Corkcoal®

The all-in-one stopper

Two natural and renewable materials combined to provide efficiency and sustainability.

No colour migration.

Under standard conditions, no discolouration has been observed in clear distillates sealed with Corkcoal®.

Corkcoal® offers a 77% improvement in colour migration compared to natural cork and a 15% improvement compared to microgranulated cork. The analyses were carried out by macerating the sample with a 50% hydroalcoholic solution.

Totally organoleptically neutral.

In all tests carried out, Corkcoal® neutralises the transmission of flavours and odours to the product, which remained below the perceptible limits.

The transfer of odours and flavours into the product is an undesirable effect of using corks as stoppers. Corkcoal® has been subjected to sensory tests where the corks have been macerated individually for 24 hours, obtaining results almost 3 times below the standards accepted by the market.

Design and cross-functionalit y in balance with natural materials.

Corkcoal® stoppers are based on contemporary and cross-cutting geometries and their composition makes them sustainable solutions for any brand.

Corkcoal® stoppers stand out thanks to the natural qualities of the material used. We want to promote the qualities of Corkcoal®, and so have come up with designs that emphasise the material and its appearance rather than its shape.

We optimise raw materials without compromising on quality.

We make better use of raw materials, thus reducing waste.

Where others see defects, we see natural qualities.

Thanks to the aesthetics of Corkcoal®, we introduce flexibility into the industrial process by allowing for variations in the granulometry and colour of the natural cork, thereby reducing the amount of wasted raw material.

Assembled with other materials without using glue.

In non-monobloc models, the Corkcoal® concept is based on assembly solutions that do not use glue between the individual parts.

The monobloc microgranulation enables us to obtain t-top stoppers made from one single piece, so that they go through one single industrial process. Most of today’s t-top stoppers are made with two materials (cork + wood, plastic or metal alloys) and use glue in the assembly process.

In contrast, Corkcoal® stoppers combined with wood are assembled and secured using pressure, without the need for glue.

Standard super short 15mm model available.

In addition to the traditional 20mm stem, Corkcoal® is available in a new 15mm short stem model. Specially designed for super short neck bottles, such as the Rude and Wildly Crafted® collections with the Choker® mouth.

The Corkcoal® short stem stopper has been specifically designed to ensure leak-tightness and to be used in bottles with smaller expansion chambers.

Undetectable global migration of non-volatile particles.

Corkcoal® shows a 57% improvement in global migration compared to natural cork and a 16% improvement compared to equivalent microgranulate caps.

In tests conducted under the UNE 25928:2004 standard, the release of material from the non-volatile components of the Corkcoal® closure is less than 1g/dm², better than both natural cork and microgranulate caps.

Undetectable particle release in liquid.

Particle detection in Corkcoal® tests is 25 times lower than established industry standards.

Corkcoal® stoppers show particle detection results up to 50% lower than equivalent microgranulated stoppers.

Corkcoal® guarantees optimum control of capillarity and absorption.

In comparative tests, Corkcoal® shows better performance in capillarity and absorption than micro-agglomerated stoppers.

Under similar conditions, the capillarity performance of Corkcoal® is 33% more efficient than that of microgranulated stoppers. Corkcoal® absorption results are 44% more efficient than microgranulated stoppers.

Do you use glue in assemblies with wood?

No, the one-piece Corkcoal® design of the head stoppers does not require assembly. And in the designs assembled with wood, the insertion and fixation of the dowel is carried out by pressure and without glue.

Does Corkcoal® have better properties than microgranulated?

Corkcoal® is 3 5% higher on average in capillarit y tests than microgranulated stoppers and also offers better overall migration results according to independent studies carried out by the Institut Català del Suro (The Catalan Cork Institute).

Is Corkcoal® as compatible as microgranulated with my product?

Yes, Corkcoal is fully compatible with the same distillates on the market as Microgranulated, and works better than Microgranulated with clear distillates, due to its lower colour migration.

