Fitting Background

• Safety in sclerals – Part 2

• Monovision –not just about principles Manufacturing

• New technology in blocking systems

Fitting Background

• Safety in sclerals – Part 2

• Monovision –not just about principles Manufacturing

• New technology in blocking systems

From lens materials to industry support, we see the importance of working together to deliver products and expertise that truly transform patients’ lives. Full Range

It all feels almost back to normal: After a two-year break, the EFCLIN Congress and Exhibition was held at the end of April. Europe's largest trade fair, MIDO, took place at the same time with around 22,000 visitors. Only two weeks later, opti Munich opened its doors with a good 13,000 visitors and the GSLS, ARVO, BCLA and NCC congresses also took place. Many international optic and optometry enthusiasts were able to meet live again. Finally, for the first time since 2019, we are seeing the start of a return to normality – at least it might seem that way.

This emerging optimism unfortunately doesn't feel as good as it could, considering what's going on in the world. War in Europe. As if the Corona pandemic and natural disasters of recent years hadn't claimed enough victims.

By mid-June 2022, the UN High Commissioner for Refugees (UNHCR) estimated that around 8 million people had fled Ukraine as a result of the war and due to attacks by the Russian military in the country, crossing the border into a neighboring country. This is a catastrophe for the people who have had to flee, for the families who are now separated and living in uncertainty, but also for the many people who have remained in their country despite the threat of danger and, of course, for the relatives on all sides who have lost their loved ones.

The economic consequences may seem secondary at first, and yet they will affect us all in time. Inflation in Europe is rising, and raw materials are becoming scarcer. While oil and gas are becoming much more expensive, raw materials such as nickel, palladium and chrome are already increasingly difficult to obtain.

This will also affect our industry. In addition, many companies have branches and employees in the affected regions on both sides of the border. Here, too, there are still many challenges and uncertainties to be resolved.

Especially in such difficult times, it is good to keep an eye on the positive. For example, that hard times can also lead to great solidarity, such as the general realization that innocent people need to be helped. The optical industry in general has already impressively proven that everyone can contribute, and many have already done so.

In this issue we report on how the EFCLIN Congress went in detail and which topics were presented in the lectures. In part 2 of our "Safety in Contact Lenses" series by Eef van der Worp, we focus Ortho-K. We also take a look at monovision, which is often used with a love-hate relationship.

There are always things to re-evaluate and optimize in the manufacturing process. Marco Iovino has written a detailed article on the blocking process. You will find these and other topics in this issue. We hope you find them both interesting and stimulating! ■

SILKE SAGE Editor-In-Chief silke@global-cl.com

Title: Contamac, www.contamac.com

Inside front cover: Bausch + Lomb Inc., www.bausch.com

Page 4: Efclin, www.efclin.com

Page 7: Optimec Systems Ltd., www.optimecsystems.com

Page 13: K & Y Diamond Ltd, www.kydiamond.ca

Page 25: LAMBDA-X S.A., www.lambda-x.com

Page 27: Larsen Equipment Design Inc., www.larsenequipment.com

Page 31: DAC International, Inc., www.dac-intl.com

Page 35: Schneider GmbH & Co. KG, www.schneider-om.com

Page 37: AMETEK Precitech, Inc., www.sterlingint.com

Page 39: OPTOCRAFT GmbH, www.optocraft.com

Page 43: Rotlex, www.rotlex.com

Inside back cover: Acuity Polymers, Inc, www.acuitypolymers.com

Outside back cover: DAC International, Inc., www.dac-intl.com

LETTER

FROM THE EDITOR

36

Safety in sclerals – Part 2 Eef van der Worp

Monovision – not just about principles Silke Sage

Top(t)ics Eef van der Worp

Quido A. Cappelli passed away on Friday, May 6th at the age of 91. Of course, as you know, Quido was the only two-time President of the CLMA and was a true stabilizing force in this organization as his leadership was outstanding and his honesty and integrity were unquestionable. After studying Civil Engineering at Georgia Tech University, he became a pioneer and icon in the contact lens manufacturing industry. In addition, he worked closely with his friend and renown cornea and contact lens researcher, Dr. William "Joe" Benjamin - who preceded Quido by six weeks as he passed away on March 24th – on advancements in contact lens standards via a working group for the International Organization for Standardization (ISO). No one has been more honored by the CLMA than Quido Cappelli including receiving their two highest honors, the CLMA Medal of

Innovega Inc. announced the issuance of two US patents and the filing of two international patents that expand their portfolio to 56 patent cases. The first recently issued US patent, Transparent Projection Screen, protects novel technology for speckle-free augmented and mixed reality displays, while the second issued US patent, Contact Lens and Method and Systems for Constructing a Contact Lens, has broad claims for delivery of oxygen to the eye with smart contact lenses containing components having limited or no oxygen transmissibility.

The new international filing, display eyewear with auditory enhancement describes a novel system and apparatus to couple gaze tracking with directional microphones in extended reality eyewear to assist the hearing impaired in noisy environments and

Haag-Streit UK has announced the launch of the Haag-Streit ‘Slit Lamp Imaging Competition 2022’. Following very successful competitions held in 2019, 2020 and 2021, the ‘Slit Lamp Imaging Competition 2022’ gives eyecare professionals across the globe an opportunity to showcase their slit lamp imaging skills. Judging criteria will include image quality, technical execution, and disease interest.

Honor and the Dr. Josef Dallos Award. Another great CLMA leader and icon in the profession, Carl Moore, summarized his legacy best: "Quido was one of the early founders of the CLMA and an enthusiastic supporter and twice President of the organization. He was always focused on the big picture for the industry. His contribution is unparalleled." By Ed Bennett, Carl

Moore

Moore

to deliver the respective voice to text to the visual display. The second international filing, display eyewear with adjustable camera direction, protects image shifting in smart eyewear as a function of camera position and natural head-tilt and gaze changes for the diversity of visual tasks undertaken by smart eyewear users. Company co-founder and lead inventor, Dr. Jerome Legerton shared, "Our portfolio covers a broad scope of patents to protect our smart contact lenses, smart display eyewear, methods of personalizing and fitting each of them, multistage contact lens manufacturing, optical components and artificial intelligence software that makes the eyewear smart. It’s very meaningful for our team to advance this technology to first assist the sensory impaired and then to enable consumers to engage in the visual experiences made possible by this technology. Extended reality eyewear is making the metaverse experience possible.”

Haag-Streit is offering a host of prizes for the first three places. In addition to receiving the ‘Slit Lamp Imaging Competition 2022’ trophy, the winner of the competition will also be featured in an ophthalmic journal and will receive a Sony Alpha 7 IV Kit (28-70 mm, 33 Mpx, Full frame). Second place will receive a Nikon Z fc Double Zoom Kit (16-50 mm, 20.90 Mpx, APS-C/DX) and third place a Peak Design Everyday Backpack (20L).

The competition is open until August 12, 2022. Applicants should send their images to hsimagingcomp@gmail.com. More information on the Haag-Streit ‘Slit Lamp Imaging Competition 2022’, including participation terms, rules and regulations can be found online: https://www.haag-streit.com/imaging-competition.

BostonSight announced that they welcomed The Ohio State University Wexner Medical Center as the newest PROSE Provider Network site along with Drs. Chantelle Mundy, OD, and Stephanie Pisano, OD. With the addition of Ohio State Wexner Medical Center, the BostonSight PROSE Provider Network now includes 19 sites in four countries.

“At BostonSight we continue to expand our network of PROSE providers so that more patients can access this life-changing treatment,” said Sara Yost, BostonSight

On May 20 th, 2022 the new, significantly enlarged Trioptics branch office in Wetzlar, Germany, was officially inaugurated. Compared to the old building, the new building offers three times as much space and has an appealing, modernly designed showroom as its centerpiece.

The Wetzlar site has already proven itself in recent years as a central location for servicing customers from the DACH region as well as the Netherlands and Belgium, and is now being further expanded as a training center for the region. The showroom with more than 100 m² is used to present the extensive Trioptics portfolio of optical measuring and manufacturing equipment. Since May 2022, the company has also offered center turning of mounted optical assemblies as prototype production and contract manufacturing for small series in an air-conditioned workshop. Site manager Stefan Best emphasizes: "Not only do we perform equipment demonstrations and training courses in our showroom, but we also offer our customers comprehensive consulting services here. In doing so, it is particularly important to us to

President and CEO. “With the addition of Ohio State Wexner Medical Center, we can help more patients in central Ohio and beyond. We are excited to welcome Dr. Mundy and Dr. Pisano, and the Wexner Medical Center team, to the PROSE Network.”

“As a practitioner in the PROSE Provider Network, I’m looking forward to offering this customizable device to improve our patients’ vision and quality of life,” said Dr. Mundy. “This treatment adds to our ability to provide the highest level of treatment and care for our patients with ocular surface disease and advanced corneal conditions,” said Dr. Pisano.

For the official inauguration, site manager Stefan Best welcomed representatives of the city of Wetzlar, Optence Wetzlar Network, IHK Lahn-Dill, Hessen Trade and Optikzentrum Wetzlar, in addition to the management of Trioptics – represented by Kristin Holzhey (CEO), Stefan Krey (CTO) and Simon Zilian (CSO).

jointly configure the devices that are suitable for the individual requirements. In order to provide our customers with optimum support, we also offer contract measurements, prototype and small series production."

Data breach costs rose from USD 3.86 million to USD 4.24 million

in 2021, the highest average total cost in the 17-year history of the Cost of a Data Breach Report, featuring research by the Ponemon Institute.

Source:IBM

The prospects for economic growth in the world's major economies are now much bleaker than they were in December 2021. For Germany, the OECD has revised its growth forecast downward by 2.2

percentage points to 1.9 percent. In Statista’s selection of countries, only Russia has been hit harder, with nominal GDP expected to fall by 10 percent year-on-year in 2022.

Of the 21.7 million wearers in the 34 countries covered in the Euromcontact 2021 market data report, 56%

of them use daily disposable, 43.9% weekly/bi-weekly and monthly replacement lenses, and 0.07% conventional soft lenses.

Source:Euromcontact

Across all sales channels, total contact lens sales in 2021 amounted to 532 million euros vs. 523 million euros in 2020 in Germany. In total, contact lens sales increased by 1.7 percent compared to the previous year.

Source: Industry Report ZVA (Central Association of Opticians and Optometrists, Germany)

According to the German industry association Spectaris, German manufacturers of ophthalmic optics and consumer optics were able to recover from the negative effects of the corona pandemic in 2021.

Overall, sales in 2021 increased by 11.4 percent to 4.75 billion euros compared to 2020.

