NAME: FARAHIN ATHIRAH BINTI MOHD NIDZAM STUDENT ID: 0352297

BLD62304 BUILDING SCIENCE SERVICES ASSIGNMENT 1 LIGHTING AND VAC DESIGN FOR COMFORT LECTURER: MS SHARON TEH AI PING

NAME: FARAHIN ATHIRAH BINTI MOHD NIDZAM STUDENT ID: 0352297

BLD62304 BUILDING SCIENCE SERVICES ASSIGNMENT 1 LIGHTING AND VAC DESIGN FOR COMFORT LECTURER: MS SHARON TEH AI PING

Table of Con en 2

Pho o of Room Befo e Rede ign 3

Di comfo of oom and p oblem 4

L Ligh S d 7

To al Hea Calc la ion in he oom befo e ede ign (B /h ) 8

Sol ion 9

Sol ion o p oblem I 9

Sol ion o p oblem II 10

Sol ion o p oblem III 11

To al hea calc la ion af e ede ign (ne e ipmen and ligh ing) 12

Sol ion o p oblem IV 12

Sol ion o p oblem V 14

Ene g Con mp ion (OLD) 15

Ene g Con mp ion (NEW) 17

Bill of Q an i 19

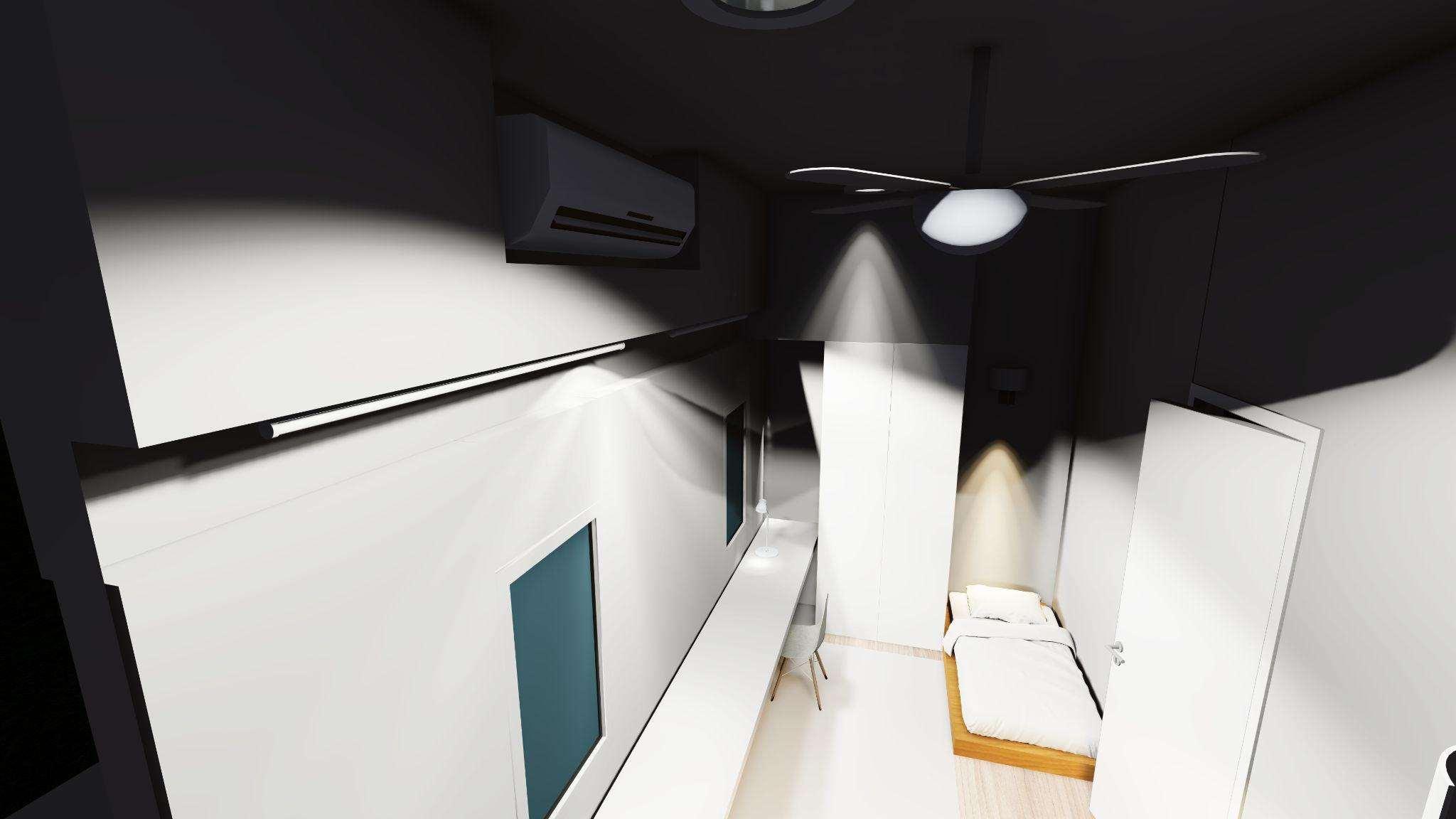

Pe pec i e Vie 21

CAD D a ing 22

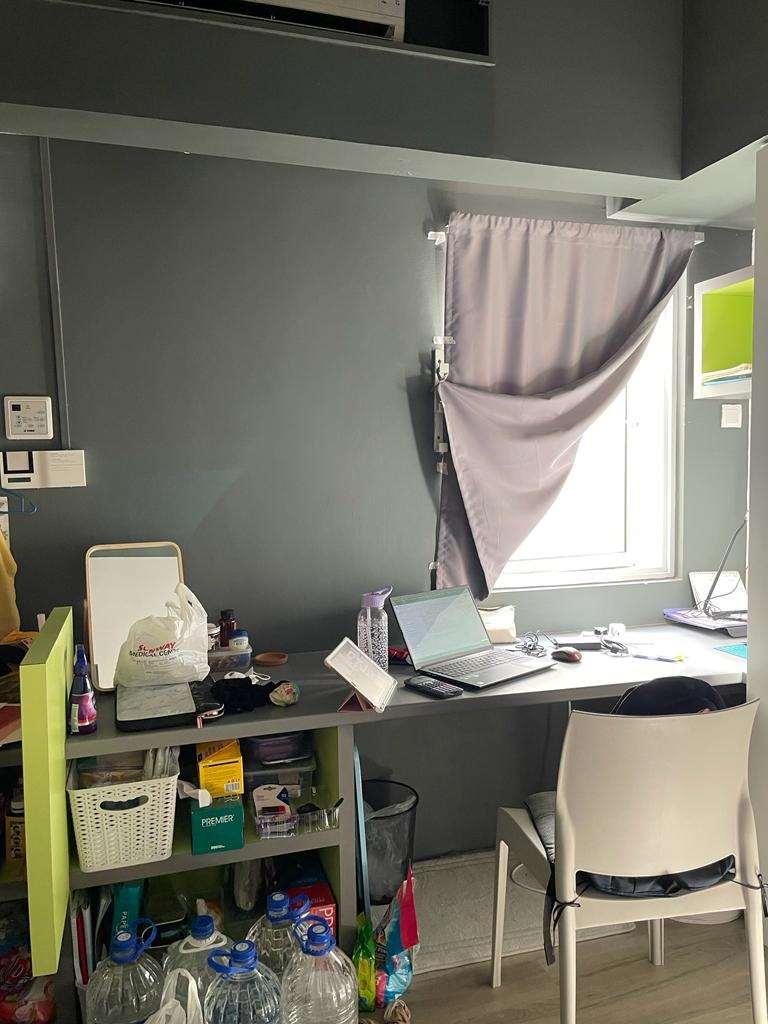

The pace cho en i m ho e ha I en ed in S bang Ja a. Thi ho e ha a o al of 6 people incl ding me i h a o al of 5 oom . In hi a ignmen e ill foc in m oom and he alk a . Hence he plan d a ing. I onl d e ha pa . I pend mo of m ime in he oom, I onl come o of he oom o ha e m meal and o go o he oile .

image of m oom ide

image of m oomma e ide

image of alk a

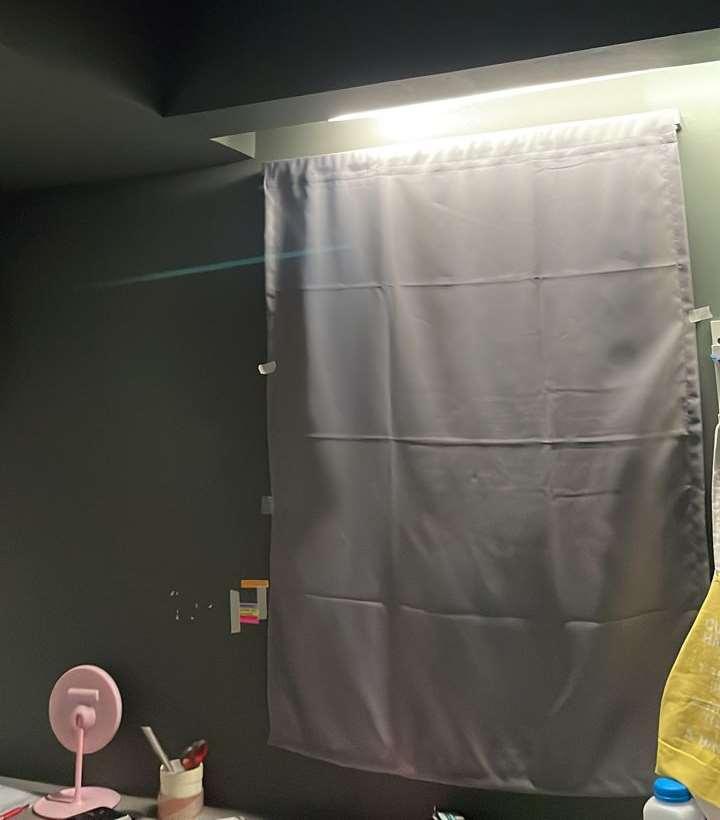

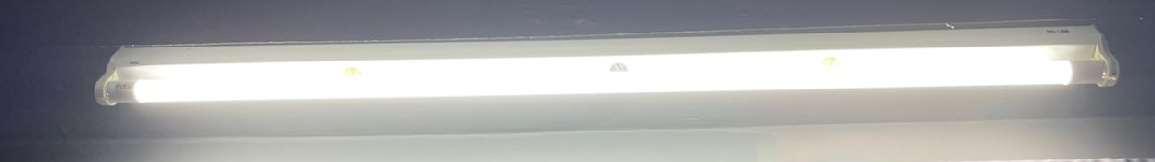

M leeping ched le i di bing m oomma e beca e e leep in hi ha ed oom and he ill al a leep a 12am, mean hile I of en do a ignmen be ond 12 am, i h m fl o e cen be (ligh 1) ligh ing on and ca ing i al di bance. Thi i d e o he hi e di ec ligh ing abo e being oo b igh and i ill im la e h man e e hich a e ed o da kne d ing leeping ho .

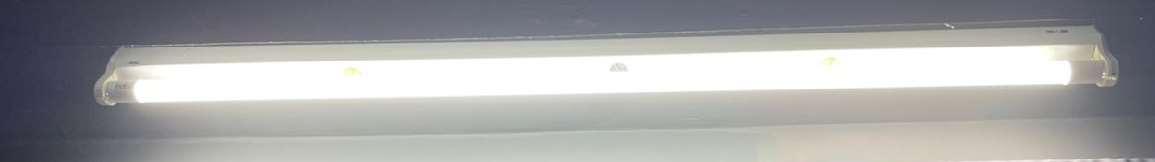

The b igh ne of fl o e cen ligh (ligh 1)

I ied o e he do nligh (ligh 2) behind m d able b i ill gi e a hado of m o n bod ha di b me f om ie ing m o k.The do nligh and he colo of he ligh a he back of he d able i no fficien eno gh fo o king p po e . The gla e f om he fl o e cen ligh al o ca e di bance.

So in o de o p e en f om ca ing incon enience o he , d ligh ill be added.

Ne , he do nligh (ligh 2) nea m a d obe ( hich a e he ame do nligh men ioned a abo e/ do nligh back of m d able) ill mina e a m hi e ca ing i ha d fo me o iden if he colo of m clo he , I ill al a choo e he ong hade of m clo hing e peciall if he colo i almo he ame, I end p needing o go o of m oom j o check he colo . I al o a el i ch on hi ligh ince i i no ef l

The oom ge ho fa in he af e noon o e en a nigh ince he fan i i e old and e en hen he fan i al ead e a he ma im m peed. I of en ake p in he mo ning e i h ea . I ho e in he da . I al o made noi e hile pinning, di bing me d ing o e en leeping.

The ai cond empe a e in hi oom i of en oo cold, e en hen he emo e empe a e i high. A a e l , I of en ake p ge ing chill and nee e . A a ol ion, he ai cond ho ld be eplaced i h one ha ha in e e o main ain he oom a i able empe a e d ing nigh ime and al o i he ho epo e fo hi oom

The alk a in hi ho e onl ha 1 ligh o ce in he middle ca ing i o al a be da k , e peciall he oom a he co ne . The l eading ho ha he alk a ha 47 l . F om m e ea ch, l eading fo alk a ho ld a lea be 100 l .

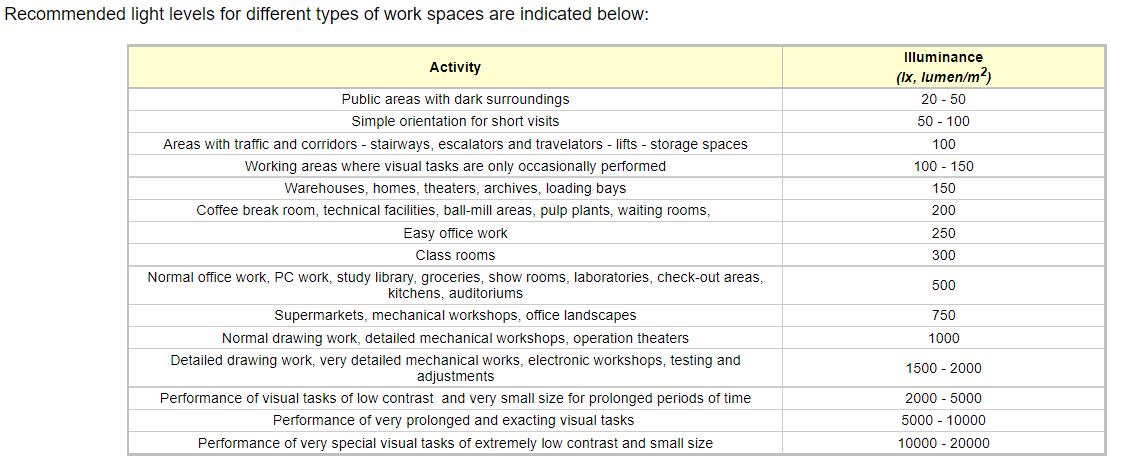

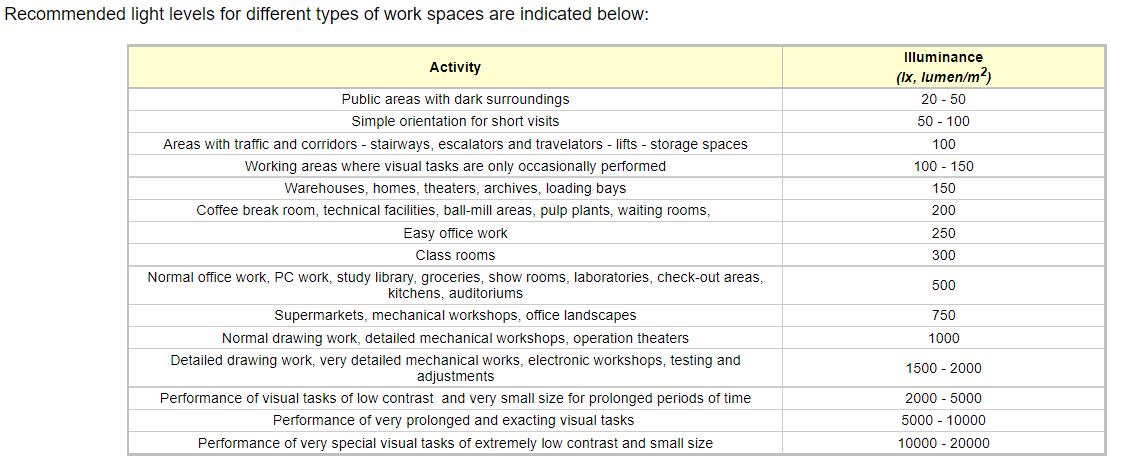

F om m d and e ea ch, he a e age of L in a bed oom fo gene al e i 100 o 300 l hile fo a ki 500 l .

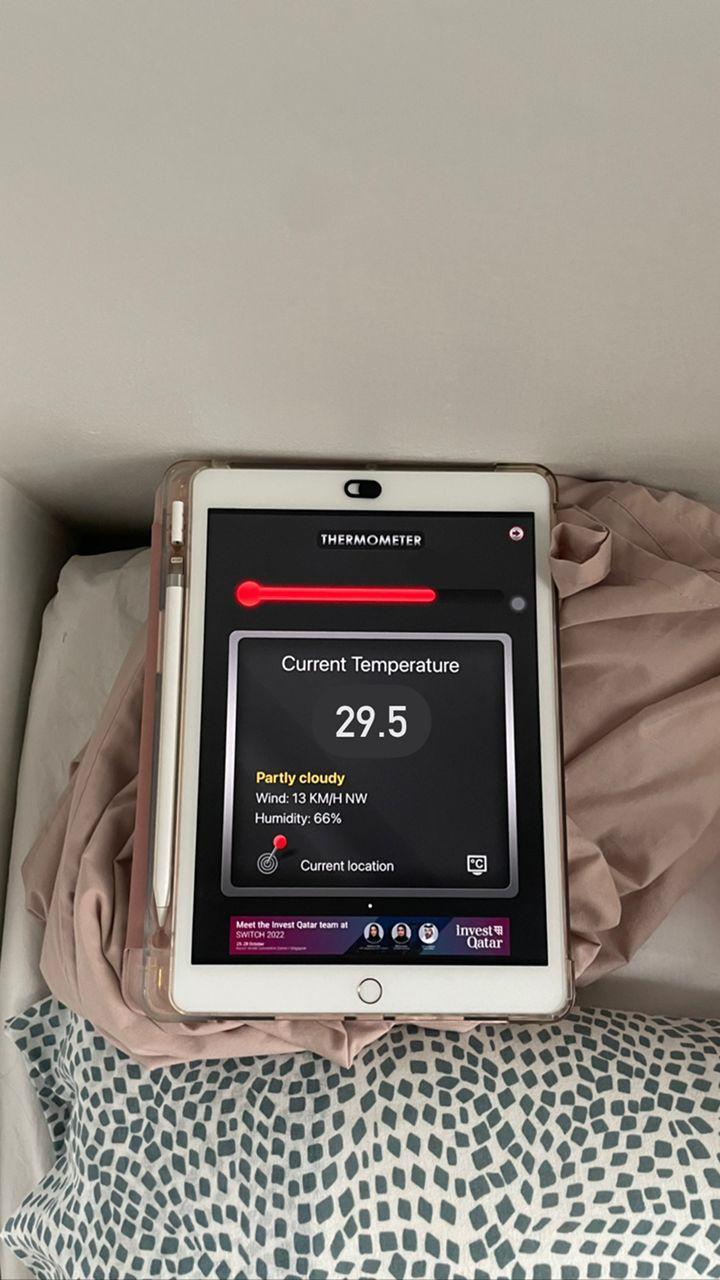

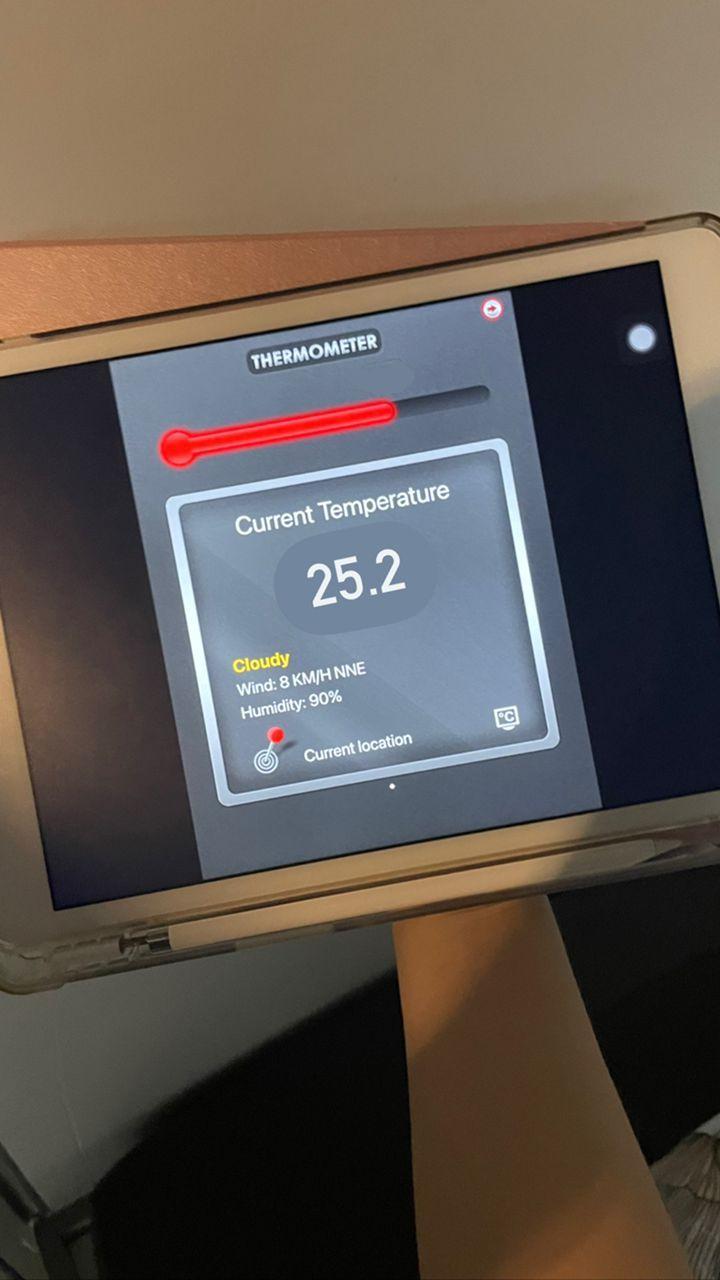

Fig e belo ho l eading hen I place m phone nea he indo in he da i h ligh off.

Thi l ho ha l eading i i able fo a k p po e b hi eading i ob ained hen he phone i placed e ac l nea he indo .

