Improving a Niagara Region water intake facility

PFAS concerns shape Quebec’s new biosolids code

Studying pharmaceutical levels in wastewater and biosolids

Improving a Niagara Region water intake facility

PFAS concerns shape Quebec’s new biosolids code

Studying pharmaceutical levels in wastewater and biosolids

odour and corrosion in

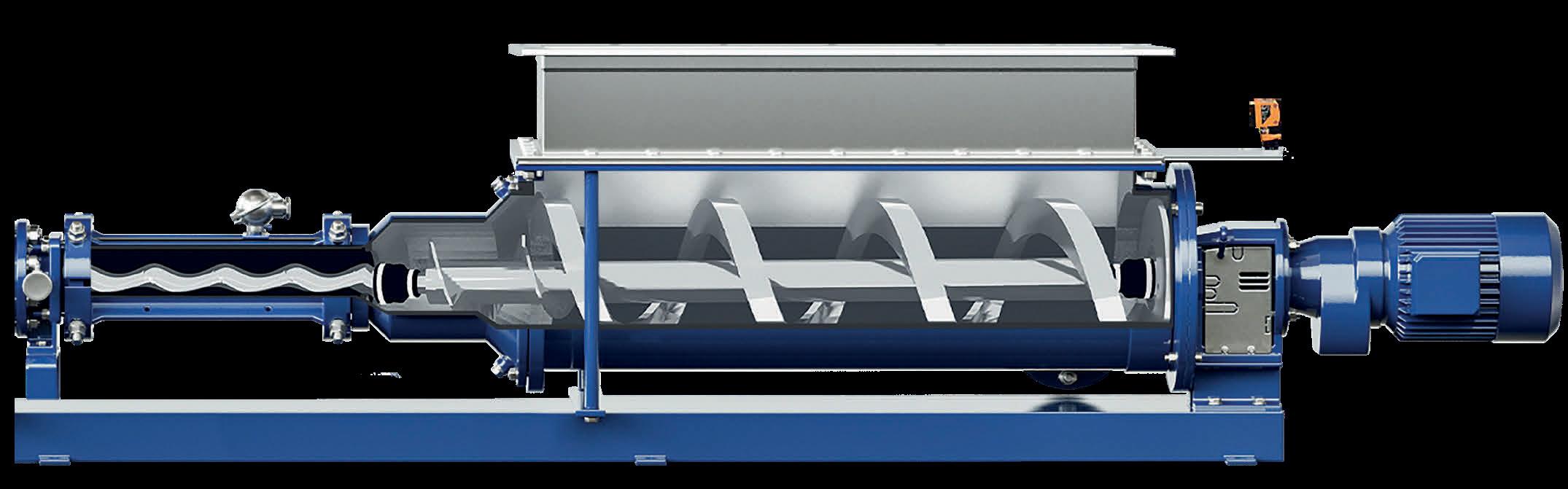

Sewage sludge dewatering offers a wide range of potential savings for operators of wastewater treatment plants. The cost of transport and disposal of dewatered solids can amount to as much as 80% of the operating costs of mechanical dewatering. Since dryer solids result in less volume for disposal, the decision to invest in an efficient, reliable and, above all, peakperforming dewatering system is critically important to reducing operating costs.

“The Flottweg centrifuges and the dryer biosolids they produce have saved us about $900,000 annually. Our plant was able to incinerate the dryer sludge without the aid of natural gas, which equated to our high savings. The Flottweg centrifuges also produce cleaner and more consistent centrate.”

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Contributing Editor DAVID NESSETH david@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

Archis Ambulkar, Toledo Technology Academy of Engineering

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales Second Class Mail

Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey

Sales Director 416 807 3812 penny@esemag.com

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6

Tel: (905) 727 4666 www.esemag.com

6 Remembering Peter Laughton: Engineer, mentor, friend and champion of the wastewater industry

8 Improving debris management at a Niagara Region raw water intake facility

10 Northeast Regina stormwater system improvement project well underway

14 Revolutionizing effluent pond sediment surveys with underwater acoustic sonar

17 Understanding power generation fundamentals for water utilities

20 New funding supports Winnipeg’s North End biosolids facility and algal bloom reduction projects

22 Swedish study spotlights THM cancer risks

24 Water use audits can reduce consumption, increase capacity and reduce costs

28 The Gordie Howe International Bridge project required precise measurements, mapping, and data analysis

30 How do you make the right choice for wastewater disinfection?

32 Monitoring temperature is critical to ensuring the integrity of Arctic sewage lagoons

36 The growing use of above ground pump stations

38 Transporting dewatered sludge over long distances

40 Canada signals move toward banning some PFAS uses

42 Halifax Water working with city, province to ‘formalize’ approach to alerts

44 Restoration project ensures wetland can mitigate the impact of rainfall and runoff

45 London begins flood protection work for two wastewater treatment plants

46 Upgrading process piping systems at Toronto’s Highland Creek WWTP

48 What to consider in selecting the right isolation valve for municipal water solutions

50 PFAS concerns shape Quebec’s new biosolids code

52 Modified hydrothermal liquefaction removes PFAS from wastewater

58 The role of chemical monitoring for water fluoridation

60 Studying pharmaceuticals and personal care product levels in Canadian wastewater and biosolids

Are The Exclusive Suppliers

Pro Aqua, Inc. ca rr ies a co mpl ete range of market leading and innovative products. Let us show you

Providing treatment solutions for more than 30 years.

• Archimedes Screw Pumps

• Screens – Multi-Rake, Perf Plate, Drum, Travelling Band, Step, Climber, Vertical Pump Station Screens, Screenings Washer /Compactors

• Grit Separation, Washing & Dewatering

• Conveyors – Shafted & Shaftless Screw, Belt

• • Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Blowers – Rotary Screw, Rotary Lobe, Single Stage and Multistage Centrifugal, Turbo, Integrally Geared, Advance Control, Rebuilds

• Aeration – Surface, Membrane & Ceramic, Fine & Coarse Bubble, Gas & Liquid Cleaning, DO Control, AlphaMeter

• Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

• Tank Components –

Decanters, Swivel Joints, Telescoping Covers, Watertight Doors

• Primary & Secondary, Circular, Chain & Flight, Inclined Plate Settlers, Weir Washing

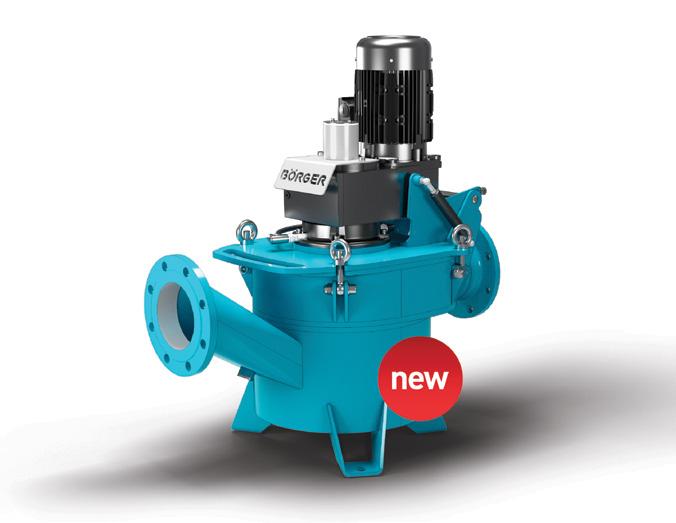

• Rotary Lobe Pumps & Grinders

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recovery

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – snoitatS pmuP & retawmrotS ,OSC

Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vortex Valves, Storm Screens

• Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dry Systems

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

It was with profound sadness that I learned that Peter Laughton had passed away. I first met Peter in the mid1970s when he was on the board of the Water Environment Association of Ontario (WEAO) and a partner at the consulting firm R .V. Anderson & Associates (RVA), and I was but a gangly teenager.

Throughout the years since then, the friendship, support and encouragement he showed to my family and I was remarkable. My father, Tom Davey and mother, Sandra Davey, had the pleasure of working with Peter on WEAO’s history book “Recollections” in the mid ’80s and I had the pleasure of working with him on the 30th anniversary retrospective of the Ontario 5S Society in 2013.

Peter started at RVA in 1966 and worked there continuously until he retired as its chairman in 2005. Subsequently, he launched his own engineering firm and didn’t fully retire until 2015. Over his 49-year engineering career, he published and presented numerous technical papers at national and international conferences and wrote for many industry publications, including ES&E Magazine. His numerous awards and recognitions by the wastewater and engineering sectors are a testimony to his dedication and hard work. These include, but are not limited to:

2018 — Appointed WEF Fellow by the Water Environment Federation.

2011 — Recipient of WEAO’s Geoffrey T.G. Scott Memorial Award in recognition of outstanding leadership and inspiration in the water environment industry.

2001 — Inducted into the University of Toronto Engineering Alumni Hall of Distinction.

2001 — Awarded the “Dr. Albert E. Berry Medal” by the Canadian Society for Civil Engineering (CSCE), which is given to a civil engineer who has contributed significantly to the field of environmental engineering in Canada.

1999 — Recipient of the “Freedom of the City of London” (England) in recognition of those who have achieved success and recognition in their chosen field.

1997 — Appointed a Fellow of the Canadian Society for Civil Engineering in recognition of his excellence in

engineering and for services rendered to his profession and to Canada.

I will always be grateful for the assistance and guidance Peter gave us when we launched ES&E Magazine in 1988. From that first year, up until 2006, he was a member of our editorial advisory board. During that time, he also authored many articles for ES&E and encouraged his colleagues at RVA to do so as well.

Even after his retirement, Peter’s regular visits to our office and phone calls to see how we were doing, were much valued, and a testimony to his caring nature. Peter had a profound effect on my career and approach to human interaction. My deepest condolences to his wife, Jane, and the rest of the Laughton family.

Peter J. Laughton was truly an extraordinary engineer, leader, mentor, friend and champion of the wastewater industry. Thank you, Peter.

Steve Davey is the editor and publisher of ES&E Magazine. Email: steve@esemag.com

In an increasingly complex and demanding world, you must be flexible and prepared to rethink and readjust your goals. We are living in an era of dramatic changes that are taking place in all aspects of society. The sweeping changes in the marketplace are global and they are affecting the everyday lives of us all. The economies of the world are undergoing major transformations.

Peter J. Laughton, address to the 2017 annual luncheon of the Ontario Select Society of Sanitary Sludge Shovelers.

