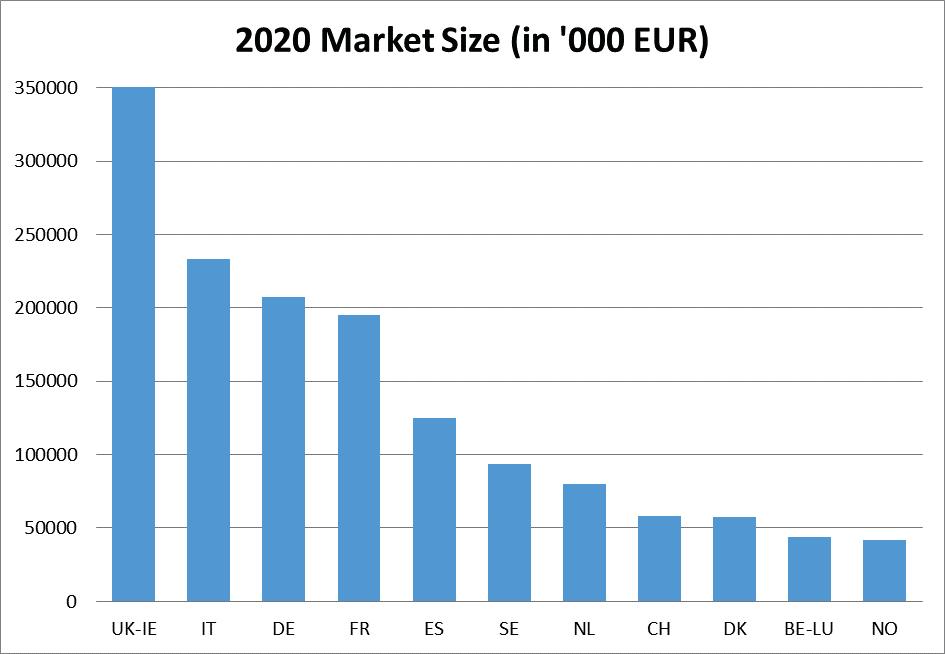

After more than a year in the corona pandemic, including several weeks of lockdown, it's time to look not only back but also forward. In the vast majority of industries, the deep V-curve from spring 2020 is strikingly visible in sales diagrams. The (ophthalmic) optical industry was not spared. But the figures also recovered quickly in many countries. Because vision is important. So important, in fact, that opticians and optometrists were allowed to keep their practices open in many countries.

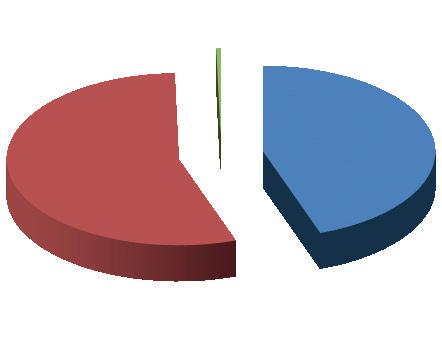

They could perform eye tests, fit contact lenses and sell glasses. And while the cash registers may be ringing there, other industries have experienced (and are currently experiencing) historic sales slumps, which will certainly also result in some bankruptcies after high losses. It is still not possible to predict exactly how long this tense situation will last. After all, according to Euromcontact data, there was a drop of around 9.6% compared with the previous year (industry to ECP).

The contact lens industry thus got off lightly – given the circumstances. Nevertheless, it is worthwhile to study the figures from 2020 closely. One of the "winners" was the segment of disposable lenses. These can be delivered home quite easily – whether we like it or not – without even setting foot outside the door. The bare figures do not reveal the extent to which contact lens fitters are involved here. This is because online sales also had a share in the figures.

In these times when even groceries are purchased online, a pack of monthly contact lenses is quickly added to the digital shopping cart. It would be very unfavorable for traditional fitters if sales were to drift further into online retail. After all, the industry needs qualified and passionate optometrists to fit specialty lenses. Therefore, customer loyalty is an important issue even in times of a pandemic. Specialty contact lenses offer opportunities for this.

Last but not least, the pandemic has caused a rethink in many businesses. In order to bring customers into the store in a controlled manner, appointments have to be made. What previously seemed quite unthinkable for some contact lens fitters pays off. These appointments allow more time for the individual. Those who take time for their customers/patients, value their individuality and are interested in a customized solution for them, could look forward to continued good business. And this is also reflected in current figures (Eurolens). RGPs remain on a stable plateau overall, albeit a flat one.

People are now spending much more time in front of screens, which is particularly challenging for the eyes. Poor vision may continue to increase in the medium term due to more home office work. So in addition to health, modality and customized geometry, comfort continues to play a big role in contact lenses.

Calculations are always made at the end. Let's talk again in a year's time.... hopefully with a good résumé. ■

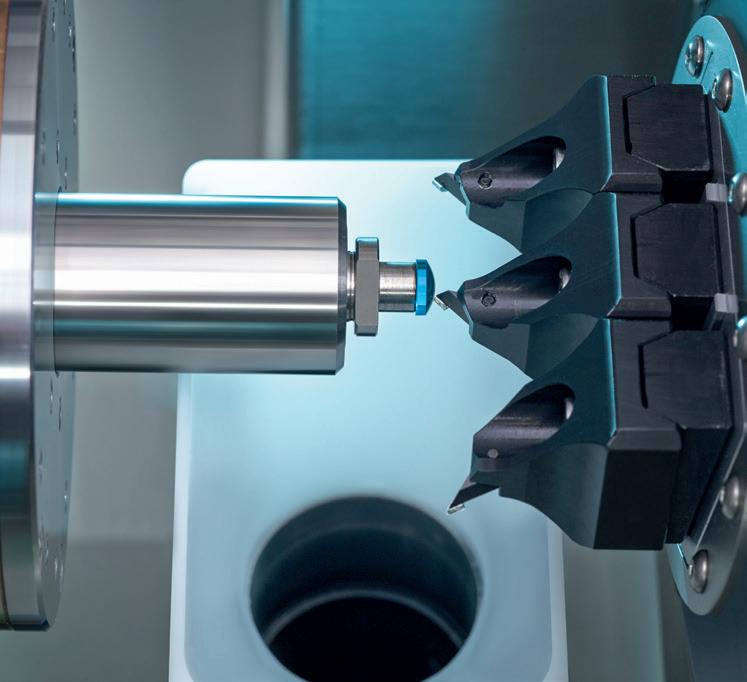

Highest surface accuracy and quality meet unprecedented productivity.

The compact and fully featured UPC 100 Vision is optimized for highly dynamic diamond turning of complex freeform surfaces like polish-free IOLs, mold inserts or complex contact lens designs.

The UPC nano is the most affordable and compact machine with on-board freeform capabilities and an optional laser for manufacturing high-quality contact lenses at maximum cost-efficiency.

Both machines can be easily integrated with an optional automation system.

Title: Contamac, www.contamac.com

Inside front cover: Bausch + Lomb Inc., www.bausch.com

Page 4: Schneider GmbH & Co. KG, www.schneider-om.com

Page 15: K & Y Diamond Ltd, www.kydiamond.ca

Page 19: OPTOCRAFT GmbH, www.optocraft.com

Page 29: LAMBDA-X S.A., www.lambda-x.com

Page 31: Optimec Systems Ltd., www.optimecsystems.com

Page 33: AMETEK Precitech, Inc., www.precitech.com

Page 39: Larsen Equipment Design Inc., www.larsenequipment.com

Page 43: GlobalCONTACT, www.gclabsite.com

Inside back cover: Efclin, www.efclin.com

Outside back cover: DAC International, Inc., www.dac-intl.com

Brandstätter, Manfred 44 Fantony, Bruno 24 Fischer, Hartmut 40 Keutgen, Danyon 23 Larsen, Erik 28 Metzger, Lukas 23 Roth, Hans-Walter 34 van der Worp, Eef 16, 32 Yuste, Alejandro Cubel 24

Carolin Truckenbrod – First reference curve for refraction in Central Europe created Hanna Diewald & Rebekka Nurkanovic

Imaging techniques – case study Lukas Metzger, Danyon Keutgen

Cubel Yuste

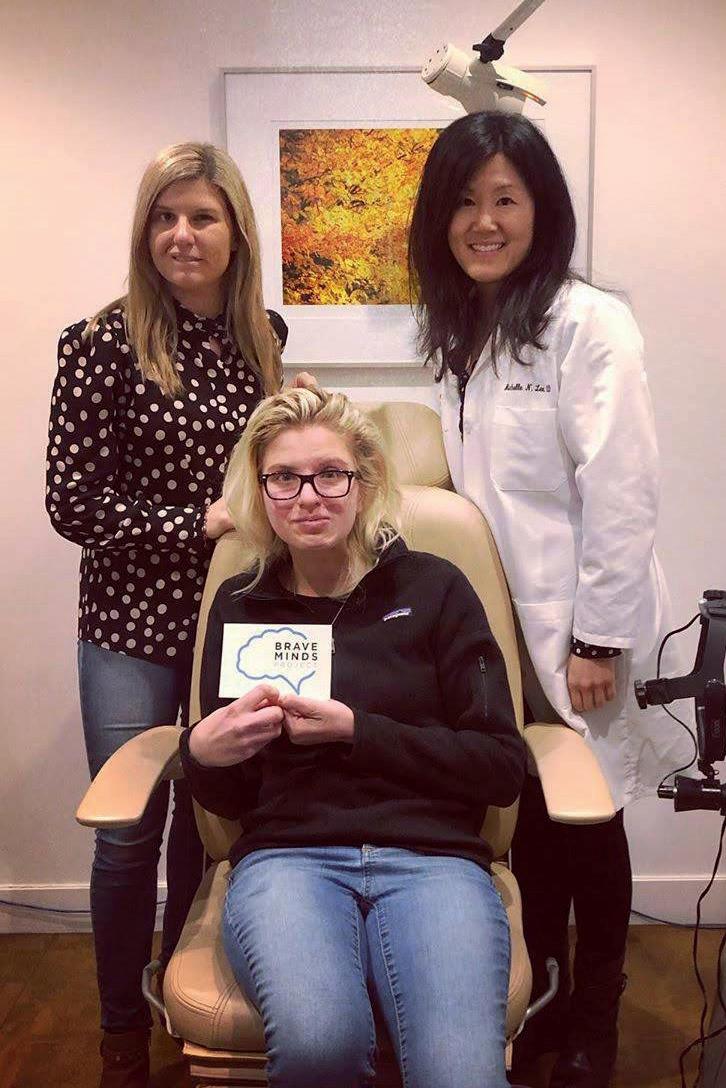

BostonSight has shared an inspiring story about a PROSE Network patient. Alyssa Carfi had a brainstem cavernoma, a condition where blood vessels are clustered together, and in her case, lodged deep in her brainstem. The condition caused bleeding in her brainstem multiple times. Just three days after graduating high school, Alyssa went in for surgery. Based on their location, brainstem cavernomas can cause significant surgical challenges. Following her surgery, Alyssa had facial paralysis, affecting her eyelid and ability to open and close her right eye. She was unable to blink, leaving her right eyelid permanently open.

