OPHTHALMIC LABS & INDUSTRY

We help you to stay in contact

4/2023

▶ Special topic: Data Handling & Security

AI and machine learning algorithms

Highest level of lens personalization thanks to “big data” and recent scientific findings

▶ MAFO live on site SLUGFest 2023 — first-hand information and visions for the future Leica Eyecare — back to its roots

ALL-IN-

▶ Market Survey

Dip- and spin hard coating machines

M dulo Center

Imagine one single machine featuring all the technology to surface 80 lenses/hour, in just 72 sq. f t. (7m²). This is Modulo Center ONE. The compact all-in-one surfacing center is a full-fledged production line without limitations: a milling station // a lathe turning station // one or two 4-spindle polishing units // a CO₂ or excimer laser. Modulo Center ONE features highly advanced process technology, based on robust and reliable components proven in hundreds of installations across the globe.

The all-in-one surfacing center substantially saves time, running all processes simultaneously and perfectly synchronized – even milling and lathe turning. And with the chambers placed right next to one another, the smart automation transfers the lenses in virtually no time. There is no faster way to surface a lens.

The dedicated Control Center (MES) informs at a glance about the current status of the machine, production parameters, and efficiency.

Labs can now run larger scale productions even in small locations and under nonindustrial conditions. Little to no operator intervention is needed as the center works fully automated with all essential components on board. Simply put: Blank in, surfaced lens out.

ISSN 1614-1598 66527 Volume 19

Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr 66527 Germany

www.schneider-om.com

in 1 hour 72 sq.ft. 80 lenses 4 processes

CHC1000 - Maximum Output, Minimum Effort

The CHC1000 is the ultimate unit for large scale cleaning and hard coating of lenses for customers that need to produce high volumes easily.

When fully loaded, the CHC1000 is capable of producing up to 1100 lenses per hour, with the system comprising of 10 stages of effective cleaning and drying, followed by a twin dip coating system for hard coating.

Unleash your full potential with the CHC1000

t: +44 (0) 1462 491616

e: sales@optimal-technologies.com

www.optimal-technologies.com

Hanna Diewald Chief editor

Hanna Diewald Chief editor

Tell us your opinion, ideas and suggestions: hanna.diewald@mafo-optics.com

Artificial intelligence everywhere

At the beginning of 2019, we asked the ophthalmic optics industry what relevance AI has. At the time, most experts agreed: AI plays almost no role in our industry! In general, many people back then, only had a theoretical knowledge of the term. It was filed away under “futuristic technology” for trendy companies like Tesla.

Now, just four years later, the situation has been turned on its head. According to Statista, the AI tool ChatGPT reached the threshold of one million users in just five days. By comparison, other popular online services such as Instagram or Spotify took months to achieve this. Whether you are doing research for your boss or searching for help with a school essay – AI can seemingly take on anything. The upheaval of AI in the ophthalmic industry did not happen overnight, as with ChatGPT, but still — there is now hardly any machine- or lens-manufacturer that has not jumped on the bandwagon. Today, almost every company uses – and advertises the use of – AI in their products. Lens designs can be enhanced thanks to the technology and production processes optimized. For example, AI can refer back to huge databases of “defects” to spot errors during automatic lens inspection.

AI is also one focus of this issues special topic Data Handling & Security which adresses the opportunities offered by this technology.

▶ Gaetano Volpe and Pasquale Fanelli of ProCrea Tech discuss the

use of AI and machine learning in the design of spectacle lenses.

▶ In another article, Manuela Weinreich describes how Zeiss lenses are becoming even more customized thanks to Big Data.

▶ And we summarized some important facts about ChatGPT in professional life.

In our industry, AI, machine learning and similar technologies can thus be used in a wide variety of profitable ways.

It is equally self-evident that a technology that can flood a market so quickly and so comprehensively may also harbor risks. Warnings about the risks of using AI, and the need for regulation, have come from many different quarters – from prominent researchers to the World Health Organization. And if you ask ChatGPt directly, even the AI itself refers to five risks: spreading misinformation, reinforcing prejudices, misuse, privacy and dependence on AI systems.

That AI could suddenly replace the skills of human beings overnight is nonetheless an illusion, or as Sven J. Körner described the first golden rule of AI at the SlugFest (page 10): “Hard problems are easy, easy problems are hard.” This means that simple tasks for humans, like fetching a book from the next room, at first seem impossible for AI. On the other hand, AI can easily sift through 100,000 data sheets to find one criterion.

Nonetheless, new technologies can be useful, provided that the risks are realistically assessed and, if necessary, regulated.

READ FOR FREE

MAFO 4-23 3 LETTER

app.mafo-optics.com

THE CLS RANGE IS THE CULMINATION OF DECADES OF RESEARCH AND OFFERS CLASS LEADING PERFORMANCE.

By refining and milling our own particles to tightly control the particle size distribution, we have created two products offering a level of performance which others will strive to imitate.

CLS: Designed primarily for freeform polishing, giving class leading stock removal, excellent polished lens surface quality along with an extended polish life. Specifically designed for polycarbonate lenses but can be used on all lens types.

CLSR2: Designed for both conventional and freeform polishing, giving excellent stock removal and class leading polished lens surface quality, along with an extended polish life. Suitable for all lens types.

We are so proud of this polish, we named it after our founder. Clive Laurence Sangster spent his life constantly striving for perfection. We can now present a new range of polish worthy of his name, entirely manufactured by Cerium.”

“ Head office: Cerium Technology Park | Tenterden | Kent TN30 7DE | T: +44 (0) 1580 765211 | james@ceriumoptical.com ceriumoptical.com LEADERS IN OPTICAL PRODUCTS, LAB SERVICES, RESOURCES & RESEARCH UK – USA – EUROPE – ASIA – AUSTRALIA

our product

:

Available in both 1G and 5G containers.

See us at

launch

Booth #F9045, Vision Expo West, Las Vegas: 28th-30th September

MAFO 4-23 5 JULY / AUGUST 2023 MAFO issue July / August 2023 Content Topics in this edition Special Topic Special Topic Special Topic At a glance 6 All about you News from the international ophthalmic industry 7 All about markets Data in graphics 8 All about products Innovations and products for your lab 52 Suppliers Guide 56 Closing Words Ivette Bruguera — a technical affine all round talent and music lover 57 Outlook Technology 14 AI and machine learning algorithms By Gaetano Volpe and Pasquale Fanelli 18 The new algorithm of lens development By Manuela Weinreich 21 ChatGPT in enterprises Five facts MAFO live on site 10 SLUGFest 2023 First-hand information and visions for the future 32 Leica Eyecare Back to its roots 24 Transitions Academy 2023 Anything but ordinary Spotlight 22 PFAS – what we know and what we do not know yet An interview with Spectaris 26 Combination treatment in myopia management By

Business 36 Ensuring that jobs and skills go hand in hand By

Urschinger 32 Setting priorities By

Surveys 41 Dip- and spin hard coating machines Page 10 Page 21 Page 36

Torben Othersen

Timm

Hartmut Fischer

All about you News from the international ophthalmic industry

Education program for VEW announced

The Vision Council and RX, organizers of Vision Expo, announced the education program for Vision Expo West 2023, taking place September 27-30 at the Venetian Convention & Expo Center in Las Vegas. The

Show’s VisionEd optometry and opticianry educational programs, including OptiCon@Vision Expo, will open Wednesday, September 27. Exhibits will open Thursday, September 28. This year’s education program will feature more than 320 hours of clinical content. OptiCon@Vision Expo returns with an education program and exhibit hall experience for opticians, contact lens practitioners, and ophthalmic allied professionals. Download the Vision Expo West 2023 education brochures: west.visionexpo.com/en-us/seminars.html

Dr. SriniVas R. Sadda named 2023-2024 ARVO President Elect

SriniVas R. Sadda, MD, was recently named President Elect of the Association for Research in Vision and Ophthalmology (ARVO) during its 2023 Annual Meeting in New Orleans, LA. This recognition is a testament to Dr. Sadda’s leadership in his field, and contributions toward vision research. Dr. Sadda has been a member of ARVO for a number of years, and served on the Board of Trustees for the past three years. Dr. Sadda is the Director of Artificial Intelligence & Imaging Research at Doheny Eye Institute and Professor of Ophthalmology at the University of California – Los Angeles (UCLA) David Geffen School of Medicine.

New sustainability award at opti Munich

opti – the international platform for ophthalmic optics taking place from 12 to 14 January 2024 in Munich – will focus on one of the most important challenges of our time: sustainability. With the “opti Sustainability Award” competition, the trade show invites

national and international opticians to present their current activities in terms of sustainability. Based on the three pillars of the Sustainable Development Goals (SDGs) of the United Nations in its Agenda 2030 – social, economic, and ecological – relevant initiatives of the companies such as the design of the business premises, relevant approaches to the avoidance of microplastics, alternative energy supply, climate-neutral behaviour, diversity within the workforce and much more count towards the competition.

200 potentially unsafe eye drops

Dry Eye Foundation has identified over 200 eye drops (62 brands) sold online that have potential safety issues. Of these, the majority are packaged exclusively for sale in a country other than the USA. Many are advertised as preservative-free but are pictured in bottles designed only for preserved eye drops. Over 60 individual products have been found on Amazon. Dry Eye Foundation has reported all products of concern to the Food and Drug Administration, and continues to maintain a watch list for consumers and physicians at eyedropsafety.org

Optical retailer Fielmann Group enters US market

The Fielmann Group, a leading European eyewear provider, announced that it is entering the US market with two complementary acquisitions. This is an important milestone in the internationalization that the German family business pursues with its Vision 2025 growth strategy. The Fielmann Group has entered into a definitive agreement to acquire 100% equity ownership of SVS Vision, an optical retailer that operates more than 80 stores across 9 US states. As the market leader in the state of Michigan, SVS Vision generated more than US$100 million in sales in 2022. The transaction is expected to close by 31 August 2023, subject to customary closing conditions.

