CONSULTANTS AND EQUIPMENT/SERVICE SUPPLIERS New technologies helping locate water pipe leaks What can you do with adaptive wastewater treatment mixers? Prefabricated pumping stations for remote communities 2023 GUIDE TO PM40065446 FEBRUARY 2023 WWW.ESEMAG.COM @ESEMAG

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

TECHNICAL ADVISORY BOARD

Archis Ambulkar, OCT Water Quality Academy

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors. Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales

Second Class Mail

Product Agreement No. 40065446

Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727 4666 www.esemag.com

35 Tripling wastewater energy recovery for Vancouver’s False Creek

36 New reality show navigates sewer infrastructure with divers

37 Ontario puts brakes on York Region sewage expansion plan

38 A sonic alternative to controlling harmful algal blooms in reservoirs

39 California’s groundwater warning should resonate in Saskatchewan, scientist warns

42 Precast concrete flood box saves BC town from floods

44 Best practices for watermain repair and replacement programs

47 Recycled wastewater showed less toxicity than tap water in new study

48 Seneca College rolls out new avenue for asset management education

50 Calls to modernize Canadian Iron Ring ceremony for new engineers continue

52 Demystifying cybersecurity for smaller water utilities

56 Report

63,73

FEATURES

In many ways television can educate the public better than we can 8 Calgary’s new Shaganappi Pump Station designed for energy efficiency and resilience

Extreme rainfall could add $700M per year to Ontario’s storm and wastewater costs

Understanding the impacts of FOG on wastewater systems 14 Manitoba investing millions in wastewater upgrades 16 Canada reaffirms maximum concentration for antimony in drinking water

Fibre balls in the fight against micropollutants 20 Gatineau water plant pressure losses highlight boil water notification process 22 What can you do with adaptive wastewater treatment mixers? 26 Pilot Butte, SK upgrades its wastewater lagoons 28 Prefabricated pumping stations address wastewater challenges for remote communities 30 Ontario Onsite Wastewater Association helps regulators and property owners in rural municipalities 32 Preserving a town's natural resources with an all-terrain sewer 34 3M exits the PFAS business amid flurry of contamination lawsuits

6

10

12

18

on water, wastewater and waste management in Europe

Paving the way to make cities more rain ready

New technologies helping locate water pipe leaks DEPARTMENTS

60

94

Professional Cards

Product Showcase 94 Ad Index CONTENTS February 2023 • Vol. 36 No. 1 • ISSN-0835-605X

@ESEMAG Environmental Science and Engineering Magazine 202 3 GUIDE TO CONSULTANTS AND EQUIPMENT/SERVICE SUPPLIERS Environmental Consultants .... 62 Equipment & Service Suppliers .... 70 4 | February 2023

91

www.esemag.com

t e wat e r, Biosolids & Bi o g a s

o mple te ra n g e o f ma rke t p ro du c t s. Le t u s sh ow yo u

•

Rotary Lobe Pumps & Grinders

• Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circur, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – Stations Pump & Stormwater CSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

T: (905) 864-9311 F: (905) 864-8469 www.proaquasales.com 7-264 Bronte St. S., Milton, ON L9T 5A3 04 16

In many ways televison can educate the public better than we can

As many involved in the wastewater industry have experienced, there is often a puzzled look from your audience when you describe the field you work in when social situations lead to discussions of occupation.

If we get past the “ick” factor, I often get asked to elaborate on what exactly the wastewater industry is all about. Most people are fascinated to learn that the wastewater industry in Canada is well over 100 years old and is of vital importance in protecting public health, water quality and the overall environment.

In our modern society, there are vital functions that are needed, that are not at all glamorous, or even palatable to most. “Dirty Jobs” is an American television series that ran for eight seasons until 2012. In each episode, a worker or team of workers took on the star of the show Mike Rowe as a fully involved assistant for a typical work day. Rowe would work hard to complete every task as best he could despite discomfort, hazards, or repulsive situations.

Apparently, when asked what was the grossest dirty job he ever tried, Rowe said it was as a sewer inspector. He said that “aside from sloshing through a relentless chocolate tide, inspectors encounter a myriad of man-made products that shouldn't be flushed down toilets— along with roaches the size of thumbs and rats the size of bread loaves. It's hot, dirty and too smelly to describe.”

An article in this issue (See page 36) describes “Sewer Divers”, which is a new series from the Discovery Channel that takes viewers on a journey through sewer systems in several major cities as they tackle clogs and broken pipes.

Highlighting the challenges of the dirty job, as well as the age of the deteriorating infrastructure, the show goes to great lengths to show how workers keep systems running and toilets flushing.

Climate change is now an everpervasive topic. In the summer months especially, the news is dominated by forest fires, flood and storm events, which are exacerbated by it.

“Apocalypse Plan B” is a film about climate cooling ideas by Mark and Caitlin Starowicz, that features debate between host David Suzuki and Canadian-born Harvard physicist David Keith. Keith has proposed spraying the stratosphere with massive amounts of aerosol-like sulphur to reflect away sunlight.

Dr. Sarah Doherty of the University of Washington was inspired by satellite images of lines of bright clouds over the oceans, directly over the path of freighters and other large vessels. Dr. Doherty reasoned that this smokestack

emission-caused phenomenon could be replicated with benign salt spray instead.

Apocalypse Plan B also profiles NASA’s Dr. Lola Fatoyimbo, who studies forests from space, and graphically demonstrates how they clean the skies.

“We’ve got an existential choice,” says Starowicz. “Radical climate intervention through geoengineering, or radical global restoration of ecosystems”.

I look forward to watching Sewer Divers to witness the practical use of technology and human endurance. I also want to watch Apocalypse Plan B, to learn about the theoretical and global scalability possibilities profiled in it to address climate change.

Steve

Davey is the editor and publisher of ES&E Magazine. Please email any comments you may have to steve@esemag.com

The Earth will be here for a long, long, long time after we’re gone and it will heal itself, it will cleanse itself ’cause that’s what it does. It’s a self-correcting system. The air and the water will recover, the earth will be renewed…

Excerpted from “Saving the Planet”, an essay by George Carlin

Credit: Discovery Channel

6 | February 2023 EDITORIAL COMMENT BY STEVE DAVEY

Learn more about the M3 and Wall Skids at www.blue-white.com Fluid Metering Solutions Made Simple. FLEXFLO® M3 For Simple and Precise Chemical Dosing with No Vapor Lock and No Loss of Prime. Simple Solutions for Precise, Dependable Chemical Dosing CHEM-FEED® WALL SKIDS Short on Floor Space? Here’s the Solution. Ships Fully Assembled.

Calgary’s new Shaganappi Pump Station designed for energy efficiency and resilience

By Andy Barr

By Andy Barr

The Shaganappi Pump Station is the largest and most critical of the City of Calgary’s 42 drinking water pump stations. The facility provides safe and reliable drinking water to over 200,000 citizens in the city’s North Hill and Glendale Pressure Zones in the northwest, as well as critical institutions such as the Foothills Hospital and the University of Calgary.

The original Shaganappi Pump Station was constructed in 1977, serving Calgary for many decades. In later years, it began to experience mechanical and structural issues. An investigation determined that replacing the pump station would be more cost-effective and efficient than repairing or rebuilding the facility in its original location.

In 2015, the City of Calgary retained Associated Engineering (AE) to assist in site selection, and provide design and construction services for a new pump station. The selected site for the new pump station was a city-owned greenspace adjacent to the Bow River. The site was chosen primarily for its proximity to the original pump station and existing large diameter water feedermains. This would facilitate connecting the new pump station to the existing piping.

Since the new pump station serves established neighbourhoods, it was designed at its maximum buildout capacity. Flows were not anticipated to change due to increased growth and demand.

Having extensive operating data from the original station was advantageous, particularly typical pump flows and hydraulics. With this information, the AE team designed the pumps to achieve their highest efficiency for the most frequent operating conditions, rather than at peak operating conditions. This maximizes energy efficiency over the life cycle of the station.

The new facility includes three 447 kilowatt pumps rated at 100 million litres per day and three 447 kilowatt pumps rated at 30 million litres per day, pumping into the North Hill and Glendale Pressure Zones, respectively.

Pumping equipment is housed in a single-storey building, designed as a “post-disaster” structure using resilient materials, such as concrete columns and steel trusses. Given the proximity to the Bow River, the team considered climate change, and revised flood zone mapping available from updated flood modelling. The building was designed to resist flotation.

The new pump station was also designed for ease of use by maintenance and operation staff. An emergency generator was included in the design to facilitate pump operation should the utility’s electrical supply be interrupted.

This site is close to a public park, bicycle path, condominium and businesses. Therefore, limiting the impact of noise from the facility on nearby residences and park areas was important.

Noise reduction measures for the new Shaganappi Pump Station included concrete block wall construction, heavy duty noise-cancelling overhead doors, duct silencers on the cooling air intake and exhaust louvres, and a super extreme grade exhaust silencer.

Noise reduction measures included concrete block wall construction, heavy duty noise-cancelling overhead doors, duct silencers on the cooling air intake and exhaust louvres, and a super extreme grade exhaust silencer.

Connecting the new facility to the existing feedermain network was one of the most technically complex aspects of the project. This work needed to be completed in a tight three-month time frame, during the city’s low water demand period, but avoiding the main freeze up period from January to February.

The facility’s 1350-mm diameter suction, 1200-mm diameter north discharge and 900-mm diameter south discharge steel piping from the new station were connected to the existing concrete piping from the old pump station.

To retain the contractor, the city used a request for proposal process, rather than conventional tender. This meant a better understanding of the contractor’s proposed work plan and approach, considering the site constraints, traffic and public areas. Graham Infrastructure was awarded the construction contract and partnered with Whissell Contracting to complete the underground scope of work.

Andy Barr is with Associated Engineering. Email: barra@ae.ca

Environmental Science & Engineering Magazine 8 | February 2023 WATER

MAY 9

ENVIRONMENTAL COMPLIANCE AND DUE DILIGENCE TRAINING EVENT

COURSES & CHAIRS

MAY 10

MAY 11

Environmental Regulation and Compliance 2023

Contaminated Sites and Excess Soils

Water & Wastewater Regulation and Compliance

Janet Bobechko WeirFoulds LLP

Due Diligence In Environmental Prosecutions: A Mock Trial

Julie Abouchar Willms & Shier Environmental Lawyers LLP

Rosanna DiLabio ERCO Worldwide

Environmental Management Systems: The Journey from EMS to ESG

Marc McAree Willms & Shier Environmental Lawyers LLP

Matthew Gardner Willms & Shier Environmental Lawyers LLP

Air Quality Challenges and Compliance: Managing Industrial Emissions

Brad Bergeron RWDI John Georgakopoulos Willms & Shier Environmental Lawyers LLP

Randy Sinukoff Stantec Consulting Ltd.