The GP Lens Institute's has named Dr. Jason Jedlicka as its 2021 Practitioner of the Year and Dr. Daniel Fuller as Educator of the Year. A renown scleral lens innovator, educator, author, and lecturer, Dr. Jason Jedlicka is currently chief of the Contact Lens Service at the Indiana University School of Optometry. He is a diplomate in the Cornea, Contact Lenses & Refractive Technologies Section of the American Academy of Optometry and is a co-founder and past president of the Scleral Lens Education Society as well as an advisory board member of the GP Lens Institute.

BostonSight appoints scientific advisory board BostonSight announced that they have formed a scientific advisory board comprising medical experts to help guide BostonSight’s robust research initiatives.

“As leaders in the eye health industry, we’re excited to bring together medical experts to provide expertise and guidance as we plan future studies that will advance the understanding, treatment, and care of complex corneal disease”, said Sara Yost, BostonSight President and CEO.

The BostonSight Scientific Advisory Board, chaired by Dan Brocks, MD, BostonSight’s Chief Medical Officer, includes Yost along with

Over a treatment period of six months, Alyssa and Dr. Michelle Lee at Weill Cornell Medical Center worked on fitting a PROSE device which is a rigid, gas-permeable specialty lens that rests on the sclera of the eye and vaults over the cornea. The vaulted reservoir is filled with a preservative-free saline solution, which continually bathes the eye in a tear-like environment. Because of their strong material construction, the devices protect the surface of the eye.

Today, eight years later, Alyssa feels lucky that she was able to receive the PROSE treatment and has launched the Brave Minds Project, a 501(c)(3) nonprofit that supports teen and young adults living with brain and brainstem conditions. The organization aims to help patients and their families from diagnosis through recovery by offering financial support for therapies and off-setting medical costs such as PROSE, providing community connection, and delivering goods that are sent to patients in the hospital and to their siblings. Read Alyssa’s full story on www.bostonsight.org

The first to be honored with the new award Educator of the Year, Dr. Daniel Fuller is professor and chief of the Contact Lens Service, Southern College of Optometry. He is a diplomate in the Cornea, Contact Lenses & Refractive Technologies Section of the American Academy of Optometry and is currently vice-president of the Scleral Lens Education Society and an advisory board member of the GP Lens Institute.

Demi Niforos, MS, Vice President of Biostatistics and Statistical Programming at eClinical Solutions; Michael Raizman, MD, a practitioner at Ophthalmic Consultants of Boston and Associate Professor of Ophthalmology at Tufts University School of Medicine; Ali Djalilian, MD, Professor of Ophthalmology, Cornea Service and Director of the Stem Cell Therapy and Corneal Tissue Engineering Laboratory at Illinois Eye and Ear Infirmary; and Gloria B. Chiu, OD, FAAO, FSLS, Associate Professor of Clinical Ophthalmology at the USC Roski Eye Institute, Department of Ophthalmology at the University of Southern California Keck School of Medicine.

On December 12, 2020, a new CLMA president was elected. Josh Adams (Valley Contax) succeeded Kurtis Brown (DAC intl.) as the 27th president. Josh Adams follows in the footsteps of Janice Adams, who served as CLMA president from 2006 to 2008. GlobalCONTACT congratulates!

He was often described as “one of a kind”, dedicated, detail-oriented, kind, and hard-working; he was always beloved. The contact lens world lost an important part of what makes our industry so special with the passing of Milt Kallas. Milt died peacefully on March 2, 2021 in Pleasanton, California at the age of 77. He is survived by his loving wife of 46 years, Marion, his son Matthew, and his daughter Mollie.

Milt’s professional career in contact lenses began in the early 1990s with Polymer Technology Corporation (PTC). After the acquisition of PTC by Bausch + Lomb, he served as Regional Sales Manager for 17 years for The Boston Group. He left Bausch + Lomb in 2008 but never actually left the contact left industry. He was very influential in helping Menicon America in numerous GP initiatives while establishing his own consulting company.

Milt Kallas was a beloved long-time industry professional, mentor, and friend to so many in the contact lens field worldwide. Known as “Uncle Miltie” for his kind, generous, and positive demeanor, he was well known for his selfless devotion to helping others and worked tirelessly to answer questions, return phone calls and emails (in record time!), working to ensure excellent customer support, while training his sales team how to use the various reports and computer programs. This is especially significant as computers were in their infancy

but Milt’s many strengths included the ability to quickly learn new skills – and pass those skills onto others – so therefore, he embraced the benefits of computers long before they became commonplace.

His work ethic, dedication, and attention to detail were legendary. According to his long-time colleague Jonathan Jacobson, “Those of you who attended trade shows or conferences at which Milt was present will know that Milt was always the first to show up at the booth and the first in the seminar room, checking to see that all had been done to ensure a smooth operation. And Milt reveled in this too … knowing that he was always the first on the spot. As one whose job it was to worry that things were done correctly and on time, it was always reassuring to know that Milt was on site. Details were Milt’s fixation.”

His family always came first and he loved his wife and was very proud of his children. And his extended family are most appreciative of the impact he has had on their life. He mentored so many people in the industry and part of his legacy will be the quality of the individuals and the impact they have had on the contact lens profession as a direct or indirect result of the influence of Milt Kallas.

By Ed BennettAcknowledgements: John Hibbs, Jonathan Jacobson, Jay Woychick, David Bland, David Moreira, and Craig Norman

LettertotheEditor

The use of lead scleral shells

In the 3-2020 (85) edition of GlobalCONTACT, Dr Hans-Walter Roth published three excellent photographs of a small set of scleral contact shells which comprised six pairs of PMMA shells, one for each eye, together with corresponding lead shells.

Some readers of this magazine may have wondered about the purpose of the lead shells. An essential clue about their use is provided in the photograph of the ‘instruction manual’ in which they are identified as ‘shields’. Since lead can provide shielding against high-energy sources of radiation such as gamma rays and x-rays, shells made from this metal have been used to protect the eye when malignant tumours in orbital region were subjected to radiotherapy.

More than 55 years ago, Jenkin and Tyler Jones wrote the following, which appears to be an exact description of Dr Roth’s shells:

“Six shells of different sizes are supplied for both right and left eyes. Transparent duplicates of each size are included with the set. Trial fittings are made with transparent shells until a fair fit is obtained, the corresponding lead shell is then inserted and worn during treatment.”

As the lead shells were worn for only a brief period, a fitting set of six pairs was sufficient to find one which was large enough while providing some clearance of the cornea. Clement Clarke of London, a firm that supplied a wide range of ophthalmic instruments and devices, manufactured the fitting set mentioned by these authors.

Reference: Jenkin, L and Tyler-Jones, R, (1964). Theory and Practice of Contact Lens Fitting, p124-5, The Hatton Press Ltd, London.

Richard M PearsonModern modalities such as Sclerals and Orthokeratology have been propelled into the forefront of practitioners’ attention in recent years. However, traditional high/hyper Dk materials struggle to meet the requirements of these growing modalities. In contrast to previous technologies, Optimum Infinite offers hyper Dk (180Dk) that retains rigidity, provides excellent wettability and is durable during lens handling and wear, and of course, it is easy to machine. Optimum Infinite changes the paradigm so you don't have to compromise when using hyper Dk materials. Contamac's expert R&D chemists have rewritten the rules on Hyper Dk materials to give you infinite possibilities. sales@contamac.co.uk , www.contamac.com

