11 minute read

Back to its roots

Back to its roots

Leica Eyecare: a traditional brand returns to Germany

The first state-of-the-art Leica Eyecare production facility is being built in Heuchelheim near Wetzlar (Germany). “Starting from scratch” is the motto here because, for the first time in its history, the famous company is setting up its own spectacle-lens production. For CEO Jörg Bauer, this is like having a baby – his baby, to be precise. When asked why, he answers promptly: “Because Leica spectacle lenses have always belonged here.” So MAFO went on site to take a closer look at the new production facility. (Note: Mafo visited the production a few weeks before the official opening in July 2023). By Hanna Diewald

We are greeted by Jörg Bauer, CEO of Leica Eyecare, and Marketing Manager Claudia Rehm: “Welcome to Wetzlar, the City of Optics. There is no way we can withhold the Leica world from you.” What is behind this statement soon becomes clear. We are standing right in front of the company headquarters, which is clearly an architectural gem. The entire building is designed to resemble a camera and round the roof there is a path with a spectacular view of the surrounding area. This makes even more curious to find out what lies hidden within the building itself.

The Leica brand

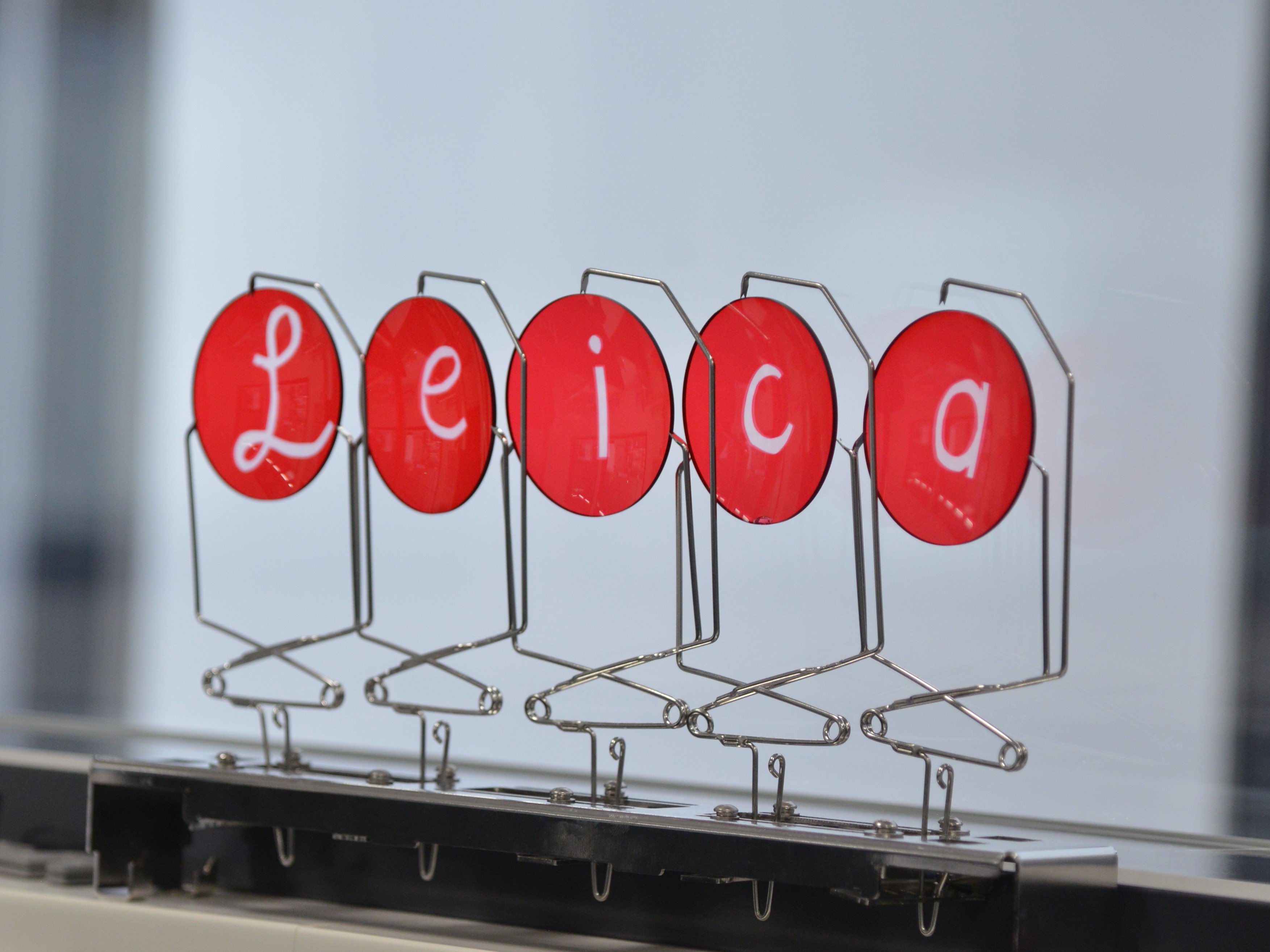

Our tour starts in the photo exhibition area and at the same time allows us to catch a glimpse of the camera production. Behind a pane of glass sit highly focused employees painting the edges of lenses black. At another station, a camera is being assembled from hundreds of components – some of them tiny. Here, absolute silence reigns, everything is neat and tidy. The meticulousness with which the employees go about their work is almost infectious and making everyone in front of the glass want to hold their breath. There are hardly any machines. Everything seems perfectly attuned, running like clockwork. Every operation is performed by hand. So this is where the world-famous premium cameras are made. Besides the production and administration, the neighboring buildings house a museum and a hotel as well as an academy, where one can attend photography courses, for example. All in all, around 730 employees work at the site. However, the reason for the visit is not about the headquarters, of course, but about spectacle lenses. And there we are to dive into a completely different world

Green-field production site

Our tour next takes us to the small town of Heuchelheim, about 15 minutes by car from the headquarters. Here, Leica Eyecare’s first purpose-built production hall has recently been erected – the contrast to the camera production could not have been starker.

A new, state-of-the-art lens production facility has been built here from nothing in just a few months. In contrast to our first stop, it is loud, lively, everything is fully automated and the machines are of the latest design. No need to whisper here.

The excitement of the managing director and the employees is palpable. No wonder, because in a few weeks, their “baby” will finally come to life. The first Leica spectacle lens production facility in Germany. But how did this come about, and why now?