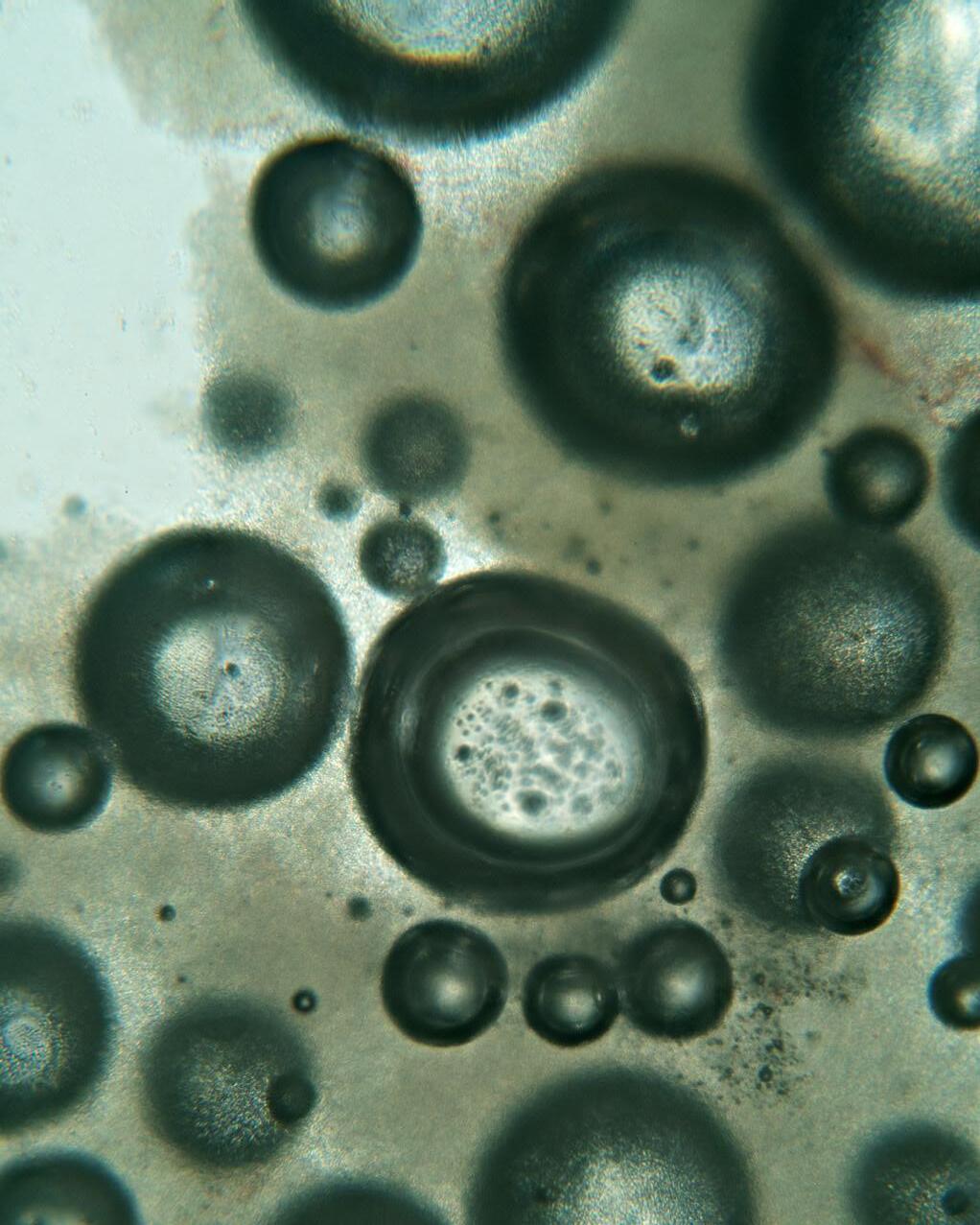

Does the use of AC eliminate TCA from cork?

Yes, it traps and neutralises it, to levels that are not measurable by laboratories. This is an unprecedented achievement that solves a historical problem inherent to cork as it is an organic material.

Does the use of AC improve the organoleptic performance of cork?

Due to its properties, the pores of the AC naturally trap all the unwanted substances (flavours and smells) of the cork, even neutralising the TCA (it is the best stopper on the market in this respect).

Why are some designs monobloc?

Monobloc designs are more efficient and sustainable, require just one single industrial transformation process and can be recycled more easily as the separation of their components is not necessary.

Does Corkcoal® help me build the story-telling of my product?

Yes, in many cases, the use of activated charcoal or other coal derivatives is key in the production of wines and spirits (e.g. the charring of the wood inside barrels). Therefore, the visual association of cork with charcoal enhances and demonstrates the story.

Inner diameter of 21.5mm