Source: Spectaris

At K&Y Diamond Ltd, it’s all about finding

Whether it’s manufacturing a special diamond tool used to make scleral lenses (as shown) or helping to solve surface finish issues, out team of dedicated technicians and engineers are always willing to go the extra mile. It’s one reason why we’ve grown into one of the world’s largest manufacturers of single-crystal diamond tools used to make RGP lenses, IOL’S and optical molds. Our diamonds are found in both large and small labs in over 60 countries earning us a reputation for delivering a superior product at a fair price. Consistent growth and service has allowed us to invest in both state-of-the art manufacturing systems and the latest metrology; some of which is found nowhere else. Let us put our +45 years of experience to work for you! www.kydiamond.ca / kydiamond@kydiamond.ca

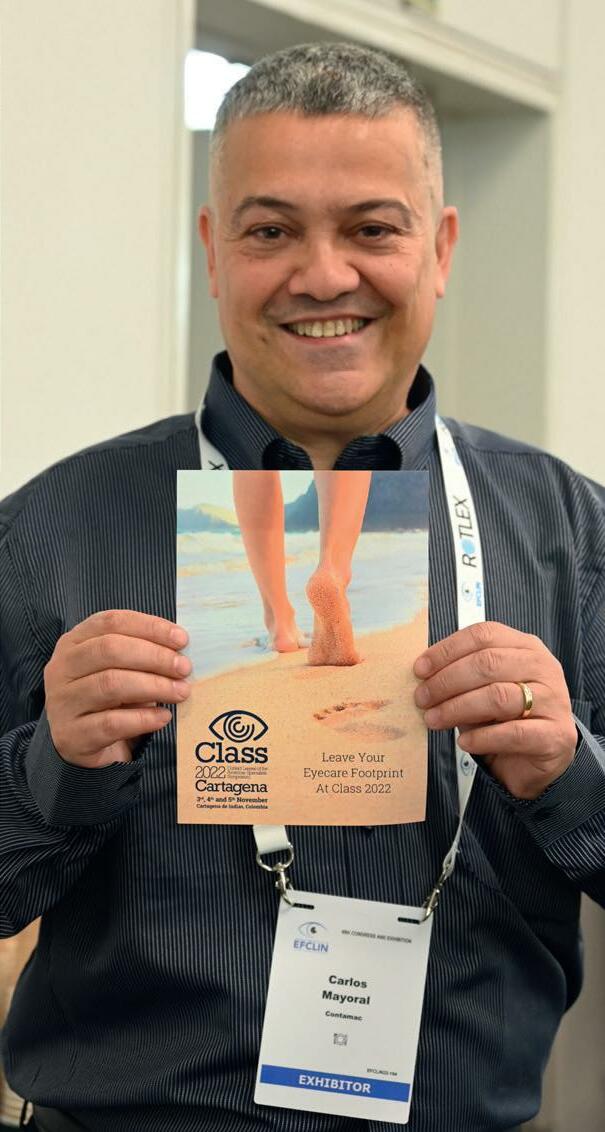

Contamac has received 510(k) clearance from the U.S. Food and Drug Administration (FDA) for the therapeutic use of its Optimum Infinite (180Dk) lens material in scleral contact lenses. Already FDA-cleared for daily wear in spherical, toric, multifocal, and orthokeratology modalities, obtaining expanded 510(k) clearance to include ocular surface disease offers an additional treatment option, with enhanced material characteristics to support the ocular health of such conditions, according to Contamac. Optimum Infinite, Optimum Extra, Optimum Extreme, and Hexa100 lens materials are suitable for therapeutic use in eyes that have ocular surface disease (e.g., ocular Graft-versus-Host disease, Sjögren’s, dry eye syndrome, and filamentary keratitis), limbal stem cell deficiency (e.g., Stevens-Johnson syndrome, chemical radiation, and thermal burns), disorders of the skin (e.g. atopy, ectodermal dysplasia), neurotrophic keratitis (e.g., herpes simplex, herpes zoster, familial dysautonomia), and corneal exposure (e.g., anatomic, paralytic), where the expanded tear reservoir and protection against an adverse environment afforded by a scleral lens might prove beneficial. www.contamac.com / sales@contamac.co.uk

The metrology of diffractive IOLs is challenging due to multiple factors. Time management is one of the most dominant issues as it takes up to 2 minutes to fully characterize one lens, therefore restricting the production line to its capacity to certify the IOLs. Furthermore, most of the existing metrology instruments imply complexity in use and installation due to the sensitivity of the machines. To drastically reduce the measurement time while improving the convenience and the characterization of the lenses, Lambda-X has tackled those issues and will soon launch the latest generation of Nimo metrology instrument: NIMO TEMPO. Speed, stability, traceability and R&r (Repeatability & reproducibility) are many of the advantages of this newcomer to the ophthalmic market. For several weeks now, beta testers have had the chance to experiment with a new technology, providing them with accurate, reliable data. Efficiency and repeatability are at the center of this new development, allowing the operator to work faster and in a more stable environment. The accompanying software opens the doors to various data analysis as well as new measurements of the contact lens. Interested in an exclusive preview of the NIMO TEMPO during which we will demonstrate the many features and benefits of NIMO TEMPO by characterizing your own IOLs during a live workshop with your team? Visit our website: Ophthalmics.lambda-x.com/nimo-tempo - sales-ophthalmics@lambda-x.com - +32 67 79 40 80.

OptiSpheric® IOL PRO 2 offers fully automated IOL measurement. It is completed with WorkStation IOL and integrated SortStation IOL. This workplace is the best choice when it comes to carrying out all the steps upstream and downstream of the measurement in a simple, fast and safe process. It includes loading the sample holders with optimal illumination that makes it easy to ensure the ideal positioning of the lenses. Moreover, the lenses can safely be sorted after the measurement: Test results are automatically transferred to the display and made visible directly at the location of the samples. The fulfillment of the pass/fail criterion is displayed in a red/green color scheme and the reliable assignment of each lens is enabled. www.trioptics.com / sales@trioptics.com

A research team has developed a smart contact lens-type wearable device to prevent diabetic retinopathy and treat it in its early stages. Soft contact lenses may soon become a bioinstrumentation tool for unobtrusive monitoring of ocular diseases. Scientists have developed an AI system that can analyze eye scans and identify patients at a high risk of a heart attack. A study found that pupils reveal ‘aphantasia’ – the absence of visual imagination.

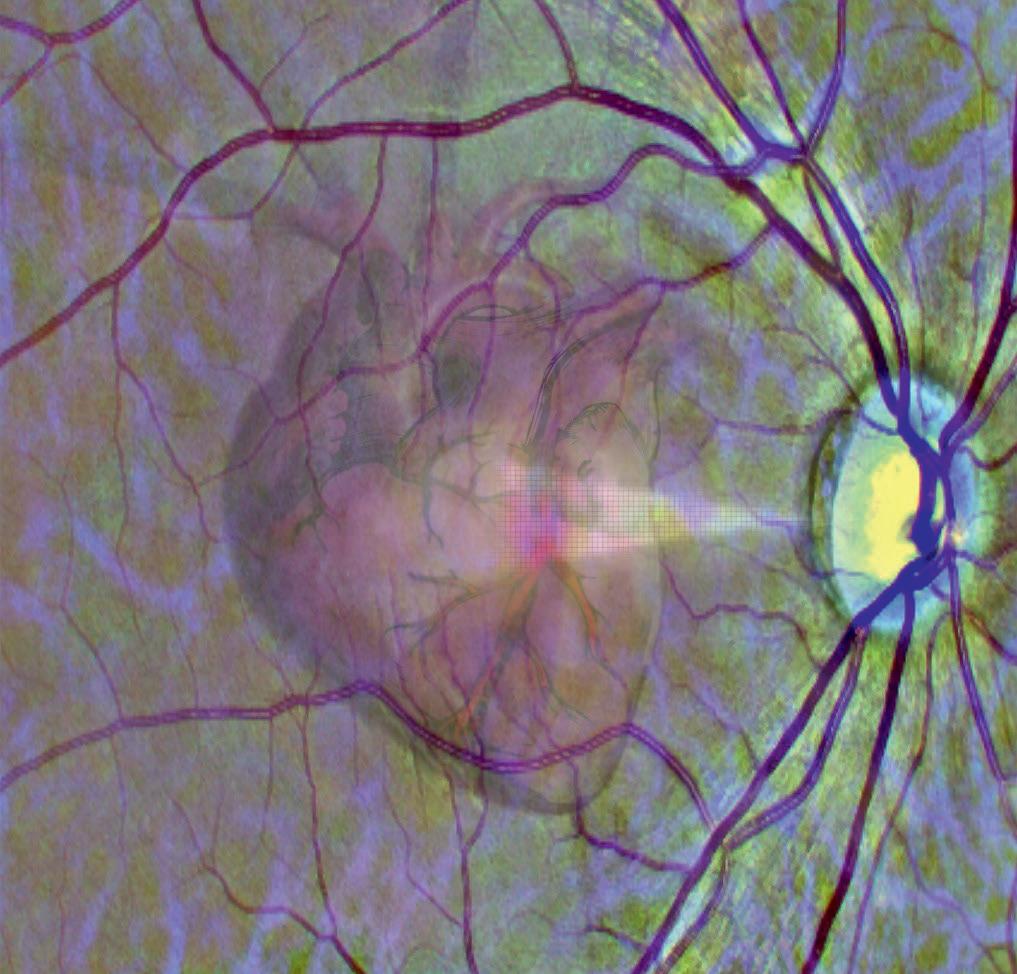

By Rebekka NurkanovicA POSTECH research team led by Professor Sei Kwang Hahn and Ph.D. candidate Geon-Hui Lee (Department of Materials Science and Engineering) in collaboration with Dr. Sangbaie Shin of PHI BIOMED Co. has recently developed a smart contact lens-type wearable device to prevent diabetic retinopathy and treat it in its early stages by irradiating 120 µW far red/LED light to the retina. Diabetic retinopathy is currently treated by invasive repeated therapeutic injections to the eyeball or thousands of small burns made with a laser to destroy capillaries near the edges of retina under anesthesia. Both procedures are considered highly painful for the patient.

Through the study with diabetic animal models, the researchers confirmed that the diabetic retinopathy did not appear in animals that wore the smart contact lenses for 15 minutes three times a week for a total of eight weeks. In contrast, the animals that did not wear the lenses showed retinopathic conditions. The safety and effectiveness of the lenses were also confirmed by the histological analysis of the cornea and retina.

Professor Sei Kwang Han who led the study, says that it has demonstrated the feasibility of a lens-type wearable device for the applications not only to monitoring oxygen saturation, heart beating rate, and ophthalmologic diseases, but also to treating depression, insomnia, neuronal diseases and more.

