Using flow data to reduce SSO and CSO conditions

Using flow data to reduce SSO and CSO conditions

Tougher than PVC, its unique layered structure provides three times the impact absorption and prevents crack-propagation. What’s more, Bionax can handle extreme bends and even withstand 100% wall-to-wall crushing that would destroy any other piping system. Now available in larger diameters—up to 30” (750 mm) — Bionax offers enhanced versatility for a wide range of demanding applications.

Optical Fluorescence Dissolved Oxygen

Near Infra Red Total Suspended Solids

pH, ORP

Microwave Density

Ultrasonic Interface Level

Spectrophotometric Online

Ultrasonic Doppler – Transit Time

Insertion/Immersion/Clamp-On

Multi Parameter Single – Dual – Multi-Channel-Wireless

Venture/Flume Partially Filled Conduit

Non Contact Radar

Indoor or Outdoor

Refrigerated or Non-Refrigerated

Portable or Stationary

Integrated Billing System

Fully Automated Control and Data Collection

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Contributing Editor DAVID NESSETH david@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

Archis Ambulkar, Toledo Technology Academy of Engineering

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales Second Class Mail

Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising

Penny Davey

Sales Director 416 807 3812 penny@esemag.com

6 The environmental costs of AI and the digital age — Editorial comment

8 Guelph prepares for new regulations by commissioning a strategic assessment of PFAS in its source water

10 Are we bound to oversize municipal stormwater infrastructure to limit flooding risks?

18 The importance of off-gas testing in determining wastewater treatment GHG emissions

20 Accurate flow data helps operators act quickly and strategically to reduce SSO and CSO conditions

24 Using advanced diagnostic tools for wastewater pump health assessment

41 International research project aims to create utility guidance for smart sewers

42 UBC students win international award for green infrastructure design

43 Vancouver’s Second Narrows Water Supply Tunnel completes construction, begins connections

49 The iceberg we can’t see: Mapping Canada’s hidden chemical threats

51 Ontario makes changes to records of site condition and excess soils

56 Metro Vancouver shifts to phased upgrades for Iona WWTP to reach secondary treatment quicker

60 Alberta endorses four new steps for oil sands water reclamation

62 Expedition 501 confirms vast freshwater supply beneath Atlantic

26 Consultants need to understand how GenAI will impact new engineers — Cover story

32 What major trends will define the Canadian environmental industry in 2026?

34 How science and engineering can create real value from the digital transformation

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6

Tel: (905) 727 4666 www.esemag.com

44 Managing hazardous chemical vapours in storage systems

45 New research could reshape Canada’s drinking water guidelines for uranium

46 Achieving successful dosing of viscous or abrasive chemicals

48 Hope, B.C., invests in wastewater lagoon cleanup after outfall fine

36 Mediation: The preferred dispute resolution technique

38 AI promises gains for engineers, but responsibility remains human

treatment solutions for more than 30 years.

• Archimedes Screw Pumps

•

• Disinfection – UV, Ozone

• Screens – Multi-Rake, Per f Plate, Drum, Travelling Band, Step, Climber, Ver tical Pump Station Screens, Screenings Washer /Compactors

• Grit Separation, Washing & Dewatering

• Conveyors – Shafted & Shaftless Screw, Belt

• Blowers – Rotary Screw, Rotary Lobe, Single Stage and Multistage Centrifugal, Turbo, Integrally Geared, Advance Control, Rebuilds

• Aeration – Sur face, Membrane & Ceramic, Fine & Coarse Bubble, Gas & Liquid Cleaning, DO Control, AlphaMeter

• Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

• Tank Components –

Decanters, Swivel Joints, Telescoping Covers, Watertight Doors

• Primar y & Secondar y, Circular, Chain & Flight, Inclined Plate Settlers, Weir Washing

• Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

• Rotary Lobe Pumps & Grinders

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• CSO, Stormwater & Pump Stations –Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

This issue marks the publication of Environmental Science & Engineering Magazine’s 30th annual focus on challenges, trends and opportunities facing consulting engineers. I would like to thank everyone who has taken the time to write about their observations, concerns and predictions facing their industry.

In particular, I would like to thank Patrick Coleman, PhD, P.Eng., who is a principal wastewater process engineer with Stantec. Year after year, Mr. Coleman takes considerable time to research and share his valued observations on pressing issues with our readers, particularly those involving younger engineers. In his latest article “Consultants need to understand how GenAI will impact new engineers” (page 26) he provides an in-depth look at a fundamental technical development: “Don’t just ask what AI can do for us. Ask what it is doing to our minds,” says Mr. Coleman.

While reading and editing the other articles in this Consultants’ Forum, that also deal with the promises and complexities of embracing AI, I have come to appreciate just how far along this new technology has come and how fast.

During my editing and review process, a couple of articles came into my email inbox, warning of the environmental costs of the expanding digital age, in terms of ever-growing electrical power and cooling water demands. Google estimates that the median Gemini Apps text prompt uses 0.24 watt-hours of energy and consumes 0.26 milliliters (or about five drops) of water, an impact that it says is similar to watching TV for under nine seconds.

While these amounts seem inconsequential, a recent article published by the Center for Secure Water, which is part of the University of Illinois, says Google’s largest data centres, which support major services such as Gmail and Google Drive (seemingly

“legacy” products in the AI boom), can require approximately 2.1 million litres of water per day for both cooling and electrical power generation. Smaller data centres average 68,100 litres per day, which is equivalent to the needs of 4,200 people.

Electrical use by data centres was estimated to be about 415 terawatt hours, or about 1.5% of global electricity consumption in 2024. However, that figure has grown at over 10% per year over the last five years, and is expected to double to around 945 terawatthours by 2030, according to the International Energy Agency, which adds that demand from AI will be the most significant cause of this increase.

The Center for Secure Water article says that despite efforts at increasing efficiency, AI’s global annual water consumption is still projected to reach between 4.2 billion and 6.6 billion cubic metres by 2027. It adds that with the competitive need for resources, many tech companies are strategically positioning their data centres in developing regions where real estate and energy are cheaper. This practice may further strain local water resources, amplifying the water crisis.

However, incorporating climate change considerations in data centre design and operations may help with operational efficiencies, energy and water consumption, build infrastructure resilience, and meet sustainabil-

ity commitments.

Given that data centres need water, power and security, could Canada become a data centre powerhouse? Provinces like Alberta think so. Last year, the government introduced Alberta’s AI Data Centre Strategy, which outlines what the province has to offer. Alberta says its abundant supply of natural gas will allow the scaling up of new power generation, while providing a proven and cost-effective source of energy for AI data centres.

Also, Alberta’s climate offers natural cooling for several months of the year, reducing the need for artificial cooling systems while reducing operational costs. The government also feels that Alberta’s existing water infrastructure will enable AI data centres to reduce both time and costs associated with accessing resources and establishing operations.

Many other areas of Canada also offer these advantages and are currently working to attract AI and other data centres. According to a report released earlier this year by Norton Rose Fulbright, a global law firm, “the government of Canada is showing its commitment to developing AI data centres and plans to invest $2 billion over five years to launch new initiatives that will provide companies and researchers with the tools they need to compete in the global AI data centre race.”

As with every past technical revolution, the fast-evolving digital age has created environmental problems. However, these are not insurmountable and it is clear that AI offers substantial potential in the fields of drug development, medical imaging, forest fire management, etc.

Also, for many ES&E readers, AI will play an increasing role in tackling critical water-related challenges, such as optimizing agricultural irrigation, improving wastewater treatment, and detecting harmful chemicals in drinking water.

Steve Davey is the editor and publisher of ES&E Magazine. Email: steve@esemag.com

In August 2024, Health Canada finalized their Objective for Canadian Drinking Water Quality, Perand Polyflouroalkyl Substances (PFAS). This decreased previous drinking water guidelines for PFAS by an order of magnitude and moved to a class-based approach. This means a value of 30 nanograms per litre (ng/L) for the summed concentrations of 25 specific PFAS.

As a result of these changes, municipalities are now faced with the challenge of understanding what the potential PFAS impacts are in source water and how to manage the changing guidelines.

The challenge of PFAS stems from the widespread use of these persistent chemicals in manufacturing over the past 80 years which has led to their ubiquitous presence in the environment, including source water used for drinking water systems. Provincial public health agencies have acknowledged the presence of PFAS in the environment and the need for exposure reduction measures. However, provincial regulatory frameworks are still evolving to address these substances more comprehensively.