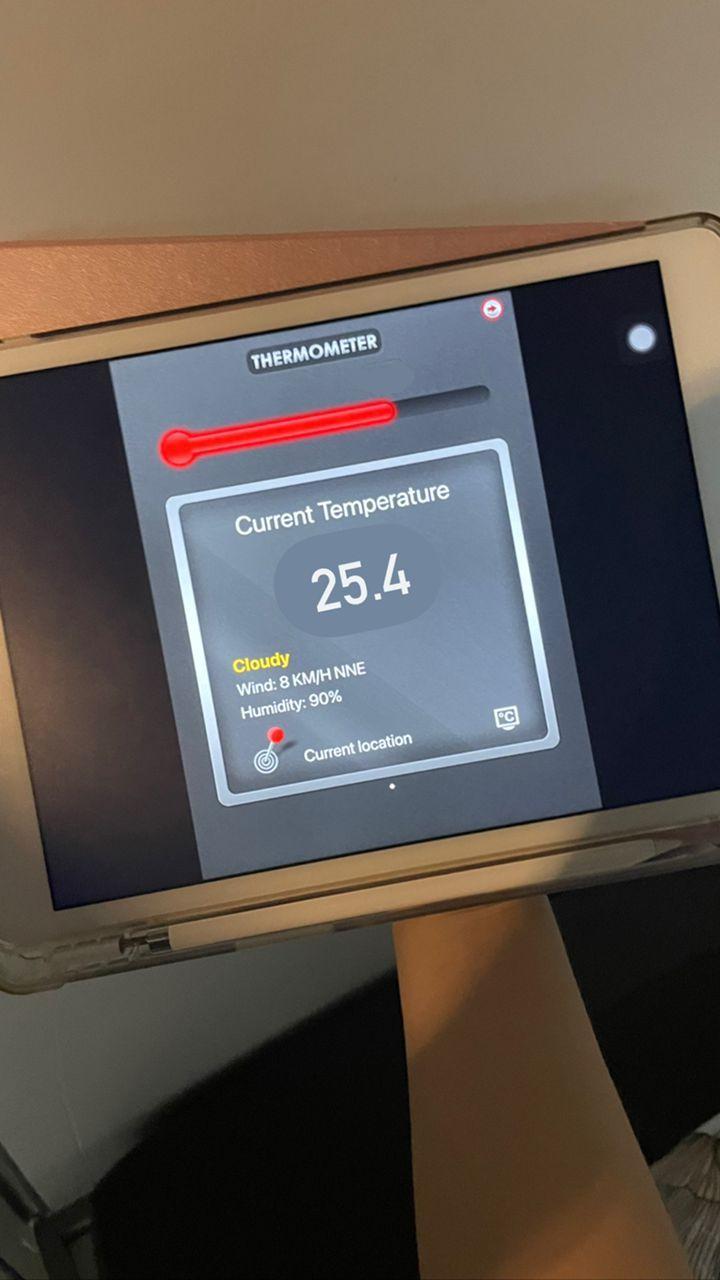

Fig e belo ho l eading hen i place m phone on m able ( o kplace) d ing he da i h ligh off

F om he e, e can ee he eading doe no e en each l ha i i able fo a oom.

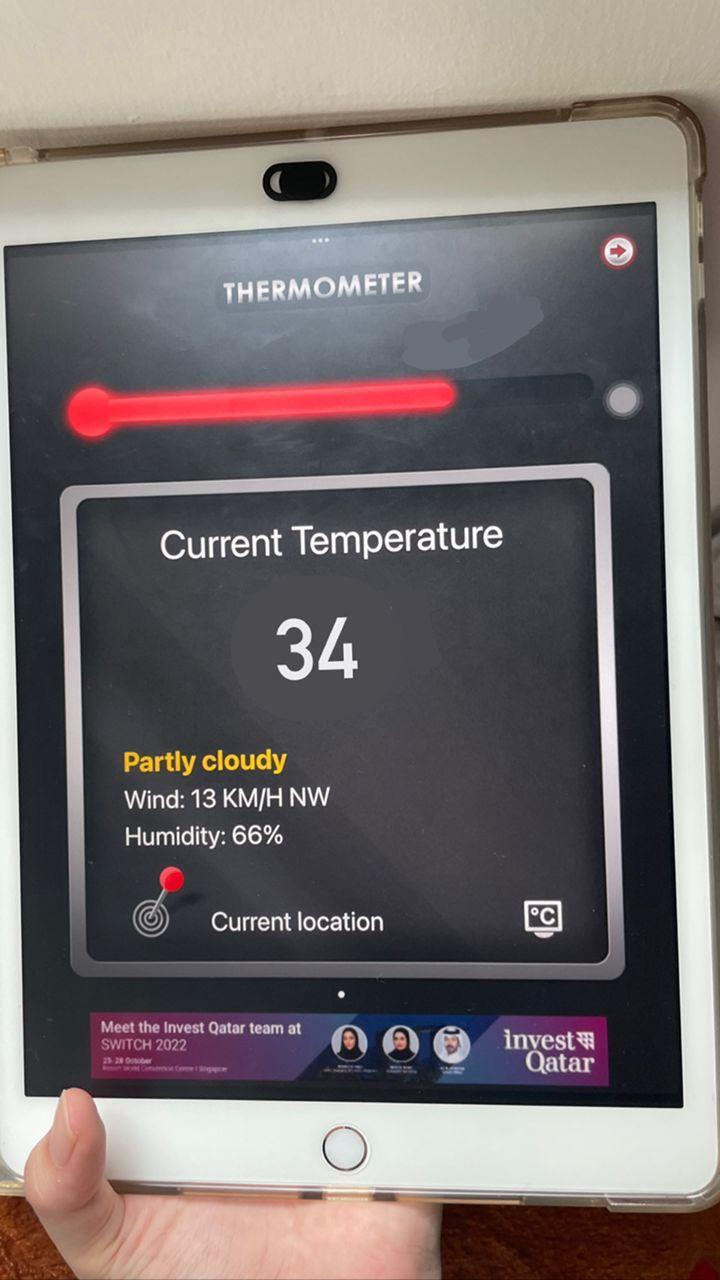

Fig e belo ho l eading a nigh i h ligh on f om m o king po .

F om he e, e can ee ha m oom ha an in fficien amo n of ligh ing ince mo of he ligh in hi oom a e a m hi e and he po i ion of hi ho e i loca ed in he middle ca ing hi oom no ge ing eno gh na al ligh in he da f om m o kplace able. F om he fi fig e, he l eading 510 l e ceed he amo n fo a a k oom 500l b he eading ho ed i hen I placed he ligh me e e ac l nea he indo . When I placed a ligh me e f om m o king po he eading a 85 l . A fo nigh , i h ligh on he eading i 150 l hich doe no each he i able l me e fo o king p po e .

Room a ea = 4.8am 2.6m = 12.584 � B /h = 12.584 700 = 8808.8 B /h 2 people 500 = 1000 B /h

Elec ical e ipmen

Lap op 1 & 2 = 210 W

Ceiling fan = 73 W

Ligh ing = 72 W

To al = 355 W

So 355W 3.5 = 1242.5B /h

To al B /h = 8808.8 + 1000 + 1242.5 = 11051.3B /h

Ai condi ione i e

11051.3 9800B /h = 1.12

Sho ld choo e an ai condi ione i h 1.5hp b he c en ai cond in he oom i 2.5hp making m oom pe cool and e en m oom i e i o mall fo he ai cond hi hp.

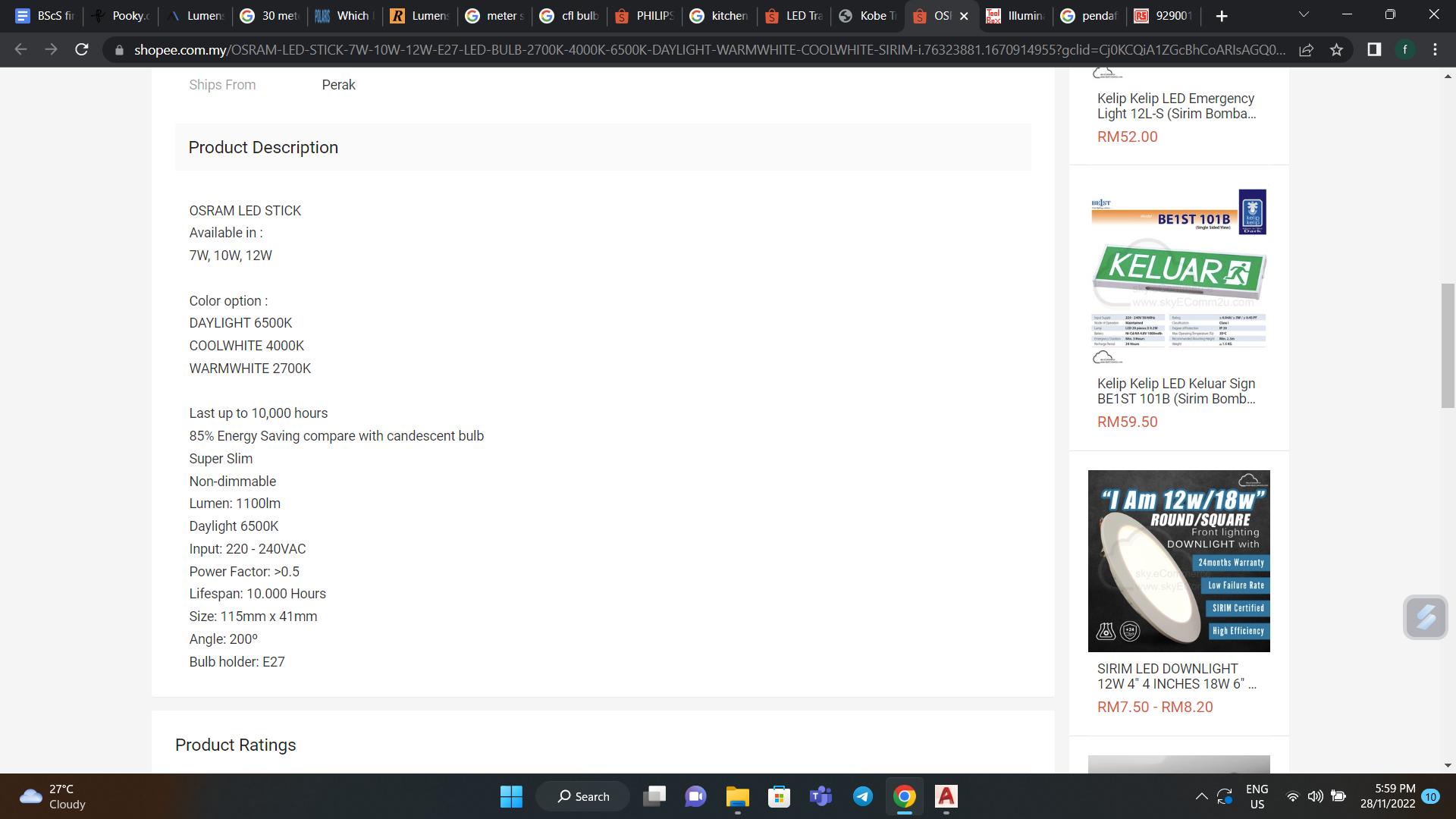

HP3616 Adj able Table Lamp

Po e ( ) 8W

Vol age 230

Colo Tempe a e 2700K

Thi able lamp ill help me o foc on m o k pace ince i i adj able. Mo eo e , I can d i ho feeling g il fo i ching on he ligh a hi ligh ill be di ec ed o he e I an i o foc and ill no di b m oomma e o leep. Thi ligh can al o be ed a nigh o add mo e ligh ing fo me d ing d . Mo eo e hi lamp i mo able, hence I can mo e i acco ding o m p efe ence.

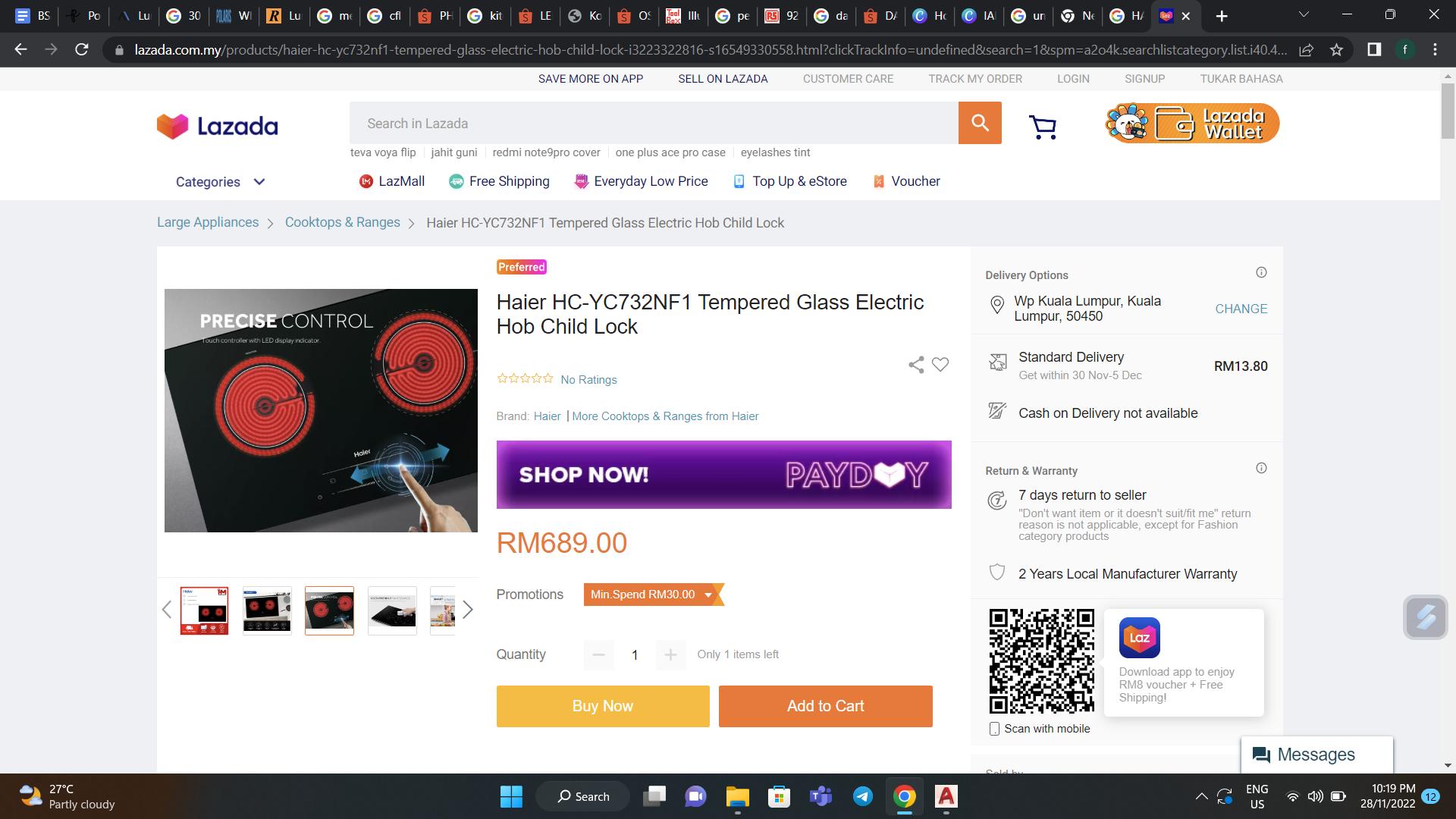

I p opo ed o change he ligh nea m a d obe OLD NEW

Image

T pe Compac Fl o e cen Lamp (CFL) a m hi e o am d l a 18 /827

LED Do nligh Cool hi e NNV70048WE1M

Wa age (W) 18 15 Colo empe a e (K)

3000K 4000K

Life pan 8000 ho 20 000 ho

The ne ligh i an LED Do nligh hich ha lo e a age, hence i e le ene g 15 K compa ed o he old ligh ing hich i 18W. The life pan fo ne ligh ing hich i 20 000 ho i longe compa ed o old ligh ing i h 8000W. Hence, he ne ligh ing can la longe . E en ho gh he colo empe a e emi ed fo ne ligh ing i highe , a lea I'm able o ee clea l and able o choo e he igh hade of clo hing. O he han ha , hi ne do nligh . The ne ligh ing al o i an i Gla e i h hi e pla ic f ame. Hence i ill be ef l a I can al o e ha ligh hen I'm d ing.

Compa i on of LED and CFL

● LED emi e li le hea . In con a , incande cen b lb elea e 90% of hei ene g a hea , CFL elea e abo 80% of hei ene g a hea

● Ano he LED ligh benefi i ha LED , beca e he emi ligh in a pecific di ec ion, do no need diff e o eflec o ha ap ligh . Thi help inc ea e LED efficienc fo e ch a do nligh

● LED b lb a e mo e ene g efficien han CFL

● LED b lb a e mo e e pen i e han CFL

● LED b lb a e d able and long la ing a compa ed o CFL .

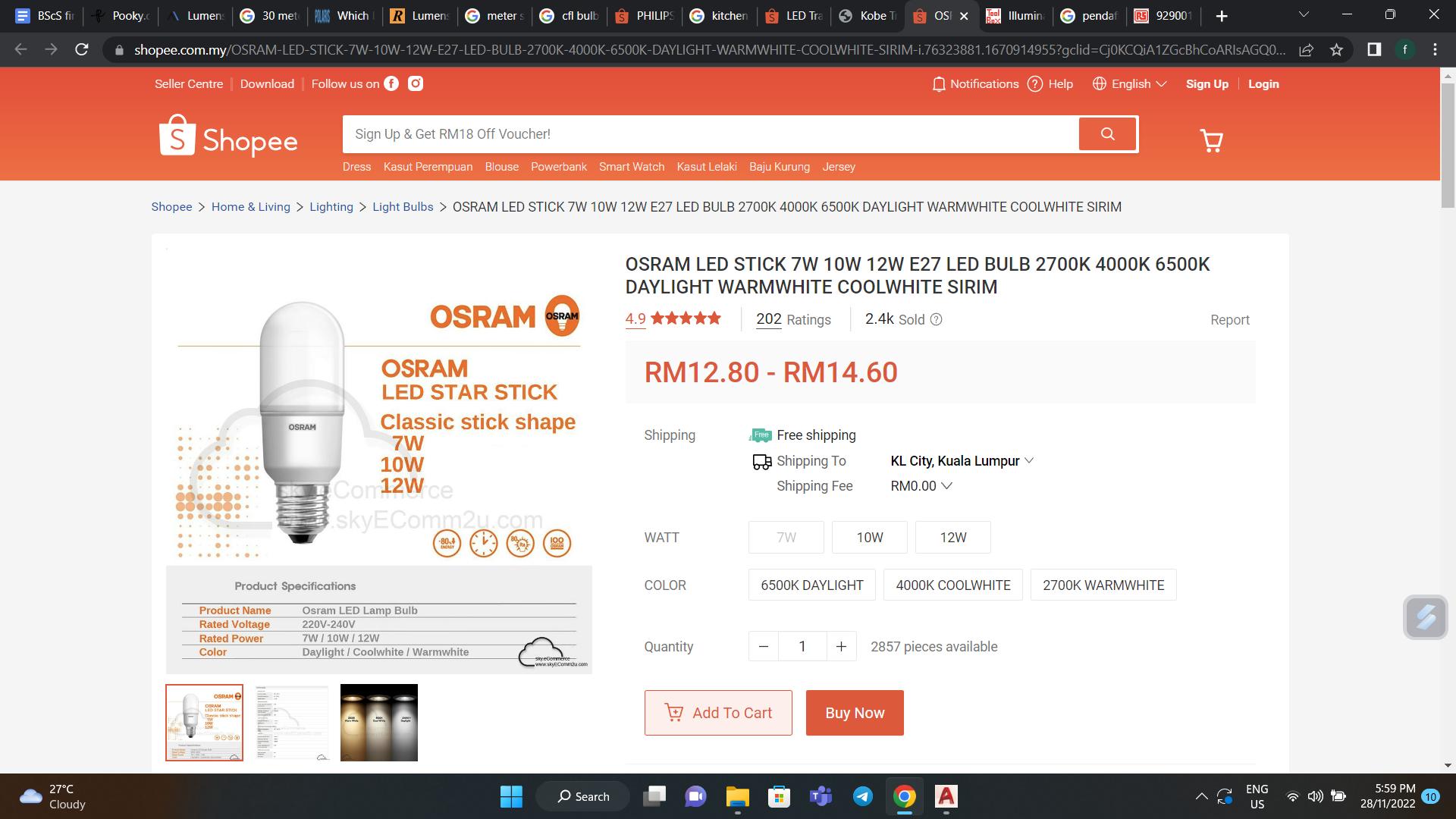

Fan

I em Old MSI ceiling fan M60

De c ip ion

Po e : 73W

Calc la ion Po e = 73W = 0.073kW Pe da = 0.073 18 ho = 1.314kWh Pe mon h = 1.314kWh 30 da = 39.42 kWh

Bil co ing

= P o a ed block (kWh) Ra e (RM) = 39.42 kWh RM 0.218 = RM 8.59

Ne Pana onic 56 Inch Ceiling Fan PSNFM14CZVBWH

Po e : 68W

Po e = 68W = 0.068kW Pe da = 0.068 18 ho = 1.224kWh Pe mon h = 1.224kWh 30 da = 36.72kWh

Bil co ing = P o a ed block (kWh) Ra e (RM) = 36.72 kWh RM 0.218 = RM 8.00

Ne a ing pe mon h af e i ching = RM 8.59 - RM 8.00 =RM 0.59

The abo e calc la ion ho ed he ne a ing pe mon h af e i ching o a ne ceiling fan i RM 0.59 (Pana onic 56 Inch Ceiling Fan PSN-FM14CZVBWH). Al ho gh i onl a e RM 0.50 pe mon h, i al o a e ene g con mp ion a he old ceiling fan (MSI ceiling fan M60) con me mo e po e han ne ceiling fan hich a e 73W and 68W e pec i el . Thi i d e o he old ceiling fan ing he old echnolog and mo o o ope a e, hence i need mo e ene g o n.

al hea calc la ion af e ede ign (ne e ipmen and ligh ing)

Room a ea = 4.8am 2.6m = 12.584 � B /h = 12.584 700 = 8808.8 B /h 2 people 500 = 1000 B /h