By Kaleb Mudrik and Lindsay Jones

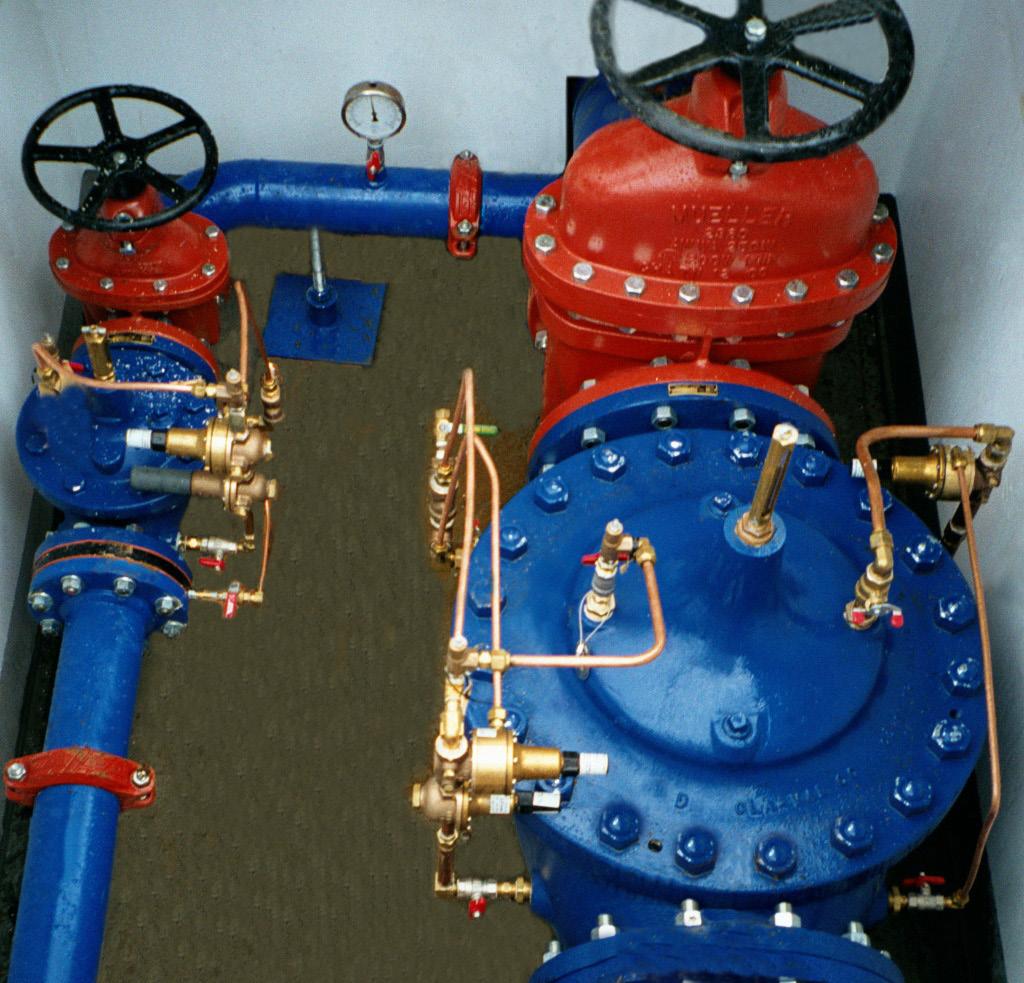

There is a great deal of variability in raw water screening requirements, depending on the source from which a water treatment plant (WTP) acquires its water. In the case of many plants adjacent to large bodies of water, long intake pipes that extend far from shore tend to minimize the debris experienced at the plant.

However, WTPs that draw water closer to shore can be prone to excessive fouling at their raw water intake. This can pose a particular maintenance and operation challenge when seasonal events, such as spring flooding, summer algal buildup and falling leaves in autumn, cause an increase in debris. Ontario’s Niagara Region recently undertook a project to improve the debris handling system at their Decew Falls WTP to reduce this burden on their staff.

The Decew Falls WTP draws raw water from a protected manmade drinking-water reservoir. The reservoir is fed by Lake Erie through the Welland Canal and a manmade raw water channel. The reservoir, canal and raw water channel all feature ample shorelines that produce leaves, logs and other debris, along with the typical algae and sediment.

The plant’s intake building, which was constructed in 1951, is a structure built directly on the shoreline of the drinking water reservoir. A ground-level floor slab provides access to the above-water equipment, while water flows below through two intake channels and a common wet well in the concrete structure. Two 900mm ductile iron pipes, equipped with gate valves, carry raw water north under Decew Road to the main plant property, where a below-grade channel ultimately feeds the low-lift pumps.

The original design of the intake building featured a bar screen at the mouth of each channel to capture large

The snowplow-like shape of the floating boom helps to deflect large items away from the water treatment plant's intake.

items before they enter the building. These screens could be cleaned by operators via a rear access platform. However, this task was labour intensive and required operators to work over water.

In order to limit the accumulation of debris on the bar screens, a specialized floating boom was installed in the reservoir around the entrance of the intake channels. It is designed to deflect logs and other large items, minimizing cleaning requirements of the existing bar screens. The screen is fastened to the intake building on both sides and secured in the middle by a submerged concrete block, effectively forming a snowplow-like shape around the intake structure.

Finer debris that is not captured by the new floating boom and existing bar screen is carried into one of two intake channels under the building. Each channel is equipped with a new thru flow travelling screen, which have replaced exist-

ing travelling screens that were nearing end of service. The existing wash-water pump was also replaced to supply high-pressure water to the cleaning nozzles of the new screens.

The thru flow travelling screens consist of a series of overlapping screen baskets fastened to a rotating chain/sprocket assembly. There are 10-mm square openings in the mesh, which allow water to flow easily through the channel while depositing solids into the baskets.

Ultrasonic level sensors upstream and downstream of each screen measure the level differential, which can indicate excessive fouling of the screens. Both screens were integrated into the plant’s SCADA system, allowing remote operation and monitoring of the screens. The baskets are automatically rotated and cleaned with high-pressure water at a regular interval, or more frequently if significant debris causes the level differential to exceed a range set by the operator.

The existing thru flow travelling screens at the Decew Falls facility discharged collected refuse into a concrete trough built into the floor slab. Limited debris storage capacity and unpleasant manual cleaning of the troughs were among the complaints from plant staff. To reduce the frequency and extent of operator intervention, the new thru flow travelling screens are now designed to discharge directly into screening handling conveyors.

Two independent screw-conveyor trains each serve the purpose of dewatering, transporting and depositing the screenings into rolling waste-disposal bins. Operators may now roll the bins to the exterior of the building.

In addition to the process upgrades, the project also included improvements to other elements of the intake facility. All existing electrical equipment was replaced and upgraded as required to meet the new loads, including new panels, disconnects and LED lighting. Existing electric unit heaters were replaced, and a new ventilation and dehumidification system was installed to better manage the moist environment.

Upgrades were also made to the controls and site security system, including installation of a new fibreglass PLC enclosure and updated SCADA software.

Architectural features were also upgraded, including a new peaked metal roof, doors, glass block windows and brick façade, all carefully selected to improve visual cohesion with the main plant’s facilities.

Structural upgrades at the intake building included minor concrete repairs, new ladders, platforms and handrails, as well as new hatches designed to better facilitate future maintenance activities. The project also included decommissioning of nearby valve chambers that were built well over a century ago. Engineered cellular grout was used to fill the chambers, reducing risks associated with the now obsolete structures.

Staff have reported a reduction in manual cleaning of the bar screens and inside

the facility, as well as reduced equipment downtime. Additional instrumentation and integration with SCADA have further led to operators’ confidence in their system and ability to intervene remotely as required.

Construction on the project was completed in the spring of 2024. The general contractor was North America Constructors Ltd. Engineering design and construction services were provided by R.V. Anderson Associates Limited.

Kaleb Mudrik is with R.V. Anderson Associates Limited. Email: kmudrik@rvanderson.com. Lindsay Jones is with Niagara Region. Email: lindsay.jones@niagararegion.ca

By Trevis Hanson

Construction continues in northeast Regina to replace and upgrade the Saskatchewan city’s stormwater system to better handle rainwater and melted snow from a once-in-25-years event.

Home and business owners in those neighbourhoods will appreciate less ponding and a lower risk of street and basement flooding during significant storms, thanks to the City of Regina’s $14 million Northeast Neighbourhood Drainage Improvement Project. The project also aims to improve the management of increasingly severe storm impacts from climate change and reduce the risk of untreated wastewater being discharged into the environment.

AECOM, the engineering consultant for this project, began work in the fall of 2020. The firm’s project team includes key personnel who have been working on the detailed design and construction of city-wide stormwater upgrade projects in Regina over the last decade. The City of Regina manages stormwater with storm sewers that collect rainwater and snowmelt to drain into Pilot Butte, Wascana, and Chuka creeks.

Upgrading the stormwater system in Regina’s northeast required a design that is constructible, cost-effective, low-maintenance, and hydraulically efficient. Like other similar projects, this one required extensive stormwater modeling and simulation, the installation of large-diameter sewers, coordinated crossings of critical city infrastructure, utilities and railway lines to minimize service disruptions during construction, and comprehensive street rehabilitation.

AECOM provided the City of Regina with conceptual design, preliminary design, detailed design, tender preparation, procurement assistance, and construction administration support for this project.

Construction began in 2023 with the general contractor, CBS Contract-

The large diameter sewer pipes are designed to be installed at depths greater than five metres below grade.

ing, using Souris Valley Industries (SVI) to supply the concrete pipe, manholes, vaults, T-risers, and bends required for this project.

“Relying on a local supplier made sense for this project because it makes communicating and collaborating among all the stakeholders during the project easier,” said Toby Hess, AECOM’s project manager.

Construction on this project progresses block by block, with the surface being removed to access the existing infrastructure for removal. New pipe is then installed to replace it. The large diameter sewer pipes are designed

to be installed at depths greater than five metres below grade, ensuring they maintain their structural integrity under significant loads of earth for a long time.

Eric Donnelly of CBS Contracting plans ahead by determining the supplies he requires several weeks in advance. Many of the bigger products are made when an order is placed. For some products not made in regular production, new drawings sometimes need to be produced for an engineer to approve.

SVI then sends CBS Contracting’s order into production, ensuring there is enough concrete pipe, manholes, vaults,

WE HAVE AN EASY

INSTALL A SWM SHIELD TO PRE-TREAT YOUR POND

T-risers, and bends available ahead of when the construction company requires them.

“Producing bends and T-risers is labour-intensive,” said Ryan Watt of SVI. “While pipes can be produced using a concrete form, no such form exists for these two other products, so they require welding and special forming, which adds hours to their production.”

SVI employees check the product to ensure its quality meets standards before arranging for it to be transported. There is very little room for storage at the construction site, because the work is being done on existing city streets, so the products can only be brought in a day or two in advance. SVI ensures the products are transported to the site just in time for installation.

Another challenge of this project involved meeting the depth requirements of Canadian National Railway (CN). A section of the project crossed the railway company’s property. To meet the requirements, AECOM devised an innovative solution. Instead of using only an 1800-mm pipe for that section, two 1524mm casing pipes were installed.

Two 1200-mm diameter PVC carrier pipes were placed within these casing pipes. This approach allowed for stormwater to be received, contained, and funneled where it needs to go while adhering to CN’s depth requirements.

Transitioning from an 1800-mm storm

sewer pipe upstream to dual 1200-mm pipes involved installing a 3600-mm x 3600-mm box culvert. The same box culvert configuration was constructed downstream of the crossing. Using dual casings and box culverts was not only compliant with CN’s regulations, but also provided a cost-effective and feasible solution for the stormwater management system.