Published in Advanced Science, this study was conducted by

Prevention of diabetic retinopathy, monitoring of ocular diseases, AI for eye scan analysis, pupils reveal ‘aphantasia’

the support from the Nano · Material Technology Development Program, Disease Oriented Translational Research, Mid-career Researcher Program, Brain Korea 21 Fostering Outstanding Universities (FOUR) project, and the Korea Medical Device Development Fund of the National Research Foundation of Korea, and by the World Class 300 Project of the Ministry of SMEs and Startups of Korea. DOI: 10.1002/advs.202103254

Sources: Pohang University of Science & Technology (POSTECH)

A new contact lens technology to help diagnose and monitor medical conditions may soon be ready for clinical trials. A team of researchers from Purdue University worked with biomedical, mechanical and chemical engineers, along with clinicians, to develop the novel technology. The team enabled commercial soft contact lenses to be a bioinstrumentation tool for unobtrusive monitoring of clinically important information associated with underlying ocular health conditions. The team's work is published in Nature Communications. The

Purdue Research Foundation Office of Technology Commercialization helped secure a patent for the technology and it is available for licensing.

"This technology will be greatly beneficial to the painless diagnosis or early detection of many ocular diseases including glaucoma" said Chi Hwan Lee, the Leslie A. Geddes assistant professor of biomedical engineering and assistant professor of mechanical engineering at Purdue who is leading the development team. "Since the first conceptual invention by Leonardo da Vinci, there has been a great desire to utilize contact lenses for eye-wearable biomedical platforms."

New contact lens technology to help diagnose and monitor medical conditions may soon be ready for clinical trials. The team enabled commercial soft contact lenses to be a bioinstrumentation tool for unobtrusive monitoring of clinically important information associated with underlying ocular health conditions. Photo: Pete Kollbaum

Sensors or other electronics previously couldn't be used for commercial soft contact lenses because the fabrication technology required a rigid, planar surface incompatible with the soft, curved shape of a contact lens.

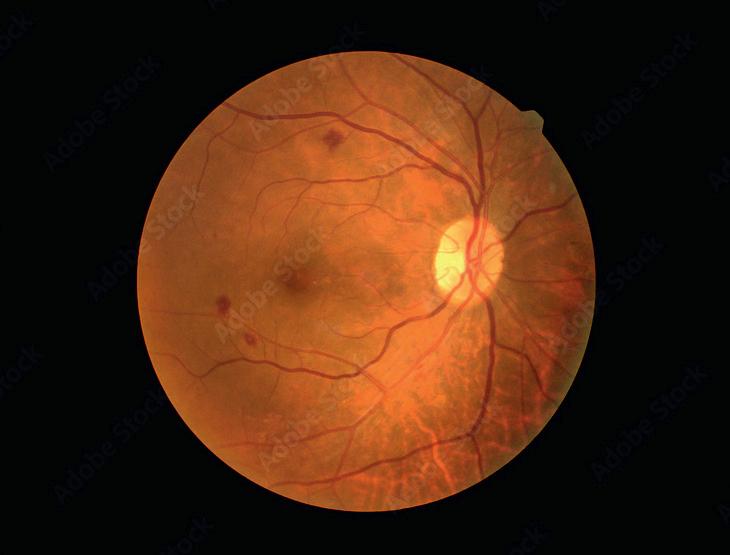

Scientists have developed an artificial intelligence system that can analyze eye scans taken during a routine visit to an optician or eye clinic and identify patients at a high risk of a heart attack. Doctors have recognized that changes to the tiny blood vessels in the retina are indicators of broader vascular disease, including problems with the heart.

In the research, led by the University of Leeds, deep learning techniques were used to train an AI system to automatically read retinal scans and identify those people who, over the following year, were likely to have a heart attack.

Deep learning is a complex series of algorithms that enable computers to identify patterns in data and to make predictions.

Writing in the journal Nature Machine Intelligence, the researchers report in their paper – Predicting Infarction through your retinal scans and minimal personal Information – that the AI system had an accuracy of between 70% and 80% and could be used as a second referral mechanism for in-depth cardiovascular examination.

A study, led by researchers from UNSW Sydney and published in eLife, found that the pupils of people with aphantasia did not respond when asked to imagine dark and light objects, while those without aphantasia did.

To first gauge the pupillary reflex of non-aphantasic people, the researchers sought 42 study participants, self-reported as having a visual imagination, and fitted them with glasses

The team has paved a unique way that enables the seamless integration of ultrathin, stretchable biosensors with commercial soft contact lenses via wet adhesive bonding. The biosensors embedded on the soft contact lenses record electrophysiological retinal activity from the corneal surface of human eyes, without the need of topical anesthesia that has been required in current clinical settings for pain management and safety.

"This technology will allow doctors and scientists to better understand spontaneous retinal activity with significantly improved accuracy, reliability, and user comfort," said Pete Kollbaum, the Director of the Borish Center for Ophthalmic Research and an associate professor of optometry at Indiana University who is leading clinical trials. DOI : 10.1038/s41467-021-21916-8

Sources: Purdue UniversityProfessor Alex Frangi supervised the research. He said: “This technique opens-up the possibility of revolutionizing the screening of cardiac disease. Retinal scans are comparatively cheap and routinely used in many optician practices. As a result of automated screening, patients who are at high risk of becoming ill could be referred for specialist cardiac services. The system could also be used to track early signs of heart disease.”

The study involved a worldwide collaboration of scientists, engineers and clinicians from the University of Leeds. The UK Biobank provided data for the study. During the deep learning process, the AI system analyzed the retinal scans and cardiac scans from more than 5,000 people. The AI system identified associations between pathology in the retina and changes in the patient’s heart.

Once the image patterns were learned, the AI system could estimate the size and pumping efficiency of the left ventricle, one of the heart’s four chambers, from retinal scans alone. An enlarged ventricle is linked with an increased risk of heart disease. With information on the estimated size of the left ventricle and its pumping efficiency combined with basic demographic data about the patient, their age and sex, the AI system could make a prediction about their risk of a heart attack over the subsequent twelve months.

DOI: https://doi.org/10.1038/s42256-021-00427-7

Sources: University of Leeds

to track their eye movements and pupil sizes. Participants were then exposed to bright or dark shapes against a grey background, which predictably evoked pupillary constriction in response to bright shapes (comparable to looking up at a bright sky) and pupillary dilation in response to dark shapes (after switching a light off). Next, to test visual imagery – the mind’s capacity to visualize objects – participants were asked to simply imagine those same light or dark shapes (with their eyes open, for their pupils to be tracked) and subsequently

report the ‘vividness’ of that imagery. The researchers found that even in response to imagined bright and dark shapes, the participants’ pupils still constricted and dilated appropriately, a pupillary response that was larger in those reporting greater imagery vividness. Finally, with the link between visual imagery and pupillary response established, the researchers sought to test the effect in aphantasic individuals. The researchers repeated the study with 18 participants self-reporting aphantasia. Exposing participants to bright and dark shapes, the researchers found that aphantasic individuals exhibited the same pupillary response as the general population: constriction to bright, dilation to dark. However, during the study’s second component where participants were asked to visualize those same shapes, the pupillary response of aphantasic individuals did not significantly differ in response to imagined dark versus imagined bright objects. To ensure the aphantasic participants were really attempting imagery, the researchers included a further experimental condition, requesting aphantasic individuals to visualize four shapes, instead of one. While the pupils of those with aphantasia

showed no difference when imagining light versus dark objects, they did show a difference imagining one versus four objects, suggesting more mental effort, thereby negating an explanation of non-participation by aphantasic individuals. Next, the team of researchers plans to investigate how this new method could be scaled up and run online to allow a global, efficient and objective measurement of imagery and aphantasia. DOI: 10.7554/eLife.72484

Sources: University of New South Wales

Referenzen: [1] Campigotto A, Leahy S, Zhao G, Campbell RJ, Lai Y. Non-invasive Intraocular pressure monitoring with contact lens. Br J Ophthalmol. 2020 Sep;104(9):1324-1328. doi: 10.1136/bjophthalmol-2018-313714. Epub 2019 Jul 2. PMID: 31266776.

This year's EFCLIN Congress, held from April 28-30, 2022, welcomed nearly 300 attendees in Sitges, Barcelona, after a Corona-related two-year hiatus. A large amount of time was given over to regulatory issues (MDR), which continue to preoccupy the entire industry. Innovations in contact lens and IOL design, new technologies in manufacturing and the proper evaluation of software were other important topics discussed in the presentations. There was a great sense of joy at being together again throughout the entire event.

By Silke Sage

By Silke Sage

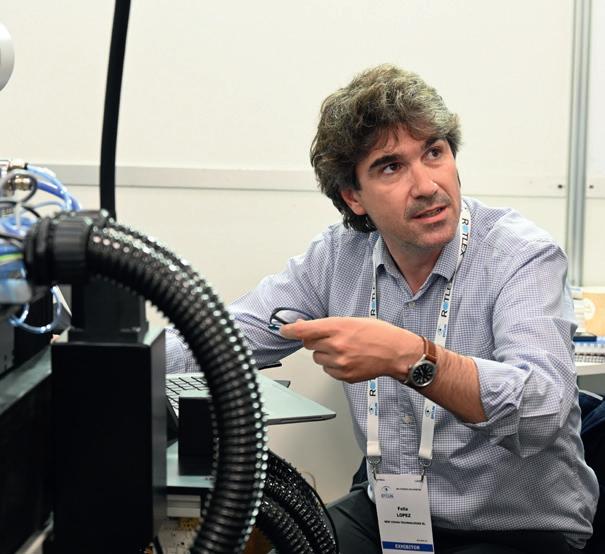

After a long break due to Corona, the exhibitors and visitors at this year's EFCLIN Congress were very happy to see each other again. A relevant and attractive lecture program, a manufacturers' forum and an interesting industry exhibition attracted 289 visitors from 31 countries to Sitges, southwest of Barcelona. Over the three days, visitors were able to learn about materials for contact lenses and intraocular lenses (IOLs), manufacturing machinery, measuring equipment, diamond tools, contact lens and IOL innovations as well as service offerings. This meant that the number of visitors was almost back to the same level as in the years prior to the Corona pandemic. The industry is characterized by long-standing business relationships, friendships and lively exchanges. Thus, the general mood was very good. “Not to have come would have been a mistake,” said one visitor from

Australia. With delegates from all over the world, the 48 th EFCLIN Congress and Exhibition proved once again that it is “the place to be” when it comes to everything related to contact lenses and IOLs.

The venue for this year's event was the beach resort of Sitges, Spain, which offered plenty of space for business and evening activities within a setting of the pretty old town, beach bars and a very well-equipped congress hotel.