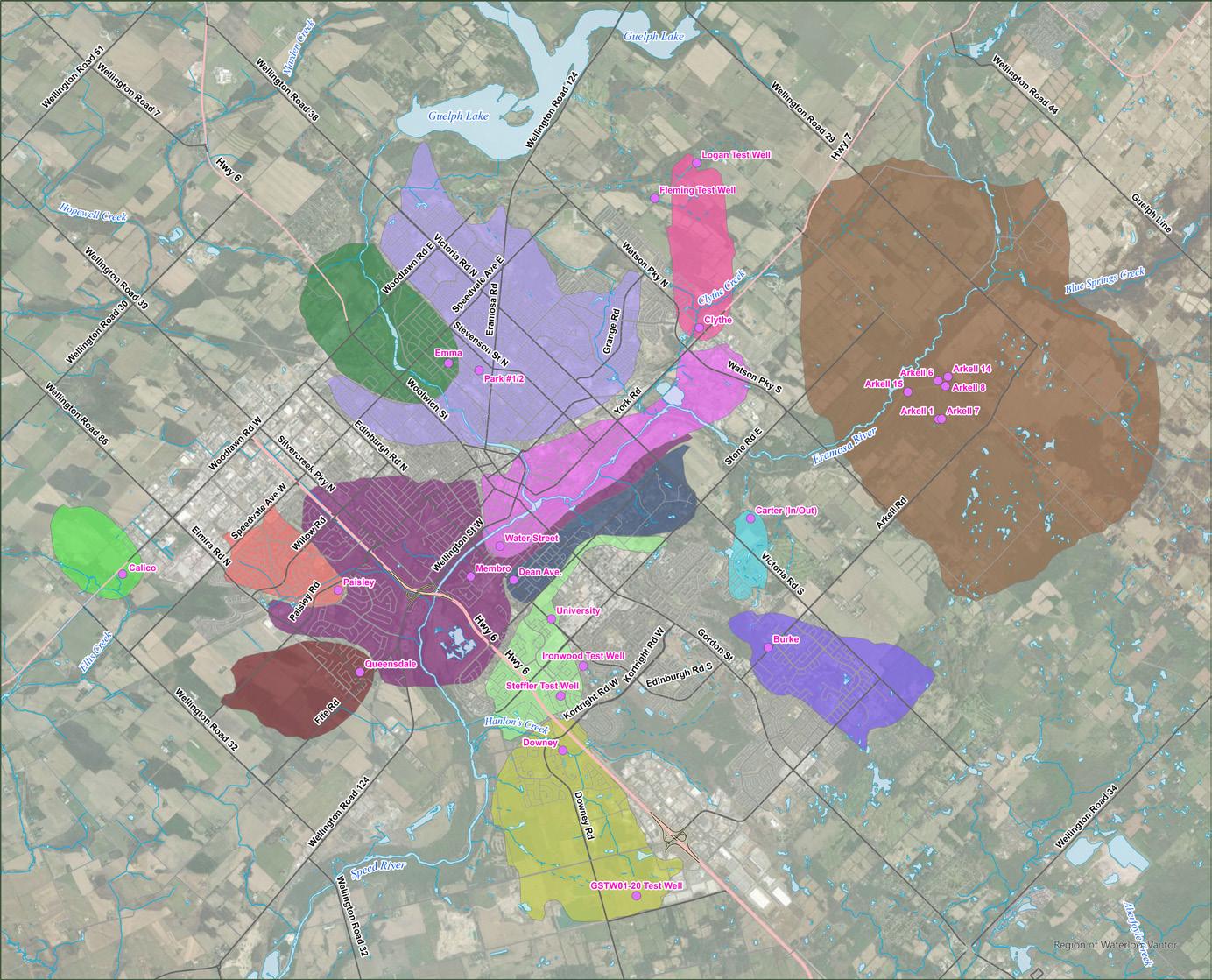

The City of Guelph is the largest Canadian city to depend almost exclusively on groundwater as a drinking water source. Like all other Ontario municipalities, the city ensures safe drinking water by abiding by the Ontario Safe Drinking Water Act (2002) and the Ontario Drinking Water Quality Standards (ODWQS) requirements developed by the Ontario Ministry of Environment, Conservation and Parks (MECP).

To date, PFAS is not regulated in drinking water provincially in Canada and, therefore, is not routinely tested in drinking water in Ontario or other provinces.

In preparing for the future, Guelph recognized the need to understand whether or not PFAS was locally present in groundwater as part of planning for potential capital infrastructure expenditures (i.e., new drinking water treatment facilities). To support proactive risk management and capital planning, the city initiated a screening approach to evaluate whether PFAS concentrations in its source water exceeded federal objectives.

Guelph’s forward-thinking approach included the development of a risk

screening methodology, as well as the development and implementation of a groundwater sampling program. The first step was to adopt a risk screening strategy that aligned with the MECP’s best practices for assessing drinking water quality per the Source Water Protection Program required under the Clean Water Act, 2006

The purpose of the risk screening was to identify priority areas for groundwater sampling. Guelph focused its screening on active Wellhead Protection Areas (WHPAs), as well as projected future water supply areas represented by test wells.

Using Canada’s State of Per- and Polyfluoroalkyl Substances (PFAS) Report and local knowledge, Guelph identified major potential PFAS sources including landfills, wastewater treatment plants,

fire halls, airports, and current and historic manufacturing zones. This effort remained focused on larger, long-term potential sources of PFAS.

Guelph identified risk factors and a ranking system to assign risk criteria to each WHPA and test well area. Areas with more identified PFAS contributing sources that were in closer proximity to the supply or test wells were assigned higher risk rankings.

Additional factors beyond those associated with risk of PFAS impacts were included in the screening process to facilitate prioritizing areas for groundwater sampling. For example, greater prioritization was assigned to areas that were actively suppling drinking water to Guelph, and where monitoring wells screened in the potable aquifer were present and could serve as sampling locations.

A scoring matrix was developed to assess areas by: risk to the water supply; sampling feasibility; and the presence of operational and future test wells. Ultimately, each area was ranked in order of priority for further investigation.

SLR Consulting was engaged to develop and implement a targeted and defensible groundwater sampling and analysis plan (SAP).

Guelph’s monitoring network includes hundreds of wells that have been installed over decades and are screened across various geological formations. SLR conducted a detailed review to identify wells that were screened in the city’s source water formations.

Well construction was also reviewed to understand whether materials used in the wells could serve as a source of PFAS.

A shortlist of wells was identified and then reviewed against Guelph’s risk screening results and the proximity of each well to the supply or test wells. The overall spatial distribution of the shortlisted wells was also considered in the final selection of locations for sampling.

As Ontario does not currently have a regulated standard for PFAS in drinking water, a decision needed to be made regarding what criteria could be applied to support data interpretation. Two useful and useable criteria were identified:

• The federal objective of 30 ng/L to be

compared to the summed concentrations of 25 specific PFAS.

• The Ontario Interim Potable Groundwater Criteria (IPGC) of 70 ng/L to be compared to the summed concentrations of 11 specific PFAS.

To apply these criteria, data for 27 PFAS were needed, along with low detection limits for each PFAS. To meet these requirements, a modified EPA Method 1633 was selected for groundwater sample analysis. This method provided the necessary low detection limits and data for up to 47 PFAS, including the 27 PFAS required to facilitate use of the screening guidelines. Data for this greater number of compounds proved valuable, given the screening exercise aimed to understand vulnerability to PFAS impacts.

Given the unique nature of the sampling program — groundwater sampling for PFAS in deep, historic monitoring wells not typically used for water quality sampling — a custom protocol was developed to facilitate the collection of representative and defensible samples.

The protocol included:

• Guidance to field staff to minimize the potential for cross-contamination of PFAS via specified sampling and handling procedures.

• Instructions regarding well development and sampling requirements to address the challenges associated with sampling deep, historic wells.

• Specifications for collecting quality assurance/quality control (QA/QC) samples to support appropriate data assessment and interpretation.

The sampling program was completed in August 2025. Most of the monitoring wells sampled were below the federal objective and Ontario IPGC. However, there were a few locations with concentrations that were elevated.

Overall, 94% of the well-parameters were non-detects and only 6% of sampling results were elevated and/or indicated potential trends that were identified for continued future monitoring. In such cases, these locations were resampled and, with protocols to facilitate very low turbidity of the sample, such samples resulted in duplicate sample results below the federal objective and Ontario IPGC.

In some locations, elevated concentrations of PFAS are also suspected to be a result of the materials used for well construction (Teflon tape and coated bentonite pellets). A number of wellhead protection areas were unable to be sampled due to the lack of suitable wells screened in the correct formation to serve as sentinel wells for groundwater screening. To allow for assessment of these water sources, the city is working to establish representative test wells for these sources to permit similar PFAS sampling.

Guelph’s proactive approach to PFAS risk management exemplifies how municipalities can prepare for evolving regulations. By leveraging existing data and programs of work, applying strategic screening, and partnering with experts, the city has positioned itself to make informed decisions about its drinking water infrastructure. As PFAS guidelines continue to develop, Guelph’s experience offers a valuable blueprint for other communities navigating similar challenges.