You have news for the ophthalmic industry? Submit your press releases to: hanna.diewald@mafo-optics.com or constanze.classen@mafo-optics.com

Vision Expo West 2022. Source: VEW

MAFO 4-23 6 INTERNATIONAL NEWS

Picture: getty images/unsplash

All about markets

Graphical data

The OECD country, leading the internet speed and uptake ranking, is South Korea with 45 broadband lines per 100 inhabitants, of which 99%

Singapore was rated as number 1 ,

were fast broadband. Similar uptake with more than 90% high-speed connections can be found in Belgium, Portugal, Switzerland, the Netherlands and Sweden. No data was available for Japan.

of the healthiest countries of the world, having the top service and state of health globally in 2023. In the top five follow: Japan, South Korea, Taiwan and Israel. Meanwhile, the United States trails just behind the UK in rank 38. The bottom five places are Somalia, Lesotho, Chad, South Sudan and the Central African Republic.

Source: statista.com

Source: statista.com

The spectacle lenses segment is projected to witness a significant growth in the year 2023, with a revenue of

58.98 billion US$.

The market is estimated to grow annually by 4.03% (CAGR 2023-2027) on a global scale.

Source: statista.com

MAFO 4-23 7 INTERNATIONAL NEWS

All about products

Innovations and working materials for your lab

Satisloh focuses on future challenges

At Satisloh’s 10th SLUGFest Meeting in Wetzlar, from 13th – 16th June, the company showcased 29 technology innovations. Satisloh focused on four key topics: EFFICIENCY, with faster, smarter machines and next-level intelligent software & automation; SIMPLICITY to save time & costs; SUSTAINABILITY both in terms of environmentally friendly products and in operations management to reduce carbon footprint; and finally in PARTNERSHIP PROGRAMS, including a new self-serve customer portal, a knowledge data base, e-learning options, and more. Satisloh presented its new 900-TLX mid-sized box coater, as one of the 29 innovations. Due to its new revolutionary sector dome design, it can accommodate different sector types at once. Therefore, it produces up to 129 lph and presents the fastest and most efficient box coater in the market. Visit: www.satisloh.com

3D-Micromac introduces new laser engraving solution for spectacle lenses

3D-Micromac introduced the new microMARK RXe BLUE, a laser solution for marking spectacle and contact lenses. The new product offers excellent marking quality for all types of blocked plastic lenses, including CR39. The system is equipped with an industry-proven solid-state laser source, which guarantees a significantly higher number of emitted laser pulses compared with similar classes of laser sources. No gas is required to operate the laser system. As a result, customers benefit from low investment and operating costs. The microMARK RXe BLUE should meet customers’ demand for high-quality laser engravings comparable to excimer laser markings. Visit: www.ophthalmic-marking.com

Advertisement MAFO 4-23 8 INTERNATIONAL NEWS

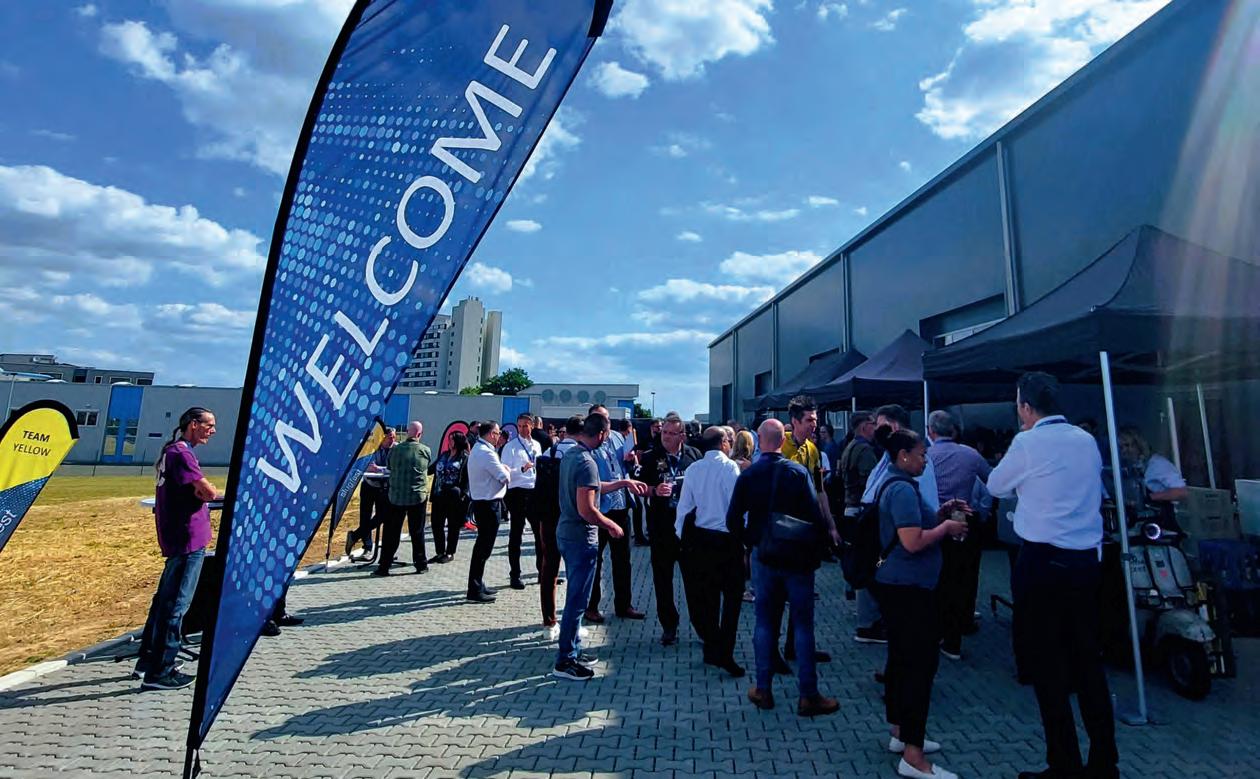

First-hand information and visions for the future

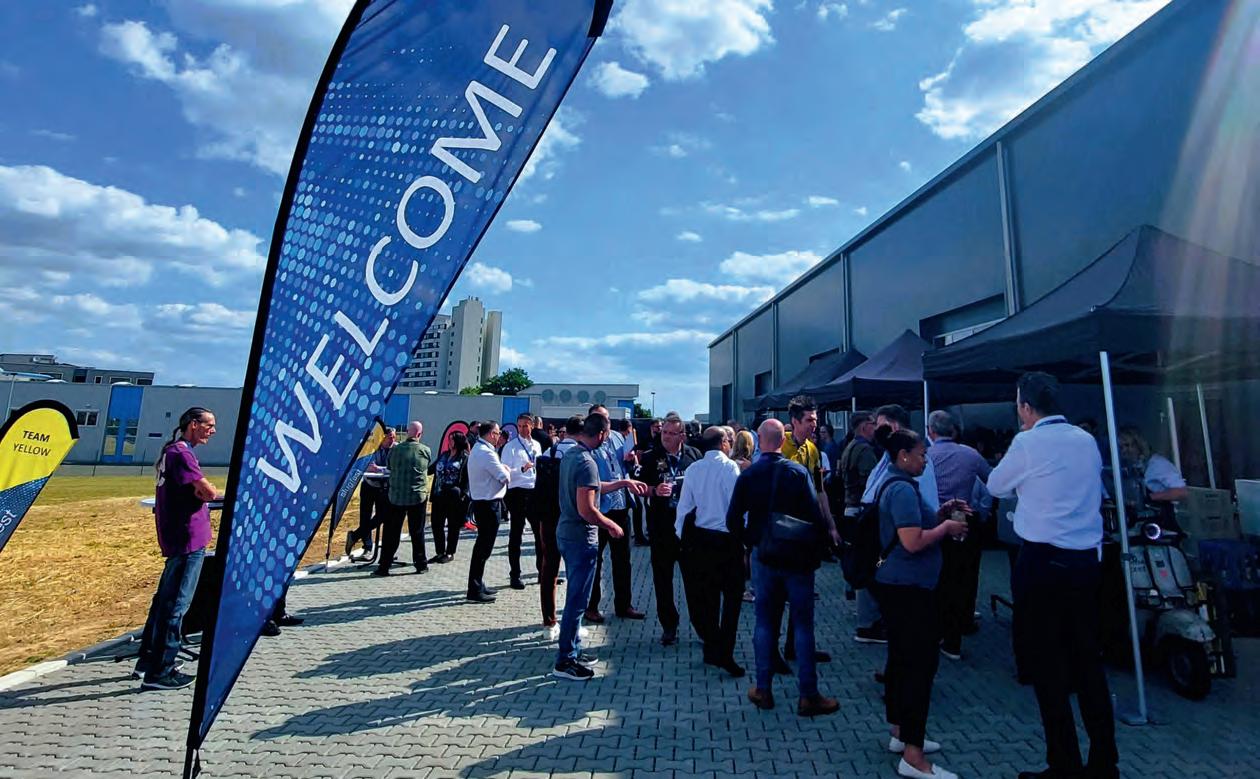

SLUGFest 2023

Paperless production, artificial intelligence or the way towards block-free production – at this year´s SLUGFest (Satisloh User Group Meeting) in Wetzlar, visitors were introduced to a number of technological highlights and gained unique insights into the ophthalmic lens production of the future. Some of the technologies presented are already available, some will be market-ready in a few months, and for others it can take years – but as soon as they are available, they have the potential to radically change ophthalmic lens production.

