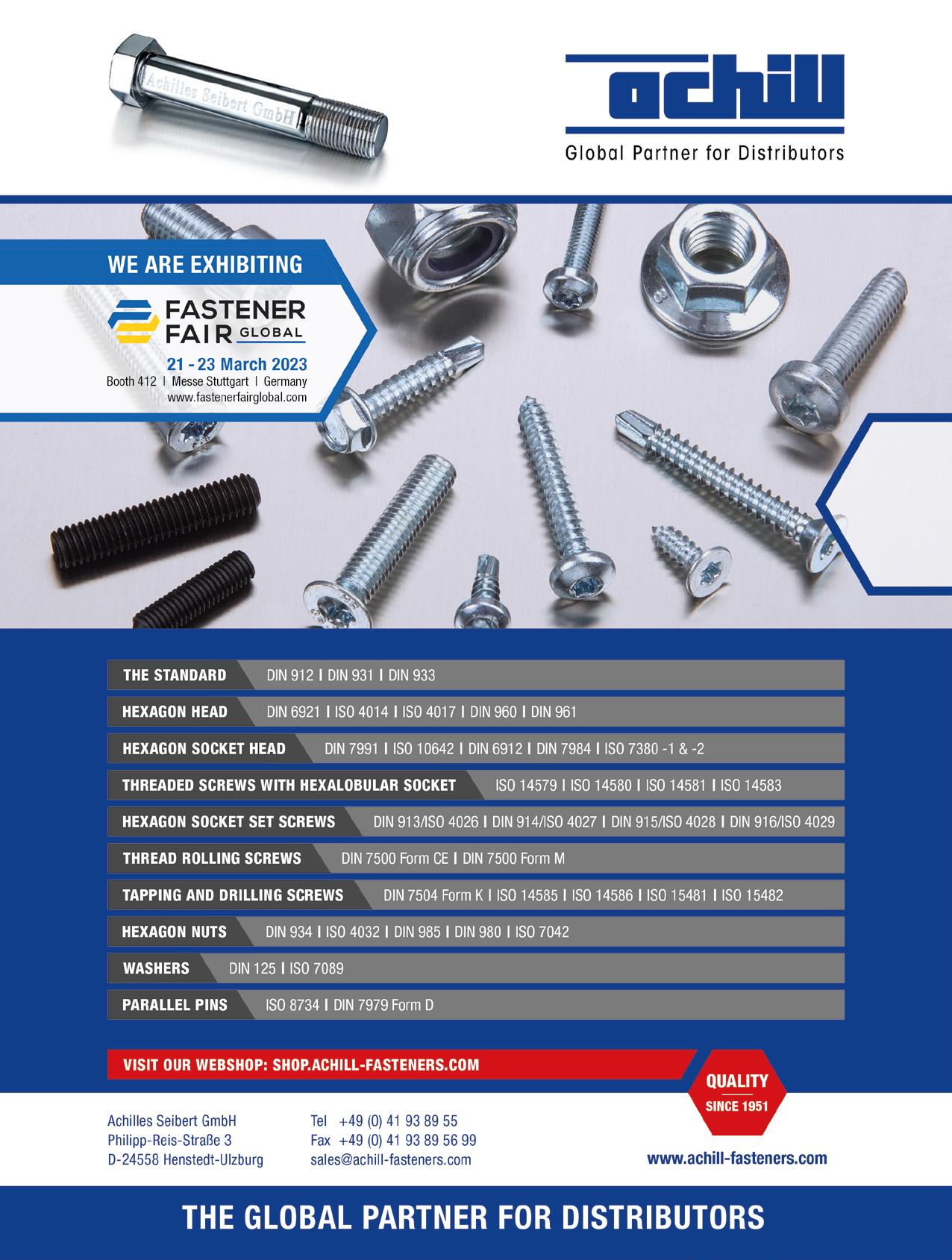

140 ACHILLES SEIBERT GMBH (Germany)

Tapping Screws, Drilling Screws, Thread Rolling Screws...

115 AEH FASTEN INDUSTRIES CO., LTD.

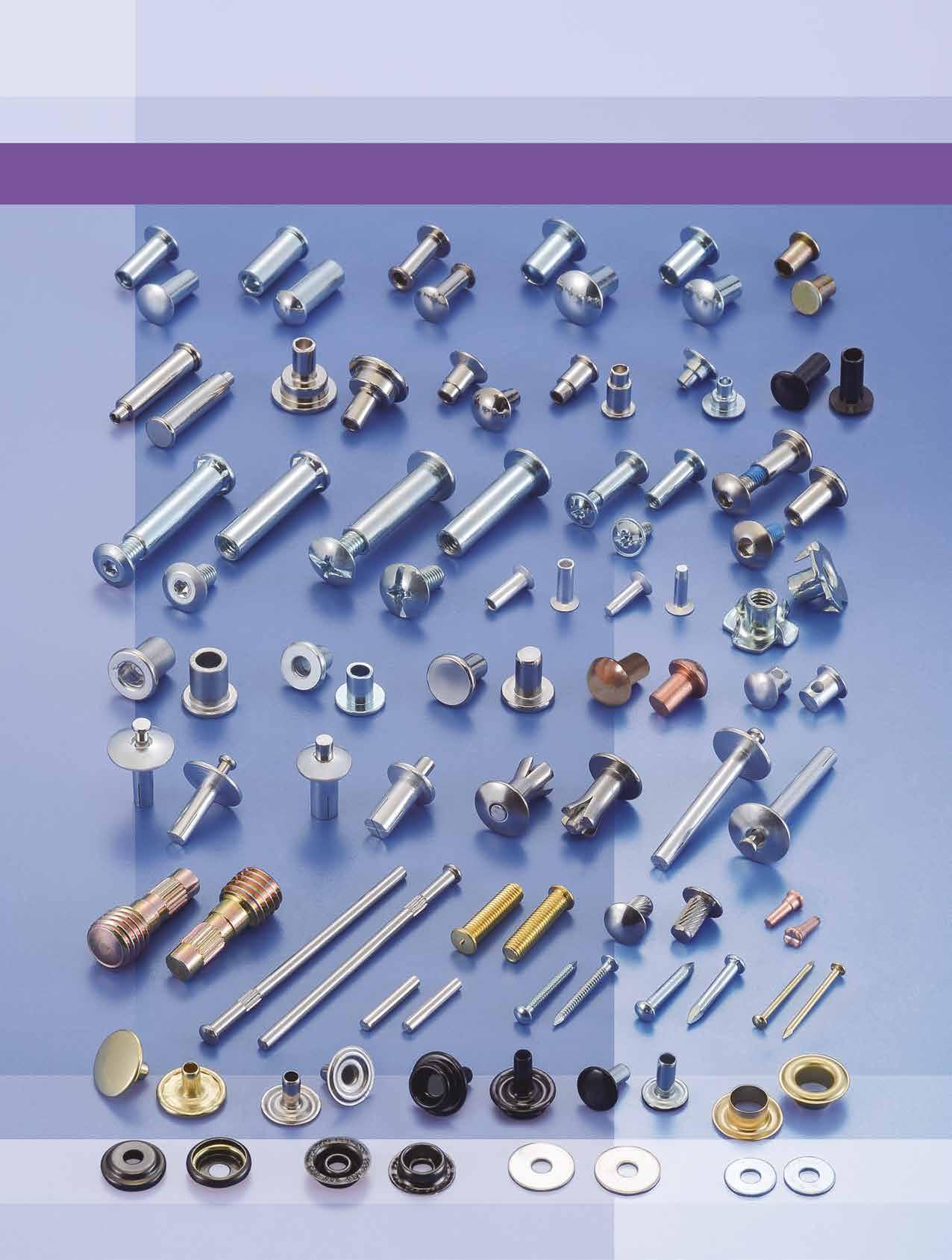

Clevis Pins, Dowel Pins, Hollow Rivets...

23 ALEX SCREW INDUSTRIAL CO., LTD.

Button Head Cap Screws, Button Head Socket Cap Screws...

122 ALISHAN INTERNATIONAL GROUP CO., LTD.

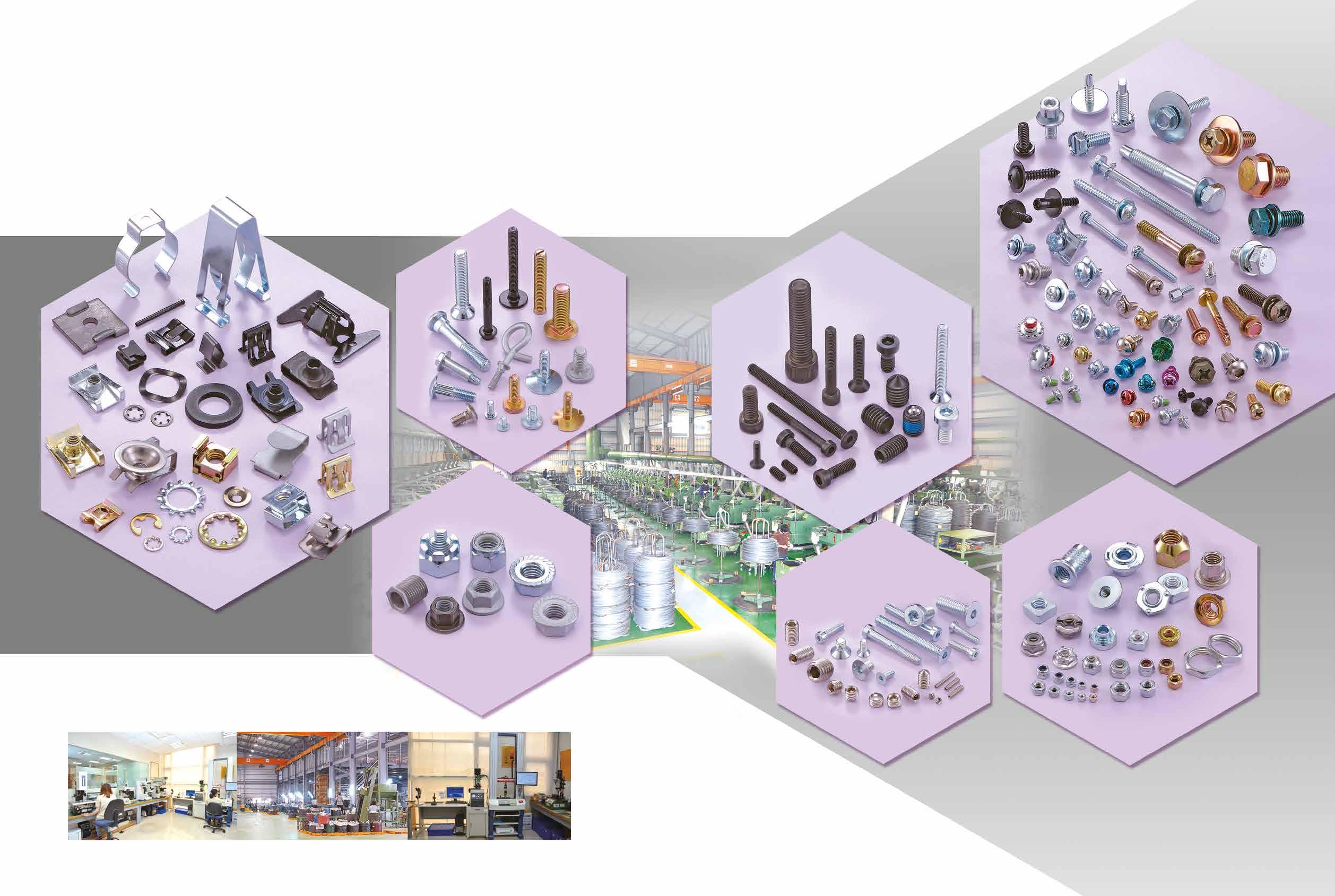

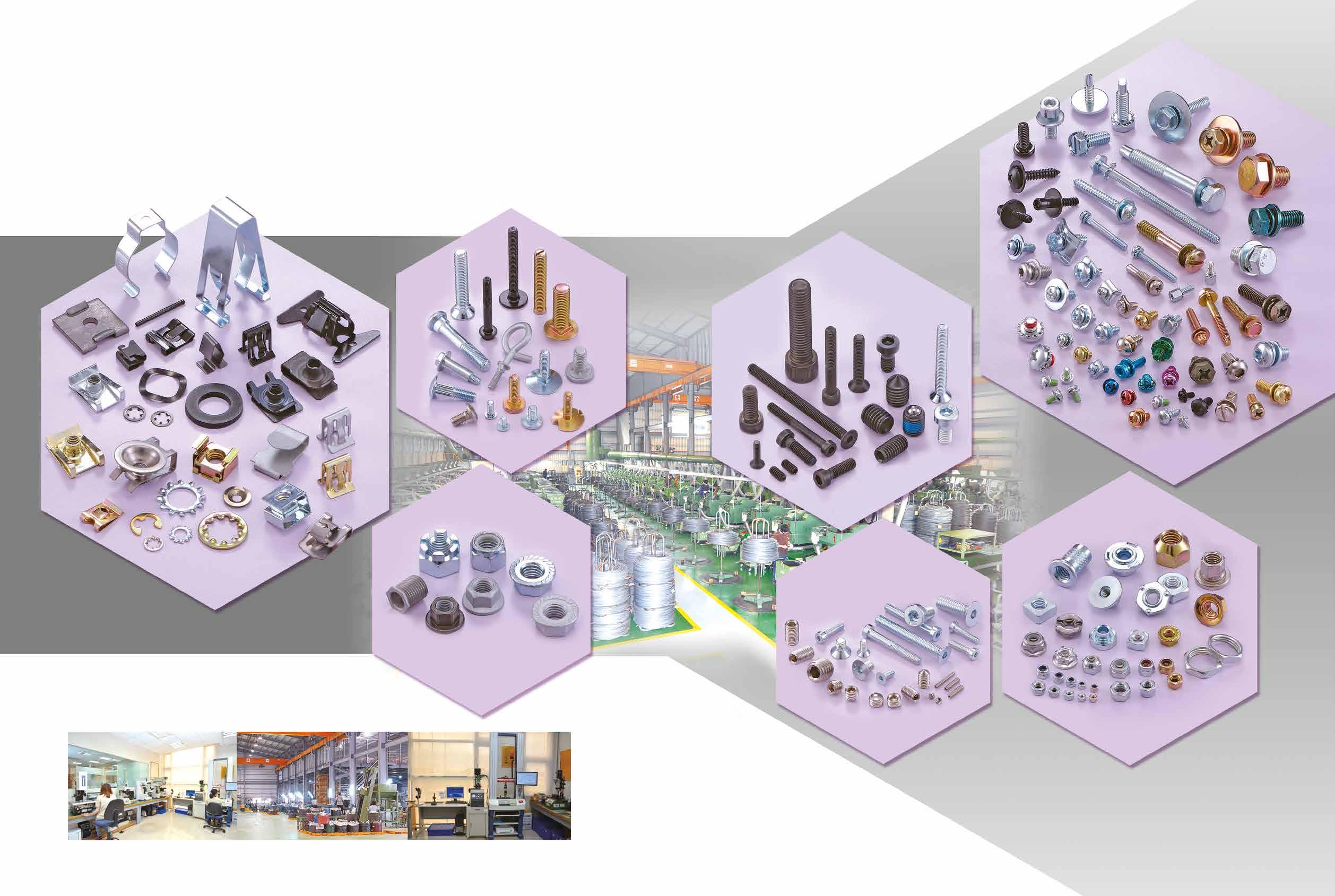

Fastener Tools, Bolts, Screws, Nuts, Stamping Parts...

228 ALLMATE FASTENER CO., LTD.

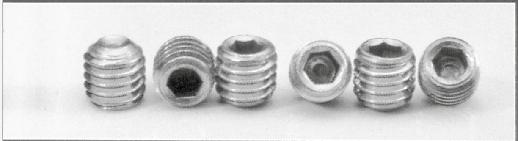

Cap Screws, Socket Set Screws, Pins...

88 AMBROVIT S.P.A. (Italy)

Chipboard Screws, Combined Screws, Machine Screws...

123 AMPLE LONG INDUSTRY CO., LTD.

Hollow Rivets, Drive Rivets, Semi-tubular Rivets...

342 ANCHOR FASTENERS INDUSTRIAL CO., LTD.

ETA Series, Anchor Bolts, Anchor Nuts, Automotive Parts...

67 APEX FASTENER INTERNATIONAL CO., LTD.

Nuts, Wing Nuts & Bolts, Turning Parts, Stamping Parts

167 ARK FASTECH CORP.

Multi-Station Cold Forging Bolts / Nuts...

142 ART SCREW CO., LTD. (Japan)

Anti-loosening Screws, Motiontite®

84 ARUN CO., LTD.

Bi-metal Screws, Chipboard Screws, Drywall Screws...

136 AUTOLINK INTERNATIONAL CO., LTD.

Automotive Screws, Machine Bolts, Flange Nuts...

80 BCR INC.

Automotive Screws, Piston Pins, Weld Bolts (Studs)...

130 BESTWELL INTERNATIONAL CORP.

Eye Bolts, Flanged Head Bolts, Hanger Bolts...

282 BIING FENG ENTERPRISE CO., LTD.

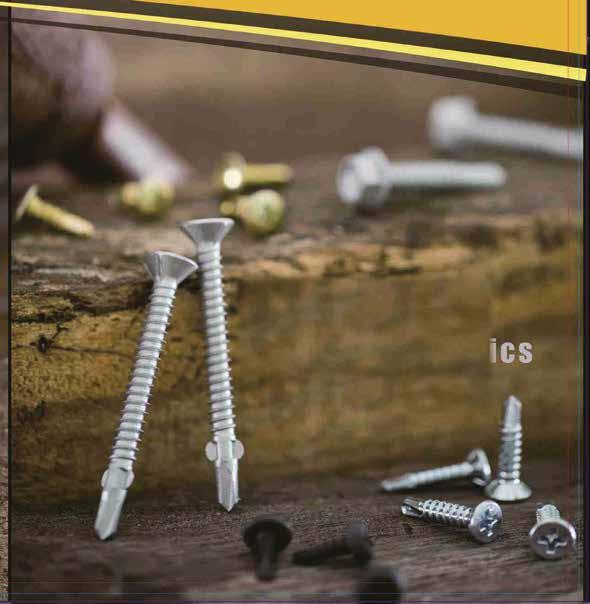

Blind Nut Formers, Multi-station Cold Forming Machines... 44 BI-MIRTH CORP.

Carbon Steel Screws, Chipboard Screws, Concrete Screws...