Albanie Douglas is with the City of Guelph. Krista Barfoot is with SLR Consulting. Email: albanie.douglas@guelph.ca, kbarfoot@slrconsulting.com

As urban flooding increases with our changing climate, municipalities and conservation authorities in Ontario are actively assessing surface flooding areas and updating floodplain maps.

Although stormwater engineering has advanced significantly over the past 20 years, outdated Ministry of Natural Resources (MNR) floodline mapping guidelines (Technical Guide for River and Stream Systems: Flooding Hazard Limit, 2002) challenge the recognition of current stormwater management best practices. A key concern is that the 2002 guidelines have not kept pace with advances in floodplain mapping technologies. While suitable for analyzing large rural sub watersheds, many practitioners note that these guidelines fall short in smaller, urbanized areas, often overestimating peak flows. The coarse resolution of existing analyses can lead to overly conservative floodplain limits that restrict development and higher capital costs for larger culverts, flood controls, and stormwater infrastructure.

During the development boom between the 1950s – 1980s, stormwater drainage systems were designed to convey water rapidly away through sewers and roadside ditches, with little consideration for flood control or overland flow management. In many older urban neighbourhoods, once these drainage systems reach capacity (typically sized up to a five-year storm event), areas

Figure 1: The balancing act of floodplain modelling.

may be prone to flooding during intense localized storms due to the lack of design for overland flow pathways and outlets.

By the 1990s, the Ontario Ministry of the Environment, Conservation and Parks (MECP) guidelines and requirements for stormwater management controls expanded to include wet and dry ponds, wetlands, and low impact development (e.g., rain gardens, bioswales, green infrastructure) to mitigate the impact of urbanization by storing excess runoff and reducing peak flow rates.

The updated Stormwater Management Planning and Design Guidelines released in 2003 remain the current standard for stormwater management design. However, the infrastructure identified by the MECP guidelines are not always recognized by conservation authorities in flowline mapping, since they are basing the mapping on the guidelines administered by the MNR.

Floodplain management in Ontario began with began with the 1954 amendments to the Conservation Authorities Act. Over time, floodplain mapping has

advanced from documenting observed high-water levels to using sophisticated modelling techniques. Many maps cre ated in the 1980s relied on early DOSbased hydrologic and hydraulic mod els using total station surveys and coarse topography. Even in the early 2000s, mapping updates were limited to 1D hydraulic modelling that assumed steady-state flow (peak flow constant with time) along the main channel.

Today, hydraulic modelling software integrates GIS tools, enabling the setup of watersheds with both surface and sewer flow components (dual drainage). Models can now simulate steady (1D) or unsteady (2D) flows across channels and tributaries, using detailed topographic data. This allows for much better defi nition of how water moves once it over tops riverbanks and whether sufficient volume exists to cause flooding.

Two-dimensional models can represent unsteady flows in multiple directions and across surrounding lands, incorporating hydrographs from various tributaries. They are preferred where multiple streams converge, because they

continued overleaf…

WE HAVE AN EASY

INSTALL A SWM SHIELD TO PRE-TREAT YOUR POND

account for coincident peak flows, which are critical for urban flood analysis. Also, they can more accurately depict overbank or spill-area flow where channels are overtopped.

One of the most significant improvements to floodplain mapping is the availability of improved high resolution mapping data made available by the MNR through a province-wide Light Detection and Ranging (LiDAR) data program. LiDAR imagery can capture terrain surfaces within 10 cm of resolution and penetrate tree cover.

Before LiDAR, the ability to assess overland flows could only have been done through manual geodetic surveys using total station equipment. These surveys are time-consuming, expensive on a large city-wide scale, prone to human error and cannot practically cover expansive land areas as effectively.

The City of London commends the province of Ontario for undertaking the initiative to provide LiDAR information to all municipalities. This is a key component to improve the quality of models and to achieving realistic flow outputs.

Due to advances in modelling and topography, practitioners have been able to increase the accuracy of inputs

into hydrologic and hydraulic models using monitoring data, which is important given that the quality of model outputs relies heavily on the quality of their inputs (i.e., garbage in = garbage out).

Despite the advancements in the engineering industry, modelling software, and LiDAR data, the provincial technical guide that influences updates to floodplain mapping is outdated. While the MNR’s 2002 Technical Guide for River and Stream Systems: Flooding Hazard Limit guidelines express the need to employ “engineering judgement,” the text of the document does not offer clarity when there are technical differences of opinion.

As a result, water resources engineers, municipal managers, and conservation authorities are left to work together to

balance flood protection, uncertainty, and the level of service (See Figure 1).

The balance can be challenging without consistent provincial guidelines. This is because both municipalities and conservation authorities rely upon the province to establish minimum levels of service for infrastructure as it relates to sewers, watermains, bridges, and other infrastructure.

In stormwater floodplain modelling, there are no guidelines for climate change, or updated guidelines to reflect industry practices in modelling (i.e., 2D, dual drainage, stormwater management facilities) or LiDAR. The problem is that the older modelling methods and guidelines are less accurate and prone to creating over-designed systems.

Bringing aging water infrastructure forward 100 years wasn’t easy. But with Pentair’s help, engineers upgraded the Springfield and Sangamon County facility that serves over 100,000 people.

Conservation authorities and municipalities manage flood risk with structural controls such as dams, reservoirs, dykes, storm sewers, and stormwater management ponds. These systems regulate peak flows for events ranging from frequent (1 to 5 year) storms to the 1 to 100 year or regulatory storm. However, traditional floodplain delineation guidelines often exclude municipal infrastructure, assuming inadequate maintenance and performance.

In practice, municipalities such as the City of London dedicate a portion of the annual budget to operate, maintain infrastructure, and ensure intended performance. Overlooking these controls can overstate peak flows and result in oversized and costly bridge/culvert designs downstream.