Elec ical e ipmen Lap op 1 & 2 = 210 W Ceiling fan = 68 W Ligh ing = 74 W

To al =352 W So 355W 3.5 = 1232 B /h

To al B /h = 8808.8 + 1000 + 1232 = 11040.8B /h

Ai condi ione i e

11040.8 9800B /h = 1.13 Hence, e ho ld ho ld choo e ai condi ione i h 1.5hp

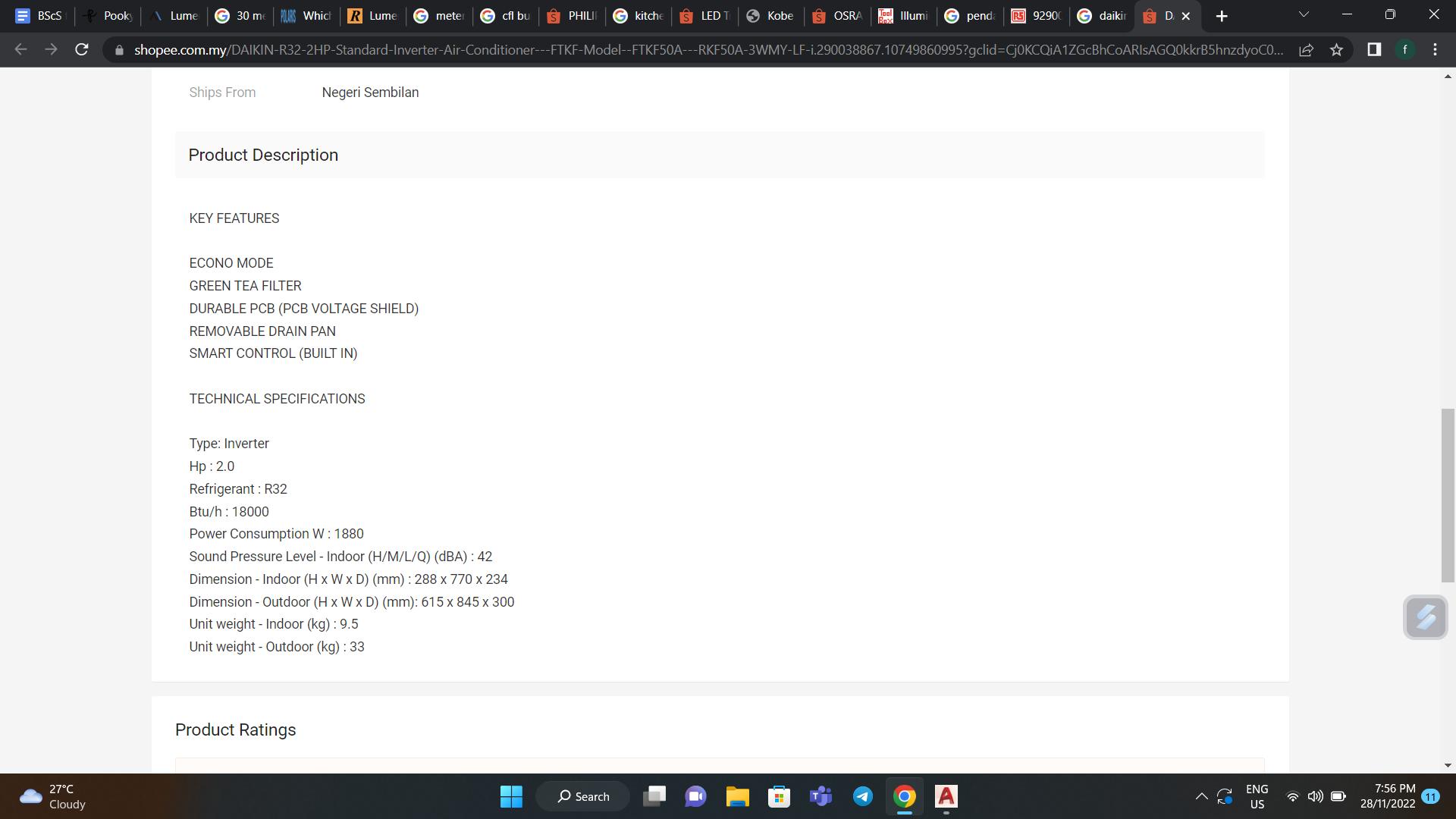

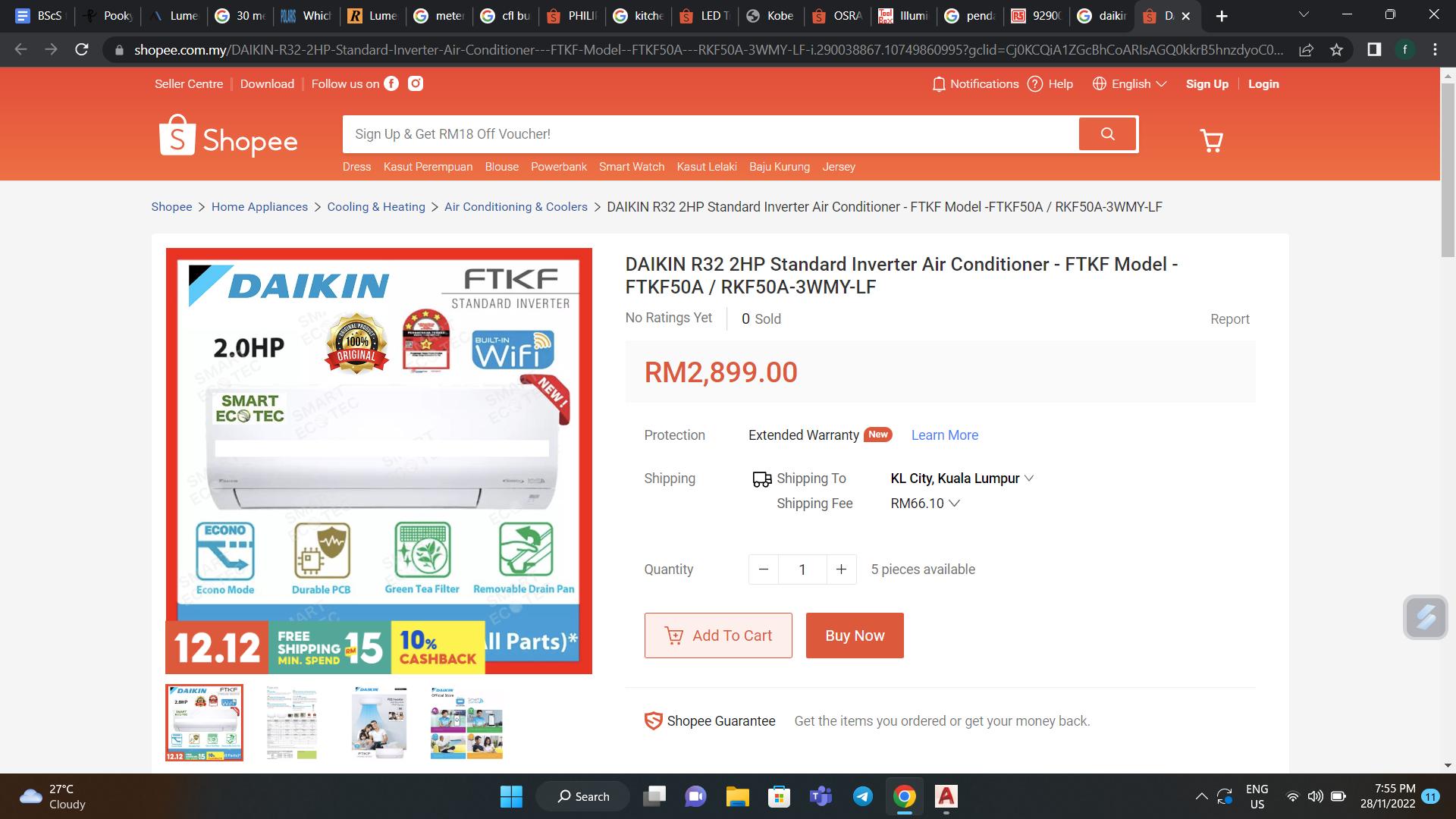

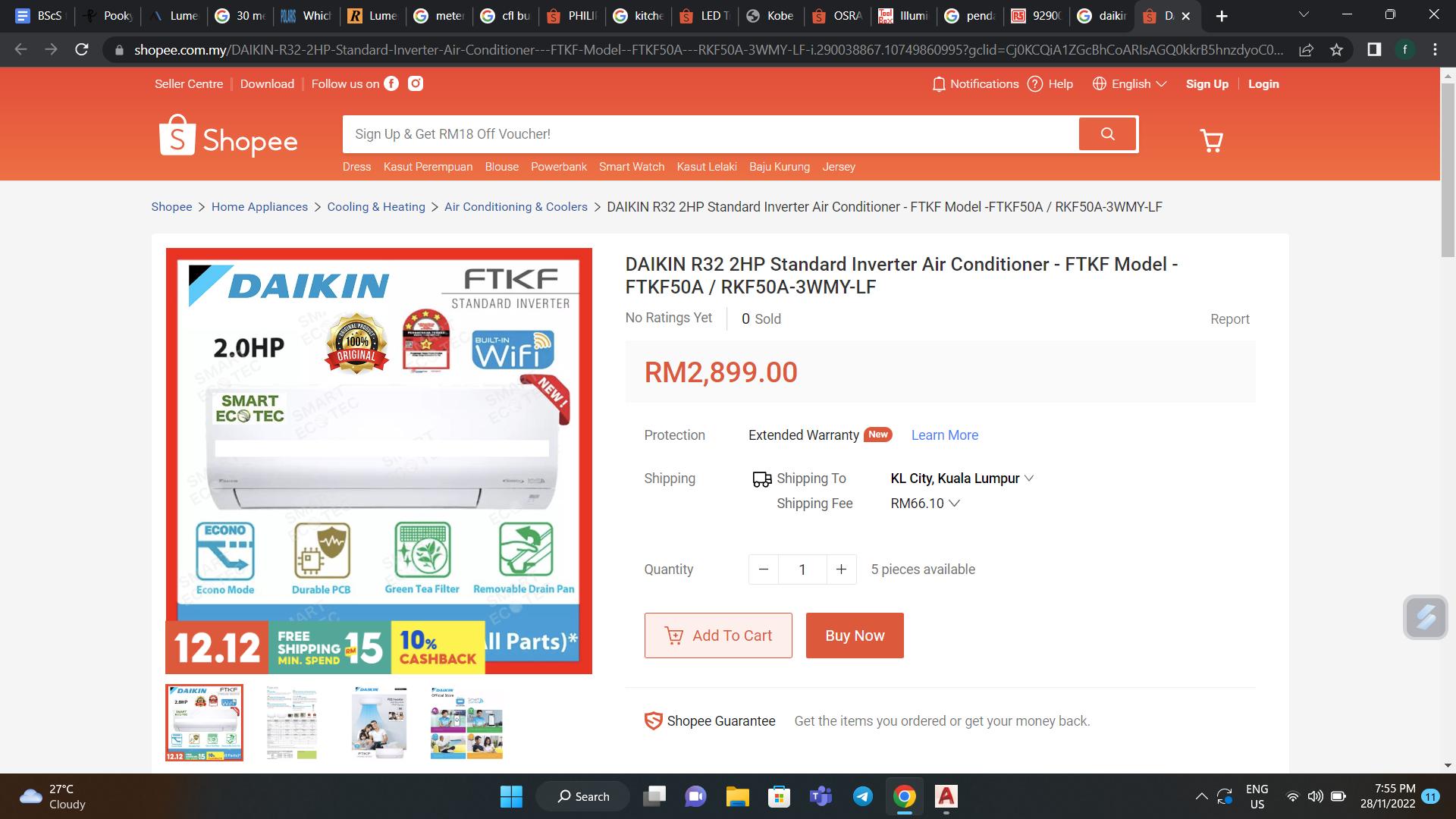

Sol ion o p oblem IV

Ai condi ioning

OLD Yo k YWM3F25CAS-W / YSL3F25AAS

NEW DAIKIN 1.5HP R32 FTKF-B SERIES STANDARD INVERTER AIR COND

Ho epo e 2.5hp 1.5 hp

Ra ed cooling capaci (B /h) 24000 12300

Ra e po e con mp ion(W) 2450 1200

Ra ed c en (A) 10.65 5.37

Coolant/ Refrigerant T pe/ Control R410A R32

In e e Non-in e e In e e

Energ Efficienc ratio EER (Btu/hr/W) 9.80 12.88

Minim m Ene g Pe fo mance (MEPS) 3 star 4 star

F om he able abo e, he a ed cooling capaci of he cho en ne ai cond i lo e han he old model b i i clo e o he ecommended ai cond cooling capaci fo m oom hich i 11040.8 B /h o ed ce he hea gain ha occ hen he ene g con mp ion diffe ence i oo high, he efo e ed cing he o e all ene g con mp ion. In he p e io calc la ion e kno ha 1.5 hp i eno gh fo hi oom. Lo e ho po e al o mean lo e ene g con mp ion and a ing elec ici co . The MEP ene g a a ing of he ne model (4 a ) i al o highe han he old model (3 a ). The ne model al o ha e lo e po e con mp ion (2450W - 1200W =1250W diffe ence) and a fo a ed c en (10.65A - 5.37A = 5.28A) The EER i al o highe (12.88 Btu/hr/W - 9.8Btu/hr/W = 3.08 Btu/hr/W difference), hence it able to reduce energ loss. The new aircond has an inverter where it can regulate the speed of its compressor motor once the room is cool enough to save energ and refrigerant used to cool the air. Hence, it is suitable to be used in m room since I'll be on it for a long period of time in an enclosed room, meanwhile the old non-inverter aircond motor will turn off once room temperature drops to the desired level. This repeated on-off process will make unnecessar noise. In addition, R32 refrigerant of the new aircond is also more sustainable. To clarif , carbon has a GWP of 1. R410A (old model refrigerant) has a GWP of 2,088, meaning that if one kilogram is released into the atmosphere it would have 2,088 times the harmful effect of one kilogram of carbon. (4) That is wh the new aircond with R32 is chosen, which has a GWP of 675.

● eco-friendl refrigerant R-32, which has reduced global warming potential b a third, emits 75% less CO2, has ero o one depletion potential and best overall life-c cle climate performance. R-32 is not onl the most balanced refrigerant but is also fairl eas to rec cle.

● Quiet Operation technolog : Daikin are equipped with the Quiet Operation technolog which ensures a whisper-quiet functioning for the perfect peaceful slumber

● Save power with optimised cooling: The compressor used in Daikin inverter ACs like the 2 ton split AC, optimises peak performance to give perfect cooling even in extreme temperatures. With this technolog , the compressor is alwa s on but draws less power or more power depending on the temperature of the incoming air and the level set in the thermostat.

Fluorescent tube lighting is added, the old fluorescent tube is relocated to the corner. Hence both lighting is located in the corner.

T8 Fluorescent tube light bright white

Colour temperature : 6500K

Quantit : 2

Watt : 18W = 0.018kW

Dail time use : 16 hours

Dail energ consume : 2 x 0.018kW x 16h = 0.576kWh

Monthl : 0.576kW x 30 da s = 17.28 kWh

MSI ceiling fan M60

Q an i : 1

Wa : 73 W = 0.073kW

Dail ime e : 18 ho

Dail ene g con me : 0.073kW 18h = 1.314 kWh

Mon hl : 1.314 kWh 30 da = 39.42kWh

Yo k YWM3F25CAS-W / YSL3F25AAS

cooling capaci : 24000

Refrigerant T pe: R410A

Q an i : 1

Wa : 2450W = 2.45kW

Dail ime e: 6 ho

Dail ene g con me: 2.45kW 6h = 14.7kWh

Mon hl : 14.7kWh 30 da = 441kWh

Compac Fl o e cen Lamp (CFL) a m hi e

Q an i : 2

Wa : 18 W = 0.018kW

Dail ime e = 0.5 ho

Dail ene g con me: 2 0.018kW 0.5h = 0.018 kW/h

Mon hl : 0.018kWh 30 da = 0.54 kWh

Light 1

Light 2

Osram duluxstar fluorescent lamp

Quantit : 2

Watt: 18 w = 0.018kW

Dail time use: 0.5 hour

Dail energ consume: 2 0.018kW 0.5h = 0.018 kWh

Monthl : 0.018kWh x 30 da s = 0.54 kWh

Q an i : 1

Wa : =18W = 0.018kW

Dail ime e: 13 ho

Dail ene g con me: 0.018kW 13h =0.234 kWh

Mon hl : 0.234kWh 30 da = 7.02kWh

Total kWh per da = 0.576kWh + 1.314 kWh + 14.7kWh + 0.018 kW/h + 0.018 kWh + 0.234 kWh = 16.86kWh

Total kWh monthl = 17.28 kWh + 39.42kWh + 441kWh +0.54kWh + 0.54 kWh + 7.02kWh = 505.8kWh

T8 Fluorescent tube light bright white Colour temperature : 6500K

Quantit : 2

Watt : 18W = 0.018kW

Dail time use : 16 hours

Dail energ consume : 2 x 0.018kW x 16h = 0.576kWh

Monthl : 0.576kWh x 30 da s = 17.28kWh

HP3616 Adj able Table Lamp

Quantit : 1

Watt : 8W = 0.008kW

Dail time use : 3 hours

Dail energ consume : 0.008kW x 3h =0.024 kWh Monthl : 0.024kWh x 30 da s = 0.72 kWh

Pana onic 56 Inch Ceiling Fan PSNFM14CZVBWH

Q an i : 1

Wa : 68W = 0.068kW

Dail ime e: 18 ho

Dail ene g con me : 0.068kW 18 h = 1.224kWh Mon hl : 1.224kWh 30 da = 36.72kWh

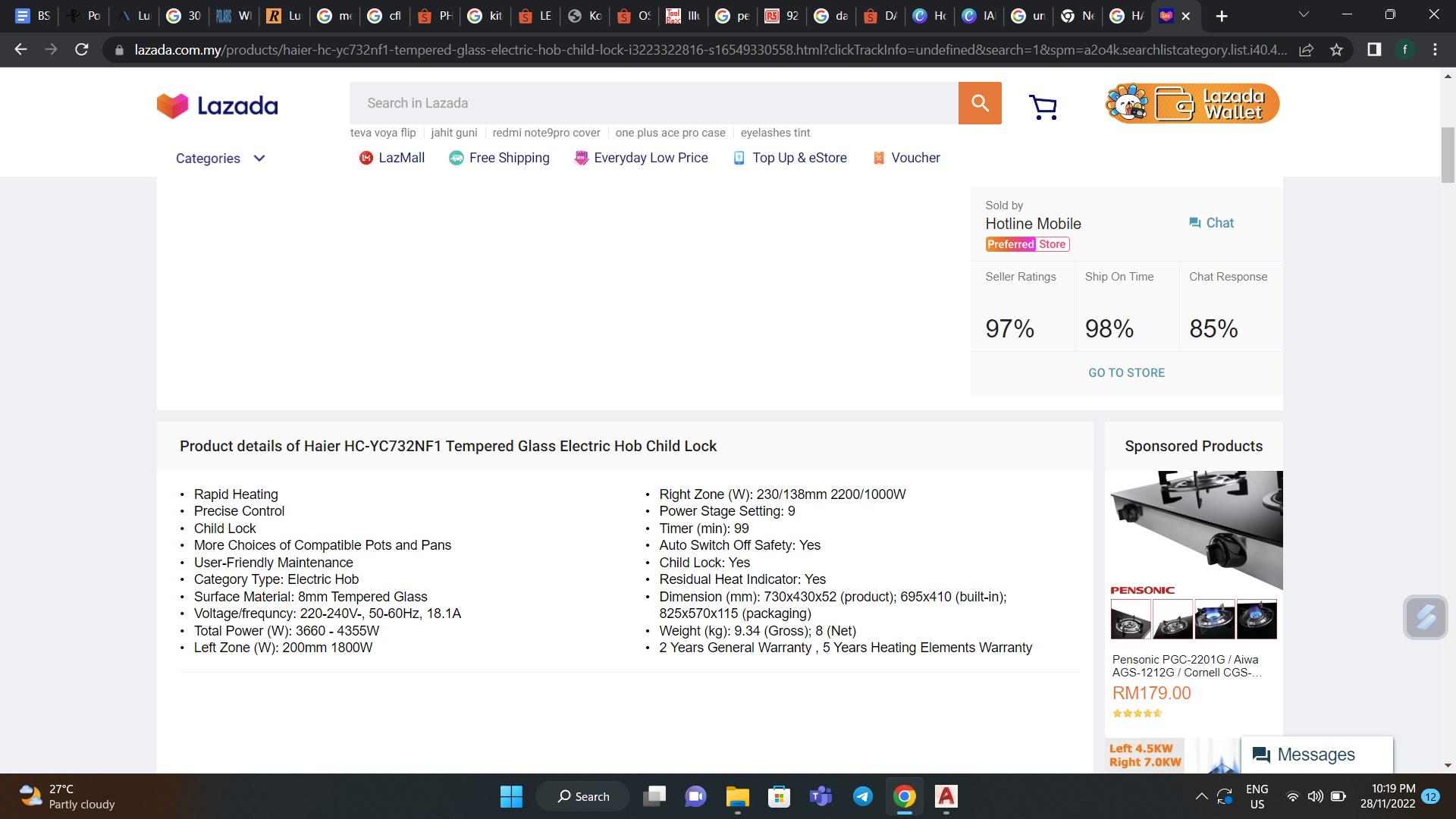

Daikin FTKG-Q Se ie FTKG50Q/RKG50

Q an i : 1

Wa : 1200 w = 1.2kW

Dail ime e: 6 ho

Dail ene g con me: 1.2kW 6h = 7.2kWh Mon hl : 7.2kWh 30 da = 216kWh

LED Do nligh Cool hi e NNV70048WE1M

Q an i : 2

Wa : 15 =0.015kW

Dail ime e: 0.5 ho

Dail ene g con me: 2 0.015kW 0.5h = 0.015kWh

Mon hl : 0.015kWh 30 da = 0.45kWh

T8 Fluorescent tube light warm white

Q an i : 2

Wa : =18W = 0.018kW

Dail ime e: 13 ho

Dail ene g con me: 2 0.018kW 13h = 0.468 kWh

Mon hl : 0.468kWh 30 da = 14.04kWh

Total kWh per da = 0.576kWh + 0.024 kWh + 1.224kWh + 7.2 kWh + 0.015kWh + 0.468 kWh = 9.507kWh

To al kWh mon hl = 17.28kWh + 0.72 kWh + 36.72kWh + 216kWh + 0.45kWh + 14.04kWh = 285.21kWh

F om he calc la ion, i ho ha p opo ed ligh ing and ac e ipmen e lo e ene g compa ed o c en e ipmen . Thi i beca e e e a i able hp ai cond fo he oom i e, choo e he fan and all he ligh ing e ipmen ha ha lo e a age.

Item Description

Unit Qt Rate (RM) Total (RM)

Source

A-1 HP3616 Adjustable Table Lamp NOS 1 89 89 JLL ElectricaL SDN BHD A-G-3A, Kuchai Exchange, No.43, Jalan Kuchai Maju 13, 58200 Kuala Lumpur, Mala sia.

A-2 LED Downlight Cool white NNV70048WE1M NOS 2 299 598 lmSenheng (Sunwa P ramid) Mass Merchandise Outlets LG2.09 - LG2.11, Lower Ground Two, Sunwa P ramid, No 3, Jalan PJS 11/15, Bandar Sunwa , 46150, Petaling Ja a, Selangor 46150

A-3 T8 Fluorescent tube warm white NOS 1 15.91 15.91 Philips, 29, Jalan Ros Merah 2/12, Johor Ja a, 81100 Johor Bahru, Johor

B-1 Panasonic 56 Inch Ceiling Fan PSNFM14CZVBWH

NOS 1 360 360 Panasonic Mala sia SDN BHD, 2,2A,2B, Jalan Impian Emas 7, Taman Impian Emas, 81300 Skudai, Johor

B-2 Daikin 1.5hp R32 FTKFB Series NOS 1 2029 2029 Kaili Aircon Trading Sdn Bhd Address: 23, Jalan Perlaluan Makmur 74, Taman Damai Ja a, 81300 Skudai, Johor, Mala sia. Total 3091.91

em

A-1 A-2 A-3 B-1 B-2

T cla if , I did hi a ignmen hen i a in bang ja a a ell a hen i'm back in J h Bah d ing eek 8, hence he e a e fe e in Selang and me in J h Bah .