These box culverts were produced by SVI in Weyburn and transported to

Regina. This product required the creation of a form for the walls of the box. After the concrete was poured, additional work was needed to ensure everything fit properly.

Work continues on this project through 2024, with completion scheduled for 2025.

Trevis Hanson is with the Canadian Concrete Pipe & Precast Association. Email: trevis.hanson@ccppa.ca

By Paul Makar

Effluent ponds are a crucial component in waste management for industries like petrochemical, oil and gas refineries, mining, pulp and paper, agriculture, hydroelectric power generation and wastewater treatment. However, they often go unnoticed in discussions about technological innovation.

Yet, beneath their seemingly placid surfaces lies a complex world of sediment and sludge accumulation that demands our attention. Traditional methods of monitoring these sediments are labour-intensive, risky, and sometimes environmentally disruptive. Recently though, acoustic sonar sediment remote surveying, a

cutting-edge solution, is transforming how we understand and manage these hidden depths.

Over time, effluent ponds collect sediments composed of organic matter, minerals, and other particulates. This gradual buildup can significantly reduce capacity, affect its efficiency in processing waste, and even pose environmental risks if not properly managed.

Conventional surveying methods often involve manual probing or draining the pond, which are not only hazardous but also interrupt the pond’s operation. Underwater acoustic sonar offers a non-invasive alternative. By emitting sound pulses into the water and analyz-

ing the echoes that bounce back from the pond’s bottom and sediment layers, sonar systems create detailed maps of underwater topography.

Coupling sonar technology with remote survey vessels amplifies the benefits. These unmanned, GPS-guided boats can autonomously navigate across the pond’s surface, collecting thousands of data points efficiently and safely. Equipped with high-resolution sonar equipment, they eliminate the need for human operators to be physically present on the water, reducing safety risks and operational disruptions. Here is how it works.

Deployment — The remote survey

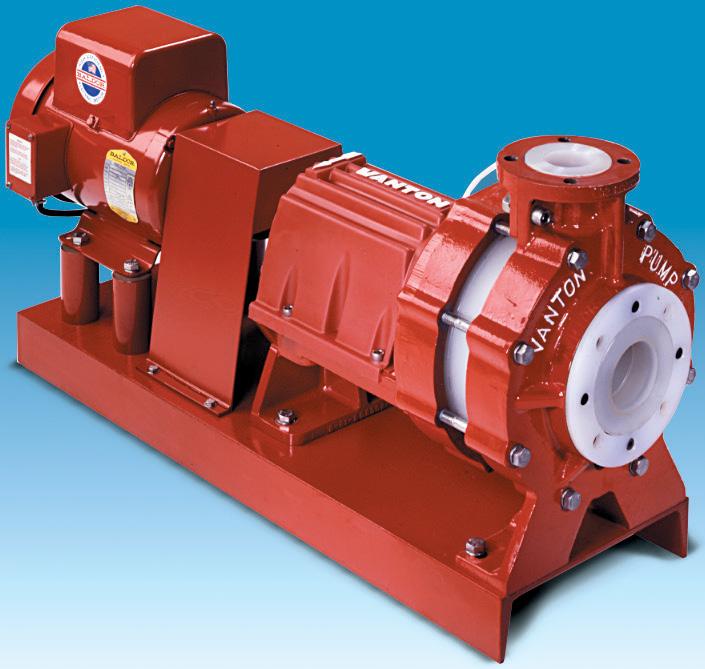

• No Corrosion or Contamination

• No Chemical Absorption or Wicking

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant.

Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for:

• Chemical Transfer

• Neutralization

• Dosing

• Effluent Control

• Lift Stations

• Odor Control

• Recirculation

• OEM Applications

vessel is released onto the ponds and open top clarifiers often by a crane, since vehicle access close to the water edge may be very restrictive. Once the vessel is on the pond’s surface the navigation is either guided by pre-programmed navigation paths or controlled remotely.

Data collection — As it glides over the water, the remote vessel’s sonar system emits acoustic signals downward. These signals penetrate the water column, reflecting off different layers, most notably the sediment-water interface. Remote survey vessel GPS tracking in real-time on the pond is seamlessly integrated with the sonar data, that is collected and stored in a powerful computer system. This sonar computer system is located on the survey vessel in a water-proof housing secured to the hull.

Utilizing radio frequency, the sonar and GPS data can be sent from the survey vessel's onboard computer system to a computer system onshore, for the sonar specialist to review. To ensure adequate survey coverage, especially on large ponds, survey vessel tracking, which incorporates location and speed, is scrutinized closely.

Data interpretation — The time it takes for the acoustic signals to return is meticulously measured. Differences in return times and signal strengths help determine the depth and density of sediment layers. Multiple transducers of different frequencies are utilized to create a more effective and accurate sonar system.

By embracing this technology, industries can make informed decisions that promote operational efficiency, regulatory compliance, and environmental protection.

The low-frequency transmitter (50 kHz and below) emits sound waves that can penetrate deeper into the water and sediment capturing the pond's sub-bottom or its “liner” i.e., clay, riprap, concrete contour profile. Medium-frequency transmitters (83 kHz to 160 kHz) offer a balance between depth penetration and image resolution. They can cover a wider area and provide more detailed information than low-frequency transducers.

High-frequencies (200 kHz and above) emit sound waves with shorter wave lengths, resulting in more detailed pond sediment mapping of the bathymetry or the top of the sediment layer.

Utilizing a specific configuration of transducers specifically engineered for shallow depth effluent ponds and open top clarifiers helps to validate bathymetric and sub-bottom sediment depths and ultimately the total sediment volumes when further data processing is completed.

Mapping and analysis — Collected data is translated into vivid, three-dimensional maps and cross-sectional profiles of the pond’s sediment deposits. Advanced software allows for real-time visualization and analysis.

This approach removes personnel from potentially hazardous environments, minimizing the risk of accidents. Surveys can be conducted without halting pond operations, saving time and resources, while precise measurements surpass the capabilities of manual methods. Finally, non-invasive surveying protects aquatic life and maintains the integrity of the pond’s ecosystem.

While effluent ponds are a prime beneficiary, this technology extends to various aquatic settings, such as monitoring sediment for stability assessments in mining tailings ponds, guiding dredging activities by pinpointing sediment levels and ensuring capacity and integrity of reservoirs.

Underwater acoustic sonar sediment remote surveying represents a significant leap forward in how we manage and understand aquatic sedimentation. By embracing this technology, industries can make informed decisions that promote operational efficiency, regulatory compliance, and environmental protection. It is a great example of how innovation can turn challenges into opportunities.

Paul Makar is with PW Makar Coatings Inspection Ltd. Email: paul.makar@cogeco.ca

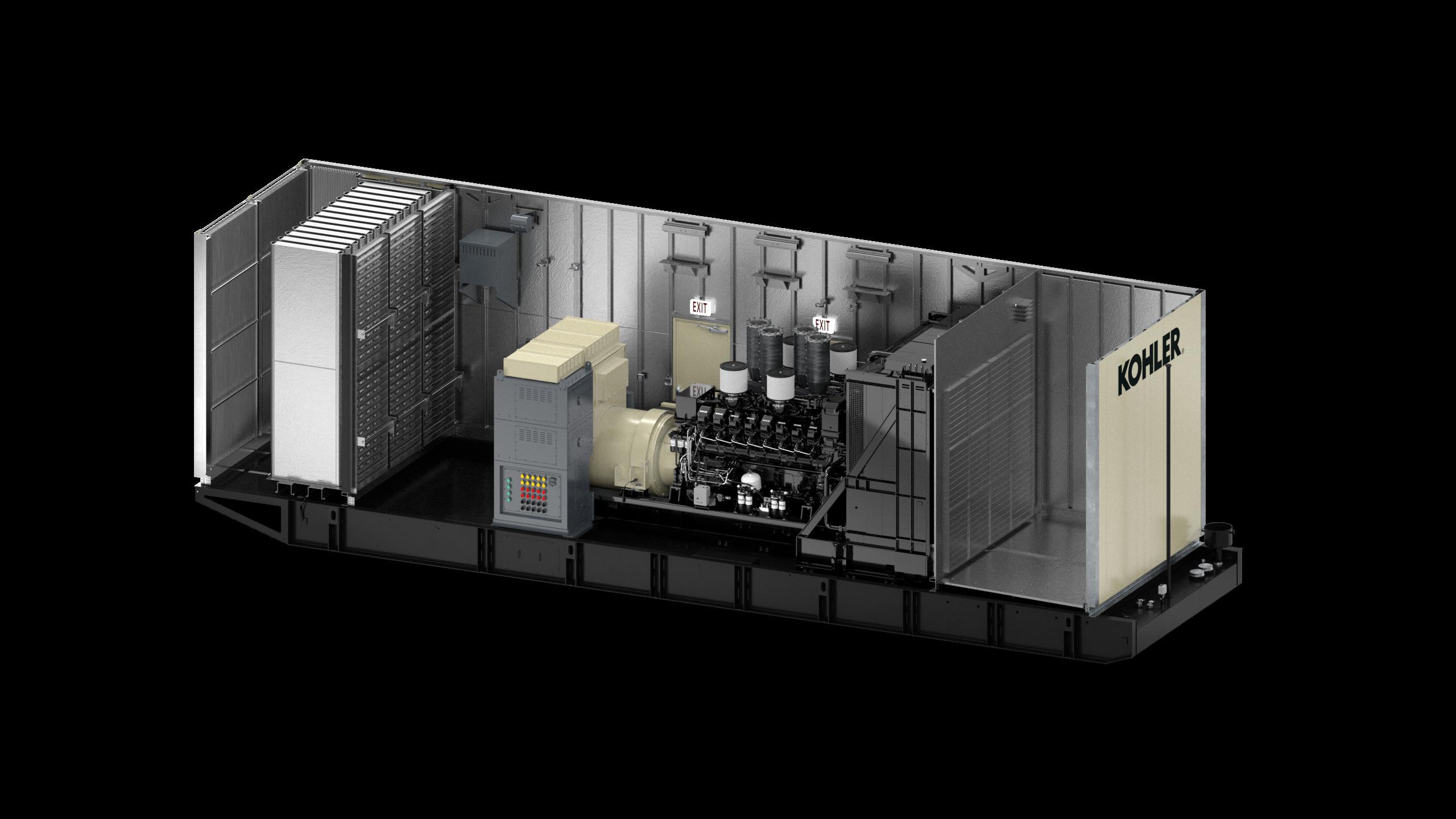

By Ross Kirschbaum

Within water and wastewater treatment plants (WWTPs) are critical power electrical systems, such as generators that provide backup power during grid outages. But, how do engineers correctly size generators for water applications, while meeting all applicable codes and standards? Also, how do they meet other criteria such as minimizing noise and emissions? These factors all need careful consideration when specifying a generator to ensure reliable and sustainable operation over the long term.