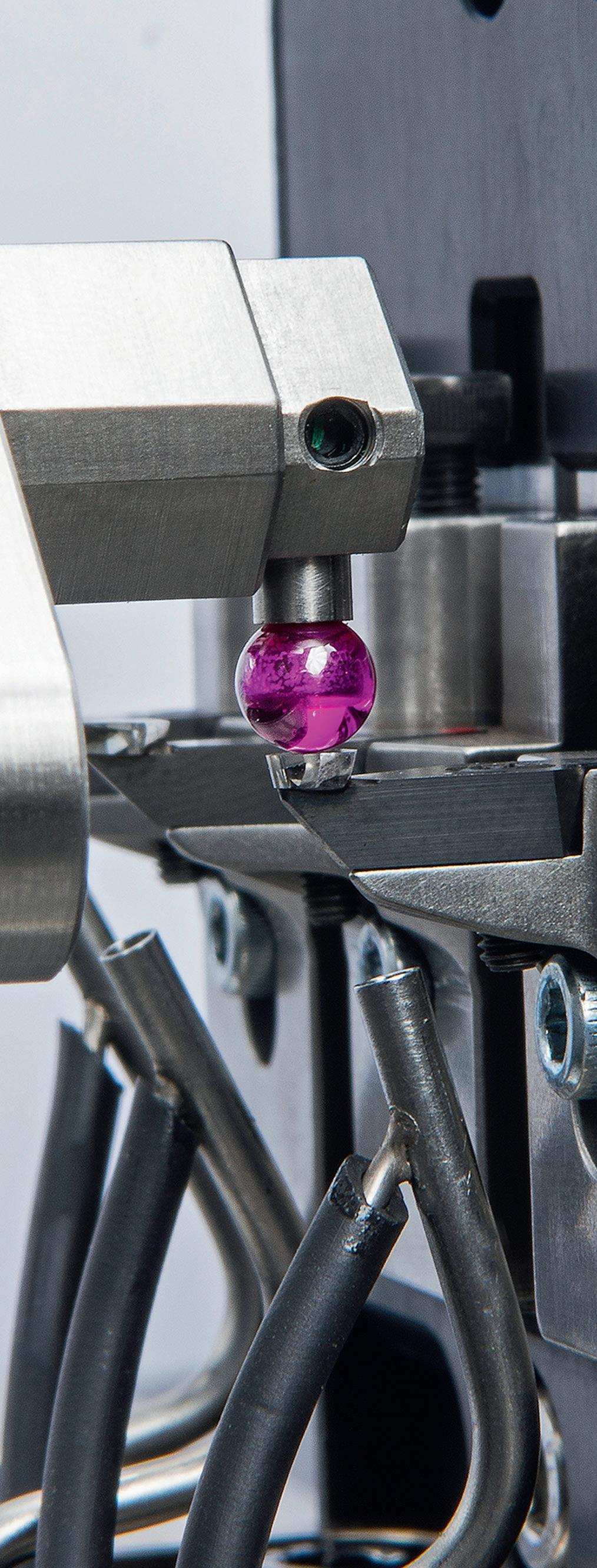

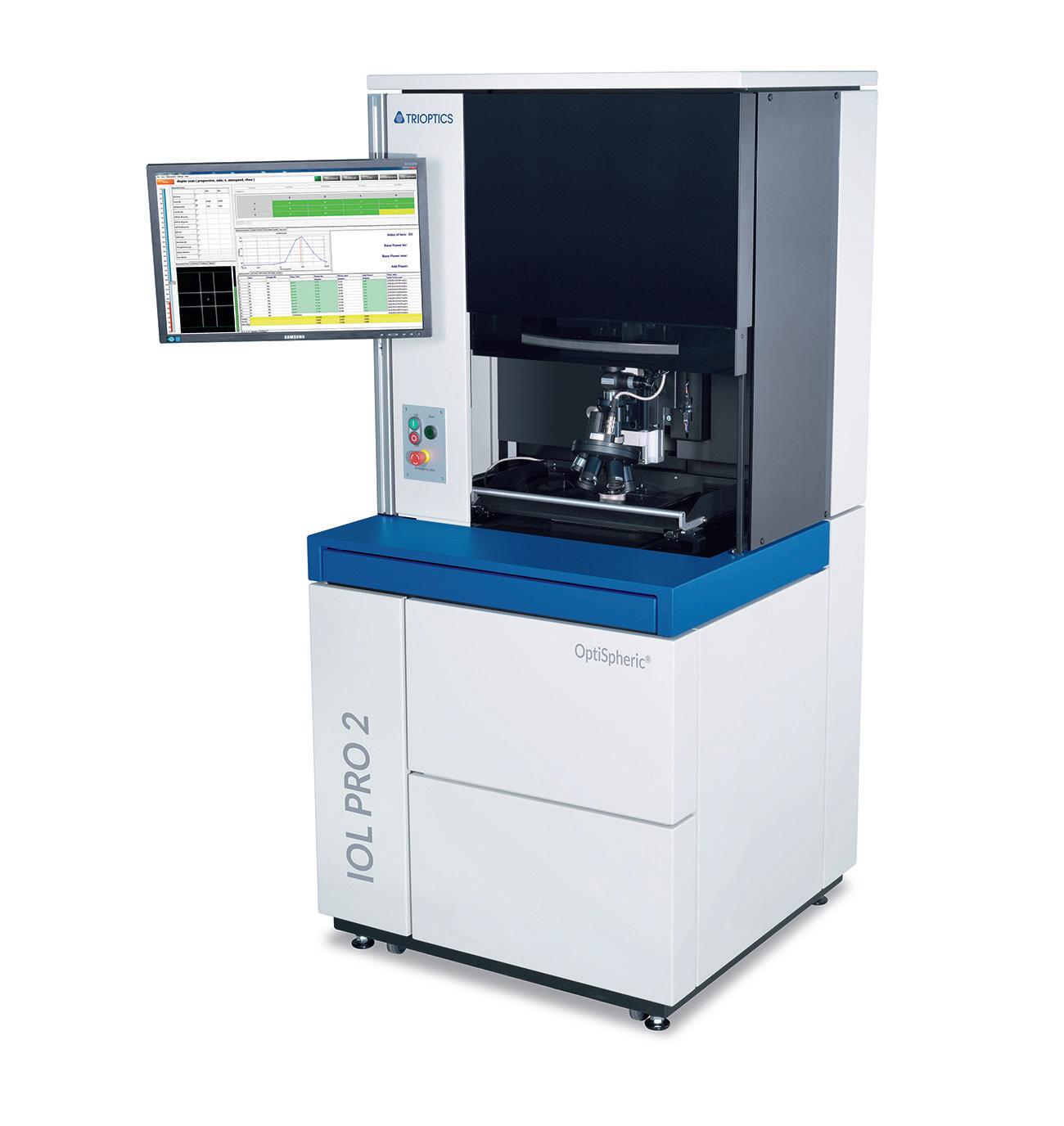

OptiSpheric® IOL PRO 2 is TRIOPTICS’ fully automated optical IOL test stand. Developed for use in production, it provides a throughput of up to 100 lenses per batch. The ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in-situ can be performed with an accuracy of 0.3 % (power) for all types of intraocular lenses (incl. EDOF, multifocal and trifocal). With the latest software module, the system can be connected to your database in accordance to FDA 21 CFR PART 11. This allows you to retrieve sample-specific data and measurement scripts from the server as well as to archive your measurement results in conformity with the standards. info@trioptics.com, www.trioptics.com (due to the corona crisis, please check via the websites whether the event takes place)

EAOO Helsinki 2021 Apr 23-25 online event https://e.eventos.fi/events/naery/helsinki-2021/home

ARVO 2021 May 1-7 online event www.arvo.org/annual-meeting/ Virtual Ortho-K Boot Camp May 12 online event www.orthokmeeting.com

BCLA 2021 June 13-14 online event www.bcla.org.uk

ICSC 2021 July 23-24 Fort Lauderdale, FL (USA) www.icscmeeting.com

IOFT 2021 International Optical Fair Tokyo Oct 18-20 Tokyo (JPN) www.ioft.jp/en-gb.html

NCC 2022 Mar 13-14 Eindhoven (NL) www.contactlenscongress.com/en/

EFCLIN 2022 Apr 28-22 TBA (South Europe) www.efclin.com

Two of the following contact lens studies have focused on children in the past year. While one aimed to clarify how safe soft contact lenses are for children, the other looked at the effect of contact lenses on myopia progression in children. There's also news from the field of contact lens development – a smart CL that shows potential for eye health monitoring.

fitted while eight to twelve years old with various SCL designs, prescriptions and replacement schedules, and observed through to age 16. Compared to AE results derived exclusively from clinical trials, these data are thought to be more generalizable to real world experiences as myopia control soft contact lenses are prescribed more widely to young patients.

Robin Chalmers et al. have examined the safety of wearing soft contact lenses for children [1]. The research was funded by CooperVision Corporation and was initiated to support CooperVision's regulatory submissions of MiSight 1 day contact lenses.

The study measured the rate of adverse events (AE) in children who were prescribed soft contact lenses before they turned 13 years old to establish wearing safety among that age group.

The review documented AE details from clinical practice charts and clinical trial data of 963 children and observed 2,713 years of wear across 4,611 visits. The evaluated subjects were first

Clinical records from office visits with potential AEs were independently reviewed by an adjudication panel to determine a consensus diagnosis. The current findings are very similar to but slightly lower than rates reported in previous studies of similar age groups, possibly attributed to the higher proportion of daily disposable lenses in the current study. The study found the annualized incidence rate of inflammatory events was less than one percent per year of wear. The majority of events were conjunctivitis or foreign body abrasions, reflective of this young population.

The authors note that the study found a lower rate of microbial keratitis (7.4/10,000 years of wear) with a tighter confidence interval than other pediatric post-market studies. That rate has been found to be comparable to established rates of microbial keratitis in adults.

Sources: abstract of study [1], EurekAlert 2020-12-10 [2]

Early diagnosis is important for avoiding severe eye problems, such as exophthalmia or glaucoma. Such diagnoses rely on facile and reliable monitoring of several features with pathologic relevance, such as the amount of tears and intraocular pressure. Current methods usually require complex procedures and instruments operated by professionals, causing difficulties for point-of-care (POC) ophthalmic health monitoring. A research group led by Prof. Du Xuemin from the Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences has developed a "smart" contact lens that can show real-time changes in moisture and pressure by altering colors. The results were published in the Journal of Materials Chemistry B [3]

This contact lens features periodic nanostructures within the poly(2-hydroxyethyl methacrylate) (pHEMA) hydrogel matrix, resulting in bright, tunable structural colors ranging from red to green to blue.

The structurally colored contact lens sensor is made solely from a biocompatible hydrogel, without the addition of any chemical pigments, thus exhibiting biosafety and comfort for wearable applications.

The spacings of periodic nanostructures within the pHEMA hydrogel are sensitive to changes in moisture and pressure, leading to real-time color changes in the contact lens.

Zhao Qilong, first author of the study, reports that its color will not change over time in normal eye-simulation conditions but changes from red to blue in a xerophthalmia-simulation condition in about 25 minutes.

Additionally, a linear decrease in the wavelength of the reflectance peak of the "smart" cosmetic contact lens is observed when human intraocular pressure changes in the pathological range. It can potentially be used for point-of-care (POC) diagnosis of xerophthalmia and high intraocular pressure disease.

Source: Abstract of study [3], EurekAlert 2020-02-18 [4]

Nearsightedness tends to begin between the ages of eight and ten and progresses up to about age 18. In a trial, conducted by Jeffrey Walline et al. at Ohio State and the University of Houston, almost 300 nearsighted children age 7-11 years were randomized into one of three groups of contact-lens wearers: single vision or multifocal prescriptions with a medium reading add of 1.50 diopters or a high add of 2.50 diopters. The findings were published in the Journal of the American Medical Association [5]. The study was funded by the National Eye Institute, part of the National Institutes of Health, and supported by Bausch + Lomb, which provided contact lens solutions. As a group, the participants' average prescription at the start of the study was -2.39 diopters. After three years, both the degree of myopia progression and the extent of eye growth were lower in the kids who had worn the high-add lenses. On average, the three-year eye growth among kids with the high-add bifocals was .23 millimeters less than in kids wearing singlevision lenses. Medium-add lenses did not slow eye growth any more than single vision lenses. A bifocal contact lens prescription with the highest near-work correction slowed nearsightedness

Referenzen:

progression by 43 percent when compared to single-vision contact lenses.

The researchers were aware of the need to balance the reduction of eye growth with any risks associated with subjecting children to strong reading power long before they need that level of correction. When testing their ability to read gray letters on a white background, there was a two-letter difference between single-vision lens wearers and those wearing multifocal lenses.

The research team is continuing to follow the same participants, treating them all with the high-add bifocal lenses for two years and then switching them all to single-vision contact lenses in order to evaluate the permanence of the treatment effect.