The Leitz Camera

To understand Leica spectacle lenses better, it is worth taking a step back to look at the company’s history. Founded in the 19 th century as a family business, the company is now active worldwide. Under the founder Ernst Leitz, and later his son of the same name, the company became famous around the world.

The name Leica is a contraction of Leitz Camera. The company only entered the spectacle lens market in 2018. Novacel became the exclusive partner for the production and distribution of Leica Eyecare spectacle lenses in Europe. That the lenses were previously produced in France Jörg Bauer explains with the fact that the focus of the business at that time was simply elsewhere.

Sometimes the timing and the people have to fit perfectly – and that's exactly what’s happened now: “Maybe what was missing was someone

who had the energy to say, ‘We’re going to do this on our own here on site,’ who could work out a project and really convince the board. That's what I did in 2020,” Jörg Bauer explains.

Building up the company from scratch was a real challenge for the CEO. After all, it called for a motivated team, a viable concept and setting up production in a place where at the beginning of 2021 there had only been an empty warehouse. But he and the team made it happen.

Novacel will remain an important partner, especially for sales in other European markets: “I can't imagine a better partner for France, for example, where Novacel is number three in the market,” says Bauer.

State-of-the-art production

The excitement that has built up over the past few months to bring the baby to life is almost palpable; everyone seems highly motivated and enthusiastic. Right now, the final test spectacle lenses are still running on the production line.

There is always some detail that needs fine-tuning or a setscrew adjusted to make the end product – the lenses – just that little bit better. Currently, 20 employees work at the site. By the end of the year, the team is expected to grow to around 30 people.

From July 1, around 600 orders per day are to be produced. That is the initial volume planned, but it can then be increased relatively easily, for example by switching to 2- or 3-shifts a day.

Setting up such a production is a challenge: “There was nothing there to start with and everything has to be created. And it's not just about the production, it's about the entire supply chain. Everything has to run smoothly, from the interface with the customer to the development of the Super Clean Code, compliance with standards – such as the Medical Devices Regulation – to the toilet paper holder. That's when the team quickly has 15- to 16-hour days,” says the CEO as he describes the demands on himself and his employees.

But starting from scratch has many advantages, too, because there is no legacy from the past. There are dozens of machines in the hall. They are the latest available on the market. The majority of them come from manufacturers located in the immediate vicinity.