To answer those questions, we first

need to understand different types of loads. Water facilities have dynamic electrical loads that impact generator sizing. The single largest load and starting method drives the minimum electrical requirements for motor starting and corresponding alternator selection for the standby generator. Generator manufacturers offer multiple alternators on a single model to provide an oversized alternator when electrical loads have high motor starting requirements.

Overall minimum or maximum load requirements can impact the longevity of the equipment. Diesel engines run-

continued overleaf…

ning at low loads (less than 35% of the nameplate rating) for extended periods may experience performance issues when not maintained properly.

Failure to perform routine maintenance can cause excessive moisture in the oil, leading to scoring or glazing of the cylinder walls and excessive soot and unburnt fuel in the overhead assembly and exhaust piping, which is known as “wet stacking.”

Minimally loading gas generators can also be an issue.

Another crucial factor to consider is the maximum average load factor. This is different from a generator’s electrical power factor. The load factor is the average percentage of loading applied to a generator. The average load factor is defined in ISO 8528-1.

pump stations, must also adhere to the latest Canadian emissions standards.

Another factor that may impact the overall size of the generator equipment is the desired power quality performance or acceptable voltage and frequency dips and time to recover. Highly inductive or capacitive loads may present a significant challenge to a generator compared to an “infinite” utility source.

There is a difference in transient performance between diesel and gaseous generators, and ISO 8528-5 defines three class type standards (G1/G2/G3) that generator manufacturers use for each fuel type. Water applications often demand more stringent performance, which stems from large motor starting requirements.

A transition is taking place in some areas, where less utility-scale generation is being produced and there are increasing power demands on the infrastructure. Utility companies are now incentivizing end-users to install equipment that can operate at any time to counter demand or potentially even return surplus power to the grid.

Larger water facilities with substantial megawatt (MW) installation bases are considering moving from emergency standby (Tier 2 or Tier 3) to Tier 4 certified engine generators required for operation in non-emergency applications. Any mobile (non-stationary) generators, commonly seen at treatment plants and

Incentives are offered by utilities for these peak shaving, curtailment, or demand response programs. Utility companies are even providing the equipment themselves on behalf of an end-user in instances for flexibility to control equipment operation times and reduce grid power demand for improved stability.

Understanding Tier 4 applications requires additional exhaust after-treatment components driving complexity with diesel oxidizing catalysts, selective catalytic reduction, and/or diesel particulate filters.

The starting sequence of loads or load set management is important in balancing the starting and running loads and sizing the generator properly. As referenced earlier, the single largest load and starting method will drive the required starting kilovolt-amps to select the correct alternator to use for a specific generator model.

Therefore, we must ask specific questions to understand the application and sequence of steps. For example, how many loads are considered emergency or life safety loads? Are line-input filters required to reduce line harmonics? How is the starting sequence initiated (e.g., SCADA System, ATS, VFD Master Control, or other)? These questions, and others, can help optimize load management as required.

The starting method for a motor is also a significant factor in ensuring an appropriately sized generator. A reduced start method like a soft-start, VFD, or wyedelta may be more cost-effective than up-sizing a generator to handle the large instantaneous load in a worst-case acrossthe-line start (ALS). In many cases with an ALS, any high horsepower motor will require such an oversized alternator, or it will not work with the generator model sized for the running loads.

A reduced voltage starting method decreases the size of equipment. Input filtering or a higher quality VFDs (18-pulse vs. 6-pulse) can mitigate overall harmonics on the alternator, reducing equipment size. Typically, ensuring less than 10 – 12% total harmonic distortion (THD) ensures the VFD will stay engaged, but design engineers should reference and specify required power quality characteristics to avoid the VFD disengaging.

Non-linear loads can drive larger alternators within the system to manage harmonic distortion of the waveform. Non-linear loads create harmonics (i.e., current harmonics). Depending on its characteristics, an alternator simply enhances or mitigates the voltage distortion (i.e., voltage harmonics) at its output terminals.

Several alternator features can be specified to mitigate harmonics. For instance,

an alternator with lower sub-transient reactance will produce less voltage harmonics. Meanwhile, Class H insulation offers better “cushion” than Class F insulation against overheating, and a lower alternator temperature rise reduces the chances of overheating.

For water applications, current sizing needs are often compared to potential future state scenarios. Increased power demands are usually a direct result of projected population growth and the need for larger facilities. The focus is to understand optimal-sized equipment requirements and standardize generator models in multiple scenarios to allow modular plug-and-play for future equipment to address growth. This provides for commonality of parts, identical service requirements, and familiarity with the same footprints.

There are many benefits when connecting multiple generators to act as a larger power source, including redundancy, efficiency, different kW size generators, diesel and gas combinations, and value and scalability. However, a few items to be aware of are space constraints for the multiple generator systems, more complex operations & maintenance, and additional complexity in the overall control system.

Considerations must be made for low versus medium voltage generation on larger projects. When generating at 5kV or 15kV class, it must be decided whether to have a disconnect at the generator or in a switchboard panel. This can be a fused disconnect or a medium voltage breaker; however, both are large gear sections and drive custom packaging inside the generator enclosure.

Medium voltage automatic transfer switch (ATS) requirements can increase packaging footprint. Manufacturer assistance early in the design phase can address physical size, footprint, and power delivery voltage variances, clearly outlining low or medium voltage advantages and disadvantages. Medium voltage applications require a decision about where to locate and wire a fused disconnect (when desired) and a potential neutral grounding resistor (NGR), as well as determining if it should be arc-resistant and required

withstand ratings.

Additionally, the human-machine interface (HMI) monitors and protects the engine and alternator. A controller with UL 6200 is the latest standard for generator controls and may allow for removing the line circuit breaker on the generator, protecting against overcurrent conditions. It can also act as an energy reduction maintenance mode switching

device, as now required by the latest code standards.

Finally, a breaker-free generator with a UL 6200 controller can facilitate short-circuit selective coordination.

Ross Kirschbaum is with Rehlko. Email: ross.kirschbaum@rehlko.com

By ES&E Staff

The City of Winnipeg is celebrating two recent announcements, as local officials were approved for $150 million in federal funding towards phase two of upgrading the North End Water Pollution Control Centre, as well as $1.2 million from the Canada Water Agency to combat harmful algal blooms.

The wastewater treatment plant funding is over four years, starting in 20262027 as part of a 10-year agreement between Manitoba and the federal government for $209.8 million under the Canada Housing Infrastructure Fund (CHIF), which will also cover other drinking water, wastewater, stormwater, and solid waste projects in the city. An additional $16 million of funding for the North End upgrades will come from a provincial stream for a total of $166 million for the facility commissioned in 1937.

Phase 2 upgrades involve the construction of a new facility to turn wastewater sludge into biosolids, which will cost more than $1 billion, according to local officials. The biosolids facilities upgrade project will be led by Red River Biosolids Partners General Partnership, a consortium comprised of Aecon Group Inc., Oscar Renda Contracting of Canada Inc. (a subsidiary of Southland Holdings Inc.), and MWH Constructors Canada Ltd., of which Aecon is the lead partner and holds a 33.3% interest.

Stantec is leading the design of the biosolids facility project alongside Hatch Engineering.

Current estimates for all three phases of the North End upgrades are approximately $3 billion, with a completion deadline of 2030. That means that Winnipeg still requires upwards of $500 million to round out phase two funding for the facility upgrade. There is no funding for the final phase at this juncture.

Major upgrades at the North End Sewage Treatment Plant include a new facility to process biosolids, a new facility to remove nitrogen and phosphorus from wastewater, as well as a new power substation and new headworks facility. Credit: City of Winnipeg

The North End WWTP provides 70% of Winnipeg’s wastewater treatment. The three major upgrades include a new facility to process biosolids, a new facility to remove nitrogen and phosphorus from wastewater, as well as a new power substation and new headworks facility.

“This agreement is a significant step toward ensuring we have the wastewater capacity needed to support more homes, more jobs, and a growing population,” announced Winnipeg Mayor Scott Gillingham, who called the upgrades project the “most complicated capital infrastructure project in our city’s 150-year history.”

The Canada Water Agency is investing $1.2 million in several Winnipeg-area projects to address challenges related to algae blooms caused by the presence of excess phosphorous.

The projects funded include:

• $450,000 for Grand Council Treaty #3 to participate in collaborative processes and actions to reduce phosphorus, as

well as coordinate community engagement on nutrients and algae blooms in Lake of the Woods.

• $395,000 for the Lake of the Woods Water Sustainability Foundation to develop a phosphorus management plan for the Rainy River — Lake of the Woods Watershed.

• $380,800 for Trent University to study phosphorous sources and nutrient interactions.

• $24,150 for the Métis Nation of Ontario to continue engagement with the northwestern Ontario Métis community to foster collaboration, participation, and capacity building on phosphorus reduction actions and nutrient and algae science in the Lake of the Woods Basin. The funding is over four years for the partner-led projects through the Lake of the Woods Freshwater Ecosystem Initiative under the federal Freshwater Action Plan.