Already at noon on Thursday, April 28, during the Manufacturers' Forum, a topical issue was taken up by the EUROMCONTACT Secretary General and put up for discussion. The potentially problematic use of per- and polyfluorinated alkyl substances (PFAS). These are industrial chemicals that are used in numerous industrial processes and consumer products because of their special technical properties.

The congress motto “A World of Opportunities 2022” was taken up by many of the speakers in the strong and very varied lecture program. Three keynote speeches opened the lecture sessions on Friday morning. Dr. Diego Lopez Alcón addressed the possibility of multifocal scleral lens designs. As they are often the first choice for irregular corneas or surface diseases, correction for presbyopia is desirable while at the same time being an enormous challenge, not only for manufacturers but also for scleral lens specialists.

Prof. Dr. Andrés Vásquez Qintero addressed the Past, the Present and the Future of smart contact lenses in his presentation. He highlighted the evolution of the different possibilities in this field and gave an exciting outlook into the future in which these lenses will play a role in biomedical diagnostics as well as being important for entertainment vision.

In his presentation, “Accommodating IOLs and the Holy Grail”, Dr. David Spalton shared with his audience the current multifocal possibilities after cataract surgery. Unfortunately, these are limited by halos, glare and loss of contrast and the

results are somewhat sobering. However, hope lies in the possibilities of accommodative systems. He showed vividly how far progress has been made in this area: Unfortunately, not so much progress has been made as yet – but with good approaches things look more promising further into the future. The contact lens session continued with an illustrative presentation on new technologies in blocking systems by Marco Iovino. He showed the mechanical conditions during the blocking process and what impact they can have on a finished contact lens! Marco Iovino presents his paper in this issue of GlobalCONTACT starting on page 22.

Dr. Randy Kojima presented a modification of Ortho-K lenses for myopia control. Among other factors, the optical diameter plays a crucial role here. He explained very clearly the impact this can have on design and effectiveness in myopia management. “Software Validation in the CL Industry” was the title of Filippo Selden's lecture. He described the concept of Software Validation, the Regulatory Context, its role in a Lab's own Quality Management System and how Advance Medical has tackled the subject with its own Software Validation Protocol.

The final highlight of the event was the congress dinner on Saturday evening. The Congress Hotel provided the festive setting with an aperitif and three-course menu. The current EFCLIN president Armin Duddek and three past presidents did not miss the opportunity to cut a cake for 50 years of EFCLIN.

In the IOL session, which was held in parallel, Dr. Gonzalo José Bernabeu Arias discussed the following topic: Multifocal Intraocular Lenses after more than 10 years of proper use. In his presentation, he conveyed to the audience the importance of the correct use of these lenses, when they should be used, where they should not be used, why patients in some cases are dissatisfied, and how to select the ideal patient for this kind of implant.

Dr. Ana Hervás Ontiveros discussed the challenges of toric IOLs in her presentation and provided an update on this topic.

In his lecture, Prof. Dr. Gerd Auffarth showed the Optical Effects of IOL Complications. In addition to normal monofocal lenses, today there are also the modern EDOF lenses with increased depth of focus as well as diffractive trifocal lenses. His presentation reviewed each type of lens and its impact on optical side effects backed up by illustrative examples. Saturday offered the audience a wide-ranging program on MDR and regulatory issues.

The traditional golf tournament was held prior to the actual EFCLIN Congress. This year the tournament was won by Marco Iovino/Medlac Italiy.

On Thursday evening, REM, Optocraft, Larsen LED and Acuity Polymer sponsored an Open Bar. This event was held in the hotel bar and was very well received.

On Friday evening, Bausch+Lomb Boston celebrated their 50 th anniversary. The company invited business friends, partners, colleagues and customers to a trendy restaurant in Sitges directly on the promenade.

Also on Friday evening, Contamac again organized a friendly football (soccer) competition for the 4th time, with Contamac playing against customers, business partners and employees.

Mark your calenders: the EFCLIN Board announced that the 2023 event – the 49th EFCLIN Congress and Exhibition – will be held in Budapest, Hungary, from April 20-22, 2023. n

The EFCLIN Manufacturers’ Forum was again the ‘kick off’ of the 2022 EFCLIN conference in Sitges. The topic of the forum was the European situation on PFAS* and the impact on our industry. Following Pascal Rouhiers great presentation in Manufacturers’ Forum three questions were asked and discussed in the format Erik Smidt introduced several years ago. Again, the attendees were divided in discussion groups at several tables. They had to discuss three questions and sort them in order of importance.

How can the industry be of assistance to organizations like Euromcontact in the struggle in Europe to be able to let the European Union know the significance of certain polymers in contact lenses? Also, it is important to let the authorities know what is happening with the waste in production of contact lenses. The outcome of the discussions was as follows.

1. The most important way to get help from the industry is to collect data and to reduce waste.

2. Creating new materials and processes. Remarkably reduce waste also got into the second place.

3. Reduction or replacement of PFAS in the contact lens material and or get exception.

The first step: Advocacy Investigation Definition

The second step should be according to the attendees: Development Chemistry Communication

The wishes of the attendees were: Derogation Tolerance Collaboration Participation

What

1. The organizations should find a path to slow down the transition or at last make it manageable.

2. Continuous updated information is of great importance to the attendees.

3. To help and to provide data to create a closed recycling loop of the material.

In one word: what should be the first, the second and the third step to do?

It was a Manufacturers’ Forum that, above all, raised participants' awareness of what is to come in Europe in terms of all kinds of environmental situations and their impact on our industry. It is clear that EFCLIN, Euromcontact and the industry should put their efforts together in creating a solid and good base to be able to produce contact lenses in a safe and healthy manner with low restrictions of the European Union. Of course, in such a way that production has as little impact on the environment as possible. n

*Per- and polyfluorinated alkyl substances (PFAS) are industrial chemicals that are used in numerous industrial processes and consumer products due to their special technical properties. The substance group comprises more than 4700 different compounds.

In the subgroup of perfluoroalkyl substances, the compounds perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) are the best studied. Like many PFAS, these two compounds are also difficult to degrade and are now detectable in the environment, the food chain and in humans.

In September 2020, the European Food Safety Authority (EFSA) published a re-evaluation of the health risks posed by PFAS in food.

An industry reunion – EFCLIN 2022 Sitges/ Barcelona. It’s what we were all waiting for, and what was anticipated to be a great meeting became true. The congress was buzzing: providing opportunities to see familiar faces once again, meet newcomers in the industry, and connect and share ideas for the future. Contamac continued to share the success of Optimum Infinite, its balance of properties providing hyper Dk (180 Dk) with a tailored modulus and excellent wettability. The material also recently received 510(k) clearance for therapeutic use in scleral lenses to treat ocular surface disorders. Continuing the tradition of the ‘ContaCup’, Contamac customers, industry friends and staff gathered to play five-a-side football. After warming up (or brushing off the cobwebs for some), the competitive spirit came through. Thank you to all those who took part or spectated, and special congratulations to Philipp Polonyi who was awarded Best Player, Oli Gubler for Best Goal and Garth Barnard for Best Goal Keeper. The football tradition was extended to the Contamac booth, where everyone was encouraged to play foosball (table football) for a chance to win. The lucky winner was Edwin Fierkens of Sub Micron Tooling!

-30

The MDR continued to be a hot industry topic, and Contamac was pleased to share the NAMSA MDR webinar series with the industry. This was originally delivered in June 2021 and is now available to watch on demand. For more information, visit contamac.info/mdr Finally, Contamac thanks EFCLIN and everyone involved for delivering another top-class congress - plus, congratulations on your 30-year anniversary! We would also like to praise our very own Gareth Browne on being re-elected to the board. We look forward to seeing you all again in Budapest 2023!

After two long years, the EFCLIN Congress & Exhibition finally took place again from 28th

April in sunny Barcelona/Sitges. For all those who could not have been there, we from GlobalCONTACT have created the possibility to show some of the highlights and product presentations and to recall the three exciting days of this event.

It was great to assemble in Sitgés for the 2022 EFCLIN Congress. Acuity Polymers was pleased to participate as a Silver level sponsor, and to co-host the festive Thursday night reception. Acuity’s mission at the Congress was to showcase its highly vaunted Acuity 200™ Ultra Dk gas permeable material. Following is important information about the unique Acuity 200 material, from its conception to where it is today.

The concept for the Acuity 200 material came out of a new product brainstorming session focused on creating an innovative material that would feature the highest amount of gas permeability while being both “lab friendly” and “patient friendly”. Our priority for this new material was that it be optimal for scleral lenses (high gas permeability for large diameters ) and overnight orthokeratology (safe overnight wear). Essentially, we were looking to invent a material with higher permeability than Menicon Z with many of the strongest characteristics of hexafocon A (Boston XO, Acuity 100). We were aiming to create a new material that would combine the best properties for a high performing, world-class specialty lens material that was much needed and long overdue in the market.

We embarked on this project in early 2017 and had a viable prototype 12 months later. The development of the material took us in a novel new direction to boost the oxygen permeability, resulting in the granting of a patent for the formulation as well as the method of producing the polymer.

Starting in the spring (northern hemisphere) of 2018, we began shipping small quantities of Acuity 200 to the leading specialty lens manufacturer in New Zealand. The initial feedback was highly favorable and re-orders followed. We purposely limited the trial of the new product to make sure that any potential issues could be identified and properly addressed, and we needed to figure out how to produce the material in larger production lot quantities before introducing it to others. Scaling up proved to be challenging as we had to develop polymerization chambers different than anything we had worked with before.

During the 2018 EFCLIN Congress in Dubrovnik, we introduced Acuity 200 to the world. There was immediate interest from manufacturers across Europe and beyond, and thus began a very exciting journey and growth phase, both for Acuity 200 and also for Acuity Polymers. In effect, Acuity 200 transformed Acuity Polymers from being a material producer to being a true material innovator, consistent with the mission of the company to be the innovation leader in the custom contact lens market.

It would take another two years before Acuity 200 was FDA cleared. Because Acuity 200 is a totally new chemistry, requiring a new USAN, Acuity Polymers had to conduct an FDA clinical study to confirm safety and efficacy. This was the only prospective 510(k) clinical study of a new GP material in literally decades!

Acuity 200 is now one of Acuity’s leading products and its sales are growing exponentially. Many custom lens labs around the world are offering it for scleral lenses and an important number of labs are featuring it for overnight orthokeratology. Practitioners and patients appreciate the inherent wettability of the material which is one of its important characteristics, though it is possible to use Tangible® Hydra-PEG® with the material as Acuity 200 is licensed by Tangible Sciences for use with their coating.