157 CANATEX INDUSTRIAL CO., LTD. 保力德 Nuts, Turning Parts, Bolts, Plastic Injection Parts...

251 CENTRAL FASTENER CO., LTD. 昇宙 Gas Framing Nailer, Gas Finishing Nailer, Concrete Pins...

310 CHANG BING ENTERPRISE CO., LTD. 彰濱 Hook Bolts, Holders / Hooks / Rings, Dowel Screws...

132 CHANG YI BOLT CO., LTD. 長益 6 Cuts/ 8 Cuts Self Drilling Screws, A2 Cap Screws...

292 CHAO JING PRECISE MACHINES ENTERPRISE 朝璟 Cold Forging Bolt Formers, Thread Rolling Machines...

286 CHI NING COMPANY LTD. 旗林 Machine, Nuts, Tooling...

58 CHIAN YUNG CORPORATION 將運 SEMS Screws

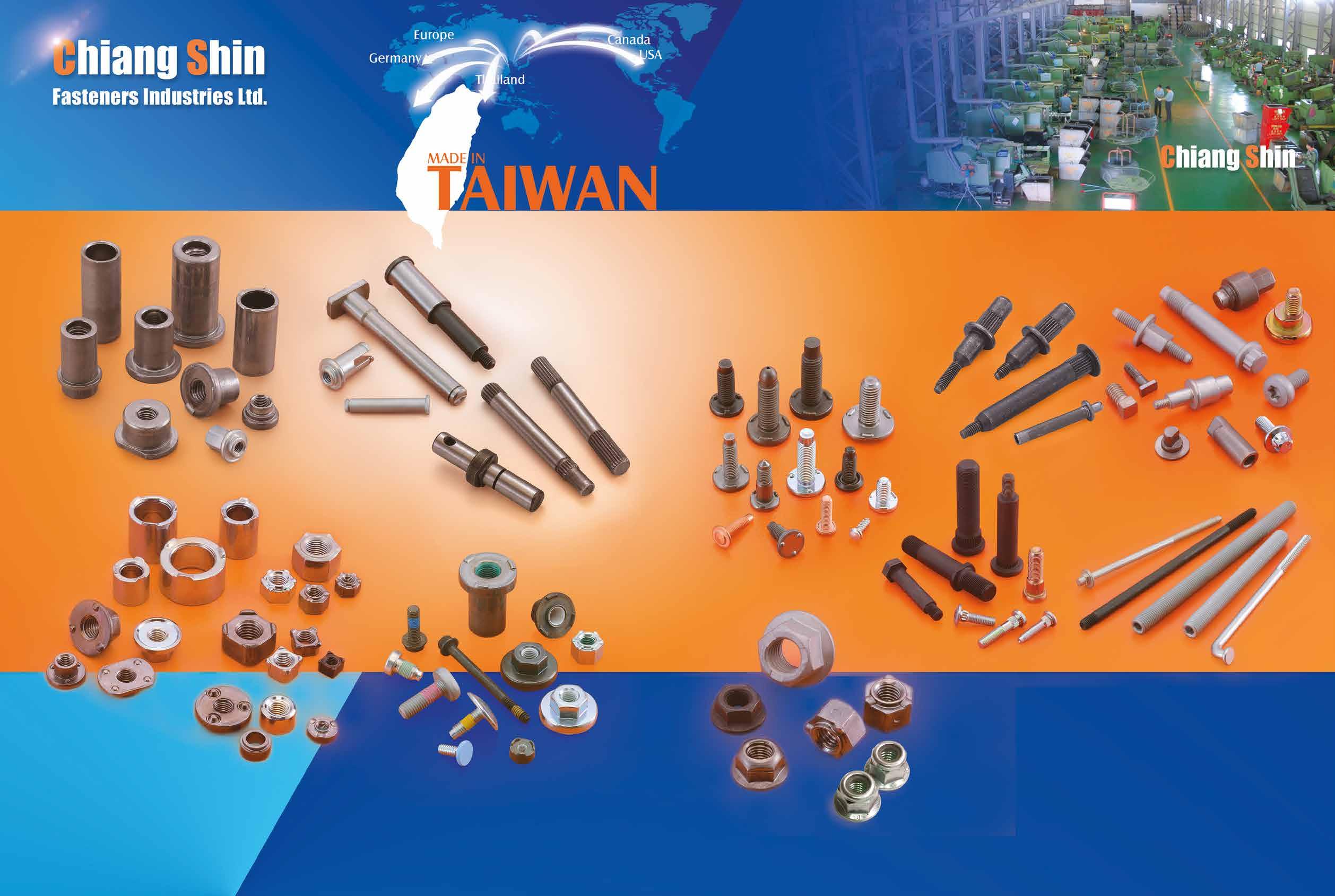

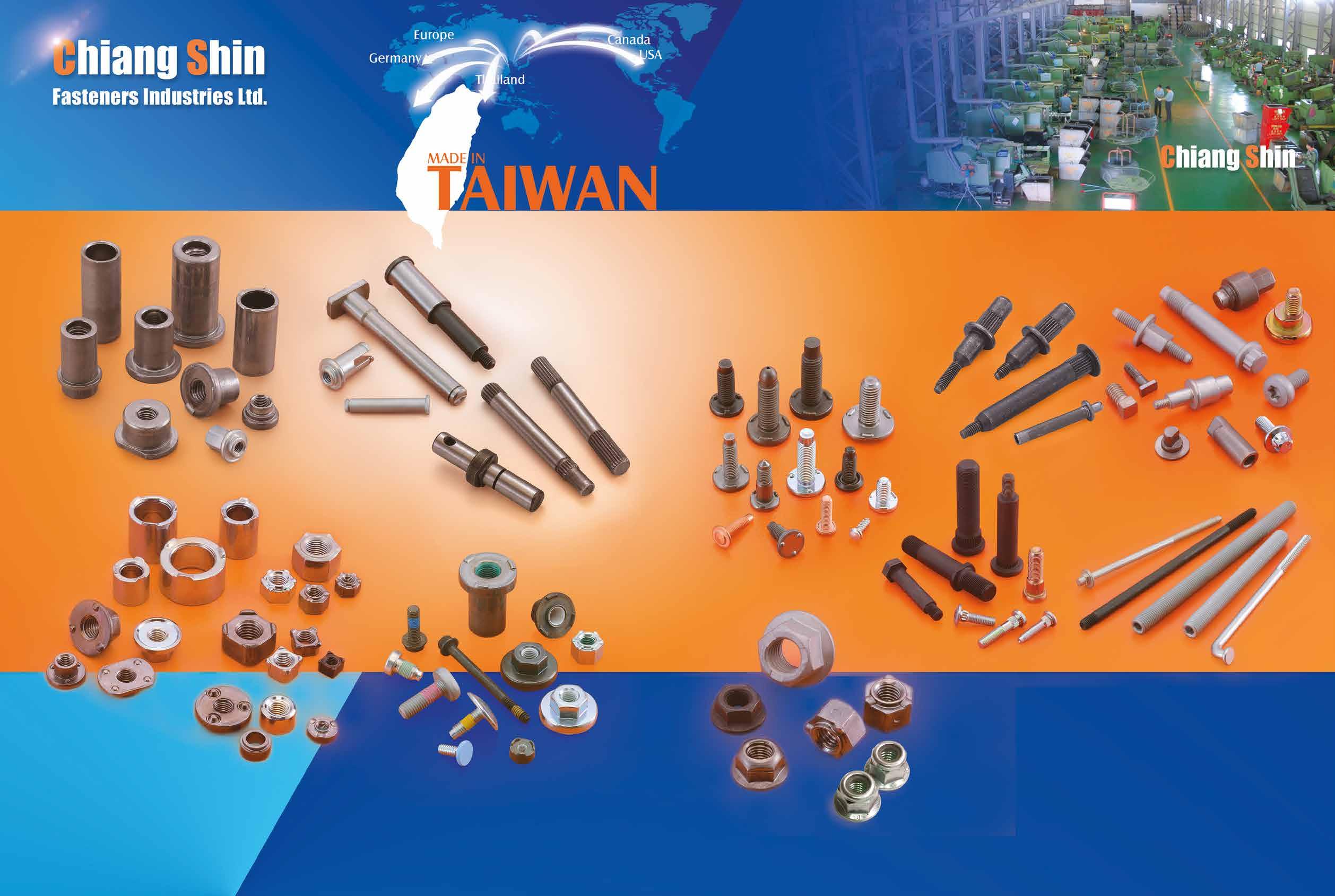

246 CHIANG SHIN FASTENERS INDUSTRIES LTD. 強鑫 Flange Screws, Hexagon Head Bolts, Hexagon Head Cap Screws...

283 CHIEN TSAI MACHINERY ENTERPRISE CO., LTD. 鍵財 Thread Rolling Machines

91 CHIN LIH HSING PRECISION ENTERPRISE 金利興 Automotive Nuts, Brass Inserts, Bushes, Bushings...

280 CHING CHAN OPTICAL TECHNOLOGY CO., LTD. 精湛 Eddy Current Sorting Machines, Fastener Makers...

40 CHONG CHENG FASTENER CORP. 宗鉦 Cap Nuts, Coupling Nuts, Conical Washer Nuts...

112 CHUN YU WORKS & CO., LTD. 春雨 Drywall Screws, Socket Head Cap Screws , TC Bolt Sets...

278 CHUN ZU MACHINERY INDUSTRY CO., LTD. 春日 Cold Headers, Header Toolings, Heading Machines...

257 CO-WEALTH ENTERPRISE CO., LTD. 竟丞 Spring Pins, Flange Washers, Sems Washers...

181 CONTINENTAL PARAFUSOS S.A. 巴西商友暉 Automotive Part & Nut, Home Appliance Screws, Sems...

275 COPA FLANGE FASTENERS CORP. 國鵬 Hex Nuts, Hex Flange Nuts, Combi Nuts, Weld Nuts...

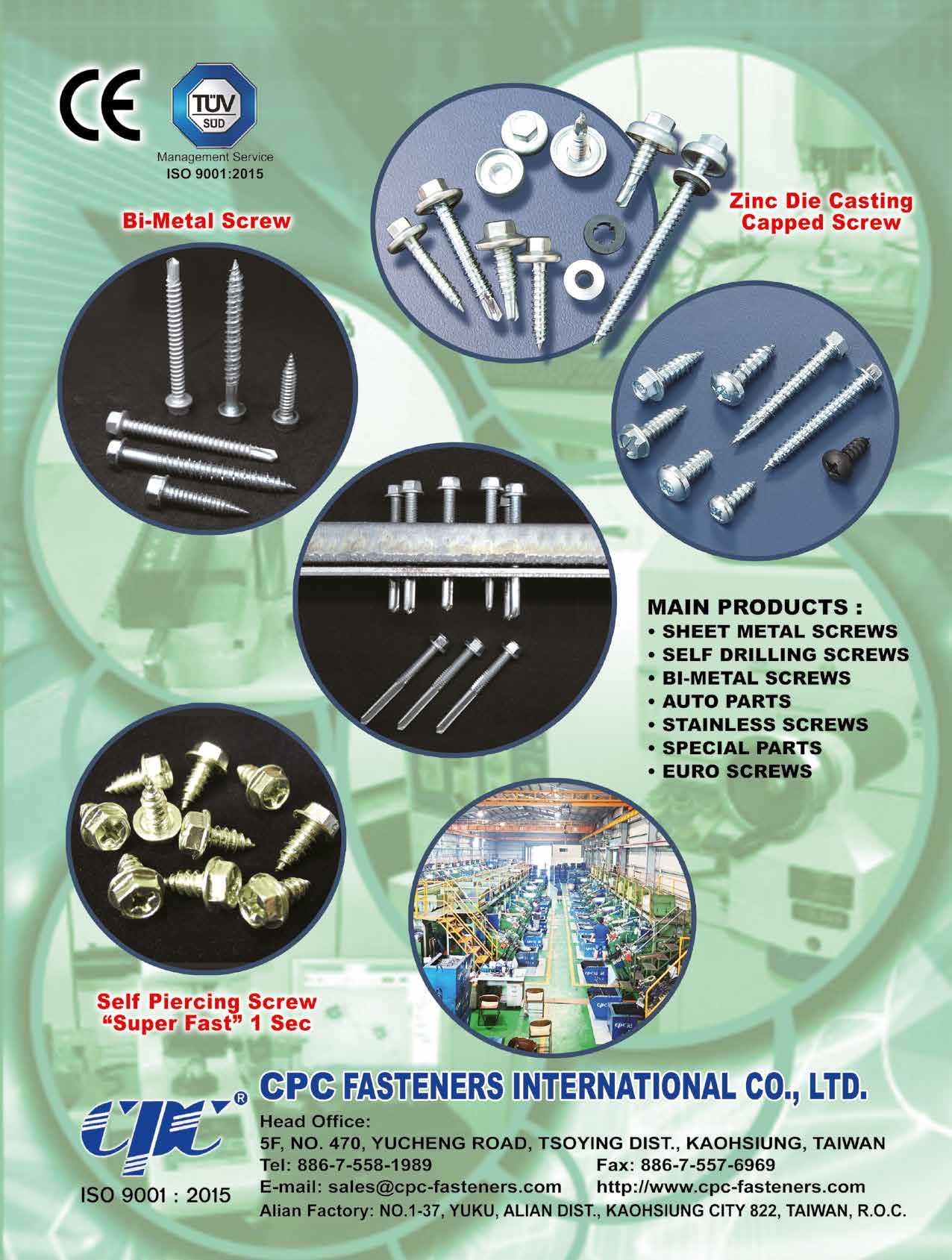

81 CPC FASTENERS INTERNATIONAL CO., LTD. 冠誠 Stainless Steel, Bi-metal Self-drilling Screws...

25 DA YANG ENTERPRISE CO., LTD. 大楊 Special Automotive Nuts, Special Weld Nuts...

94 DAR YU ENTERPRISE CO., LTD. 達宇 Chipboard Screws, Drywall Screws, Screw Nails…

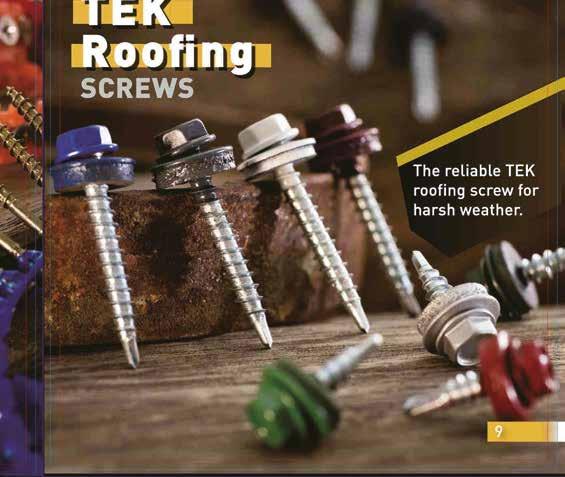

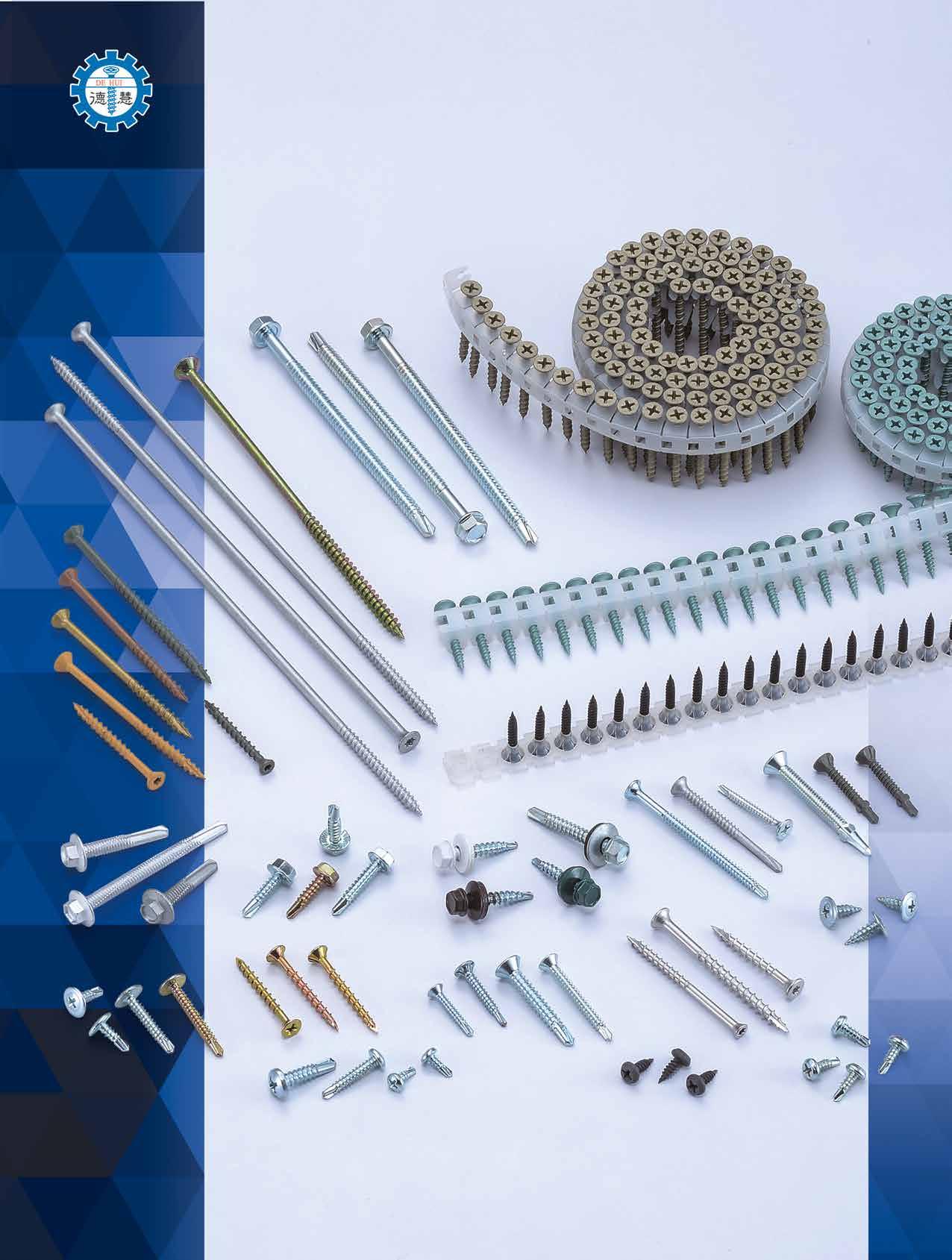

211 DE HUI SCREW INDUSTRY CO., LTD. 德慧 Drywall Screws, Decking Screws, Self-drilling Screws, Roofing Screws...

155 DELTEKS INDUSTRIES INC. 見承 Wheel Bolts, Bushes, Thread Forming Screws, All Kinds of Screws...

159 DER GANG STAINLESS CO., LTD. 德鋼 Marine Hardware & Screws, Rigging Hardware…

224 DICHA FASTENERS MFG. 集財 Expansion Anchors, Sleeve Anchors, Nylon Nail Anchors...

DIING SEN FASTENERS INDUSTRIAL CO., LTD. 鼎昇 Chipboard Screws, Corrosion Resistant Screws...

13 DIN LING CORP. 登琳

Chipboard Screws, Drywall Screws, Furniture Screws...

Blind Rivets...

241 FIXI SRL. (Italy)

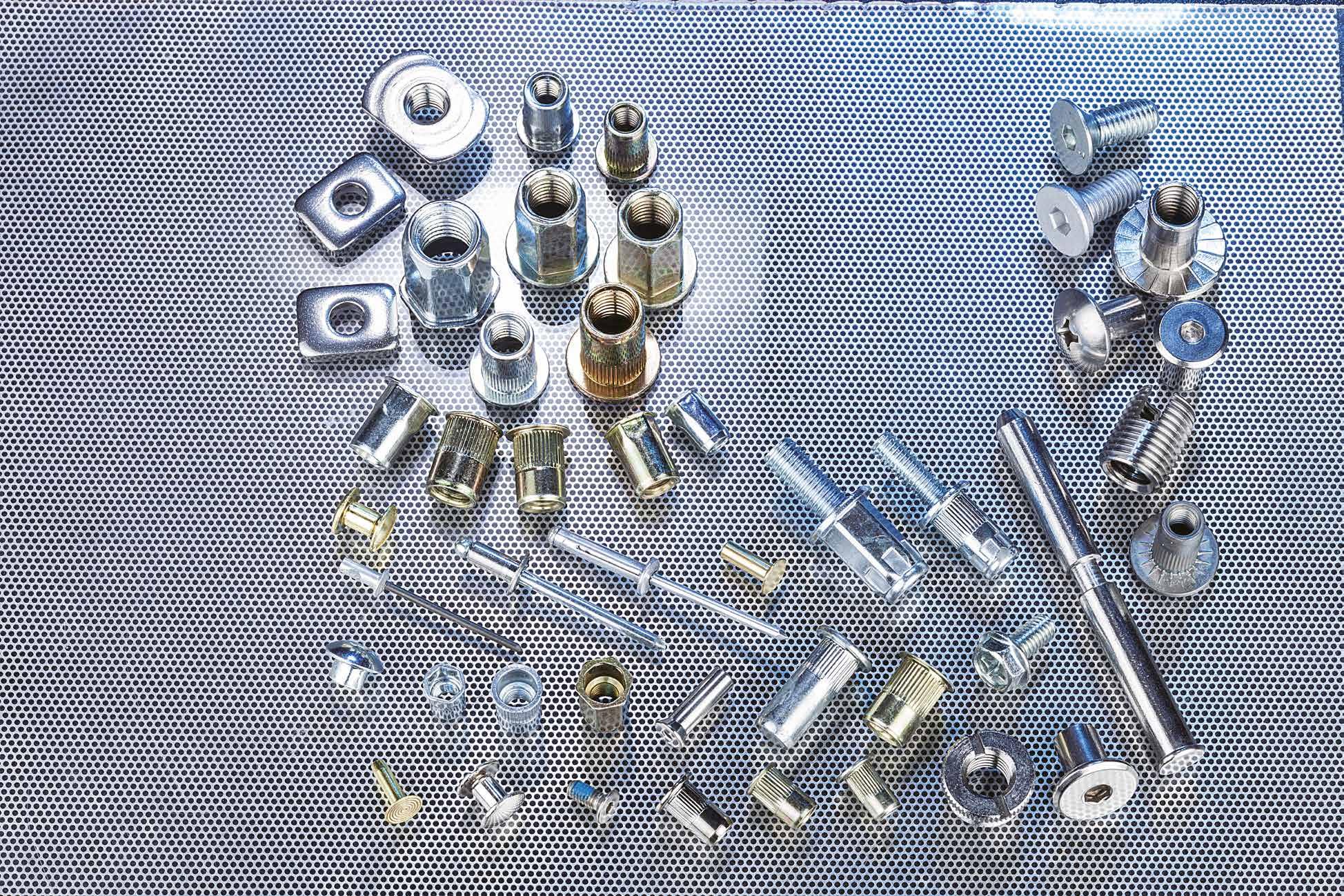

Rivet Nuts, Blind Rivets, Self-clinching, Welding Studs...