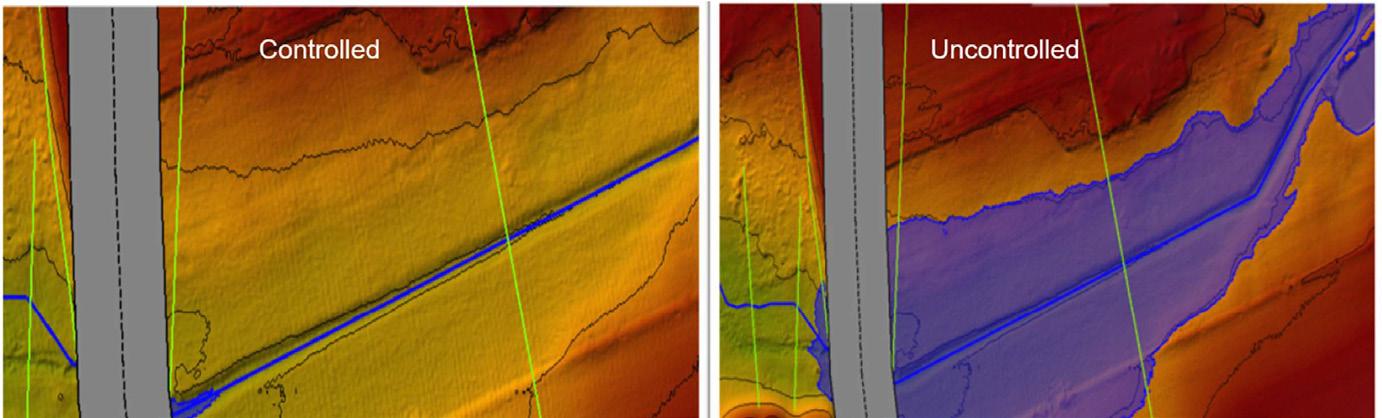

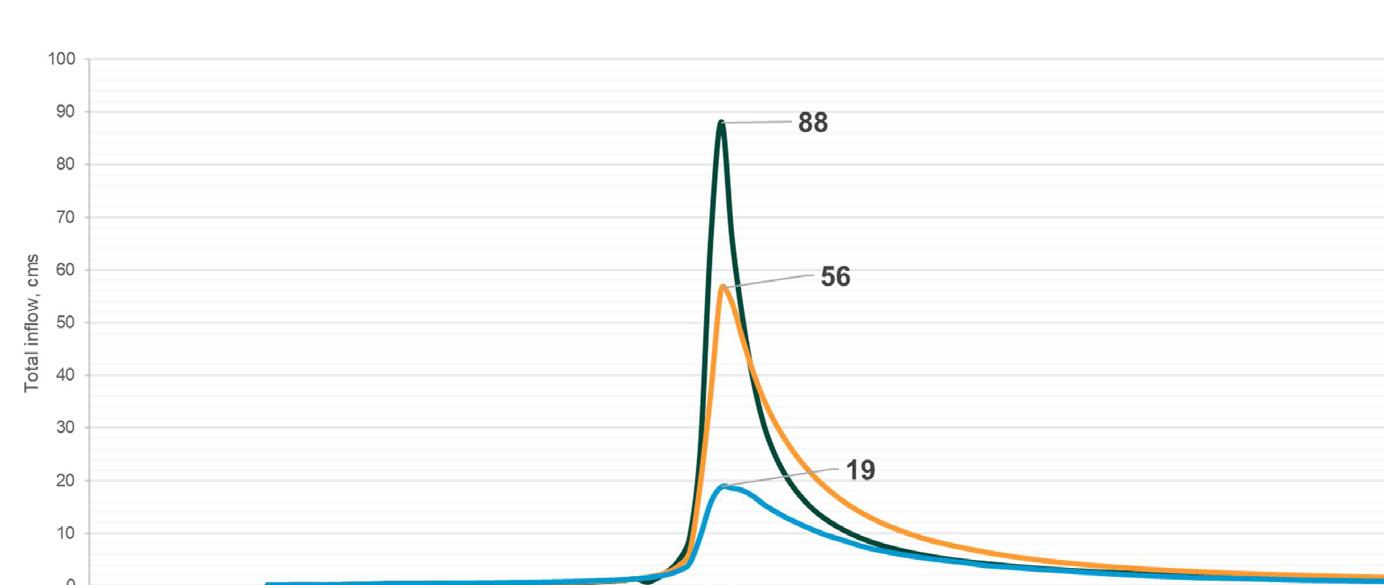

Figure 2 illustrates the difference in predicted peak flows and floodlines between a model that recognizes upstream SWM pond attenuation and a model that does not include SWM attenuation. It clearly demonstrates the importance of recognizing these controls in land use planning.

To demonstrate the impact of modelling assumptions on peak flows, the City of London conducted a detailed dual drainage modelling study in the 240ha Westmount Subdivision within the Thornicroft Drain headwaters, Dingman Creek watershed.

Developed from 1970 to the 2000s, this mixed use, residential and commercial area drains via storm sewers designed for the 5-year storm with no formal overland flow routes. Key storage feature includes a 50,000 m² forested area (providing ~16,000 m³), 48,000 m2 park (~20,000 m3), 37,000 m2 soccer field (~20,000 m³), and a 17,000 m2 wet pond (~19,000 m3). The wet pond was built in the early 2000s to service 13% of the catchment.

Two modelling scenarios were completed for comparison: The uncontrolled scenario consists

of large catchments, no minor/major system flow separation and assumes no storm sewers, wet pond, or depression storage. Uncalibrated hydrology uses conservative parameters for flow lengths (up to 100m for ~11 hectares of subcatchments), high percentage impervious and coarse soils information.

The controlled dual drainage scenario includes minor/major system separation, storm sewers and considers surface

flow paths, peak flow control from the wet pond and depression storage. Calibrated to flow monitoring data.

The regulatory storm for the modelled area is the 250-year design storm which was simulated using Chicago storm distribution over 24 hours for all scenarios. The controlled dual drainage model was calibrated using flow monitoring data.

Three models were compared for the same headwaters area using PCSWMM modelling software.

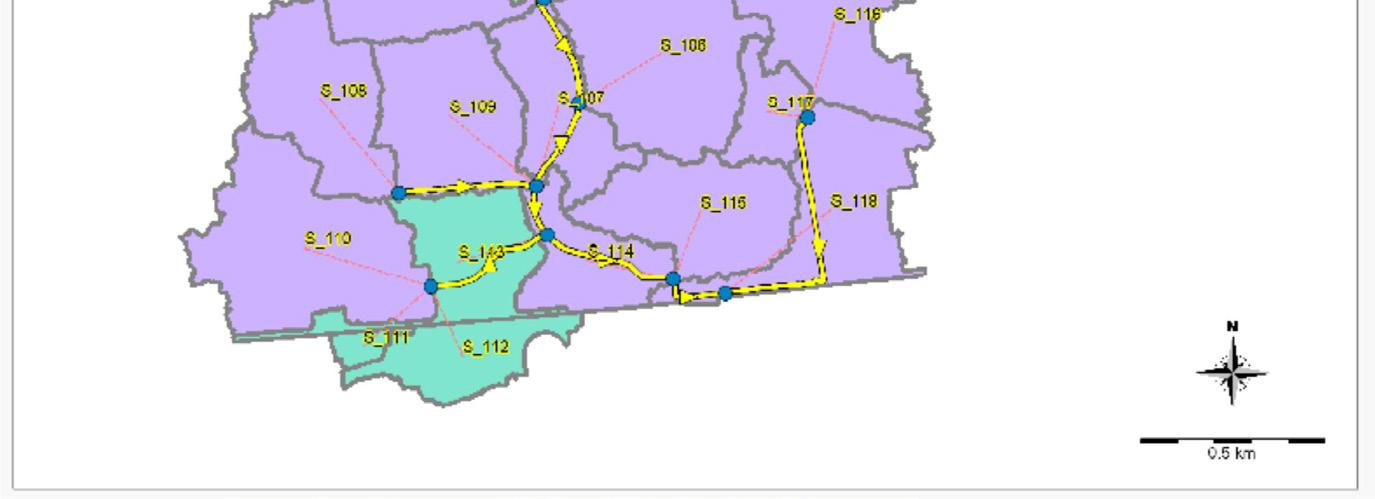

Two models were developed as uncontrolled scenarios at a watershed scale. In these models, the headwaters area was divided into 15 sub catchments with an average drainage area of ~11 hectares (Figure 3). The main difference between the two uncontrolled scenario models was the selected flow length parameter (average 100 m vs 470 m).

With the modelling software used, this parameter is not a physical measure, but rather a calibration parameter, thatneeds to be adjusted against monitored flows. Peak flows are sensitive to this parameter.

By contrast, the detailed dual drainage scenario represented the same drainage area across 381 sub catchments, with an average drainage area of one hectare, and included representation of the minor/major system as well as SWM controls (Figure 4).

The three models resulted in varying peak flows ranging from approximately 20 cubic metres per second (cms) to nearly 90 cms for the same storm event, See Figure 5.

The variability of the resulting peak flows highlights that the detailed phys-

ical characteristics and assumptions implemented in a model directly impact the outputs and when "controls" such as the minor storm sewer system, depression areas, overland flow capacity, and stormwater management ponds are not

represented in the model, the estimated flows are much higher. Therefore, it was critical to confirm which model was most realistic through calibration of the model to flow monitoring data.

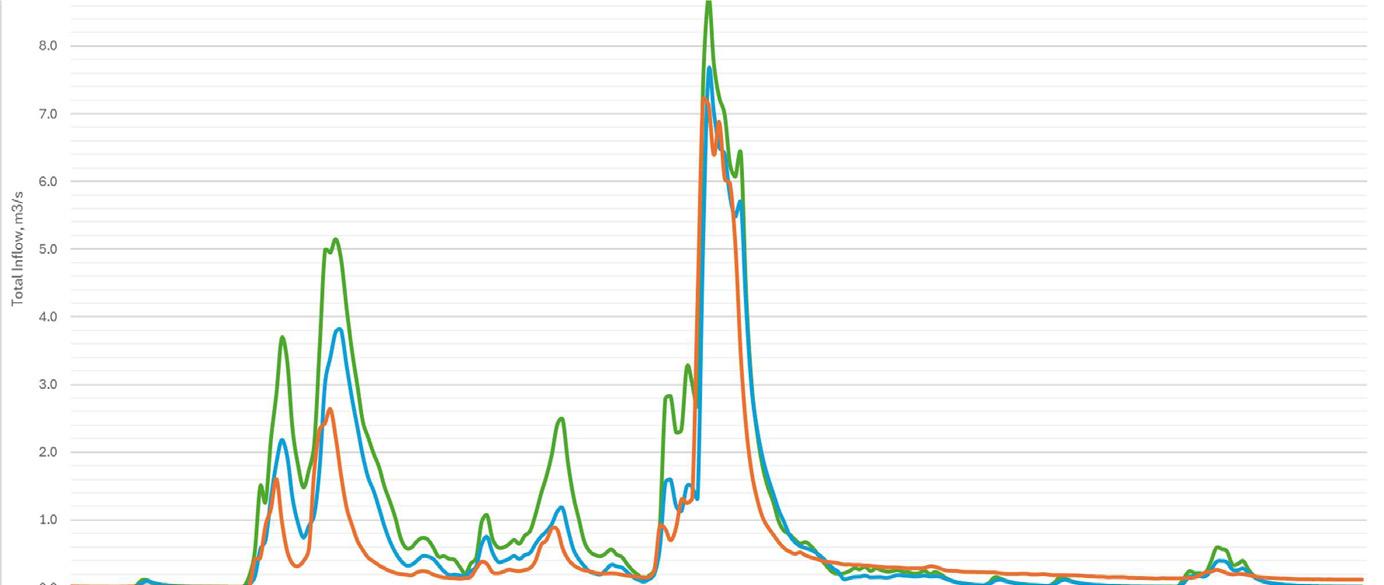

Monitoring data collected between July 2021 and June 2024 captured several significant storm events. On September 22, 2021, a 147-mm storm over 37 hours (with no antecedent rainfall) produced a peak flow of 7.2 m³/s. In contrast, on July 3, 2023, a 109-mm event over 26 hours, combined with two weeks of antecedent rainfall and saturated soils, generated a peak of 9.7 m³/s.