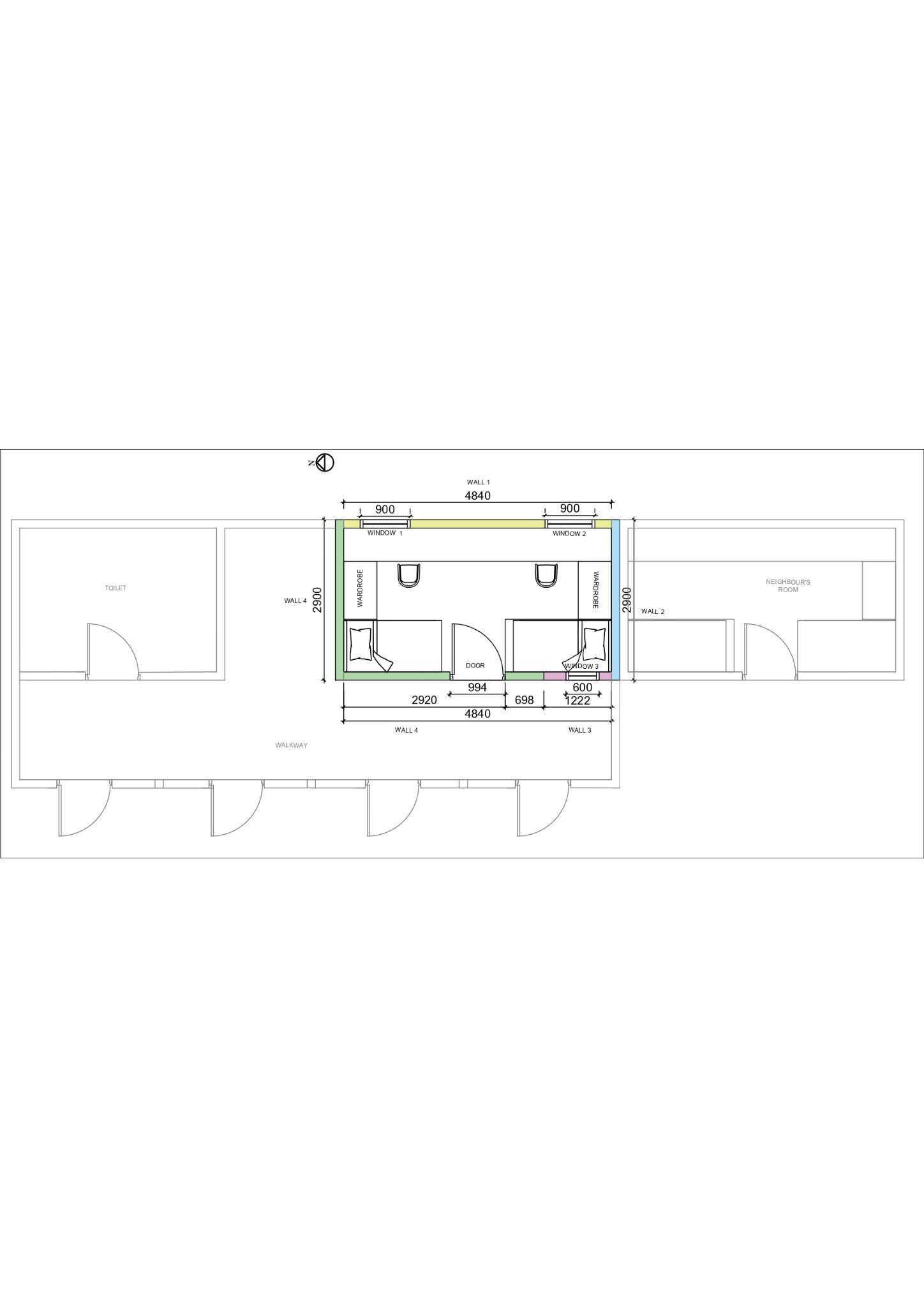

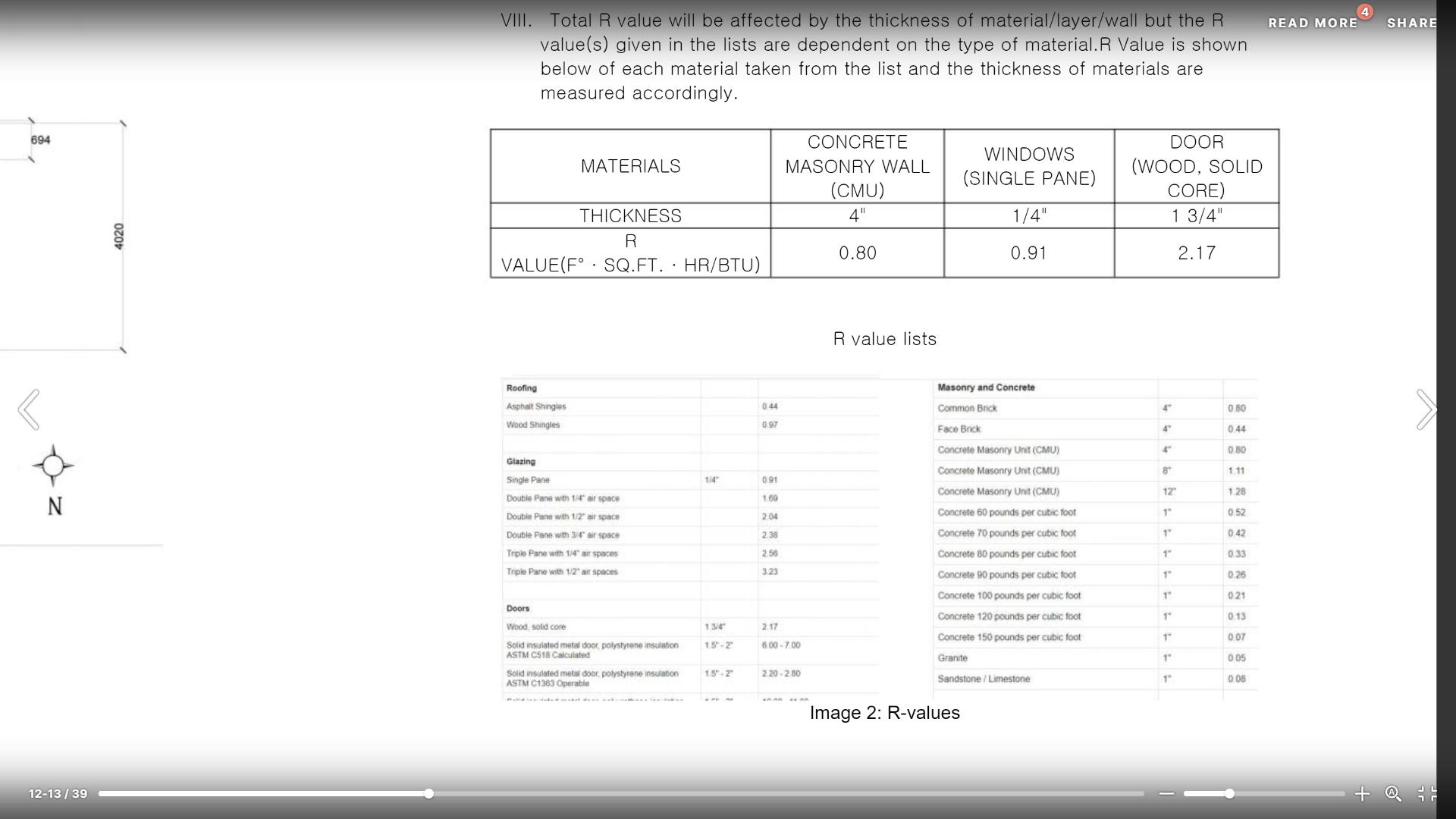

Table of Contents 2

PARTA 3

Floor Plan 3

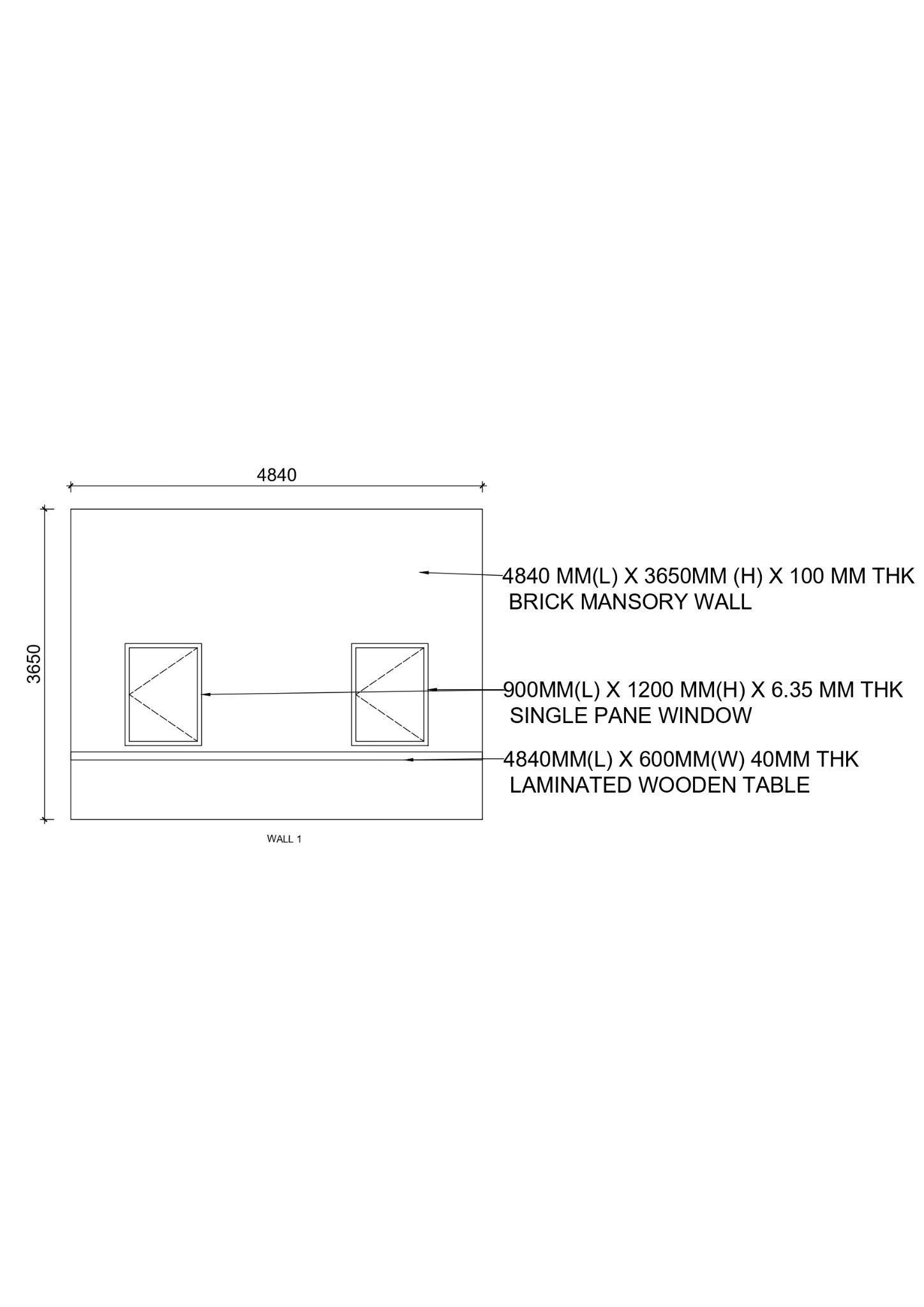

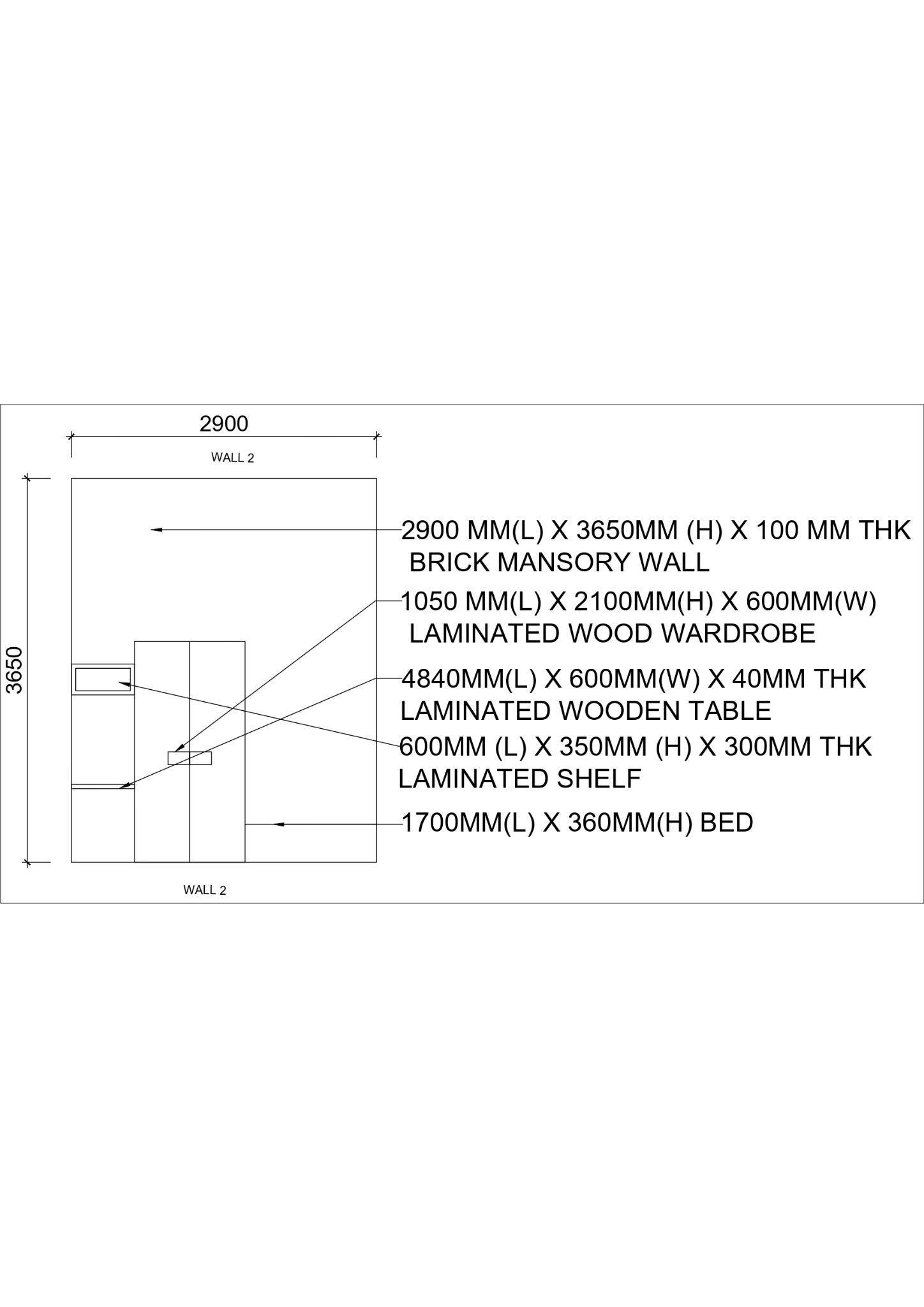

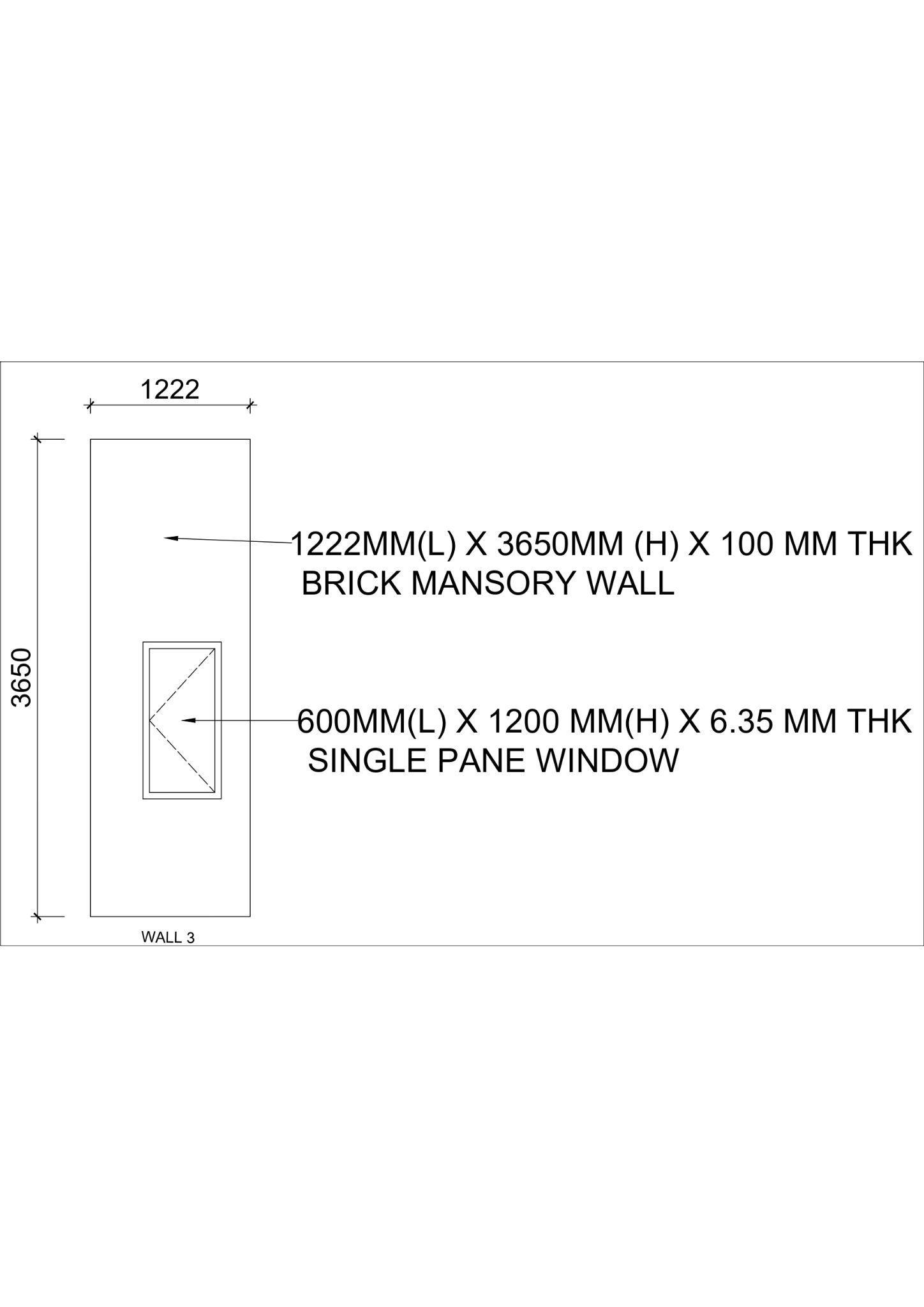

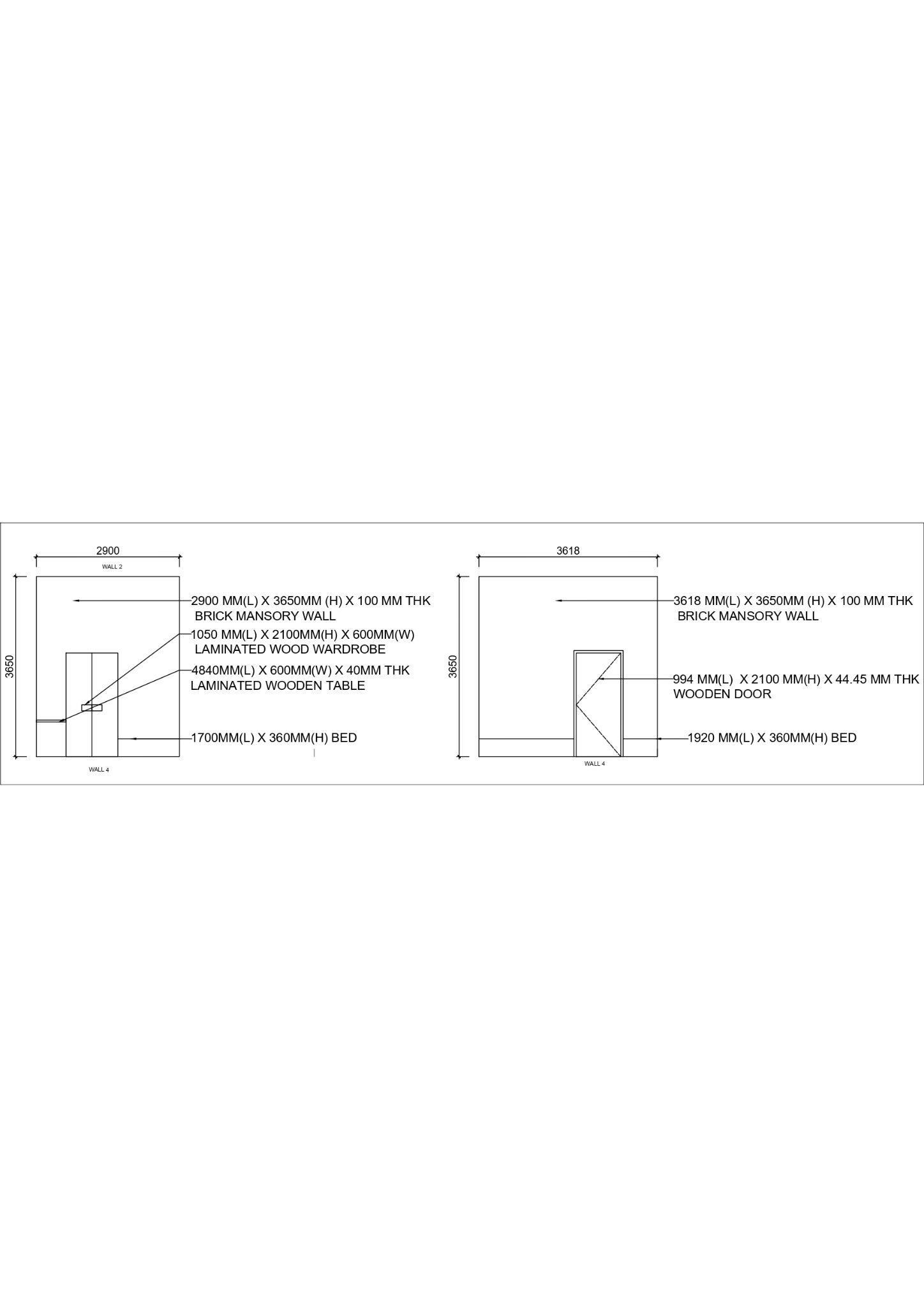

Area of Wall (include window and door) , Door & Window 4

R-Value Table for Building Material 5 Temperature of Wall 6 Calculation of Heat Gain & Heat Loss 6 Wall 1 7 Wall 2 8 Wall 3 9 Wall 4 10 Conclusion 12

PART B 13 Inspiration 14 MaterialAnalysis 15 Process of Making Product 18 Final Prototype 24 Cost of Material 25 Reflection on Financial Value of the Design Idea 26

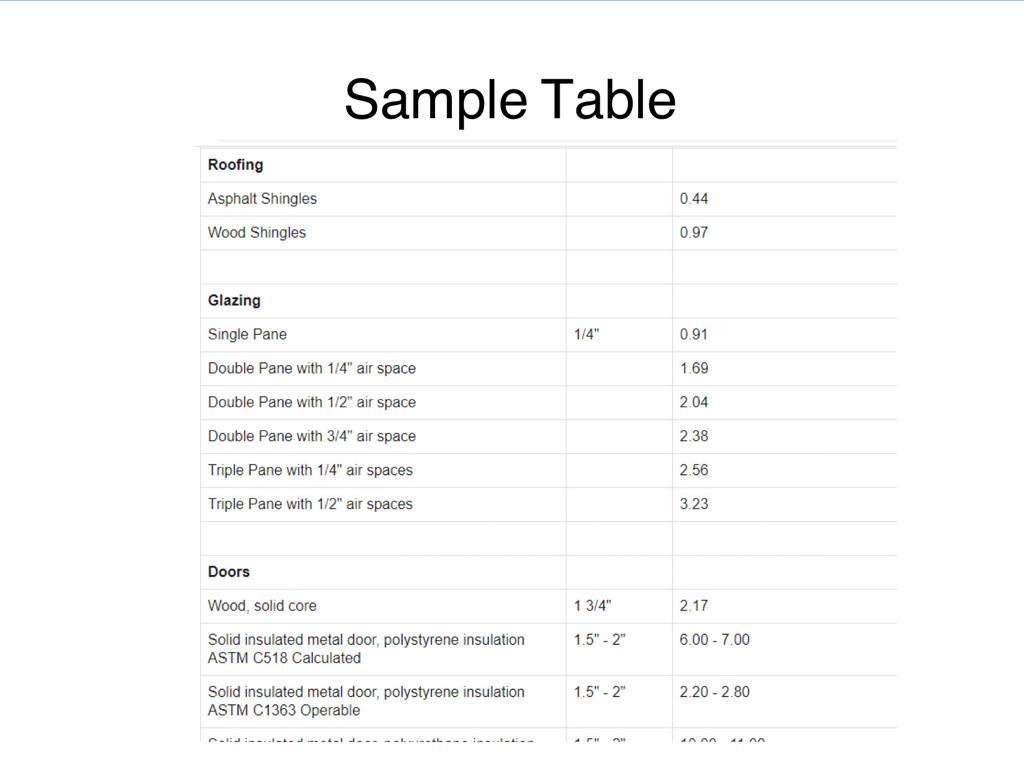

Length Height Area Thickness

Door 994mm = 3 26ft 2100mm = 6 89ft 3 26ft x 6 89ft 22.46����2 44 45mm

Window 1 & 2 900mm = 2 95ft 1200mm = 3 94ft 2 x 2 95ft x 3 94ft 23 25����2 6 35mm