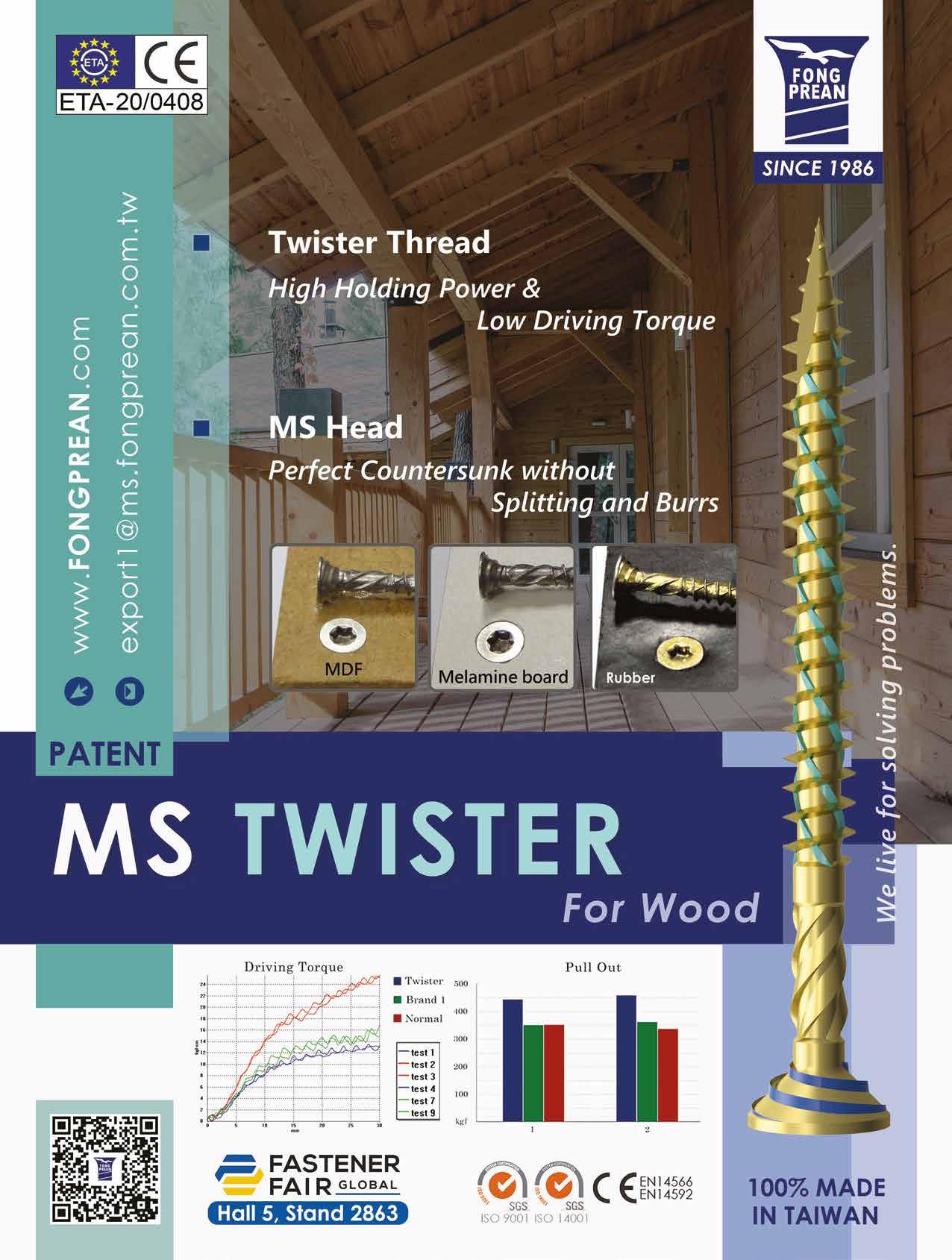

83 FONG PREAN INDUSTRIAL CO., LTD.

Automotive Screws, Bi-metal Screws, Brass & Bronze Screws...

138 FONG WUNS CO., LTD.

Flange Nuts, Stainless Steel Nuts, Special Parts...

110 FONG YIEN INDUSTRIAL CO., LTD. 宏盈 Eyebolts, Spindles...

22 FORTUNE BRIGHT INDUSTRIAL CO., LTD. 鋒沐 Cap Nuts, Dome Nuts, Nylon Cap Insert Lock Nuts...

78 FU HUI SCREW INDUSTRY CO., LTD. 福輝 Automotive & Motorcycle Special Screws / Bolts...

206 FU KAI FASTENER ENTERPRISE CO., LTD. 福凱 Precision Electronic Screws, Special Screws, Weld Screws...

106 FUSHANG CO., LTD. 甫商 Carbon Steel Screws, Chipboard Screws, Concrete Screws...

263 GELA & COMPANY 蕙寶 Expansion Anchors, Eye Bolts, Hanger Bolts...

281 GIAN-YEH INDUSTRIAL CO., LTD. 健業 Rivet Dies, Self-drilling Screw Dies, Screw Tip Dies...

273 GINFA WORLD CO., LTD. 濟音發 Chipboard Screws, Countersunk Screws, Drywall Screws...

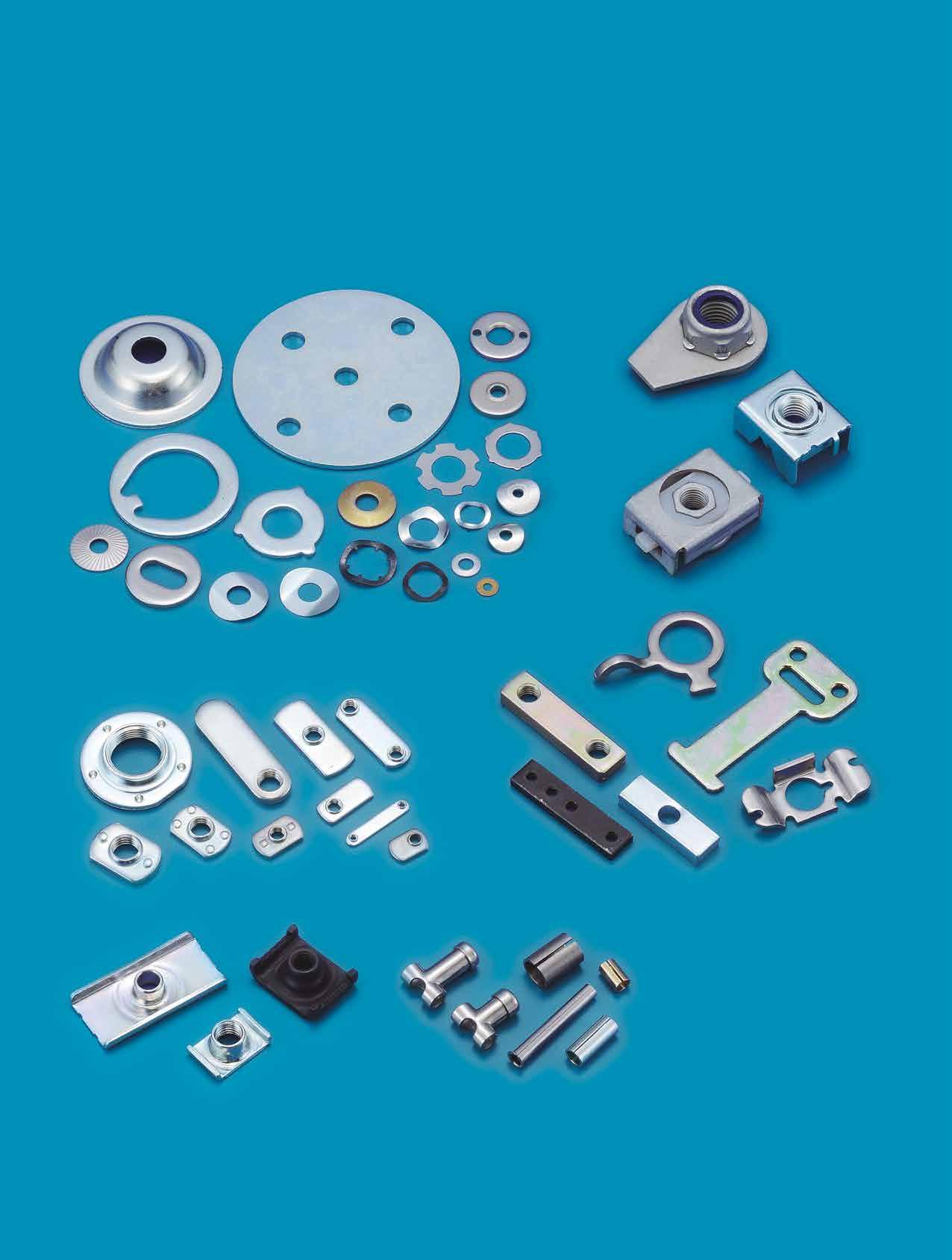

261 GLORBAL SALES COMPANY LIMITED 宗暉 Various Stamping Products, Multi-process Assembly Parts...

156 GOFAST CO., LTD. 喬邁 Open Die Parts, Stamping Parts, Assembly Parts...

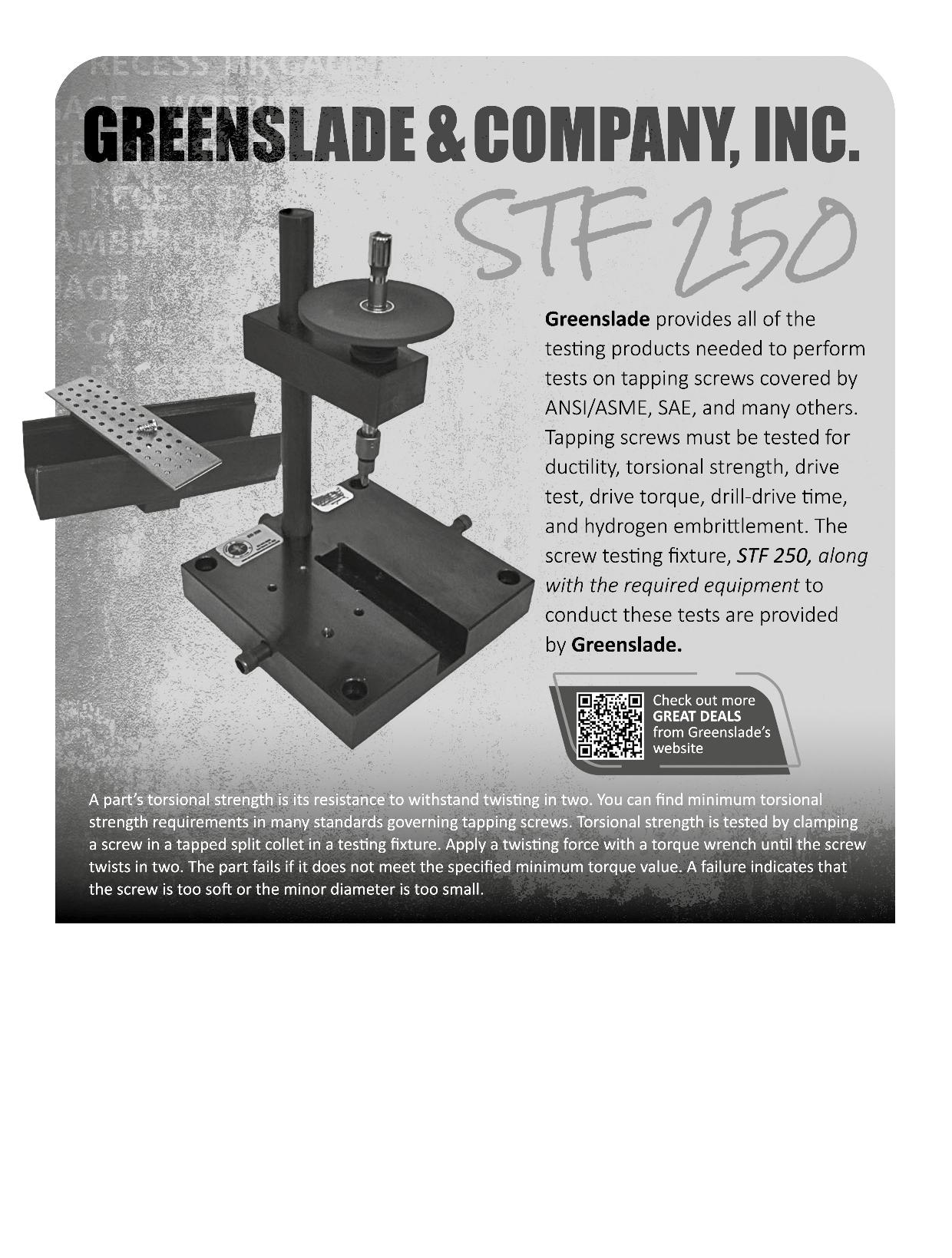

289 GREENSLADE & COMPANY, INC. (U.S.A.) Concentricity, Ring Gage, Plug Gage Calibration, Gages...

256 GUANGZHE ENTERPRISE CO., LTD. 光柘 Collated Washer Paper Tape, Collated Screw Tape...

95 HAO CHENG PLASTIC CO., LTD. 皓正 PP Boxes, PET Jars, ABS Boxes, PC Boxes..

90 HARVILLE FASTENERS LTD. 豪威爾 Special Screws and Bolts, Sems Screws, Stainless Steel Fasteners...

260 HAUR FUNG ENTERPRISE CO., LTD. 豪舫 External Tooth Washers, Long Carriage Bolts, Roofing Bolts...

244 HEADER PLAN CO., INC.

Chipboard Screws, Collated Screws, Deck Screws...

239 HELIC CUTTING TOOLS CO., LTD. 和俐

Wood Auger, TCT Hole Cutter, Adjustable Hole Cutter...

262 HEY YO TECHNOLOGY CO., LTD 恆勇

Precision Pins, Rollers, Dowel Pins...

131 HO HONG SCREWS CO., LTD. 合鋒

Alloy Steel Screws, Button Head Cap Screws, Chipboard Screws...

336 HOME SOON ENTERPRISE CO., LTD. 宏舜

Bit, Bit Holder, Magnetic Nut Setter, Spring Nut Driver...

249 HOMEYU FASTENERS CO., LTD.

Cold Forging Stage, Machine Molds, Lathe, CNC Machining...

128 HOMN REEN ENTERPRISE CO., LTD.

Bi-metal Screw, Collated Screws, Composite Screws...

294 HONG TAY YUE ENTERPRISE CO., LTD. 鴻大裕

Wire Straighteners, Hydraulic Clamping Machines...

255 HONG TENG HARDWARE CO., LTD.

Bi-metal Screws, Carbon Steel and Stainless Steel Screws...

274 HSIN CHANG HARDWARE INDUSTRIAL CORP. 欣彰

Anchor Bolts, Anchors, Plastic Fasteners...

59 HSIN JUI HARDWARE ENTERPRISE CO., LTD.

Bushes, Construction Bolts, Special Cold / Hot Forming Parts...

223 HSIN YU SCREW ENTERPRISE CO., LTD.

Acme Screws, Hexagon Head Cap Screws... 35 HU PAO INDUSTRIES CO., LTD.

Automotive Nuts, Flange Nuts, Hexagon Nuts...

162 HUANG JING INDUSTRIAL CO., LTD.

Washers, Chipboard Screws, Drywall

214 JINGFONG INDUSTRY CO., LTD.

Hex Nylon Insert Lock Nuts, Wing Nuts with Nylon Insert...

235 JIN-YINGS ENTERPRISE CO., LTD. 晉營

Special Custom Fasteners, Auto/Motorcycle Fastener…

17 JOKER INDUSTRIAL CO., LTD. 久可 Hollow Wall Anchors, Concrete Screws, Jack Nuts...

195 K. TICHO INDUSTRIES CO., LTD. 帝潮

Bi-metal Self-drilling Screws, Timber Screws, Collated Screws...

229 KAN GOOD ENTERPRISE CO., LTD. 鋼固 Fastener, Hardware, Plastic, Instruction Booklet Package in Bags...

237 KAO WAN BOLT INDUSTRIAL CO., LTD. 高旺 Hex Head Cap Screws, Carriage Bolts, Hex Lag Bolts...

185 KARAT INDUSTRIAL CORPORATION 寶資 Rivet Tools & Rivet Nut Tools

139 KATSUHANA FASTENERS CORP. 濱井 Collated Screws, Drywall Screws, Roofing Screws...

290 KEIUI INTERNATIONAL CO., LTD. 鎧渝 Self-drilling Screw Forming Machines

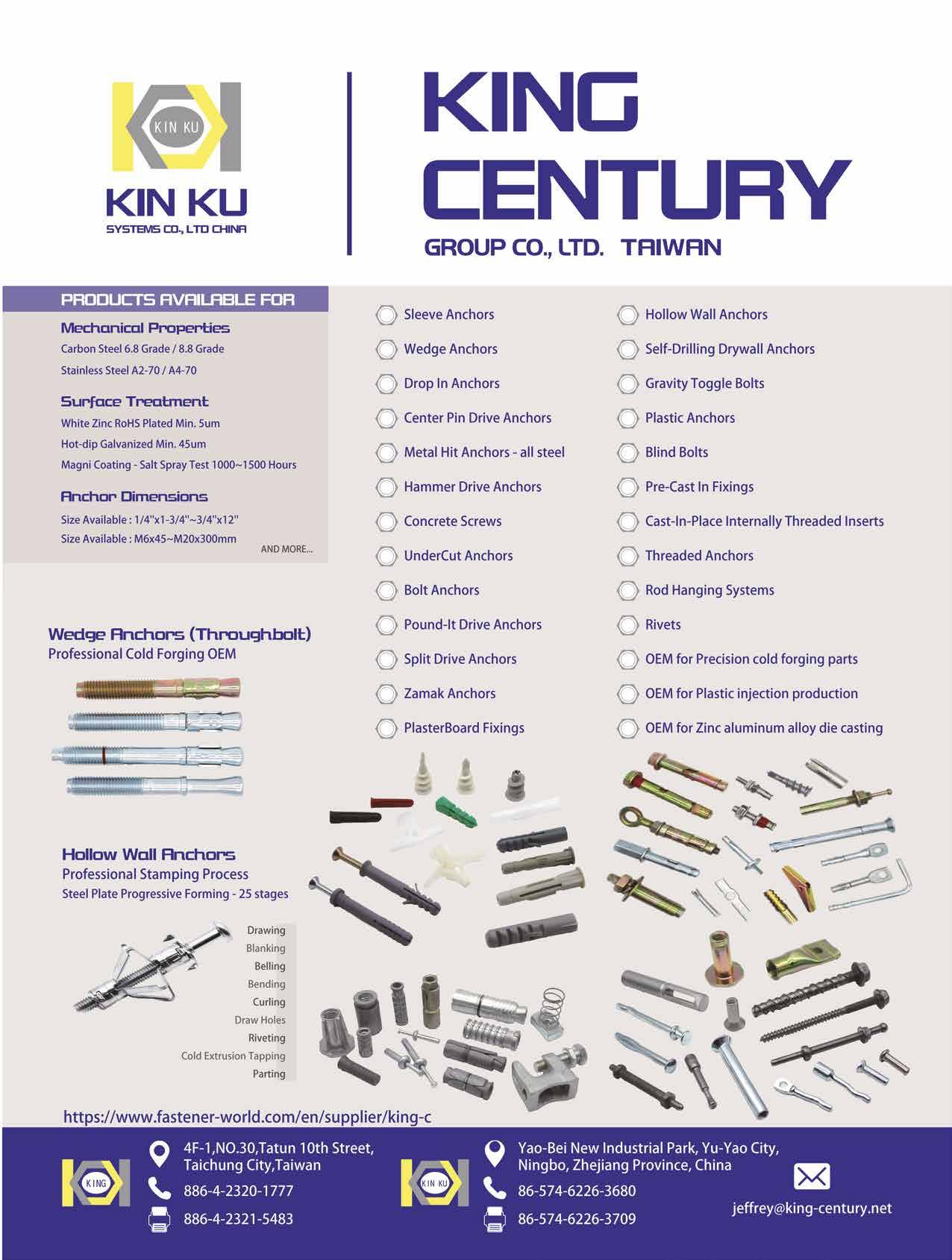

86 KING CENTURY GROUP CO., LTD. 慶宇 Drop-in Anchors, Self-drilling Anchors, Sleeve Anchors...

284 KING YUAN DAR METAL ENTERPRISE CO., LTD. 金元達 Continuous Type Heat Treating Furnace

227 KUO CHEN MOLD CO., LTD. 國鎮 Self-Drilling Dies

76 KWANTEX RESEARCH INC. 寬仕 Chipboard Screws, Drywall Screws, Furniture Screws...

126 L & W FASTENERS COMPANY 金大鼎 Construction Fasteners, Flat Washers, Heavy Nuts...

307 LAIEN CO., LTD. 高昱 Screws, Multi-stroke Forming Screws, CNC Machined Parts...

301 LAN DEE WOEN FACTORY CO., LTD. 藍帝 Blind Rivet Heading Machine, Hollow Heading Machine...

158 LIAN CHUAN SHING INTERNATIONAL CO., LTD. 連全興 Weld Nuts, Special Parts, Special Washers, Flat Washers...

332 LIAN SHYANG INDUSTRIES CO., LTD. 連翔 Nut Formers, Nut Tapping Machines

248 LIANG YING FASTENERS INDUSTRY CO., LTD. Automotive, Hand Tool, Electronic , OEM, Furniture, Shaft ...

114 LINK-PRO TECH CO., LTD. 超傑

Customized Screws/Nuts, Pressing & Deep Drawing...