These observed flows were used to calibrate the dual drainage model, demonstrating strong agreement within 5% – 15% (Figure 6). Both observed data and detailed modelling highlight that coarse watershed-scale estimates overstate peak flows, reinforcing the importance of site-specific calibration and accounting for local storage dynamics.

Results showed that the uncontrolled model generated higher peak flows by a factor of 4.5. By contrast, the calibrated dual drainage model flow rates were within 5% – 15% of the actual flow monitoring data, providing a more realistic balance of conveyance and storage.

Considering that the peak flow rate drives the sizing in the design of culverts and associated downstream infrastructure, such as channel reconstruction, higher flow rates have a domino effect on infrastructure sizing and an exponential increase in construction costs. This modelling example demonstrates the value of flow monitoring and modelling calibration.

The total project costs for recent culvert projects in the City of London are presented in Table 1. It illustrates cost implications of higher design flows to municipalities. In the case of the Thornicroft example, the calibrated and uncalibrated modelling results of 20 cms versus 90 cms may result in a culvert construction cost difference of $400,000 and $5 million.

The Thornicroft modelling shows that calibrated models using flow monitoring data better represent catchment storage and controls than outdated assumptions, which risk overestimating flows and oversizing infrastructure.

While provincial guidelines lag industry practices, the guidelines support engineering judgment which we believe places a responsibility on engineers to apply current standards and tools.

The City of London promotes updates to the MNRF floodplain guidelines to support calibrated models that include municipal infrastructure as a technically sound methodology to design and construct cost-effective and resilient stormwater infrastructure for the future.

Shawna Chambers is the Director of Climate Change, Environment & Waste Management, for the City of London, Ontario.

Amna Tariq is an Environmental Services Engineer / Program Manager, Stormwater Engineering, for the City of London, Ontario. Email: atariq@london.ca

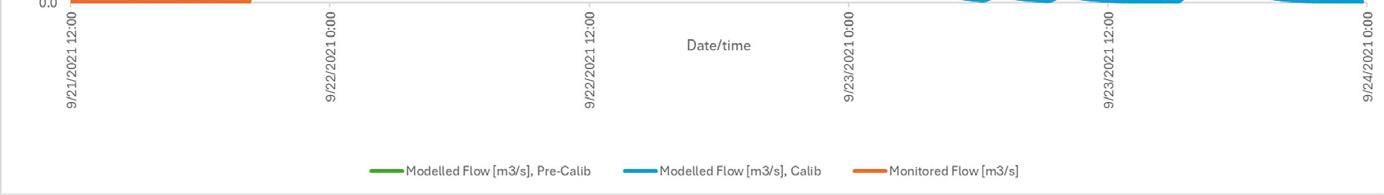

• No Corrosion or Contamination

• No Chemical Absorption or Wicking

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant.

Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for:

• Chemical Transfer

• Neutralization

• Dosing

• Effluent Control

• Lift Stations

• Odor Control

• Recirculation

• OEM Applications

Lightweight, inflatable hoods and portable multigas analyzers allow utilities to perform testing with minimal disruption and setup time.

Greenhouse gas (GHG) emissions are an inherent part of wastewater treatment. Water resource recovery facilities (WRRFs) emit a variety of GHGs throughout the plant from known and fugitive emissions points. Recently, more scrutiny has been given to emissions from aeration basins. Since aeration accounts for about 45% to 60% of energy consumption at WRRFs, attention has often centered on the indirect (Scope 2) GHG emissions tied to fossil fuel-based power generation.

However, the increasing introduction of renewable energy sources is reducing the carbon intensity linked to electricity production, which in turn is diminishing the relative impact of Scope 2 emissions.

In this context, attention is increasingly shifting towards understanding the sources of direct (Scope 1) process emissions like nitrous oxide (N₂O), methane, and carbon dioxide (CO2).

Canada has been at the forefront of monitoring and reporting greenhouse gas emissions. Since 2017, Canada’s Greenhouse Gas Reporting Program (GHGRP) has required facilities emitting 10 kilotonnes (kt) or more of CO2 equivalents (CO2e) per year to report their emissions annually. Several provinces and territories have added their own monitoring requirements

The Canadian GHGRP requires Canadian businesses to file both a federal GHG emissions report and a provincial report. Within this evolving GHG regulatory landscape and the

growing focus on Scope 1 emissions, WRRFs are seeking ways to directly measure, quantify, and mitigate their emissions through process monitoring and optimization.

While many facilities associate GHGs with Scope 2 emissions or fugitive methane emissions from anaerobic digestion, GHGs are also emitted from aeration processes, including N2O, methane, and CO2. In fact, N2O is approximately 300 times more potent than CO2 and can account for as much as 70% of a WRRF’s total carbon footprint. Hence, more recent attention has been paid to direct monitoring of N2O emissions.

N2O is emitted during biological nutrient removal at WRRFs, primarily through pathways such as nitrifier denitrification, incomplete heterotrophic denitrification, and the chemical oxidation of hydroxylamine during ammonia oxidation. Conditions like limited carbon availability or sudden shifts between aerobic and anoxic environments usually trigger these emissions.

As WRRFs adopt more advanced nutrient removal strategies, which often involve advanced dissolved oxygen (DO) control structures and intensification solutions, conditions favoring N2O formation may become more common. This variability makes N2O difficult to monitor using traditional modelling or

grab-sampling approaches. As research and monitoring efforts expand, aeration basins in secondary treatment are increasingly recognized as a hotspot for N2O emissions. In these zones, dissolved nitrous oxide in the liquid can be stripped into rising air bubbles and released into the atmosphere.

Historically, off-gas monitoring in aeration zones has focused on evaluating the in-situ oxygen transfer capacity of diffused aeration systems. This is done by measuring the residual oxygen in the exhaust off-gas and calculating key performance metrics such as oxygen transfer efficiency (OTE) and the alpha factor (αF).

Off-gas testing typically involves placing a floating hood on the liquid surface of aerated zones within the biological reactors of the secondary treatment process, capturing the off-gas, and analyzing its composition using a suite of gas analyzers. Field-based OTE measurements have provided utilities with valuable insights into aeration system performance, helping them optimize their energy use.

Today, advancements in portable, low-cost gas sensors have enabled the development of compact analyzer systems capable of continuously logging minute-by-minute concentrations of multiple gases in the off-gas stream. These innovations have expanded the scope of off-gas testing beyond traditional aeration performance analysis to include CO2, N2O, and CH4

As a result, off-gas monitoring has evolved from a single-parameter diagnostic tool into a more comprehensive platform, which is capable of capturing a broader set of indicators that reflect both aeration performance and biological process dynamics in real time.

While off-gas testing is a valuable diagnostic tool, it has traditionally been considered logistically complex and labour intensive. Ideally, representative testing would involve coverage of the entire aerated zones of a basin. However, this is generally impractical unless the tanks are fully enclosed. The use of larger hoods can improve spatial representativeness of samples, but such equipment is typically bulky and heavy, often requiring multiple personnel and, in some cases, crane support for deployment.

Recent innovations are beginning to address these challenges. Lightweight, inflatable hoods and portable multi-gas analyzers allow utilities to perform testing with minimal disruption and setup time. Inflatable and collapsible designs, such as the Inflatable Fast and Lightweight Off-Gas Analysis Technology (I-FLOAT) developed by Carollo Engineers, eliminate the need for rigid frameworks and heavy lifting, thus minimizing labour costs.

These hoods can be packed into compact cases, shipped easily between sites, and deployed by one or two people within a few hours. This removes a key logistical barrier, making offgas testing a more practical option for large and small utilities.

Portable equipment enables a level of process insights not possible with grab sampling, drone sweeps, or monthly energy data gathering. It also allows for real-time data collection

across multiple aeration zones to identify emission hotspots, benchmark aeration performance, and inform capital planning of aeration systems.

As Canadian WRRFs respond to evolving emissions regulations and sustainability goals, off-gas testing is emerging as a more versatile and accessible tool for process evaluation. Once primarily used to assess aeration performance, off-gas testing has evolved into a multi-parameter platform that can offer real-time insights into both energy efficiency and process-related GHG emissions.