The road to Satisloh is well known to many people in ophthalmic optics. After all, the company is located in a stronghold of the optical industry – in Wetzlar (Germany). Several internationally active machine manufacturers and other optical groups have their headquarters in the immediate vicinity, including Satisloh.

By Hanna Diewald

The tenth so-called SLUGFest took place from 13 to 16 June 2023, this time under the motto: “The art of making lenses – reimagined”. The special event for Satisloh customers attracted some 100 visitors from around the world, who waited eagerly for the doors to open in the bright sunshine. In the opening ceremony, Bruno Fischer, President and CEO of the Satisloh Group, got the audience in the right mood for

MAFO 4-23 10 MAFO

ON SITE

LIVE

the coming days, followed by Michael Kreis (VP Global R&D), Xavier Bultez (VP Integrated Solutions), Pascal Elsener (Head of Region EMEA & India), Andy Huthoefer (VP Product Management and Marketing) and Steele Young (VP Business Development North America) – who introduced the audience to the program and hinted at some of the important technology highlights to come.

A versatile technical program

The line-up of the 3-day event consisted of technology round-ups, technical presentations, a tour of the machine production, a visit to the research & development department, together with a rich and varied supporting program, including dinner at Gleiberg Castle. On Friday, participants were offered a special adrenaline kick in the form of a visit to the world-famous Hockenheim race track.

But first, let's go back to the machines: following the opening speeches, it was time for the technology round-ups. In the adjacent hall, right next to the Satisloh production, the team had set up all the relevant machines for production.

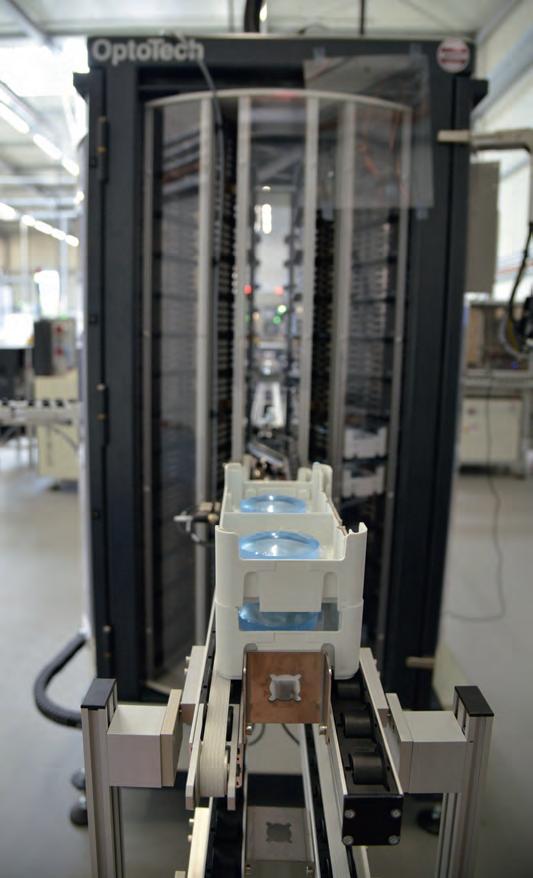

Divided into twelve separate groups, participants had ample opportunity to learn about all the important details of the machines directly from the experts. The Satisloh technicians enthusiastically answered all the questions and never tired of showing each individual group all the highlights.

Participation expressly welcome!

On display were the well-known work horses in their latest versions, such as the VFT-Orbit 2i digital generator, the Multi-Flex-2 polisher or the 1200-DLX-2 vacuum-box coater, with improved dome design, for a more efficient arrangement of the lenses and optional in-chamber tinting. But there were also completely new machines on display. Some technologies are still in the beta stage of development, so participants were actually the first “outsiders” to see and touch the innovations, thus giving them the chance to voice an opinion and express their wishes with regard to the final products – a unique opportunity to influence the products during the development stage. On the topic of automatic cosmetic inspection, Satisloh organized sessions in which the pros and cons of particular features and areas of application were discussed directly with the customers.

The technologies which perhaps most interested participants concerned paperless production, automatic cosmetic inspection, the current state of development of blockless manufacturing, elastic beveling and the fully automated warehouse system.

Paperless production

Much has been said about paperless production in the lab. At the SLUGFest, visitors could experience live how the system works. It is based on the so-called e-ticket, a visual display on which the most important job information is shown, such as the refractive index or type of coating. The ticket works with electronic ink and only needs power when being updated. It communicates via WiFi with the LMS and MES-360.

Tickets are available both with and without batteries. The version with a battery has integrated LEDs and can light up in different colors, so that jobs with particular attributes such as “urgent” can be seen at a glance. Battery life is expected to be about two years.

Automated cosmetic inspection

A prototype with great potential was on display in the R&D department. ACI-Theia is the name given to the automated cosmetic inspection machine of the future. The machine takes 46 high resolution images of each lens which is inspected, and can detect scratches, fingerprints, central dots or the engraving to check that it is flawless. Depending on the zone (center or periphery), a decision is then made as to whether the defects are critical or less critical. Thanks to AI, it should be possible to recognize trends, so that problems on the machines can be detected early and thus the production of further defective lenses can be avoided.

The standards and threshold values according to which lenses are rejected can be defined by the labs independently; or separate specific standards set for low or premium lenses. Power measurement is not yet integrated, but will be in the final version.

Future vision: blockless manufacturing

Blockless production in the lab solves several problems at once and is thus a desirable goal. After all, with blockless machines, both alloys and adhesives become obsolete, thus marking a significant step toward more sustainable production, while at the same time eliminating operations such as blocking and de-blocking.

Satisloh is also working on such a technology and gave its customers an honest appraisal of the current state of development; and why the machines – its developers are working on – are not yet ready for market.

For example, the machine manufacturer has the ambitious goal of being able to incorporate existing blockless technologies, so that labs would not have to completely retool. In addition, the system should be able to process a wide range of products.

MAFO 4-23 11 MAFO LIVE ON SITE

Bruno Fischer, President and CEO of the Satisloh Group, at SLUGFest 2023. Picture: Hanna Diewald

The engineers are working flat out on both of these goals, as well as on many other technical details. However, it is not yet clear when customers can expect to see the final version.

Elastic beveling

An innovation in edging awaited participants at another stand. Here, the edge is no longer milled, but built up by an additive process. The edge remains elastic, thus diminishing the pressure on the lens, so that the stress is significantly reduced. It can also compensate for small defects in the frame edge.

Thanks to another prototype in the edging department, it will be possible to significantly reduce the visibility of myopia rings as from 2024. To achieve this, a machine applies paint to the edge of the lens. The paint can be chosen to match the color of the frame.

Warehouse system

Installing a new warehouse system may sound like a lot of work. However, in reality there is hardly any other technology that can be adapted as easily and quickly as Smart Consumable Supply, a system that is already in use at companies like Tesla and whose investment costs are manageable.

Labs only need to introduce digital chips (smart labels) with key information, which are then connected to the supply chain platform. Consumables can be reordered simply by pressing a button on the smart label, which then turns black. Anyone else can then see immediately that the consumables are already in the digital shopping cart, ensuring timely delivery.

Multiple orders in a week – each shipped individually – or accidental double orders should thus become a thing of the past.

What else was important

There were also a few other highlights for customers to see and hear. For example, in the second half of 2023 the new iAcademy will be launched. Here, employees can receive continuous training and, thanks to QR codes on the machines, quickly and easily view all machine details, or contact customer service directly via video or chat.

As from October 2023, the Rx-Bot Luke will become available, a machine which can automatically unpack spectacle lenses thanks to the help of a CO2 laser.

The Tech-Film AR will also be available with front side lamination from 2024, so that both the front and back of the lens can be coated.

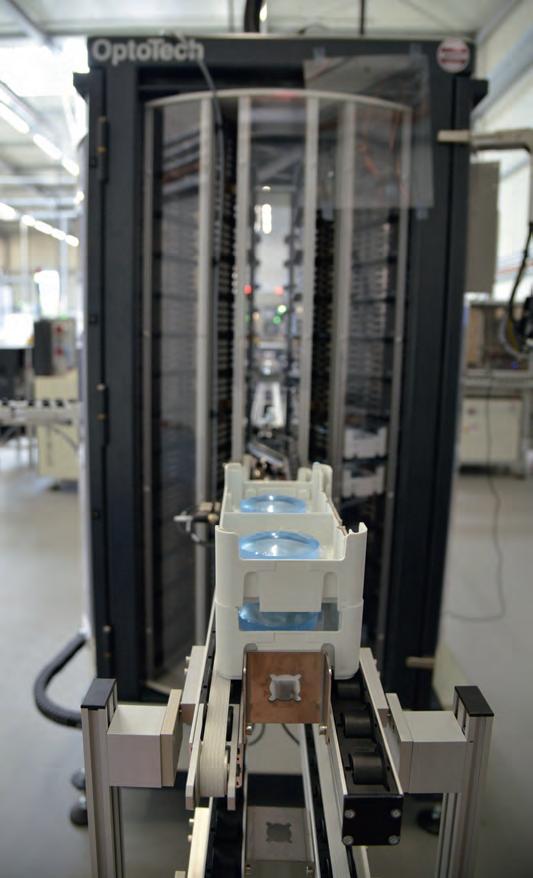

All machines were presented to the participants in technology round-ups. Picture: Satisloh

A lens, coated with the "Tech-Film AR" technology. Picture: Hanna Diewald

All machines were presented to the participants in technology round-ups. Picture: Satisloh

A lens, coated with the "Tech-Film AR" technology. Picture: Hanna Diewald

MAFO 4-23 12 MAFO LIVE ON SITE

Participants could explore the machines in detail. Picture: Hanna Diewald AR and mirror coating for visors. Picture: Satisloh

The MES-360 will also be equipped with some additional features including, for example, the display of energy consumption and consumables status. And anyone wanting a “super kitchen” in the lab should take a look at the tinting machine from SCL, which can automatically tint spectacle lenses even with a gradient!