For more information, email: editor@esemag.com

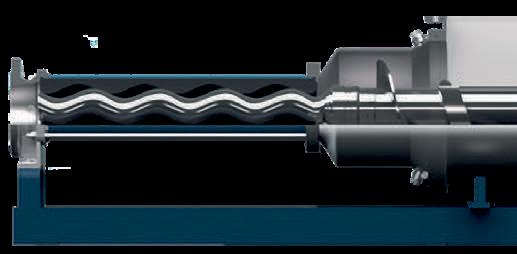

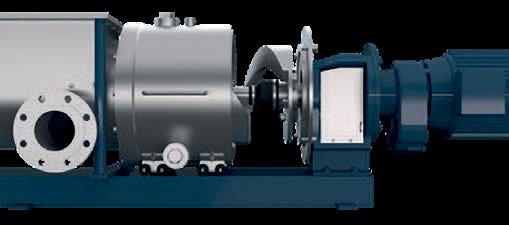

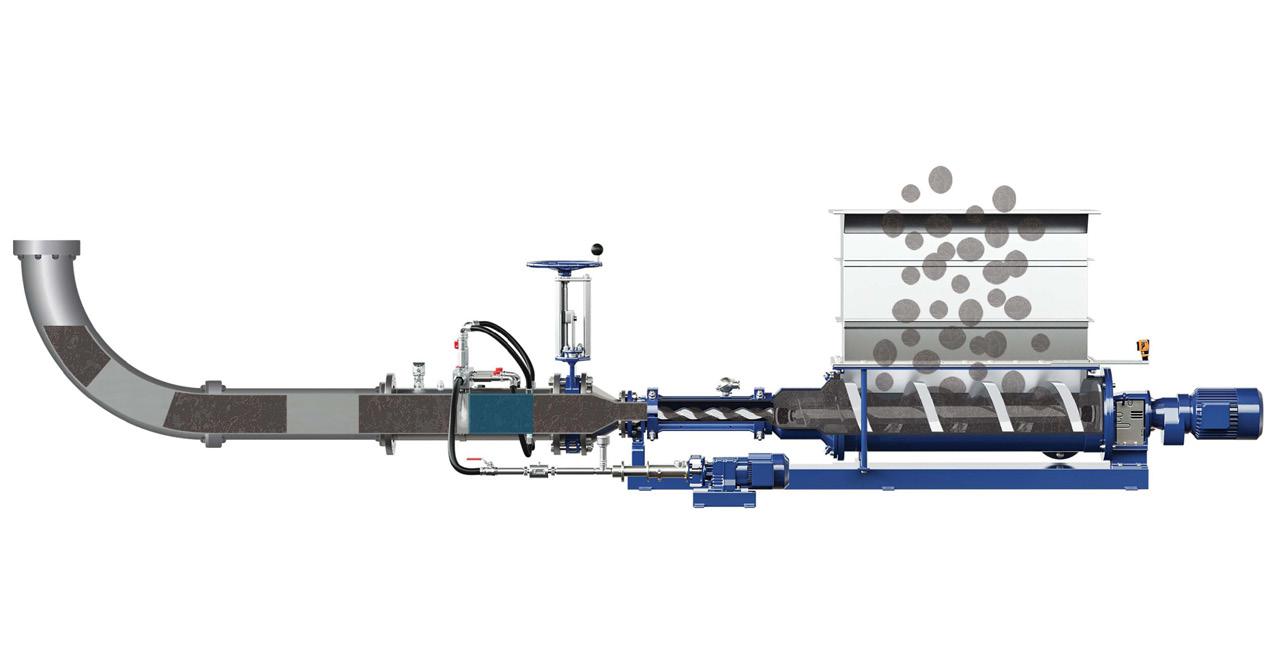

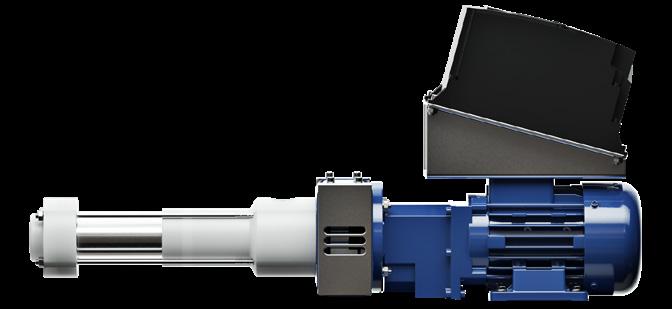

At SEEPEX, we make cake conveying a piece of cake! Our open hopper progressive cavity pumps are designed to handle highly viscous, non-flowable products with high dry solids content, like dewatered cake. Unlike traditional large pumps, which require cumbersome maintenance and disassembly, SEEPEX solutions streamline your operations for greater efficiency.

SEEPEX’s Drive Joint Access (DJA) and Rotor Joint Access (RJA) transform maintenance for large hopper pumps. The innovative RJA enables easy access to the rotor-side joint without dismantling the pressure branch or stator, minimizing downtime. Similarly, the DJA allows quick access to the drive-side joint without the need to remove pipework or other components, enhancing efficiency.

For long-distance cake conveyance, the Smart Air Injection (SAI) system revolutionizes the way we tackle energy-intensive processes, efficiently transporting cake over distances of up to 1,000 meters

SEEPEX is your dependable partner, delivering effortless, reliable, and highly efficient solutions for cake pumping. Scan to start!

By ES&E Staff

Arecent Swedish study is warning of increased bladder and colorectal cancer risks from trihalomethanes (THMs). It says that disinfecting water with chlorine creates these chemical byproducts that can increase the risk of bladder cancer by 33% and colorectal cancer by 15%.

THMs are made up of four compounds: chloroform, bromodichloromethane, dibromochloromethane and bromoform.

Total THMs is the sum of the four THM species, of which chloroform is most often found at the highest concentration in drinking water.

In Canada, the MAC for THMs has been 0.100 mg/L (or 100 parts per billion). In its consultation, which ended on April 14, Health Canada proposed

Health Canada notes that health risks from disinfection byproducts, including THMs, “are much less” than the risks from consuming water that has not been disinfected.

Credit: oasisamuel, stock.adobe.com

maintaining that value.

In the recent study, connected to Sweden’s Karolinska Institutet, researchers found that elevated cancer risks can

occur with THM levels as low as 40 parts per billion.

“Given the potential health effects of THMs, and the limited information on the risks and uncertainties of other chlorinated, brominated and iodinated disinfection by-products, it is recommended that treatment plants strive to maintain THM levels as low as reasonably achievable,” Health Canada advised in its recent consultation document.

Health Canada goes on to note that health risks from disinfection byproducts, including THMs, “are much less” than the risks from consuming water that has not been disinfected. “Therefore, efforts to manage THM levels in drinking water must not compromise the effectiveness of water disinfection,” the department adds.

In 2008, Health Canada convened an expert panel to review the reproductive and developmental toxicity associated specifically with one of the THM compounds known as bromodichloromethane or BDCM.

The panel found that the evidence from epidemiological studies to be inconsistent to support an association between adverse reproductive and developmental effects.

For more information, email: editor@esemag.com

With over two decades of installed experience at more than 100 facilities worldwide, Nereda® technology is the One and Only true aerobic granular sludge on the market today.

Since its introduction to the U.S. and Canada in 2017, more than 40 AquaNereda® plants are currently in design, under construction or in operation throughout North America.

Consultants and end-users continue to realize the process and cost saving benefits associated with AquaNereda technology through on-site pilot testing, installation visits and technical seminars.

ADVANTAGES OF AQUANEREDA ® TRUE AGS TECHNOLOGY:

• Design MLSS of 8,000 mg/l greatly reduces footprint

• Capable of enhanced nutrient removal

• Suitable for retrofits and greenfield sites

• Exceptional effluent without chemical addition

• Robust process that adapts to changing conditions

• Applicable for municipal and industrial waste streams

• Significantly less construction cost compared to conventional treatment

• Energy and chemical savings results in lowest cost of ownership

Represented by:

www.acg-envirocan.ca sales@acg-envirocan.ca

By Lloyd Hipel

Conserving water ensures that more is available to meet the consumption demands of growing populations. It also avoids (or at a minimum, defers) building expensive infrastructure to treat and distribute more water and/or to access more distant water sources. This is of significant concern to areas that rely on limited groundwater supplies to serve their populations. In Ontario, there are several excellent municipal water conservation programs that industrial, commercial, and institutional (ICI) facilities can take advantage of.

These programs essentially “pay” ICI facilities to conserve water through capacity buyback programs, free water audits, access to co-funding, etc., as these approaches are less expensive than building new infrastructure to free up water supplies .

For ICI facilities, conserving water is a way to save money while demonstrating environmental stewardship. It also protects profit margins as water rates continue to increase at a pace faster than the rate of inflation in many jurisdictions in Ontario and throughout Canada. Furthermore, it reduces the facility’s demand on local water resources, freeing up capacity for additional users in growing communities.

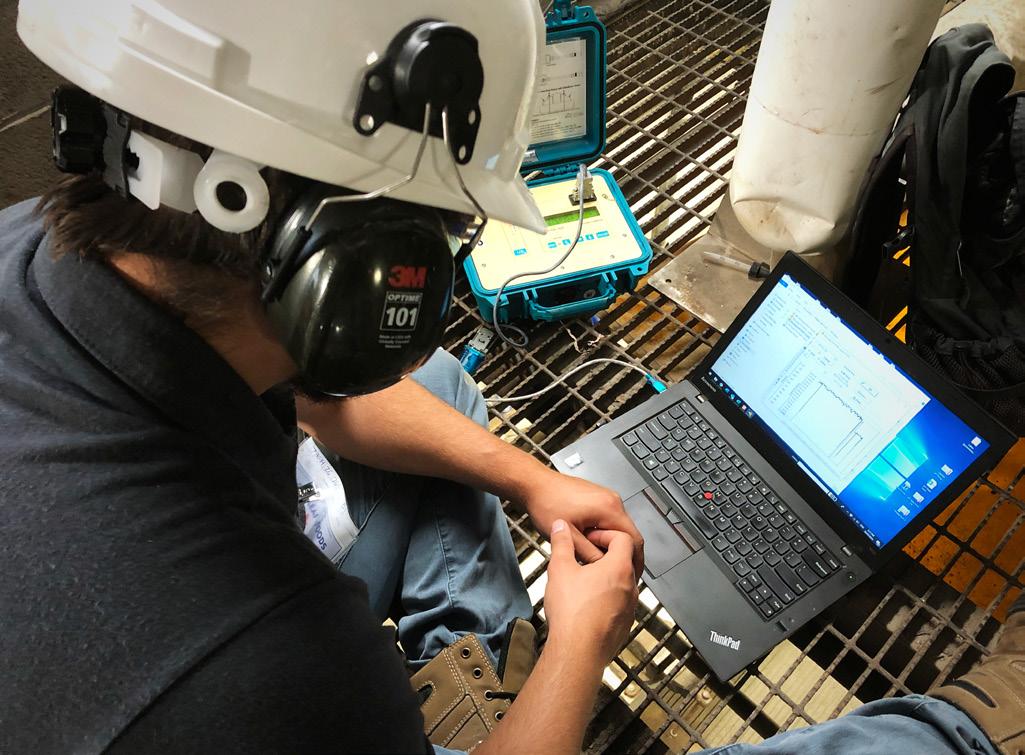

At Enviro-Stewards, we divide our methodology for a water audit into three main categories: assess, implement and monitor.

The first step in the assess phase is to establish baseline water consumption. This can be done by analyzing monthly utility data, or reviewing recorded daily watermain and sub-meter readings.

However, our approach is to also install meters (either permanent or clamp-on) on the incoming water main and major water-consuming processes to get minute-by-minute water consumption data. Since monthly water consumption often appears consistent, identifying inefficiencies, except in cases of extreme anomalies, can be challenging. Daily meter readings are helpful, but again they don’t always provide the required resolution to notice excessive water use.

Recording hourly or even minute-by-minute water consumption, however, provides excellent resolution into daily (and nightly) water consumption patterns that can help unlock efficiency opportunities.