Dealing with Environmental Emergencies and Spills

Janet Bobechko WeirFoulds LLP

Len Griffiths Bennett Jones LLP

Sarah Gilbert Bennett Jones LLP

Len Griffiths Bennett Jones LLP

Sarah Gilbert Bennett Jones LLP

15% OFF REGISTRATION COSTS! USE PROMO CODE: ESE23

SAVE

Venetian Banquet & Hospitality Centre Vaughan, ON @CANECT23 #CANECT Produced by Environmental Science & Engineering Magazine WWW.CANECT.NET 23

The

Extreme rainfall could add $700M per year to municipal storm, wastewater costs

By ES&E Staff

Without further adaptation to climate change, a new report warns that more extreme rainfall in Ontario could add $6.2 billion to the costs of maintaining storm and wastewater infrastructure by 2030. The Financial Accountability Office of Ontario (FAO) projection is a 27% increase above a “stable climate scenario”. This means the province will spend an average of $3 billion per year over the century to bring these assets into a state of good repair and maintain that state.

This includes stormwater assets such as pipes, ditches and culverts, as well as wastewater assets like sewer pipes and sanitary force mains belonging to the province’s 444 municipalities, and valued at $124 billion.

The December FAO report, Costing Climate Change Impacts to Public Infrastructure: Linear Storm and Wastewater, states that as extreme rainfall increases, un-adapted assets will increasingly face capacity constraints, raising the flood risk to surrounding areas. On an annual basis, extreme rainfall caused by climate change could cost municipalities in Ontario an additional $700 million a year to maintain storm and wastewater assets.

Peter Weltman, the province’s financial accountability officer and author of the report, said Canadians will really see the impacts of climate change around 2050 if significant action isn’t taken.

Under consistently extreme rainfall, pipes and ditches will require more frequent and costly inspections and preventive maintenance, as more debris, sediment and vegetation are expected to enter stormwater systems. Channel protection will also be subject to accelerated erosion.

For wastewater, increased intensity of short duration rainfall events will increase the inflow of surface water into sewer pipes, while increased intensity of longer duration events will cause groundwater to infiltrate sewer pipes.

For sanitary force mains, more extreme rainfall will result in higher inflow and infiltration, increasing the volume of wastewater being conveyed to treatment facilities, as well as the pressure required to do so.

The FAO report states that adapting assets to climate change can mean increasing their capacity or incorporating source control measures such as green infrastructure. However, climate action also comes at a cost, representing a financial increase between 29% and 53%, albeit lower than the cost of inaction, the report states.

“Regardless of which asset management strategy is pursued, the future path of global climate change will be a key determinant in the extent of additional climate-related infrastructure costs,” states

the FAO report.

In terms of further emissions impacting assets, a medium emissions scenario, where global emissions peak by mid-century, could mean an additional $1.1 billion per year to maintain assets. In a high emissions scenario, where global emissions continue rising throughout the century, these maintenance costs could increase by $1.8 billion per year.

For more information, email: editor@esemag.com

Examples of adaptations to extreme rainfall for linear storm and wastewater infrastructure detailed in a new report from the Financial Accountability Office of Ontario. Credit: FAO

Environmental Science & Engineering Magazine 10 | February 2023 STORMWATER

Understanding the impacts of FOG on wastewater systems

By Daryl Mandoza

Fats, oils, and grease (FOG) can dramatically reduce efficiency while increasing the operational costs of a wastewater treatment system. Food processing facilities in particular often experience buildup of grease deposits or caps in their lift stations and piping.

A complex chain of events occurs to create FOG deposits. This involves cooled water, hydrolysis (splitting of chemical bonds), and saponification, all of which lead to the buildup of FOG deposits in lift stations and underground piping.

FOG buildup can require the need to clean facility piping to ensure water is moving efficiently. An accumulation of FOG in lift stations or collection pits may need to be removed to restore treatment capacity. Disposal of collected FOG can be a one-time fee and up to $500 or an annual service fee for scheduled removal, with price ranges varying.

Failure to treat FOG in lift stations or piping can result in odours as it breaks down. As the FOG decomposes, bacteria in the water release pungent nitrates and rotten-egg-smelling sulphates as they digest it. These odours can lead to consumer complaints, causing loss of goodwill and the incurred cost for odour control treatment.

If left untreated, FOG can increase the need for repairs or replacement of equipment, while escalating degradation of existing system infrastructure.

There are several solutions to protecting and maintaining wastewater systems. Removal of FOG in the production stage can prevent the need to treat downstream. In some cases, a gravity grease interceptor can be used to remove FOG prior to additional treatment or discharge. Source grease traps identify and treat for FOG at specific high FOG areas and remove them before they make it to the waste stream.

It is important to evaluate cleaning and sanitation preventative maintenance programs to mitigate the impact of FOG on your wastewater treatment system. The implementation of a supplemental bioaugmentation program with microorganisms specifically selected and blended to reduce FOG buildup is effective. It provides an effective quick reduction of the existing fat cap, as well as enough bacteria to mitigate future FOG buildup.

Incorporating any of these solutions will help reduce operational cost, as well as capital expenses a facility may be experiencing. A comprehensive analysis of the treatment process with a water treatment expert is the best way to determine the level and type of solution that best meets a facility’s needs.

Food processing facilities often experience buildup of grease deposits or caps in their lift stations.

Environmental Science & Engineering Magazine 12 | February 2023 WASTEWATER

Daryl Mandoza is with Kurita America. Email: d.mandoza@kurita-water.com

Manitoba invests millions in wastewater upgrades

By ES&E Staff

Manitoba has announced more than $34.4 million in funding, primarily for a series of wastewater management projects. The largest of the upgrades consists of $9.1 million in federal and provincial funding to expand the City of Dauphin’s lagoon reactor system for ammonia reduction and disinfection in the west of the province. Dauphin officials, who are contributing $3.3 million to the upgrades, also plan to add a new sewage treatment facility and new pipes.

“We identified the need to expand our lagoon over a decade ago, so we are excited to see this investment through the Investing in Canada Infrastructure Program for the project. Completion of the lagoon expansion will allow Dauphin to grow our population and industry,” announced Dauphin Mayor Christian Laughland.

Dauphin’s lagoon system is designed for a population of 11,000 and has a production capacity of 8.8 megalitres per day. Water is treated through flocculation, ozonation, disinfection

Dauphin’s lagoon system is designed for a population of 11,000 and has a production capacity of 8.8 megalitres per day.

Credit: City of Dauphin

and sedimentation. The total capacity of the system is approximately 891 megalitres, and it is currently operating close to capacity.

Another project made possible with the new funding will be upgrades to the wastewater treatment system in Neepawa, just two hours west of Winnipeg.

The system will be expanded and upgraded to increase capacity for wastewater and stormwater. The total federal and provincial investment of $4.2 million involves implementing a moving bed biofilm reactor system, upgrading the treatment building, adding a lab, as well as decommissioning the primary and secondary lagoon cells. Neepawa officials are contributing $1.5 million to the upgrades.

Other major lagoon projects will take place in Russell-Binscarth, where municipal officials will invest more than $8 million to update the lagoon site and undertake a partial demolition and reconstruction of storage cells.

The community of Glenboro – South Cypress will invest some $5.5 million to upgrade its current facultative lagoon, which consists of a primary treatment cell and secondary exfiltration cell that discharges into the Assiniboine Delta Aquifer. It will become an aerated primary cell, with two submerged attached growth reactors.

Upgrades will also be made to water and wastewater pipes in Killarney-Turtle Mountain, as well as sewer lines in Prairie View.

Lastly, the District of Pinawa landfill will undergo an expansion to include an area for electronic waste, scrap metal, paint products, as well as used oil and tires. Phase 3 will include an area for composting.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 14 | February 2023 WASTEWATER

80 GHz level sensor with fixed cable connection (IP68) www.vega.com/vegapuls All advantages of the radar technology: $1422 VEGAPULS C 21 RADAR ULTRASONIC IS THE BETTER

Canada reaffirms maximum concentration for antimony in drinking water

By ES&E Staff

Canada is proposing a risk-managed approach that would reaffirm a maximum acceptable concentration (MAC) of 0.006 mg/L (or 6 µg/L) for antimony in drinking water that was developed in 1999.

Antimony (Sb) is a metal naturally present in small quantities in water, rocks and soils. It can be harmful to the gastrointestinal system and the liver, as well as the eyes and skin, and cause problems with the kidneys.

The MAC for antimony is being revisited by the Federal-Provincial-Territorial Committee on Drinking Water, particularly in relation to private wells and for small systems, where some have suggested that lowering the MAC could significantly increase health protection.

The proposed guideline technical document, however, suggests that lowering the MAC would not provide additional protection, although its authors note that they will continue to monitor new research in the area and recommend any changes.

“At the municipal level, treatment technologies that are available to achieve antimony drinking water concentrations below the proposed MAC include coagulation, adsorption, membrane filtration and coagulation followed by ultrafiltration,” states the newly-proposed guideline.

In water monitoring data obtained from the provinces, antimony detection frequency was very low, indicating that a large number of the samples had antimony concentrations below the detection limit, states the document published in the December edition of the Canada Gazette.

The National Drinking Water Survey of Canada had maximum antimony concentrations below 1.0 μg/L during the summer months, but had some higher concentrations in the raw and treated lake water during the winter months. There were slight differences between raw, treated and distribution system waters.

In water monitoring data obtained from the provinces, antimony detection frequency was very low, indicating that a large number of the samples had antimony concentrations below the detection limit. Credit: concept w, stock.adobe.com

Monitoring for total antimony and other contaminants (e.g., iron, manganese, arsenic, lead) should be conducted when water quality changes or physical disruptions occur in the system, recommends the guidance document.

“The release of antimony and other contaminants may be indicated by the presence of discoloured water or increased turbidity resulting from the release of deposits or scales present on the pipe wall,” states the guideline.

Antimony can come naturally from windblown dust, weathering of mineral rocks, predominantly sulphides and sulphosalts, or volcanic ash. It can also come from coal combustion, including mining and smelting, or from busy vehicle areas in the form of abrasions in tires and brake linings.

Antimony, minimally produced in Canada, is absorbed by the roots of vegetables and other crops grown on antimony-containing soils; however, dietary exposure to total antimony is low. Polyethylene terephthalate (PET) food pack-

aging materials, such as trays and bottles, may also contribute to antimony in food, the new document states.

Other sources of antimony include fire retardants, shooting ranges, pharmaceuticals and pesticides. It may also enter drinking water from plumbing solders in drinking water distribution systems.

Over 200 inorganic compounds of antimony exist in the environment, with stibnite being the most abundant, followed by the oxides of antimony and the antimonides of heavy metals, with arsenic being the most predominant.