Recent advancements in portable, lightweight analyzer systems have lowered the logistical and financial barriers traditionally associated with off-gas monitoring. These innovations make it feasible for utilities of all sizes to adopt this approach without major infrastructure or staffing demands.

With the ability to simultaneously track oxygen transfer efficiency, nitrous oxide emissions, and other key indicators, off-gas testing offers a practical path for Canadian utilities to benchmark and manage Scope 1 and Scope 2 emissions. By integrating this data into dynamic process modelling and operational planning, utilities can make more informed decisions, advancing both environmental and performance objectives.

Michelle Young and Sam Reifsnyder are with Carollo Engineers. Email: myoung@carollo.com, sreifsnyder@carollo.com

By Vincent Favre

Flow monitoring is the backbone of informed decision-making for wastewater operations, especially for overflow prevention. Whether it’s part of an inflow and infiltration (I&I) reduction program, tracking wet weather surges or optimizing system performance, accurate flow data enables operators to act quickly and strategically.

I&I alone can account for as much as half of all water treated in older systems with cracked pipes or leaky connections.

During rain events, that figure can spike sharply, pushing pump stations and treatment plants to their limits and creating operational strain on top of potential environmental violations.

Rather than looking at flow meters as just another equipment purchase, more utilities are taking a circumspect, operationally strategic approach. This prevents common pitfalls, like sensors that are mismatched to their environments, data that requires proprietary platforms or is hard to interpret, or flow metering systems that are abandoned after a few years because maintenance costs and demands were underestimated.

To get the most from overflow prevention efforts, wastewater treatment operators should adopt a three-pronged approach: Align flow meters with real-world conditions, plan for the full lifecycle of equipment, and leverage data into actionable decisions.

No single type of flow meter can handle every scenario. Municipal and industrial sites often require a mix of sensor types to capture reliable data across a range of conditions. Fully understanding the situational, environmental and existing infrastructure conditions is key to selecting the right sensor for the job. Variables that can make or break a deployment include pipe or channel size and shape, flow depth and variability, velocity range, turbulence, solids and debris content, chemical composition, access constraints and safety factors.

By mapping these conditions first, utilities can narrow sensor options to those best suited for long-term performance. Two basic kinds of flow meters serve the majority of wastewater flow monitoring needs: submersible area-velocity flow meters and non-contact radar flow meters. More often, facilities are combining the strengths of both sensors in developing a more resilient system.

Submersible flow meters, typically mounted in the invert (bottom) of a pipe, measure velocity using ultrasonic Doppler technology and depth using a pressure level sensor. They are widely used in I&I studies because they’re cost-effective,

For large-diameter interceptors or channels with hazardous access conditions, non-contact sensors are a safer and often more reliable option.

proven in the field, and easy to deploy in large numbers.

Since pressure sensors tend to wear our first, usually after two to three years of service, the whole device has traditionally had to be replaced. Newer models have replaceable pressure level sensors, which significantly reduce lifecycle costs and maintenance requirements by allowing operators to swap out only the worn component.

For large-diameter interceptors or channels with hazardous access conditions, non-contact sensors are a safer and often more reliable option. Mounted above the water, they measure surface velocity (via radar) and depth (via ultrasonic or radar level sensing), then calculate flow internally.

Because installation and servicing can be done from outside the flow stream, these sensors minimize confined space entry

risks and downtime. They also excel in highly turbulent or debris-laden conditions where a submersible device might become buried or damaged.

Some non-contact flow meters are designed for industrial sludges, such as those from mining operations, which can be highly corrosive. In these conditions, sensors must be fully protected against chemical attack to avoid rapid deterioration.

Some sites experience extreme seasonal variation. For example, a discharge pipe may run partially full for most of the year, but become surcharged for weeks during spring snowmelt or rainy season. In these cases, utilities sometimes install both non-contact and submersible meters, switching between them as conditions dictate.

When it comes to flow monitoring, the “total cost” isn’t the purchase order, it is the entire lifecycle of owning and operating the equipment. Many utilities have learned the hard way that a low upfront price can balloon into high operational costs if maintenance is frequent, parts are proprietary, or integration is limited. While utilities sometimes treat flow monitoring as a single capital purchase, achieving cost control requires accounting for both purchase and operating costs, and depends on actively managing the flow metering program.

A meter that looks like a bargain at purchase can become a budget sink if it requires constant cleaning, frequent recalibration or expensive proprietary parts. Meters installed in locations that require confined space entry can rack up labour costs quickly. Non-contact sensors mounted above the flow can often be installed and serviced without special permits or large crews.

Purchasers should beware of vendors who sell flow meters that work only with their software, which will tie up more of a capital budget and reduce future flexibility. Opt instead for flow meters that are built on an open communication protocol that will integrate with existing SCADA, GIS or asset management systems, regardless of the manufacturer.

This allows a utility to upgrade sensors without replacing the entire network, saving substantial capital and personnel resources.

Devices that compute flow internally and output ready-to-use data simplify deployment and reduce the need for external processors. If your flows are challenging or subject to harsh conditions, consider devices with chemical-resistant materials and debris-tolerant designs. And, if your system needs sensors that can adapt to sudden surges and high turbulence without losing accuracy, look for devices with rapid response capability.

Wastewater systems change over time through rehabilitation projects, new connections or upstream development. A site that was hydraulically “perfect” for a meter five years ago might now surcharge after every heavy rain. Lifecycle planning means regularly reassessing whether each meter is still in the best possible location and configuration.

A sensor claiming “±2% accuracy” under controlled conditions may not perform the same way when faced with real-life conditions, siltation, turbulence or intermittent surcharge. Always ask vendors for independent test data in conditions similar to your own. Better yet, run your own comparison under live flow.

The value of a flow monitoring program is measured not just in the collected data but in the operational decisions that data enables. When data is timely, accurate and integrated into planning and response workflows, it becomes a strategic asset.

Data from advanced flow meters can trigger automated responses, such as diverting excess flow to storage basins, when depth or velocity thresholds are exceeded. For combined sewer systems, these alerts can make the difference between a managed storm event and an unplanned overflow. The accuracy and speed of the sensors in detecting rapid depth and velocity changes are critical in rapid response situations.

For proactive overflow risk reduction measures, accurate and localized

flow data from multiple points allows utilities to pinpoint I&I sources, rather than launching broad, costly repair campaigns. That precision reduces unnecessary excavation and focuses budget where it will have the most impact. For optimal, long-term overflow mitigation planning, multi-year flow data sets can reveal chronic capacity issues, justify expansion projects and help time upgrades to align with actual system demand, rather than assumptions.

In regions at risk of flash flooding, utilities can use flow monitoring data from stormwater channels and drainage ditches. When rainfall has the potential to overwhelm a system, these flow meters can feed hydraulic models that predict flood onset, giving emergency managers more lead time to deploy resources or issue warnings.

Flow data should influence operational and capital decisions, decisions that should then be evaluated for effectiveness using subsequent flow data. If a rehabilitation project doesn’t reduce I/I as expected, you’ll see it in the numbers, allowing for course correction.

Overflow prevention is no longer just a regulatory requirement; it’s a core responsibility for protecting public health, the environment and municipal budgets. By embracing modern flow meter technology, optimizing deployments for site-specific conditions and building an integrated data strategy, wastewater utilities can shift from reactive crisis management to proactive system control.

When the next heavy rain hits — and it will — utilities with a well-matched mix of sensors, a plan for keeping them in top condition, and a strategy for acting on the data they provide will be the best insurance against overflows, fines and public trust erosion.

Vincent Favre is with FLOW‑TRONIC S.A. (www.flow tronic.com), represented in Ontario by ACG‑Envirocan Inc. For more information, email: blake@acg envirocan.ca, or visit: www.acg envirocan.ca

THE EVOLUTION OF THE CHEMICAL

BEFORE complex. cluttered.

AFTER simple. intuitive. Made in Canada!

Up to 50% reduction in mechanical room space required 90% fewer joints = 90% less risk of leakage

Simple, consolidated operation

Support Canadian Industry - Buy DICE

By Barry Jongsma and Logan Peak

Several advanced diagnostic methods are available to help identify the correct remedy for failing and underperforming pumps. When used correctly and diligently, these tools can keep costs at a minimum and reduce risks while ensuring vital pumps perform at the standards needed to continue protecting public health.

Trending diagnostic tools refer to continuous monitoring of conditions such as vibration, flow, pressure, speed and more. Advanced data acquisition software records more than 20 analog inputs, allowing a user to visualize the various data streams at once, making it much easier to detect anomalies and diagnose issues. Trending diagnostic monitoring can be a time and cost saving endeavour for pump owners, helping to identify the source of equipment problems without stopping operation or dismantling machinery.