Sources: Abstract of study [5], EurekAlert 2020-08-11 [6]

[1] Chalmers, RL, McNally, JJ, Chamberlain, P, & Keay, L. Adverse event rates in the retrospective cohort study of safety of paediatric soft contact lens wear: the ReCSS study. Ophthalmic Physiol Opt. 2020. https://doi.org/10.1111/opo.12753, [2] https://www.eurekalert.org/pub_ releases/2020-12/mc-lso120820.php, [3] Wang, Y., Zhao, Q., Du, X. Structurally coloured contact lens sensor for point-of-care ophthalmic health monitoring. J. Mater. Chem. B, 2020, 8, 3519-3526. https://doi.org/10.1039/C9TB02389E, [4] https://www.eurekalert.org/pub_releases/2020-02/ caos-scl021820.php, [5] Walline JJ, Walker MK, Mutti DO, et al. Effect of High Add Power, Medium Add Power, or Single-Vision Contact Lenses on Myopia Progression in Children: The BLINK Randomized Clinical Trial. JAMA. 2020;324(6):571–580. doi:10.1001/jama.2020.10834, [6] https://www.eurekalert.org/pub_releases/2020-08/osu-ynk080620.php

As a board member of EFCLIN and managing director of Optocraft, Johannes Pfund has experience of different aspects of our industry. In an interview with GlobalCONTACT, the doctor of physics shares insights into changes at EFCLIN and looks back on the extraordinary year 2020. He also outlines possible scenarios for 2021 and – on the occasion of Optocraft's 20th anniversary – looks back on the milestones of his own company to date. By Silke Sage

GlobalCONTACT: You have been a member of the board of EFCLIN since 2017. What were your expectations when you joined?

Pfund: My motivation was a mixture of curiosity and my inner desire to play a part in professional associations and networks. I have long been active in a photonics network, and EFCLIN interested me because I wanted to understand how the contact lens industry works, what the specific challenges are and also to get to know the customer side. Another aspect was – and still is – that I wanted to contribute my knowledge of other industries.

GlobalCONTACT: What has changed at EFCLIN since 2017?

Pfund: It’s not just one person alone on a board who gets things done. Martina Clifford was elected to the board at the same time as I was and she has a completely different background to me. Right from the start we brought in our respective ideas and worked on changes together. Also, thinking about the future beyond the next congress and strategic planning interests me.

GlobalCONTACT: What is your main focus and which areas are you responsible for?

Pfund: As a physicist with a doctorate in metrology, aspheric lenses test engineering and precision optics, it seemed logical for me to focus more on technical matters for the Manufacturers Forum and shed light on these topics. As the founder and owner of my own business, I am also acutely aware of the need to attract start-ups and small businesses to become members of EFCLIN at an early stage.

In order to breathe new life into the Manufacturers’ Forum, Erik Smidt, Peter Vermeulen and I have jointly built on ideas from the experience and suggestions from the community. This has already progressed through several evolutionary stages. Our aim is to create a lively discussion forum around appropriate topics which should also be an enjoyable experience.

The Manufacturers’ Forum always risked being a front panel, with the panel of experts on the podium and the other attendees sitting in the auditorium. Sometimes it seemed as if the audience was reluctant to contribute because they did not want to give the impression that they didn’t understand everything. We thought about how the forum could be made more lively and communicative. The approach we came up with was to stop asking people individually where their challenges lay and instead try to identify topics of common interest and create a format where short stimulating introductory lectures would be followed by round-table discussions. The outcome of these discussions was then again summarized, leading in turn to new topics for discussion. This format has proved to offer a great deal of freedom and, in most cases, resulted in new topics of interest for future events.

GlobalCONTACT: What does a digital Manufacturers’ Forum look like? Pfund: At first we tried to somehow adapt this format to the digital world. But we soon concluded that spontaneity would suffer and that it would be better to focus on a “physical Manufacturers’ Forum” as part of the congress in 2022. The good news is that we are working closely together in the board and with some volunteers to stay in contact with the community, so that we can offer interesting topics in the form of short webinars month by month. We will continue to provide up-to-date information on these activities.

GlobalCONTACT: How was 2020 from your perspective as a board member? What particular challenges did you have to face?

Dr. Joha n n es Pfund

Pfund: 2020 was an amazing year. As in other years, we started with intensive discussions and planning of how the EFCLIN Congress should be organized and the allocation of tasks. But we all know how this ended – in the cancelation of the event. It was a very hard decision but one that had to be made. We initially thought about how the congress could go

ahead in spite of everything, e.g. with a sort of hybrid or video format, but no satisfactory solution could be found.

In March, just before the lockdown in Germany, we also held a one-and-a-half-day workshop on strategic topics. Funnily enough one of the question which came up was, "How can we digitize EFCLIN; how can we best stay in contact with the community?" At the time no one could have imagined what a positive accelerator the pandemic would prove to be in this regard. As already mentioned, we have now set up a monthly digital program for 2021 – that’s how fast things can change.

The remainder of 2020 was very much dominated by crisis management. The center of our attention was on the 2021 Congress: should we go ahead with it or not; and, if so, how should it be planned? After all there’s much more to the organization and cancellation of a congress than meets the eye. Marion Beeler did an amazing job in this regard. In coordination with the board, she had to juggle with a lot of imponderables – in March no one could have foreseen how Corona would pan out.

One characteristic of 2020 was that not only was there a pandemic a problem, but the MDR was also coming into force. This is an awkward topic for many people and particularly for smaller companies. In terms of communication with EFCLIN as an institution, this issue certainly took precedence over the pandemic. Maybe this was because its effect is likely to be more permanent. The MDR will keep the industry busy for a long time to come.

GlobalCONTACT: MDR from the point of view of measurement technology. Do you feel that manufacturers have a lot of catching up to do?

Pfund: There is currently something like "transformation pains". The new MDR has to be integrated into your existing processes and that means an initial investment. However, for every product there is also a recurring investment. As I see it, for each product certified, the effort required for documentation and quality assurance will be significantly higher than before. This will increase costs which have to be recovered somehow, leading to questions such as: Can I raise the price of contact lenses as a result of this? How do I continue to do business with the new cost structure? The MDR remains an ongoing issue and each individual has to position himself with his product portfolio in such a way that it is easy to manage from an organizational point of view.

GlobalCONTACT: In the past year, many smaller labs have been bought by industry giants. What are the consequences for the association?

Pfund: I think one should consider two different aspects. The trend that smaller companies are being bought by larger companies or grouping together is a real opportunity for the entrepreneurs in these companies and could lead to a major

boost in innovation. It may also benefit the end customer in terms of new, exciting products. For our industry-wide network it is of course different, because the more companies merge, the greater the risk that subsequently of the two, three or four former companies only one EFCLIN member will remain. The challenge for EFCLIN is to retain its critical mass. For the moment, this is still ok, but thought needs to be given to how to maintain the growth of EFCLIN in the future.

GlobalCONTACT: What is your forecast for the industry for the current year?

Pfund: This year, as with last year in particular, experience shows that forecasts are likely to be wrong. Thus I prefer to think in terms of scenarios. At the moment I see two alternative scenarios: If we assume a seasonal decline in the number of infections for March to May and assume that vaccination is successful, then we can hope that the infection rate will not increase as drastically again next winter. For manufacturers of customer specific contact lenses, this could mean that customers return in droves, manufacturers have plenty of work and this in turn will lead to the recovery of production figures for the companies concerned. It could even mean demand suddenly exceeding capacity and production reaching its limit; perhaps a luxury problem from today's perspective. There may also be a catch-up effect in the area of specialist and IOL lenses. Remember that cataract operations have been difficult or impossible to perform for some considerable period because some “routine operations” were not possible or at least difficult due to the overload of pandemic-related cases in hospitals. This would be the promising scenario.

A less promising scenario would occur if mutations were to arise. What if there was a mutation that not only spread faster but was also more deadly; or against which the vaccines proved ineffective? It would mean that everything would start all over again. This would be the pessimistic scenario – but one also has to be prepared for it. What should the new business model look like in the case of this scenario?

GlobalCONTACT: How do you think the industry would have to position itself to prepare for such future scenarios?

Pfund: The manufacturers of daily contact lenses are certainly already well positioned. Their production is automated at every stage and customers can buy what is in stock on the Internet. For the manufacturers of specialty or customized lenses, the lens fitting process at the contact lens fitters or optometrists needs to become faster, easier and more straightforward. For this industry, the aim must also be to streamline and automate production processes wherever possible.

GlobalCONTACT: Optocraft will be 20 years old this year. With your background in precision optics, what have been the milestones for your company?

Pfund: One key milestone of course was when we set up Optocraft in 2001. I founded Optocraft together with another physics graduate from the faculty of optics at Erlangen University. Our initial product was a small sensor, the Shack-

Hartmann SHSLab wavefront sensor, which I developed as part of my doctorate.

We founded the company without any major investment, so to speak with the feet on the ground. We just moved into a small room, started going to trade fairs and landed an order here or there. Starting off with the small SHSLab sensor, we gradually evolved in the direction of instrument technology; our first market was more in optics testing. For example, we got a good order from a manufacturer of high-quality binoculars for birdwatchers and rifle scopes for hunters. Thus we managed to get established and continued to grow organically.

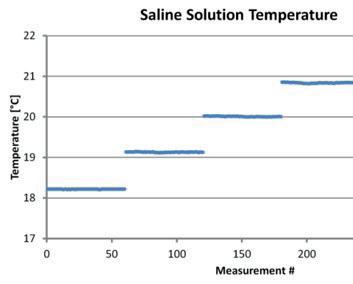

Another milestone came around 2008 when we launched SHSOphthalmic in the contact lens market. It was fascinating to learn the ropes of this industry. In the precision world, everything revolves around ultimate accuracy, whereas in the contact lens field things are structured very differently. The optics themselves are usually far less precise with regard to the wavefront, but they require answers to completely different questions, such as: “Does the lens have the correct base curve? Does it scratch the eye? Does the lens have the correct refractive power, even when measured several times after repeated handling? What is its refractive power at different temperatures?”

Entry into the market for intra-ocular lens manufacturers also went hand in hand at the time. Interestingly, the 11979-2 regulations and others brought this market much closer to

what we were used to dealing with in precision optics in terms of measurement technology. Be that as it may, we apply our expertise gained in other fields to the contact lens and intra-ocular lens markets and we are constantly advancing our technology and the performance of our instruments.

GlobalCONTACT: In your opinion, what has been the biggest change in the field of contact lenses and IOLs over the past 20 years?

Pfund: We first had to get to know how the ophthalmic market works, how an operator in production ticks, what he needs, how and under what conditions he works. We then learned how to adapt our devices to these requirements. At the same time our potential customers, i.e. the lens manufacturers, have evolved too. They have changed their approach and gained a much better understanding of the fact that digital measuring devices offer an opportunity. They have become aware that simply measuring a refractive power is only one approach, and that there are also other hot topics, such as measuring the refractive power

distribution across the lens – for example for multifocal contact lenses. A rapid growth in expertise relating to measurement technology and its application can be observed in such companies today. With regard to measurement technology, they now also have a much better understanding of what is possible and how procedures and results should be interpreted.