At the residential scale, certified treatment devices relying on reverse osmosis and distillation have proven most effective for the removal of antimony.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 16 | February 2023 WATER

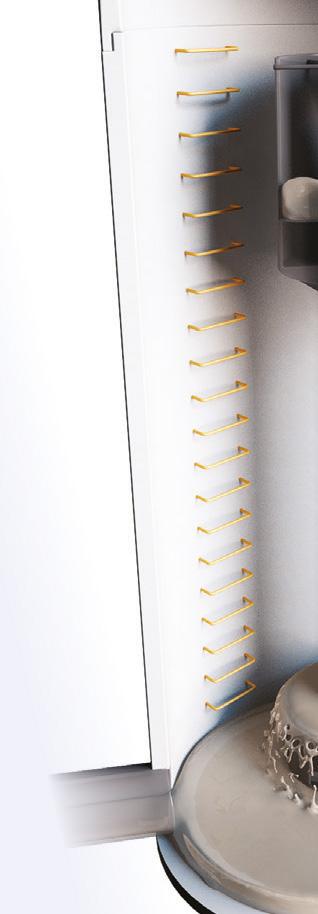

Fibre balls in the fight against micropollutants

By Greg Smith

By Greg Smith

One of the ways that microplastics (measuring five micrometres to five millimetres) and trace substances can be removed from wastewater is by adding activated carbon powder to the water in a contact tank.

Activated carbon, with its porous and brittle structure, has a large internal surface area. In physical terms, one teaspoon of activated carbon powder has the same surface area as a football field. This surface area provides lots of room for the trace substances to accumulate. The activated-carbon-enriched water is therefore kept in the contact tank for 15 to 20 minutes.

In conventional wastewater treatment plants, a sedimentation tank is also required to remove the activated carbon from the water after this purification process. It falls to the bottom of the tank and, together with the attached trace substances, is later separated with the sewage sludge.

Studies have shown that this method

removes 80% of the pharmaceutical residues and X-ray contrast agents from the wastewater. Wastewater treatment plants without this fourth purification stage only hold back around 30% of the trace substances collected.

However, removing 80% of the micropollutants was still not enough for one town, so it opted to install Fuzzy Filters® from Bosman Water Management. The company claims that this filter system can eliminate as much as 95% of all trace substances and also remove microplastics and phosphorus from the wastewater. The core of the filter system is formed by the Fuzzy Filter balls, which are made from synthetic fibres and shaped into a sphere, with a diameter of around 33 millimetres, using a clip.

Unlike conventional filter systems, the liquid to be filtered flows both around the outside of the filter material as well as through it. The suspension to be filtered flows into the distribution chamber under the filter bed. In the distribution chamber, inflowing water is evenly distributed over the filter surface before it flows through the lower fixed perfo-

rated plate and into the filter bed.

Micropollutants absorbed by the activated carbon, as well as the phosphorus and microplastics that fell to the bottom of the tank, are collected in the filter bed and the filtered water flows back out the top of the Fuzzy Filter.

As soon as a specified turbidity value or predefined maximum pressure is reached in the filter bed, a backwash cycle is started. Backwashing involves pumping raw water into the filter while an external fan blows in purge air to set the filter medium in motion. The filter balls, which move freely between the perforated plates, are set into motion by the air flow. Contamination particles adhering to, and stored in, the filter are thus loosened and flushed out.

The activated carbon is pumped back into the aeration tank with the backwash water and a further purification process is started, since the activated carbon may still be holding micropollutants after the first flushing cycle. After one purification cycle, the amount of trace substances is reduced to a fraction of what it was originally.

The butterfly valves and gate valves, which allow wastewater containing the micropollutants to flow in and the purified water to flow out, are automatically opened and closed using FESTO pneumatic DAPS quarter and DLP linear actuators. Other butterfly valves and gate valves, in combination with the pneumatic actuators mentioned, supply the purge air and open/close the sludge outlet. Automated gate valves are also used in the small pumping station that pumps water from the biological clarification stage into the fourth purification stage.

For more information, email:

greg.smith@festo.com

Fuzzy Filters are said to be able to eliminate as much as 95% of all trace substances and also remove microplastics and phosphorus from wastewater.

Fuzzy Filter balls are made from synthetic fibres.

Environmental Science & Engineering Magazine 18 | February 2023 WASTEWATER

Thinking about retirement?

It’s time to make your money work for you.

Retirement is finally approaching… now what? The Engineers Canada-sponsored Financial Security Program registered retirement income fund (RRIF) and life income fund (LIF) that turns your hard-earned savings into a steady stream of income for your retirement years.

You’ll also continue to enjoy the advantages you’re already used to with your group plan – such as lower-than-retail fees*, certified Canada Life support and continued access to the Canada Life website and statements.

Committed to helping you enjoy the retirement you deserve

Speak with an investment and retirement specialist to see if the program is right for you. They’ll help you understand your income options, give you a detailed income estimate and build a plan with you.

Email: retirementready@canadalife.com

Phone: 1-800-724-3402

weekdays from 8 a.m to 8 p m ET

The Engineers Canada-sponsored Financial Security Program is exclusive to engineers and geoscientists, as well as their families, across Canada.

Learn more about the Engineers Canada RRIF and LIF

canlife.co/RIF

*Lower investment management fees, when compared to typical individual RRIFs and LIFs. Canada Life and design are trademarks of The Canada Life Assurance Company

A plan built just for you.