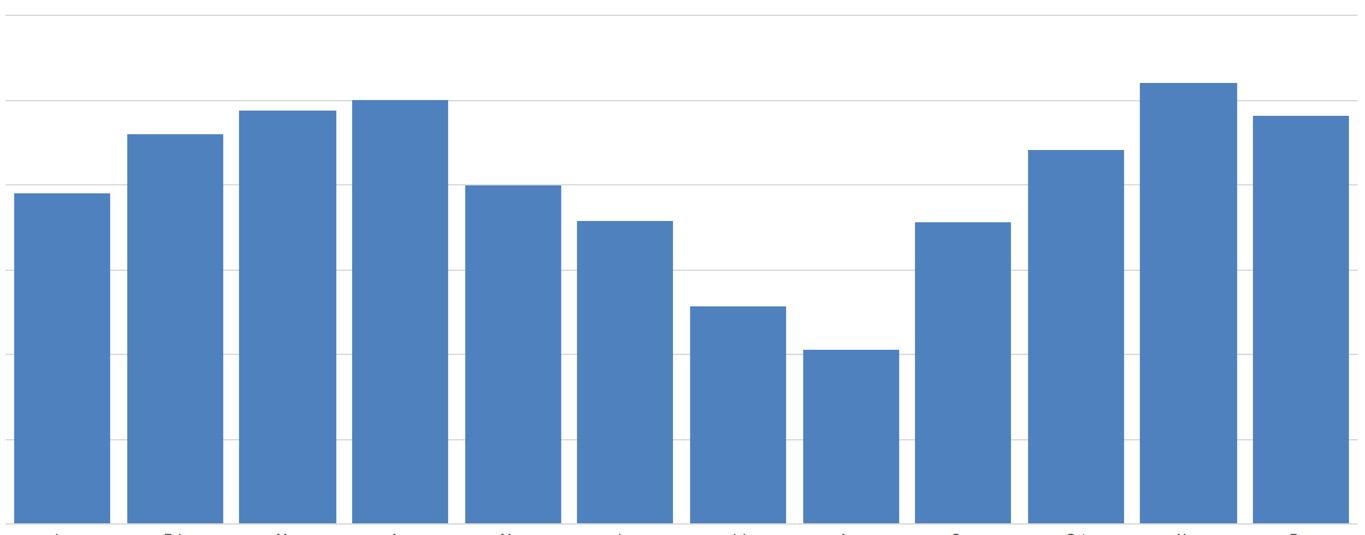

Figure 1 shows monthly water consumption for a facility. From the graph, we can observe some seasonal variations and determine the maximum and minimum water consumption by month. However, beyond that, we don’t have insight into 24-hour, hourly, or per-minute flow rates to delineate consumption patterns.

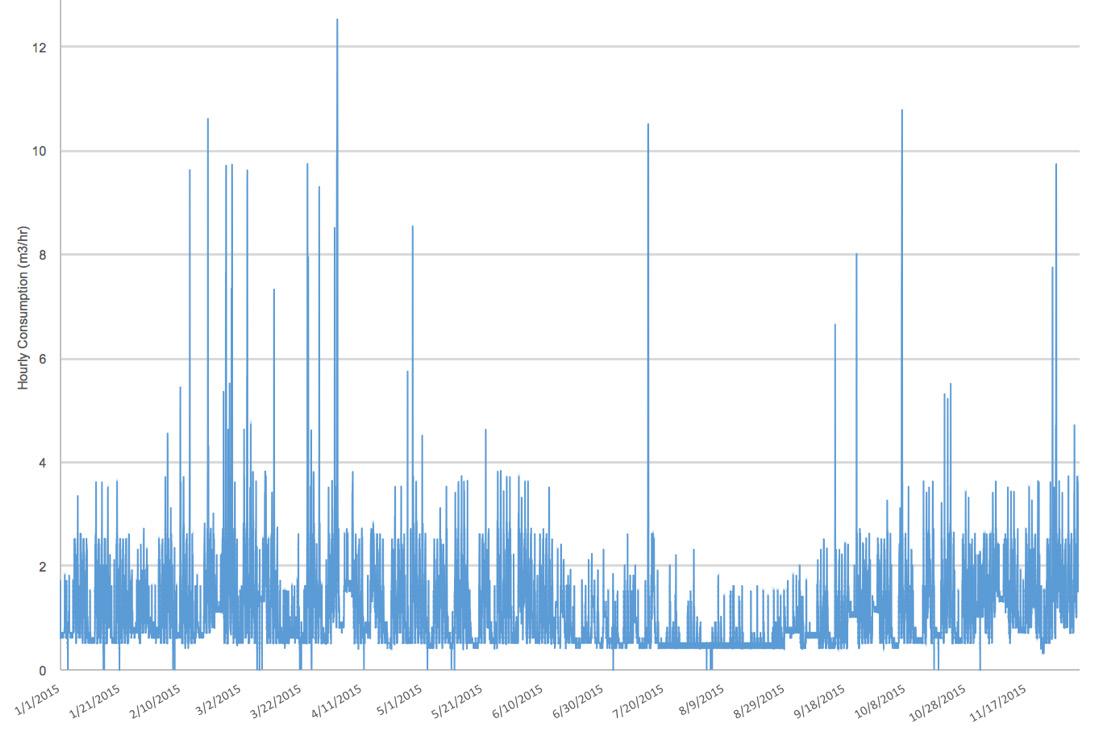

However, by analyzing even hourly readings we can begin to identify consumption patterns. For example, the constant anomalous water consumption that can be seen in Figure 2

Recording hourly, or even minute-by-minute, water consumption provides excellent resolution into patterns that can help unlock efficiency opportunities.

(represented by the red line) would have been “hidden” in the monthly consumption chart. Without knowing this background consumption is occurring, you wouldn’t begin to investigate it and implement measures to eliminate (or reduce) it.

Once the detailed hourly or per-minute metering data is collected and analyzed, it needs to be organized to know what to tackle first. To do this, we develop a facility-wide water balance in a Pareto chart format, like the simplified one in Figure 3.

In this example, you want to focus your attention on processes A and B first, because they represent 75% of this facility’s total water consumption. This makes sure that you focus on what matters most so that the time and effort invested in the water audit will have the most significant impact.

Once you have your water balance and have selected the top water consumers, you can begin investigating opportunities to reduce or eliminate water use for each component of the water balance (starting with the largest consumers from your Pareto chart or table).

It is advisable to ask “what job is the water solving for us?” to identify creative conservation measures. Opportunities to eliminate or reduce water use are typically low- to no-cost and simplest to implement. Reuse opportunities may require more investigation and/or capital investment.

Identified opportunities are then listed in a table with a description of the opportunity, potential water and dollar savings, estimated capital and operating costs, and projected financial return (such as straight-line payback, net present value, etc.). Your team can then determine how to prioritize the opportunities based on financial considerations (which

will yield the most significant dollar savings and quickest payback) or environmental considerations (which ones will save the most water).

A quote commonly attributed to Thomas Edison puts it bluntly: “Vision without execution is just hallucination.” In other words, the opportunities identified in a water audit report (that provide the mathematical numbers for water savings) remain theoretical if they aren’t implemented.

As such, the list of opportunities should also lay out an implementation sequence/ schedule and assign a person to each conservation measure who will be responsible for guiding it through to completion. Many good intentions to implement water conservation measures have been buried under short-term but pressing issues such as production issues, staff turnover, compliance audits, among many others.

As such, developing an implementation team and pre-booking regular meeting times in schedules (that can be shifted if other priorities arise that day) can keep the overall momentum going.

As water conservation measures are implemented, it is important to continue metering to ensure that the projected savings are being realized. We have developed a system called Stewwi (System for Tracking Energy, Water, and Waste Improvements) that is implemented during the assess stage to help quantify baselines, and which can then track savings post implementation.

In the energy conservation world, this type of solution is called an Energy Management Information System (EMIS), into which you could easily incorporate water. The advantages of incorporating water consumption into an EMIS include consolidating utility consumption data into one “dashboard” (along with electricity and natural gas consumption, for example), and alerting users when there is anomalous consumption.

Data can be accessed whether you’re on or off site, new water conservation opportunities can be discovered, and visual figures and tables can be generated at the touch of a button to verify your

Once the detailed hourly or per minute metering data is collected and analyzed, it needs to be organized to know what to tackle first. To do this, we develop a facility-wide water balance in a Pareto chart format, like the simplified one in Figure 3.

gains relative to your savings goal(s). Other monitoring methods can include installing sub-meters or visual

checks of the implemented measures (e.g., confirming that a repaired valve is continued overleaf…

In this example, you want to focus your attention on processes A and B first, because they represent 75% of this facility’s total water consumption. This makes sure that you focus on what matters most so that the time and that effort invested in the water audit will have the most significant impact.

Once you have your water balance and have selected the top water consumers, you can begin investigating opportunities to reduce or eliminate water use for each component of the water

no longer leaking or that a rotameter to control flow rate has been installed).

Arla Foods participated in York Region’s Water Use and Wastewater Quality Consultation and Capacity Buyback Incentive Program, which found opportunities to reduce the facility’s water consumption by 32%. By implementing measures like replacing spray nozzles with more efficient ones and implementing water recovery systems, this equated to a financial savings of $143,000 per year.

As an example of the benefits of ongoing monitoring post-implementation, we were able to work with Farm Fresh Poultry to identify close to $3,000 per month of unneeded constant water use due to malfunctioning components of their cooling tower system. Once repaired, consumption was observed to return to normal baseline values.

Following a detailed water audit of another industrial facility, follow-on flow monitoring identified a baseline water use over the weekends (when there was no production), of approximately 60 litres-per-minute (LMP) on Sunday (see Figure 4).

However, between the final sanitation shift on Saturday and the start of production on Monday morning, there should

not have been any water consumption.

To more easily identify the source(s) of the anomalous water use, a team conducted a detailed walkthrough on a Sunday, when there were no production or sanitation activities. They installed a clamp-on ultrasonic flow meter on the main meter to record minute-by-minute flow data throughout the duration of the investigation. The initial baseline water flow recorded by the ultrasonic flow meter was 60 litres-per-minute (LPM).

During the investigation, five major areas of water losses were identified throughout the facility. These included water flow due to a back-pressure valve, a faulty level sensor in a water tank, a leaking water pipe, cooling water overflow, and a valve that was left open by accident. None of this water was required on a Sunday and most of this water was not required during the week.

Once the major areas of water loss were identified and addressed, the baseline flow was reduced to almost zero. The implemented measures from this single day of investigation are projected to save 32,000 m3/yr of water and 75,000 m3 per year of natural gas ($175,000 per year).

To maintain these savings, the facility will continue closely monitoring its water use to make sure the weekend baseline does not creep up. If weekend water con-

sumption does increase, another water assessment can be conducted to find and fix the root cause(s) of the excessive water consumption.

The One Water concept views all water (potable, stormwater, sanitary, etc.) as a single unified resource. For example, wastewater can potentially be part of a circular economy, where it can be reused as process water in industrial facilities. The One Water outlook also helps us to find opportunities for climate resilience and low-impact design measures in the face of droughts, torrential rain, urban growth, and climate change.

One technology that we’ve implemented at our head office is a blue roof, which retains rainwater to allow it to slowly drain to the municipal stormwater system. This low-impact design aspect can help alleviate flooding during extreme rain events.

In addition to stormwater retention, the blue roof also incorporates other One Water benefits such as water reuse, where stored water can be reused for flushing toilets and/or irrigation. An additional benefit is that the stored water provides evaporative cooling for buildings during summer months, which reduces energy use for air conditioners.

We call our blue roof design an Affordable Smart Blue Roof (ASBR) because it uses conventional roof materials and integrates various technologies to automatically control water storage levels, track the volume of conserved water and energy, detect leaks, irrigate our living wall, flush our office toilets, and can be operated remotely.