Window 3 600mm = 1 97ft 1200mm = 3 94ft 1 97ft x 3 94ft 7.76����2 6 35

Wall 1 4840mm = 15 88ft 3650mm = 11 98ft 15 88ft x 11 98ft 190 24����2 100mm

Wall 2 2900mm = 9 51ft 3650mm = 11 98ft 9 51ft x 11 98ft 113.93 ����2 100mm

Wall 3 1222mm = 4.01ft 3650mm = 11.98ft 4.01ft x 11.98ft 48 04����2 100mm

Wall 4 6518mm = 21 38 3650mm = 11 98ft 21 38ft x 11 98ft 256.13����2 100mm

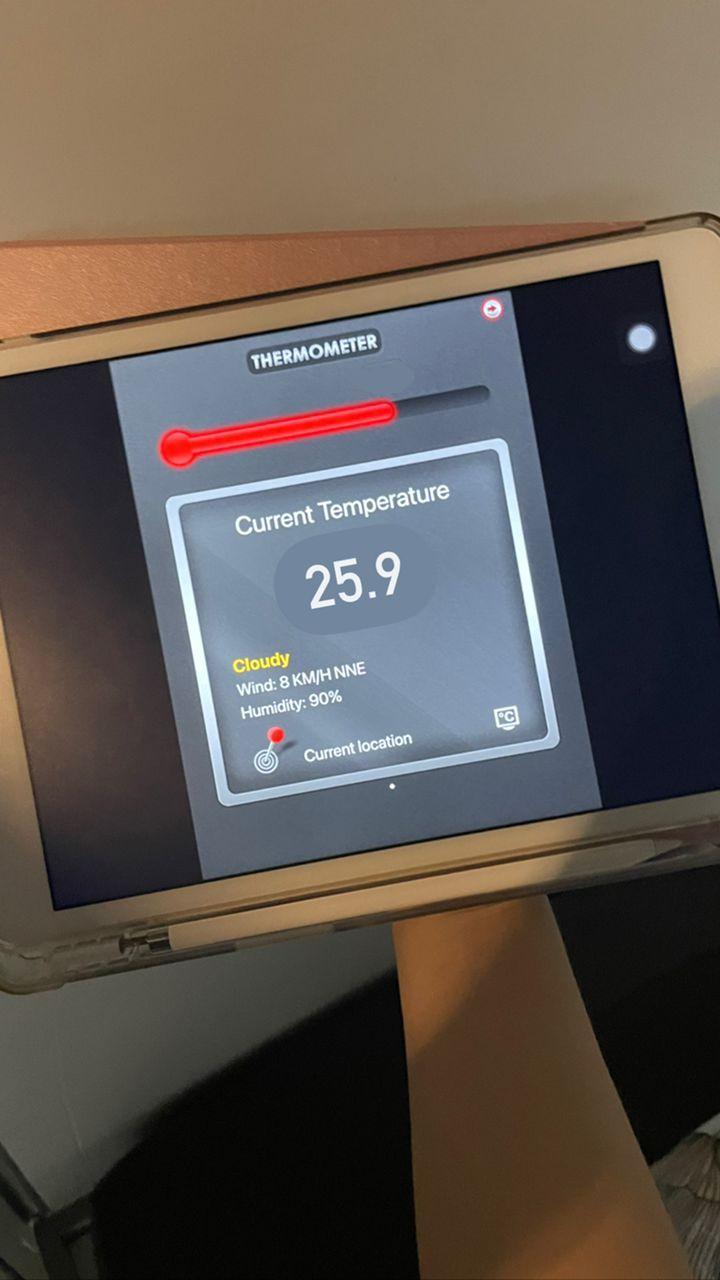

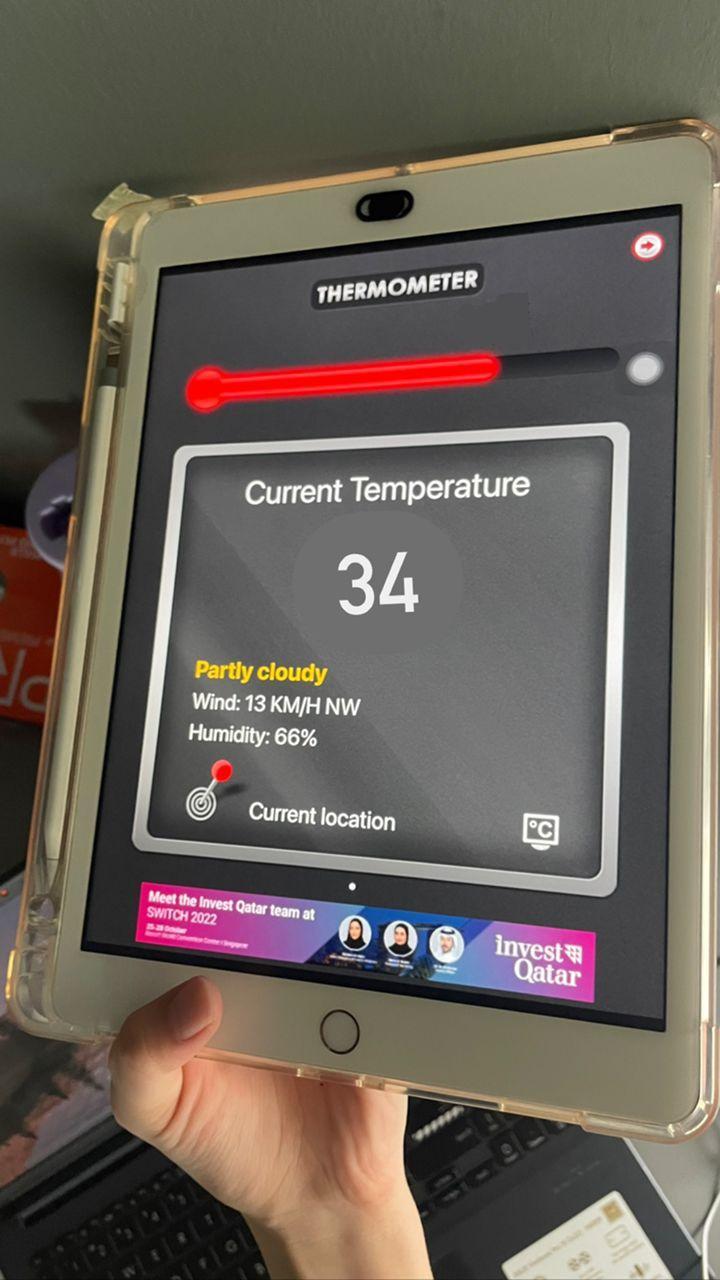

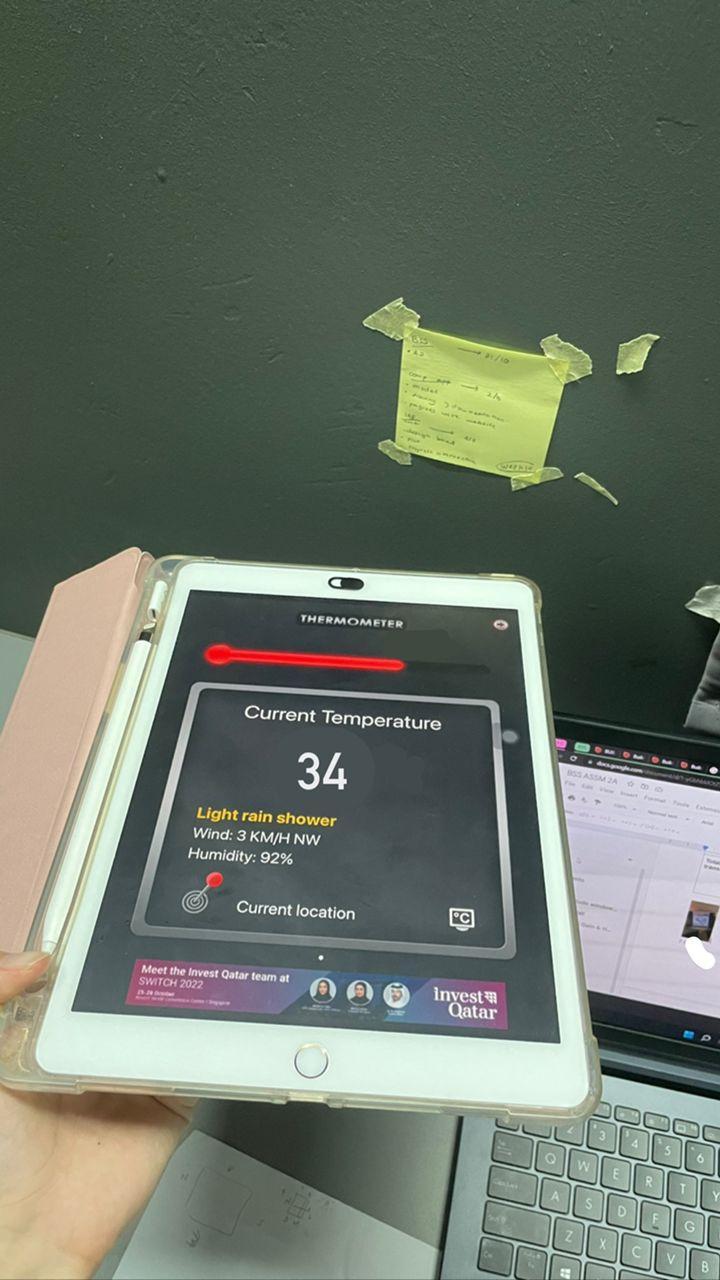

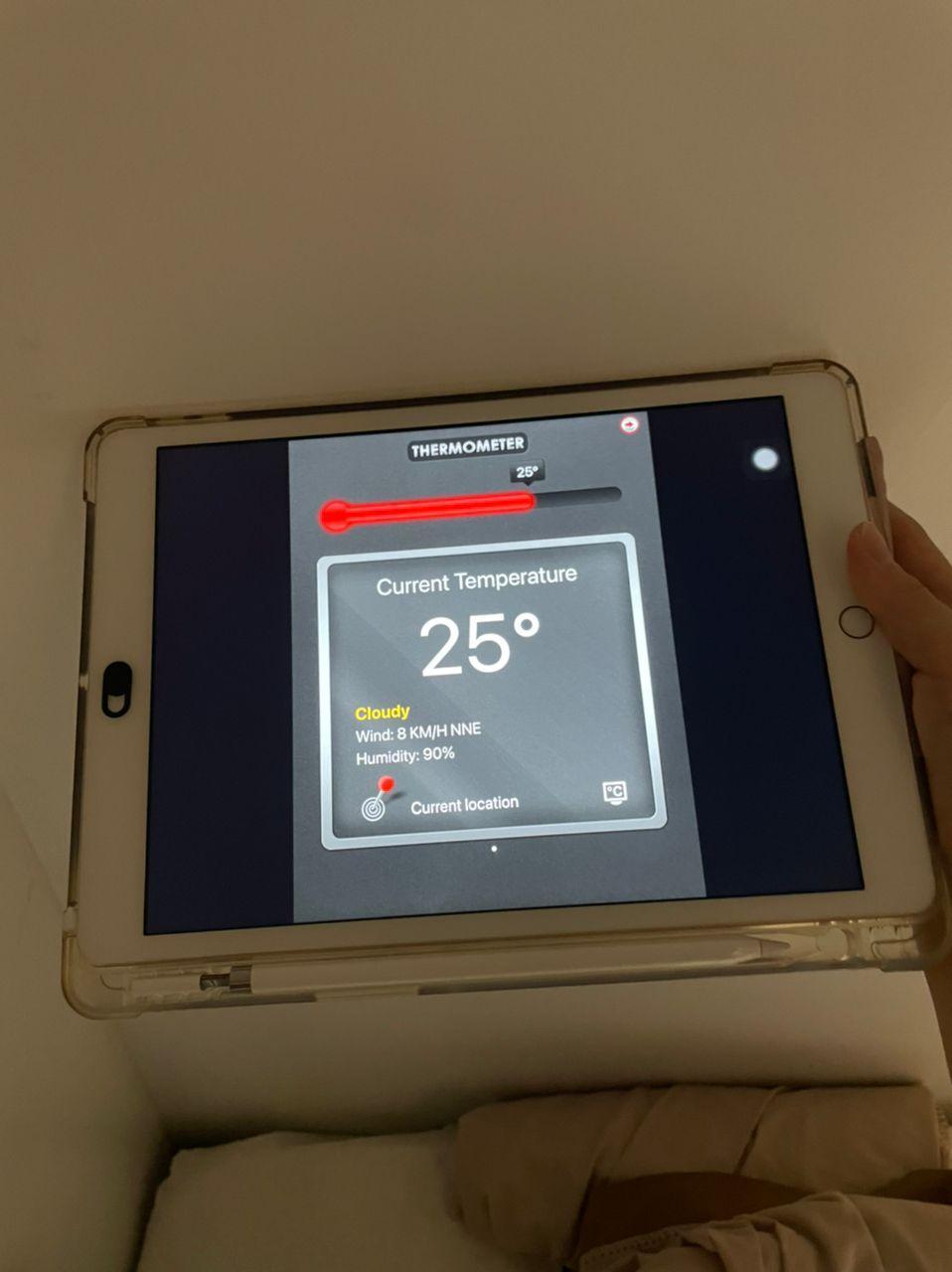

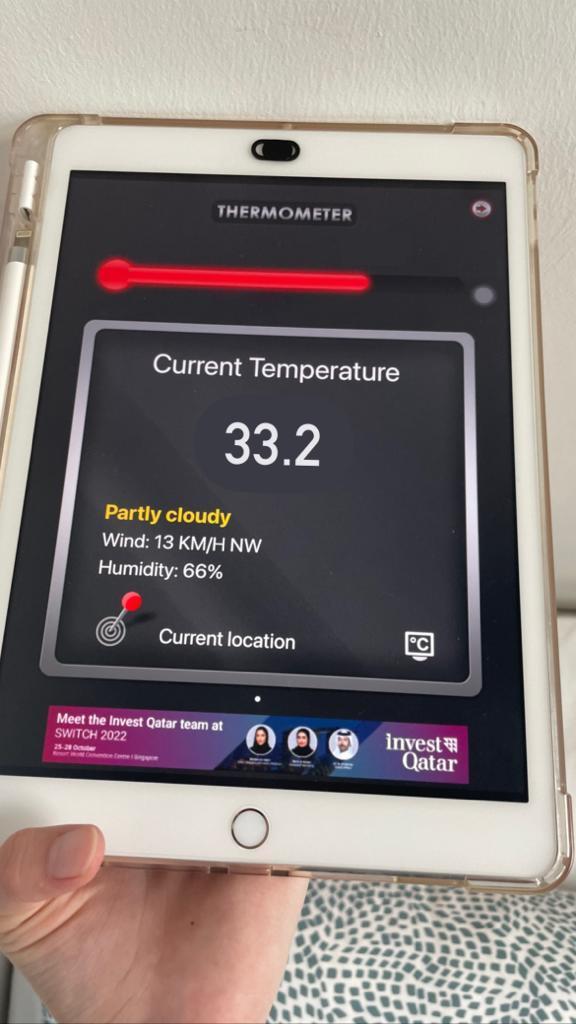

Temperature of Wall

7am 12pm 5pm

Wall 1 25.9°C = 78.62°F 34°C = 93.2 °F 30.1°C = 86.18°F

Wall 2 25°C = 77°F 33.2 °C = 91.76°F 29.5°C = 85.1 °F Wall 3 25.4°C =77.72°F 34°C = 93.2°F 32°C = 89.6 °F

Wall 4 25.2°C = 77.36°F 33.7°C = 92.66 °F 29.7°C = 85.46 °F

InternalTemperature 24 °C = 75.2 °F

Calculation of Heat Gain & Heat Loss Equation for conduction q= �� �� ����

Where, q= heat flow, Btu/hr A= area,����2 R= resistance, °F/Btu ����2 ℎ�� T= temperature differential, °F (higher temperature - low temperature)

R for wall 4 = 0.8 R *R value can value refer page 5

InternalTemperature 24 °C = 75 2 °F Time 0700 1200 1700 Temperature 25.2°C = 77.36°F 33.7°C = 92.66 °F 29.7°C = 85.46 °F

Change in temperature, T

Heat transfer rate of Concrete wall 4

77.36°F - 75 2 °F = 2.16 °F 92.66 °F - 75 2 °F = 17.46 °F 85.46 °F - 75 2 °F = 10.26

��1 = 23367����2 08����2 ℎ�� °��/������ �� 2.16°�� = 630 91������/ℎ��

Heat transfer rate of Single-glazin g window

��2 = 2246����2 217 ℎ�� °��/������ �� 2.16°�� = 22.36 Btu/hr

Total heat transfer rate = +��1 ��2 = + 630.91 ������/ℎ�� 22.36 Btu/hr =653.27 Btu/hr

��1 = 23367����2 08����2 ℎ�� °��/������ �� 17.46°�� = 5099 85������/ℎ��

��2 = 2246����2 217 ℎ�� °��/������ �� 17 46°�� =180.72 Btu/hr

= +��1 ��2 =5099.85������/ℎ�� + 180.72 ������/ℎ�� = 5280.57 Btu/hr

��1 = 23367����2 08����2 ℎ�� °��/������ �� 10.26°�� = 2996 82������/ℎ��

��2 = 2246����2 217 ℎ�� °��/������ �� 10 26°�� =106.19 Btu/hr

= +��1 ��2 = + 2996.82������/ℎ�� 106.19 Btu/hr = 3103.01 Btu/hr

7am 12pm 5pm

Wall 1 (EAST) 801.26 Btu/hr 4217.17 Btu/hr 2568.29 Btu/hr

Wall 2 (SOUTH) 256 34������/ℎ�� 2358 35������/ℎ�� 1409.88 Btu/hr

Wall 3 (WEST) 148.37Btu/hr 1059.79 Btu/hr 847.84 Btu/hr

Wall 4 (NORTH & WEST) 653.27 Btu/hr 5280.57 Btu/hr 3103.01 Btu/hr

In conclusion, from the table, we can see that at 7 in the morning, wall 1 which is facing the east has the highest heat transfer which is 801.26Btu/hr.This is because this wall receives heat from sunlight in the morning. While for 12 pm and 5pm, wall 4 has the highest heat transfer rate which is 5280.57 Btu/hr and 3103.01 Btu/hr Wall 3 has the lowest heat transfer rate for all three timings because it has the smallest area compared to the other 3 walls.From the observation, wall 4 has highest heat rate transfer, this depends on the area of the wall, thickness of the door and r value for each material. From the table, we can also conclude that the heat transfer rate is higher in the evening compared to in the morning, as it is hotter in the afternoon than in the morning.

Based on the calculation, I can identify that wall 4 which is facing the north and west is the critical wall as it has a higher heat transfer rate compared to the other 3 walls However, there is nothing I can do with that wall since it is facing the walkway in my house and there is no window at that wall. There’s also nothing I can do to wall 2 since it is connected to my neighbour’s room As for wall 3, Therefore, I have chosen Wall 3 even though it has the lowest heat transfer rate compared to all the other walls but for me out of all the walls, this wall gives the most inconvenience to me. Since my built-in bed is placed and attached to the wall 3 where a window is located exactly where a window is placed In the morning the lighting from that window will always disturb me and cause me to wake up earlier, this also causes disturbance to me when I want to have a nap in the afternoon Moreover, since this wall is facing the outside, it's hard for me to sleep as the position of the bed causes me to sleep near the wall and I feel so uncomfortable and hot whenever I lay on the bed sound

Windshield sun shades (also known as sun car shades, sun shields, heat shields, or UV shields) are protective shields attached to a car's windshield or side window to keep the sun from reaching the interior and help reduce the temperature inside it

Typically, sun shields are made of a layer of mylar or aluminium foil which covers the inside of the car's windows, to reflect the sun's rays away, and preventing the interior from being exposed to those rays

To solve the sound insulation problem, the studio room is one of my inspirations. Acoustic foam tiles, sound absorption panels, and bass traps (acoustic energy absorbers designed to damp low-frequency sound energy) are the best way to outfit your roomThe cheapest way to soundproof a wall is to use thick blankets and quilts To block outside noise, put blankets over the walls, doors, or windows, depending on where the sound is coming from. To keep the sound in, hang blankets on both sides of the doors or inside walls

Aluminium (Heat shield aluminium foil)

This material can reflect sunlight and thermal radiation from sunlight Silver colour is a good reflector of heat, and the smooth surface eases heat deflect off the surface Hence heat gain from the wall and window can be reduced It is also durable and lightweight

Cardboard is actually a great insulator as it has poor thermal conductivity because of its double walls and its molecular makeup. These are used to keep heat from transferring between objects or locations Cardboards can trap heat very efficiently Besides, it is firm , easily cut and assembled, and it is cheaper. It is a common biodegradable and recyclable waste

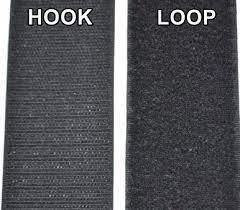

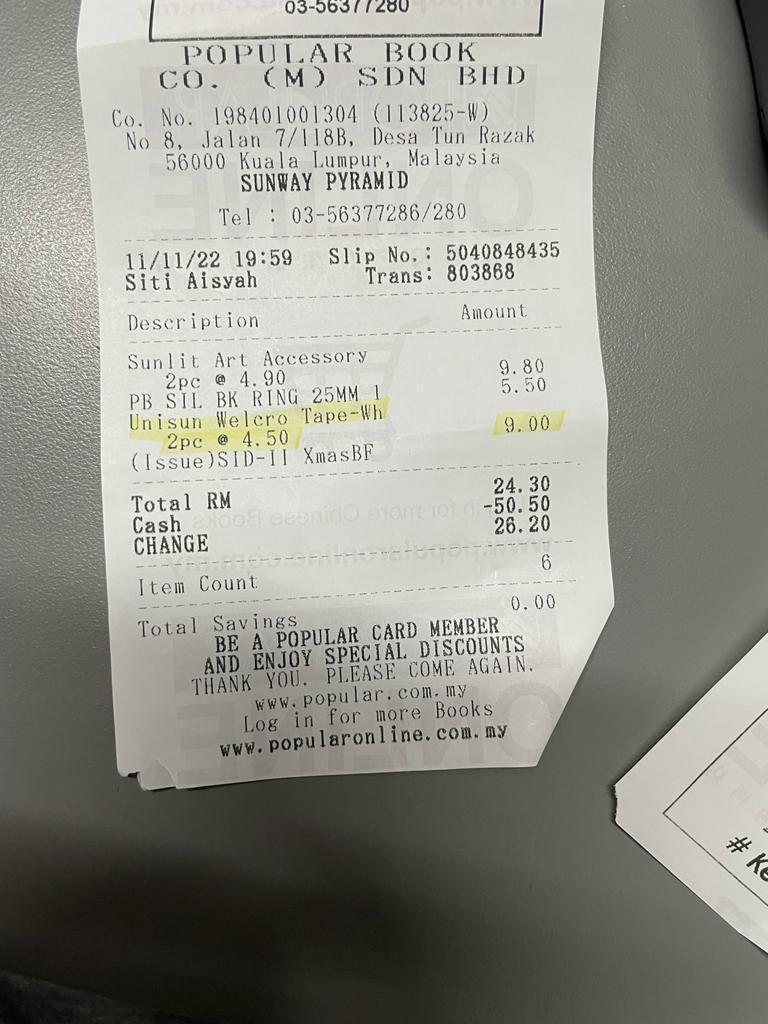

This material is chosen to stick the two boards with each other Velcro has great strength and low maintenance One of its greatest advantages is the ease of use Hook and loop are locked together with just a press of the material Velcro’s hook and loops are commonly made from nylon and polyester with the hools being more rigid and thicker than the loops Hence, hook and loop is a great fastener