Gatineau water plant pressure losses highlight boil water notification process

By ES&E Staff

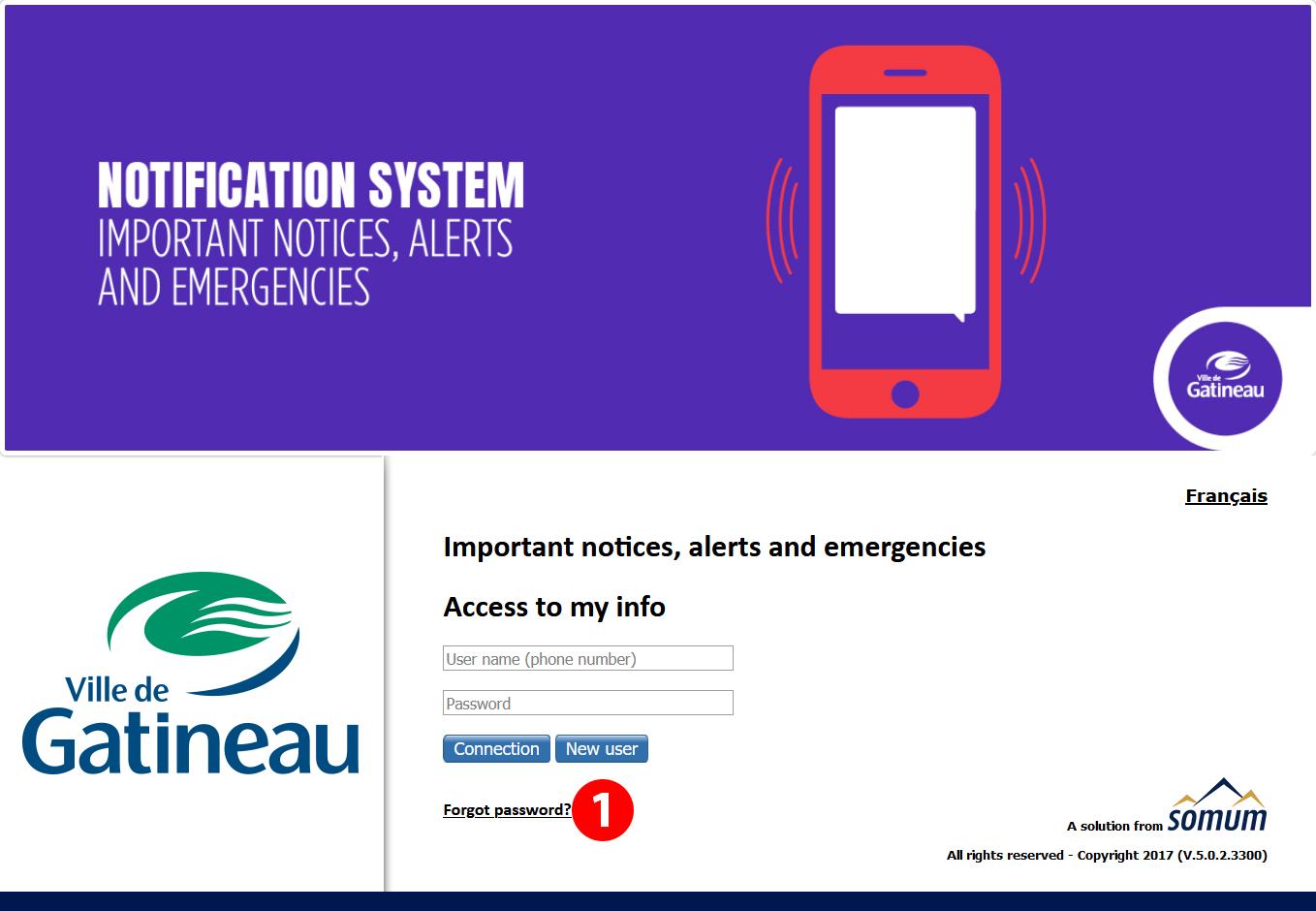

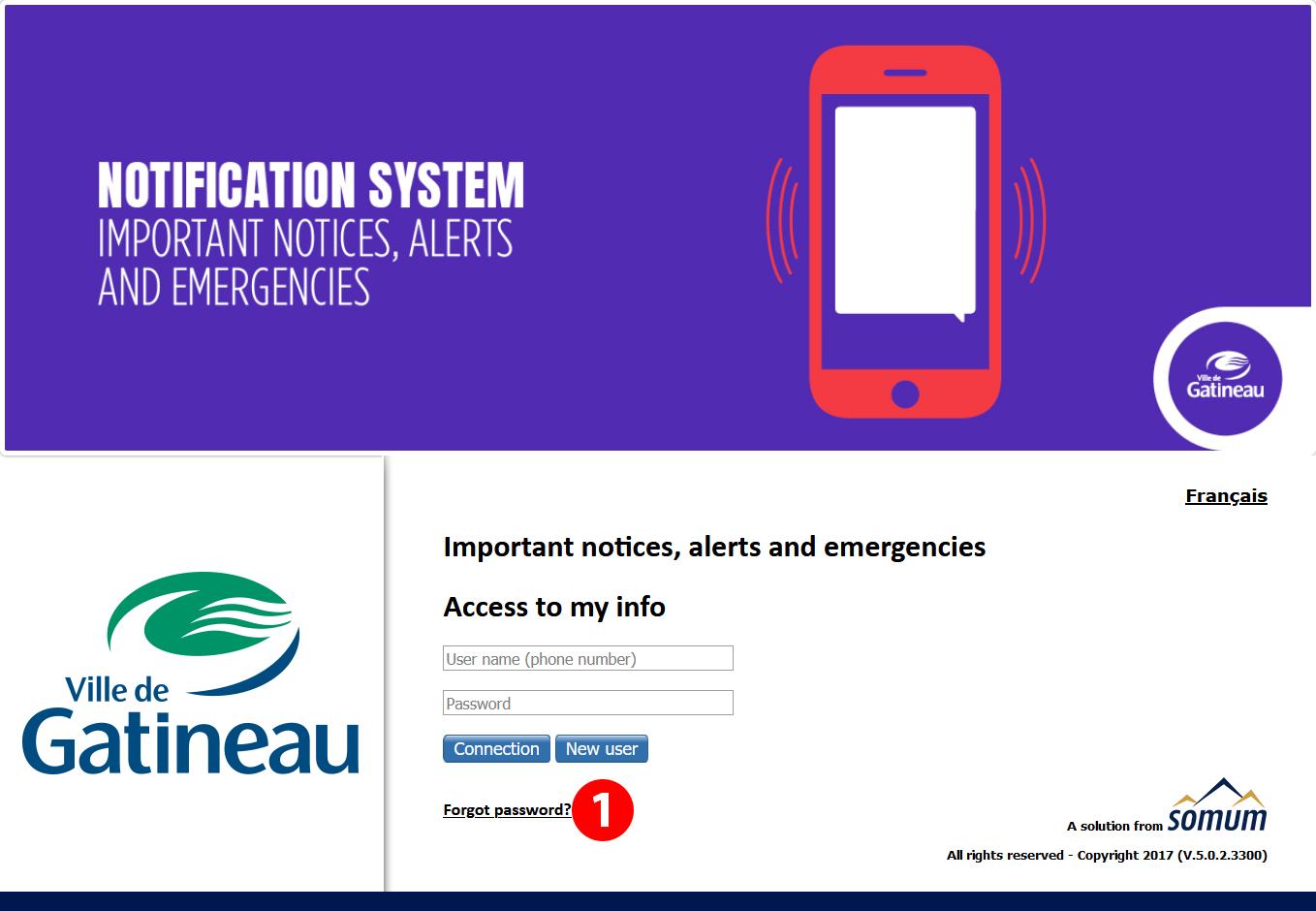

Gatineau residents have the option to register for a digital notification.

Some 35,000 water customers in the Quebec Village of Gatineau were recently under a boil water advisory due to a depressurization issue at the local water plant, just one week after a similar situation left millions of customers under a boil water advisory in Houston, Texas.

The Gatineau depressurization in December 2022 was caused by a “mechanical malfunction”, local officials said, while the Houston event was caused by a power outage.

Pressure drops, generally speaking, are caused by issues with pump malfunctions or lost power; however, sometimes one of the water lines or mains may have had a break or failure.

“Gatineau will not take any chances in those cases, and asks everyone to boil their drinking water as a preventive measure before consuming it, until the test results are out, which generally takes 48 hours,” local officials stated on the municipality’s website. “If the tests are negative, the boil water advisory is lifted. If the tests are positive, Gatineau issues a regulatory advisory.”

!"#$%&'($%)#%*"$

!"#$%&'()*$)+#(&,)$*$%&-"".)*$+&.')$(+/0

Gatineau public works repaired the water main and lifted the advisory within 24 hours after lab test results found no bacteria. Houston needed more time to process its lab water samples for the Texas Commission on Environmental Quality, eventually lifting the boil water advisory after some 36 hours.

The advisories in both recent cases were considered preventative, as the drop in pressure increased the potential for contaminants to be introduced, as well as the risk of backflow. A pressure loss is typically defined as the pressure having dropped below 20 psi.

In Gatineau’s case, however, the potential for a pressure loss or interruption in the water supply was foreseen, and officials sent out preemptive notifications almost one week in advance of the repair. In Texas, the situation was more unexpected, particularly in terms of the plant not being able to access backup power.

!"#$%&'%!(")(*+(,--($%*%&!

.,/0(!+12(03(4++$(56(78$%&8 0(*5&"!*%&!

*%$)%&8*"&%(816(6%)*5(&%86+"*

9 ;(5+"&!(+)%&8*<+1(*<$%()%&(758&'% 0/=(>'(,?@(A(,=@(A(;@

=(56(86B"!*8#C%(C%6(C<'5*! D<.<(!<'18C(8*(!"&.87% ,/;($E!%7(!)%%6

How customers are notified in these situations has also drawn scrutiny since the Houston situation, where many local residents were critical of how the boil water notice rolled out. Initially, it was communicated through an evening media advisory and a post on Twitter. However, many residents said they did not learn of the notice until the following morning, when news outlets announced that local schools would be closed.

While Gatineau officials posted on Twitter as well, they also give residents the option to register for a digital notification system that alerts users through text, email, or phone message in the case of water events or other urgent situations. In the case of water, the notifications could cover current boil water advisories, temporary water shut-offs, no water use advisories, or even the testing of fire hydrants.

For more information, email: editor@esemag.com

Credit: Ville de Gatineau

Credit: Ville de Gatineau

Environmental Science & Engineering Magazine 20 | February 2023 WATER

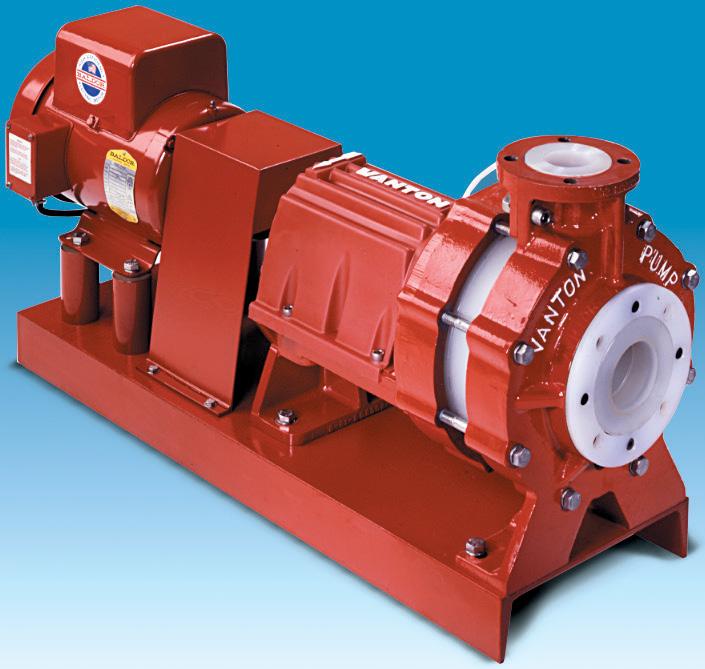

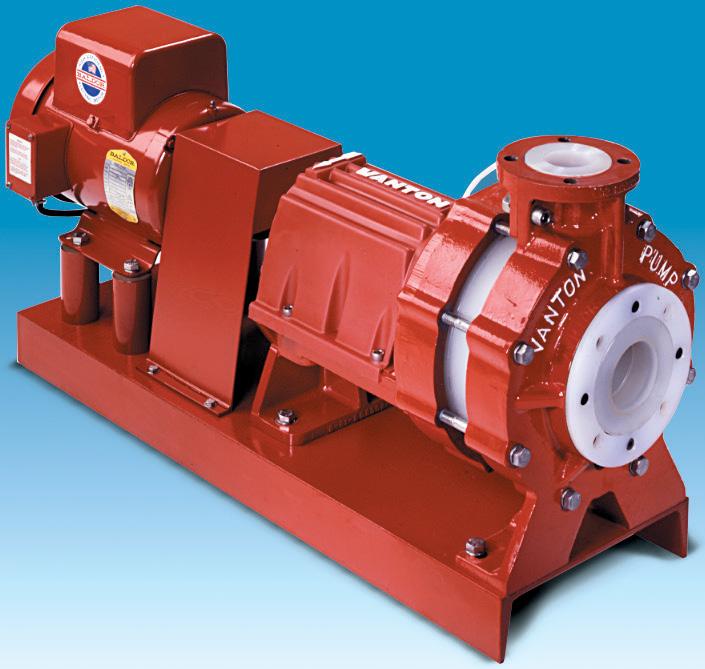

The Key to Ending your Pumping Problems

• No Corrosion or Contamination

•

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant. Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for: • Chemical Transfer

The Vanton AdVantage

No Chemical Absorption or Wicking

Effluent

• Lift Stations • Odor Control • Recirculation

OEM Applications PUMP & EQUIPMENT CORPORATION vanton.com e-mail: mkt@vanton.com • 908-688-4216 Sump-Gard® Vertical Centrifugal Pumps Flex-I-Liner® Rotary Peristaltic Pumps Pump/Tank Non-metallic Systems Chem-Gard® Horizontal Centrifugal Pumps Chem Action Inc. 4559 Boul Métropolitain E Saint-Léonard, QC H1R 1Z4 514-593-1515 Vissers Sales Corp. 20-220 Industrial Parkway South Aurora, ON L4G 3V6 905-841-4073

• Neutralization • Dosing •

Control

•

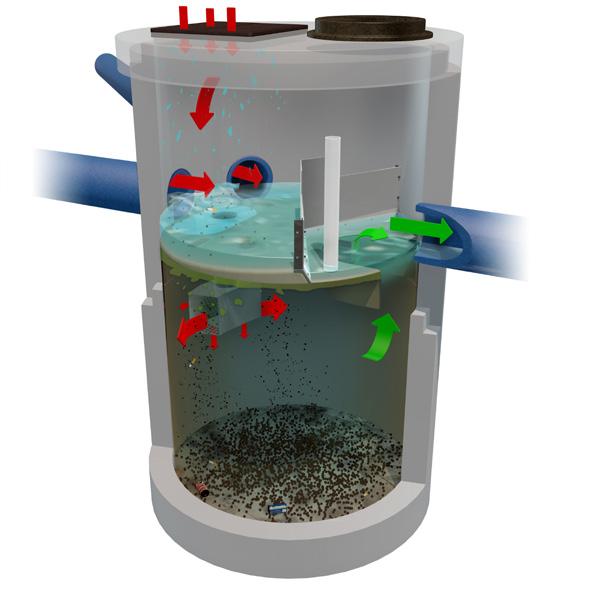

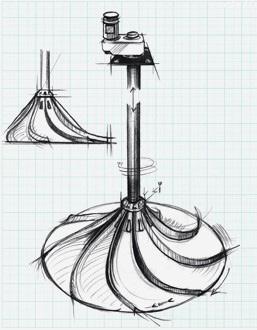

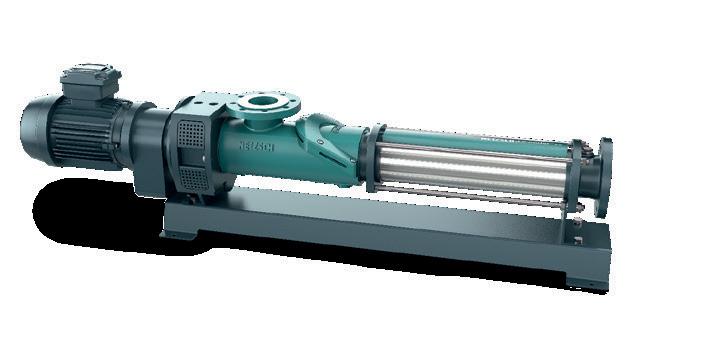

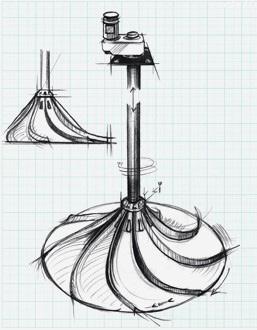

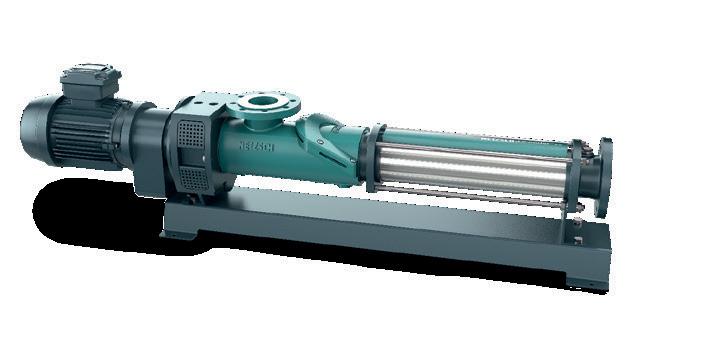

What can you do with adaptive wastewater mixers?