With more than four years on the market, in demanding lens wear applications, Acuity 200 is becoming an important part of the practitioners’ toolbox for all kinds of fits. Besides the clinical trial data, Acuity Polymers has conducted all of the essential biological and physical-mechanical tests required by the most demanding regulatory agencies. This data is available to labs to help support their lens product applications. And, Acuity 200 is available in a broad range of diameters, tints, with and without UV blocker.

Acuity Polymers thanks all those who visited our booth at the 2022 EFCLIN Congress in Spain. And, for those who could not attend, we hope we can answer your questions about Acuity 200 and how it will enhance your product portfolio. Thank you for taking the time to learn about Acuity 200 and for further information, please visit acuitypolymers.com

After a two year hiatus, everything came together well for the exhibition in Sitges, Spain. The compressed air staff was helpful and resourceful in making the connection to our stand. The MCI team and AV staff were very helpful in setting up the commercial presentations. As I mentioned in my commercial presentation, we have seen huge growth in our business which comes with a huge thank you to our customers and distributors. It is a testament to how we address the current needs of the industry and the longevity of our products.

Of the many presentations, I would like to highlight Dr. Iovino’s research into the effects of heat relative to blocking wax shrinkage with the arbor and BC. Readers may recall that I submitted an article outlining the possible effects of wax shrinkage a few years ago. I have a deep appreciation for Dr. Iovino to take up this important subject so rigorously. His presentation should be made available on the EFCLIN website for lab managers to review. His findings illustrate how to reduce rejects and make the lab run more smoothly and could be included in the Standard Operating Procedures of every lab.

The Manufacturers' Forum continues to be, as it has for the past few congresses, an interesting variation on a theme. The topic was about a specific chemical compound present in RGP materials. This material “PFAS” has become a banned substance which our industry will need to address. At first, I didn’t see a direct connection to my company’s use of plastics, but after further consideration, we do make a lot of blocking arbors in acetal resin under the trade name Delrin (RTM DuPont). With a cursory investigation this material does not contain PFAS. My thanks to Ms. Pascale Rouhier of Euromcontact for her presentation.

Pam and I would like to personally express our gratitude to everyone involved in the planning and execution of the 2022 EFCLIN Congress. Of course, it was great to see everyone again and renew friendships and create new business relationships.

Pam and I feel we were “taken care of” better than any other event. Of special appreciation was Marion Beeler’s offer to Pam of a littleknown elevator to assist her mobility.

See you in Budapest.

At the EFCLIN meeting this year, Bausch + Lomb celebrated 50 years of the technology behind Boston® gas permeable (GP) lens materials. Since the technology’s inception in 1972, Boston® materials have transformed into a large product portfolio that can be made into a variety of special designs for demanding visual needs. The materials are also used in authorized lab networks that span more than 35 countries. It was wonderful to see you all again.

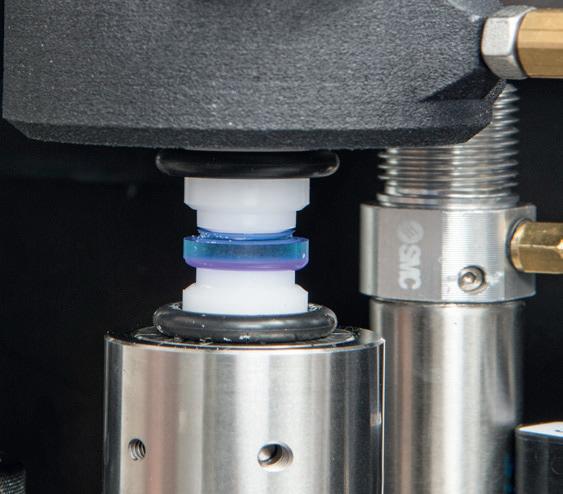

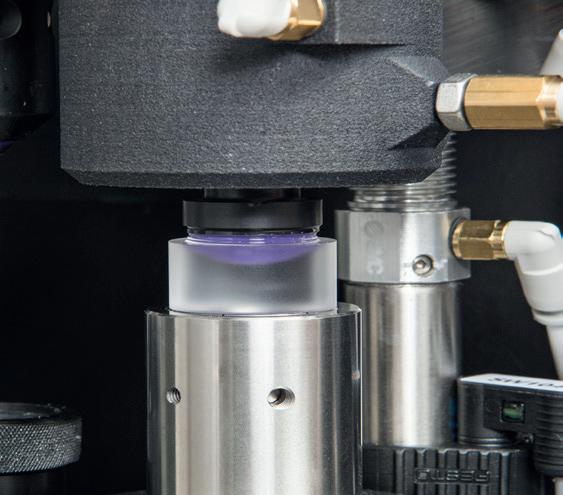

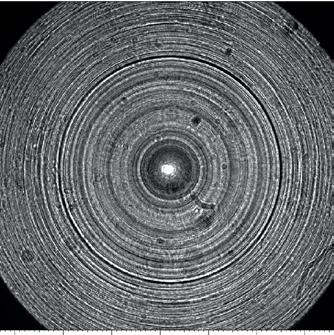

Contact lenses produced by turning have undergone enormous progress in terms of surface cutting precision, and then digitization has created the possibility of producing a wide variety of surfaces with the same lathe and with the same tools. A modern laboratory must be open to cutting under licensed lenses designed by others of which it does not know exactly the profile of the back surfaces. By Marco Iovino

Also, new free-form asymmetrical designs become more and more common in this age. All these conditions put a strain on the production process where the blocking system becomes the weak link in the production chain. Since the compounds used for the blocking of the internal surface introduce shrinkage during solidification, the control of the thickness in every point of the surface becomes essential to achieve optimal levels of

precision and repeatability because if not under control it would introduce distortions that would generate poor optical quality on the surface of final lens. A new arbor conforming system greatly improves the quality of the product regardless of the shape of the lens. A scientific approach was used to evaluate the actual benefits by comparing it to the cost of the technology itself.

Talking about the quality of a production process is always complex, and in order to draw reliable conclusions, the right method of evaluation must be used. Lathe cut contact lens manufacturing consists of several processes that have a certain degree of influence on the repeatability and final quality of the lens.

Scientific investigations are necessary in order to establish which production stage has the greatest influence on the quality of the lenses produced.

Basically, there are three main processes in our production:

• Lathe cutting of the surfaces: Modern lathes have an accuracy of more than one micron (1/1000 mm), so differences in final lens power and final optical quality are hardly attributable to this stage.

• Polishing: Modern surfaces cut by modern lathes, have a degree of finish that often requires very short and delicate polishing. In addition, geometric variations induced by polishing are easily detected by checking the surface before and after polishing.

• Blocking: The process of blocking the blank with the concave surface is very delicate and deserves to be studied in depth as it is the least controllable and most variable stage of the entire production process, affecting the optical quality and final power of the contact lenses.

Using the transfer blocking method avoids tension of the collection on the blank, which is why it is the method of choice in our workshops.

This method allows the blank to be clamped onto a flat arbor and then machined into the back surface of the lens. Once the surface has been polished, the blank is fixed to a convex arbor which will allow the outer surface to be machined.

SINCE THE COMPOUNDS USED FOR THE LOCKING OF THE INTERNAL SURFACE INTRODUCE SHRINKAGE

DURING SOLIDIFICATION, THE CONTROL OF THE THICKNESS IN EVERY POINT OF THE SURFACE BECOMES ESSENTIAL TO ACHIEVE OPTIMAL LEVELS OF PRECISION AND REPEATABILITY […]

The material used for fixing is wax. This material has several special properties that characterize the production process. In general, all substances that are solid at room temperature and liquid at higher temperatures are called 'waxes'. The wax therefore needs to be heated in order to become sticky and thus ensure fixation during solidification. In order to gain a better understanding of the wax clamping system and its qualityinfluencing characteristics, we studied two related components:

1. Heat transfer

2. Shrinkage

Three characteristics of wax.

As the wax needs heat to become liquid and can be injected onto the surface to be blocked, this heat will be transferred to the parts to be blocked. By heating a polymer block a so called plano-concave blank will result in changes in its shape.

Study on heat transfer - polymer graph and temperatures.

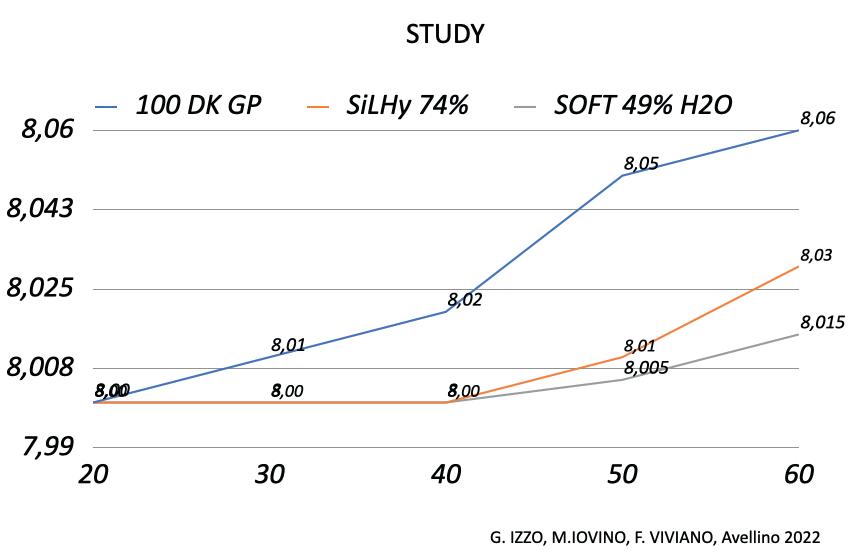

This study confirmed that the flattening of the curvature with respect to the basal curvature at room temperature of the blanks is different from one polymer to another. In general, gas-permeable RGP polymers are more sensitive to thermal transfer, whereas hydrophilic soft lens polymers do not undergo strong curvature changes when subjected to heating up to 60° C.

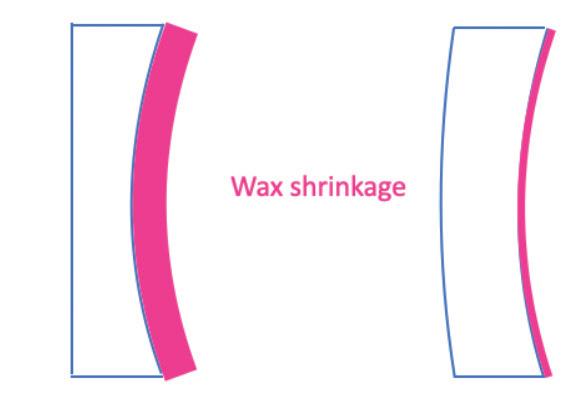

The wax undergoes a shrinkage phenomenon when passing from the liquid to the solid state, then during the blocking phase. This phenomenon has an impact on the quality of the blocking because this shrinkage causes stress on the lens during blocking and these stress will be released upon deblocking, so the front surface will change shape in proportion to the degree of shrinkage of the wax used.