GlobalCONTACT: How do you intend to mark this 20th anniversary? Pfund: Due to the uncertain situation regarding the pandemic, things are difficult to plan. Either we will celebrate virtually with a few bottles of whiskey and champagne, or – and we truly hope this will be possible – we will hold a "family party" outdoors in summer, and repeat this later in autumn with business partners and employees in a more formal setting. During the course of the year, we will also run various promotional campaigns in the market, but I don't want to say any more about that just now.

GlobalCONTACT: Thank you for the interview!

Recently, the Global Specialty Lens Symposium (GSLS) was held online with a staggering 4000 delegates registered and with 83 countries represented – truly a ‘global’ symposium. I was put in charge of the myopia session, to be the myopia management moderator, so to speak. The panel was an exhibition of global excellence, with a constant flow around the globe, swinging back and forth from the east coast of Australia (Scott Read from the Queensland University of Technology in Brisbane and Kate Gifford of myopiaprofile.com) to the Netherlands (Jan Roelof Polling from Erasmus MC in Rotterdam) and North America (Langis Michaud, Université de Montréal in Canada). By Eef van der Worp

It is no secret that myopia is increasing, quite drastically in fact, worldwide. But what may be new is that during the year 2020, and presumably because of home confinement during the COVID-19 pandemic, concerns have been raised about whether this home confinement may have worsened the burden of myopia owing to both decreased time spent outdoors and increased screen time at home. In short: our kids have been ‘living in a box,’ at least partly, during the last year. A study by

Wang et al in JAMA Ophthalmology looked into this and found indeed that in the 123.535 children included in the study, a substantial myopic shift was seen (approximately −0.3D) in the school-based screenings in 2020 compared with previous years (2015-2019) for younger children aged 6 (−0.32 D), 7 (−0.28 D), and 8 (−0.29 D) years. Numerous limitations warrant caution in the interpretation of these associations, including use of non-cycloplegic refraction and lack of orthokeratology history or ocular biometry data. But the authors do conclude

that home confinement during the COVID-19 pandemic appears to be associated with a significant myopic shift for children aged 6 to 8 years. And that younger children’s refractive status may be more sensitive to environmental changes than that of older children, given that younger children are in a critical period for the development of myopia.

With this in mind, and as a starting point, the panel at GSLS tried to analyse what is the best way in clinical practice to reduce myopia progression to the max, while staying on the safe and ethical side of things. The first appraisal made was a very important and critical one: don’t be mean! We hear all these stories about ‘50%’ or ‘60%’ reduction, also with new spectacle lenses now for myopia management. But what does this really mean? Work by Noel Brennan and Mark Bullimore, originally posted at ARVO 2019, has shown that these numbers are very relative in nature. First and foremost, it is important to realize that these are all average (or ‘mean’) numbers. ECPs can never present, promote or promise this in that way to patients and parents. Furthermore, even if these numbers of reduction are met, it is only the case within a relatively short period of time. Let’s say for convenience and to avoid complex discussion about that (hot) topic that the bulk of the treatment in myopic children needs to take place between the ages of 8 and 12 years. That is a pretty narrow window of opportunity.

What this also means is that we need to do everything we can to get as much treatment in during that limited time frame. Depending on the child and the situation, this could mean that we need to combine treatments if/where possible to get the most out of it in terms of efficiency. The session at GSLS showed that not only do we need to customize the treatment for each child, we also need to customize the intervention method –optical or not – to the max.

What this means for pharmaceutical intervention (basically atropine drops currently) is to look at the optimal concentration. Kate Giffford and Jan Roelof Polling shed some light on this. The latest research shows that higher concentrations of atropine seem to be the most effective (and less rebound effect after treatment is tapered), at the cost, of course, of more side effects including reduced accommodation, pupil size enlargement (hence photophobia), irritation and possibly headaches. And a low 0,01% concentration may unfortunately not meet the expectations we have of it.

How effective a certain concentration of atropine is for a given child can be best monitored by following the axial length growth charts, almost like what we have for children’s height every time we visit the paediatrician (see figure 2). Basically, if the child is diverting from the designated path or line ‘upward,’ it is time to upgrade the atropine concentration; but if the kid is ‘lower’ than the designated line – then it is time to decrease atropine concentration and/or to add additional intervention methods such as optical intervention. This is a really nice way of following and monitoring myopia progression, with at least some kind of apparent control over the potential outcome.

In this category, our number one ‘champion’ is still orthokeratology, which has the longest track record and good evidence in the literature. However, here too, customization to optimize the outcome seems warranted. The myopia-reducing effect of orthokeratology was pretty much found by accident using standard orthokeratology lenses. We can most probably ‘upgrade’ the effectiveness of the modality by first looking at the optical zone treatment diameter on the cornea and the power profiles achieved. Langis Michaud and Kate Gifford explored ways of doing this. First, optical zone diameters should

not be too large to be effective; ideally, they should be limited and customized to roughly the pupil zone area. But the optical treatment zone shouldn’t be too small either: there is a small sweet spot between being too small and too large.

Furthermore, in essence orthokeratology converts peripheral hyperopia into relative peripheral myopia for low to average myopic eyes. The degree of relative peripheral myopia increases with the magnitude of central myopia that is corrected, Langis Michaud explained. Kate Gifford warned against not correcting low myopes with orthokeratology though, as there is not enough evidence to say that it would be less effective in low myopia.

What seemed relatively new to many delegates was the optics side of things and how important spherical aberrations and other higher-order aberration measurements are and their implementation in myopia management. The good thing is that it is all optics, which is (or should be) our core business. With respect to slowing myopia progression, the most important advantage of orthokeratology over either spectacles or soft contact lenses is that orthokeratology can induce very large optical effects in moderate to high myopes. But there is a need to customise orthokeratology fitting, according to Langis Michaud, to optimise the outcome. The optical profile and the treatment zone diameter can be altered, and back-toric lens design can be used to optimize the result.

According to Scott Read’s presentation, soft contact lenses to slow myopia progression make use of two or more focal

distances in the lens: a primary focal distance for far vision (i.e., the myopia correction) and a secondary plus power to slow eye growth (either a concentric design, aspheric design or Fresnel design). These designs aim to introduce positive/ myopic defocus to the retinal image. Optically, most lens designs tend to introduce increased levels of positive spherical aberration. This is pretty complex, however, and the amount of defocus induced will depend on a range of factors, including lens design, interactions with the eye’s natural optics, pupil size and accommodation and, lastly, lens (de-)centration.

Natural accommodation of the human eye alters the eye’s normal optics and introduces negative spherical aberration. This would reduce the amount of peripheral myopic defocus. Accommodation through the lens influences the myopic vs. hyperopic stimulus to human eye growth. This is where ‘Zernike polynomials’ come in, which describe complex aberrations of the eye. According to Scott Read, optimising soft contact lens designs for increased myopia control efficacy may be possible if these lenses are customized to the individual child. Langis Michaud took it ‘one step up’ from here by looking at choroidal thickness in the human retina in response to different optical profiles provided by soft lenses for myopia management. He coined the term ‘dose response’ in this regard: by varying the amount of peripheral ‘plus,’ the myopia reduction effect can be optimized. The newest BLINK study results show that with higher add power, typically a more significant rate of myopia progression reduction can be achieved. Studies at the Université de Montréal also show the same results as well as that the

treatment zone diameter can significantly influence the choroidal thickness (larger treatment zones result in reduced choroidal volume – which means longer eyes). They even found quadrant-specific differences in this regard, with a high inter-subject variability (threshold). This screams for customized designs to be developed.

If this session made one thing clear, it is that we not only need to customise the treatment for myopia (chosing the right option in the right situation) but also that we will need to further customise the treatment (e.g. increase efficiency by looking at concentrations of atropine and/or optimize optical profiles). In other words: it starts with the children and their individual needs and circumstances. Within that frame, and within a narrow window of time, we need to carefully chose the myopia management method for the individual. And within each category, it seems like we’ll have to customize the treatment itself as well – in atropine concentration and in terms of aberrations corrected and applied. Especially within the optical intervention methods, there is a lot to gain in that regard within our industry.

References:

[1] Brennan NA, Toubouti YM, Cheng X, Bullimore MA. Efficacy in myopia control. Prog Retin Eye Res. 2020 Nov 27:100923.

[2] Tideman JWL, Polling JR, Vingerling JR, Jaddoe VWV, Williams C, Guggenheim JA, Klaver CCW. Axial length growth and the risk of developing myopia in European children. Acta Ophthalmol. 2018 May;96(3):301-309.

[3] Wang J, Li Y, Musch DC, Wei N, Qi X, Ding G, Li X, Li J, Song L, Zhang Y, Ning Y, Zeng X, Hua N, Li S, Qian X. Progression of Myopia in School-Aged Children After COVID-19 Home Confinement. JAMA Ophthalmol. 2021 Jan 14: e206239.

Eef van der Worp, BOptom, PhD, FAAO, FIACLE, FBCLA, FSLS is an educator and researcher. He received his optometry degree from the Hogeschool van Utrecht in the Netherlands (NL) and has served as a head of the contact lens department at the school for over eight years. He received his PhD from the University of Maastricht (NL) in 2008. He is a fellow of the AAO, IACLE, BCLA and the SLS. He is currently adjunct Professor at the University of Montreal University College of Optometry (CA) and adjunct assistant Professor at Pacific University College of Optometry (Oregon, USA). He lectures extensively worldwide and is a guest lecturer at a number of Universities in the US and Europe.

Myopia progression is much higher in China and Korea than in Germany

Reference percentile curves are commonly used in pediatric practice in order to estimate body height and weight development. They are used as a screening tool to assess the development and well-being of children and percentiles are also useful to monitor the development of ametropia in children.

Recently, Carolin Truckenbrod and a team of researchers created the first reference curve for refraction in Central Europe and they investigated the extent to which differences exist in refractive development in children in Germany and Central Asia. The researchers published their findings in March 2020. GlobalCONTACT has summarized the key findings and has spoken with researcher Carolin Truckenbrod about the study background. By Hanna Diewald & Rebekka Nurkanovic

GlobalCONTACT: Your analysis is part of the Life Child-study. What was the background to the study?