Flygt introduced the first submersible mixer in 1951 and today, more than 250,000 have been deployed. However, they are often given little consideration in the overall design and operation of wastewater facilities, and are generally selected for worst-case scenarios, based on flow or loading.

Because the need for mixing varies greatly in the course of any given treatment cycle, the result is overmixing, a practice often employed to address the worst-case scenario. In other words, to avoid the risk of under-mixing, engineers design for seldom-occurring peak conditions of maximum plant flow or maximum load, setting aside more common average conditions, and mostly ignoring minimum conditions. Unfor-

tunately, this practice wastes energy and often results in a sub-optimal process.

Seeking more efficient mixing, wastewater treatment plant operators are increasingly turning to mixers with integrated variable speed control, which can dramatically lower energy use and reduce wear. Unlike traditional single-speed mixers that always have to be operated at 100% capacity, regardless of how much mixing is actually needed, Flygt adaptive mixers are designed to automatically adjust to a wide range of operating conditions.

With a growing focus on nutrient removal, energy management and optimization, mixers present an extraordinary opportunity for improvement for most wastewater treatment facilities.

MIXING BASICS

Mixing is performed in many stages of wastewater treatment to ensure blending, suspension and/or distribution. In order to provide adequate mixing, the energy from the mixer must be imparted to the liquid to create a bulk flow loop throughout the tank. The amount of energy is measured in terms of newtons (N) and is referred to as thrust (the standard for measuring thrust in submersible mixers is ISO Standard 21630:2007).

For example, as a mixer propeller exerts a thrust on liquid contained inside a tank or vessel, the liquid will start to move and accelerate until the losses associated with the flow in the tank balance the mixer’s thrust. The velocity attained at the balance point is the “equilibrium velocity.” Higher thrust

HOW EFFICIENT IS YOUR AERATION PROCESS?

Environmental Science & Engineering Magazine 22 | February 2023 WASTEWATER

Scott

450 424 3966

LET’S TALK

McLeod, Aerzen Canada Sales Manager +1

ext.226 scott.mcleod@aerzen.com

Real e ciency means operating the consumption profiles in wastewater treatment plants with precision. Aeration consumes up to 80% of total energy requirements; the greatest savings potential can therefore be found here.

TALK! We’ll be happy to advise you! www.aerzen.ca

With our Performance3 product portfolio consisting of Blower, Hybrid, and Turbo technologies, we always find the most e cient and tailor-made solution for you. Benefit from up to 30% energy savings! LET’S

equates to higher equilibrium velocity, resulting in more intense mixing.

It should be noted that mixing can be achieved with almost any rotating device, provided that unlimited power is available. The thrust produced by a mixer and its associated power draws, however, are the key performance parameters of a submersible mixer. Among a set of comparable mixers, the mixer that produces the most thrust using the least power is the most efficient mixer. Efficient mixing, using the lowest amount of power, requires an optimally designed mixer.

WHAT IS ADAPTIVE MIXING?

To put it simply, adaptive mixing is adjusting the mixer’s speed so that the required output (thrust) matches the changing conditions. With adaptive mixing, the mixer is NOT always running on one previously determined set speed. The speed varies as the need changes.

WHY ADAPTIVE MIXING?

Wastewater treatment is not a static

process and therefore a mixer’s thrust should not be either. Mixing requirements vary over time depending on a range of factors, including flow rates,

input aeration rates, seasonal variations, etc. Conventional mixers that operate at a fixed output often result in turbulence,

overleaf… February 2023 | 23 www.esemag.com @ESEMAG Proud distributor of these brands: WATER AIR SOIL METEOROLOGY BIODIVERSITY HEALTH & SAFETY LABORATORY GEOMATICS Vaughan Montreal WWW.GENEQ.COM ENVIRONNENT ENVIRONMENT 10700 Secant St, Montreal (Qc) H1J 1S5 910 Rowntree Dairy Rd. Unit #15, Vaughan (ON) L4L 5W5 T (514) 354-2511 F (514) 354-6948 | 1 800 463-4363 info@geneq.com T (365) 527-2508 F (365) 527-2509 | 1 855 527-5808 sales@geneq.com SCIENTIFIC INSTRUMENTS www.hydratek.com | www.fabianpapa.com CAREER OPPORTUNITIES 2023 Corporate Retreat Guanacaste Province, Costa Rica Join our growing team in the fields of: • Land development & municipal engineering • Urban water system hydrology & hydraulics Visit the Careers section of our websites to apply: (Divisions of FP&P HydraTek Inc.)

In wastewater plants, mixers can be added to reduce the demand on aeration equipment.

continued

wasted energy, unnecessary wear on the mixer, and increased maintenance due to inefficient operation of the mixer.

Adding variable thrust technology to a submersible mixer allows operators to efficiently adjust mixing thrust to meet varying application demands, thereby enhancing operational capabilities while reducing mixing energy costs. Variable speed capability allows for continuous thrust variation to be acquired while operating more reliably than manual “switch-on/switch-off” practices. Energy savings may be gained through automated operation of mixers when the produced thrust is set to what is required.

With an adaptive mixer, thrust (and associated power draws) can be simply increased or decreased to meet the current thrust requirements. Operators can modify the output by way of a tankside control panel, a programmable controller or plant-wide SCADA system to match mixing needs.

While some plants install tank-side variable-frequency drives (VFDs) to

achieve some operational flexibility in a single speed mixer, Xylem has engineered a drive integrated with the mixer’s submerged motor. As such, electromagnetic compatibility issues and other installation, commissioning and operational issues often associated with installing external, tank-side VFDs are eliminated.

Integrated drive technology coupled with the mixer’s hydraulically optimized propeller work effectively to meet process objectives.

Integrating the variable frequency drive into the mixer makes the mixer/ VFD combination very compact and simplifies operation, installation and commissioning. By adjusting mixing to actual process conditions, the integrated VFD also results in a more efficient mixer, and the lowest life cycle mixing energy costs.

IMPROVED PROCESS RESILIENCY

Flygt adaptive mixers let operators adjust output, manually or automatically, to achieve the required mixing process result. With the Flygt Dirigo® technology platform, adaptive mixers can self-monitor. When an adaptive mixer senses a near overload condition, instead of shutting off, it slows itself down, so the process is still up and running. That’s a great benefit in terms of process resiliency and compliance.

APPLICATION OPPORTUNITIES

Mixers of different designs deployed in aeration basins, sludge storage tanks and other treatment processes have varying

Environmental Science & Engineering Magazine 24 | February 2023 WASTEWATER VALVE AUTOMATION RETROFIT EXPERTS WE PROVIDE: New AUMA Intelligent Actuators Custom Designed Adaption and Stems Installation Services Start Up and Long Term Service Single Source Responsibility Toll free: 888-835-3045 Phone: 705-721-8246 Fax: 705-721-5851 121 Commerce Park Drive, Units H-K, Barrie ON L4N 8X1 www.troy-ontor.ca

Xylem has engineered a drive integrated with the mixer’s submerged motor.

degrees of effectiveness. They can also be significant consumers of energy, especially if operated in an “always on” mode.

Because treatment processes are variable, mixers should be too. Adaptive mixing technology is an effective solution for a variety of water and wastewater treatment processes. With the introduction of full automation capabilities, plant owners and operators are assured simplicity and reliability in a variety of treatment processes, including the following:

Secondary treatment – Air flow has become a crucial parameter used to control the level of treatment and also to reduce the amount of energy needed for aeration applications. As load increases, air increases and as loads are reduced, air flow is reduced and with that, mixing energy can also be increased or decreased to save energy.

Mixers can be added to reduce the demand on the aeration equipment. This not only reduces the amount of energy used, it also decreases the amount of air in the tanks and improves processes.

Enhanced biological phosphorus removal (EBPR) – EBPR is utilized when phosphorus discharges below 1 mg/l are required. Side Stream EBPR (S2EBPR) is a type of EBPR where a portion of the RAS is conveyed to a separate tank to allow for fermentation. Whether the EBPR is performed within the process flow or in a side stream, the creation of volatile fatty acids (VFAs) and anaerobic zones are paramount for successful phosphorus removal.

Adaptive mixers provide process control in these systems by providing slow, non-air-introducing mixing. In addition, the thrust from adaptive mixers can also be increased to re-suspend and move fermenting sludge blankets, when needed.

Biological nutrient removal (BNR) –BNR is the most common application for mixers in wastewater treatment. Proper mixing within anoxic and anaerobic zones can help ensure improved treatment efficiency and lower effluent nutrients. Being able to vary the speed of the mixing in treatment processes will improve the BNR

process, reduce energy requirements, and save money.

Sludge holding – As wastewater treatment plants become larger and more sophisticated, so do the demands for handling large amounts of sludge, which is an expensive and complex operation.

For tanks at wastewater treatment plants that contain solids slurries, either for anaerobic digestion or sludge storage, mixing is a key factor in the proper design, operation and maintenance of the system. Submersible mixers are often used in sewage treatment plants to keep solids in suspension in the various process tanks and/or sludge holding tanks.

Adaptive mixers can be used to increase and decrease the applied thrust based on fluctuations in sludge concentration and/ or sludge levels in the tanks.