Warming a blank surface will cause an expansion that flattens the curve during blocking.

Diagram of blanks expansion at different temperatures.

The result will be an expanded plano-concave blank that will have a significant change in the curvature of the concave surface resulting in some degree of flattening due to expansion. We studied this effect with laboratory tests by heating various blanks of different materials with a cut inner surface and recording the increases in radius base at various temperatures.

Shrinkage and stress demonstration.

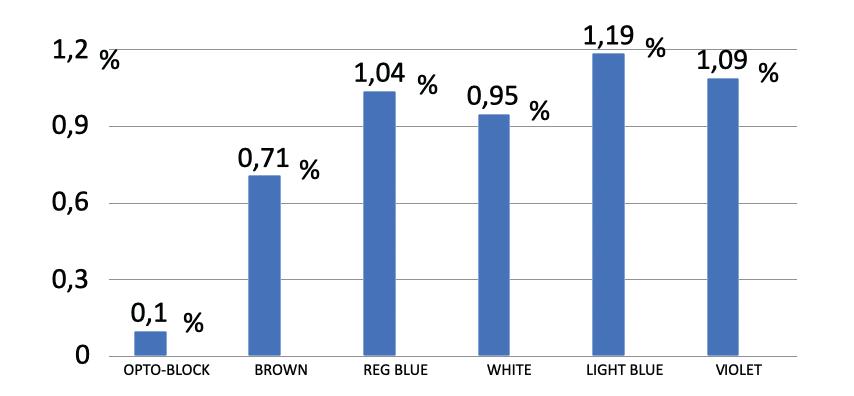

We conducted a scientific study to analyze and investigate the true degree of shrinkage from waxes used in contact lens manufacturing. This study evaluated the linear shrinkage of different commonly used waxes by constructing a cylindrical mold of 21 mm diameter with silicone compound, we filled the mold with the wax and measured the diameter of the sample once cooled and solidified at the same condition used during blocking.

This study showed that non-water-soluble waxes exhibit lower shrinkage values than water-soluble waxes but, nevertheless, the maximum linear shrinkage value is 1.19%, so much less important than we thought.

Isolating only these two factors studied, it can therefore be affirmed that heat transfer has the greatest influence on the quality of blocking, even going as far as 0.10 mm front radius errors, while wax shrinkage is negligible if the wax thickness remains constant along the inner surface of the lens and if wax thicknesses greater than 1.00 mm are not exceeded during blocking.

• Our research center has developed a simple formula to give our blocking system a quality index (BQI=Blocking Quality Index)

• BQI= Front radius blocked – front radius de-blocked

Where:

• Front radius blocked is the front radius of the lens after front cut and polishing sitting on the arbor prior to deblocking

• Front radius de-blocked is the front radius of the lens after deblocking

This index must be as low as possible (maxi 0.02 mm). If the BQI is bigger than 0.02 mm, the blocking system has some issue, most possibly the wax temperature is too high or the wax type melting point is too high.

At this stage we spent a lot of time on setting our blocking system to achieve a BQI that is as low as possible and under 0.02 mm. During one test day in production we manufactured 350+ GP contact lenses and three of them did not pass the final quality control because the power was not correct. Analyzing

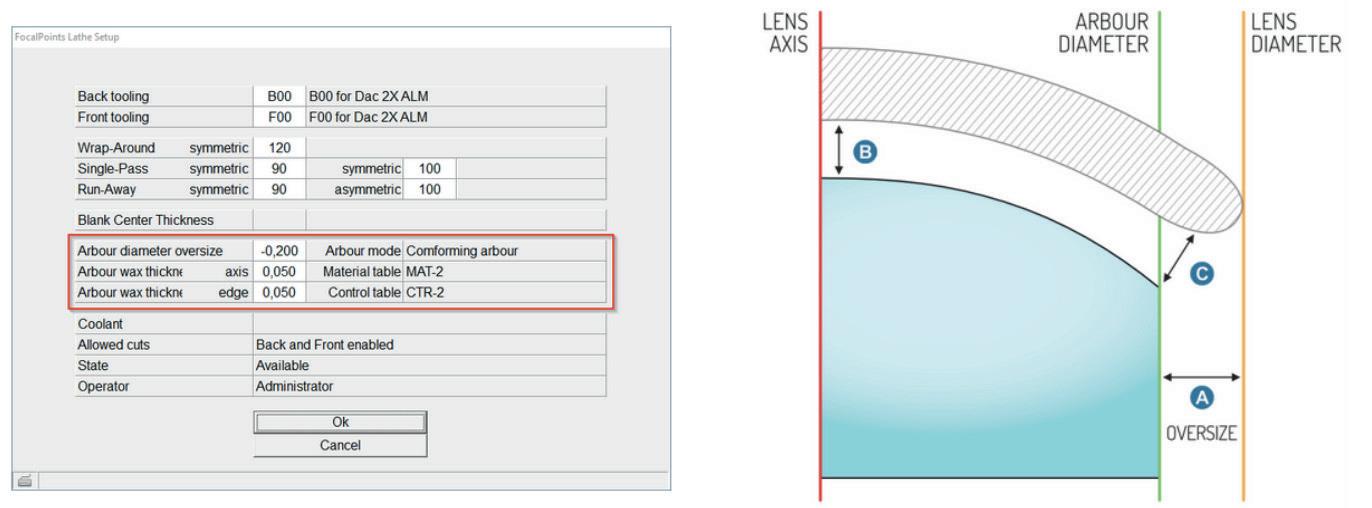

Conforming Arbor is based on FocalPoints.

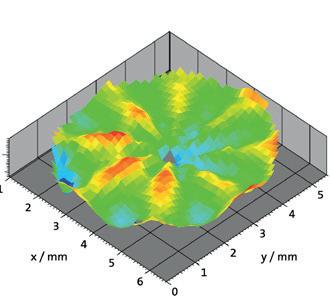

SLC EVOLUTION (17.80) BACK TORIC

R Rs Ab Sph Cyl A D

9.00 8.00 180 +2.75 -4.50 180 17.80

Spheric / dpt: 2,251 2,797

Cylinder / dpt: -4,128 -4,540

Cylinder angle / °: 2 180

Wave-front PV: 43,0493 40,3866

Wave-front RMS: 7,74724 7,94233

Center prism: 0,109 0,041

those lenses we discovered that all three had very complicated back surface designs and were blocked with standard mono curve or bicurve arbor tools. Their wax thickness was very irregular, in some places thicker than 1.00 mm due to the difference between back surface and arbor shapes. With the help of Advance Medical company we developed a software tool based on FocalPoints called: Confirming Arbor. This software allows the lab to cut blocking tools conformed to the back surface of the lens to cut, where you can choose to cut symmetrical arbors following the steep meridian of the lens or asymmetrical arbors following the back surface in every meridian. The operator could also choose the wax thickness in the center or the wax thickness in the periphery. After installing the software, we reconstructed the discarded lenses from the quality control using the new blocking technology by constructing a conformed arbor specifically for each lens.

This time, the lenses showed a very high final quality, accurate powers to 1/100 diopter, but above all, the wavefront value measured with Optocraft Cito was much lower (Rms 0.08 vs Rms 0.14), thus indicating a better optical quality.

The new technology makes it easy to achieve the best quality in the production process of lathe-cut contact lenses. The cost/ benefit ratio remains to be evaluated, which if used for all production could be too high and unsustainable. We therefore recommend using Confirming Arbor only for:

• Large diameter GP lenses (Sclerals)

• High toric GP

• Free form asymmetrical GP

• All third party licensed designs GP lenses

The actual cost of plastic lathe cut arbors is about 7-9 Euro each and they could be reused 2-3 times. Therefore, the final price will not grow so much if we intend to use the technology on a "use as needed" basis. n

Dr. Marco Iovino is an ophthalmology assistant and optometrist from Italy who graduated from Second University of Medicine of Napoli. He exclusively fits specialty contact lenses and he is the director of the designs office at Medlac S.r.l. in Avellino Italy. He specializes in process innovation for the contact lens manufacturing, he is the owner of many successful contact lens designs for regular and irregular corneas. He speaks at major optometry and ocularist congresses and manages the contact lens research center of Avellino.