Presentations on AI and sustainability

The participants were given a lot of information to take home with them and are now up-to-date on which technologies will play a key role in the ophthalmic labs today and tomorrow. With so much technical input at one’s finger tips, the lectures on the second day were a pleasant relief.

Dr. Sven J. Körner, a researcher in the field of cognitive/semantic computing, gave an entertaining introduction to the basics of artificial intelligence – what it is useful for and what humans can still do better.

For example, the first golden rule of AI is that “Hard problems are easy, easy problems are hard”. This implies that the strengths of humans and of AI are significantly different. Whereas walking up a flight of stairs or opening a door are difficult for AI, sifting through enormous amounts of data to find a specific criterion, on the other hand, is easy.

The second presentations were about sustainability. Here, Eric Mugnier, Partner at EY, and Dr. Jochen Gassner, of South Pole, explained how companies can become sustainable; that employees today want to work for such companies; and that investors today want to invest in companies that have strategies and data which underpin a sustainable corporate culture.

Things got faster at the end

Things speeded up on Friday, the last day of the event, with a visit to the Hockenheim race track. Here, participants were able to leave all thoughts of work behind and experience a completely different kind of technology.

Attendees took a VIP tour of the Hockenheimring, with teams competing against each other in electric cars driving round an obstacle course, and seeing who could change Formula 1 racing car tires in the shortest possible time. Just like in the production, everything here was loud and fast, but adrenaline levels were certainly higher driving round the race track than when operating a generator in the lab. A fitting and successful finale to the event! Many participants are already waiting eagerly to hear when and where the next SLUGFest will take place. ◆

F.l.t.r.: Tobias Gelada, Andy Huthoefer and Michael Kreis from Satisloh and Denis Gehrig (SCL) in front of Gleiberg Castle. Picture: Hanna Diewald

The machines were presented in an adjacent hall. Picture: Satisloh

One could see how humans and machines interact in many places. Picture: Satisloh

F.l.t.r.: Tobias Gelada, Andy Huthoefer and Michael Kreis from Satisloh and Denis Gehrig (SCL) in front of Gleiberg Castle. Picture: Hanna Diewald

The machines were presented in an adjacent hall. Picture: Satisloh

One could see how humans and machines interact in many places. Picture: Satisloh

MAFO 4-23 13 MAFO LIVE ON SITE

The participants listened attentively. Picture: Satisloh

AI and machine learning algorithms

Artificial intelligence (AI) is revolutionizing numerous industries, and there are numerous approaches to design these algorithms. How can these technologies be implemented in the design of progressive freeform lenses?

By Gaetano Volpe and Pasquale Fanelli

By Gaetano Volpe and Pasquale Fanelli

In today's rapidly evolving technological landscape, AI has become an integral part of our daily lives. In recent years, this technology has been implemented in smartphones, voice assistants, in customized search results of popular streaming platforms, in social networks and so forth. But what exactly is AI?

Background

The term AI refers to the machines ability to perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision-making, and language translation. To make these technologies work, it is necessary to “teach” machines how to perform these tasks successfully, through developing specific algorithms: this process is called machine learning and is a subset of AI research. As we explore the world of machine learning, one might wonder: what are the most used algorithms for programming AI software? What strategies are they based on? What is the role of AI in the design of progressive ophthalmic lenses? Is an AI revolution taking place, as in many other sectors?

This article aims to provide a general overview of the main types of machine learning algorithms, including “supervised learning ” , “u nsupervised learning ” , “reinforcement learning ”, and “multitask

learning”, and aims to propose a use scenario in progressive addition lenses (PAL) engineering.

Supervised learning

Supervised learning is a type of machine learning where the algorithm is trained on a labelled dataset, which means that the input data is paired with the correct output. In simpler terms, the programmer provides the algorithm with both the source information (input) and the precise result to be obtained (output) like a teacher guiding a student through a learning process. The teacher provides the student with examples of inputs and their corresponding correct outputs, allowing the student to learn the relationship between the two. The algorithm's goal is to learn the correlation from inputs information to outputs one, allowing it to make predictions on new, unseen data. Supervised learning is widely used in various applications, such as image recognition, speech recognition, and natural language processing. For example, in image recognition, a supervised learning algorithm might be trained on a series of images (dataset) labelled as either “cat” or “dog”. After learning the features that distinguish cats from dogs, the algorithm can then classify new, unlabelled images as either cats or dogs.

Data Handling & Security

MAFO 4-23 14 TECHNOLOGY

Unsupervised learning

Unlike supervised learning, unsupervised learning algorithms work with unlabelled dataset, meaning that the input data does not have any associated output. To put it simply, unsupervised learning is like a student looking for connections between information while studying a new subject, without any guidance from a teacher.

The goal of unsupervised learning is to discover hidden patterns or structures within the data. This type of learning is particularly useful for tasks such as: grouping similar data together based on their inherent characteristics or patterns (called clustering); or identifying errors, unusual patterns, rare events in a dataset (called anomaly detection).

An example of employing this type of algorithm might be a company that trying to group customers according to purchasing behavior. Imagine a dataset containing rough information about customers' shopping habits: an unsupervised learning algorithm could search patterns in this dataset to group customers with similar purchasing behaviors, allowing businesses to tailor their marketing strategies accordingly. It isn’t appropriate to use a supervised algorithm in this case as we don't know the purchasing groups' characteristics (output) when starting the analysis.

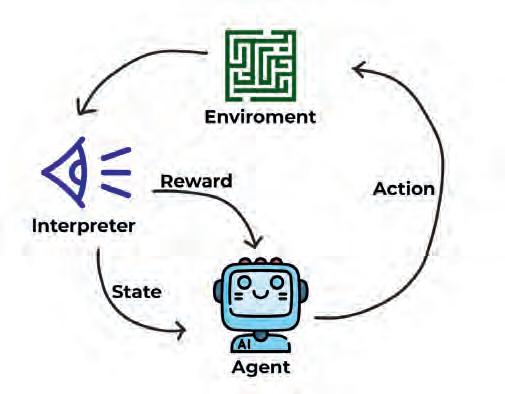

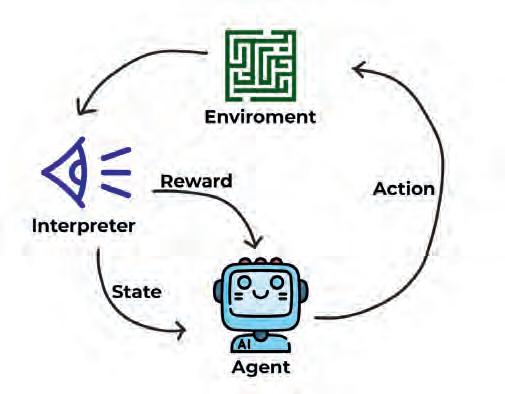

Reinforcement learning

Reinforcement learning is a type of machine learning where a decision-maker software (called agent) learns to make decisions by interacting with a controlled environment. Think of reinforcement learning as a trial-anderror process, where the agent learns from its experiences and it adjusts its choices accordingly, improving its decision-making skills.

One way to structure this type of algorithm is to design a reward system: the agent will be rewarded in the case of a correct answer and will receive a penalty in the case of a wrong answer. His task is to maximize the reward.

A classic example of reinforcement learning is teaching a robot to navigate through a maze (Fig. 1). The robot receives a reward for reaching the goal and a penalty for hitting a wall or taking too long. Over time, the robot learns the optimal path to exit the maze by maximizing its cumulative reward. Reinforcement learning has been successfully applied to various domains, such as robotics, game playing, and recommendation systems.

Multitask learning

Multitask learning is a machine learning approach where a single model is trained to perform multiple tasks simultaneously. Imagine a student studying multiple subjects at once, leveraging the knowledge gained in one subject to improve their understanding of another. The idea behind multitask learning is that the model can leverage shared knowledge across tasks, leading to improved performance and generalization.

For example, a multitask learning model could be trained on this two tasks: edge detection and shape recognition. The model can use the information gained in each assignment to improve the performance in both tasks. This approach has been applied to various domains, such as computer vision, natural language processing, and drug discovery.

Neural networks

Most of these techniques leverage a software framework called neural network also known as Artificial Neural Networks (ANNs). The neural network model is inspired by the functioning of biological brain networks. In fact, in the brain each neuron cell has an input and output signal, and all signals are aggregated according to their strength. Similarly, in ANNs each neuron or “node” takes an input and generates an output, and the outputs of all nodes are computed based on a property called “weight”, that represent the importance of the single node.

Using this model, one can easily increase the operation complexity at each layer of neurons, solving very complex tasks otherwise unsolvable with linear classical algorithms, just as it happens in our brain.

In the visual cerebral cortex, in fact, many simple neuronal cells are all connected to a complex cell, which computes their information based on their strength. Many complex cells are then connected to one hyper-complex cell, creating a hierarchical structure with levels that increases the complexity of visual processing at each step (like an upside-down tree).

When the number of hierarchical levels and the amount of initial information (dataset) increases significantly, the algorithm is called “deep neural networks” (or deep learning). Thanks to these characteristics, deep neural networks have achieved extraordinary accurate results in image classification, object detection, speech recognition, natural language processing, and more.