Velcro MagicTape

Velcro MagicTape

This material is added to overcome the acoustic issue They are made of tightly-woven strains of fibres that act as a natural barrier against sound When sound encounters a towel, it is absorbed by its fabric, preventing the sound from travelling

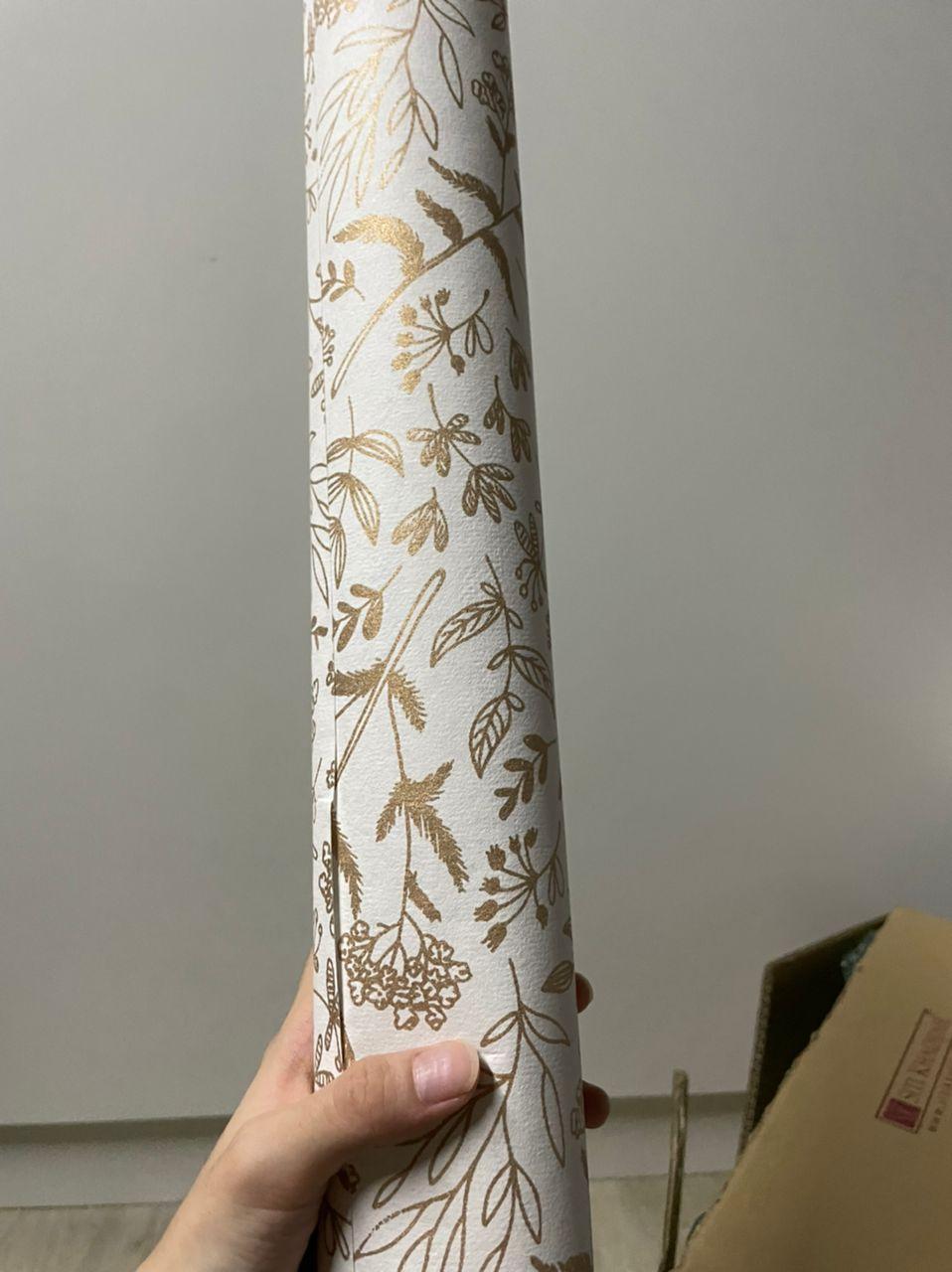

Wrapping paper

To wrap the old recycle board to make it more pleasant looking

This is used to hang the panel on the curtain railing This material will not cause stain traces to the wall The application is as simple as looping over a bar or hook The s-shaped allows for even weight distribution.

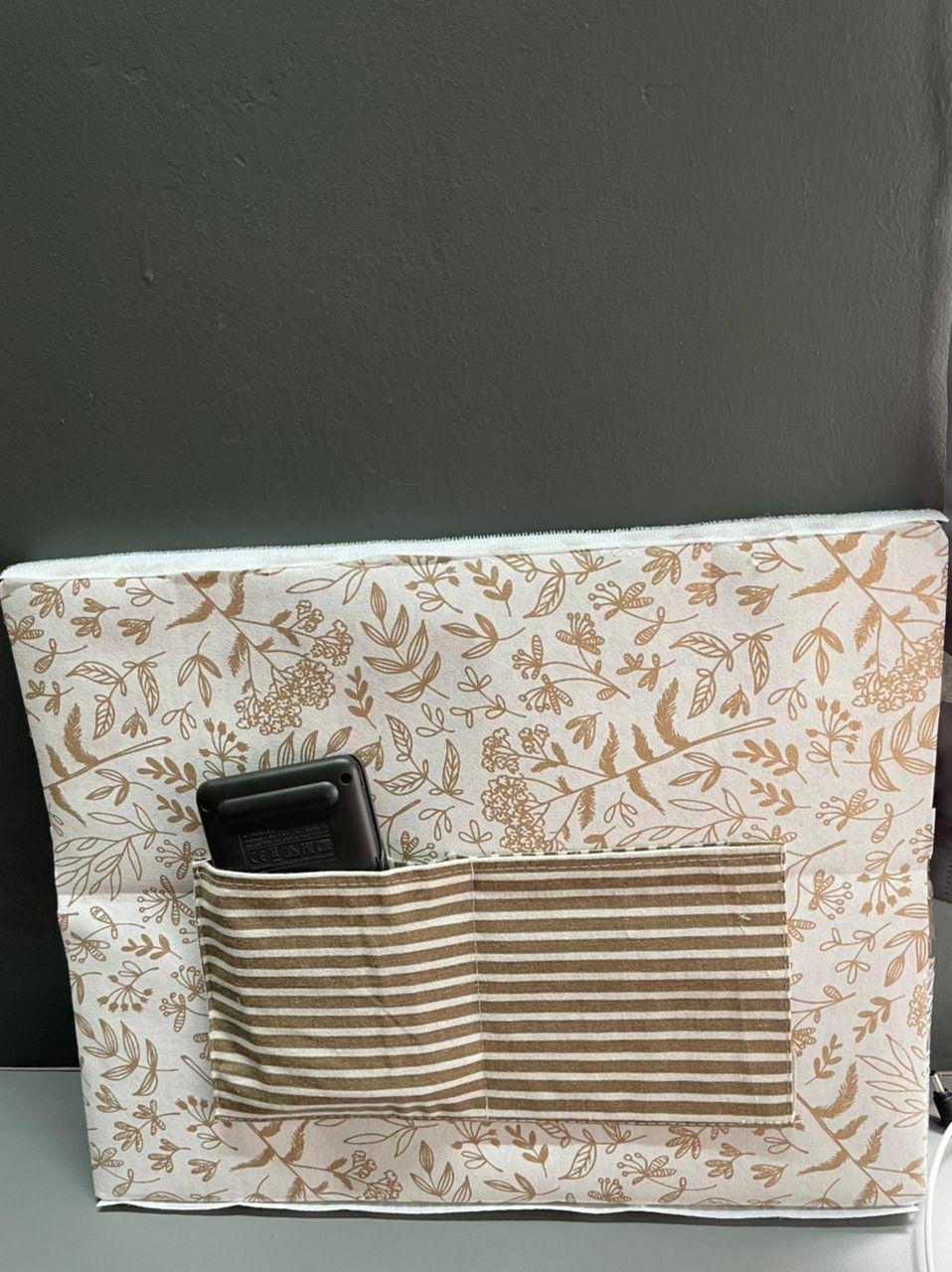

Fabric (recycle) Using this old fabric to create a pocket at the board to store things There is no table near the window to store things so this pocket will solve the problem I can place my spectacles in the pocket instead of walking to my study table to put my spectacles

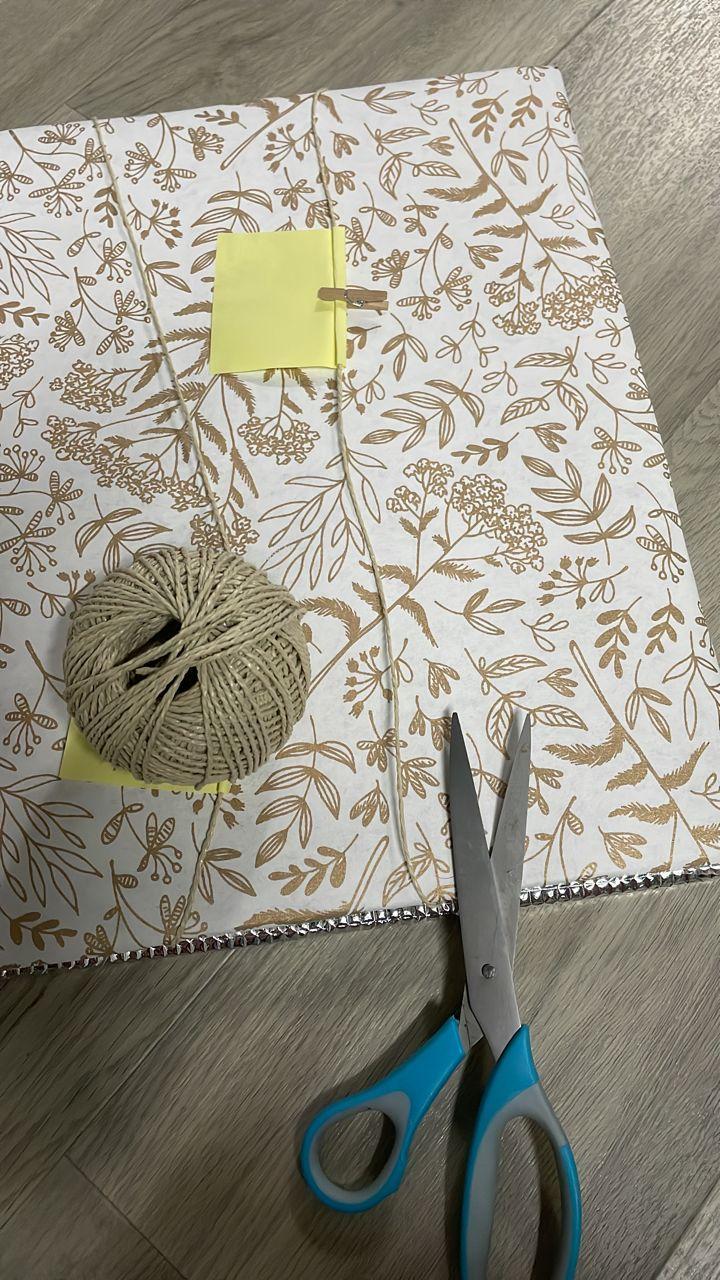

Natural Jute String String will be attached to the front part of the board so it can be used to hang important notes using clips

Small clips (recycle) Clips are used to clip paper on the string so it can hold the paper in place

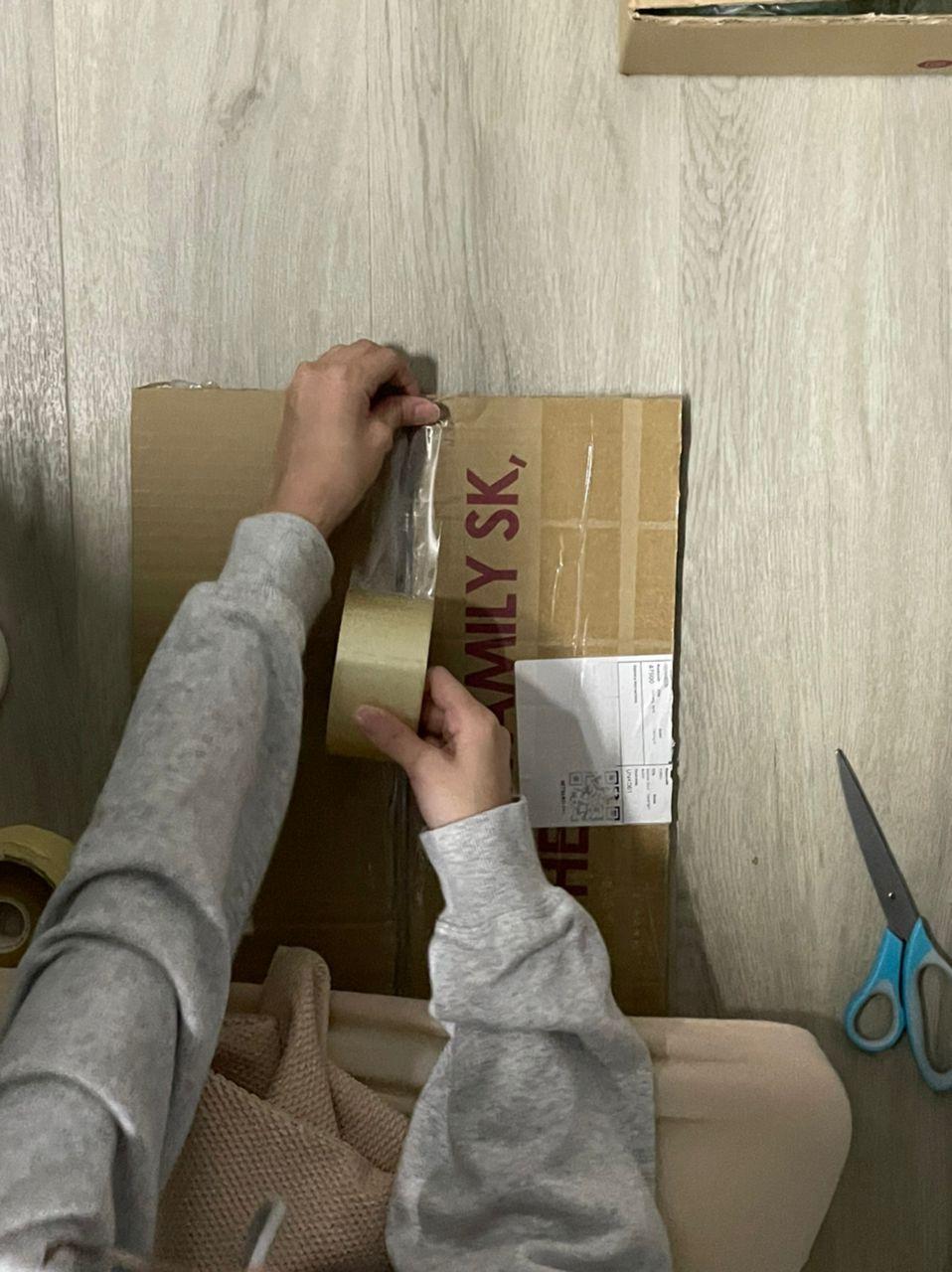

1 Measure and cut the boards and attach it with sellotape to create a bigger size of board since im using a recycle board so it's hard to get exact measurement from the board.

2 Measure, cut the wrapping paper according to the size of the boards The wrapping paper is then wrapped around the board

3 Measuring the towel and cut it according to the size of the boards The towel is then attached to the board using hot glue gun

Preparation of Board B (3rd layer)