Photo presentation: Students present their findings

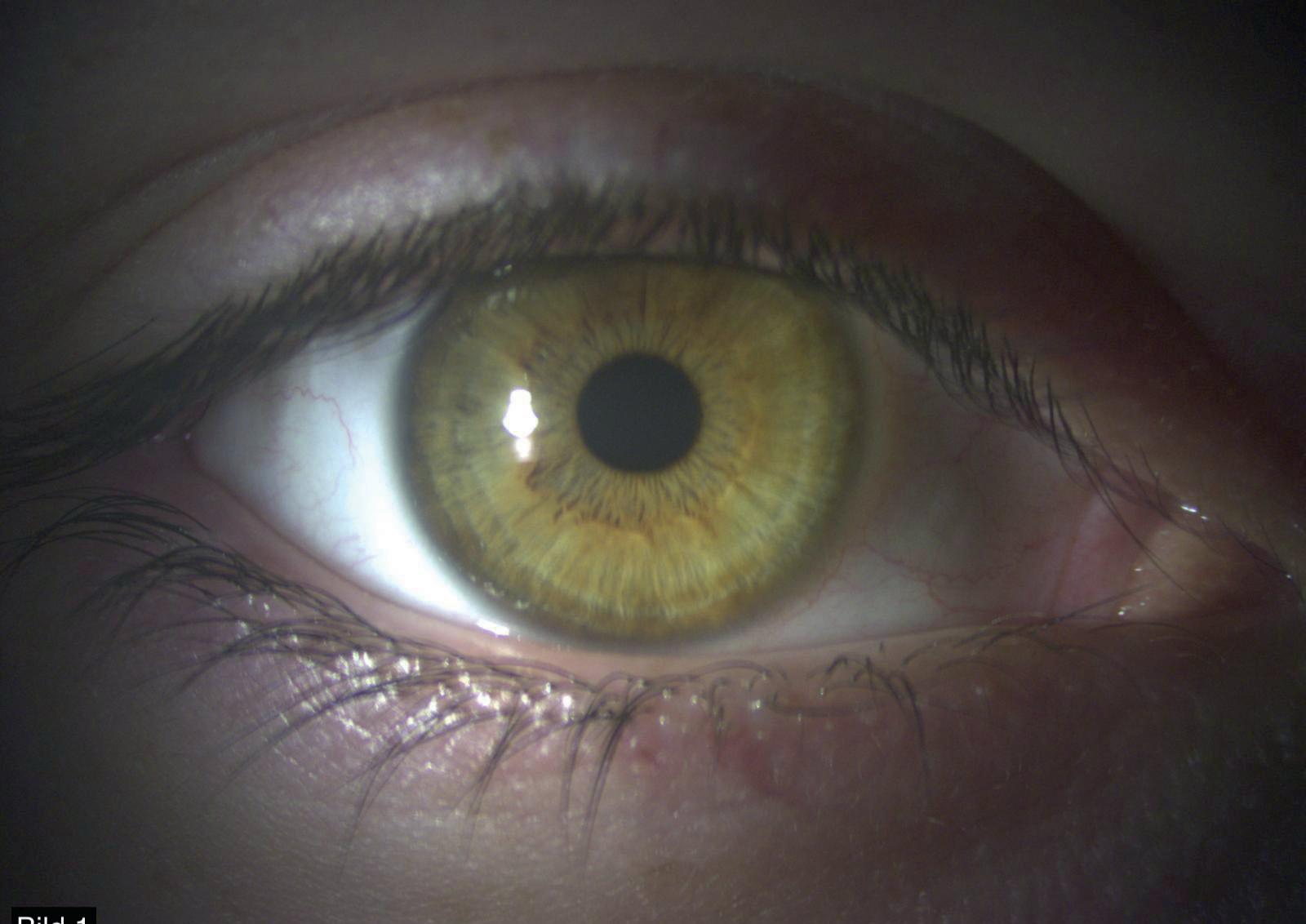

Slit Lamp (Haag-Streit BQ 900, Koeniz, Schweiz)

Photo 1: Diffuse illumination, 10 x magnification

Photo 2: Diffuse illumination, blue light and yellow filter, 25 x magnification

Photo 3: Diffuse illumination, 25 x magnificatio

The proband (20 years old, male, no contact lens wearer) does not show any particular signs in the anamnesis, as in the general overview (picture 1) with the slit lamp. Only slight elevations are visible on the caruncle, which suggest papillae on the tarsal conjunctiva. However, the routine meibography examination during the contact lens training shows severe papillae on the upper eyelid. These can be caused by allergies or bacterial conjunctivitis, for example. Papillae are characterised by a cobblestone-like shape and a centrally located blood vessel. These central blood vessels of the papillae can be seen particularly well in picture 2. The fluorescein is deposited here in the vessel opening and appears light green. Due to the depression created by the centrally located blood vessel, the shape of these papillae is reminiscent of a donut. For the image acquisition, the upper eyelid of the subject was ectropionated in order to more easily observe abnormalities of the tarsal conjunctiva. Picture 3 shows the size of the papillae. They rise from the eyelid surface and are easily visible by diffuse illumination. This report demonstrates that a complete, uninterrupted examination of the anterior segment of the eye is critical at the outset of contact lens fitting.

The patient is allergic to his shampoo, which is now being replaced. Closely monitored examinations will follow to document the healing of the papillae.

In 2004, Keith Parker and I opened Advanced Vision Technologies (AVT). At that time, the economy was going through a very bad recession and as a result, it was impossible for a new business starting up to get a loan. We immediately reached out to Erik and Pam at Larsen Equipment to get refurbished equipment to use in our Laboratory. As AVT’s business grew, we invested in many different pieces of new equipment from Larsen Equipment and this helped us grow into one of the Premiere Labs in the United States. Our success is due in part to Erik and his Team with their state-of-the-art equipment and maintenance of their products. AVT is forever grateful for Larsen Equipment’s support of AVT. It is great to know AVT is working with Industry leaders with the Larsen Equipment and their Team!

Janine Bungo, VicePresidentI have known Erik Larsen since 1992. Since then I have used just about every piece of equipment his company has built. My experience with Erik and the Larsen team has been one of great appreciation as they have always helped me in my needs of fully understanding equipment used to manufacture quality contact lenses. Erik has also been able to engineer any part needed for me even it was a custom part. Erik (Larsen Equipment) has been and still is a pioneer in the contact lens and optical industry, and I am thankful to him for his support over the years.

Randy Mingoy Quality ManagerI have had the pleasure of working with Erik since the beginning of Larsen Equipment. The first piece of equipment, a 6 spindle horizontal arm polisher revolutionized our production of GP contact lenses. Through the years, I watched his business grow as he and his team listened to our Industry needs and developed now numerous products not only simplifying many tasks of manufacturing but improving the consistency of quality in our finished products. Innovation has been an ongoing experience of our Company only made possible through the innovation of necessary equipment developed and made available by the Larsen team.

Advanced

Vision TechnologiesThere can be a lot of moving parts when it comes to managing operations, so it is key to have reliable precision equipment that assists in overall efficiency. Larsen Equipment delivers just that! I have been utilizing Larsen manufacturing equipment for over 15+ years and have yet to run into an issue they could not resolve. I am a satisfied owner of bladder polishers, edge roller’s and auto-blockers etc. Each one of these units greatly assists in the reduction of rejects and manufacturing waste. Their ability to customize and retrofit specific tools certainly sets them apart from the competition. Larsen stands behind their equipment with a knowledgeable staff that provides exceptional service. Simply put, we are a better laboratory because of our relationship with the folks at Larsen.

Jordan Gobel Director of Operations/Consultant Advanced Vision Technologies

Larsen Equipment is a family owned business hosting a team of willing Staff all having the attitude of serving their Customer’s needs. As a Customer, we are made to feel like we have a friend in the business helping us develop a more efficient process allowing our Company to deliver better products for our Customers.

Our success of AVT simply could not have been possible without the help, assistance and dedication of Larsen Equipment. I will be forever grateful for my opportunity to work with Erik and his very capable Staff.

Keith Parker President

Keith Parker President

A pleonasm: The term ‘overnight orthokeratology’ (ortho-k) can be seen to a large degree as a pleonasm, derived from the ancient Greek word pleonasmós – pleon, or 'to be in excess' – which means a redundancy in linguistic expression. In this case, the ‘overnight’ would be the redundant part, as there is hardly a situation thinkable in which ortho-k lenses are worn during the daytime hours; there is not a need to reshape the cornea for a corrected corneal surface during the sleeping hours. Ortho-k lenses in some parts of the world are called ‘night-lenses’: that is, worn during the night for vision during the day. Originally started as a clever management term, it is now the leading nomenclature to describe ortho-k in a generic way in the Netherlands, for instance, and has even been adopted by professional organizations. The ‘overnight’ part of this modality though, carries most of the weight regarding ‘safety’ issues. So, let’s circle back to the title and assess the special circumstances surrounding this overnight modality. By Eef van der Worp

Back to basics regarding contact lens safety: according to a study by Stapleton et al,1 the incidence of a microbial keratitis (MK) with loss of visual acuity in daily wear with soft lenses (silicone hydrogels) is 0.00011%. This is more easily interpreted as a chance of 1.1 per 10,000 patient years. The 95% confidence interval (CI) with these lenses is between 0.9 and 1.4. What does this tell us? The interval of confidence basically suggests that if this study were to be repeated 100 times, then the outcome in 95% of the cases would be between these values (0.9 and 1.4 here). The smaller this range, the more certainty there is regarding the outcome numbers.

Comparing the relative risk of MK (not per se leading to vision loss) by lens modality, the annualized incidence per 10,000 wearers was determined to be 1.2 (CI 1.1-1.5) for daily wear rigid corneal lenses; 1.9 (CI 1.8-2.0) for daily wear soft; 2.0 (CI 1.7-2.4) for daily disposable; 11.9 (CI 10.0-14.6) for silicone hydrogel soft; 19.5 (CI 14.6-29.5) for overnight wear soft; and 25.4 (CI 21.2-31.5) for overnight wear silicone hydrogel. No real data regarding overnight rigid lens wear is available.

From this data, a couple of things become clear: corneal rigid lenses are the gold standard and are by far the safest contact lens modality out there. Period. The data further clearly shows

that daily wear is the safest lens wear modality, occasional overnight wear increases the risk, and regular overnight wear further increases that risk.

In ortho-k the lenses are only worn during the night, and the wearer is lens-free during the day. What are the risks, considering this? Bullimore et al (2013)2 reported a survey involving 1,317 patients (640 adults and 677 children) that resulted in 2,599 patient years of data (1,164 in adults, 1,435 in children). Fifty cases of painful red eye were reported, eight cases of corneal infiltrates, and two cases of microbial keratitis (MK). They reported an incidence, per 10,000 years of wear, of 7.7. The confidence interval here was 0.9 to 28. Note that the CI here is larger; hence, there is less certainty, or confidence, that the absolute number of 7.7 is correct, it is roughly somewhere between one and 30. The latter is most probably the preferred estimate to use toward patients, not the absolute 7.7 number. For children, the MK risk was found to be 13.9 per 10,000 patient-years, again with a large CI of 1.7 to 50.4, while for adults the estimated incidence was zero per 10,000 patient-years (with a CI of zero to 31.7).

In essence, there is a higher risk of MK with ortho-k, but it’s not from the lens or the material; ortho-k lenses are not substantially thicker (as is the case with scleral lenses, as described in the previous paper in this GlobalCONTACT trilogy) or made in any different materials (if anything, the Dk is higher in ortho-k lenses). It is the ‘overnight’ part that is different in ortho-k.

Ophthalmologists are advising against using this modality in children for myopia control in some parts of the world, for instance in the Netherlands – hence putting an important pillar in myopia management partly ‘off-side’, in football terms, for eye care practitioners. There are a few complicating factors when discussing this topic. The first problem is that large sample sizes are needed to be able to present confirmatory results on the risk of infection. If the incidence of a corneal infection is one in 100,000, then information from hundreds of thousands of lens wearers, ideally under controlled conditions, is needed. This is problematic for specialty lens modalities, including for ortho-k. Chance plays an important role in any numbers that are generated if sample size numbers are smaller.

Another paper by Bullimore et al reported on a retrospective study of the safety of ortho-k. 3 All episodes of infiltrative keratitis from a children's hospital in Moscow were recorded and adjudicated by three ophthalmologists, which resulted in 139 cases of infiltrative keratitis in children, of which 45 were MK (32%). Five of them were overnight ortho-k wearers. The annual incidence thus reported was about 5.0 (CI, 2.1 to 12.4). One of the findings of the Bullimore studies is that the group with the biggest risk of MK was not the younger age group (8- 12-year-olds) but rather the 13- to17-year-olds, and the highest risk was in the 18- to 25-year-old group.