344 LINKWELL INDUSTRY CO., LTD. 順承 All Kinds of Screws, Automotive & Motorcycle Special Screws...

16 LOCKSURE INC. 今湛 Custom Washers, Flat Washers, Automotive Screws...

51 LONG THREAD FASTENERS CORP. 長隆順 Bi-metal Self-drilling Screws, Chipboard Screws...

173 LOYAL & BIRCH CO., LTD. 龍業百起

Construction Fasteners and Building Fasteners

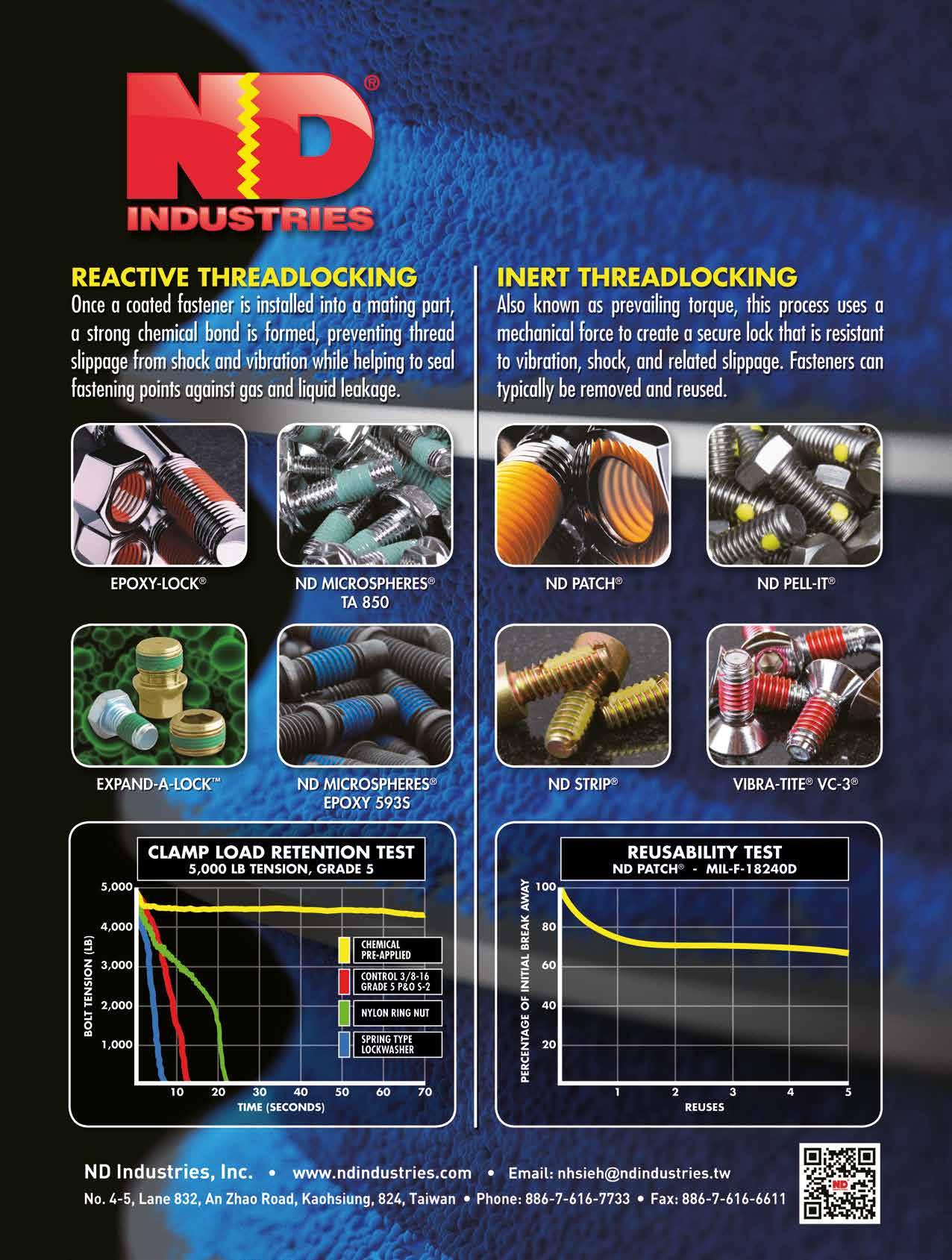

ND Pre-Applied Processes, Advanced Sealing Technologies...

287 NEW BEST WIRE INDUSTRIAL CO., LTD. 強新 Iron or Steel Wire Rod, Alloy Steel Wire & Rod, Stainless Steel Wire...

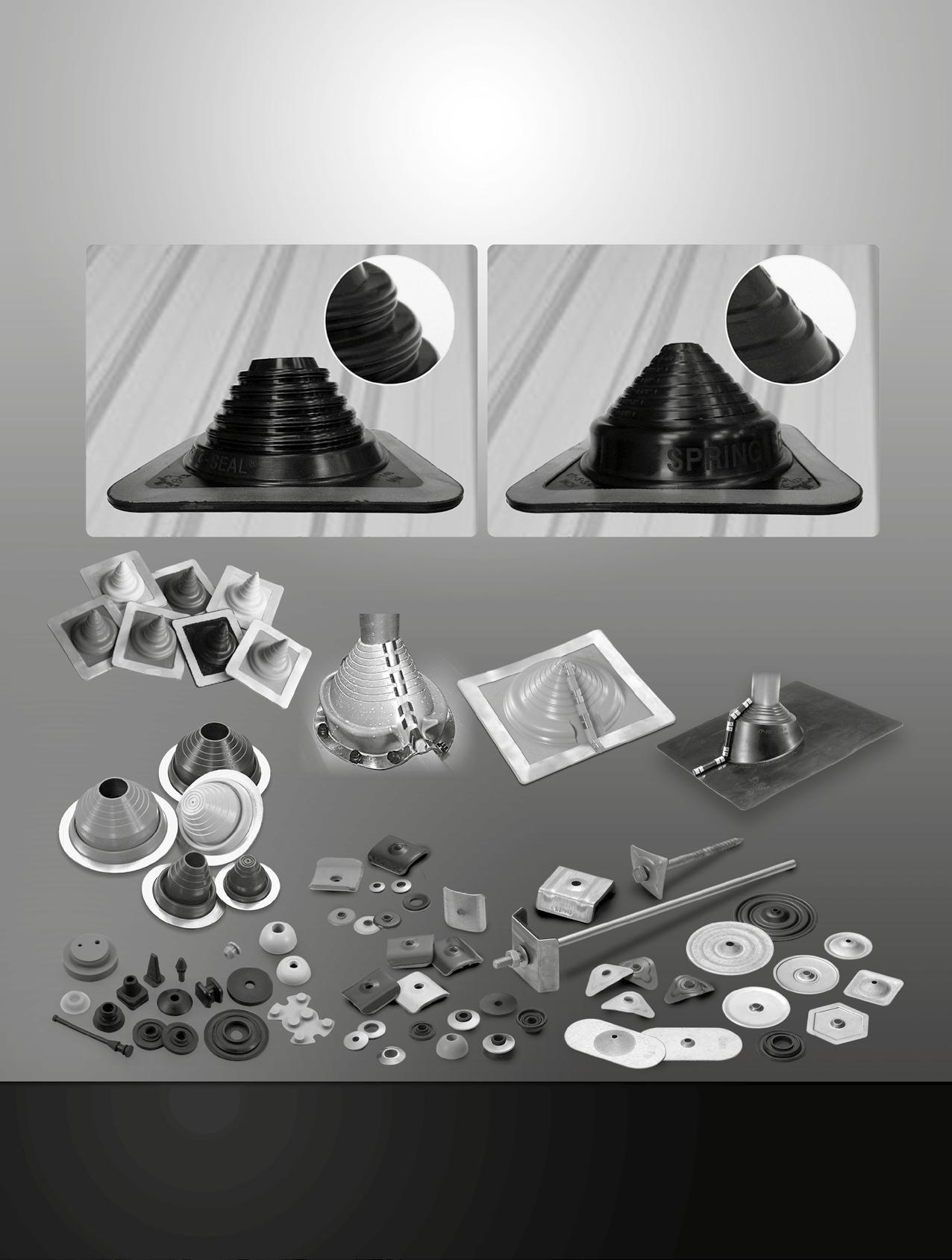

267 ON-SPRING INDUSTRIAL CO., LTD. 彩羽

Spring SealTM Pipe Flashings, Roofing Washers...

143 PAKWELL GROUP 開懋

Bi-metal Screws, Stainless Steel Screws

31 PENGTEH INDUSTRIAL CO., LTD. 彭特

SEMs Screws, Special Screws, Binder Screws, PT Screws...

50 PPG INDUSTRIES INTERNATIONAL INC. 美商必丕志

Chromium-free Coating, ED Coating...

209 PRO POWER CO., LTD. 鉑川 Screws, Bolts...

97 PRO-VISA (LIN) INT'L CORP. 佾鼎

Self-drilling Screws, Stainless Steel Screws, Furniture Screws...

125 PS FASTENERS PTE LTD. (Singapore) 汎昇 Washers, Socket Set Screws, U Bolts, Alloy Steel Screws...

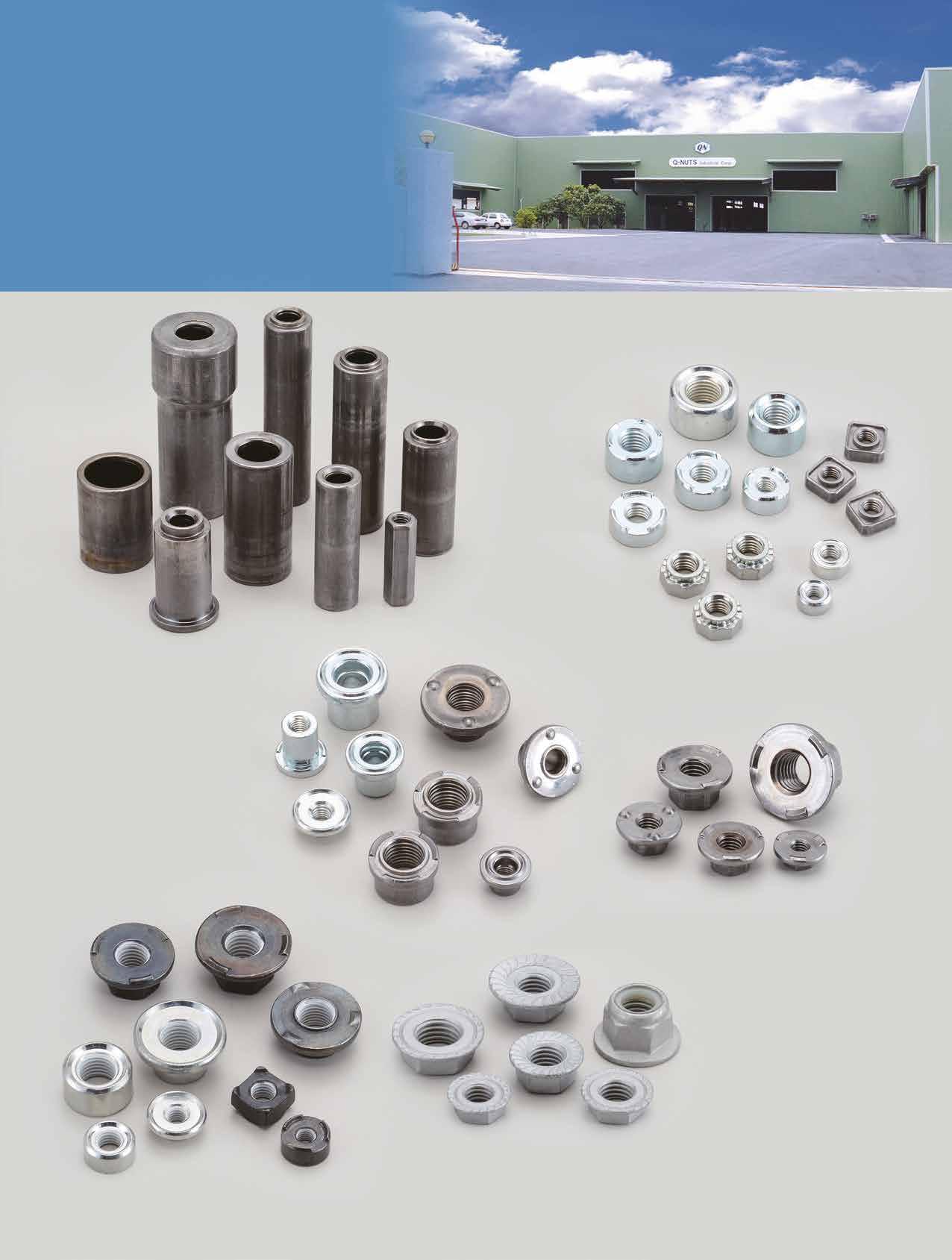

145 Q-NUTS INDUSTRIAL CORP. 友俊 Flange Nuts, Weld Nuts, Special Nuts, Spacers...

152 QST INTERNATIONAL CORP. 恒耀國際 Hexagon Head Bolts, Square Head Bolts, Weld Bolts (Studs)...

164 RAY FU ENTERPRISE CO., LTD. 瑞滬 Construction Screws, Automotive Parts, Special Fasteners...

14 REXLEN CORP. 連宜 Clinch Nuts, Clinch Studs, CNC Parts, Stamped Parts...

161 REXSON FASTENERS INC. 睿驊 Stainless Steel Screws, Automotive Parts, Special Products Development...

6 SAN SHING FASTECH CORP. 三星 Automotive Nuts, Automotive Parts, Carbide Dies...

170 SANSOAR ENGINEERING SALES, INC. 上碩 Machine Parts, Industrial Components...

62 SCREWTECH INDUSTRY CO., LTD. 銳禾 Machined Parts, Thumb Screws, Micro Screws...

337 SEN CHANG INDUSTRIAL CO., LTD. 昇錩

Customized Special Screws / Bolts, Socket Head Cap Screws...

304 SHANGHAI FAST-FIX RIVET CORP. 飛可斯

Blind Rivets, High Shear Rivets, Closed End Rivets...

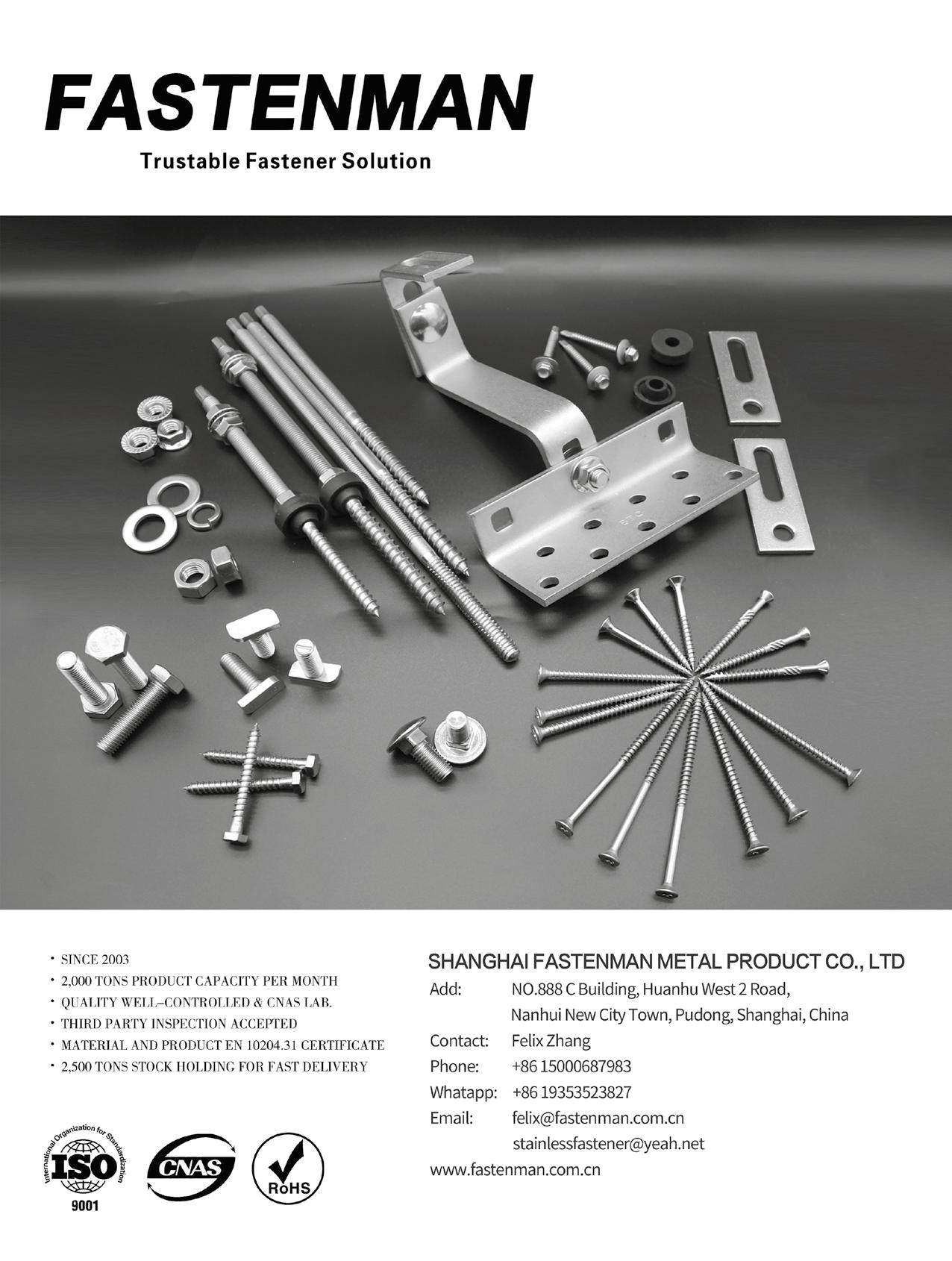

201 SHANGHAI FASTENMAN METAL PRODUCT 緊通

Stainless Steel Solar Roof Hook, Hanger Bolts, Bolts, Nuts, Screws...

295 SHEEN TZAR CO., LTD. 新讚 Self-Drilling Screw Machines & Dies

176 SHEH FUNG SCREWS CO., LTD. 世豐 Chipboard Screws, Countersunk Screws, Wood Screws...

174 SHEH KAI PRECISION CO., LTD. 世鎧

Bi-metal Concrete Screw Anchors, Bi-metal Screws...

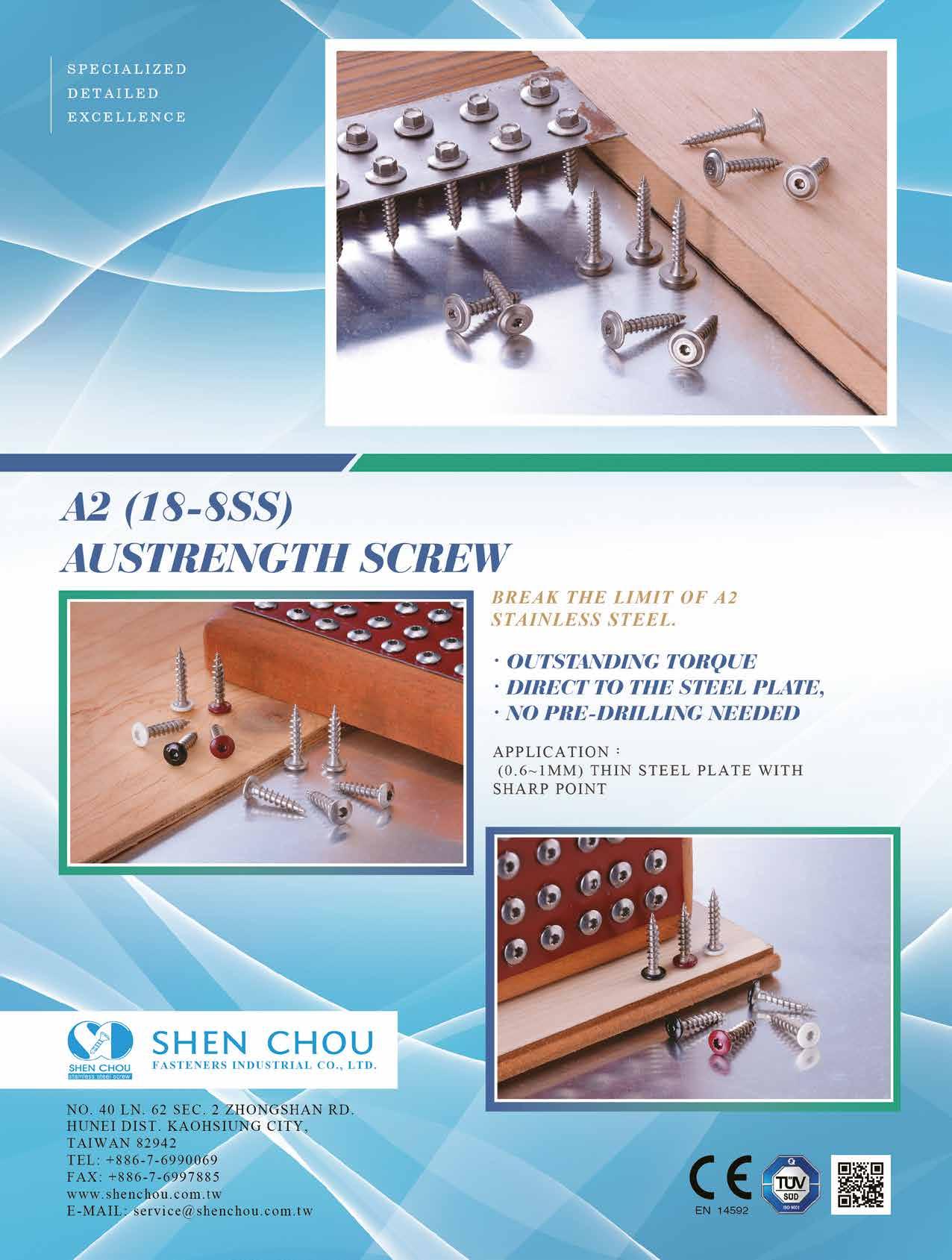

99 SHEN CHOU FASTENERS INDUSTRIAL CO., LTD. 神洲 Button Head Cap Screws, Chipboard Screws...

32 SHIH HSANG YWA INDUSTRIAL CO., LTD. 新倡發 Flange Nuts, Flange Nylon Nuts With Washers...

168 SHIN CHUN ENTERPRISE CO., LTD. 昕群

Automotive Screws, Chipboard Screws, Customized Screws...