This article was adapted from a recent white paper on adaptive mixers by Flygt, a Xylem brand. For more information visit: www.xylem.com/en-ca

www.esemag.com @ESEMAG ® ®

Wastewater Sludge Digestate HRS Heat Exchangers info@us.hrs-he.com | +1 (770) 726 3540 www.hrs-heatexchangers.com/us MANAGING ENERGY EFFICIENTLY Industrial Effluent Agricultural Waste Product Recovery

HRS

Heat

Exchangers operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide, focusing on managing energy

efficiently

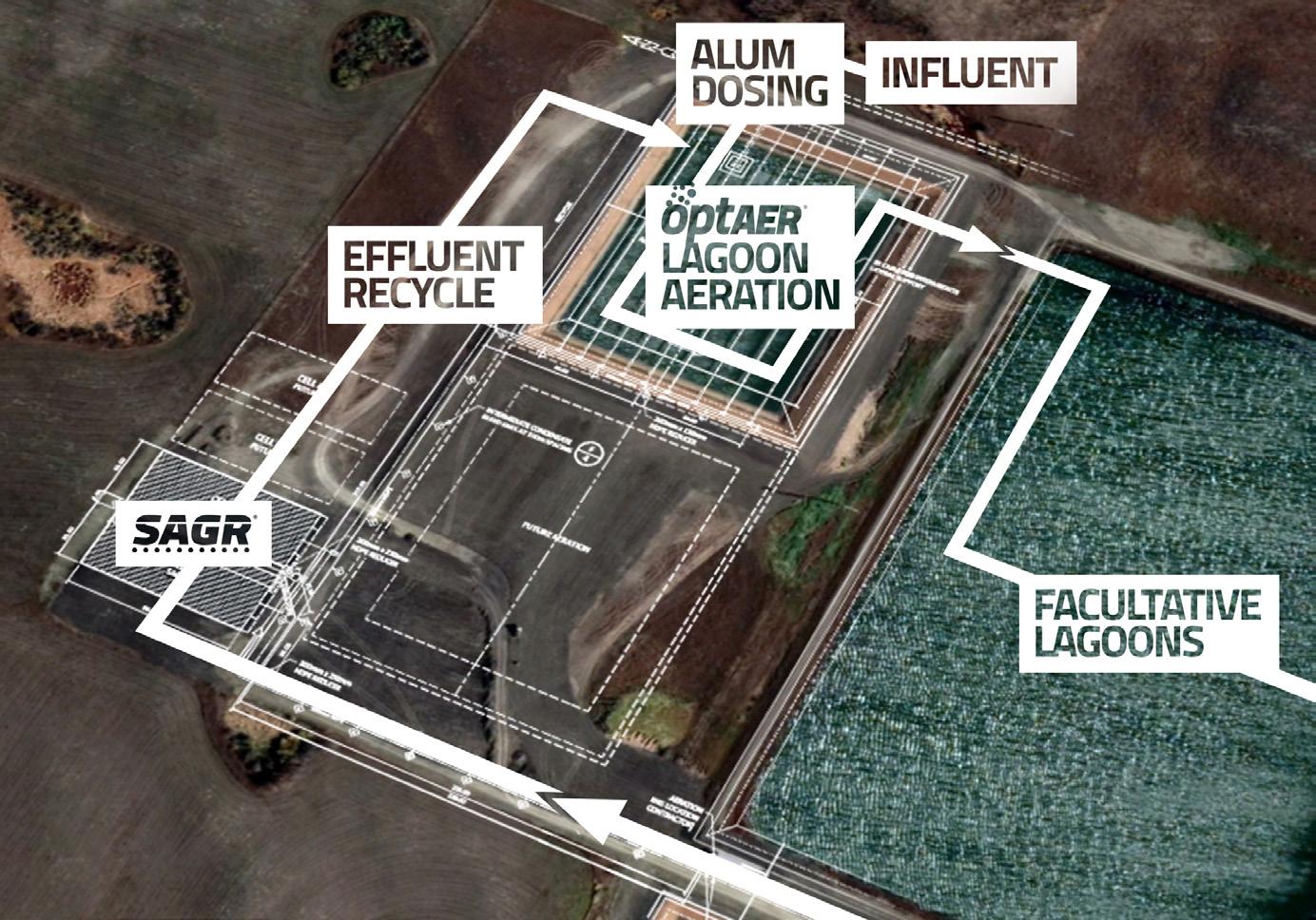

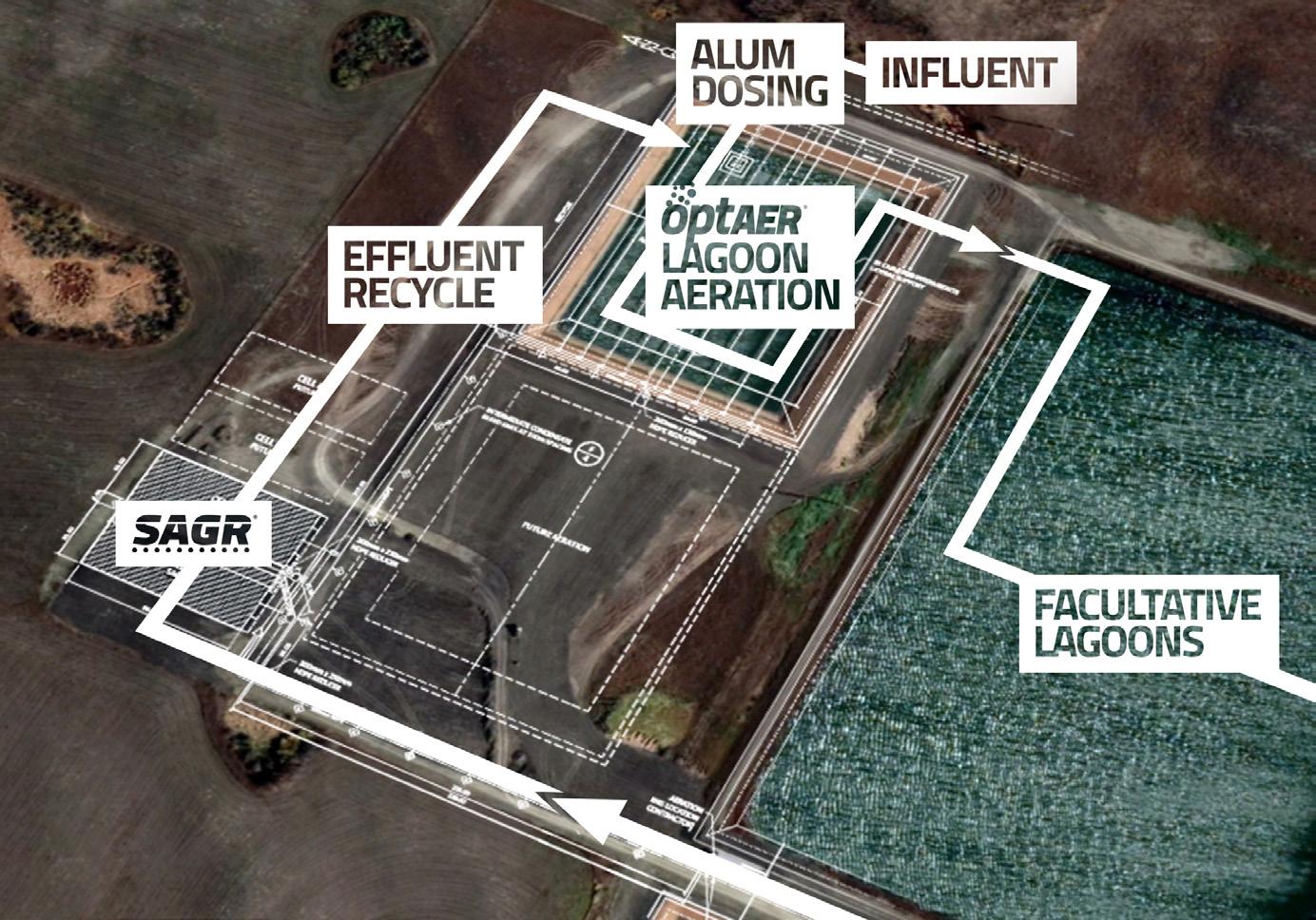

Pilot Butte, SK upgrades its wastewater treatment lagoons

By Kelly Paul, Philip Wiebe and Tanner Devlin

Pilot Butte was becoming a substantial bedroom community because of its 10 km proximity to Regina. In 2014, with developers and prospective homeowners alike investing, and with the town’s population rapidly exceeding 2,500, the municipality needed to upgrade the existing two-cell facultative lagoon system to allow for more treatment capacity.

Around the same time, Boggy Creek, which is part of the Qu’Appelle River watershed and where Pilot Butte’s existing lagoons had been bi-annually discharging, had been reclassified by regulators. A downstream use and impact study examined the effect the treatment plant would have on Qu’Appelle River ecological systems, and established the new effluent targets. Therefore, the upgraded treatment system needed to meet more stringent effluent limits, in addition to expanded capacity.

Overall, it was determined that the system would need capacity to serve 7,500 citizens. It also has to treat a design influent flow of 3,550 m³/day (0.94 MGD) to <10 mg/L five-day carbonaceous biochemical oxygen demand (cBOD5), <15 mg/L total suspended solids (TSS), federal wastewater systems effluent regulations (WSER) inspired non-toxicity requirements of <0.2 mg/L of un-ionized ammonia, <10 mg/L of total nitrogen (TN), and <1 mg/L of total phosphorus (TP).

IDENTIFYING THE SOLUTION

Pilot Butte’s engineers completed an evaluation of treatment technologies that could meet the expanded capacity and new effluent limits. A major consideration during evaluation was that a municipality going from facultative, seasonal discharge ponds would be accustomed to low operating and maintenance requirements.

Therefore, it was important that any upgrades comprised simple and reliable

technologies. Working together with Nexom’s Winnipeg-based lagoon process team, the project engineers designed a solution that would enable Pilot Butte to maximize the use of their existing lagoon infrastructure without sacrificing the operation and maintenance simplicity, to meet additional capacity and more stringent effluent limits.

COLD CLIMATE CONSIDERATIONS

A new constant-level primary lagoon cell with optAER® aeration equipment was constructed in front of the two existing facultative lagoons. The existing facultative lagoons were converted to variable-volume storage cells 1 and 2.

Although the upgraded system would switch from bi-annual to continuous seasonal discharge, there was still a need to store water in the coldest winter months, when the receiving body would freeze and prevent the possibility of year-round continuous discharge. Therefore, a new vari-

able volume storage cell 3 was constructed to provide adequate storage capacity for the expanded design population.

Two new SAGR® cells were constructed to provide final treatment of storage cell effluent prior to discharge. Positive-displacement blowers were installed to supply air to the optAER and SAGR systems.

IMPLEMENTING NITROGEN REMOVAL

Both facultative and aerated lagoons are cost-effective solutions for removing pollutants, such as cBOD5 and TSS, found in wastewater. Implementing a primary aerated lagoon cell followed by three variable-volume storage cells was the first step that would allow Pilot Butte to maximize the use of its existing infrastructure without increased operation and maintenance requirements.