In the case of vibration monitoring, the data software generates Time Waveform (TWF) and Fast Fourier Transform (FFT) outputs, which help determine failure modes. Several advanced analysis techniques for TWF and FFT data can be utilized to determine the cause of vibration issues. When viewing these results alongside other monitored conditions, operational deficiencies can be identified and transient events like startups, shutdowns or valve closures can be captured.

Based on this multitude of information about a pump system, equipment can then be fine-tuned to optimize performance. The accumulation of data over longer time periods also allows for analysis of historical trends and frequencies of issues. Not only does this assist greatly with the effort to pinpoint the source of

a known issue, but it also enables predictive maintenance by helping to detect imminent malfunctions which may have otherwise gone unnoticed. Identifying and addressing equipment issues early can lead to significant cost and labour savings by reducing downtime.

Experimental Modal Analysis (EMA) is a valuable tool for measurement and analysis of modal properties of a pump system, such as damping and shape. EMA techniques aim to align an analytical model of a structure’s dynamics with measured data that reflects its actual behaviour. The measured data comes in the form of Frequency Response Functions (FRFs), allowing the natural frequencies of a system to be visualized. By examining relative movements and mode shapes, users can determine the ideal points where a structure can be stiffened to alter the natural frequencies. Targeted corrective action can lead to cost reduction and increased resolution speeds. Remediation based on EMA can prevent a catastrophic failure of a pump.

Operating Deflection Shape (ODS) is a modelling technique used to measure and visualize the vibrations of a pump system while it is operating. An animated 3D model highlights the amplitude and direction of vibration at various points on the pump. Often deployed following Experimental Modal Analysis, the ODS provides in-depth data on the actual vibration forcing function of the system and corresponding dynamic behaviour.

This visual portrayal of the movement of a system allows for quick and focused solutions to reduce vibration. The ODS can also be used to identify the root cause of vibration issues. Through shape estimation of the pump equipment, foundation and piping, it can be determined if excessive vibration is caused by a structural defect with the pump or by external factors such as a poor foundation or misaligned piping. ODS can even assist with preventive maintenance efforts by monitoring pump vibration patterns over time to detect potential problems before they reach a critical stage.

Overall, ODS modelling is extremely important in vibration analysis because

of the depth and quantification of information generated. It can reveal not only the location of unwanted vibration, but also the amount and direction of the movement under normal operating conditions. This information is paramount to determining corrective measures to reduce vibration.

An alternative to ODS is the Motion Amplification Video (MAV) technique. Using a high definition and high dynamic range camera with proper lighting, every pixel of the recorded video acts as an individual sensor, generating millions of data points. MAV offers an advantage over ODS through quick setup time as the data is collected and analyzed in a matter of seconds.

An additional advantage of MAV is the ability to capture data over larger areas of the system, providing an extensive view of the asset. A single data capture can be used for multiple pumps, motors, piping networks and other

large structures. Analysts can then fixate on particular problem areas seen in the video or pointed to by the data. The closer examination might use a higher frequency data collection or a different camera angle.

MAV can also offer a baseline set of data conveying the behaviour of a pump during commissioning, allowing pump owners and the pump OEM to be aligned during the installation phase. This initial data can then be used as a reference for future diagnosis of the health of the pump. MAV also enables analysis of areas in a pump system which cannot be accomplished through traditional vibration measurement methods.

Small-bore piping vibration is typically not analyzed because of the large quantity of measurement points that would be required, but a complete view of the system through MAV can easily pinpoint areas in the piping where shaking is occurring. Mechanical seals can also be examined through MAV because of the noncontact nature of

the procedure. Finally, the ability to see motion at specific frequencies supports the diagnosis of all failure modes of a pump system such as misalignment and poor foundations.

Lack of funding and the ever-increasing environmental and quality standards imposed on wastewater treatment plants are causing a strain on the local governments that manage these facilities.

A comprehensive assessment of pump health can help explore all possibilities for rehabilitation before replacement is considered, helping to avoid unnecessary spending. A full suite of diagnostic tools can also allow users to employ predictive maintenance on their equipment, helping to reduce the risk of failures and catastrophic events, leading to additional cost savings.

Barry Jongsma and Logan Peak are with Pentair. For more information, visit: pentair.com/psg

Credit: peopleimages.com, stock.adobe.com

By Patrick Coleman

Ahiker set off on a hike across the wilds. He relied on his portable global positioning system (GPS) device to map his trip. Part way his GPS failed. The story has two endings. In one scenario he pulls out a map and a compass and continues his trip, much more engaged in mapping his route. In the second scenario, like a handful of hikers last year, he didn’t make it home. The GPS is GenAI and the fate of the hiker is what this article is about.

John McCarthy, one of the founders of the discipline of artificial intelligence, coined the term “Artificial Intelligence” in 1955 to mean “the capability of computer systems or algorithms to imitate intelligent human behavior”. Artificial

Intelligence became a branch of computer science dealing with the simulation of intelligent human behavior by computers, not a product.

Generative AI (GenAI) is artificial intelligence that can generate new content (such as images or text) in response to a submitted prompt by learning from a large reference database of examples.

GenAI is a form of Narrow (Weak) AI as it is designed to perform a narrow range of tasks with remarkable efficiency without operating beyond its programmed domain. The textbook ChatGPT Ate My Homework includes one chapter on what GenAI does well and one on what it does not. For example, GenAI is not good at original thought, eliminating bias, knowing its limits, creating new empirical knowledge, applying empirical verification, taking courses (large language models are frozen), exercising morality, empathy or fear or eliminating hallucinations or biases. In fact, GenAI can be inaccurate and dishonest.

tise. We have time to sort out the issues because the adoption lags the hype.

We all work in teams with other humans. Teams facilitate the natural evolution from the apprentice to the master, creating a career path and sustaining a company reliant on knowledge workers.

Unlike previous iterations of technological breakthroughs, GenAI impacts our brain function, and the tool becomes part of the team. In a way, we become “cyborgs” or “MePTs”. The worry is, like the Star Trek Borg, can we survive being separated from the “collective” and think for ourselves? Do we know what cognitive skills are too precious to give up?

Mentors worry companies reward task performance over critical thinking. GenAI is unique as a tool since an engineer can perform without growing. Faster is not always synonymous with better (Ahned 2025). AI accelerates, automates and optimizes, but what if that efficiency costs us depth, understanding and even identity? What if we start to produce “workslop”, AI generated content that looks like work but lacks substance to move projects along?

Mentors worry when a company focuses on rapid adoption of AI without developing a mature quality, risk and procedural ecosystem around the tool. A young engineer’s career can be ruined by a misstep with such a powerful tool. The World Economic Forum identified this as a major cyber risk in 2025, stating that “despite growing reliance on AI for cybersecurity, many organizations lack processes to properly assess the security of AI tools before deployment, creating a gap in managing associated risks.”

Insurance companies have similar concerns, warning coverage may be limited when GenAI is used. GenAI challenges fundamental concepts like authorship, ownership and understanding.

Engineers require a blend of traditional skills as well as knowledge of how to effectively manage and interact with AI systems. Firms with skill gaps are uncompetitive and vulnerable.

Before we panic, remember we are tool-using creatures. Using tools allows us to punch above our weight. We use tools, like GenAI, to amplify our exper- continued overleaf…

With over two decades of installed experience at more than 100 facilities worldwide, Nereda® technology is the One and Only true aerobic granular sludge on the market today.

Since its introduction to the U.S. and Canada in 2017, more than 40 AquaNereda® plants are currently in design, under construction or in operation throughout North America.

Consultants and end-users continue to realize the process and cost saving benefits associated with AquaNereda technology through on-site pilot testing, installation visits and technical seminars.

ADVANTAGES OF AQUANEREDA ® TRUE AGS TECHNOLOGY:

• Design MLSS of 8,000 mg/l greatly reduces footprint

• Capable of enhanced nutrient removal

• Suitable for retrofits and greenfield sites

• Exceptional effluent without chemical addition

• Robust process that adapts to changing conditions

• Applicable for municipal and industrial waste streams

• Significantly less construction cost compared to conventional treatment

• Energy and chemical savings results in lowest cost of ownership

Represented by:

www.acg-envirocan.ca sales@acg-envirocan.ca

Companies must ask how GenAI adoption impacts succession planning. If AI makes an experienced person more effective, is AI then displacing the less experienced person who formerly did that role? Therefore, who will replace the experienced person when they retire or leave the firm?

Therefore, it is important to look before you leap, document everything well, train your staff and implement quality control procedures.

Brains atrophy if not used. For example, London taxi drivers, who have to memorize all possible routes across tens of thousands of roads to earn their

• Loss of agency: We stop trusting our own judgement as AI takes over the how, why and what of thinking. We fall victim to “automation bias”. When a tool speaks like an expert but reasons like a parrot, trust becomes a trap. Artificial intelligence is not artificial wisdom.