144 SHINJO INTERNATIONAL

Washers, Flanged Head Bolts, T-head or T-slot Bolts...

34 SUNCO INDUSTRIES CO., LTD. (Japan)

Distributor Specializing in Fasteners

109 SUPER DPD CO., LTD. 三御

All Kinds of Screws, Bi-metal Screws, Carbon Steel Screws...

208 SUPER NUT INDUSTRIAL CO., LTD. 傑螺

Blind / Rivet Nuts, Security Fasteners, Barrel Nuts, Machine Parts...

291 TAIEAG CORPORATION

Designed peripheral equipment suitable for fastener packaging

182 TAIWAN FASTENERS INTEGRATED SERVICE 全聯鑫

Bolts, Screws, Nuts, Precise Mechanical Parts, Stampings...

200 TAIWAN LEE RUBBER CO., LTD. 台力

Bonded Washers, E.P.D.M. Vulcanized, Pipe Flashing...

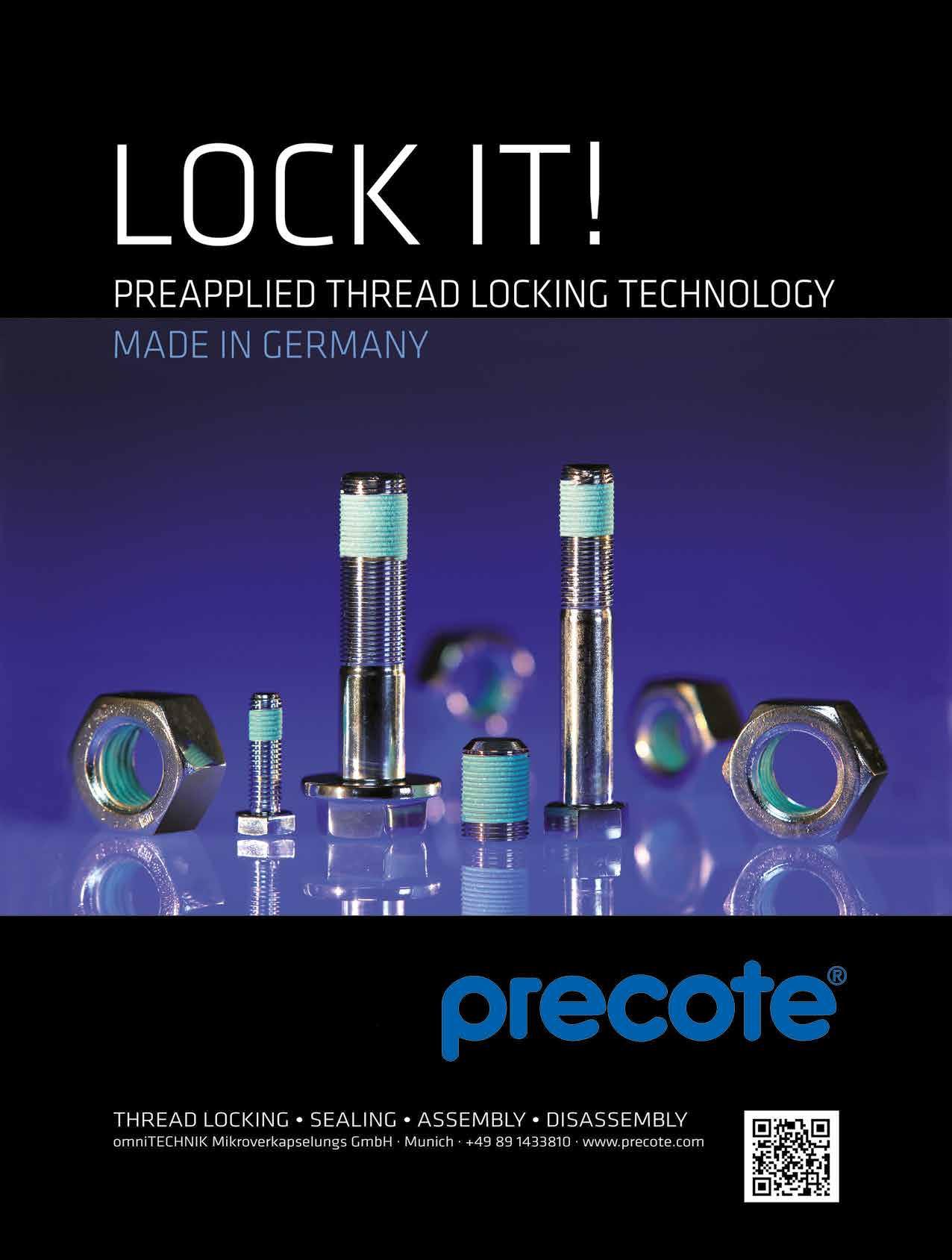

150 TAIWAN SELF-LOCKING FASTENERS IND. (TSLG) 台灣耐落

Nylok®, Precote®, Nycote®, Nyplas®, Loctite®...

149 TAIWAN SHAN YIN INTERNATIONAL CO., LTD. 慶達

Bi-metal Self-drilling Screws, Chipboard Screws...

134 TANG AN ENTERPRISE CO., LTD. 鏜安

Customized Automotive Parts and Special Fasteners

12 THREAD INDUSTRIAL CO., LTD. 英德

Chipboard Screws, Flange Nuts, Heavy Nuts...

56 TONG HEER FASTENERS (THAILAND) CO., LTD.

Hex Bolts, Stud Bolts, Socket Cap Screws, Hex Nuts...

57 TONG HEER FASTENERS CO., SDN. BHD (Malaysia)

Stainless Steel Metric Screws, Stainless Steel Screws…

205 TONG HO SHING INTERNATIONAL CO., LTD. 桐和興

Hex Washer Head Screws, Indent Hex Head Screws...

18 TONG HWEI ENTERPRISE CO., LTD. 東徽

A2 Cap Screws, Button Head Socket Cap Screws...

57 TONG MING ENTERPRISE CO., LTD. 東明

Stainless Steel Fasteners, Wire Rods…

93 TSAE FARN SCREWS HARDWARE CO., LTD. 采凡

2 Cap Screws, Aircraft Nails, All Kinds of Screws...

96 TSENG WIN / ORIENTAL MULTIPLE ENTERPRISE 成盈 Ceiling Anchors, Cut Anchors, Drop-in Anchors...

202 TSIN YING METAL INDUSTRY CO., LTD. 晉英 Stainless Steel Cold Heading Wire, Oxalate Coating Wire...

297 TZE PING PRECISION MACHINERY CO., LTD. 智品 Open Die Machines, Cold Headers, Cold Forming Machines...

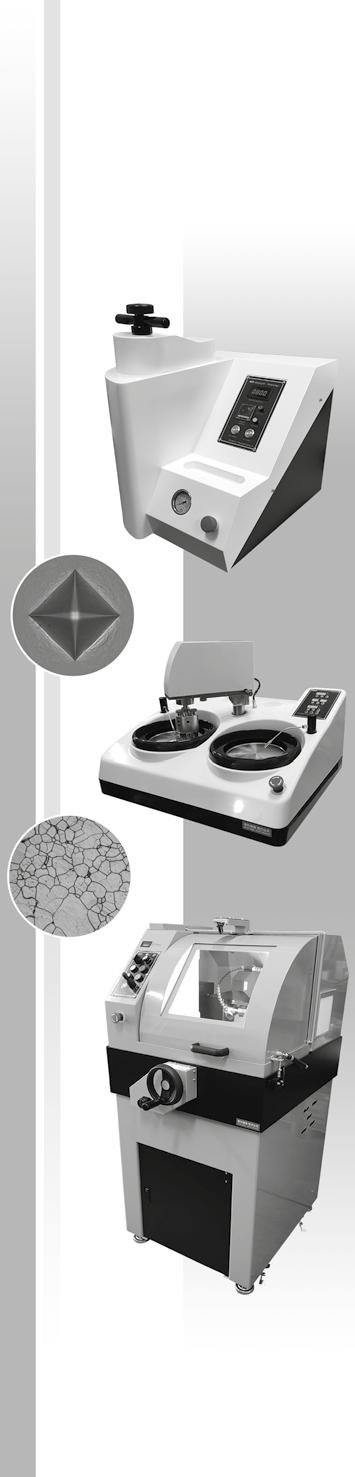

328 U-JUNE-INSTRUMENT CO., LTD. 宇駿 Hot Mounting Machine, Grinding & Polishing Machine...

154 UNISTRONG INDUSTRIAL CO., LTD. 六曜 Retaining Nuts, Sleeve Nuts, Weld Nuts, Automotive Screws...

293 UNITAPPING CO., LTD. 欣曜 Dual-Spindle Automatic Tapping Machine

327 UNIVERSAL PRECISION SCREWS (India) Dowel Pins and Shoulder Bolts...

187 VAJRA POWER INDUSTRIES, INC. 金和鋼 Insert Bits, Power Bits, Bit Sets, Bit Holders & Adapters, Nut Setter...

38 VERTEX PRECISION INDUSTRIAL CORP. 緯紘 6 Cuts/ 8 Cuts Self Drilling Screws, Barrel Nuts, Cap Screws

299 WAN IUAN ENTERPRISE CO., LTD. 萬淵 Punches/Dies of Various Nuts, Screws, Sleeves and Socket Boxes

64 WE POWER INDUSTRY CO., LTD. 威力寶 Chipboard Screws, Concrete Screws, Drywall Screws...

146 WEI MENG METAL PRODUCTS CO., LTD. 偉盟 Standard / Customized Parts, Machining Parts, Stamping Parts...

165 WEI ZAI INDUSTRY CO., LTD. 葦在 Anchors, Automotive Nuts, Cap Nuts, Flange Nuts...

334 WILLIAM SPECIALTY INDUSTRY CO., LTD. 威廉特 Chipboard Screws, Concrete Screws, Drywall Screws...

253 WINKEP INDUSTRIAL CO., LTD. 威肯 K-Lock Nuts, Nylon Flange Conical Washer Nuts…

82 WINLINK FASTENERS CO., LTD.

Stainless Steel Screws, Flange Bolts, Security Bolts,

36 WYSER INTERNATIONAL CORP.

Open-Die Parts, Automotive Parts...

231 YAMAWA ASIA CO., LTD.

Taps, Dies, Center Drills, Thread Inspection Tools

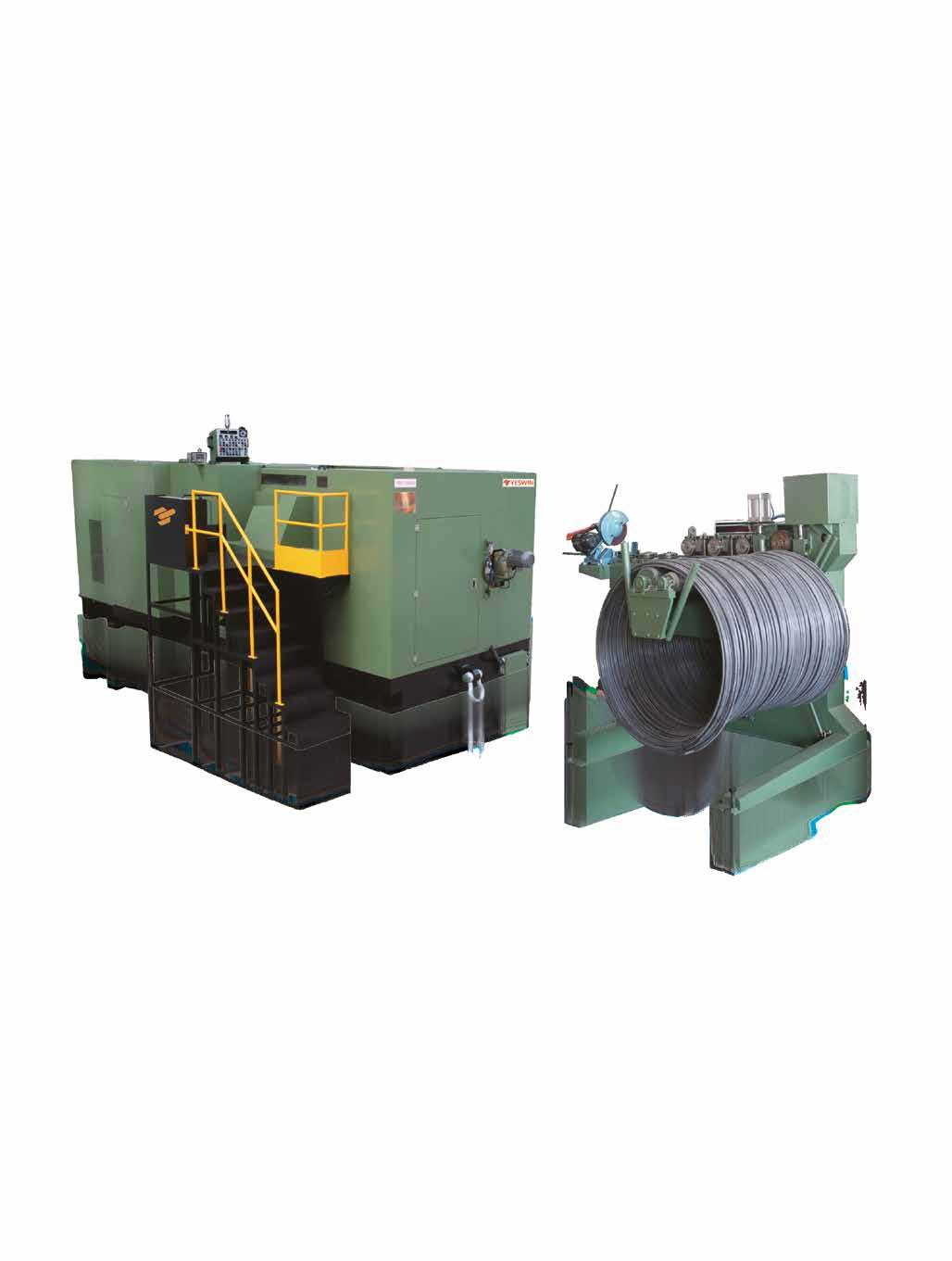

333 YESWIN MACHINERY CO., LTD.

Bolt Formers, Multi-station Cold Forming Machines...

60 YI CHUN ENTERPRISE CO., LTD.

Cap Screws, Socket Set Screws, Cage Nuts, Automotive Parts...

108 YI HUNG WASHER CO., LTD.

Rubber Washers, Plastic Screws, Custom Washers...

52 YING

Rexson Fasteners Inc. specializes in the development and production of various screws and parts. Its main products and services include: stainless steel screws, automotive parts, special products, special function parts, and customer sample production. Its products are available in dimensions of M1.4*2-M10*200 and can be produced in stainless steel, carbon steel, brass, and copper. As the global industry is gradually recovering after the epidemic and the economy is picking up, in response to the growing demand for fasteners and in order to optimize its services, Rexson has recently set up a new factory in Guanmiao, Tainan, and the original factory in Guiren will continue to operate. It is expected that with the synergy of the two plants in Guiren and Guanmiao, the company will be able to provide the best quality products and services to meet the diversified needs of global customers.

“The main purpose of the Guanmiao plant is to expedite the solution of the existing capacity of the Gueiren plant, which is about to run out of capacity. The new plant is expected to be in operation by the end of March. In addition to expanding production capacity, the new plant will also introduce some equipment and machines with specific differences to meet customers' needs for a wide range of products and to enable faster and more efficient delivery of products,” said Kevin Wu, General Manager of Rexson.

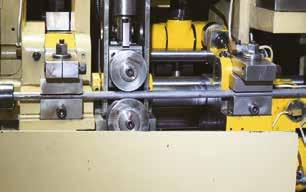

The new factory area of 2,380 sq m is clearly defined with dedicated areas for 1-die 2-blow forming, multi-blow forming, thread rolling, sorting, packaging, etc. Among them, the stainless steel screw, sorting, and packaging areas are new highlights from the old factory. The equipment has also been upgraded, including the introduction of 1-die 2-blow rounding and shearing machines, 5-die 5-blow forming machines, thread rolling machines (M12*200L) and several 1-die 2-blow and thread rolling machines, which can help provide customers with better and stable quality products. With the expansion of production capacity and more brand-new equipment, it expects to be able to improve the development of special screws and the manufacturing of stainless steel/carbon steel products. With the addition of the new plant, the monthly production capacity of stainless steel products will reach 80-100 metric tons.

Rexson has obtained the ISO 9001-2015 quality management system certification and its products are mainly sold to industrial customers in the U.S. and Europe, with the U.S. accounting for nearly 60% and Europe accounting for about 30%. This shows that its products and services are well trusted by its customers in Europe and the U.S.

“Our stainless steel products are used in a wide range of industries and can significantly reduce maintenance costs. We will also focus on the EV and stainless steel construction screw markets in the future as demand trends continue. In the face of the opportunities and challenges that lie ahead in 2023, I believe that crises are opportunities. In the current market with uncertainties, we will first make physical adjustments to meet the future challenges, and more importantly, provide customers with faster and better quality service to meet the market demand,” said General Manager Wu.

Rexson contact: General Manager Kevin Wu

Email: kevin@rexson.com.tw

After President Terry Tu chaired the Board of Directors in 2019, Sheh Fung Screws, specialized in the production of construction screws such as drywall and self-drilling screws, achieved a record-high revenue in 2021, followed by a new milestone in 2022 in its overall profit. The company is one of the few major fastener manufacturers in Taiwan that has been able to generate outstanding profitability during the pandemic. Over the past three years, under the guidance of President Tu and the cooperation of the company's team, Sheh Fung has not only improved its product technology, but also reported good results for times in the market expansion. President Tu’s eagerness to learn and pursue innovation as well as his diversified cross-industry experience seem to be imperceptibly influencing every Sheh Fung employee.

"I must have been in the fastener industry since I was six!”, said President Tu humorously.

The history of Sheh Fung can be traced back to 50 years ago, when it was started as a small factory in Shezidao, Taipei. At that time, Taiwan fastener industry was still underdeveloped, not to mention that threads were even machined with improper tooling. However, Tu’s father with an engineering background established Sheh Fung Screws by chance and imported equipment and technology such as drywall screws, threading dies, continuous heat treatment furnaces, electroplating, automatic phosphating facilities and so on from Japan, which later initiated Tu’s fastener career. Tu, at the age of 6, already showed a keen interest in technology and often helped pack and sort screws after school until he came to serve in Sheh Fung’s Shulin factory at the age of 20. Nowadays, he has been “officially” in the fastener industry for more than 3 decades.

"Since its inception, Sheh Fung has set a goal to reach the technology and quality on par with Japan. At that time, there was no high-quality wire in Taiwan. As a result, my father introduced 1018 wire from Japan to support Taiwan CSC’s wire development, which later laid the foundation for Taiwan’s fastener wire supplies to be on par with the international standard for the next 40-50 years. Before leaving Sheh Fung to establish Sheh Kai Precision, I’d spent 15-16 years learning

heading, threading, heat treating, phosphating, degreasing, pickling, etc. I don’t think there’ll be any disagreement if I say I’m a fastener expert. At that time when there was no self-drilling screw manufacturing technology in Taiwan, I even flied to a Japanese factory in person to observe their procedures, and then by my own exploration, I tried to develop the mold by myself and successfully developed the first self-drilling screws in Taiwan. Throughout the years, I’ve participated in all screw manufacturing and R&D procedures, and Sheh Fung has also continued to advance in the field of drywall and self-drilling screw manufacturing, maintaining its unshakable leadership in the industry,” said President Tu.

Leading fastener manufacturers in Europe and the U.S. have dedicated themselves to the development of automated warehousing for long, but Taiwan fastener industry seems to have gradually paid attention to this area only a few years ago. "I had such an idea of introducing overseas advanced automated warehousing more than 20 years ago. What I wanted to do at that time was based on the concept of 'logistics' (i.e., While barrels arrived, they would be temporarily stored at the warehouse and operators would only need to push buttons to deliver them separately to heat treating, electroplating and coating lines). I was even considering introducing automatic packaging machines from the Netherlands. However, as the relevant intelligent technology in Taiwan was not mature at that time and Sheh Fung mainly accepted customized orders, after considering the overall cost we decided not to do it,” said President Tu.

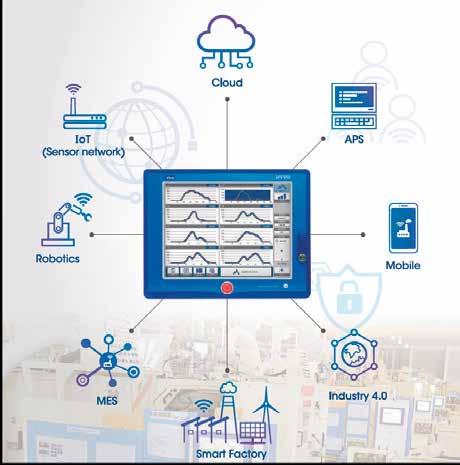

In spite of this, Sheh Fung did not stop the investment in automated and intelligent production lines in the following years, and in 2012, it became the first screw factory in Taiwan to introduce the SAP system. With this system, Sheh Fung’s production lines can connect with sub-systems (e.g., MES) and the control center more flexibly for data conversion and extension, reducing human-made errors and downtime as well as achieving more flexible space utilization of production lines, moving step by step towards becoming a smart factory as those seen in Europe, America and Japan. "The multilingual SAP with expandable connectivity allows us to replicate our experience in Taiwan to our Vietnam operation, which just started construction at the end of last year, and helps us understand the strengths of our factories and what our customers truly need. In the future, I may also consider introducing into Sheh Fung the visual inspection and AI technology commonly used in the semiconductor industry to boost the manufacturing efficiency and create a more hitech traditional industry,” added Tu.