Truckenbrod: LIFE Child is a cohort sequential design study that was established in 2011 as part of the Leipzig Research Centre for Civilization Diseases (LIFE). The measurements are carried out by the LIFE Child ambulance. The study by Prof. Dr. Wieland Kiess and Prof. Dr. Antje Körner has set the goal of examining healthy child development from pregnancy to early adulthood. The questions to answer are which factors influence child development positively or negatively.

In this context, a large amount of data is collected, which can be analyzed by scientists worldwide via a project agreement.

GlobalCONTACT: How can interested parties benefit from these data sets?

Truckenbrod: Anyone interested in evaluating data from the LIFE Child Study can contact the study clinic team via the following website: home.unileipzig.de/lifechild/project-request/

GlobalCONTACT: What is your involvement in the study?

Truckenbrod: As a doctoral candidate at the University of Leipzig, I may analyze data from the Life Child cohort via a project agreement. I also participated in the collection of the data for a while.

GlobalCONTACT: Why are centile charts for refractive development important? What is the benefit for pediatricians?

Truckenbrod: Pediatricians already use percentile curves for weight and height to assess the child's development. They allow a simple risk factor analysis for the occurrence of certain developmental abnormalities. More and more pediatricians are also performing automated refraction measurements on children. The percentile curves of the refraction allow pediatricians to assess the measurement results more quickly.

GlobalCONTACT: What were the challenges in data collection and how did you solve them?

Truckenbrod: With small children it is always a challenge to encourage them to participate. It is important to find an approach to the children and to make sure that they are not afraid of the technical devices and then sit still for a short time. However, I was only partly involved in the data collection provided by LIFE Child.

GlobalCONTACT: Were there any limitations to the comparability of the data?

Truckenbrod: Unfortunately, the refraction data were collected without cycloplegia. Since this is not a pure eye study, but the development of the child in general is the focus at LIFE Child, cycloplegia would influence the subsequent tests too much. In order to achieve better comparability with other studies, we tried to approximate data collected with cycloplegia with the help of a formula.

GlobalCONTACT: What is the main conclusion from your findings?

Truckenbrod: At the age of five, the refraction percentiles between Asian countries and our data are still very similar. Thereafter, the refraction developed significantly differently, with the upper percentiles developing in parallel with the hyperopic children. In the lower percentiles we can generally see an increase in myopia, but this is much more pronounced in the Asian countries.

GlobalCONTACT: What questions should be explored next?

Truckenbrod: Our next project is the observation of axial length growth in children.

GlobalCONTACT: Thank you for the interview.

The study is presented on the following page. >>

Carolin Tr u ckenbrod

"IN THE LOWER PERCENTILES WE CAN GENERALLY SEE AN INCREASE IN MYOPIA, BUT THIS IS MUCH MORE PRONOUNCED IN THE ASIAN COUNTRIES."

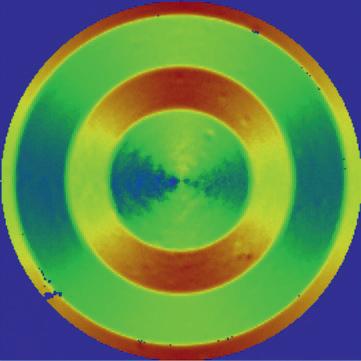

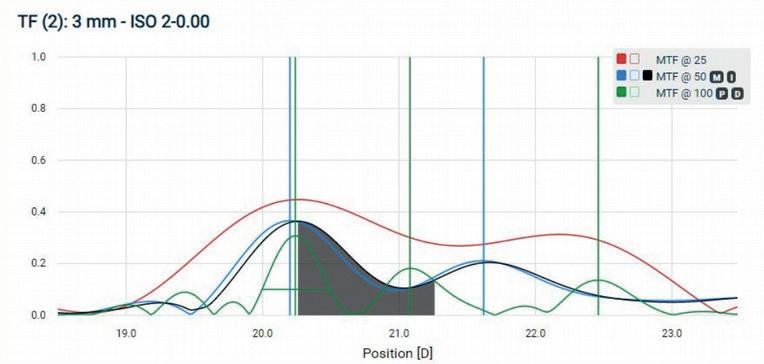

The researchers measured non-cycloplegic refraction in 1999 children, of which 1046 were male and 953 female, aged 3 to 18 years. The autorefraction without cycloplegia was carried out with the wavefront aberrometer Zeiss i. Profiler plus, which is based on a Hartmann-Shack sensor. The refractive error was analyzed at a 3 mm pupil and a vertex distance of 12 mm. Three measurements of each eye were carried out for each patient. After autorefraction the uncorrected visual acuity (UCVA) and the best corrected visual acuity (BCVA) were obtained using the Zeiss i.Polatest1 with the spherocylindrical combination measured with the Zeiss i.Profiler plus. For children from 3 to 6 years and older children who were not able to read, Colt Symbols were used, for the older children letters.

According to the WHO guidelines for attained growth curves, the refraction is presented as a continuous function of age. This results in smoother curves than using age intervals and provides better comparableness. The GAMLSS model allows for creating such reference curves from continuous variables. For statistical analysis, the software R [1], by the R foundation, with the additional package “gamlss” was used.

The results showed that there were only little differences for all centiles between the genders at 3 years and a general trend towards more myopia with increasing age. For the 97th centile and the 3rd centile, girls showed higher myopia/ less hyperopia than boys.

Between the age of 3 and 18, the median refraction became -0.68D and -0.74D more myopic for boys and girls, respectively. At the same time, the 97th centile for boys changed +0.29D towards hyperopia and in girls -0.52D towards myopia. A

general myopic trend was seen in the 3rd centile, which was -2.46D for boys and -2.98D for girls. For both genders, the median became less than zero at the age of 10 years but did not become myopic (less than -0.5D) up to the age of 18. The analysis presents the first reference curve for refraction in Central Europe. In comparison to data from China and Korea, there is only little difference at the age of 5 years in all centiles which then increases continuously.

For all ethnicities, a trend towards myopia with increasing age could be observed, but myopia progression is much higher in China and Korea than in Germany. The most marked differences can be seen in the lower centiles.

The complete study was first published on: journals.plos.org/plosone/ article?id=10.1371/journal.pone.0230291

References:

• Chen Y, Zhang J, Morgan IG, He M (2016) Identifying Children at Risk of High Myopia Using Population Centile Curves of Refraction. PloS one 11 (12): e0167642. https://doi.org/10.1371/ journal.pone.0167642

• Sankaridurg P, He X, Naduvilath T, Lv M, Ho A et al. (2017) Comparison of noncycloplegic and cycloplegic autorefraction in categorizing refractive error data in children. Acta ophthalmologica 95 (7): e633– e640. https://doi.org/10.1111/aos.13569

• Truckenbrod C, Meigen C, Brandt M, Vogel M, Wahl S, Jurkutat A, et al. (2020) Reference curves for refraction in a German cohort of healthy children and adolescents. PLoS ONE 15 (3): e0230291. https://doi.org/10.1371/journal.pone.0230291

Footnote: [1] For further information please visit: www.r-project.org/about.html

3rd, 50th, 97th centile reference curves of refraction over age for boys. The dashed lines represent the data of the LIFE Child study, the dotted lines the data of the LIFE Child study transferred by the calculation of Sakaridurg et al. into comparable data for cycloplegia and the continous lines show the results of the RESC study from a city in China. Source: PLOS ONE

3rd, 50th, 97th centile reference curves of refraction over age for girls. The dashed lines represent the data of the LIFE Child study, the dotted lines the data of the LIFE Child study transferred by the calculation of Sakaridurg et al. into comparable data for cycloplegia and the continous lines show the results of the RESC study from a city in China. Source: PLOS ONE

Corneal injuries caused by foreign bodies under a contact lens

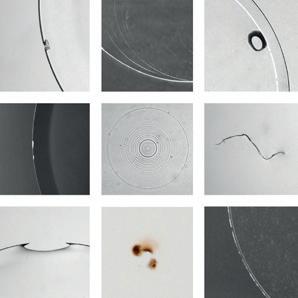

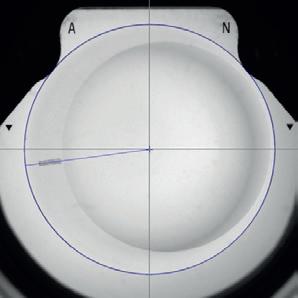

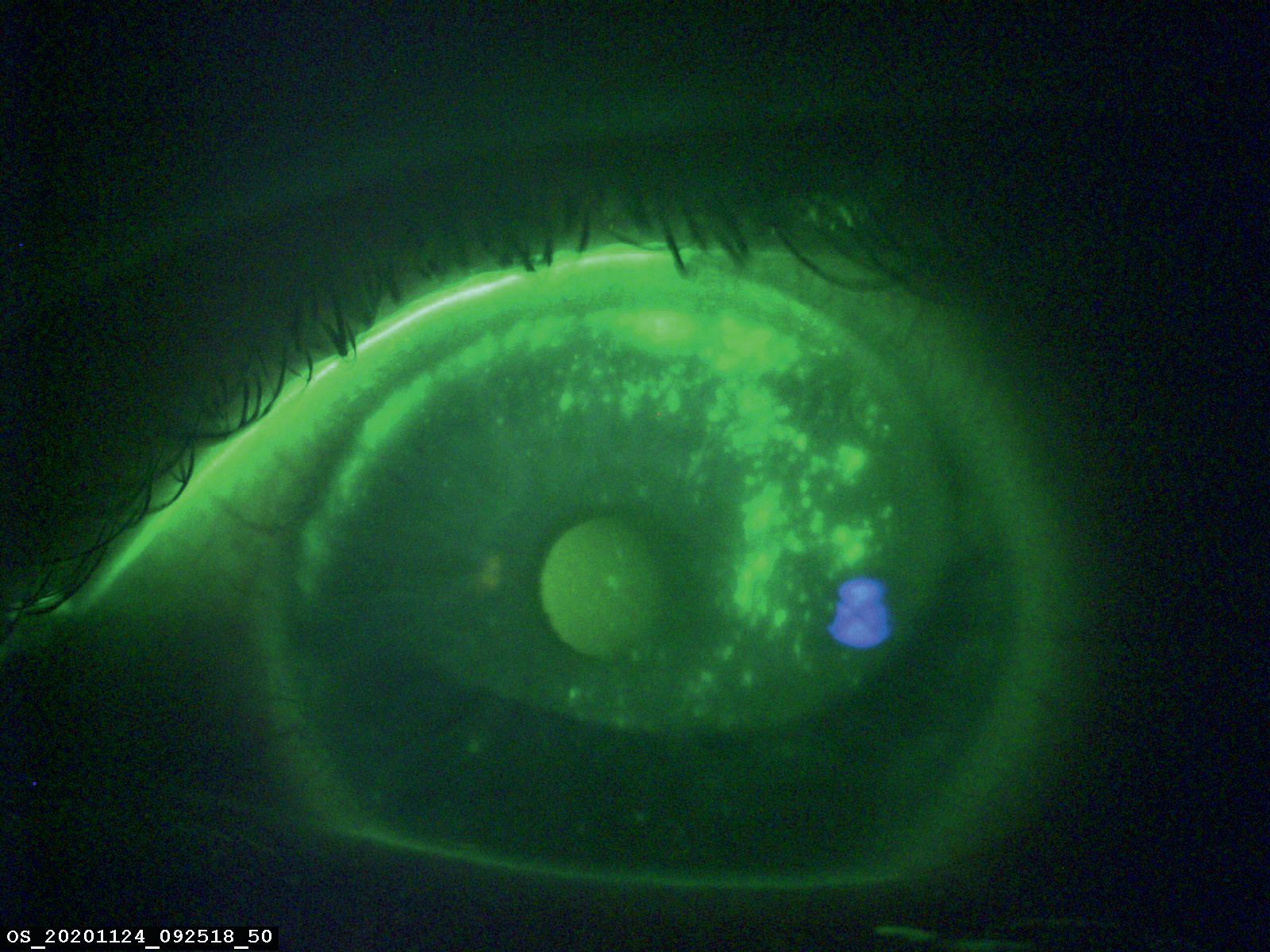

Image 1:

Slitlamp: Diffuse lighting, 10 x magnification, blue light filter and yellow filter (Haag-Streit BQ 900, Koeniz, Schweiz)

Image 2: Slitlamp: Optical section, 16 x magnification (Haag-Streit BQ 900, Koeniz, Schweiz)

Photo presentation: HFAK students present their findings in GlobalCONTACT 1 2

After insertion of an RGP contact lens, redness of the conjunctiva followed very quickly; as well as pain reactions of the test person (21 years, male). The subject described a scratchy feeling of the contact lens when blinking. A fitting with RGPs was no longer possible on this day, which is why the contact lens was immediately removed. The cornea of the subject was treated with fluorescein to visualize specks or other lesions (figure 1). Visible are a large amount of specks temporally, which resemble a starry sky. The indentations of the cornea are possible scratch marks of the foreign body that may have been on the posterior surface of the RGP lens.

The depth of the lesions was assessed using a section at 16 x magnification. The injured area was examined without blue light and without yellow filter. Due to the fluorescein, the lesions are now filled in color and the depths can be seen (figure 2). The injured area was fortunately only in the epithelium.

The subject was given eye drops to help regenerate the cornea. One day later at follow-up, no more specks were visible and the epithelium had fully recovered.

Lukas Metzger und Danyon Keutgen, HFAK (Higher College for Optometry, Cologne, Germany)With the popularization of orthokeratology and the revival of scleral lenses, RGP lenses represent an important sector for manufacturers of special contact lenses. Their manufacture requires the use of a very sophisticated machine park: nanometric precision lathes, oscillating tools to produce asymmetric geometries, robotization of pallet loading, electronic transfers of information to machines, calibration devices, and plasma surface treatment.

By Bruno Fantony and Alejandro Cubel YusteIt is surprising to find at the end of the production line a process that has not evolved: lens cleaning. In most cases, this is done by hand using microfiber cloths, cleaning fluids and physiological saline or distilled rinsing water. Small ultrasonic cleaning tanks are often used for different operations during manufacturing. This cleaning process is often poorly understood. Its optimal application allows a substantial gain in quality and profitability.

Ultrasounds are vibratory waves with a frequency between 16,000 Hertz (or 16 kHz) and 10 MHz. They have the properties of elastic waves. Their propagation is almost optical, with little diffraction. They are not audible to the human ear.

Ultrasounds are divided into 2 categories:

Power ultrasounds have a frequency between 16 kHz and 1 MHz. They can cause physical and chemical changes and are mainly used for cleaning.

Diagnostic ultrasounds have a frequency between 1 and 10 MHz. They make it possible to determine the characteristics of the environment they pass through. These properties are used for example in medical imaging.

For information, the human voice is between 125 and 4000 Hz, the most audible frequencies being between 250 and 3000 Hz (1 Hertz being one cycle per second).

Ultrasonic waves travel in a liquid medium in a sinusoidal fashion, creating waves of compression/depression. An ultrasonic cleaning device consists of an electronic power generator and piezoelectric transducers. The transducers convert electrical energy into mechanical energy by their vibrations which are transmitted to the bottom of the tank. The number of transducers is variable depending on the size of the tank.

These vibrations produce ultrasonic waves. When these meet an object, the disturbances in the wave train will create

a phenomenon called cavitation. A large amount of air bubbles is generated. These bubbles grow during the depression phase and then are compressed during the reverse phase. Their size, which ranges from 1 to 15 microns, depends on the frequency. During these movements of depression and compression the temperature in the bubbles increases until they implode, producing a micro-brushing at the molecular level which removes all the residues on the surface of the part to be cleaned. During this implosion, it was calculated that the temperature in the center of the bubble could reach 4700 ºC and the pressure 1000 bar. The gas jet can reach a speed of 400 km/h.

This explains the gradual increase in temperature in an ultrasonic bath. The whole point of ultrasonic cleaning lies in this concentration of energy, because by using globally low powers, we achieve incredibly significant local energy releases!

Frequency plays an important role: at low frequency (2030 kHz) larger bubbles (~ 12 microns) are produced with high power when they implode. This frequency range is suitable for removing heavy soiling. Areas of application: mechanical components, injection molds and engine parts, among others. At higher frequencies (40 - 60 kHz) the diameter of the bubbles is smaller (~ 8 to 4 microns) with a lower force. This frequency range is suitable for delicate cleaning. Areas of application: medical, surgical, optical, and electronic components.

Power is related to the range of motion produced by the transducers. The adhesion of the transducer to the bottom of the tank is a key element in the durability of the device. The technique of hot bonding of the transducers allows for greater regularity of cleaning and better longevity than the cold bonding used for low-end devices.

Pure water is unsuitable for ultrasonic cleaning. It is recommended to add detergent to it. This will reduce the difference in surface tension between the water and the object to be cleaned, allowing a better effect of cavitation by bringing the bubbles closer to the surface. The composition of the detergent depends on the impurities to be cleaned and the object.

40 ºC to 80 ºC are optimal temperatures: the viscosity and density of the liquid decrease and the pressure in the bubbles increases, which increases the effect of cavitation. Depending on the object to be cleaned, temperature control of the liquid is necessary due to the heating caused by cavitation.

Rinsing is necessary to remove all traces of detergent. There are different methods such as stirring the water, bubbling systems, etc. which allow better elimination of the product. Usually, demineralized water is used.

Dr Herbert Sinner (1900-1988) developed in 1959 a theory on cleaning based on the action of four elements: temperature, chemicals, mechanical action, and cleaning time. According to Sinner, for a good result, a decrease in one of the elements must be offset by one or more of the others. Thus, a decrease in chemicals must be

compensated for by an increase in either mechanical action, temperature, or time. Or by a combination of these three elements.

A field close to that of the manufacture of RGP contact lenses is that of ophthalmic lenses. In this field, ultrasonic cleaning is systematically used for washing lenses before a surface treatment: hard coating or anti-reflective coating. This allows optimum cleanliness without the risk of scratching the surface. The process is automated to ensure consistent quality throughout the day.

For RGP lenses, ultrasonic cleaning can be used for the following steps:

• After polishing the back surface, before inspection.

• For deblocking, especially for lenses attached to a plastic arbor with soluble wax.

• After deblocking before final control.

• After the final inspection, before packaging.

• Before plasma treatment.

The ultrasonic frequency must be between 40 and 60 kHz.

Exposing an RGP lens to ultrasound for too long without performing the right process and using non recommended tools can create marks on the surface. Stainless steel tools in the form of individual baskets allow processing of several contact lenses of different diameters at the same time.

The working temperature should not exceed 50 °C. Above 50 °C there are risks of deformation of certain RGP materials. The ultrasonic tank should incorporate a controlled and monitored heating system prepared to avoid overheating.

Using a certified ultrasonic detergent speeds up cleaning. In this case rinsing with DI water is necessary. Ideally the rinsing should be done in two separate tanks to have a minimum of contaminant in the last tank. The mineral content of this water must be less than 50 mg/l. Specific detergents for plastic medical devices should be preferred. The detergent concentration is significantly lower than that used for manual cleaning. It is generally one to two percent.

In the case of RGP lenses, the mechanical action is fixed by ultrasound frequency. The temperature can be increased to a certain limit. A decrease or even a removal of the detergent must be compensated by an increase in time.

An object must be clean before any disinfection or before any treatment. The effect of the conditioning solution on the lens will be optimal if no trace of pollutant remains. Most of the wettability problems will thus be avoided. Likewise, treatment with oxygen plasma will be more homogeneous over the entire contact lens surface.

As with ophthalmic lenses, it is possible to automate the entire cleaning procedure by using a multistage system. The dimensions of the device should be reduced to fit easily into the laboratory. It consists of several cleaning and rinsing tanks as well as a filtered air-drying tank. A robot transports the tools containing the lenses to the different vats.

A digital control allows the robot's movements, temperatures, and treatment times to be programmed. In this way, cleanliness

is constant throughout the working day, without manual intervention apart from placing and unloading the lenses.

Manual cleaning of RGP lenses during manufacture does not guarantee optimum cleanliness. The judicious use of ultrasonic cleaning devices leads to a gain in quality. As with ophthalmic lenses, repeatability of cleaning operations can be achieved by automating the process. Staff are relieved of repetitive and monotonous work, thus devoting themselves to more rewarding tasks. n

Bruno Fantony is an optometrist. He was Director of the Techno-Lens contact lens and ophthalmic lens manufacturing laboratory in Switzerland from 1987 to 2012. Currently he works as an independent consultant for various laboratories at Fantony LC.

Alejandro Cubel Yuste is an expert in ultrasonic cleaning solutions in both commercial and technical fields. He worked as Technical-Commercial Director of a cleaning equipment and technologies company from 2002 to 2009. He has been the co-founder and Chief Executive Officer of BRIO Ultrasonics since 2009 and is also the co-developer of the patented BRIO high-performance ultrasonic cleaning technology.