Machine learning algorithms in progressive freeform design optimization

Progressive freeform ophthalmic lenses are designed to provide a seamless transition between different focal lengths, offering clear vision at all distances for individuals with presbyopia. The production of a high-quality progressive lens requires a complex mathematical designing phase, where the lens surface is optimized to minimize optical aberrations and maximize visual performance.

Machine learning algorithms, particularly supervised learning, could be employed to model the complex relationship between lens parameters and visual performance.

Data Handling & Security

Fig. 1: Classical example of reinforcement learning.

MAFO 4-23 15 TECHNOLOGY

A critical aspect linked to progressive lenses is the final perception of the patient, as it cannot be measured.

Over the years of progressive designs development, satisfaction questionnaires were used by companies and researchers in which the end-user was asked to rate the degree of comfort at different viewing distances (example: far, intermediate, distance) on a numerical scale. Using this data, companies were able to identify the best designs and understand where to improve, but the process was time consuming and manual.

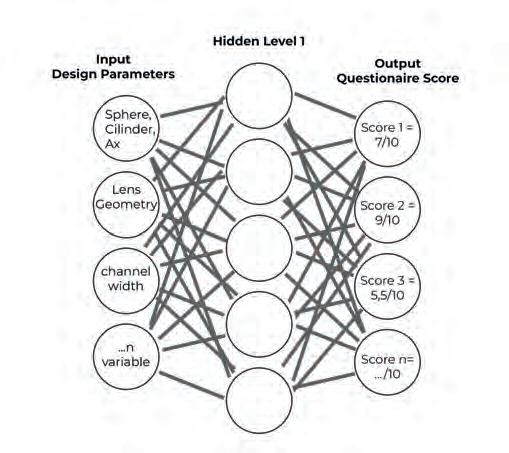

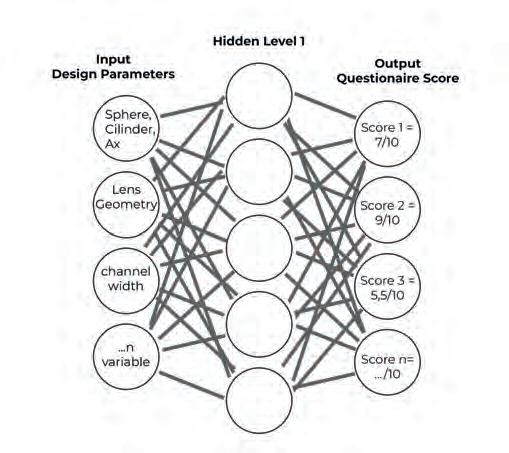

The volume of data collected from the questionnaires can be used, coupled with the lens design parameters (optical power, mounting and position of ware parameters), as an input dataset. This dataset can then be implemented in a neural network and the network can be trained to predict customer satisfaction from the input data. The questionnaire outcome, representing the wearer's satisfaction, is the output data of this neural network.

Furthermore, this type of neural network can be used to optimize some of the input parameters, thus improving the lens design as well. The algorithm tries to adjust the input parameters to maximize the output (client satisfaction) in a supervised environment. If the collection of feedback from customers continues, the network can keep learning over time and improve its predictions, also improving the efficiency in optimizing design parameters.

This neural network is schematized in figure 2, in which you can distinguish the input dataset (manufacturing parameters) and the output (result of the questionnaires). Hidden level features the trial-and-error mathematical algorithms that aim to maximize the outcome.

Conclusion

We explored the fundamental concepts behind artificial intelligence and the key types of machine learning strategies. This provides an idea of the structure of these complex algorithms and how it is possible to

train a machine to perform typically human tasks such as image recognition, speech recognition, natural language processing and so on.

Artificial neural networks are structured on the lines of biological ones and, combined with some of the learning models mentioned above, are widely used in the creation of AI tools. When the neural network becomes complex, with many layers of neurons and large datasets, one speaks of a deep neural network and the software can perform very complex tasks with greater accuracy.

Although there are no publications in the scientific literature on the application of these technologies in freeform lens design, we proposed a use case scenario.

This AI model, after being properly trained, can improve lens power map by changing the design parameters and automatically check in which cases you have the highest satisfaction score from the questionnaire (output). ◆

References:

Bishop, C. M. (2006). Pattern Recognition and Machine Learning. Springer. Hinton, G. E., & Salakhutdinov, R. R. (2006). Reducing the dimensionality of data with neural networks. Science, 313(5786), 504-507.

Sutton, R. S., & Barto, A. G. (2018). Reinforcement Learning: An Introduction. MIT Press.

Caruana, R. (1997). Multitask Learning. Machine Learning, 28(1), 41-75.

Gaetano Volpe is a computer and automation engineer. He’s a cofounder and head of research & development at ProCrea Tech. He’s pursuing a Ph.D. in electrical and information engineering with the Polytechnic University of Bari. Volpe has a long-time experience in optimization algorithms and lens design.

Pasquale Fanelli is an optometrist from the University of Salento. He works as a lens design specialist at ProCrea Tech and practices as an optometrist. His fields of interest are freeform ophthalmic lenses, specialized contact lenses and visual perception.

Data Handling & Security

Fig. 2: Schematic diagram of the neural network algorithm proposed to optimize a progressive power map.

Pasquale Fanelli

Gaetano Volpe

MAFO 4-23 16 TECHNOLOGY

cdc 500

The automated CDC 500 is one of SCL’s most reliable hard coating machines. Producing 60 lenses/h, it’s a perfect fit for small to medium size labs. It features six cleaning tanks and offers continuous and fast processing without any batching. Varnishing takes place by thermal polymerization. An automatic refill system provides consistent and stable process control - keeping detergent and varnish tanks at the same level and condition. A unique water cascading and filtrating system enables city water savings up to 75%, making the CDC 500 an environmentally-friendly coater.

Technique. Safety. Expertise. www.scl-intl.com HARD COAT LEADER

Hard coating at best price-performance ratio.

HARD COAT CLEAningTinTing PERiPHERALs COnsumAbLEs ExPERTisE

The new algorithm of lens development

Designing a spectacle lens is a highly complex science, now more than ever, and it is based on thousands of measured values and research results: increasingly detailed refraction, centering values, changing visual behavior due to digital devices, frame shapes, age-specific facial anatomy, pupil sizes and eye age. With the latest version of the Zeiss SmartLife portfolio (available since 2023), the company has succeeded in developing an algorithm based on these data volumes that combines “big data“ with subjective and objective measurement results – and thus lays the foundation for even more individualized lenses.

By Manuela Weinreich

Optical spectacle lenses have a history of more than 1,000 years of development. Since Abu Ali al-Hasan ibn al-Haitham, Alhazen in short, described the optical effect of curved lenses and ground magnifying glasses in the 11th century, we have seen countless innovations and milestones over the centuries that have made spectacle lenses better and better and correction options more and more individual. Today’s development and manufacturing of modern eyeglass lenses at Zeiss is based on four pillars:

1. K now-how about vision needs and visual behavior: consideration of visual behavior for the desired visual need and the intended use of the lens.

2. K nowledge about age-specific visual needs: consideration of visual needs in relation to anatomical and physiological changes, differences in lifestyle and habituation of the eyeglass wearer according to date of birth and age.

3. O ptical know-how about the lens-eye-system: consideration of the interaction between lens and eye and its impact on the calculation and manufacture of lenses for the desired optical performance.

4. Know-how to optimize the aesthetics of the eyeglass lens: consideration of the interaction of the physical appearance of the lens and its optical performance.

The focus is not only on progressive lenses – which are known to place the highest demands on the production of spectacle lenses for many reasons. Lenses for young people are becoming more complex, they are changing and need to be adapted to our changing visual habits, as the latest developments show.

It is all about preventing high-grade myopia in young people, and new solutions for vision are currently groundbreaking. Finally, it is important to counter the “pandemic of progressive myopia,” especially in China. In brief: for the manufacturing of individual spectacle lenses, it is enormously important to understand our vision behavior and our lifestyle habits better and better in order to be able to offer products that enable better, clearer and also healthier vision — and are no longer based purely on statistics and standard parameters or on a “one size fits all” approach. As trivial as this may sound, it is in fact complex. After all, the basis of the latest vision research is “big data”. There has never been so much data about every single person in this world and

Data Handling & Security

MAFO 4-23 18 TECHNOLOGY

How “big data” and recent scientific findings led to the highest level of personalization available in a Zeiss lens

the specific visual requirements of entire population groups and age groups as there is today. Zeiss makes use of this data, structuring and analyzing it in order to understand human vision better and better. As a result, the range of increasingly sophisticated, more individualized lenses is growing.

A case study of the individualization of a lens

Zeiss launched a completely new portfolio of premium lenses in 2018, named Zeiss SmartLife. The portfolio ranges from single vision to digital and progressive lenses. It is based on numerous technologies that are in place to ensure that those spectacle lenses (depending on the level) offer everything a modern lens must offer: refraction and centering values, consideration of the individual’s main activities, facial anatomy, frame shapes, consideration of individual habituation and the age-specific pupil dynamic and size.

In addition, the company has succeeded for the first time in incorporating data on actual viewing behavior across an entire portfolio into the lens design. The new portfolio is thus adapted to our mobile lifestyle, which is primarily characterized by the use of smartphones and tablets. But the special lens is even more: it is adaptive. This means that more and more knowledge about human vision is being incorporated into the lens design, resulting in increasingly individualized lenses for all age groups. The decisive factor here is that the complexity of the design is not at the expense of the partner eye care professionals. They get an improved and more individual product at hand but the consultation process, the fitting or even the ordering process does not change, everything remains as before.