After being elected as Sheh Fung’s new president in 2019, President Tu, together with General Manager Kent Chen and the company's task force, immediately decided to set up the company’s first overseas operation in Phan Thiet City of Vietnam. The construction of the more than 20-hectare Vietnam plant has been launched since December 2022 and is expected to be completed this August or September and become operational in Q4. The capacity of the phase-1 plant will be around 800 tons per month.

“Compared with other Southeast Asian countries, Vietnam is with less uncertainties, and its young labor force and easy access to raw materials have attracted investors from many countries. The phase-1 plant is a complete experience replica of our Taiwan plant, with heading, thread rolling, electroplating, heat treating and coating processes. In the past, our Taiwan plants mainly accepted orders for high-end products (small quantities and diverse items) but those for lower-end ones. In the future, with the addition of our Vietnam plant, we can also accept orders for large quantities and specific items. Moreover, Vietnam's advantageous geographical location could help expand our sales to the neighboring ASEAN countries, and we could also benefit from the Europe-Vietnam FTA to expand sales to Europe. In the future, our Vietnam plant will be also upgraded towards intelligent automation. At present, we are also actively training the seed staff for our Vietnam plant in Taiwan, so that we can seamlessly connect with the Vietnam plant after it is officially launched. I hope to lead Sheh Fung to play a leading role and attract other Taiwanese manufacturers to join us,” said Tu.

After becoming the company’s president for just 1 or 2 years, Tu, together with his team, witnessed the nearly doubled revenue growth from NT$1.817 billion in 2019 to a new record of NT$2.859 billion in 2022. In the future Sheh Fung will shift its focus to the development of high value-added products. In terms of management and decision making, in order to avoid blind spots, Sheh Fung has a six-person team to discuss and make decisions, and it also encourages employees to throw out good ideas and provide appropriate rewards if they are finally adopted. In recent years, Sheh Fung has even become the first in the industry in offering employees stock warrants to participate in the company’s operation, boosting the centripetal force.

"Sheh Fung’s success can be not only attributable to favorable factors in the market but also to the efforts of our whole team. I just came back to lead everyone to go forward. I think a successful business must be based on cooperation and treat all as partners to create ideas. When the company is gaining profit, employees rather than shareholders should be considered first to receive incentives, as they are the group that creates the most profit for the company,” Tu said modestly.

"In the future, Sheh Fung will continue to focus on technology innovation and product R&D. Currently, I’m Sheh Fung’s president and Sheh Kai’s president, too. Although both companies specialize in different products, they have started to pass on some orders to each other through the 'joint sales' model. In the future, we hope to integrate the products of both companies into one system, which is expected to strengthen Sheh Fung’s competitiveness in the market. In addition to consolidating the OEM in Europe and the U.S., Sheh Fung will also be able to establish its brand in the Asian market. Last but not least, as 2023 happened to be the 50th anniversary of Sheh Fung, we’ll hold a celebration banquet at the Kaohsiung Marriott Hotel on March 10th, and we sincerely invite our partnered suppliers to come and share the joy with us,” said Tu. Sheh

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

The company has a robust quality and environmental management system in compliance with the main certifications such as IATF 16949:2016, ISO 9001:2015 as well as ISO 14001:2015, besides of the CQI-9 for our internal heat treatment (Case Hardening and Quenching & Tempering process).

Also, with excellence for our customers, we have certifications VDA 6.3 Grade A for Volkswagen, we are Best One Supplier for Stellantis, BIQS for General Motors, Q1 for Ford and ASES for Renault Nissan, with strong experience and partnership with customers.

Founded in 1974, Continental Parafusos S.A. has been producing a complete portfolio of high-quality industrial fasteners for almost 50 years in Brazil. We are specialized at manufacturing screws, bolts, nuts, rivets and special cold-formed parts in carbon steel/stainless steel/copper/aluminum in sizes from Ø2mm up to Ø24mm and lengths from 3mm up to 180mm in order to serve the customers' high-speed assembly lines such as automotive, home appliances, construction, electronics and other industries. Along the days, we have been developing more than 20,000 items supplying to our valued vehicle and home appliance customers around the world. Our factory is equipped with fully automated production lines with the total built area of 50,387m2 and total land area of 103,711m2.

Continental Parafusos S.A. has real-time integrated management through the SAP ERP system since 2008 at the headquarters in Brazil and 2011 at Taiwan Branch, which enables management of the entire company with a focus on quality management, with reliability and traceability throughout the production chain. With its safe and optimized operation, its customers rely on punctual deliveries and safety stocks.

Continental Parafusos S.A. has the headquarters, factory and distribution center based in the Diadema city of São Paulo State and established a statutory branch in Taiwan that enables the global sourcing with the best benefits and acts the multiple roles interacted with the headquarters in Brazil. With the solid strong base in Taiwan, Continental Parafusos S.A. owns the solid system of corporate governance, external audit and compliance, including environmental and social governance.

With innovation differentials in all fields, the company is a pioneer on Digital Accounting Audit together with the independent audit supplier, Consultative accounting with automation of activities, partnership with technical schools and laboratories for technology improvement, advanced projects of energy efficiency using only renewable energy sources and continuous improvement of our process in minimal carbon footprint and efficient use of natural resources. The company works hard and right for a better and sustainable future.

The strong partnership with its internal and external customers enables Continental Parafusos S.A. to mark its outstanding position in the manufacture, supply and commercialization of fasteners and others for several applications.

We are a modern, ethical and legalistic company, which ensures integrity in all relationships and invests in the sustainability of our business and customers.

KARAT is a professional and well-organized manufacturer of Rivet Tools and Rivet Nut Tools in Taiwan since 1982, backed with strong R&D team, advanced lab equipment, reliable production system, strict QA system, and efficient after-service.

KARAT offers a wide-ranging product line for Rivet Tools and Rivet Nut Tools. KARAT is dedicated to presenting new products and upgrading product quality to satisfy the critical requirements from loyal clients. KARAT Hand Rivet Tools and Hand Rivet Nut Tools offer One Year Warranty and have been fully trusted by clients and users for decades, while the KARAT Air-Hydraulic Tools, from the basic professional models to the top industrial models, all have got the 3RD party CE Certification tested and certified by the German TÜV Rheinland to ensure good design and reliable quality.

KARAT's dedication to innovation and quality includes the following new tools:

Air-GripTM 2/2V, 3/3V, 4/4V Series PneumaticHydraulic Rivet Tools with different riveting capacity, strokes, traction forces, and without or with vacuum system for the specific applications. All models feature the unique design for convenient operation.

Air-GripTM

4H Air Installation

Tool is approved by the original, it can install different Nose Assemblies to set various Huckbolts and Structural & Standard Blind Rivets 4.0 ~ 6.4 mm or 5/32" ~ 1/4".

ANS-120 Air Rivet Nut

Tool has powerful setting force, adjustable fastening speed control and manual operation of screwing & unscrewing fasteners that can easily set maximum M12 or 1/2" Stainless Steel Rivet Nuts and maximum M8 or 5/16" Rivet Bolts (Studs) without scratching the painted auto body.

The above models' Hydraulic Cylinders are all made of high strength Forged Aluminum Alloy with heat treatment and the surface is finished in titanium color, they have robust structure and valuable look.

GH-1, the First Hand Installation Tool in the world , has super power-saving design that allows hand force to install the included 3 Nose Assemblies for setting MG Huckbolts 3/6" & 1/4", and Structural & Standard Blind Rivet 4.0 ~ 6.4 mm or 5/32" ~ 1/4".

LR-1 Lever Type Hand Rivet Tool features the extra-long handles and patented 4-IN-1 design (Spent Mandrel Container + Nosepieces Storage Box + Rivet Size Hole Gauge + Service Wrench Insertion) for easily setting 3.0/3.2 ~ 6.4 mm or 1/8" ~ 1/4" Structural & Standard Blind Rivets and special BT 7.7 mm Structural Rivet simply by exchanging the BT7.7 Nose Kit.

HRN-4X4 Multiplex Hand Tool Kit allows one tool to set 4-size Blind Rivets in maximum 4.8/5.0 mm or 3/16" + 4 or 5-size Rivet Nuts in maximum M6 or 1/4 + 2 or 3-size Rivet Bolts (Studs) in maximum M5 or #10 + 3-size Jack Nuts in maximum M6 or 1/4" + Preset Slotted Body Rivet Nuts in maximum M6 or 1/4, etc. It is an amazing tool.

These factors have built a good reputation of "German Quality at Taiwan Price" for KARAT Tools. Therefore, KARAT Tools are 90% sold to the renowned brands in the USA, Europe and Japan for the automotive, industrial and construction markets.

Honest, reliability and long-term cooperation are the policies of KARAT. Quality, innovation, performance, warranty and service are the features of KARAT Tools. Try KARAT Tools once, you will trust KARAT forever!

2831 FASTENER WORLD INC.

2578 SPRING LAKE ENTERPRISE CO., LTD.

2709 SHEH KAI PRECISION CO., LTD.

2730 MAUDLE INDUSTRIAL CO., LTD.

2731 REXLEN CORP.

2732 & 2736 KUANG TAI METAL INDUSTRIAL CO., LTD.

2733 VERTEX PRECISION INDUSTRIAL CORP.

2737 Y.Y. CABLE ACCESSORIES CO., LTD.

2738 ALL GAIN INDUSTRIAL CO., LTD.

2830 SPECIAL RIVETS CORP.

2832 DA YANG ENTERPRISE CO., LTD.

2836 JACKWAY ENTERPRISE CO., LTD.

2837 WHIRLPOWER ENTERPRISE CO., LTD.

2850 DIING SEN FASTENERS INDUSTRIAL CO., LTD.

2850 WE POWER INDUSTRY CO., LTD.

2854 LOYAL & BIRCH CO., LTD.

2855 A-STAINLESS INTERNATIONAL CO., LTD.

2856 WEI IN ENTERPRISE CO., LTD.

2857 HSIEN SUN INDUSTRY CO., LTD.

2858 SCREWTECH INDUSTRY CO., LTD.

2859 S&T FASTENING INDUSTRIAL CO., LTD.

2862 FONTEC SCREWS CO., LTD.

2863 FONG PREAN INDUSTRIAL CO., LTD.

2866 YICISCREW CO., LTD.

2867 CPC FASTENERS INTERNATIONAL CO., LTD.

2868 ANCHOR FASTENERS INDUSTRIAL CO., LTD.

2869 SHEN CHOU FASTENERS INDUSTRIAL CO., LTD. 2870 CHUM YUAN CO., LTD.

2871 HSIN HO MFG. CO., LTD.

2875 RIU PRECISION HARDWARE FASTENER CO., LTD.

2876 MIDAS UNION CO., LTD. 2877 DAR YU ENTERPRISE CO., LTD. 2882 FENG YI TITANIUM FASTENERS 2883 TAIWAN CMC CO., LTD.

2886 CHIREK FASTENER CORPORATION

2887 DESIRABLE ENTERPRISE CO., LTD.

2888 CHANG YI BOLT CO., LTD.

2889 BOSS PRECISION WORKS CO., LTD. 2930 CHIAO CHANG PNEUMATIC TOOL CORP.

YOW CHERN CO., LTD.

JAU YEOU INDUSTRY CO., LTD.

MAO CHUAN INDUSTRIAL CO., LTD.

SUPER DPD CO., LTD.

METIZ ALLIANCE

TAIWAN SHAN YIN INTERNATIONAL CO., LTD.

BOLTUN CORPORATION

SEN CHANG INDUSTRIAL CO., LTD.

ALEX SCREW INDUSTRIAL CO., LTD.

2950 SAN YUNG ELECTRIC HEAT MACHINE CO., LTD.

HUANG JING INDUSTRIAL CO., LTD.

YOANG MING INDUSTRIAL CO., LTD.

3036 SHIN CHUN ENTERPRISE CO., LTD.

3037 GUANG ZHE ENTERPRISE CO., LTD.

3042 CHONG CHENG FASTENER CORP.

3043 GOFAST CO., LTD.

3044 DRA-GOON FASTENERS INC.

3045 HOME SOON ENTERPRISE CO., LTD.

3048 CHIAN YUNG CORPORATION

3049 YOUR CHOICE FASTENERS & TOOLS CO., LTD.

3050 CHIN LIH HSING PRECISION ENTERPRISE CO., LTD.

3050 HWALLY PRODUCTS CO., LTD.

3054 SUPER NUT INDUSTRIAL CO., LTD.

3055 HSIN JUI HARDWARE ENTERPRISE CO., LTD.

3056 CHANNG CHIN INDUSTRY CORP.

3057 YUN CHAN INDUSTRY CO., LTD.

3058 FWU KUANG ENTERPRISES CO., LTD.

3059 LOCKSURE INC.

3062 CHU WU INDUSTRIAL CO., LTD.

3063 KCS ENTERPRISE COMPANY LIMITED.

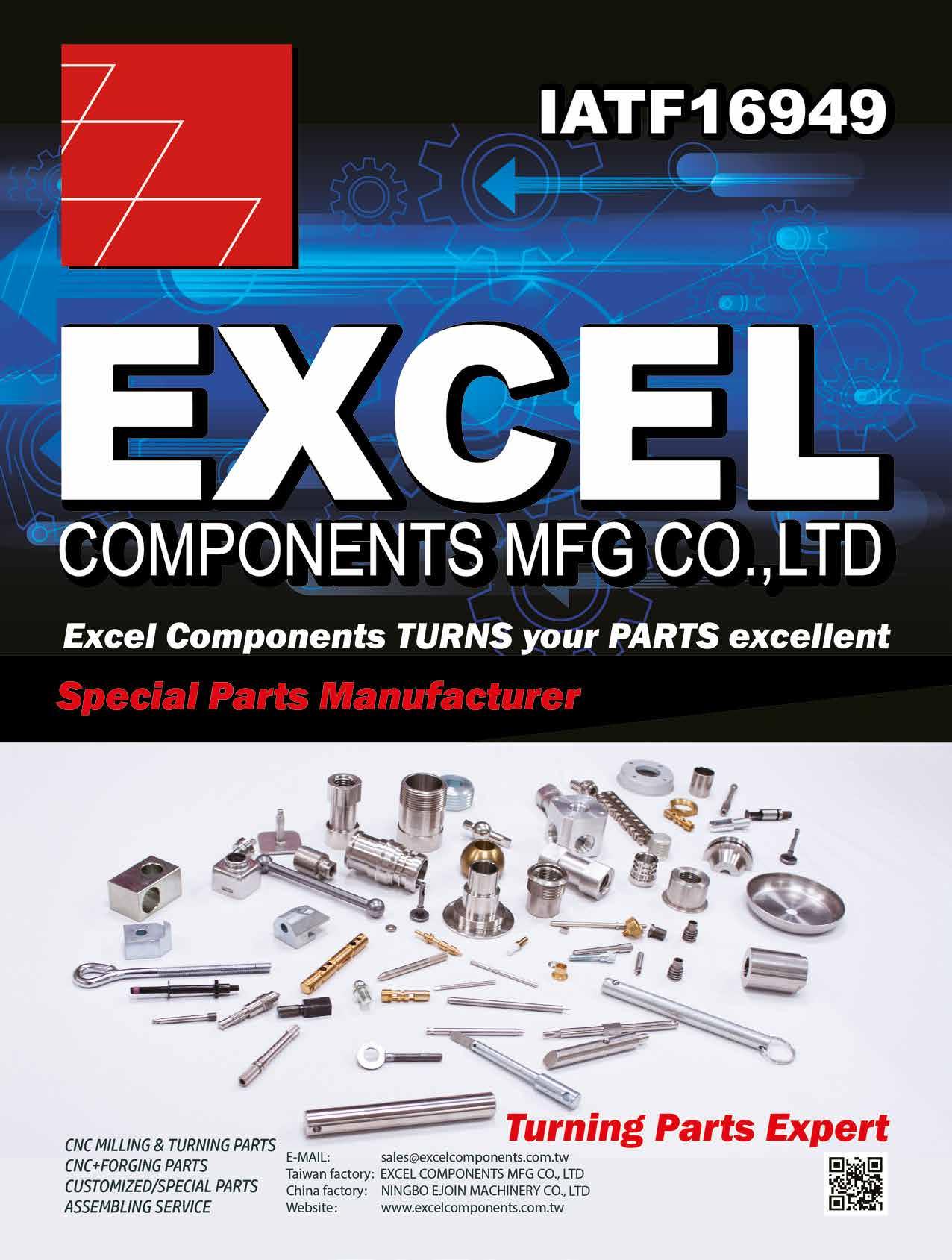

3066 EXCEL COMPONENTS MFG CO., LTD.

3067 HOMN REEN ENTERPRISE CO., LTD.

3068 SUN THROUGH INDUSTRIAL CO., LTD.

3069 SOON PORT INTERNATIONAL CO., LTD.

3070 SPEC PRODUCTS CORP.

3074 CO-WEALTH ENTERPRISE CO., LTD.

3075 CORNWALL ENTERPRISE CO., LTD.

3076 LONG I INDUSTRIAL CO., LTD.

3077 FAST ASIA SCREWS CO., LTD.

3078 RENETSAF CO., LTD.

3079 SHIN JAAN WORKS CO., LTD.

3104 RODEX FASTENERS CORP. DURA FASTENERS CO., LTD.

PT. SHYE CHANG BATAM INDONESIA

WA TAI INDUSTRIAL CO., LTD.

2967 KATSUHANA FASTENERS CORP. 2968 TAIWAN INDUSTRIAL FASTENERS INSTITUTE

NOVA. FASTENER CO., LTD.

FRATOM FASTECH CO., LTD.

K. TICHO INDUSTRIES CO., LTD. 2974 KAI SHYUN ENTERPRISE CO., LTD. 2975 STANDING INDUSTRIAL CO., LTD.

2976 HSIUNG JEN INDUSTRIAL CO., LTD.

2977 JI LI DENG FASTENERS CO., LTD.

2978 KAO WEIN PRECISION CO., LTD.

2979 GOOD USE HARDWARE CO., LTD.

2982 CANATEX INDUSTRIAL CO., LTD.

2983 YANG YI TECHNOLOGY CO., LTD.

2986 MASTERPIECE HARDWARE INDUSTRIAL CO., LTD.

3030 EVEREON INDUSTRIES, INC.

3031 AIMREACH ENTERPRISES CO., LTD.

3032 KEY-USE INDUSTRIAL WORKS CO., LTD.

SZU I INDUSTRIES CO., LTD.

3108 A-PLUS SCREWS INC.

HEADER PLAN CO. INC.

3109 WYSER INTERNATIONAL CORP.

3120 KWANTEX RESEARCH INC.

3124 BI-MIRTH CORP.

3125 FU HUI SCREW INDUSTRY CO., LTD.

3130 NCG TOOLS INDUSTRY CO., LTD.

3131 HWA HSING SCREW INDUSTRY CO., LTD.

3136 LONGHWA SCREW WORKS CO., LTD.

3137 WAN IUAN ENTERPRISE CO., LTD.

KOT UNIONTEK CO., LTD.

3142 TAIWAN PRECISION FASTENER CO., LTD.

3143 TAIWAN FASTENER TRADING ASSOCIATION - TFTA

3144 DE HUI SCREW INDUSTRY CO., LTD.

3145 HAO MOU NUTS MFG. CO., LTD.

3148 OFCO INDUSTRIAL CORP.

3149 CHUN YU WORKS & CO., LTD.

CO., LTD.

3589 BEN YUAN ENTERPRISE CO., LTD.

3590 J. T. FASTENERS SUPPLY CO., LTD.

3594 RONG YIH JIANG ENTERPRISE CO., LTD.

3680 DUNFA INTERNATIONAL CO., LTD.

3682 ZI EA FACTORY COMPANY LIMITED

3690 RAY FU ENTERPRISE CO., LTD.

3890 YESWIN MACHINERY CO., LTD.

3892 LUNA'S LIGHT INTERNATIONAL SOURCING CORPORATION

3893 HSIN YU SCREW ENTERPRISE CO., LTD.

3894 WINGTONE INDUSTRIAL CO., LTD.

4233 LEADERWING HARDWARE INDUSTRIAL CO., LTD.

4233 SCREW KING CO., LTD.

4276 DAH-LIAN MACHINE CO., LTD.

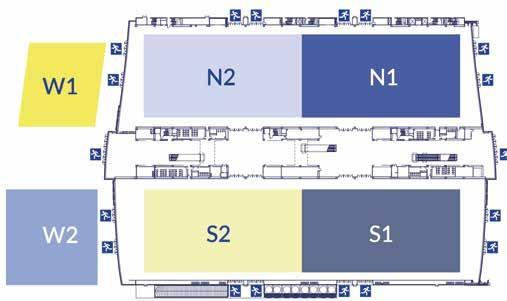

"Taiwan International Fastener Show” will return to Kaohsiung Exhibition Center on May 3-5, 2023! This year's exhibition will focus on the three main highlights of Taiwan fasteners: "High Quality", "High Technology", and "High Added Value" and is expected to attract nearly 300 exhibitors using nearly 900 booths to display a variety of fasteners, screws & nuts, production equipment, fastening tools, molds & dies, inspection instruments, wire materials, and other related products and services. It is expected that more than 1,500 foreign buyers will come to Taiwan for purchasing, which will bring more business opportunities to the fastener industry.