Many manufacturing facilities pay a surcharge fee to their municipality because the facility’s effluent concentrations of certain chemical or biological parameters exceed the sewer-use bylaw threshold. In such cases, facilities may be reluctant to participate in a water audit because a reduction in water volume will lead to an increase in parameter concentrations and potentially increase surcharge fees.

To alleviate this concern, we’ve successfully incorporated a pollution prevention (P2) component into the water audit. P2

was observed to return to normal baseline values.

Following a detailed water audit of another industrial facility, follow-on flow monitoring identified a baseline water use over the weekends (when there was no production), of approximately 60 litres-per-minute (LMP) on Sunday (see Figure 4)

is the use of processes or practices that avoid or minimize the creation of pollutants or waste at source. Thus, as part of a water audit we would also conduct a concurrent P2 investigation to find ways to reduce the effluent loading at source before it enters the drain and ultimately discharges to the sanitary sewer.

For example, a first rinse of a vessel containing ingredient residue can be diverted to animal feed (or potentially to reuse for liquid products) instead of being flushed down the drain. Similarly, dry scraping the residue before cleaning activities can significantly reduce the amount going to the sewer. This decreases the chemical or biological parameter concentration(s) of the effluent.

Furthermore, we can often demonstrate that even without the implementation of the P2 practices, the water savings are financially greater than the increase in the surcharge amount, resulting in an overall net dollar savings.

Municipalities disclose the formula they use to calculate the surcharge amount.

0:001:002:003:004:005:006:007:008:009:0010:0011:0012:0013:0014:0015:0016:0017:0018:0019:0020:0021:0022:0023:00

when there was no production.

However, between the final sanitation shift on Saturday and the start of production on Monday morning, there should not have been any water consumption.

Thus, we can use this formula to calculate various scenarios to demonstrate the net financial savings achievable (assuming a 5%, 15%, 25%, etc., reduction in water use) following implementation of the measures identified during the water audit.

To more easily identify the source(s) of the anomalous water use, a team conducted a detailed walkthrough on a Saturday, when there were no production or sanitation activities. They installed a clamp-on ultrasonic flow meter on the main meter to record minute-by-minute flow data throughout the duration of the investigation. The initial baseline water flow recorded by the ultrasonic flow meter was 60 litres-per-minute (LPM).

Reducing water use cuts costs for every consumer. However, business owners can also use their water conservation efforts to promote sustainability initiatives to sup-

pliers, customers, and the public. Many companies we have worked with, like Tim Hortons, Dextran, Maple Lodge Farms, Maple Leaf Foods, and Bimbo Canada (among others) have won Clean50 awards as a result of their sustainability efforts, which included water conservation and other initiatives, such as energy efficiency and food waste prevention.

During the investigation, five major areas of water losses were identified throughout the facility. These included water flow due to a back-pressure valve, a faulty level sensor in a water tank, a leaking water pipe, cooling water overflow, and a valve that was left open by accident. None of this water was required on a Sunday and most of this water was not required during the week, either

Lloyd Hipel is with Enviro-Stewards Inc. Email: lhipel@enviro-stewards.com

Once the major areas of water loss were identified and addressed, the baseline flow was reduced to almost zero. The implemented measures from this single day of investigation are projected to

By Christopher Oyler

Land surveyors play an essential role in large infrastructure projects like the Gordie Howe International Bridge (GHIB) in Windsor, Ontario, providing precise measurements, mapping, and data analysis.

Control points, which serve as reference coordinates, allow surveyors to accurately position elements on the construction site. Their work ensures the project adheres to design specifications and regulatory standards, minimizing risks. The services of an Ontario Land Surveyor act as an insurance policy based on the control point network, ensuring that project owners receive tangible value for their investment.

The establishment of a reliable control point network for the GHIB will provide long-term benefits, extending beyond the initial public works phase and continuing into the actual construction and post construction of the bridge.

Before construction begins, surveyors conduct topographical surveys to assess the land’s natural features, elevations, and boundaries. This information enables engineers to design the bridge in harmony with the existing landscape while ensuring compliance with legal boundaries and environmental conditions. Surveyors also identify environmentally sensitive areas, such as water bodies or wetlands, that must be preserved during construction. Additionally, they establish property lines and clarify land ownership to prevent encroachment on private or restricted areas.

One of the first surveying tasks for the Canadian port of entry at the GHIB involved relocating and installing over 4.3 km of natural gas pipeline, constructing a 4 km perimeter access road, and installing new utilities, including water,

sewer, fibre optic, and transmission lines. Surveyors conducted a control survey of a 130-acre site, which served as the base for all construction activity.

As construction progressed, surveyors continuously replaced or relocated control points that were disturbed by the movement of equipment or structural components.

The land surveyors used advanced technology, including Leica robotic total stations, network real-time kinematics GPS, and Leica digital leveling equipment. Strict adherence to proper field procedures was crucial, and all data was processed and adjusted using MicroSurvey’s STAR*NET software. On any given day, there were about 150 control points across the site.

A key to the success of surveying for the GHIB was the principle of redundancy. Redundancy builds confidence in the accuracy of surveyors’ calculations and field measurements over time. Ran-

dom errors caused by small, unavoidable fluctuations due to imperfections in tools, human perception, or environmental conditions, are mitigated by averaging repeated measurements, discarding outliers (extreme values that differ from most other data points in a dataset), and using independent checks. By measuring a point from multiple locations or using different methods, surveyors could identify and correct errors through redundancy.

This redundancy allowed surveyors to quickly and efficiently reestablish control points when they were disrupted by construction, maintaining the accuracy of the control network.

Throughout the construction process, surveyors provided real-time feedback to ensure structures were built according to horizontal and vertical specifications. They also monitored compliance with material tolerances, such as concrete and steel, ensuring construction met design requirements.

The control network was maintained using the aforementioned software. The dataset of observations contained over 1,300 GNSS (Global Navigation Satellite System) and terrestrial observations, 1,497 point-to-point distances, and 4,700 independent measurements. This software helped surveyors adjust instrument specifications, assess the quality of their work, and fine-tune coordinates for use by other contractors on-site. Specific controls were established for the bridge layout, ensuring precise alignment.

For a complex, cross-border project like the GHIB, surveyors played a critical role in ensuring the exact alignment of the bridge span between Canada and the U.S. This involved accounting for factors like the curvature of the Earth and compliance with local regulations.

After the bridge is completed, surveyors will conduct as-built surveys to verify that the structure was built according to plan, ensuring its integrity and safety. They will also engage in long-term monitoring to detect any settlement or structural shifts over time, which is crucial for the ongoing maintenance and safety of the bridge.

Scheduled for completion in 2025, the Gordie Howe International Bridge will connect Windsor, Ontario, to Detroit, Michigan. Spanning 2.5 kilometres and featuring the longest cable-stayed main span in North America at 853 metres, the bridge will accommodate six lanes of traffic and two pedestrian paths.

Christopher Oyler overlooking storage area for equipment and materials.

Establishing the control network for this massive infrastructure project, which spans an international border and straddles a major river, was a significant undertaking, especially given the coordination needed among the numerous subcontractors involved in road building, utility installation, and earthmoving activities.

Christopher Oyler is with Surveyors On Site Inc. For more information, visit: surveyorsonsite.com

By Jeanne Hendrickson

The first and most important thing to consider when comparing disinfection technologies is how effective they are at disabling pathogens, such as cysts, viruses and bacteria. In a water treatment system,

from penetrating the water entirely, rendering it largely ineffective. This may be especially true with industrial wastewater or in systems where public and industrial wastewater are mixed.

Residual disinfection occurs downstream as the disinfectant travels through the distribution system, and only chlorine offers residual disinfection. Ozone and PAA react too quickly, dissipating within minutes of being administered. UV cannot provide any disinfection

cations, particularly for wastewater that is discharged into sensitive bodies of water. This is why it’s important that decision makers have a clear understanding of the demands that will be put on the system,

Ozone is administered as a gas and is a powerful irritant that can damage lungs. While ozone has a distinct smell, the odour is not always strong enough to detect.

Chlorine is also a powerful irritant to lungs, skin and eyes. As such, operators must wear appropriate personal protective equipment (PPE). However, chlorine also has a powerful odour that is immediately noticeable, giving operators ample warning of a leak or spill.

UV light can be harmful to eyes and skin, although the lamps are typically enclosed during operation and rarely pose a threat.

PAA can cause damage to the skin, eyes and lungs. Those handling the chemical should do so in a well-ventilated room and wear appropriate protective gear. It is also corrosive.

Neither ozone nor UV can be overdosed. UV disinfection does not add chemicals and ozone dissipates quickly, breaking down into oxygen within minutes. PAA breaks down into acetic acid, water and oxygen. This makes it safe to treat effluent that is discharged into source water, or other bodies with high levels of organic content. It oxidizes almost instantly, so there is rarely any residual chemical after discharge.

The same is not true for chlorine. While some downstream chlorine is beneficial for its residual disinfection, operators must use precise dosing via

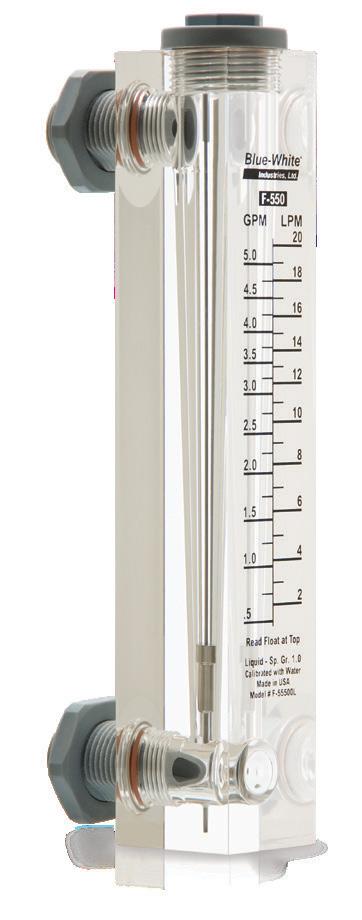

Chemical metering pumps play a critical role in the success of water and wastewater treatment.

advanced chemical metering.

UV systems have a high upfront cost but are often easy and affordable to maintain. They do not require any chemicals, and the only operating cost is electricity and the occasional lamp replacement.

Ozone, which is provided in and administered using compressed gas cannisters, has a moderate upfront cost but is very expensive to run as the gas is difficult to make. PAA is also expensive, and the number of manufacturers and distributors are far fewer. However, as adoption of PAA as a disinfectant is increasing, these factors are likely to change.

Chlorine is the most affordable. Not only is it inexpensive and easy to obtain, but chlorine can be easily dosed using efficient and cost-effective metering pumps. Even when combined with ancillary

equipment such as pH and chlorine analyzers, flow meters, and chlorine level sensors, chemical metering / dosing pumps are often more cost-effective than other disinfection technologies. Advanced features such as maintenance alerts and failure warnings can help ensure that any given pump continues to run effectively for a long time.