Study situation

Let us take a closer look at the large data pool that provided important new knowledge for Zeiss SmartLife. Over a period of more than two years, the company has collected more than twelve million data records from eyeglass wearers, more than ever before.

The starting point was an online study that collected subjective data on the lifestyle of more than 300,000 consumers worldwide, and objectively measured data obtained with the help of a tracking procedure on viewing behavior. Both data pools were incorporated into the Zeiss Global Vision Study [1] of 2020/21.

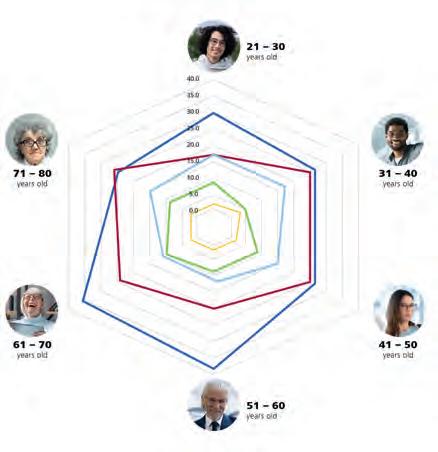

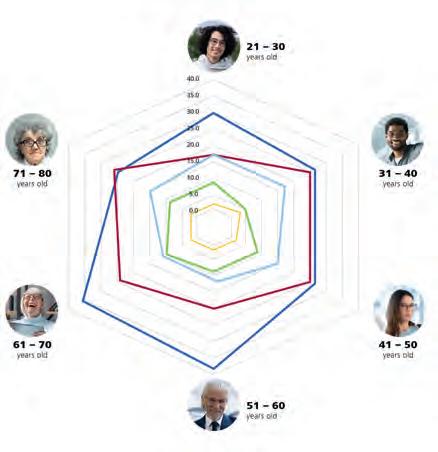

In tracking visual behavior, millions of objectively measured data points were collected from the daily lives of several hundred individuals from the U.S., China, and Germany. The subjects were from various occupational groups with different social and cultural backgrounds and ranged in age from 21 to 80 years.

They were then divided into six age groups (21-30 years, 31-40 years, 41-50 years, 51-60 years, 61-70 years, 71-80 years). The study examined how these people see in everyday life, what visual demands they have at work, at home or in their leisure time and was thus able to provide researches with conclusions about their actual visual behavior.

Among other things, the study showed that the visual demands in the six age groups differ significantly from one another – in the sense

Fig. 1: Illustration of how interaction with digital devices has increased regardless of age. Age-dependent commonalities were identified in the usage patterns, making it possible to delve deeper into the age structure and filter out age-specific details that make a difference. For illustrative purposes, these were divided into age groups.

of age-related differences in dynamics and in activity-dependent visual behavior.

It found that there is a difference between biological age and the socalled eye age, the optometric status of the eye (the actual visual acuity and habituation of the eyeglass wearer).

This information was added to the already known data from various studies on visual requirements, and based on this entire pool of data, an algorithm was developed to predict the visual behavior and thus the required lens design for the eyeglass wearer. This assumption has been transferred as the basis for the new design of Zeiss SmartLife.

More data, more possibilities

More individual data and parameters about the visual needs and behavior of eyeglass wearers allow for more possibilities and even more specific vision solutions for the individual. Nowadays it’s crucial to make use of these large and complex volumes of data by converting it into a large number of possible target designs.

While there were only a few hundred designs in the first generation of Zeiss SmartLife Individual, there are already more than forty thousand in Zeiss SmartLife Individual 3, which serve as the basis for the final lens. This is made possible by the use of the Zeiss Intelligence Augmented Design (IAD) algorithm. It uses all of the customer's data transmitted by the eye care professional, i.e. the specified lens type, individual prescription, frame data and age, and compares this data with the vision requirement profiles in the database in order to select the optimum design target. In a final step, all the customer's individual parameters are then used in an optimization process to adapt the lens to be manufactured as closely as possible to the optimal target design.

Data Handling & Security

MAFO 4-23 19 TECHNOLOGY

For illustration purposes: Let's take a 65-year-old eyeglasses wearer who is to be fitted with a Zeiss SmartLife Individual 3 progressive lens. To calculate the lens, the IAD algorithm requires the date of birth in addition to all order parameters.

This data is enriched with the large data pool, the biological age is compared with the eye age (based on the ordered addition) and the target design is calculated from this, resulting in the best possible individualized visual comfort for that 65-year-old.

This means that even if two customers of different ages have the same prescription, they will receive a lens design that is optimally matched to their visual needs, considering their individual visual habits and parameters.

In numbers that means: the optical performance of the new Zeiss SmartLife Individual 3 lenses is up to 29% better compared to previous SmartLife Individual lenses. In addition, 85% of wearers perceived wide fields of comfortable vision in all directions and at all distances [1]

Further study layers crucial for today's vision

New vision parameters have been incorporated into the large data pool for the new generation of all Zeiss SmartLife lenses. For example, the Zeiss Vision Science Lab at the University of Tübingen has researched the eye’s center of rotation.

Since the development of the eye model by Allvar Gullstrand (1911), one center of rotation has been assumed for all rotational movements of the eye based on prescription values. However, the study showed that the location of the rotation axis for vertical eye movements is significantly different from that for horizontal movements. The approach of the new SmartLife portfolio is primarily to take into account the changing visual behavior in today's smart and connected world and the increasingly dynamic vision with the many changes of gaze and “seeing out of the corner of the eye”, i.e. the increased need for peripheral vision.

Therefore, knowledge of the position of the horizontal and vertical eye rotation axis is particularly valuable in minimizing aberrations for the gazing eye when looking obliquely/peripherally through the lens. This is also shown by the investigations in our laboratories, in which we have determined corresponding limit values for determining the visual

range sizes and compared them with previous designs. This results in larger visual ranges for the new generation of Zeiss SmartLife lenses for the distance range than for the previous lenses and the digital and progressive lenses now also have larger visual ranges for looking at smartphones than for the previous SmartLife counterparts.

Conclusion: why spectacle lenses must always become more individualized

Over the past decade, refractive techniques, manufacturing processes, optical designs and consumer demands for lens performance have changed significantly. The flexibility, individuality and spontaneous tolerance of lenses is greater today than ever before.

Technology and personal needs, visual comfort and preferences, fashion trends, digitalization and big data continue to drive development. Although amazing strides have been made, for Zeiss this is only one step in the journey towards even more individualized lenses. ◆

References:

[1] Market consumer acceptance test on Zeiss SmartLife Individual 3 lens portfolio with n=172 study participants in DE, IT, CN by Carl Zeiss Vision International GmbH, DE 2022. (unpublished, data on file)

Manuela Weinreich has been working for Zeiss Vision Care as global product manager since 2009. Her official title is Head of Global Product Management Lens Designs. Accordingly, she is responsible for product management of the entire global VIS lens design portfolio. Weinreich is a qualified eye care professional with a degree in ophthalmic optics (Dipl. Ing.) from HTW Aalen (2005). She worked as an eye care professional for a while before joining Zeiss.

Data Handling & Security

Manuela Weinreich

MAFO 4-23 20 TECHNOLOGY

Fig. 2: Schematic representation of the improved distribution of the visual zones in Zeiss SmartLife Individual 3 lenses, adapted to individual visual behavior.

ChatGPT definition

Chat GPT, short for “Chatbot Generative Pre-trained Transformer,” is a new form of natural language processing. It is quickly gaining traction in the tech industry because it can simplify complex tasks. The AI program autonomously creates any text you want. All it takes is typing a question and you get an answer in seconds. The use is free of charge. Because of this, the number of users has already exploded in a short time. Students use it for essays, businesses use it for their administration, and it is even capable of writing poetry. The possibilities seem endless.

ChatGPT and real-time data

However, there is also criticism of the chatbot. For example, the widely used free version of ChatGPT is based on pretrained data (until year 2021), it cannot process information in real time. In simpler terms, ChatGPT has read an old book and can only give answers based on the information in that book. This is now to change with the new version. GPT-4 is able to analyze and convey current information. However, the new version is currently not available for free.

Employees attempting to use ChatGPT at work

According to Statista, as of June 2023, it was reported that 10.8% of employees of worldwide companies have tried using ChatGPT in the workplace at least once. Those who have put confidential corporate data into the AI-powered tool were 4.7%.

ChatGPT in enterprises

Five facts

ChatGPT has experienced immense hype after its release in 2022 and as employees are also using the new chatbot in companies, MAFO has summarized the most important facts every team leader should know.

Global cases of sensitive data spill into ChatGPT 2023

According to Statista, between the 9 th and 15th of April 2023, per 100,000 employees, 319 cases of sensitive data leaking on ChatGPT were spotted in worldwide companies. Compared to an observation between February and March 2023, the figure had increased by around 60%. The second-most common type of confidential data shared on ChatGPT was source code, with 278 cases per 100,000 employees.

Familiarity with ChatGPT in the U.S. 2023, by education

According to Statista, adults with the highest education level - particularly with a postgraduate degree - had the greatest level of familiarity with ChatGPT. The program, developed by startup OpenAI, was of far less concern to those with high school degrees or lower education. When looking at respondents with a little knowledge of ChatGPT, the numbers are far less drastically different. It is quite likely that the considerable coverage of the ChatGPT topic in media had an impact, giving most people some awareness of the topic. ◆

Data Handling & Security

MAFO 4-23 21 TECHNOLOGY

PFAS – what we know and what we do not know yet

Interview with Spectaris

PFAS are a group of chemicals comprising a very large number of substances. The number is estimated at approximately 10,000. Due to their special properties, the substances have been widely used for a long time in many industrial sectors and also in the household. However, many PFAS are toxic, accumulate through the food chain or are mobile and once released into the environment they are difficult or impossible to remove. Therefore, a ban is under discussion that could also affect spectacle lenses. MAFO has talked to Spectaris (German industry association for optics, photonics, analytical and medical technologies) about the current situation.