During the exhibition period, a series of activities will be held, including: Global Fastener Forum, inviting speakers from both domestic and overseas industries to analyze the global fastener economy, ESG, and share fastener smart manufacturing case studies; as well as a series of activities such as 1-on-1 procurement meetings, ManufacturersWin podcasts, live tours, and guided tours. The exhibition will provide visitors with an international and enriching experience.

The strength of Taiwan fastener industry is evident to all international visitors. In last edition, the show attracted 417 exhibitors booking 1,110 booths and 2,193 international buyers from 73 countries, representing a 10% increase over the previous show. The number of domestic and international visitors exceeded 30,000. 90% of the buyers were satisfied with the show, and more than 80% of them said they would come back to Taiwan in 2023.

Dedicated to the R&D in nuts for 40 years, JingFong Industry Co., Ltd. has been active in the field of precision nuts. In addition to winning Taiwan Excellence Award for two consecutive years, it has also developed a variety of lock nuts for small and mediumsized passenger cars/commercial vehicles and construction fasteners this year, and also successfully developed an antiloosening assembly part with two nuts in collaboration with a Japanese customer. The excellent technical R&D ability of this invisible champion of the industry is trusted by advanced application customers in Europe, USA and Japan.

At Fastener Taiwan 2023, JingFong aims to extend its product portfolio to EV assembly, construction, railway and other applications to attract buyers from Europe and the U.S., as well as to enter the supply chain of Japanese automotive market. At the same time, it will also exhibit 3 main products to demonstrate its OEM capability to fastener manufacturers and large traders from all over the world, including:

1. Prevailing Torque Type Hexagon Nuts with FlangeThese nylon flange nuts featuring anti-loosening, durability and corrosion resistance are specified by M. Benz for use in its automotive suspension fastening and are certified by Daimler MNB 13025 and electroplated with DBL 9440.47. The pitch difference between the nut and the bolt improves the contact tightness without stripping, and the nylon washer can also prevent other mechanical equipment joints from being damaged, reducing maintenance costs.

2. Adjustment Nuts for Shock Absorber Piston ValveIts thinness has reached the strictest requirement of the cold forging process. Compared with its competitors’ surface roughness of Rz6.3, JingFong can achieve Rz4.3. The concentric circle and cylindrical tolerance of the nut is also controlled to be less than 0.1mm. The technical specifications, stable quality and cost advantages have enabled JingFong to establish a long-term collaboration with SACHS, a major shock absorber manufacturer, and supply 50 million pcs every year to SACHS’ global assembly plants (representing more than half of its global demand).

3. Piston Nuts for Performance Car Suspension ModuleIt can replace the old lock nuts and improve the issue of chippings dropping into the piston valve to avoid noise during operation. The new pressed point design provides the shock component with loading and anti-loosening abilities. The surface roughness is improved to be Rz6.3 to reduce frictional wear. The tolerance of the bearing surface is 0.05mm (max.) and the stable drill-in torque can avoid chipping.

by Gang Hao Chang, Vice Editor-in-Chief of Fastener WorldIn the vehicle assembly and parts market, JingFong is actively developing new value-added inhouse processes to reduce costs and lead time. At the end of 2022, it completed the setup of its own zincnickel plating line with a monthly capacity of 240 tons and meeting CQI-11 requirements. It has also completed the integration of key processes such as production quality monitoring, machine networking, production visualization, IT core system integration (MES), factorywide production real-time traceability, die life management, and carrier RFID management to create a smart factory. Facing the trend of EV lightweighting, it is also actively contacting EV assembly plants, developing other metal forming processes, and working with customers on end product design. It has also introduced various CNC machines and strengthened the internal technology training in order to provide more competitive finished fasteners. It has also obtained patents from Taiwan and Thailand for the development of welding frictional rebar couplers for construction applications.

95% of JingFong’s products are sold to Europe and USA. Benz, PACCAR, Tesla, Nissan, Kia and other leading manufacturers are all end customers of its products. Recently, it has been actively developing the Japanese market by participating in M-Tech Osaka, M-Tech Tokyo, Fastener Fair Global and overseas sales missions, hoping to explore more business opportunities in the field of automotive, construction and railway fasteners. “We have unique technology, including product design and 3D stress simulation, process quality analysis tools, full equipment interconnection, quality visualization, real-time product traceability, and other intelligent manufacturing environment to meet customers’ requirements for shorter lead times and higher quality products, and to provide more immediate and flexible responses in processes such as design, production, and distribution." said JingFong. “We are also planning visits to our factory at Fastener Taiwan this year and welcome buyers to contact us early.”

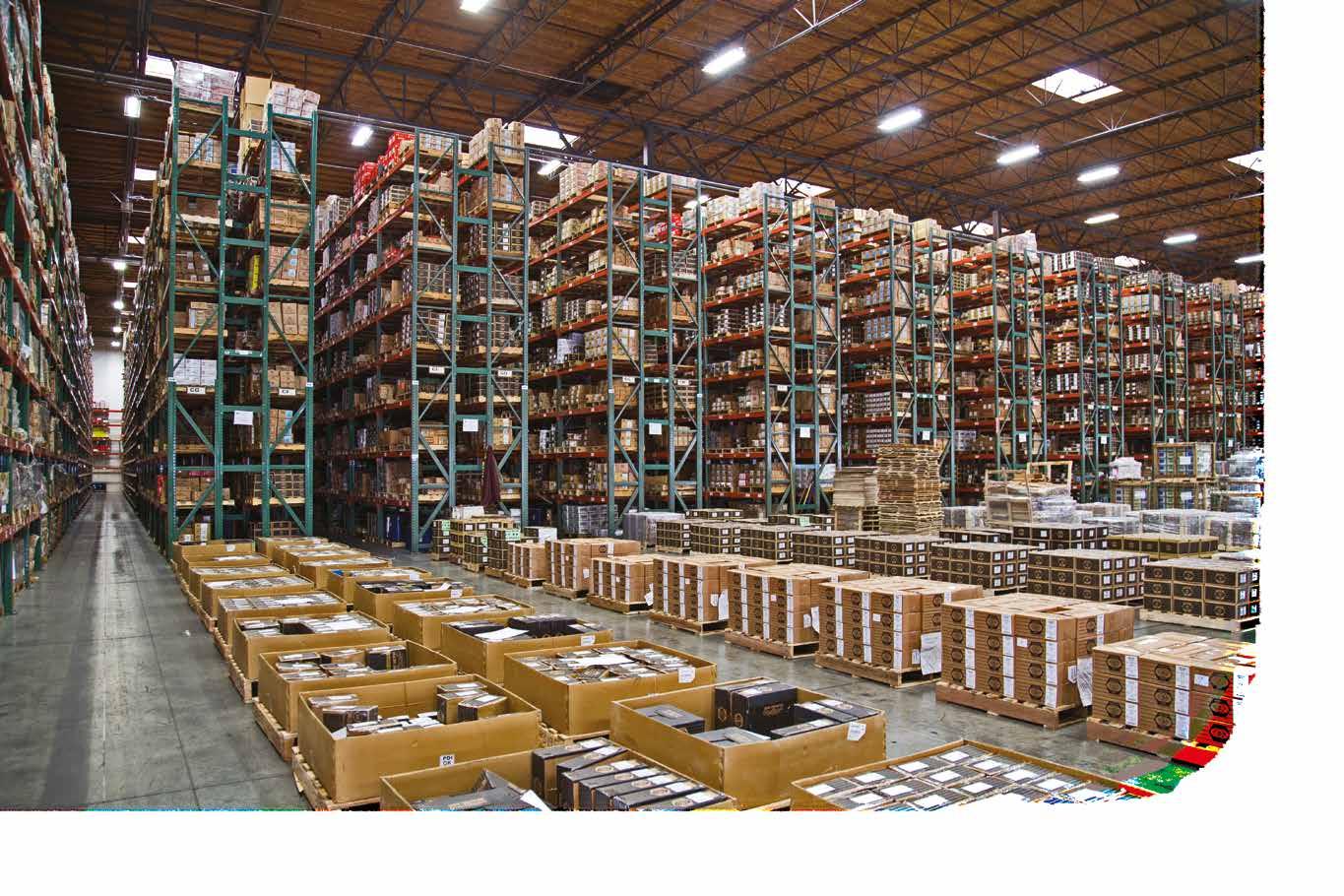

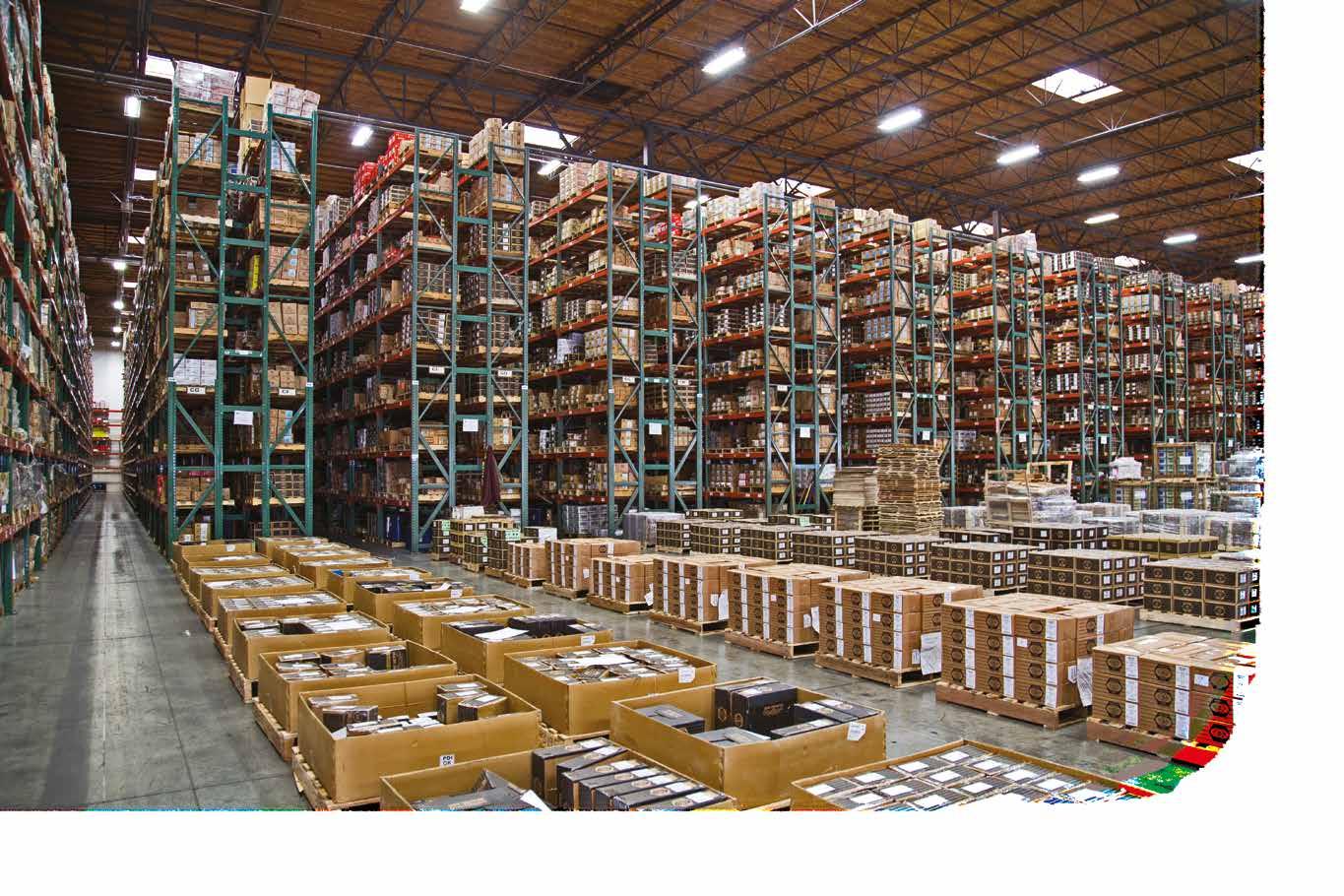

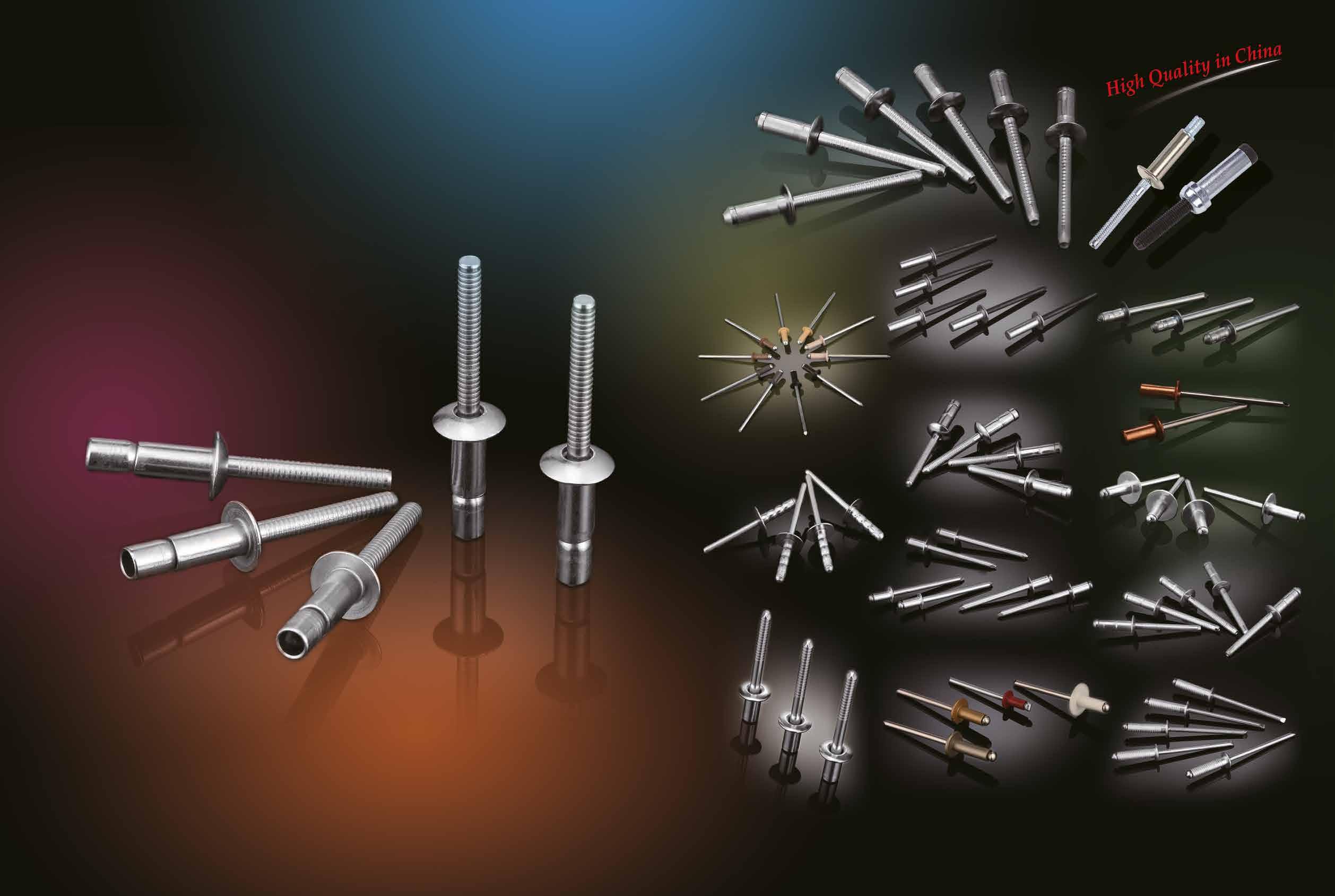

quality riveting tools. The company has invested in a factory in China and today has evolved into one of the largest manufacturers of blind rivets in Asia, with a monthly capacity of over 500 million pieces of blind rivets and 100 thousand pieces of high quality riveting tools per month. A fully automated warehouse and index system ensures accurate and rapid order fulfillment.

With a professional R&D team and rich sales experience, SRC at the 40th anniversary of corporate history has sold its products to more than 150 countries worldwide and accumulated more than 700 customers. In 2021, SRC expanded investment and set up a new factory in Thailand to fulfill customer needs, covering an area of 45,000 square meters. Now they are announcing the launch of production in this issue of Fastener World Magazine.

SRC chose to set up a factory overseas in order to serve the world’s demand for fasteners and expand client base. They see the worth of Thailand Prime Minister's ambition to develop Thailand as the top manufacturing nation of automobiles in Southeast Asia. Plus, they have many clients who identify Thailand as a key market in Southeast Asia. The new plant in Thailand will be able to serve clients from a close range.

The main task of this plant is to increase production of the existing blind rivet product line. New equipment has been purchased in large quantities to improve quality and develop flexibility for small quantity and diverse production to meet the needs of more customers. When lead time becomes a key factor, immediate delivery is far more important than lower prices, said SRC.

The new plant’s floor is currently 50% in use and has about 110 sets of automatic forming equipment, with a target of 300 sets to be added continuously. Through automation, manpower is streamlined and work shifts between departments within the plant is rationalized. At this stage, they are aiming at a monthly capacity of 100 million pieces of rivets for the Thailand plant, and planning to increase to 300 million pieces of rivets in the future. They are providing clients with better quality and cost performance by reducing costs.

With the support of the parent factory and the head office, they hope to develop the whole group into a sustainable enterprise. In addition to collaborating with more counterparts in the hardware and components market, they want to contribute to global environmental protection. In the future, the new factory will make appropriate adjustments according to the current international status and continue to integrate and expand product lines.

Under the impact of the global epidemic, SRC's export sales still reached double digit growth in 2022, with products mainly sold to the United States, Europe, New Zealand, Australia, Africa, Latin America and Southeast Asia, of which the United States accounts for 30%. “Every client is important to us. No matter where you are, we make sure our products are delivered to you," said the company, “In the face of market challenges, we will stick to the belief that makes us who we are and continue to create new markets.”

Contact: Ms. Lydia Wang

Email: srcrivet@ms12.hinet.net

by Dean Tseng, Fastener WorldWith "technology, efficiency, quality, and service" as its core values, Zyh Yin Ent. Co., Ltd. has been specializing in the production of furniture and construction screws and bolts for years. With its excellent production technology and high quality standards, its products have been successfully exported to Europe, America and Asia and other key screw demand markets, and have also gained the trust and recognition of many new market users worldwide. Not only has its annual export performance been outstanding, but it is now the largest supplier of screws to a leading furniture brand in Europe on a long-term basis. Its customer-focused insistence continues to draw the global attention to its solid and reliable manufacturing capabilities on the international stage.

Zyh Yin is able to provide a wide variety of products. As one of the exhibitors at this year's Taiwan International Fastener Show, it will present many competitive screws to visitors from all over the world, including: confirmat screws, chipboard screws, euro screws, machine screws, metal dowels, drywall screws, tapping screws, self-drilling screws, deck screws, particle board screws...etc. Among them, drywall screws and metal dowels are expected to be the main attraction for many buyers during the exhibition. The special features of these two main products are as follows:

Drywall screw users attach great importance to the convenience and efficiency of the product. Through its professional manufacturing technology and experience, as well as its management of the service life of threading dies, it has been able to control the tapping speed of the drywall screw to less than 1 second, allowing consumers to save time and effort in using the product.

In order to achieve more precise dimensional control, Zyh Yin has also imported high-end precision machines from overseas, which can control the dimension of screws more precisely and provide users with a better assembly experience.

“In addition to the exhibition in Kaohsiung, we also plan to participate in Fastener Fair Global in Stuttgart this March and INTERZUM this May to let visitors know that we can continue to provide stable quality and excellent service on our existing products, and we hope to let everyone know that we are constantly improving our manufacturing capabilities and upgrading our technology and production capacity to meet the diverse needs of customers,” said Zyh Yin.

Currently, Zyh Yin’s furniture screws are mainly sold to the European market. Its excellent quality and competitive price of products have been well received by customers. On the other hand, in the large market of North America, its construction screws have also successfully tapped into many medium and large distributors, wholesalers and DIY channels, supplying a wide range of screws for interior and exterior use.

“In the future, we will continue to expand into the European and North American markets to provide better service to customers. We also look forward to expanding our product offerings to meet the diverse needs of different buyers,” said Zyh Yin.

Zyh Yin has introduced the ERP system for years to help achieve more accurate process control. Through this system, all relevant units can clearly understand the production status and progress of orders, which facilitates the tracking and scheduling of shipments and improves the efficiency of internal operations. In terms of quality control, in case of quality complaints, the system can also help to trace the production history of products, which helps to analyze the cause of quality problems and prevent the recurrence of the same problems in the future.

In addition, Zyh Yin is also working with MIRDC to introduce intelligent management of “digital transformation.” Through the cooperation with manufacturers, production information will be fed back to the system in real time, so that the business and production management units can grasp the progress more quickly and effectively and provide better services to customers.