One wastewater plant, treating both municipal and industrial wastewater, had been using a UV system to disinfect its effluent. Although this system was in good working order, issues arose due to industrial influent. The plant gets heavy industrial flow, containing a significant number of contaminants. The existing UV system was simply unable to reliably meet mandated disinfection requirements.

It was determined that a chemical disinfection solution was needed. In this case, peracetic acid at 15% solution under minimal pressure was used. This was accomplished by installing a Duplex Skid System equipped with two Blue-White® FLEXFLO® M3 peristaltic metering pumps.

Since the switch, the plant is now experiencing reliable disinfection of wastewater and meeting all regulatory requirements.

Jeanne Hendrickson is with Blue-White: Email: jeanne@bwadvertising.com

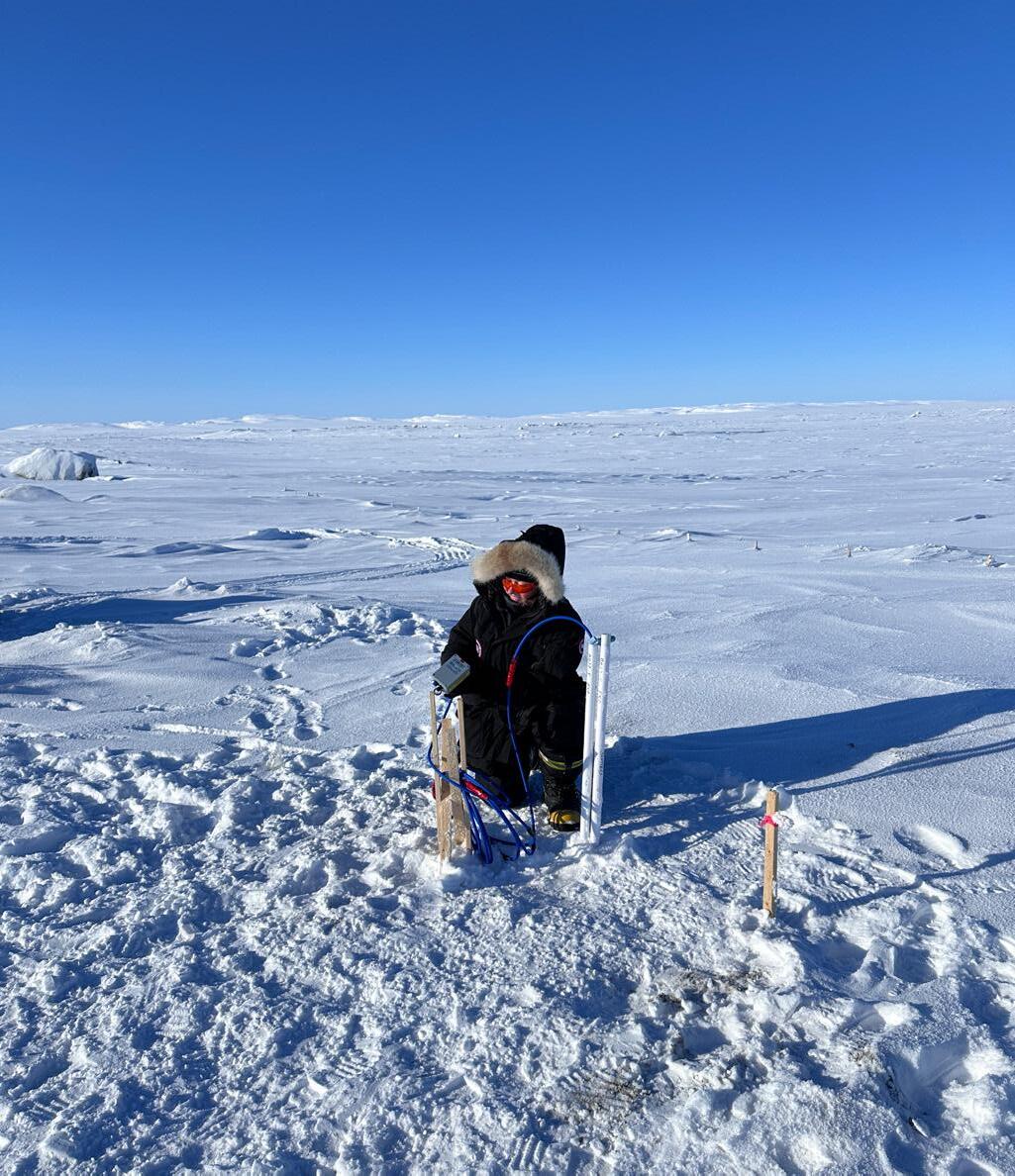

By Renata Klassen

The construction of large containment structures in the Canadian Arctic relies almost exclusively on earth berms for structural support and geomembranes to create low permeability for retention. The use of concrete may be applied to smaller structures, but the design must keep in mind the available quality of concrete prepared in the Arctic.

Earth containment structures in the Arctic may factor in permafrost to provide containment. If permafrost is expected to be preserved once the structure is built, the containment berms may be constructed of saturated, compacted, silty gravel to become part of the permafrost regime upon freeze back and serve as secondary containment.

This is not the case in sewage lagoons where permafrost is expected to degrade because of the heat from the wastewater in the lagoon. The containment berms in sewage lagoons are usually not designed as freeze back structures; however, some freezing in berms takes place over time.

For example, a temperature monitoring system I set up in the sewage lagoon in Kugluktuk, Nunavut, in 2021, and monitored by the Government of Nunavut over three subsequent years suggests that permafrost has aggraded into the perimeter berm, and the ground below the base of the berm is frozen (NTWWA Journal, 2023). This formation of permafrost would enhance the containment by the presence of the perennially frozen ground and suggest low flow condition due to frozen subsurface water. Including ground temperatures in long-term monitoring programs may be a useful tool in performance assessments of sewage lagoons.

National Resources Canada (NRC) defines permafrost (perennially frozen ground) as a state of the ground, soil or rock, that remains at or below a temperature of 0°C for a minimum period of two consecutive winters and the intervening summer. NRC (2025) emphasizes that the definition of permafrost considers only the temperature of the ground, and that permafrost is a strictly thermal phenomenon (not the material) and can exist not only at high latitudes but also high altitudes such as the mountains of western Canada.

Permafrost region in Canada covers about 50% of the country, including all of the Yukon and Northwest Territories (and Nunavut since April 1, 1999) and northern parts of British Columbia, the Prairie provinces, Ontario, Quebec and Labrador (Johnston, 1981).

Ground temperatures are usually measured with thermistor probes on a cable inserted into drilled boreholes. The cables are called ground temperature cables (GTC) because they are

Ground temperature cables (GTC) are installed in pipe casings, which are connected to data loggers. These are then positioned in premanufactured plywood enclosures sized to fit and protect the dataloggers.

intended to measure temperatures in the ground. To ensure that GTCs will reach the desired depth, the boreholes are equipped with pipe casings inserted into the boreholes after drilling. GTCs are then inserted into the casings and either backfilled with sand or left loose in the casings allowing for future replacements. As GTCs alone do not record data, they need to be connected to a reading device to acquire temperatures. A manual method of getting temperatures from GTCs uses a resistance meter connected through a switch box which allows switching between thermistor probe channels. A more sophisticated method includes a datalogger, which when connected to GTCs provides continuous temperature readings according

Optical Fluorescence Dissolved Oxygen

Near Infra Red Total Suspended Solids

pH, ORP

Microwave Density

Ultrasonic Interface Level

Spectrophotometric Online

Multi Parameter Single – Dual – Multi-Channel-Wireless

Ultrasonic Doppler – Transit Time

Insertion/Immersion/Clamp-On

Venture/Flume Partially Filled Conduit

Non Contact Radar

Indoor or Outdoor

Refrigerated or Non-Refrigerated

Portable or Stationary

Integrated Billing System

Fully Automated Control and Data Collection

to programmed frequency.

A ground temperature monitoring system was installed at a new sewage lagoon in Nunavut, completed in 2024, to monitor a defined long-term thermal regime temperature pattern existing in the ground. The lagoon was constructed above permafrost as an impermeable containment structure by lining the reservoir and the earth containment berms with a geosynthetic clay liner (GCL). It will operate as a facultative lagoon system, with a seasonal discharge into a wetland system before ultimately discharging into the ocean. The monitoring locations were determined at the end of the construction by drilling four boreholes on three berms and equipping them with 50-mm diameter casings.

Casings were installed near the top of the berms along the outside crest and reaching below the base of the berms into the berm foundations between about 3.5 m to 6 m. GTCs were inserted into the casings, and then enclosed inside remote data housings with locking caps for protection.

A site visit was completed after the facility was commissioned for the purpose of beginning to collect temperature data at the four monitoring locations. Dataloggers were present on site, ready to be connected to GTCs for continuous data recording. However, the configuration of casings inside the remote data housings did not allow the connected dataloggers to be enclosed, leaving them unprotected. Additional housing space was required to safely initiate the monitoring systems.

The additional space was provided by pre-manufactured plywood enclosures sized to fit and protect the dataloggers. The enclosures were then fastened on top of the remote data housings and secured with a steel cable wire weaved in and out through pre-made openings, tightened with plywood inserts and locked.

The initial manual data collection was completed using a multimeter and a switch box to collect temperatures at the four monitoring locations. Although intended to be redundant, the manual readings helped confirm that one of the GTCs was dislocated inside its casing. Temperatures calculated from the manual resistance readings slightly differed from the ones measured with a datalogger, suggesting the readings were taken at different depths.

A further conclusion was that the GTCs were not backfilled in their casings. Although having an advantage of being replaceable, loose GTCs could be inadvertently lifted during data collection or servicing, or have convective air flow present in the casings. Mitigation of these issues could include installing spacers on GTC cables between the thermistor probes to limit convective air flow and create some friction between the GTC cable and casing wall.

One of the first sets of data logger data collected from the ground temperature monitoring system was completed during a site visit. Data downloaded from the dataloggers provided insight into the ground thermal regime in the berms and their foundations in mid-November at the completion of construction, and confirmed that the monitoring system set-up was working.

assessments of the lagoon performance. It has been stated that an impervious berm structure, such as a dam (Johnston, 1981), is influenced not only by the water temperature on the upstream face but also by the effects of the climate over the remainder of the dam surface and freezing devices. Thawing will penetrate mainly downward only under the reservoir and the upstream slope, and later-

ally into the structure and foundation. As the lagoon continues to operate, the collection of thermistor data will provide insight into the operation of the current site under investigation, and insight for the design of future lagoon systems.

Renata Klassen is with EXP Services Inc. Email: renata.klassen@exp.com

Monitoring Solution with stainless steel pipes for ideal process water conditions and reliable conductivity values to protect your electrolyzer. a sustainable like kayaking. skilled partner, you the right decisions.

The berms have experienced one winter. All the temperatures recorded were below 0°C or slightly below 0°C. The warmest temperatures were about 2 to 3 m below the existing ground surface, irrespective of the berm height. The temperatures of the bottom thermistor beads, located about 8 to 8.5 m below the top of the berms, varied between −5.6°C and −4.0°C.