By Hanna Diewald

Which products, in the ophthalmic industry, do contain PFAS?

To answer this question, some background is necessary: Denmark, Germany, the Netherlands, Norway and Sweden have submitted a proposal to restrict the use of per- and polyfluoroalkyl substances (PFAS), with some use-specific, time-limited exemptions based on the availability and applicability of alternatives.

The proposed PFAS restrictions are the subject of study and extensive debate affecting numerous products, including medical devices, which include ophthalmic products.

All manufacturing companies are currently required to evaluate the extent to which their products contain one or more of the 10,000 substances. These tests are in full swing.

Since optical medical devices, which include frames, lenses and contact lenses, represent a wide range of materials, it is not possible to give a definitive answer to such a question at this time. To the best of our knowledge, ophthalmic lenses and contact lenses are most likely to be affected. The PFAS in high-performance materials will be the political undoing of precisely the technical property because of which they are used and are predominantly irreplaceable: their durability and resistance in industrial high-tech products, essential applications in medical technology and, of course, in ophthalmic optics products.

One thing is clear: if PFAS are present in products, it will most likely be difficult to replace them and still be able to manufacture medical products of the same high quality.

PFAS are said to be contained in coatings for spectacle lenses. Can you already say, at this stage, in which part of the coating exactly are PFAS usually used?

Modern premium spectacle lenses, such as those manufactured in Europe, are characterized by their optical performance, individual correction, as well as their long life and convenient use. Scratch resistant coatings, easy-to-clean-, and anti-reflective coatings contribute significantly to this. Modern premium lenses therefore contain PFAS in extremely small quantities.

These top coating layers provide dirt-repellent and easy cleaning properties. These coatings significantly increase the service life of spectacle lenses, which are subject to a great deal of wear and tear in everyday use due to dust, dirt and cleaning.

This is not only a matter of convenient cleaning and thus convenience for spectacle wearers, but also a matter of safety: clean and scratchresistant lenses enable the best possible vision, especially in safetyrelevant situations such as driving, in road traffic.

MAFO 4-23 22 SPOTLIGHT

Are there coated lenses that do not contain PFAS at all?

In principle, yes, but they do not have the advantages mentioned. The service life of such lenses is dramatically shorter. The quality of vision and the associated main function of the lenses is also severely impaired.

The vast majority of all premium lenses sold in Europe are equipped with high-performance coatings – a clear added value for customers and patients and a competitive advantage over no-name or low-cost suppliers from Asia.

Can you currently estimate exactly what impact a ban on all PFAS could have on the ophthalmic lens industry?

Currently, there are no known alternatives with comparable properties. With considerable effort and lead time, these could possibly be developed. In the short and medium term, however, a PFAS ban would reduce an important competitive advantage of European quality manufacturers and consumers would probably switch to cheap products from non-European production.

A shorter service life – due to higher stress on the lens surfaces from dust, dirt, cosmetic and other substances that are less easily removed – leads to the need to replace spectacle lenses more frequently, with the associated increased consumption of resources.

What can and should affected manufacturers do now?

Manufacturers support the move away from substances that are hazardous to the environment and people, and are making corresponding avoidance and substitution efforts to this end as part of their sustainability strategies. Specifically, they are working to develop substitutes for PFAS currently in use – wherever this is technically possible and feasible with reasonable timeframes to develop and industrially scale up substitutes.

As industry representatives, we are also committed to ensuring that the idea of the “essential use” concept is taken into account. This provides for blanket exemptions for essential areas of life as well as high-tech applications, including medical devices. In addition, the use of PFAS-containing intermediates, process aids and plant components in industrial plants must remain possible.

In addition, due to the sheer quantity of indispensable PFAS for essential applications, broader exemptions should be defined on the basis of suitable substance groups (“PFAS of low concern”) that have already been scientifically proven to be harmless, i.e. non-toxic. An indefinite exemption for fluoropolymers and fluoroelastomers should be considered. ◆

Advertisement WATCH VIDEO MAFO 4-23

Anything but ordinary Transitions Academy 2023

It is going to be exciting. Basically, that was clear the moment the invitation to attend the 26 th Transitions Academy in Orlando, Florida, arrived. On May 22 and 23, 1000 ECPs from more than 50 different countries made the pilgrimage to the JR Marriot Grand Lakes Hotel, where exciting topics, product innovations and immense networking potential awaited the visitors. By Sarah

Schmidt

It is 8 a.m. on May 22, 2023, and the 1,000 Transitions Academy attendees are gathering in the hotel´s massive ballroom for the official opening of the event. Under the motto “Lights on Tomorrow,” innovations are presented and new i mpulses are set.

The focus, of course, is on Transitions lenses, which are now available in seven brilliant colors. From hip amethyst purple to sapphire blue and classic brown, there is a color available for everyone. This new variety gives the entire Transitions lens technology an image makeover, and now appeals to the fashion-conscious and especially the young buyer base who may not have heard of light-changing lenses before.

Colors accompany us everywhere

When we are in love, we literally wear rose-colored glasses or we can get green with envy – colors accompany us through our lives as a matter of course, often unconsciously exerting a major influence on our

everyday lives. This is exactly where EssilorLuxottica´s future projects come in. Work is currently underway on spectacle lenses that are designed to intervene directly in the health and well-being of eyeglass wearers through certain tints. Light therapy is already being used to alleviate patients´ symptoms in the case of certain diagnoses, such as migraines or depression. A corresponding spectacle lens could follow up on this approach and help to cope better in everyday life.

Cooperation with Ray-Ban

Another news is the cooperation with Ray-Ban X Transitions, where Ray-Ban frames are increasingly offered with Transitions lenses. Furthermore, a small collection is being worked on, in which not only the lenses, but also the frame changes in the sunlight. The first prototypes, which were presented despite the early stage of development, show a light-changing pattern on the frame edges – but of course a change of the complete frame color would also be conceivable.

MAFO 4-23 24

SPOTLIGHT

An entertaining program

After the comprehensive opening lecture, the participants split up into different groups to take part in smaller workshops, the so-called breakout sessions. In this way, topics such as the psychology of colors, the customer journey or the connections between vision and light were revisited. In the so-called “Brand Experience”, the Transitions brand was brought to life once again, with fun and entertainment provided by a photo wall that generated funny avatars of the visitors thanks to whimsical filters, or the opportunity to play various games using VR glasses. The technical highlight of this Brand Experience was the presentation of motorcycle helmets whose visors adapt to the light conditions thanks to Transitions technology.

The keynote presentations were given by well-known speakers from various industries and sectors. Shawn Kanungo, for example, spoke about artificial intelligence, how it is already being used today and what possibilities are conceivable in the future.

After an eventful conference program, various ways were used to ensure an entertaining evening for the participants. Whether a joint dinner or an evening in a karting hall – there was probably something for every interest group.

Charming speakers and vibrant music on day 2

The second day started with a lot of excitement – as the opening speech was not only introduced by the charming presenter Miriam Isa, but a band attracted the participants to the great ballroom at the morning hour.

Then a panel of experts, consisting of various members of the EssilorLuxottica team and opticians and optometrists, settled on the stage to share their experiences around Transitions lenses.

One of the optometrists fitted professional swimmer Yohann Ndoye-Brouard with Transitions lenses in his swimming goggles, which enabled him to improve his performance immensely. From these stories, it was clear that Transitions lenses are capable of positively

TOOLS

impacting the vision and, in turn, the lives of consumers. Another block of breakout sessions was followed by the inspiring final key note presentation of Michelle Poler, famous as „fear-facer“.

Poler has created a social movement empowering millions to step outside of their comfort zone and tap into their full potential. In her presentation she described her personal journey from being a “scaredy-cat” to becoming a courageous power woman who faced her fears and successfully overcame them to rise above herself and fulfill her desires.

Innovation Awards

Following this presentation, the Transitions Academy Innovation Awards were presented in various categories, such as US Retailer of the Year or Canada Retailer of the Year.

After this ceremonial act, the participants moved on to the final program item of the conference schedule. Countless shuttle buses took the 1,000 participants to Mango´s Tropical Café in downtown Orlando for the closing event. In this bar not only a delicious buffet was waiting for the participants of the Transitions Academy, but also a terrific band, which provided for high spirits. There was dancing, laughing and celebrating a

SPOTLIGHT REDEFINING THE EDGE ULTRA PRECISION DIAMOND

ky diamond.ca • Diamond tools for any generator • Excellent service • Quick turnaround

Expert panel with various ECP´s.

Combination treatment in myopia management

When do Miyosmart and low-dose atropine complement one another?

A few years ago, Hoya Vision Care introduced the Miyosmart spectacle lens, at this time the first noninvasive method to slow down myopia progression in children with defocus segment technology. Additionally, experts use either special contact lenses, multifocal spectacle lenses or atropine eye drops for myopia management in children. The obvious question is whether the different approaches can be successfully combined. With initial studies showing promising results, Hoya Vision Care is now investigating with global experts when is the ideal time to prescribe atropine for patients with severe myopia progression.

Almost immediately after the market launch of Miyosmart in Germany, ophthalmologists and orthoptists began to wonder what a combination of special specatcle lenses and atropine might achieve, particularly in patients with severe myopia progression. At that time, there were no data on this, but now clinical evidence is available.