If the anti-reflective coating still needs optimizing or a process is not yet running perfectly, the experts in the companies concerned can be contacted easily and information exchanged. After all, the combined expertise of the ophthalmic optics industry is virtually on site.

And the machine manufacturers benefit, too, since they can also use the new production facility as a “show lab” for their customers – so it is a win-win situation.

Paperless production

Thanks to the well thought-out concept, the production is extremely energy efficient: “I think we've gone as far as you can go where it comes to sustainability,” Jörg Bauer proudly explains.

This also calls for genuine innovation, since the lab function is now entirely paperless: from the first operation, when the blank is removed from its packaging, to the last step, the final inspection.

In practice, this means that each pair of lenses and the tray have to be “married” up again several times.

After all, each lens has a long way to go through the 1500-square-meter hall. At no point during the various processes – grinding, polishing, cleaning, coating, tinting, final inspection and more – may the information be lost as to which lens belongs to whom, because this would result in endless searching. Discipline and order are thus top priorities for all the employees.

However, the team also has a great sense of humor. For example, employees have already given names to the machines from “Bob the Builder”, and colorful designs and patterns are sometimes tried out for children at the lens tinting station during break times, because there are no rigid structures here.

The new concept – with a lot of emotion

In addition to the new production facility in Germany, the brand's overall concept is also being updated. One reason is that Leica Eyecare also wants to support the specialist opticians with their new concept eyplains Bauer: “Opticians will be supplied with lenses that are made in Germany, by Leica, to a high quality standard and – most importantly – with a clear strategy. Because a brand like this can only be marketed by the brand itself, to ensure that the DNA, the emotions and also the intrinsic value of the brand all come across.” What is particularly important to Bauer is to be honest right from the start about what is being offered – and what is not. Five sales representatives have been given the task of successively finding suitable opticians who might be a good fit for Leica.

The company would like to have around 150 customers by the end of first year. The goals have been set realistically, since the company is starting from scratch with nothing but the customer database at the moment. Thus it's less about quantity, more about quality. This applies to the opticians too: “We don't want to flood the market and we don't have to be omnipresent.

That's not what we aspire to. We want to be partners. We want to offer retailers the chance to have an alternative. That is our goal. And that's also how we have positioned ourselves with the camera,” Jörg Bauer explains.

A select portfolio

For the company, deciding in favor of the brand and its repositioning has also meant consciously deciding against some products. For example, the portfolio will include no mineral lenses; and no polycarbonate either. As such, the lens manufacturer is pursuing exactly the opposite approach to many individual, smaller German manufacturers specializing in niche products such as mineral lenses.

Nor is it Leica Eyecare’s aim to constantly come up with a string of innovations. Instead, opticians should come to rely on consistently high quality with a dependable partner at their side. And when new products do come on the market, they should offer genuine added value. One example of this is a camera lens specifically matched to the brand which is currently under development.

Bold marketing

In the area of marketing, the company is starting from an unusually bold concept – at least for our industry. The guiding principle here is that “Everyone deserves to see the world as authentically as possible.” The background to the concept is the idea that when you look at the world on your smartphone or social media, it is very often seen through filters, whether it's in a landscape photo or a selfie. This creates peer pressure for someone to be more beautiful than the next person. “And I find it utterly incredible that a 24-year-old with a well-toned six-pack should be wearing progressive lenses in an advertisement. That just doesn't seem right with me,” says Jörg Bauer. That's why the company is deliberately working with characterful models and, above all, with real people who don’t have to conform to the common ideal of beauty. Neither do they have to be young or have perfect skin. Thus the ads feature people with pigmentation disorders as well as women with gray hair.

A unique opportunity

At the end of the day, we have come to see that people work here out of conviction – starting with the CEO Jörg Bauer, via the employees in production to those in marketing. Everyone has played their part in ensuring that Leica Eyecare returns to its roots, in supporting the brand and promoting Wetzlar. “We have been able to create something that we will probably never have the chance to do again in our lives – building it up from scratch. One project may fail, but we won’t give up. If we succeed, I'll be happy in ten years’ time that we have built up a solid production, perhaps in a larger building. That we are active internationally and well represented in our core markets. And then, in ten years, I’ll gradually start to prepare my exit and ask the question: ‘Who can carry on the good work?’ But right now, for myself, I can't imagine doing anything else.” ◆

Pictures: Silke Sage