It appears, according to experts in the field – although anecdotally and not evidence based – that practices that fit the most ortho-k take the care that the modality requires very seriously. Informed consents are obtained, for parents and for the children, and hygiene and compliance protocols are reconfirmed on all follow-up visits, and it is made very clear to exclude any tap water from the care regimen. Practices that ‘do ortho-k on the side’ may be less ‘on-top-of-things’ and may not always have the same rigor in their protocols and regulations follow up. In some of the larger ortho-k practices, for instance, patients are told that if they do not return for follow-up care, they are excluded from further lens purchases and eye care in order to show the seriousness of eye and lens assessment. Here is an important task, for the industry and profession, to work on together.

To summarize, the risk with overnight ortho-k is increased compared to with daily wear of contact lenses, and certainly if compared to daily rigid corneal lens wear – but the risk does not seem to exceed that of extended wear of soft lenses. Early detection and referral are key, as only a small portion of MK cases actually lead to permanent vision loss when managed in an adequate way.

The fact that ortho-k lenses are not worn during the day may be a plus in theory. In addition, intact immune systems result in normal healthy eyes (as opposed to in patients who require regular scleral lens or bandage soft lens wear, for instance). Corneas of ortho-k wearers have been reported to show small amounts of corneal staining, which may or may not pose a minor increased risk for corneal infection, although in rigid corneal lens wear – which has the lowest rates of corneal infection – corneal staining (especially three- and nine o’clock staining) is not uncommon either.4 In conclusion, the overnight part of the modality poses the biggest risks, it seems.

the ladder of importance than in other lens modalities. This is a very important task, for the industry and the ECP alike, to focus on in the interest of both ocular health and the future of the modality.

In the next ‘episode’ of this trilogy on specialty lens safety, soft specialty lens wear will be placed under the magnifying glass. What are the special considerations for that modality? Stay tuned. Stay safe. n

Parts of this publication appeared in a Contact Lens Spectrum article (April 2022) that summarized a 2022 Global Specialty Lens Symposium session devoted to contact lens safety featuring Mark Bullimore, Melissa Barnett, Gloria Chiu and Pauline Cho.

[1] Stapleton F, Keay L, Edwards K, Naduvilath T, Dart JK, Brian G, Holden BA. The incidence of contact lens-related MK in Australia. Ophthalmology. 2008 Oct;115(10):1655-62. doi: 10.1016/j.ophtha.2008.04.002. Epub 2008 Jun 5. PMID: 18538404.

[2] Bullimore MA, Sinnott LT, Jones-Jordan LA. The risk of MK with overnight corneal reshaping lenses. Optom Vis Sci. 2013 Sep;90(9):937-44. doi: 10.1097/OPX.0b013e31829cac92. PMID: 23892491.

[3] Bullimore MA, Mirsayafov DS, Khurai AR, Kononov LB, Asatrian SP, Shmakov AN, Richdale K, Gorev VV. Pediatric Microbial Keratitis With Overnight Ortho-k in Russia. Eye Contact Lens. 2021 Jul 1;47(7):420-425.

[4] van der Worp E, De Brabander J, Swarbrick H, Nuijts R, Hendrikse F. Corneal desiccation in rigid contact lens wear: 3- and 9-o'clock staining. Optom Vis Sci. 2003 Apr;80(4):280-90. doi: 10.1097/00006324200304000-00005. PMID: 12692484.

The unavoidable overnight component of ortho-k and the associated higher risk of an MK need to be balanced against the benefits that ortho-k can provide in terms of myopia progression reduction. Work by Gifford et al 5 showed that this balance can be favorable for lens wear if myopic retinal pathology is considered, and a recent paper by Bullimore et al also reported the potential benefits of myopia control to outweigh the risks.6 High-Dk materials are needed for ortho-k; without them, no safe ortho-k lens wear is possible. But apart from that, it seems that the biggest risk factors regarding safety are lens care and hygiene, for which the eye care practitioner together with the patient could play a crucial role. A notable consideration is that when an ortho-k lens is placed on the eye, whatever is ‘trapped’ behind the lens stays behind the lens. There is arguably almost no tear film exchange in ortho-k after the lens is placed on the eye, and the eyelid is closed – so removal of debris and of potential micro-organisms will not take place. This puts lens hygiene, especially upon lens application, on a higher rung of

[5] Gifford KL. Childhood and lifetime risk comparison of myopia control with contact lenses. Cont Lens Anterior Eye. 2020 Feb;43(1):26-32. doi: 10.1016/j.clae.2019.11.007. Epub 2019 Nov 30. PMID: 31796370.

[6] Bullimore MA, Ritchey ER, Shah S, Leveziel N, Bourne RRA, Flitcroft DI. The Risks and Benefits of Myopia Control. Ophthalmology. 2021 Nov;128(11):1561-1579. doi: 10.1016/j.ophtha.2021.04.032. Epub 2021 May 4. PMID: 33961969.

Eef van der Worp, BOptom, PhD, FAAO, FIACLE, FBCLA, FSLS is an educator and researcher. He received his optometry degree from the Hogeschool van Utrecht in the Netherlands (NL) and has served as a head of the contact lens department at the school for over eight years. He received his PhD from the University of Maastricht (NL) in 2008. He is a fellow of the AAO, IACLE, BCLA and the SLS. He is currently adjunct Professor at the University of Montreal University College of Optometry (CA) and adjunct assistant Professor at Pacific University College of Optometry (Oregon, USA). He lectures extensively worldwide and is a guest lecturer at a number of Universities in the US and Europe.

HIGH-DK MATERIALS ARE NEEDED FOR ORTHO-K; WITHOUT THEM, NO SAFE ORTHO-K LENS WEAR IS POSSIBLE. BUT APART FROM THAT, IT SEEMS THAT THE BIGGEST RISK FACTORS REGARDING SAFETY ARE LENS CARE AND HYGIENE, FOR WHICH THE EYE CARE PRACTITIONER TOGETHER WITH THE PATIENT COULD PLAY A CRUCIAL ROLE.

When planning a new manufacturing facility or optimizing an existing operation, it’s easy to focus on the lathe and neglect the role played by support processes such as material handling. While the lathe is arguably the single most important piece of equipment in a contact lens or IOL manufacturing laboratory, its precision can be easily undermined by underperforming equipment elsewhere in the process, most notably blocking. Today’s CNC lathes and lens design software combine to offer unprecedented options for meeting the needs of patients through precise control of lens geometry and sub-micron level surface accuracy, yet this can be easily undone by misaligned surfaces or unintended prism.

“If back and front [surfaces] are not perfectly aligned, you can get decentered optics, prism and poorly formed edges.”, says Manoel Carvalho, Director of Lab Operations and fitting consultant for BostonSight in Needham, Massachusetts. “All lenses need to have perfect optics. However, when dealing with multifocal or HOA correction, that becomes even more critical.”

DAC International has addressed these concerns by re-imaging the blocker from the ground up. The DAC Precision Blocker is a ‘no-compromise’ solution for RGP, Soft and IOL blocking that was developed to maximize the full potential of the DAC lathe’s edge contouring capability and form accuracy. Back or front surfaces are blocked with a high degree of accuracy and repeatability, and a minimum of time and operator attention.

The DAC Precision Blocker offers fast, reliable calibration, easy and intuitive initial setup, and stable, accurate and repeatable blocking. Additionally, the rigid, ½” steel construction and a design that manages ambient heat in the machine frame means that the DAC blocker holds calibration reliably over time, without the need to re-calibrate during the workday.

A blocker that holds calibration yields better lenses, but it also saves time and money. Greg Wicker, Maintenance Manager for X-Cel Specialty Contacts in Duluth, Georgia, has worked out the numbers: “Based on the average maintenance tech spending about 15 minutes setting a traditional blocker twice a day, [that’s] 30 minutes a day times 255 working days per year - 7,650 minutes total, or 127.5 hours per year”. Greg continues “Although more expensive than traditional blockers, I feel that it pays for itself with the reduction of prism related rejects and downtime for setting blockers.”

While accuracy and reliability are important, an ideal blocker also needs the versatility to handle the wide range of specialty products manufactured by a modern laboratory. Safe, consistent

wax dosing, interchangeable waxpots and a fully programmable interface ensure that the DAC Precision Blocker has the flexibility to cover the full gamut of RGP, soft and IOL lenses currently in production.

Drop size is fully adjustable from zero to 2.5ml, and multiple drops can be programmed. Wax pots are hot-swappable with no down-time required to rapidly switch between waxes for different applications. Additionally, an on-board timer for wax pot warm-up lets lab managers start their morning without any waiting time; different start times may be set for each workday.

Finally, the DAC Precision Blocker is fully programable, with an LCD touch screen providing an intuitive interface that allows the user to optimize blocking variables to suit individual process needs. Key parameters such as drop count, temperature, and air-cooling controls can be accessed, configured and saved to any of six independently configurable blocking tables.

Treating blocking like the mission critical process that it is means looking seriously at the needs of a rapidly evolving industry and providing a robust and flexible solution that takes no shortcuts in design, materials or construction. To DAC International, this is the meaning of blocking without compromise. n

While some people only approach the subject of monovision at arm’s length, and would probably prefer to erase it completely from textbooks, people’s heads and in practice – for others monovision is the obvious solution! So let's take a closer look at the topic. By Silke Sage

For anyone who performs an eye exam today, besides the standard increments of 0.25 D, increments of 0.12 D are also available. And in the past few years, it has been possible to be even more precise: not only has it become possible to perform eye exams within a range of 0.01 D, but also to produce the corresponding spectacle lenses as well. Examples of this are the systems from Essilor (AVA) and Rodenstock (BIG). The trend towards wavefront-optimized lenses and the measurement of higher-order aberrations of the eye is also progressing. So how does this fit in with a contact lens fitting method that deliberately avoids binocular full correction? On the one hand, we are trying to squeeze out the last drop of visual acuity during spectacle refraction, but we are then giving this away three times over during contact lens fitting? It's almost like smoothing a road with a rolling pin until it is as flat as a pancake, only to drive over it again afterwards with a tank. But what is the use to a customer of potentially fantastic vision through a spectacle lens, if he simply doesn't want to wear glasses? Some patients already feel restricted by the spectacle frame and simply don't want to wear anything in front of their face – however trendy this might be.

This is the often fine line between success and failure in contact lens fitting: the needs assessment. If you don't take the trouble to listen carefully here, and get bogged down in textbook examples, you'll get to a point in the fitting process where the frustration of the presbyopia patient becomes palpable. At the end of the day, the motivation of the contact lens wearer has an essential part to play. After all, vision is a dynamic process. Thus, a product should be fitted that the patient is at ease with. The patient should be what determines the approach – not just principles.