Miyosmart with DIMS (Defocus Incorporated Multiple Segments) Technology first became available in Germany in March 2021, and

since then Hoya Vision Care has been working with experts from around the world to build up an evidence-based foundation and consensus on how ophthalmologists might best combine the use of those spectacle lenses with atropine.

Great interest in spectacle lenses

“Spectacle lenses offer an opportunity for safe, non-invasive and effective myopia management in children and teens,” said Torben Othersen, Professional Affairs Manager for myopia at Hoya Lens

MAFO 4-23 26 SPOTLIGHT

Germany. “Since the Miyosmart spectacle lenses became available in Germany, there has been a very high level of interest in intelligent myopia management for children using Miyosmart; both on the part of ophthalmology and orthoptics as well as optometry. We are very pleased about it, because the interdisciplinary exchange between eye care professionals is enormously important for any serious and sustained discussion of myopia management,” adds Othersen.

Confidence in the special spectacle lenses by eye care professionals has been further reinforced following publication of the 6-year results from the long-term clinical study in April 2023, showing that these lenses remain effective over a long period of time.[1] This is the longest study on spectacle lenses for myopia management ever carried out.

The 6-year results are follow-up on the 2-year double-blind randomized controlled clinical trial (RCT) published in the British Journal of Ophthalmology in 2019.[2]

Results from this study indicate that the children aged 8 to 13 who received Miyosmart spectacle lenses from the beginning demonstrated a slowdown on average by 60% in axial eye length growth and on average by 59% in refractive error progression, compared to the control group who wore conventional single vision spectacle lenses during the first two year of the study.[2]

After the Miyosmart spectacle lens was able to establish itself globally, with over four million lenses already sold in Asia, Australia, Canada and Europe from launch in 2018 up to the end of 2022, [3] Othersen says: “It was appropriate for Hoya Vision Care to initiate a discussion about a combination treatment with low-dose atropine. Thus, Hoya convened a meeting with global experts in 2022, with the aim of finding a consensus on how the use of atropine could best be combined with these spectacle lenses.”

Experts from around the world

The participants included renowned experts from Europe and Asia, among them was the respected myopia researcher Professor Hakan Kaymak from Düsseldorf, Germany, who shared with the expert´s insights from his clinical experience and research.

All experts as well shared their experience with Miyosmart spectacle lenses, including their clinical use in combination with 0.01% atropine in myopic children and adolescents in Europe, when the desired results were not achieved with using Miyosmart spectacle lenses as a monotherapy.

Key findings

The experts noted a “better control effect” with the combination treatment and reported that there were no clinically significant differences in visual acuity, contrast vision or binocular vision depending on whether Miyosmart spectacle lenses were used alone or in combination with low-dose atropine. According to Othersen, the consensus helps ophthalmologists to distinguish whether a patient

should continue having a monotherapy or whether a greater myopia control effect could be achieved through the combination of spectacle lenses with low-dose atropine.

“This largely depends on whether the treatment goal has been achieved in the patient or not. If myopia progresses at the rate of emmetropic eye growth, continuation of a monotherapy with Miyosmart spectacle lenses is recommended,” Othersen explained. “However, when the treatment goal has not been achieved, it is important to inform eye care professionals about the additional benefit of combination treatment with low-dose atropine. Both procedures offer different approaches to slow down fast myopia progression; as such they are complementary.”

Treatment goals and geographical differences

Much of the discussion concerned the question of whether the treatment goal has been achieved or not. But what is the goal in myopia management? Led by Prof. Kaymak, the five experts pointed out that while the approach of using emmetropic respectively physiologic eye-length growth as a guide to myopia progression has been described in several papers, it has not been fully accepted yet.

However, eye growth in axial length of 0.10 mm per year between the ages of 10 and 13 has been shown to be associated with normal emmetropic eye growth,[4] whereas eye growth of more than 0.20 mm per year indicates that the treatment goal has not been achieved. Here it is important to mention that emmetropic eye growth is age-dependent. A Dutch study found that annual eye growth averaged 0.09 mm in 10- to 13-year-old emmetropes and 0.19 mm on average in 6- to 9-year-old emmetropes.[5]

However, treatment goals may also vary depending on which part of the world is concerned. “Treatment goals in diopters differ in Asian and Caucasian children. In Asian children, an annual increase in refractive error of less than -0.80 D is considered successful. In Caucasian children, European experts recommend a threshold of -0.50 D or less per year,” experts say.

Regarding the start of treatment, the expert panel recommended that older children with a lower risk of developing severe myopia, may initially be treated with optical interventions alone. In young children with a high-risk profile and myopia progression of -0.50 D or greater over the previous six months, starting immediately with combination treatment should be considered.

When the treatment goal has not been achieved, it is important to inform ECPs about the additional benefit of combination treatment with low-dose atropine.

MAFO 4-23 27 SPOTLIGHT

But what concentration of low-dose atropine is appropriate?

The experts explained that the dosage is usually set individually, depending on the myopia control and the side effects. They referred to the LAMP study which was conducted on Chinese children. The study evaluated the efficacy of different dosages of 0.01%, 0.025% and 0.05% over a three-year period. Dose-dependent efficacy for myopia control was observed, i.e. the higher the dosage, the better the myopia control. While side effects appeared acceptable at a dosage of 0.05% in Asian children, this was not the case in Caucasian children with lighter eyes.[6]

“The experts did not find clinically significant changes in visual acuity or binocular vision when comparing Miyosmart spectacle lenses as a monotherapy and in combination with low-dose atropine”, the consensus document states.

“Contrast vision with Miyosmart spectacle lenses alone and in combination with 0.01% atropine was investigated. No differences in contrast vision were found.[7] Where the expected treatment goal was not achieved with Miyosmart spectacle lenses alone as a monotherapy, the experts observed an improved myopia management effect using a combination treatment with low-dose atropine.” Another important consideration is variations in how atropine is prescribed in different parts of the world. Currently, atropine is prescribed in doses ranging from 0.01% to 0.5% for children in Asia.

However, this also depends on the individual country and the particular preferences of the eye care professionals concerned.

In some countries, reimbursement by health insurance companies also plays a role. In Taiwan, for example, only concentrations of 0.125% and higher are reimbursed, and thus these are more commonly prescribed than lower dosages.

In many European countries, where atropine is not reimbursed by the health insurance, the most common dosage is still 0.01%. However, the consensus of most professional ophthalmic associations now tends to be towards a higher dosage of 0.02% to 0.05%.

What studies show

In parallel with the consensus document, the investigations on combination treatment with spectacle lenses and atropine are growing.

In October 2022, Prof. Kaymak published his study examining the safety of combination treatment with Miyosmart spectacle lenses and 0.01% atropine.[7] In a pilot study of 12 young adults, he analyzed combination treatment in terms of safety. In each subject, bestcorrected visual acuity, contrast vision, and glare sensitivity were examined under the influence of the spectacle lenses alone and in combination with 0.01% atropine.

Miyosmart spectacle lenses with DIMS. technology do not pose any safety risk.[7] No significant changes were observed in visual acuity and binocular vision between Miyosmart spectacle lens alone and in combination with low-dose atropine.[8]

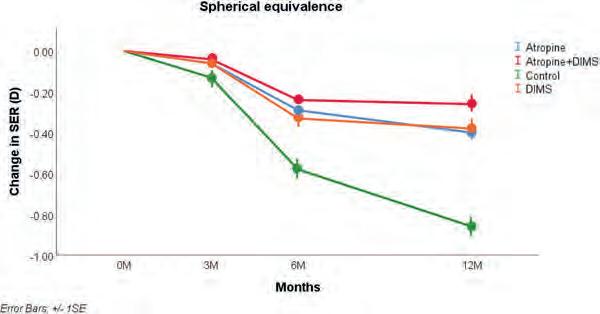

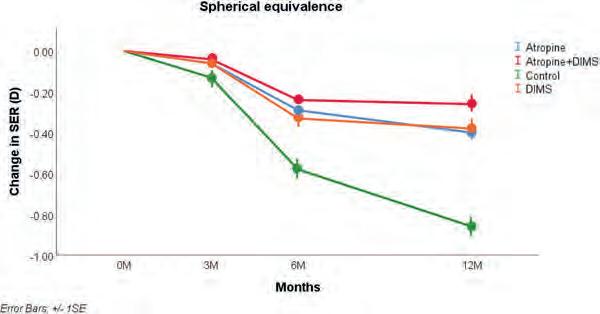

In an even more recent study, led by Zhu Huang et al. at Zhejiang University in Hangzhou, China, published in December 2022, the research team evaluated the efficacy of DIMS spectacle lenses in combination with 0.01% atropine. To the best of their knowledge, this study was the first to examine the treatment effect as a combination therapy with 0.01% atropine in terms of slowing axial eye length growth in myopic children.[9]

The retrospective study of 107 children was designed to determine whether combination treatment could slow the myopia progression, compared with a monotherapy or single vision spectacle lenses on their own.

Fig. 1: Model-adjusted mean and SE of myopia progression (SER) from baseline to 12 months.

Fig. 2: Model-adjusted mean and SE of change in axial length from baseline to 12 months.

MAFO 4-23 28 SPOTLIGHT

In young children with a high-risk profile and myopia progression of -0.50 D or greater, over six months, starting immediately with combination treatment should be considered.

“After the one-year follow-up period, the monotherapy with Miyosmart spectacle lens showed that myopia progression and axial eye length growth were lower compared to single vision spectacle lens use and even better in subjects treated with combination treatment with 0.01% atropine. This indicates a synergetic effect due to the combination treatment,” the authors report.

First European study on combination treatment [10]