However, lagoons alone can struggle with ammonia removal. Its removal is required to meet WSER effluent non-toxicity requirements, since >0.2

Process flow diagram of the Pilot Butte lagoon-based wastewater treatment facility.

Process flow diagram of the Pilot Butte lagoon-based wastewater treatment facility.

Environmental Science & Engineering Magazine 26 | February 2023 SPECIAL FOCUS: COLD CLIMATE AND REMOTE LOCATION FOCUS

mg/L un-ionized ammonia can be toxic to freshwater organisms.

It is well known that nitrifying microorganisms, which are responsible for ammonia removal by oxidation to nontoxic nitrates, are inhibited in lagoons as the water cools. This happens for multiple reasons, but mainly that ice formation prevents atmospheric oxygen transfer in unaerated ponds. Thus, the metabolism of nitrifying microorganisms slows down significantly as water temperature cools below 5°C, and the hardier heterotrophic microorganisms, the microorganisms responsible for cBOD5 removal, outcompete nitrifying microorganisms.

For these reasons, the SAGR nitrification process was installed after the storage cells as the final treatment stage. The two SAGR cells provide an ideal environment for nitrifying microorganisms to thrive despite water temperatures of <1°C. Water flows horizontally through the SAGR’s fully aerated coarse rock bed. The nitrifying microorganisms grow as a biofilm on the rock and the high-DO environment created through aeration encourages high rates of ammonia removal despite low water temperatures.

Although the SAGR cells convert ammonia to nitrates and detoxify the wastewater, the residual non-toxic nitrates from the nitrification process still contribute to effluent TN. Nitrate is removed through denitrification, which is a biological process that utilizes the same heterotrophic microorganisms already found in conventional aerated lagoons.

Typically, the heterotrophic microorganisms would use oxygen to remove cBOD5. However, if oxygen is limited and nitrate is supplied to the lagoon instead, those heterotrophic microorganisms will utilize nitrate to remove cBOD5. As a result, nitrate is reduced to nitrogen gas, resulting in simultaneous TN and cBOD5 removal. An additional benefit is that the energy required for aeration to supply oxygen to the lagoon is reduced since the heterotrophic microorganisms utilize nitrate rather than oxygen.

Nexom utilizes a nitrified effluent recycle to accomplish denitrification, and therefore TN removal, in lagoon-based treatment systems. A portion of the fully-nitrified SAGR effluent, which contains

nitrate, is continuously recycled to the primary lagoon cell. There, it combines with untreated influent, creating an environment rich in cBOD5 from the untreated wastewater and nitrate from the SAGR effluent. These conditions promote a highrate of denitrification in lagoon cells where heterotrophic microorganisms work to remove both cBOD5 and nitrate.

RETROFITTING PHOSPHORUS REMOVAL

There are many ways to remove phosphorus from wastewater. However, many biological and/or filtration-based systems would dramatically increase the complexity of lagoon-based systems. Therefore, to address the <1 mg/L TP limit most simply, a chemical dosing system utilizing alum, ferric or equivalent was installed.

The trivalent metal from alum or ferric solutions binds both directly and indirectly with phosphates, the primary fraction of TP in wastewater. The bound phosphates then settle out in the lagoons with the chemically formed floc, resulting in TP removal from the liquid stream. Settled chemical sludge is ultimately removed from the system with the settling organic sludge during desludging operations.

SITE CONSTRUCTION AND PERFORMANCE TO DATE

The retrofit of Pilot Butte’s existing two-cell lagoon began in late 2019. To avoid disruption of the existing ponds,

the new primary cell and SAGR cells were constructed to the west of the existing cells, while the new storage cell was constructed to the south. The design site layout left room to build another primary lagoon cell, another storage cell, and another set of SAGR cells should the town wish to effectively double the plant’s capacity from 3,550 m³/day to 7,100 m³/day.

Nitrification, denitrification, and phosphorus removal systems were commissioned in the summer of 2021, with engineers and Nexom field personnel on-site to provide training on the blowers, lagoon aeration system, and SAGR process. The system completed its first critical fall discharge since commissioning in 2021, as well as another full season’s discharge in 2022.

The system performed as expected, producing fully compliant effluent throughout the discharge periods. Measured effluent TN was as low as 1.9 mg/L in 2021 and varied from 4 mg – 6 mg/L throughout the 2022 discharge season, which was well below the 10 mg/L TN limit. Overall, Pilot Butte was more than able to meet their effluent limits, all while maintaining the ease of operation of a lagoon-based facility.

Kelly Paul, Philip Wiebe and Tanner Devlin are with Nexom. For more information, email: tanner.devlin@nexom.com

Floating laterals being installed on Pilot Butte’s primary lagoon cell.

February 2023 | 27 www.esemag.com @ESEMAG

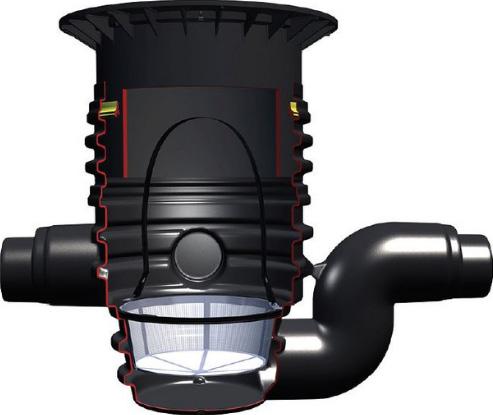

Prefabricated stations address wastewater challenges for remote communities

By Mehran Masoudi

Wastewater management in remote communities often comes with a variety of challenges, beginning with a lack of infrastructure and sufficient resources. The costs associated with installing and maintaining infrastructure traditionally used for wastewater management are often prohibitive for such communities. Inadequate maintenance inevitably leads to decreased efficiency, increases operating costs, but more importantly could result in significant environmental impacts, if left unmanaged.

Limited resources can also inhibit a plant’s ability to ensure compliance with the strict regulations meant to safeguard public health and the environment. Changes in demand, particularly for areas with rapid population growth, can lead to capacity issues and a need to upgrade or expand treatment facilities. All too often unreliable electricity supply further complicates the situation.

Aging infrastructure introduces its own additional issues, including inflow and infiltration (I&I), which is the unintentional entry of water into a sewer system from sources other than the intended wastewater flows.

As lift stations and their associated infrastructure age, they can become prone to leaks, cracks, and other types of damage that can allow rainwater or groundwater to enter the system. I&I can overwhelm the capacity of the sewer system and lead to overflows or spills. Many wastewater facilities are decades old and have outlived their useful life. This leads to increased maintenance costs, reduced efficiency, and potential health risks for people who live or work near them. Additionally, many of these systems are not equipped with modern water treatment technologies, making it difficult to meet stricter regulatory requirements.

DECENTRALIZED TREATMENT SYSTEMS

One approach that has become increasingly popular for managing wastewater in smaller communities is a decentralized treatment system (DTS). This involves the use of smaller-scale technologies, such as septic tanks, constructed wetlands, or aerobic and anaerobic treatment systems.

These technologies are tailored to the specific needs of the community and are simpler, easier to maintain, more flexible and lower in cost than larger-scale centralized treatment plants. They allow communities to treat wastewater independently without relying on external resources or sending untreated wastewater elsewhere.

Another benefit in using a decentralized treatment approach, is that the pumping needs are considerably reduced, as the need to pump wastewater to a distant plant is no longer required.

Using several intermediate and

decentralized pump stations instead of a centralized solution, helps to avoid deep excavation of the gravity sewer mains. Classic centralized systems for small communities spread over a large area often mean deep gravity mains, which can result in construction and safety problems. Deep excavation, laying of underground pipes and wet well pump station excavation quickly becomes an expensive project.

WASTEWATER PUMP STATIONS

Wastewater pump stations designed for small communities are the heart and arguably the most important component of a DTS. They include a series of pumps (usually one in operation and one standby), valves, piping and instrumentation. Pump stations serve to collect, store and move wastewater from one location to another.

They can be assembled on-site by pouring concrete and then adding each required component, or can be pre-assembled (pre-fabricated) before arriving on-site, which significantly reduces project complexity, cost, and the time required for installation.

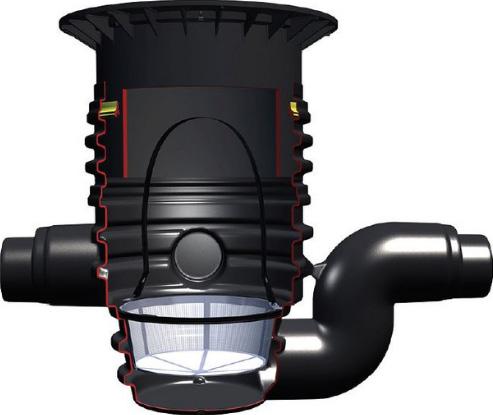

Pre-fabricated stations arrive on-site with all components preassembled in a fibre-reinforced plastic (FRP) underground tank, completely sealed to the surrounding environment.

The wet well is designed based on the actual project location’s environmental parameters to ensure long-term, efficient and trouble-free operation. The FRP wet well is designed to eliminate solids accumulation with a smooth internal finish and clog preventing features.

The vendor manages everything, including all aspects of design (mechanical, electrical, civil, controls and structural engineering,) manufacture, assembly, installation and even aftermarket support. Such stations can manage a wide range of flowrates and capacities to

3D drawing of a prefabricated lift station.

Environmental Science & Engineering Magazine 28 | February 2023 SPECIAL FOCUS: COLD CLIMATE AND REMOTE LOCATION FOCUS

meet the average daily flows as well as peak demand.

For ease of operation, prefabricated lift station systems come with a local control panel that contains all the necessary operational parameters and a digital display. This allows operators to view system performance and make changes as needed. The control panel is typically preprogrammed and tested at the shop by simulating a broad range of require-

ments for different conditions.

Once on site, installation and startup of these smart control systems is quick and easy. These systems can be connected to a SCADA (supervisory control and data acquisition) system for 24/7 monitoring and control of the water content from anywhere. Operators can easily monitor, diagnose and adjust the system remotely from a mobile phone or SCADA.

Designed and manufactured locally in Canada, KSB’s prefabricated wastewater pump stations are compliant with all local health and safety regulations and standards.

Mehran Masoudi is with KSB Pumps Inc. (Canada). Email: mehran.masoudi@ksb.com

ORIVAL WATERFILTERS

ORIVAL WATERFILTERS

For Protection of:

For Protection of:

Pollution / Wet Scrubber

• Automatic Self-Cleaning

• Automatic Self-Cleaning

Wastewater/Irrigation

• Turnkey Systems

• Turnkey Systems

• ASME Construction

• 10-10,000 gpm Units

• 10-10,000 gpm Units

• 10 mic Filtration

• 10 mic Filtration

• ASME Construction

• No external power required

• No external power required

• Heat Exchangers

• Heat Exchangers

• Spray Nozzles

• Spray Nozzles

• Instrumentation

• Instrumentation

• Pump Seals

• Pump Seals

• I.E. & R.O. Units

• I.E. & R.O. Units

• Air Compressors

• Air Compressors

• The Environment

• The Environment

Automatic Self-Cleaning WATER FILTERS

Automatic Self-Cleaning WATER FILTERS

213S.VanBruntSt., Englewood,NJ07631

(800)567-9767

(201) 568-3311

Fax(201)568-1916

www.orival.com

filters@orival.com

February 2023 | 29 www.esemag.com @ESEMAG ORIVAL ORIVAL

Pollution

Scrubber

Left: Fully assembled prefabricated lift station ready for installation. Right: Installed prefabricated lift station.