Zyh Yin contact: Mr. Jaime Hsiao

Email: jaime@zyhyin.com

In order to achieve the best quality and meet the increasingly stringent requirements of customers, Zyh Yin’s quality and professional screw supply team continues to refine manufacturing processes and quality management. In addition to obtaining ISO 9001:2015, it is also the first in Taiwan fastener industry to obtain the ISO 28000 supply chain safety management system certification in 2019, which enables it to implement supply chain safety management in manufacturing, service, warehousing and transportation. It has also obtained the TTQS, SMETA, CE, Torx Drive System 2019 and Torx Plus Drive System 2019 certifications.

“In addition to quality and delivery, customers have become more concerned about the ESG performance of their suppliers in recent years. Therefore, we have made efforts since many years ago to meet the higher standards of customers in terms of energy saving & carbon reduction, pollution treatment, work environment improvement, and enhancing the welfare rights of our employees. We expect to create a win-winwin situation for our customers, suppliers and ourselves.” added

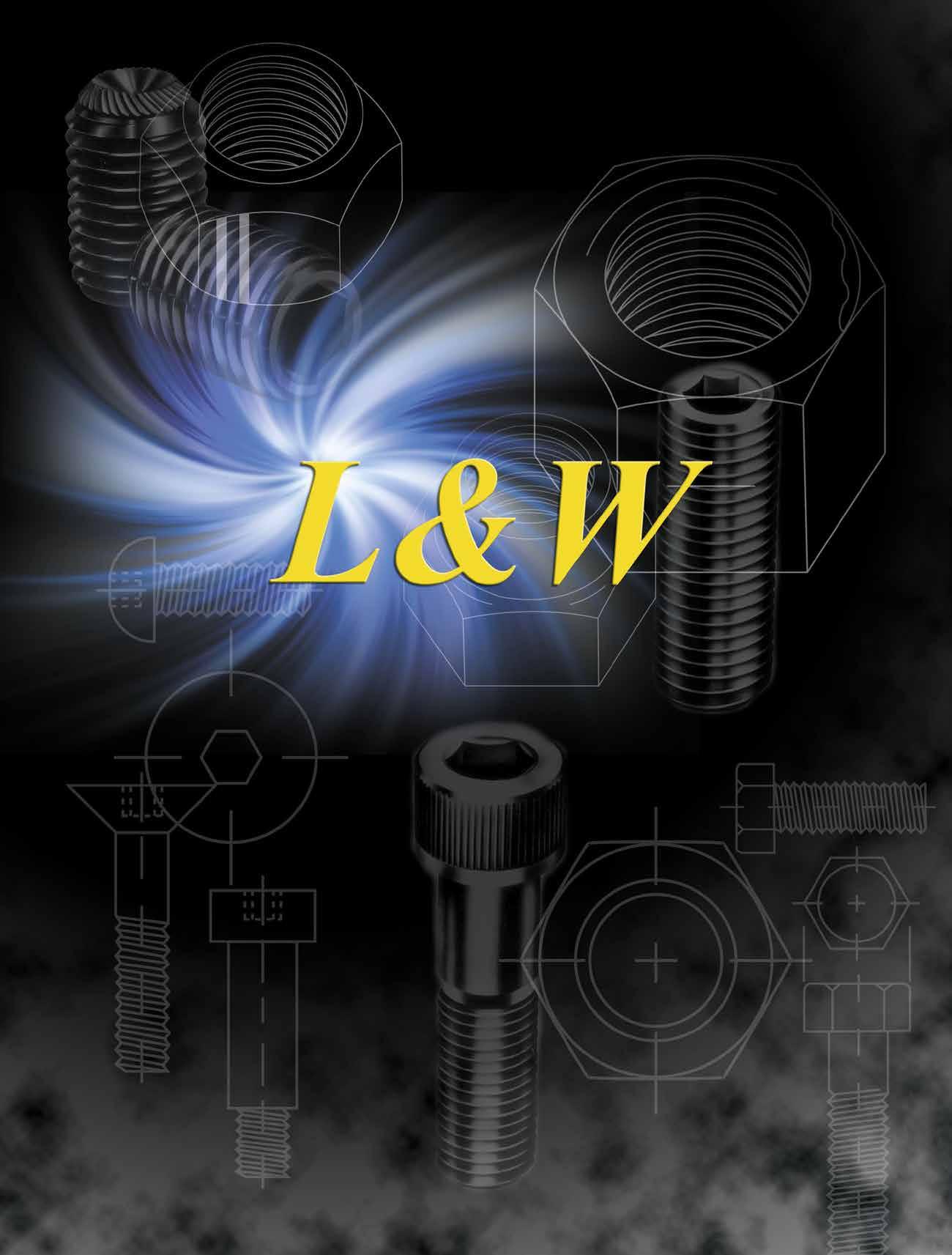

Zyh Yin. by Gang Hao Chang, Vice Editor-in-Chief of Fastener World"Buying pins? Look for Yung King!" This is the answer that many buyers often get when they want to buy pins from Taiwan. Founded more than a few decades ago in northern Taiwan to produce cotter pins, Yung King Industries Co., Ltd. has expanded its product line to include spring pins, hitch pin clips and dowel pins, and has become the largest and most representative pin manufacturer in the eyes of many buyers. Under the leadership of President Josh Chen, Yung King has continued to capture niche markets and has built its own kingdom of pins. Its annual sales volume has reached 2,000-2,500 tons.

Cotter pins, spring pins, hitch pin clips, and dowel pins are Yung King’s four major products. Although they look simple, they play a key role in many anti-loosening applications. It mainly manufactures pins in stainless steel, iron, and brass, in sizes to meet the exact length specifications required by customers. The cotter pins are available in sizes up to 16mm and dowel pins are available in sizes up to 20mm or more. In spite of the competition from overseas counterparts offering lower prices, it continues to win orders from many customers in the U.S., Japan and Australia due to its higher quality, faster delivery and better packaging service.

Its cotter pins are used in a wide range of applications such as machines that vibrate, castle nuts for wheel rims, and long chains that require anti-loosening components. Compared to screws featuring more complicated fastening mechanism, Yung King's cotter pins are more convenient to use and can be replaced easily. Once it is inserted into the mating part and its tails are pulled open, the assembly is done! The simple operation can achieve the purpose of loosening prevention. In response to the growing market demand, it has also developed spring pins with slots and double-sided chamfered angles for easy installation into holes, and the flexible steel material can be directly clamped as a rotating shaft. It has even developed toothed spring pins featuring better fit. As for hitch pin clips, they will automatically open when inserted into the bolt hole and will not be easily pulled out after fixing, achieving a stable anti-loosening effect. In the part of dowel pins requiring high precision in O.D. tolerances, Yung King has also gained a foothold in the large-size dowel pin market through its excellent processing technology.

With two factories in Hsinchuang and Sanchong (New Taipei City), Yung King has a capacity of 200 tons per month. In order to reduce costs, improve quality, increase production capacity and diversify products to remain competitive internationally, it has completed the automation upgrade of its equipment at the end of last year, shortening the process and significantly reducing labor costs and waste output. In recent months, it has even purchased several multi-stroke multi-axis forming machines to enhance its customizing capabilities and meet customers' special product requirements.

“Under the principle of selling more at lower prices, we have accumulated a good reputation for our high quality products and services over the years," said President Chen. “Our main customers are importers from the U.S., Japan and Australia, which account for 40%, 20% and 20% of our sales volume respectively. We are looking forward to extending our reach to the European market, and we do not rule out the possibility of looking for agents in European countries to develop customers for us, so that more European customers can experience the quality and durability of pins from Taiwan. At the same time, the 3rd generation of the company has also started to work in the factory since this year. We hope to create a new atmosphere for the old factory through the new ideas and practices brought by the young people. In addition, at this year's Fastener Taiwan, we’ll not only demonstrate to global buyers our strong pin manufacturing capacity, but also set up a cocktail bar at our booth. We sincerely welcome all industry peers to come and interact with us.

Yung King contact: President Josh Chen Email: yuking@seed.net.tw

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

The Fastener Training Institute (FTI), has announced Würth Industry North America (WINA) will continue as sustaining sponsor in 2023. This will mark the fifth year of partnership between the two organisations.

“Würth’s continued support is instrumental to our ability to offer frequent and robust educational opportunities which enhance knowledge, safety and reliability across the fastener industry,” said John Wachman, Managing Director for FTI. Thanks to Würth’s support, FTI will continue to offer an extensive menu of in-person fastener training classes taught by leading industry expert instructors.

“Our partnership demonstrates our ongoing commitment to the importance of quality fastener education. We are thrilled to move into our fifth year of partnering with the Fastener Training Institute and helping to support the education of seasoned and new professionals within the fastener industry,” said Tracy Lauder, Director of Marketing and Communications for Würth Industry North America.

The European Union's carbon border tax extended the list of products to downstream products at the end of last year, covering the fastener industry in Taiwan which exports 30% of fasteners to the EU. As Taiwan is a major fastener producer, the amount of fasteners exported worldwide in 2021 reached NT$166.3 billion, and 29% were sold to the EU. The impact of EU carbon tax would be monumental.

Taiwan Industrial Development Bureau is expected to allocate NT$700 million to NT$800 million to assist the metal industry in carbon inventory and equipment investment. The Ministry of Economic Affairs has appointed the Metal Industry Research and Development Center to set up a "Metal Industry Carbon Reduction Service Group", which will provide one-stop services in carbon inventory, carbon verification, technology upgrade, government counseling, subsidy resources, and talent training to accelerate the fastener industry's transformation.

Officials said that in the face of competition from China, Taiwan fastener industry is in urgent need of reducing carbon emissions to strengthen its competitiveness. Through this service group, the government can help manufacturers train their own carbon inventory talents and find out where the internal processes consume energy, and then allow government resources to subsidize them to improve equipment and technology, in addition to investment credits such as smart machine research and development.

In response to the global trend of carbon neutrality, Taiwan CSC has cooperated with Jinn Her Enterprise, a Taiwanese major fastener manufacturer, and succeeded in developing and producing 150 metric tons of steel that can be declared as carbon neutral. Taiwan CSC is now applying for various international certificates for green steel. This could be completed at the end of 2023, effectively relieving the pressure of exporting screws with an annual output value of hundreds of billions of NTD and driving the domestic steel industry upward.

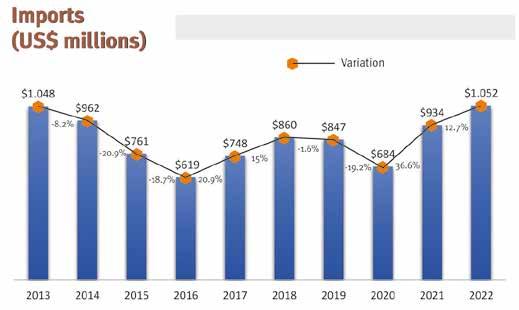

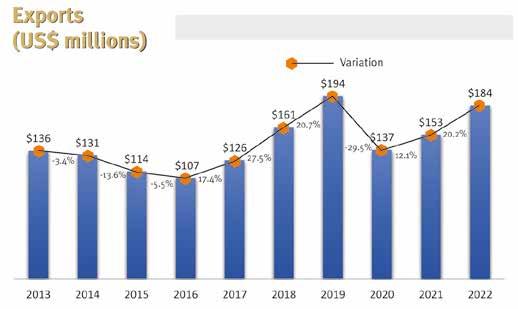

In 2022 Taiwan's fastener export result was the third highest in history, with an annual export volume of 1,665,300 tons,

down 0.7 percent YoY, while the export value exceeded US$6 billion for the first time, reaching US$6.355 billion, or nearly NT$200 billion, a record high.

Taiwan Industrial Fasteners Institute (TIFI) Chairman Tu-Chin Tsai said that the second half of 2022 was affected by the negative global steel economy, and although the number of orders received by manufacturers was more or less affected, resulting in a slightly lower export value than the previous year, the export volume exceeded the US$6 billion mark for the first time, mainly because the fastener industry gradually succeeded in transforming to the development of higher-value-added products, such as automotive screws, resulting in a higher average unit price, and continued to work toward precision machining and smart manufacturing.

Recently, with the gradual improvement of the international steel economy, the market situation in Europe and the United States has improved, and Tu-Chin Tsai believes that it will be favorable for manufacturers to receive orders. The fastener industry is expected to recover in the second quarter of 2023, especially starting this May, export orders will obviously improve, so the outlook for the fastener export market in 2023 is positive.

TIFI also pointed out that the average export price of Taiwan fasteners in November 2022 rose to US$3.98 per kilogram, a record high for a single month in history, but slipped to US$3.94 per kilogram in December 2022, down 1 % from the previous month, but up 4.78 % from the same period in 2021, the second highest for a single month in history.

The European Union will trial start Carbon Border Adjustment Mechanism (CBAM) this October, requiring imported products to declare their carbon content. In addition to steel, concrete, aluminum, fertilizer and other industries, CBAM will also extend to downstream products such as screws and bolts. Gangshan District of Kaohsiung City is the heartland of Taiwan fastener industry, and will certainly face the impact after CBAM is launched.

The Environment Protection Bureau of Kaohsiung City established the "Carbon Inventory Counseling Team" to provide free inventory counseling services to enterprises. The team will assist enterprises in establishing emission inventories, and start with two types of target, including fastener companies in Kangshan Benjhou Industrial Park. After a series of briefing sessions from January to February, on-site counseling will be conducted from March to July.

Japan External Trade Organization (JETRO) surveyed 7,173 Japanese companies around the world and published "Worldwide Overseas Japanese Companies Survey for 2022" report. The report is a barometer hinting at the future of Japanese companies in overseas markets and it draws three conclusions.

First, 65% of the 7,000 plus Japanese companies operating overseas expect to gain profit for 2022, but the losses in sectors such as auto parts are increasing. As a result of China's Zero COVID policy, more than 40% of Japanese companies in China are facing deteriorating sales, exceeding the proportion of companies having improved results.

Globally, 45.4% of Japanese companies will expand their business in overseas countries. Among them, 70% of the Japanese companies will expand in India and 60% in Vietnam, which shows that Japan is continuing to tap into the Southeast Asian market. On the contrary, the percentage of Japanese companies intending to expand in China dropped from 40.9% to 33.4%.

Second, 60% of Japanese manufacturers will re-examine the supply chain. As raw material and transportation costs rise and the risk of supply disruptions become more apparent, Japan will accelerate its localization (selfproduction) strategy for sourcing, production and sales. In the next one to two years, the number of Japanese personnel dispatched to overseas countries will be reduced by half compared to the pre-epidemic period, while the number of Japanese domestic employees will be increased.

Third, Japan is accelerating carbon reduction. More than 40% of the surveyed companies are already taking action to achieve decarbonization, an increase of nearly 10% over the previous year. Compared with the previous year, this figure increased by nearly 10%. The number of companies making green purchases (requiring suppliers to reduce carbon) has more than doubled. With awareness of carbon reduction spreading rapidly throughout the supply chain, non-compliant companies may face the risk of limited trading opportunities.

The European Parliament on February 14 formally approved a law to effectively ban the sale of new petrol and diesel cars in the European Union from 2035, aiming to speed up the switch to electric vehicles and combat climate change. The landmark rules will require that by 2035 carmakers must achieve a 100% cut in CO2 emissions from new cars sold, which would make it impossible to sell new fossil fuel-powered vehicles in the 27-country bloc.

The law will also set a 55% cut in CO2 emissions for new cars sold from 2030 versus 2021 levels, much higher than the existing target of

37.5%. "The operating costs of an electric vehicle are already lower than the operating costs of a vehicle with an internal combustion engine," Jan Huitema, the parliament's lead negotiator on the rules, said, adding that it was crucial to bring more affordable electric vehicles to consumers.

On 19 January 2023, Secretariat of Economy (Mexico) published in a public release the first final ruling on sunset review of anti-dumping against wire rods originating in or imported from China, deciding to maintain the anti-dumping duty of US$0.49/kg established in the final ruling of the initial review on 28 July 2016. The TIGIE tariff codes of the associated products are 7213.10.01, 7213.20.91, 7213.91.03, 7213.99.99, 7227.10.01, 7227.20.01, 7227.90.99, 9802.00.01, 9802.00.07, 9802.00.13, 9802.00.19 and 9802.00.23. The measure was effective from 29 July 2021 for a period of five years.

On 2 September 2015, Mexico initiated an anti-dumping investigation into wire rods originating from or imported into China. On 28 July 2016, Mexico issued a positive final determination to the case, imposing an anti-dumping duty of USD 0.49/kg on the products involved. On 22 July 2021, Secretariat of Economy published an announcement in a public release, saying to initiate the first sunset review investigation into the case upon the application by Mexican companies including Ternium México, S.A. de C.V., Arcelor Mittal México, S.A. de C.V. and Deacero, S.A.P.I. de C.V.

Airbus is developing its local or regional materials platform for different strategic commodities, but suppliers will need to have the necessary certifications such as AS-9100. “Without those certifications it will be impossible to do business with an aeronautical company like Airbus. And it is very important to have suppliers mainly from Mexico, or from the United States and Canada,” said Carlos Rivera Villalba, the company’s Global Supply Chain Manager.

During the panel perspective of the aerospace sector through Airbus, in his participation during the Seminar “Be an Aerospace Supplier”, organized by Femia, at CETYS University, Mexicali campus, Rivera added that they are looking for aluminum suppliers in sheets, plates, rivets, nuts, screws and bolts, among others.

Airbus has a presence in Queretaro with a manufacturing plant and a training center in Mexico City and another in Merida. Today

there are 150 Airbus aircraft in operation in the country and 200 in the order book which take up 60% of the Mexican market. “It was forecast to close 2022 with 354 aircraft for the different airlines in Mexico, which represents a 12% increase against 2021. The country is part of the top 20 markets,” he said.

According to the latest statistics from China Association of A utomobile Manufacturers (CAAM), China's new energy vehicle production and sales continued to grow exponentially in 2022, with 7.058 million and 6.887 million units produced and sold respectively, up 96.9% and 93.4% year-on-year, topping the world for eight consecutive years. Market share rose to 25.6%, 12.1 percentage points higher than the previous year, with global sales accounting for over 60% of the total. Of all new energy vehicles,

5.365 million pure electric vehicles were sold, an increase of 81.6% year-on-year, while 1.518 million plug-in hybrid vehicles were sold, an increase of 1.5 times year-on-year.

In 2022, the share of domestic sales of new energy passenger cars made by independent brands reached 79.9%, an increase of 5.4 percentage points year-on-year; 679 thousand new energy vehicles were exported, an increase of 1.2 times year-on-year. China accounted for three of the world's top ten companies in terms of sales volume of new energy vehicles. China's new energy vehicles have entered a period of full market expansion and are expected to continue to grow at a faster pace this year.

China's total automotive production and sales achieved 27.021 million units and 26.864 million units respectively, an increase of 3.4% and 2.1% year-on-year, achieving a modest annual growth ranking first in the world for 14 consecutive years.

China Association of Automobile Manufacturers said, "In 2022, the automotive industry has been impacted by a number of factors, but under the effective momentum from a series of policies to stabilize growth and promote consumption, and with the joint efforts of enterprises across the industry, the overall recovery of the automotive market is improving. Passenger cars achieved faster growth, contributing an important force for the steady development of the industry."

In 2022, China's passenger car production and sales achieved 23.836 million units and 23.563 million units, a respective increase of 11.2% and 9.5% year-on-year, a higher growth rate than the industry as a whole.

The Chinese fastener enterprises in Yongnian are deeply engaged in overseas markets, and their products are exported to more than 110 countries and regions, such as the United States, Japan, Egypt and Dubai (UAE). At present, the Yongnian district encompasses 476 fastener enterprises with independent export license. There are more than 50 large factories specifically dedicated to export sales and 5 industryleading fastener enterprises which has established their overseas warehouses. In 2022, Yongnian district generated about 158.6 million U.S. dollars of fastener export, a year-on-year increase of 70.8%, up against the nation-wide downtrend.

RMB 4 billion, covering an area of 410 acres. The third phase of the project is invested and constructed by Jiangsu Hengyue Hardware Technology Co., Ltd. and two other companies. The total area of the park is 170 acres. The total area of structures is about 90,000 square meters and the total investment is RMB 1.02 billion. The industrial park can produce 200 thousand tons of high-strength fasteners annually with an annual output value of RMB 1.6 billion as well as a tax revenue of about RMB 20 million.

So far, the main structure and auxiliary construction of Jiangsu Hengyue Hardware Technology whose annual output capacity is 60,000 tons of high-strength fasteners has been completed and ready for use from February 2023.

Sheh Fung announced that their consolidated revenue for December 2022 reached NT$225 million, representing a monthly growth of 0.80%. Its consolidated revenue for the fourth quarter of 2022, benefiting from a gradual pickup in customer orders, reached NT$682 million, leading to a 6.11% quarterly growth. Its annual revenue in 2022 was NT$2.591 billion. The company is working hard to promote new screw products and new deployment to provide good momentum for taking orders in the future. It maintains a cautiously optimistic outlook for the first quarter of 2023.

In the fourth quarter of 2022, its major customers in the Americas maintained good inventory depletion and gradually increased orders for replenishment, and Sheh Fung continued to increase order intake in the European region. In addition, its new long structural wood screws were able to be shipped in small quantities in December 2022.