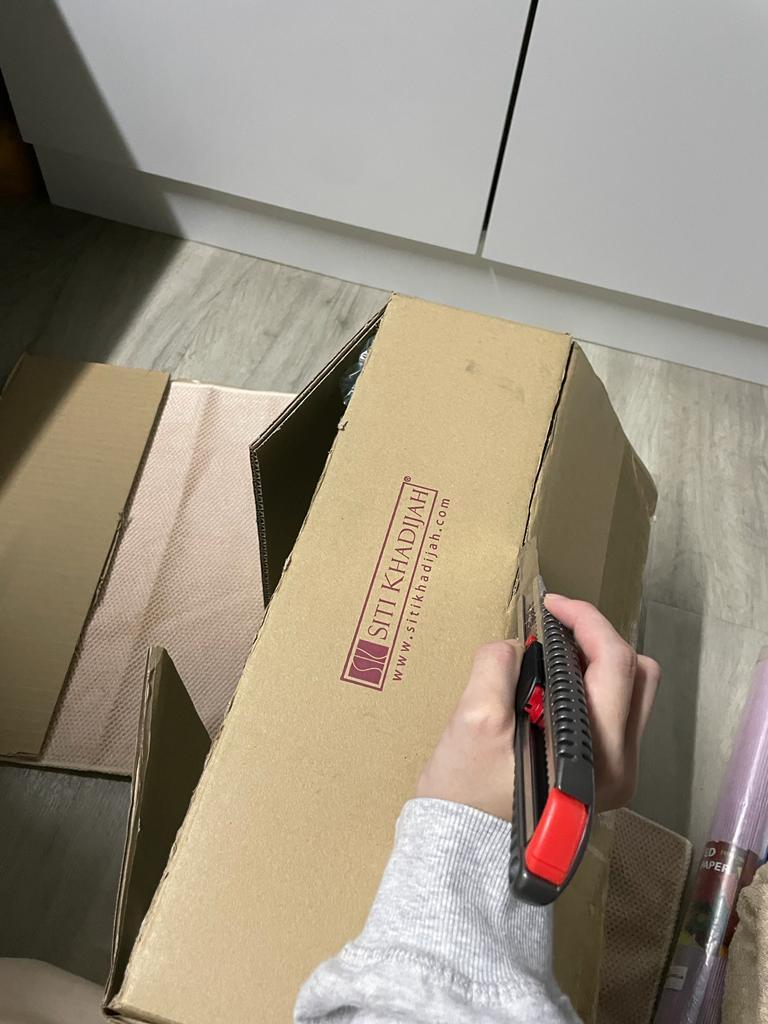

4 The second board is being measured, cut according to the size required

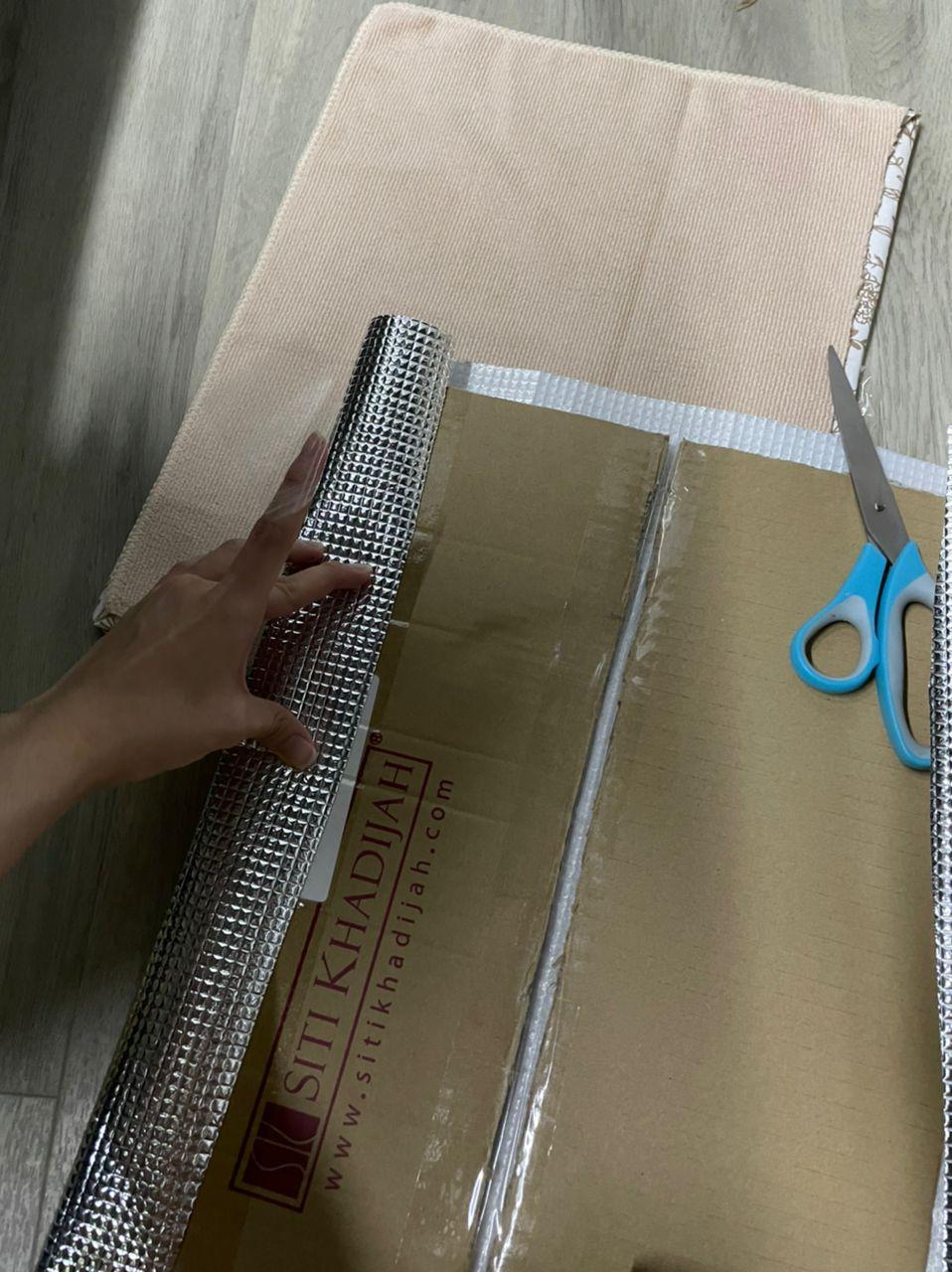

5 Aluminium mat is being measured, cut and wrapped around board B

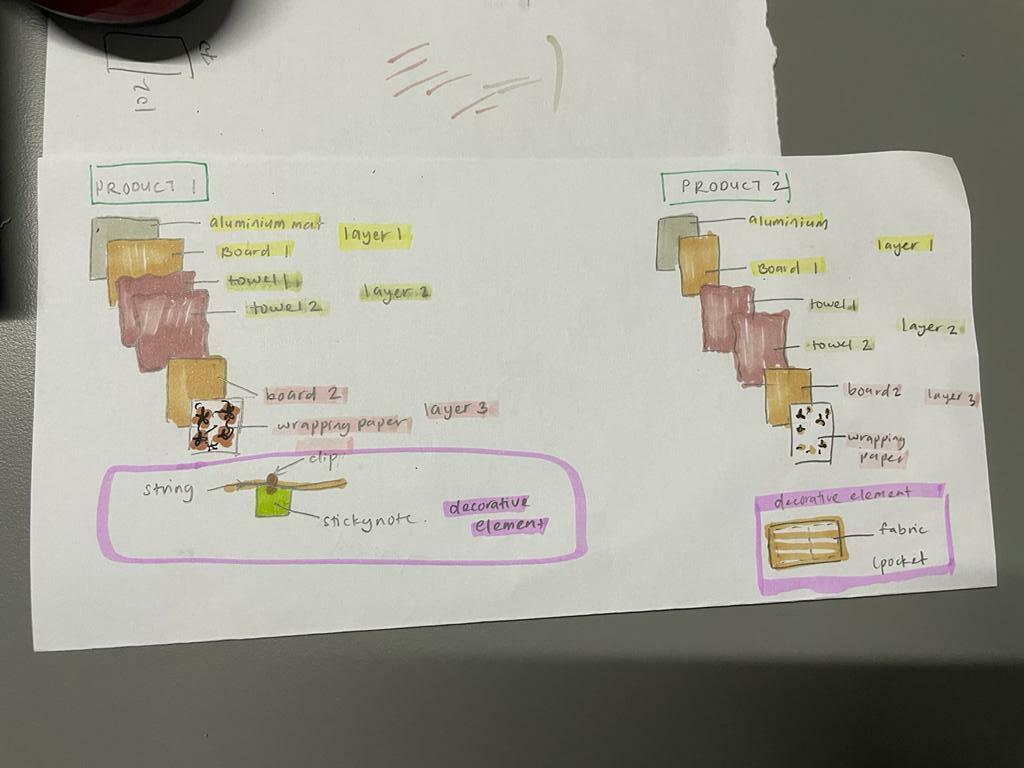

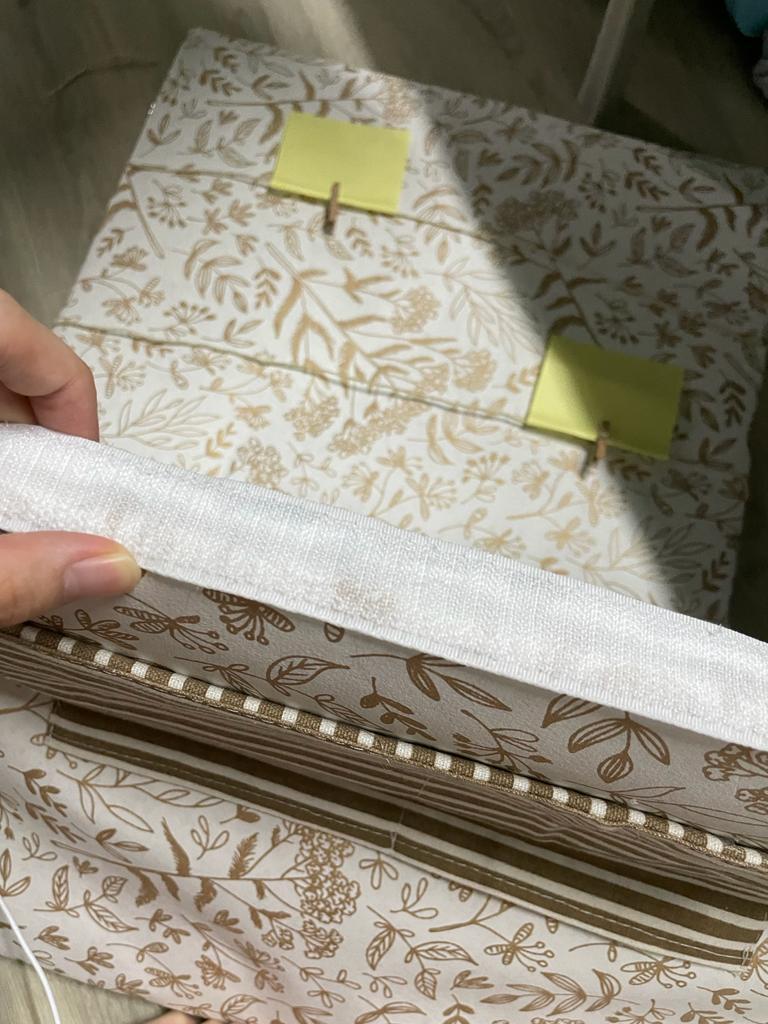

This image is to show the layering of all the material

6 All the materials are stick together using hot glue gun

Decorative element

7 Strings are added to the board for minor function

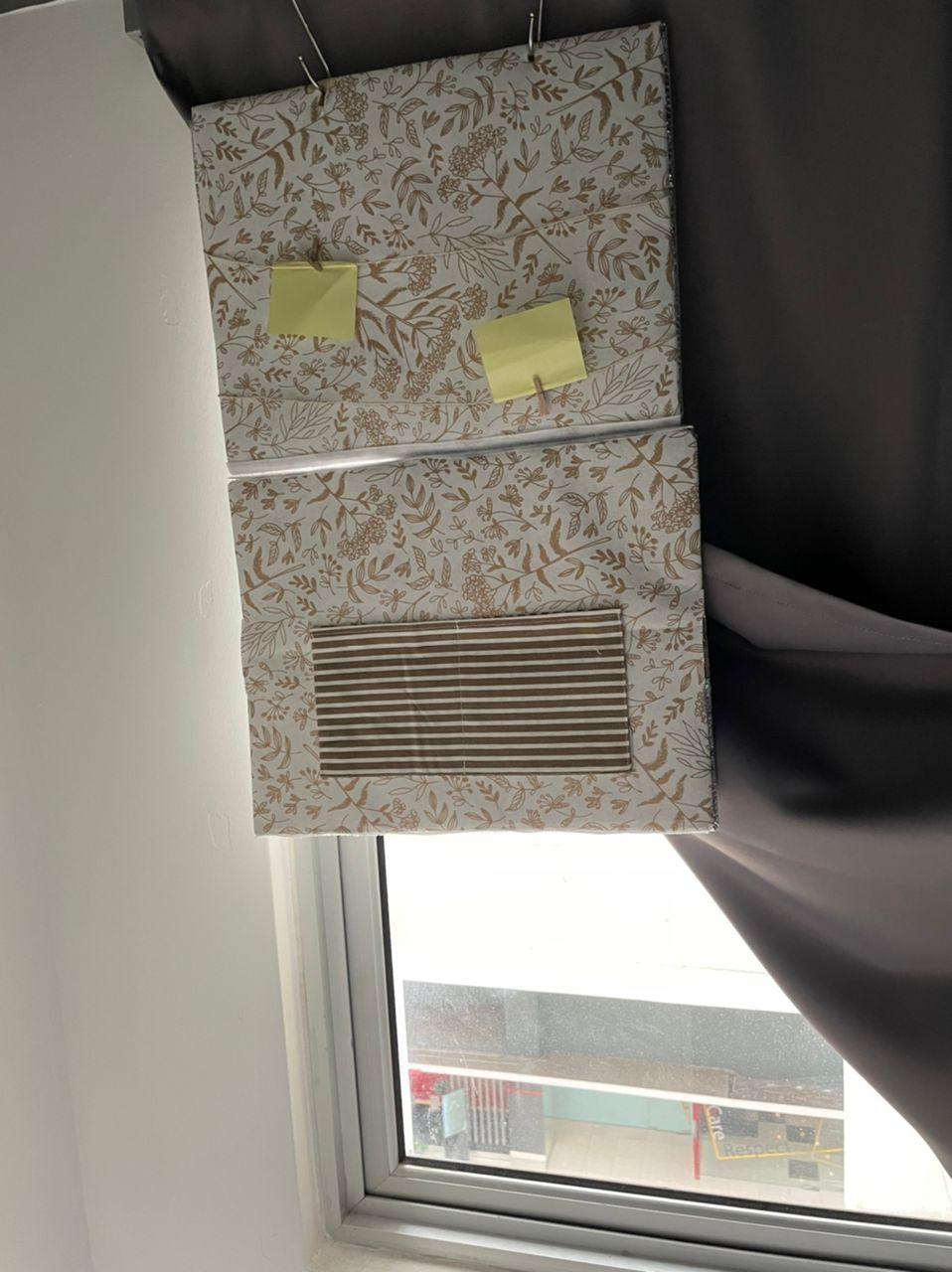

8 The board being punch with two holes to place the s hooks that function as a hook to the window

9 Process 1 to 6 is repeated for Product 2

10 Recycled fabric is cut and stuck using a hot glue gun to make it as a pocket

10 Product 1 and 2 are attached together by velcro tape

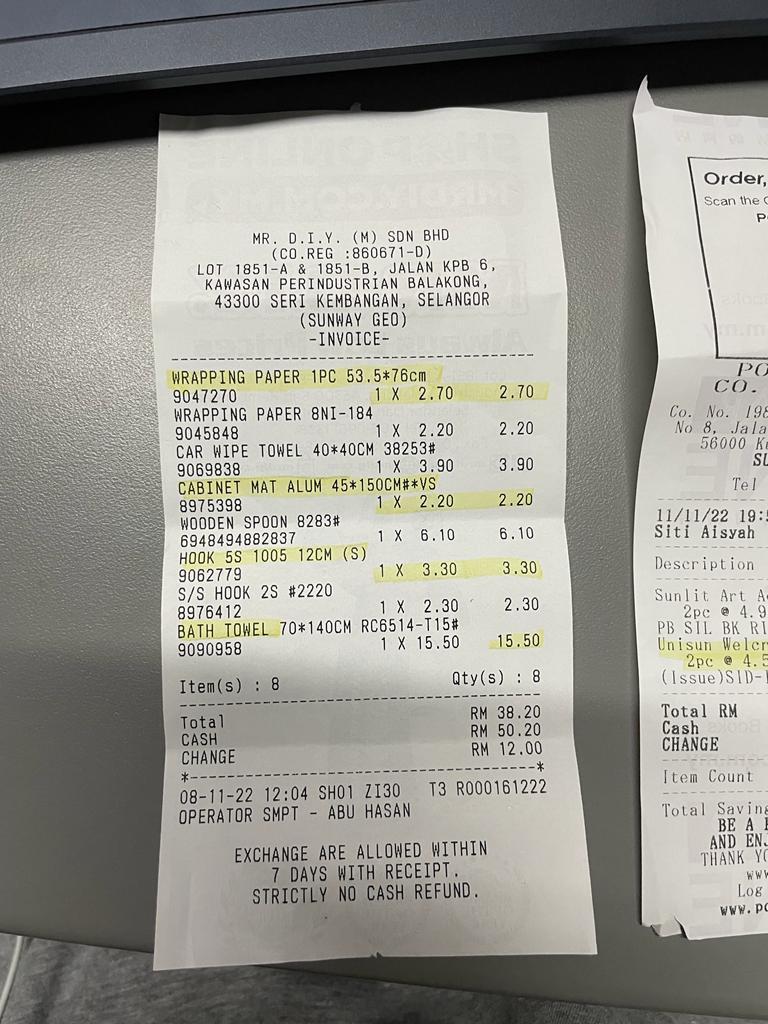

Material Cost

1 Aluminium (Heat shield aluminium foil) 45 cm x 150cm

RM 2 20

2 Corrugated Cardboard (recycle) Free (recycle) 3 Velcro MagicTape 1 meter RM 4 50 4 Towel 70cm x 140cm RM 15 50

5. Wrapping paper 53.5 cm x 76cm RM 2.70

6 S Hook 12cm RM 3 30 for 5 pieces 2 pcs = RM 1 32 7 Natural Jute String Free (recycle) 8. Small clips Free (recycle)

Total RM 26 22

Design Value

=Total Market Rating Price by audience/TotalAudience - Cost of Materials

= RM 737/29 - RM 26.22

= RM 25 41 - RM 26 22

= RM (- 0 81)

After calculating the design value, the average market rating price by the audience is RM 25.41 while the actual cost is RM26.22. This means that I have a negative value for my design value which is -RM 0 81 One of the things that I realised, when I bought the material, I did not actually do a survey and comparison for the price I just bought the materials especially for the towel, it is a bit pricey because I can get the same towel at a lower price. Secondly, I think that value is low because my product did not allow the user to open it to receive natural light My main aim is to block my window completely from receiving sunlight as it disturbs me the most, and I already receive enough natural light from my other window So for some people, my product will not solve their problem as they might still want to receive light So this might be one of the reasons too From what I learnt, I need to focus and consider other users too, not only on my problem In conclusion, from this assignment, I learnt a lot about how R- value, area of wall and many other factors will affect the heat transfer rate value. I also learn about the materials that help to reduce the heat transfer rate. I am going to use all this knowledge in my future design projects as well as in my daily use But I am still happy with my product as it is actually solving my problem in my room I am still going to use this product in my room. In conclusion, I have a deeper understanding about heat transfer