Wastewater/Irrigation

/ Wet

ORIVAL

ORIVAL

Ontario Onsite Wastewater Association helps regulators and property owners in rural municipalities

By Jenn McCallum

The Ontario Onsite Wastewater Association (OOWA) is a not-for-profit, membership-based, industry association dedicated to promoting the benefit and value of onsite and decentralized wastewater management as a permanent, cost-effective solution for communities and citizens.

With over 600 members, we represent the spectrum of roles within this sector: manufacturers, precasters, distributors, suppliers, engineers, consultants, designers, regulators, installers, haulers, private inspectors, and researchers. The onsite and decentralized industry is a means to preserve resources and OOWA advocates for sound policies through education, engagement, and guidance.

OOWA continues to sustain relationships with the Ontario Ministry of Municipal Affairs and Housing (MMAH) and Ministry of Environment, Conservation and Parks (MECP) on behalf of our members and leverages these connections to promote the need for continuing education, consistent regulations and to strengthen the influence of the association.

GUIDANCE DOCUMENTS

OOWA’s onsite technical committee meets regularly to create and refine our series of guidance documents that are available on our website (oowa.org). There are currently nine of them, including Inspection of Onsite Systems, How to Decommission an Existing Onsite Sewage System, and Flow Balancing At the end of 2022, we released a guidance document entitled, Frequently Asked Questions (FAQ) on Key Inspection Points, and we have more planned for this coming year.

The FAQ document has been prepared to provide some information and clarification of the intent of the Ontario Building Code regarding some common questions that have been brought forward by our members. These questions are primarily from building inspectors and relate to key inspection points during the installation process, such as: How many inspections should be completed? What inspection details should be recorded? Should homeowner installed systems be treated differently?

OOWA MEMBERSHIP

Since its establishment in 1999, the OOWA has provided access to a large network of onsite wastewater professionals. Our members are at the front lines of rural development, supporting onsite systems as sustainable, affordable, and permanent wastewater servicing options. We promote training courses being offered by our education partners, including the Ontario Rural Wastewater Centre and the Ontario Building Officials Association. With in-person events and training returning, our 2023 cal-

endar is filling up with various offerings of the Ontario Building Code Part 8 Exam Prep course and General Legal Process and Powers and Duties course. Recently, OOWA has partnered with the Ontario Rural Wastewater Centre to bring new training opportunities to our members, including the one-day Introduction to Design of Onsite Sewage Systems and Advanced Design of Onsite Sewage Systems courses.

Our annual convention and exposition will take place on March 26 to 28, 2023, in Huntsville, Ontario. Typically, over 350 Ontario industry professionals gather at this event to connect and learn about best practices, regulatory updates, and new innovations.

A septic tank being lowered into place during an installation for a development project. Credit: Anne Egan, R.J. Burnside & Associates Ltd.

Environmental Science & Engineering Magazine 30 | February 2023 SPECIAL FOCUS: COLD CLIMATE AND REMOTE LOCATION

FOCUS

PART 8 PANEL DISCUSSIONS

During the pandemic, OOWA began providing virtual, members-only, Part 8 panel discussions three or four times per year. Each discussion features a regulator professional, engineer or designer, and installer to discuss relevant topics pertaining to Part 8 of the Ontario Building Code. Our most recent panel discussion was held on November 2, 2022, and covered defining structures to determine clearances and the effect of heavy soils (T>50 min/cm), and highly permeable soils (T<1 min/cm), on design and installation. Although we can now move back to in-person discussions, our virtual panels have been so successful that we plan to continue delivering this benefit to our members on a regular basis.

HOMEOWNER RESOURCES

OOWA has developed several resources that are directed to rural property owners, encouraging them to regularly maintain their onsite sewage sys-

Peterborough Public Health inspectors check an onsite sewage system for compliance with the Ontario Building Code requirements. Credit: Wayne Eardley, Peterborough Public Health tems to ensure their longevity and the protection of human health, lifestyle, and the enjoyment of water resources. Some of our key resources include: the Homeowner’s Guide to a Healthy Septic

(Sewage) System (on our website), a Septic Do’s and Don’ts video (through our YouTube channel), and regular Homeowner Hints posted to social media on Tuesdays.

During Septic Awareness Week from September 19 to 23, 2022, we posted daily property owner tips for onsite sewage systems and we hosted a webinar entitled Septic System Basics for Rural and Waterfront Property Owners. This webinar was recorded and is publicly available on our YouTube channel.

A few of the ways we distribute these resources include connecting with the Federation of Ontario Cottagers’ Associations and attending the Fall Cottage Life Show.

Jenn McCallum is the Programs and Outreach Coordinator, Ontario Onsite Wastewater Association. For more information, visit: www.outreach@oowa.org

February 2023 | 31 www.esemag.com @ESEMAG

Preserving a town’s natural resources with an all-terrain sewer

By Joseph Harmes

In 1870, the first settlers christened tiny Confluence, Pennsylvania, for its location at the junction of the Casselman River and Laurel Hill Creek with the Youghiogheny River. But, like many hamlets scattered throughout the region, it has struggled to maintain a population of more than 1,000, or to attract industry of any real size.

In less than a generation, however, Confluence has transitioned from stagnation and a fading industry that could have ravaged scenic hills, old-growth forests, sparkling creeks and the remote habitats of endangered species into a robust economic juncture of prized recreational venues for hiking, fishing, kayaking, rock climbing and boating. It is also financially buttressed during the winter by four area ski resorts and miles of cross-country paths.

ECONOMIC FUTURE IN PERIL

But, as this burgeoning economy was being shaped, its aging and failing combined sewer system (CSS) threatened its future. In 2014, Confluence’s outfalls became the focus of a lawsuit filed by Pennsylvania’s Future, an out-of-town citizen group. It alleged that the Confluence Borough Municipal Authority, as operator of the publicly-owned treatment works, violated the Federal Water Pollution Control Act and the Pennsylvania Clean Streams Law.

Within a month the group offered to drop the case under a consent decree mandating “a plan to engineer and construct a new pressure sewage collection and conveyance system for the borough, to replace the existing gravity flow network in order to eliminate SSOs (sanitary sewer overflows) and maintain compliance with effluent limitations.”

The existing gravity sewer (about 7,600 m of pipe of which 4,850 m consisted of pre-1970 terra cotta pipe, rang-

ing from 200 mm – 350 mm in diameter) would be left in place to become a separate stormwater collection and conveyance system.

Five years prior to the lawsuit, Confluence had contemplated, designed and planned a sewer rehab project, calling for separating the combined sewer into a dedicated gravity sanitary sewer line and another gravity sewer for stormwater.

Septic systems were not an option as a “Sewage Facilities Plan” prepared in 2010 found approximately “80 percent of the borough’s land unsuitable for any type of on-lot disposal systems”, largely due to steep slopes and flooding. Only five percent of the land in the area contains soils suitable for septic disposal systems, the report added. “Approximately 10 percent of the land contains soils that would be moderately suitable for septic disposal systems.”

ABANDONING GRAVITY

“My first task when taking over the Confluence project (around 2014) was to finish the plan and proceed with construction,” says John Larimer, the borough’s engineer, now with CME Management. “I disagreed with the plan and proposed the pressure sewer replacement for several reasons. Gravity sewers cannot and will not work in an area surrounded by water. Pressure sewers can and will work.”

“We were contacted by the engineering firm in 2014 to explore part of the project as a pressure sewer,” says Benjamin Dorsch who was with Trombold Equipment Company at the time. “The whole pressure sewer design started as a feasibility exercise based on Google Earth. In less than two weeks we had an entire layout with calculations back in the engineer’s hands for the entire system. The Pennsylvania Department of Environmental Protection approved it to replace the entire gravity sewer system and this was written into the Consent Decree.”

Larimer says he was attracted to the All-Terrain Sewer (ATS) manufactured by Environment One Corporation (E/ One), after reading case studies about its gravity to pressure sewer conversion projects.

“Leaving the existing gravity sewers in place solved the stormwater problem,” Larimer adds. “We separated the sewer out of the stormwater rather than take the stormwater out of the sewer. Gravity sewers would have been in excess of 6 m in depth. We eliminated the lift station at the treatment plant, which was a maintenance nightmare, especially during rain events.”

The E/One grinder pump station begins with a tank about the size of a tall refrigerator that is buried in the ground, its lid easily camouflaged with

The E/One grinder pump station can send wastewater through small-diameter, inflowand-infiltration-free pressurized pipe for a distance of more than five kilometres.

Environmental Science & Engineering Magazine 32 | February 2023 SPECIAL FOCUS: COLD CLIMATE AND REMOTE LOCATION FOCUS

minor landscaping. Components include a 1-hp, semi-positive displacement pump, which can send wastewater through small-diameter, inflow-and-infiltration-free pressurized pipe for a distance of more than five kilometres, or vertically up 55 m to a force main or treatment plant.

A WATER-TIGHT SOLUTION

A critical, persistent problem plaguing Confluence’s CSS was inflow and infiltration (I&I) which can create detrimental environmental and economic effects on the overall operation of the wastewater collection and treatment station. The borough identified 101 sources of I&I, including downspout drains, catch basins, service laterals, manhole seals, and basement drains.

An ATS is constructed of PVC pipe with solvent-welded joints and leak tested to the same standards used for potable water supply piping networks. Water-tight and virtually leakfree, it is not subject to infiltration from groundwater or from surface stormwater entering through leaking pipe joints and manholes. The reduced I&I can result in smaller treatment system sizing, thereby saving capital costs. In northern climates, the pipe is buried beneath the frost line. Over 100,000 ATS units have operated for decades throughout the Nordic countries.

A CONVERGENCE OF SAVINGS

The Confluence Borough Municipal Authority Wastewater Treatment Plant was constructed in 1975 with a design capacity of 518,000 litres per day, with a peak daily flow rate of 1.3 million litres per day. Daily flow periodically exceeded design capacity during wet weather periods because stormwater and stream flow infiltrated the borough’s collection and conveyance system.

The ATS significantly reduced the sewer rehab budget and improved the WWTP’s efficiency as it eliminated the need for a 7.6 m deep confined space raw sewage pump station at its headworks. Instead, individual grinder pumps will convey sewage to the treatment plant.