We introduced our new edging machine at the annual CLMA Zoom meeting in January of 2021. It is called an edge roller, meaning that it contours the lens edge profile. This is different from our edge polishing machine that is intended to polish lathe profiled edges. By Erik Larsen

We developed the edger roller in response to labs needing to work with lenses that do not have the edges lathe profiled and require aggressive action to remove the sharp edge. While it is commonplace to lathe profile rotationally symmetric edges, non-rotationally symmetric edges pose

a challenge, especially if the edge follows an undulating surface or has a notch to avoid a scleral elevation. Many specialty corneal and scleral lenses require some attention to the detail of the edge profile that a lathe cannot accommodate.

In the past, most of the edge material that needed to be removed was ground away with a diamond coated beveling radius and/ or inverted cone tool to approximate the desired edge profile. Then the lens would be mounted on the edge roller or would be finished by hand. The task required a skilled operator. Since the edger profile affects comfort, it is important to have consistent edge profiles. The manual procedure caused variation from one lens to another and from one operator to another. A consistent profile is especially important for replacement lenses to maintain comfort.

The figure shows the edge of a typical lens on the left (1). The “un-cut” diametered shape is shown. It is clear from the diagram that there is a lot of material to be removed in order to achieve the radiused edge profile.

In the middle (2) it shows the edge with the bottom of the lens faced off tangent to a radius. Facing off the lens removes about 80% of the lens material on its way to a radiused edge as shown on the right (3).

Even if you do not have full edge profiling capability on your lathe(s), facing the lens off will remove most of the material. Using the lathe is a precision method to remove this material. This method will work well for rotationally symmetric lenses. Non-rotationally symmetric lenses will require more work.

The amount of the material to be removed on a scleral lens can be as much as ten times that of a corneal lens. This is due to the increased edge thickness of about three times that of a corneal lens and twice the diameter. So, facing a scleral lens will remove much more material as compared to a corneal lens.

In researching this article, I talked to colleagues to see if they rolled the edge in the un-cut form. The answer was: some do, some don’t. They either lathe profile (preferred method) or grind the edge by hand to the approximate profile before rolling the edge. Rolling the edge for an un-cut edge takes several minutes and adjustments to the edging machine are required to achieve the desired profile.

Most polishes utilize an average grit size of .5 to 1.5 microns. According to my colleagues, a coarser grit size removes more material, yielding a shorter cycle time. In the case of edge rolling a scleral lens, an even coarser grit size, say 5 microns, may be useful since the goal is to grind away the material. There may be some concern about a 5-micron grit polish leaving marks, but it is worth testing that out.

Our new edge roller provides a more aggressive process to contour the edge of a lens. When the irregular edge presents a challenge to achieve the desired edge profile, the edge roller will help with that process. n

Newly published research has revealed a close link between proteins associated with Alzheimer’s disease and age-related sight loss. The findings could open the way to new treatments for patients with deteriorating vision and through this study, the scientists believe they could reduce the need for using animals in future research into blinding conditions.

Amyloid beta (Aβ) proteins are the primary driver of Alzheimer’s disease but also begin to collect in the retina as people get older.

Donor eyes from patients who suffered from age-related macular degeneration (AMD), the most common cause of blindness amongst adults in the UK, have been shown to contain high levels of Aβ in their retinas.

This new study, published in the journal Cells, builds on previous research which shows that Aβ collects around a cell layer called the retinal pigment epithelium (RPE), to establish what damage these toxic proteins cause RPE cells.

The research team exposed RPE cells of normal mouse eyes and in culture to Aβ. The mouse model enabled the team to look at the effect the protein has in living eye tissue, using non-invasive imaging techniques that are used in ophthalmology clinics. Their findings showed that the mouse eyes developed retinal pathology that was strikingly similar to AMD in humans.

Dr Arjuna Ratnayaka, a lecturer in vision sciences at the University of Southampton, who led the study said, “This was an important study which also showed that mouse numbers

used for experiments of this kind can be significantly reduced in the future. We were able to develop a robust model to study AMD-like retinal pathology driven by Aβ without using transgenic animals, which are often used by researchers in the field. Transgenic or genetically engineered mice can take up to a year and typically longer, before Aβ causes pathology in the retina, which we can achieve within two weeks. This reduces the need to develop more transgenic models and improves animal welfare.”

The investigators also used the cell models, which further reduced the use of mice in these experiments, to show that the toxic Aβ proteins entered RPE cells and rapidly collected in lysosomes, the waste disposal system for the cells. Whilst the cells performed their usual function of increasing enzymes within lysosomes to breakdown this unwanted cargo, the study found that around 85% of Aβ still remained within lysosomes, meaning that over time the toxic molecules would continue to accumulate inside RPE cells.

Furthermore, the researchers discovered that once lysosomes had been invaded by Aβ, around 20% fewer lysosomes were available to breakdown photoreceptor outer segments, a role they routinely perform as part of the daily visual cycle. Dr Ratnayaka added, “This is a further indication of how cells in the eye can deteriorate over time because of these toxic molecules collecting inside RPE cells. This could be a new pathway that no-one has explored before. Our discoveries have also strengthened the link between diseases of the eye and the brain. The eye is part of the brain and we have shown how Aβ, which is known to drive major neurological conditions such as Alzheimer’s disease, can also cause significant damage to cells in the retina.”

The researchers hope that one of the next steps could be for anti-amyloid beta drugs, previously trialled in Alzheimer’s patients, to be re-purposed and trialled as a possible treatment for age-related macular degeneration. As the regulators in the USA and the European Union have already given approval for many of these drugs, this is an area that could be explored relatively quickly.

The study may also help wider efforts to largely by-pass the use of animal experimentation where possible, so some aspects of testing new clinical treatments can transition directly from cell models to patients.

This research was funded by the National Centre for the Replacement Refinement & Reduction of animals in research (NC3Rs). n

Acknoledgement: The study “Oligomeric Aβ1-42 Induces an AMD-Like Phenotype and Accumulates in Lysosomes to Impair RPE Function” has been published in Cells with DOI https://doi.org/10.3390/ cells10020413.

It’s probably best to leave 2020 behind, especially ‘in hindsight’… . Let’s take a look forward into this vision industry of contact lenses – starting by going back to look at the 2020 survey data from Eurolens Research and the great work of Phil Morgan and colleagues at the University of Manchester (UK). By Eef van der Worp

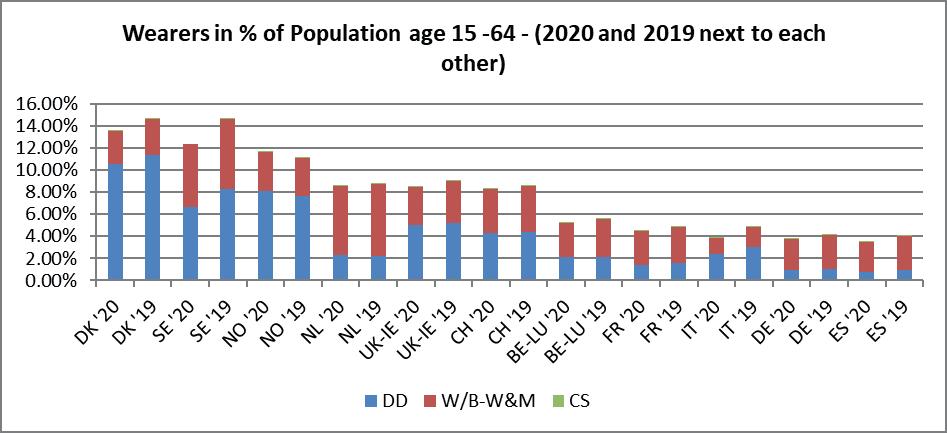

Despite the pandemic, they still managed to analyse the annual survey results, which have run over two decades now. Information was gathered from 25 countries with a total of 13.311 contact lens fits in 2020. It is important to note that this survey provides information about contact lens fits (new and refits), this is not market data on what is worn and sold. But it is presumed that information about current lens fits can hint at market shares of the future.

One of the trends is that silicone hydrogel (SH) lenses dominate the market of soft lenses now; worldwide, 72% of all soft lens fits are with SH. This is pretty similar and within a relatively narrow band for most European countries but is lagging a tad compared

to the US (84% of lens fits are with SH there). But generally, since the introduction of SH for daily wear (DW) in 2004, a steady increase is seen (see graph) in almost all countries. Another interesting trend is with regard to daily disposables (DDs); the ratio of DDs versus reusables is now almost 50-50: 46%-54% to be exact and increasing in favour of DDs. It will not be long it seems before DDs outperform reusable lenses in that regard.

Here though, remarkable differences can be seen between markets – even within relatively small geographical regions such as Europe, significant differences are reported, with Russia (8%), Bulgaria, Greece (13%), and Spain (22%) all seriously below the benchmark, while 68% of soft lens fits in Denmark are with DDs.

About half of the presbyopic lens wearers are fitted with a multifocal lens, according to the survey results, while 10% in that age group get monovision (the rest only get a distance correction, with presumably reading glasses for near). The highest newcomer in the list is the scleral lens: 3% of all registered lens fits are with sclerals, which now has finally earned its own category in the annual survey. It is not so much the absolute value in percentage that is of interest (the contact lens specialist returning the survey form may not per se always be the average eye care practitioner), but here again it may be the trend that is of interest. Of all rigid lens fits, 6% are indicated to have a myopia control purpose, while this is true for 2% of all soft lens fits – but with large differences again between countries, and with a huge potential maybe going forward.

Silicone hydrogel prescribing since 2000 for 17 markets in 2020. Data points are three-year moving averages.

I won’t dare to make any predictions after the turmoil of last year. But in terms of contact lenses, is seems that the

trends started (DDs and SH) are likely to continue. Sclerals always will stay a niche market, but while (based on pure speculation) in the US there may come a point when some saturation is reached in the market (although many have been expecting a plateau for years), in Europe there may be room for improvement and an increase in lens fits as the modality has not nearly reached its full potential in the region compared to the US. Myopia management with contact lenses has just scratched the surface, with orthokeratology having the best track record in the optical intervention category to date. On average, in all markets with substantial rigid lens fitting proportions, 22% of all rigid lens fits are orthokeratology – but with huge differences again (Spain reports 46% of all rigid lens fits being for orthokeratology). It is pretty likely that a new trend will start to emerge in the coming year, and years, regarding ‘soft lenses for myopia management’. A very positive outlook to both correct and to preserve vision. For more on this topic, and the potential, see the myopia article and Global Specialty Lens Symposium coverage in this edition of GlobalCONTACT on page 16ff. The full report on the Eurolens Research Survey was published in the January 2021 edition of Contact Lens Spectrum.

All in all, it doesn’t seem like a very daring proposition to say that the outlook for this part of the vision industry does not look bad at all in general, with great challenges but certainly opportunities ahead of us. Hope to SEE you all in 2021 somewhere. LOOK forward to it.