MOHD NIDZAM

TABLE OF CONTENT 2

Task 1(a) 3

Task 1 (b) 5

B1 1: Building Services design justification 5 A/C sizing calculation 5

Lighting Illuminance level 6

Task 1(c) & 1(d) 13

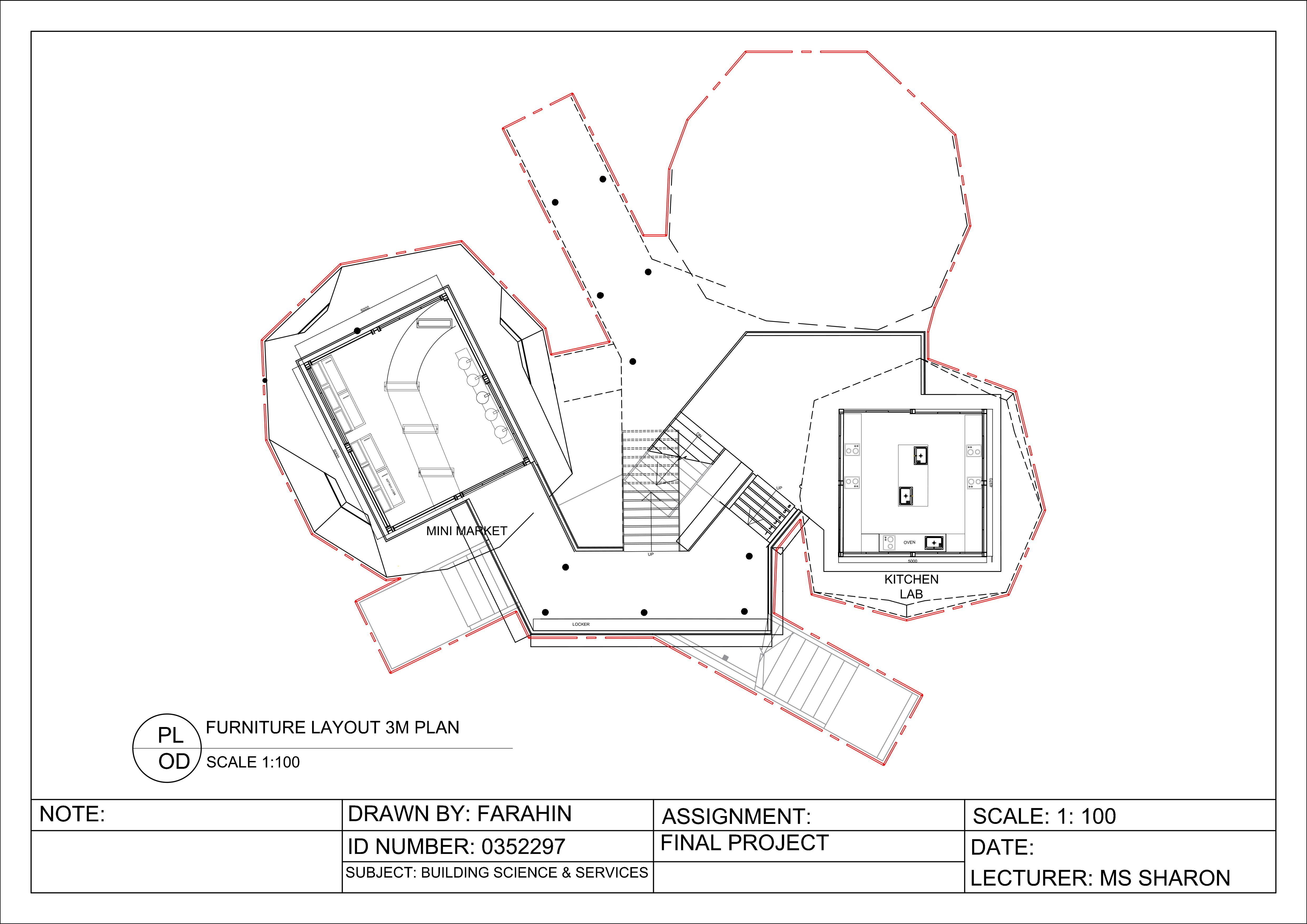

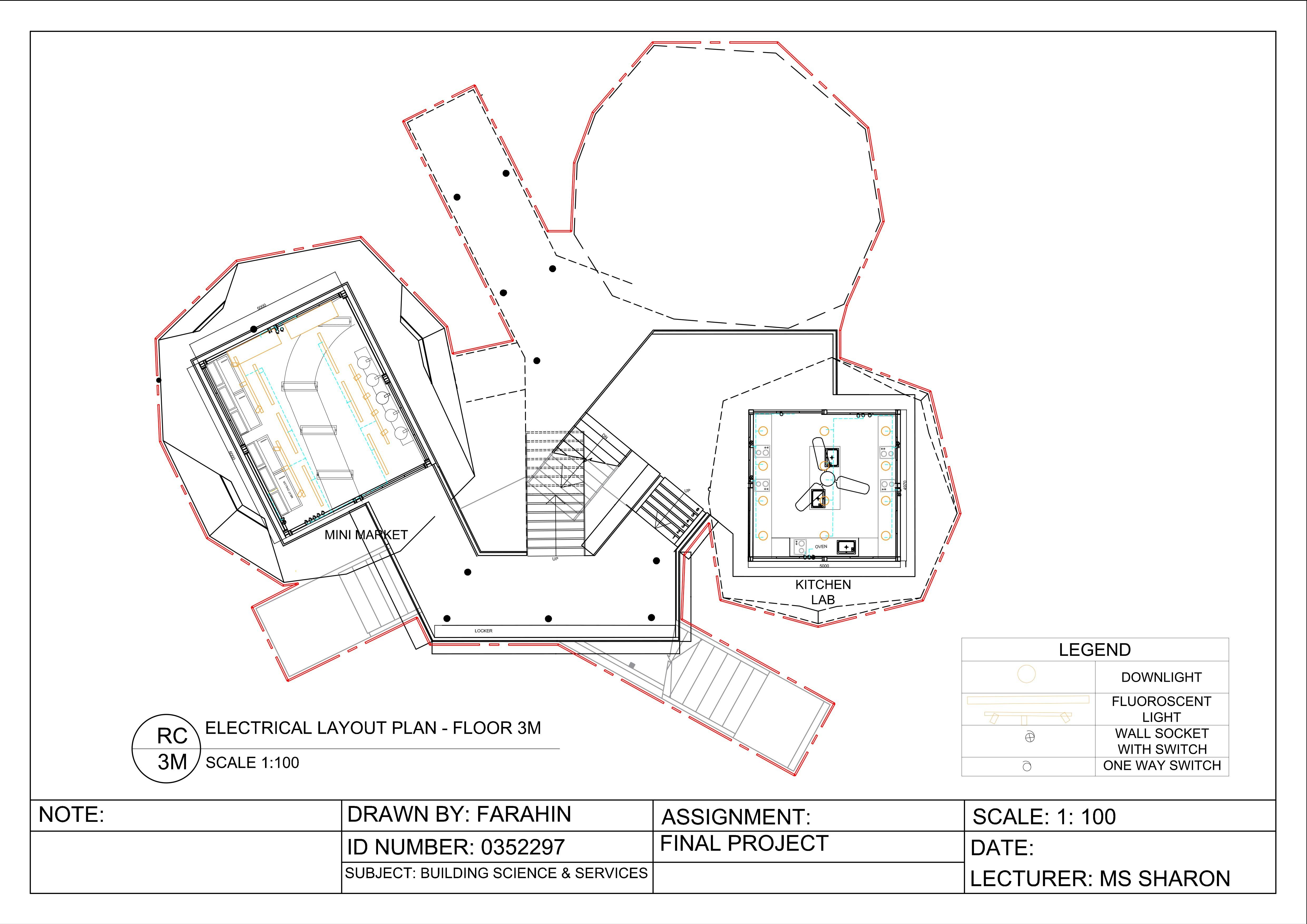

i) Electrical, lighting & VAC 14

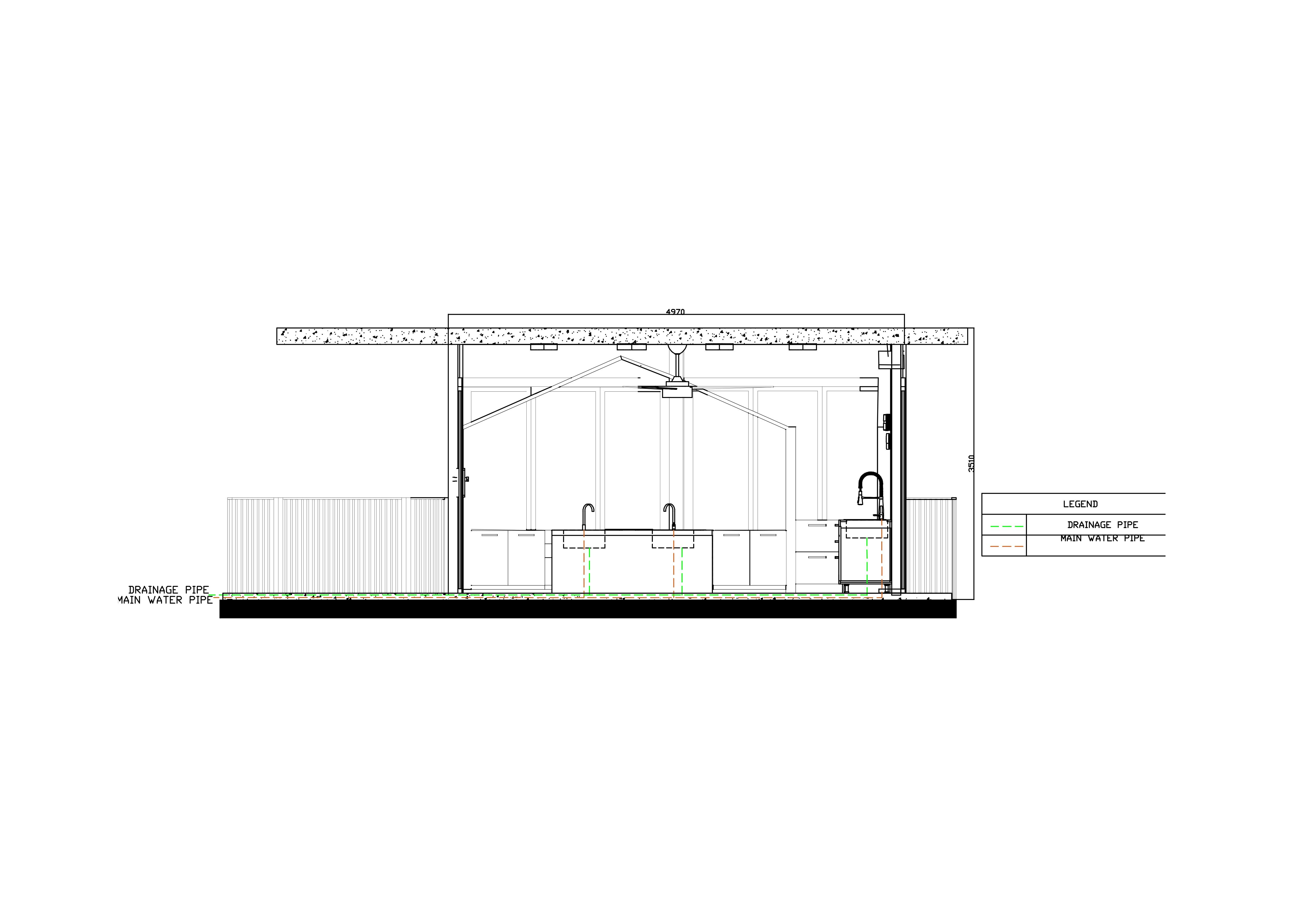

Furniture Layout Plan 14 Electrical Layout Plan 15

ii) Water supply 16 Water piping Layout Plan 16 Elevation 17

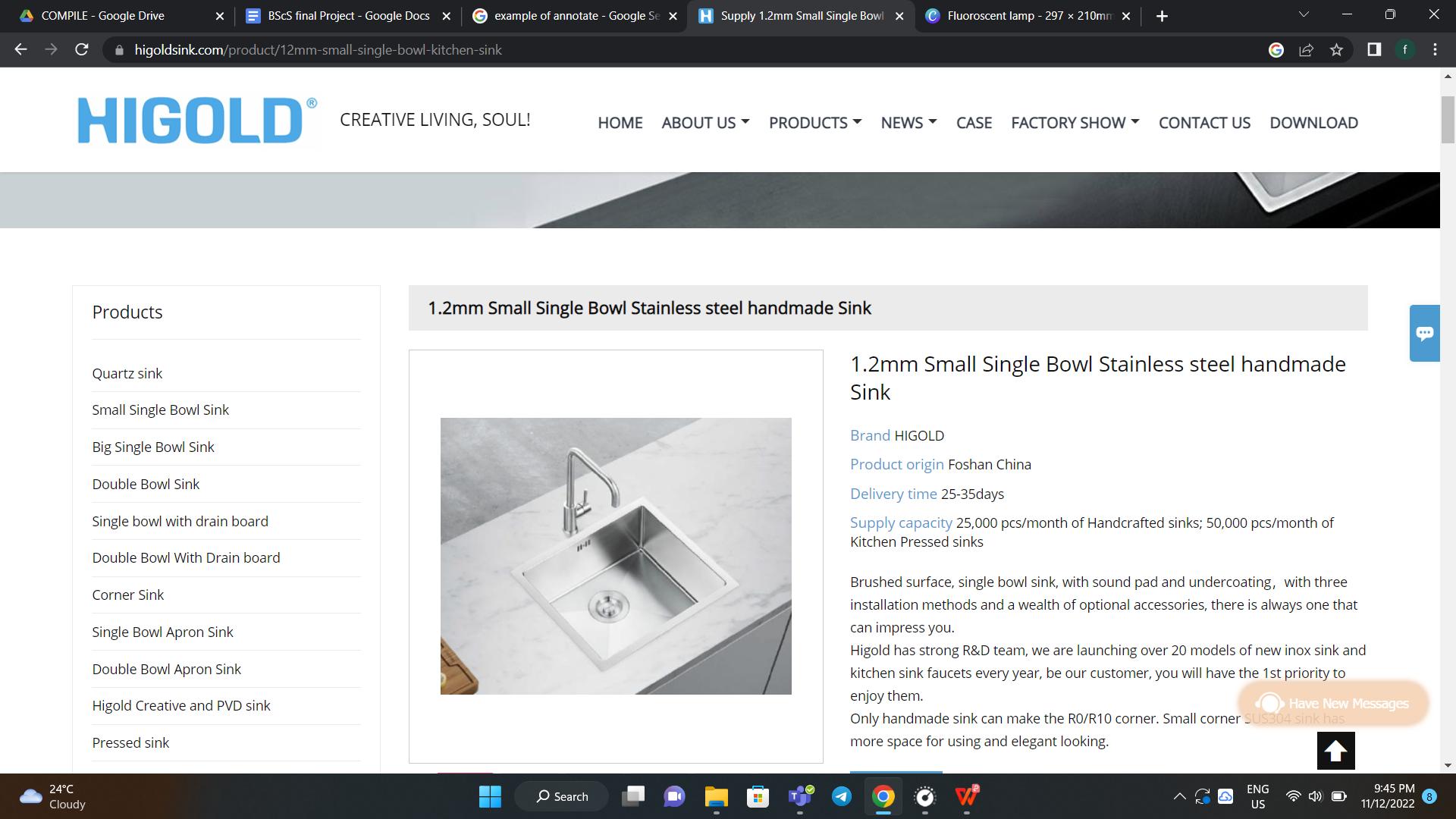

p g p g p see clearly during cooking and also for safety. Few sinks are provided for them to provide them with water supply to do any cleaning,washing and preparation during the class

10.30am to 12.30 pm which is 2 hours and the second session is from 4.30pm to 6.30 pm which is also 2 hours Hence both spaces mini mart and cooking lab operated for 4 hours per day The total number of occupants is 5 people which are 4 kids and 1 worker for each session

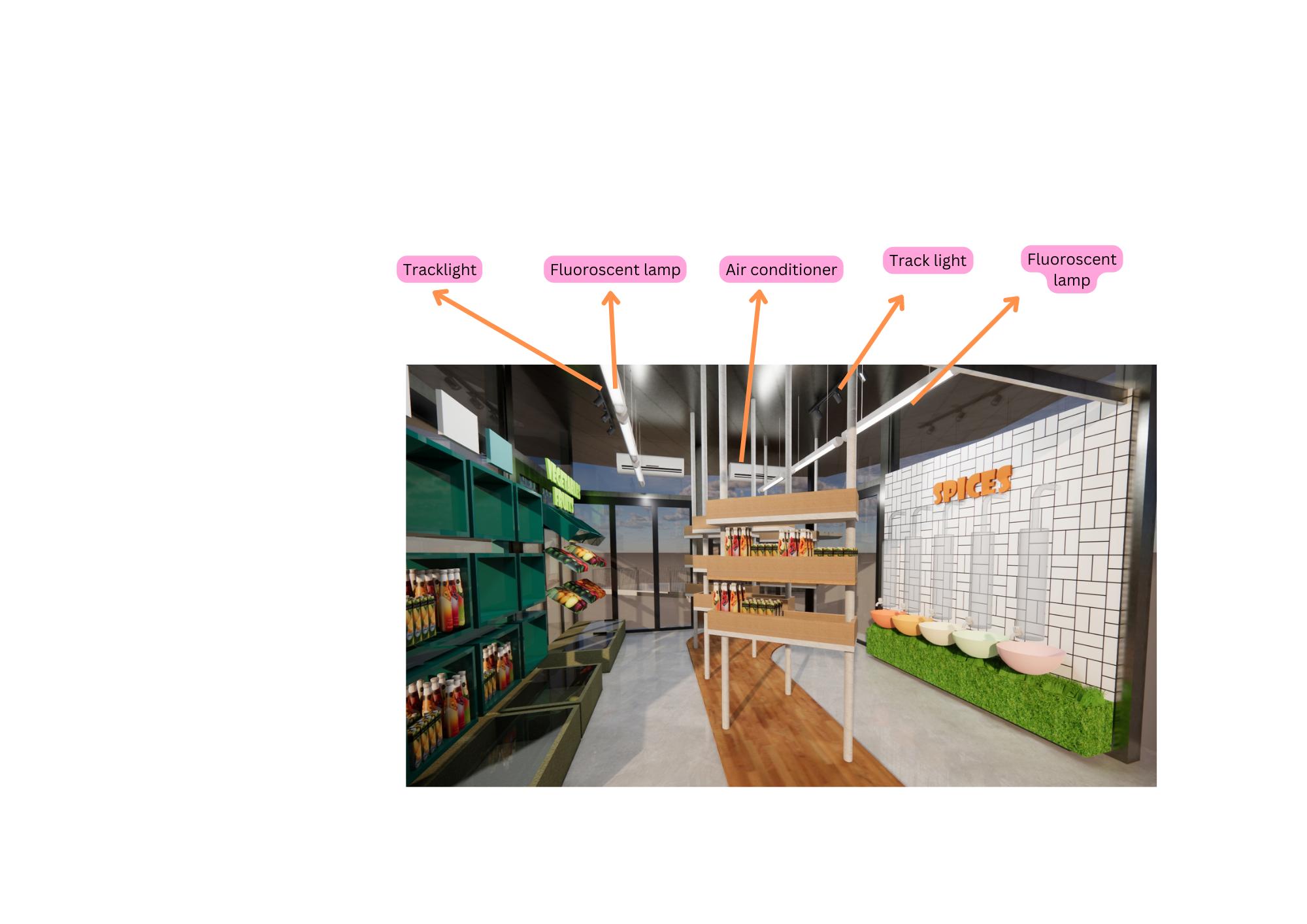

Electrical , Lighting and VAC (fans,A/C)

Total heat calculation(Btu/hr)

1 Room area (Mini market) = 6m x 5m =30�� 2 Btu/hr = 30 x 700 = 21 000 Btu/hr

2 Occupants for this room Since the number of kids for cooking class per session is 5 kids with 1 teacher, the mini market will also have the same number of occupants because only them can enter the mini market 5 x 500 Btu/hr = 2500 Btu/hr

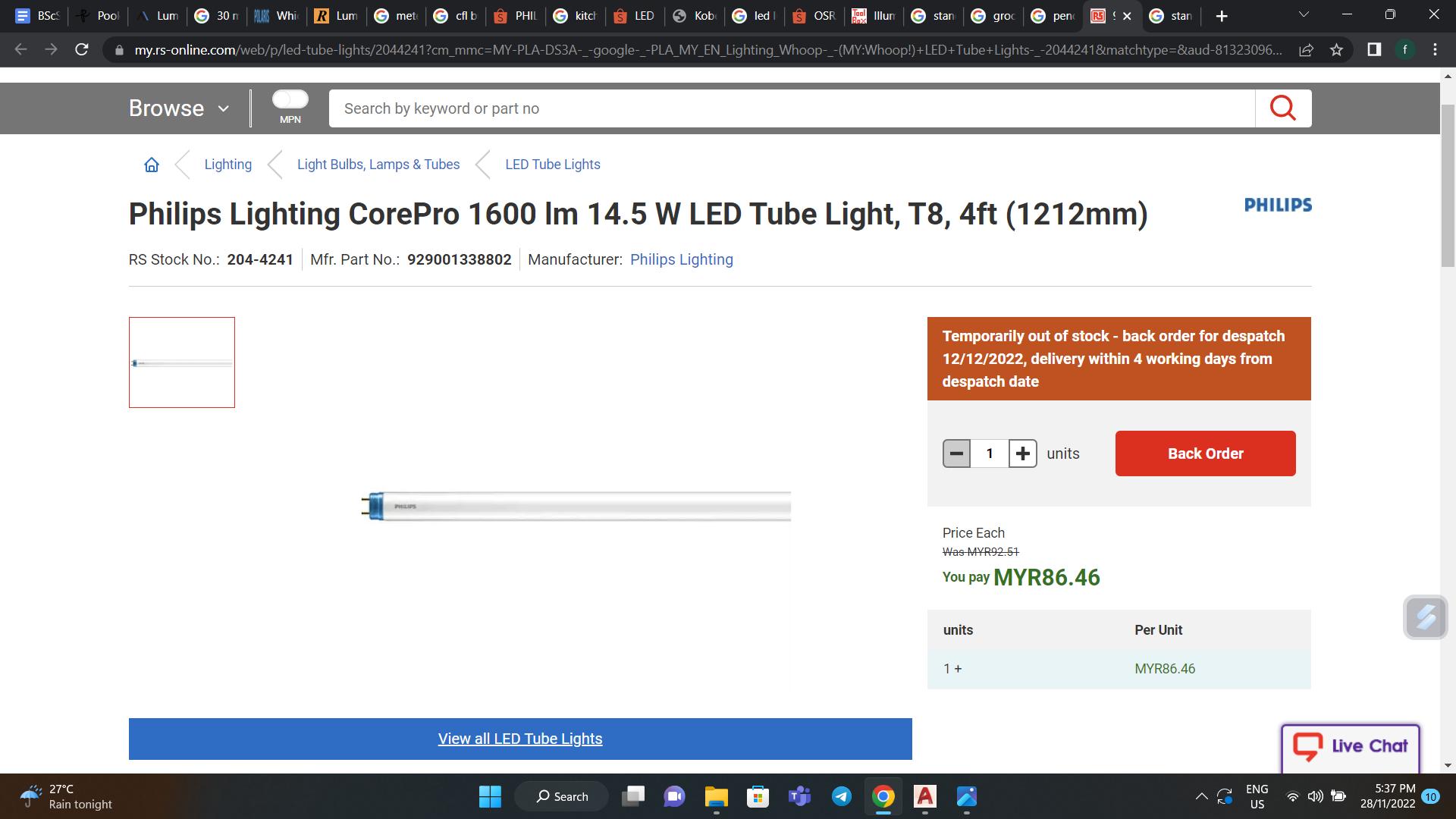

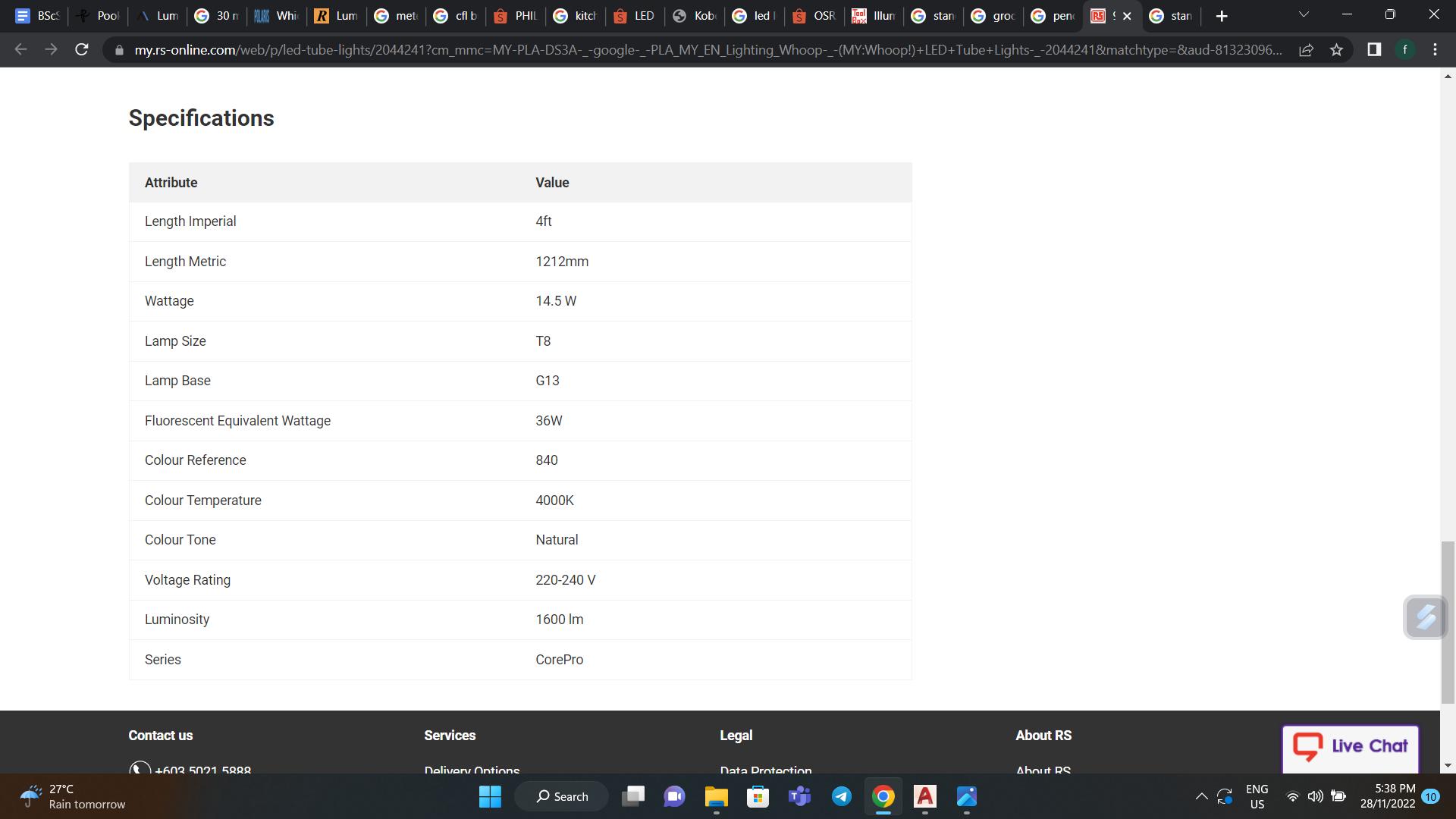

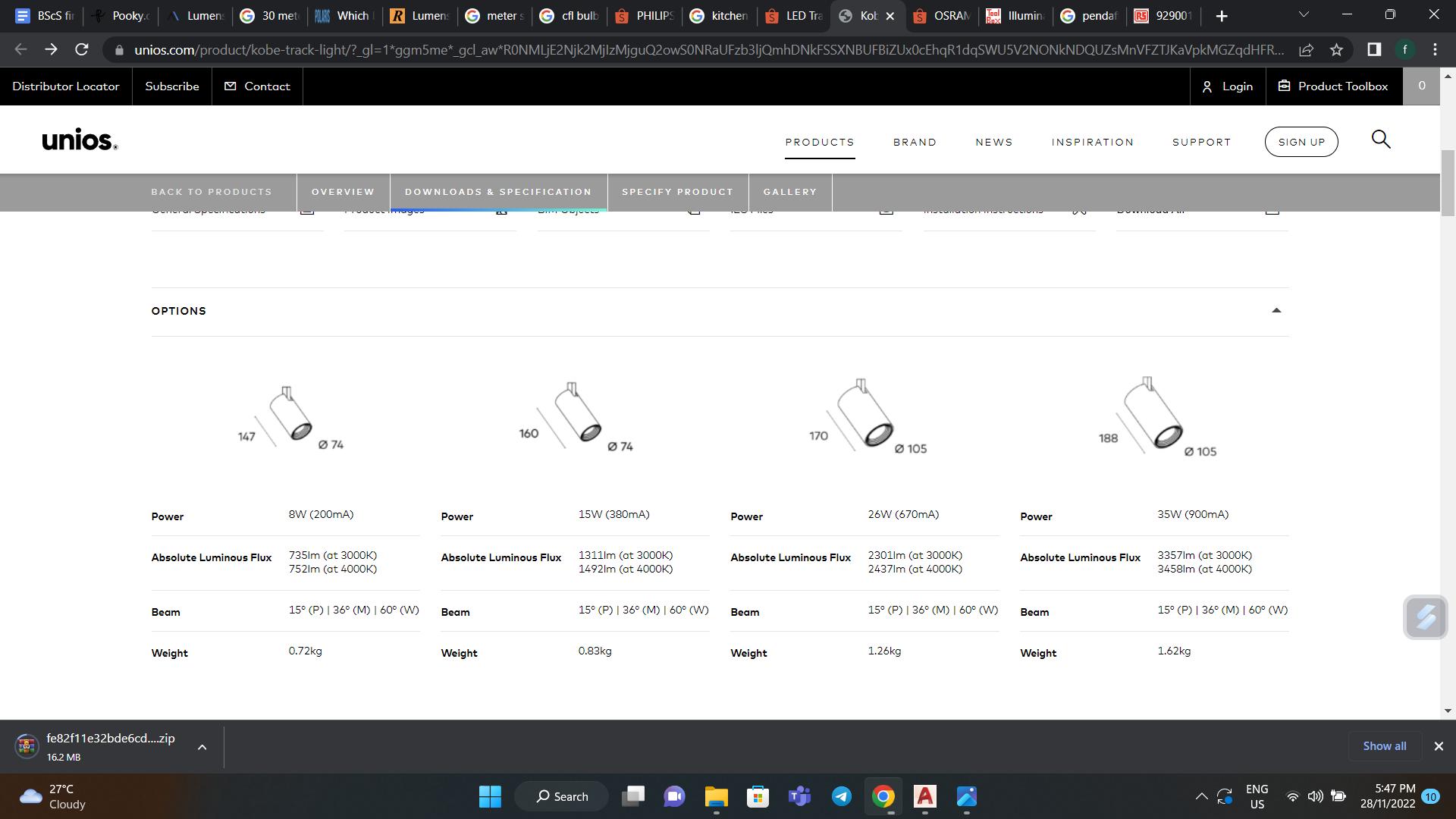

3 Heat from electrical Track light = 8W x 10 unit = 80W LEDTube light = 14 5 x 6 unit = 87W Meat chiller = 2000W Total heat = 2 167W 2 167W x 3 5 Btu/hr =7 584 5 Btu/hr 4 21 000 Btu/hr + 2500 Btu/hr + 7584 5 Btu/hr = 31 084 5 Btu/hr

5 To get air conditioning sizing = 3 17 Hp 310845������/ℎ�� 9800������/ℎ��

*From this, we can estimate to choose a 4 Hp air-conditioner for this room.

before they conditioners are program and carry the blue butterfly symbol which indicates the products best suited for people affected by asthma and allergies. Furthermore Daikin is the only split-system brand to be recognised by the Sensitive Choice program for its air filtration and purification technology When compared with other brands and models, I found that this air conditioner has the highest energy efficiency ratings of any air conditioner manufacturer.It is also one of the quietest air conditioning systems.

watt, LEDs are capable of turning about 70% of their energy into light. This makes them much more efficient than other bulbs, which waste a lot of energy by turning it into heat. Other than that LED light emits less heat as it emits electromagnetic energy as light when electrified. By turning energy into light instead of heat (rather than using heat to generate light), LEDs are able to operate at a significantly lower temperature than other types of light bulbs.

My site is actually a site that provides classes and workshops which operate at different times following sessions for each workshop According to the space chosen for this assignment is a cooking lab and mini market which have the same operating hour. For cooking class, it has 2 sessions

Operating hour: Everyday

Lunch cooking class Session 1 : 10.30 am -12.30pm (2 hours)

:

30pm - 6 30 pm (2 hours)

h

y (hour)

LED stick bulb 12 7 4 12 x 7W x 4 hours / 1000 = 0 336 kWh

Fan 1 68 4 1 x 68W x 4 hours / 1000 = 0 272 kWh

Electrical stove 3 3660 4 3 x 3660W x 4 hours / 1000 = 43 92 kWh

Oven 1 3000 4 1x 3000W X 4 hours / 1000 = 12 kWh Blender 5 250 0 167 5 x 250 W x 0 167 hours /1000 = 0 21kWh

Total daily energy consumption = 0.336 kWh + 0.272 kWh + 43.92 kWh + 12 kWh + 0.21 kWh = 56.74 kWh

Estimated monthly energy consumption = 56 74 kWh x 30 days = 1702 2 kWh