GenAI, used incorrectly by those at an entry level in their career, rewards achievement over learning, diminishing the drive to think critically, be creative, and to stay current. Mental health can deteriorate because GenAI robs the user of a sense of accomplishment, undermines self-confidence and enhances the “imposter syndrome”. Tool dependence increases anxiety, guilt and lack of confidence.

Generalized cognitive atrophy is

While AI-assisted participants demonstrated enhanced task efficiency and reduced cognitive load, these benefits came at the cost of diminished critical thinking and a slight decline in self-efficacy.

license, have a larger and more developed hippocampus relative to London bus drivers who follow preset routes.

Research also uncovered a negative correlation between frequent AI tool usage and critical thinking abilities mediated by increased cognitive offloading. Younger participants are more vulnerable to this than older participants.

Researchers characterized what we lose when we outsource our thinking to GenAI:

• Critical thinking decline: Machines cannot reason through uncertainty. We need to think critically through ambiguity, evidence and contradiction. AI doesn’t just give us answers — it quietly takes away the need to ask better questions.

• Creativity erosion: Human creativity thrives on friction — on the uncomfortable space between clarity and chaos.

• Moral and intellectual laziness: AI does not weigh consequences. It does not have values, a conscience or accountability.

already a philosophical risk in itself. But there are other risks too. If this type of tool is widely used — and it is already the case with younger generations — we are at risk of a standardization of thought. British researchers showed that when authors asked ChatGPT to improve their work, the individual benefits could be great, but the overall creativity of the group reduced.

Three research teams studied high-performance and low-performance GenAI users. The consensus is high-performance groups use was balanced and comprehensive, primarily engaging with high-level cognitive processing, while the low performance groups use was unbalanced and fragmented, primarily engaging with lower-level cognitive processing. Other takeaways from the studies are:

• Individual knowledge of the subject

area increased staff performance and value-added actions.

• Without knowledge, staff became conduits for information, not creators themselves.

• While AI-assisted participants demonstrated enhanced task efficiency and reduced cognitive load, these benefits came at the cost of diminished critical thinking and a slight decline in self-efficacy.

• Integration of AI into cognitively demanding environments must be approached with caution, ensuring that users are not merely performing better but also thinking better.

The single behaviour that separated the groups is whether they used AI to amplify their expertise or to replace their judgement.

Lee et al state that “in light of these changes, training knowledge workers to think critically when working with GenAI should focus on developing skills in information verification, response integration, and task stewardship. Training programs should emphasise the importance of cross-referencing AI outputs, assessing the relevance and applicability of AI-generated content, and continuously refining, and guiding AI processes. Additionally, a focus on maintaining foundational skills in information gathering and problem-solving would help workers avoid becoming over reliant on AI.”

Yes, but this requires both actively engaging our critical thinking and continuing to exercise our neural pathways. AI can be a tremendous lever for intelligence and creativity, but only if we remain capable of thinking, writing and creating without it.

We need to always question the answers given by text generators and make a conscious effort to think carefully about what we read, hear or believe. We must also accept that reality is complex and cannot be understood with a few superficial pieces of knowledge. But the best advice is undoubtedly to get into the habit of comparing our point of view and

A s t h e h o l i d a y s a p p r o a c h , p l a n a h e a d a n d r i d e t h e w a v e i n t o

N e x t W a v e 2 0 2 6 , C a n a d a’s p r e m i e r n a t i o n a l g a t h e r i n g f o r t h e

w a t e r s e c t o r. B u i l d i n g o n t h e l e g a c y o f O n t a r i o’s W a t e r

C o n f e r e n c e & Tra d e S h o w, t h i s f l a g s h i p e v e n t b r i n g s t o g e t h e r

m o r e t h a n 1 , 0 0 0 i n d u s t r y p r o f e s s i o n a l s a n d o v e r 1 0 0 e x h i b i t o r s

s h o w c a s i n g t h e l a t e s t t e c h n o l o g i e s , p r o d u c t s , a n d s e r v i c e s

s h a p i n g C a n a d a’s w a t e r f u t u r e . H o s t e d b y t h e O n t a r i o W a t e r

W o r k s A s s o c i a t i o n ( O W WA ) w i t h t h e A t l a n t i c C a n a d a , W e s t e r n

C a n a d a , a n d B r i t i s h C o l u m b i a S e c t i o n s o f AW WA , a n d s u p p o r t e d

b y AW WA , N e x t W a v e 2 0 2 6 o f f e r s a u n i q u e o p p o r t u n i t y t o

c o n n e c t , l e a r n , a n d i n n o v a t e .

E a r l y b i r d p r i c i n g i s n o w o p e n u n t i l F e b r u a r y 1 3 , g i v e y o u r s e l f

t h e g i f t o f i n s p i ra t i o n t h i s h o l i d a y s e a s o n .

knowledge with those of other people, preferably those who are knowledgeable.

Amlani and Davis propose in their book ChatGPT Ate My Homework a training structure based on a revised version of Bloom’s taxonomy. (see Table 1)

The authors also identified four new competencies engineers must acquire:

• Melioration: Choose the right tool at the right time to complement our thinking and compensate for the tool’s shortcomings.

• Ethical reasoning: Decision about when it is appropriate to use AI and how we can appropriately use it.

• Collaboration: AI demands new skill sets, including prompt engineering, iterative conversation questioning, trusting outputs, and discerning our diverse viewpoints.

• Reflection: Demands that we consciously monitor and review processes as we work with GenAI.

Employers must ensure staff are not merely performing better but also thinking better. They need to reimagine entry points — collaborative role rather than a servant or a conduit role, encourage skill development for augmentation, not competition and provide a Human-AI workflow design.

We need mental friction in the workflow to build understanding and thought. Otherwise, we lose the ability to hold complex ideas in our heads, struggle through uncertainty, and earn our conclusions. For example, we no longer need to run to escape predators, but we still go to the gym because we need to exercise to remain healthy. We need to develop mental endurance by initiating the following:

• The most humane technology is one that slows us down. Introduce cognitive friction into your life.

• Set limits on AI use (e.g., use after a draft of a document or a plan is prepared).

• Reflect before prompting AI for an answer.

• Use AI-free time zones or days to reengage slow thinking.

• Cultivate deep work.

1 Identify Engineers find and recognize relevant information, data and outputs. They know what tools give what output. They understand how to prompt to obtain the output they require.

2 Interpret Engineers can deduce meaning, limitations, and quality from AI output. They understand how GenAI works, so they can spot errors and shortcomings.

3 Integrate Engineers know how to combine AI input/output with traditional sources such as books, design guidelines, standards, and lived experience.

4 Evaluate Engineers have a sharp skeptical approach to assessing quality, credibility, relevance and verifiability of AI output. They know how and what to fact check, assess relevance, spot hallucinations and eliminate them, and understand the relationship between prompt quality and output veracity.

5 Reflect The engineer is competent at inward scrutiny and thinks metacognitively about their own learning biases and relationship with AI. They can recognize when they have become overdependent and need to backtrack.

6 Collaborate The engineer has strong teamwork skills, not only with AI tools but also with other humans. They contribute to constructively and actively co-create solutions, make decisions and content. They developed an ability to negotiate, question, reframe and reach consensus, identifying common ground and working around disagreements.

7 Judge The engineer instinctively and genuinely executes ethical decisions about which tools to use, when and the proper uses of outputs. They have internalized values coping with authority, bias, learning outcomes and psychological safety.

8 Curate Engineers can draw out the best in themselves and AI-generated content. A curator produces work that is defensible, truthful, original, ethical, and properly referenced.

The KPMG Generative AI Adoption Index Survey assessed 2,606 Canadians (aged 18+) from August 6-21, 2024. 67% using GenAI do not think they are learning and retaining as much knowledge, 65% feel they are “cheating” and 82% claim GenAI content as their own. These students will be our new hires. Don’t just ask what AI can do for us. Ask what it is doing to our minds. We live in a world where thinking can feel optional. We can fall into the trap where we become emotionally detached and are unable to make decisions. “A mind that always has help nearby forgets how to stand on its own (Ahned, S)”. If this happens, humans stop being mentally vigilant and they become vulnerable to manipula-

tion, misinformation and disruption. Mentors stress that GenAI is best used as a co-pilot, not an autopilot. We need to do our own thinking and then use AI to sharpen it. Readers please note that Gen AI was not used for this article.

Patrick Coleman, PhD, P.Eng., is a Principal Process Engineer, Wastewater with Stantec. Email: pat.coleman@stantec.com. Complete references are available upon request.

IE3-rated air-filled motor reduces energy consumption and operating costs

Integrated cooling system keeps the motor cool to extend overall pump life

Clog-resistant impeller and volute designs reduce maintenance

Learn more: crane pum p s.com/product-ty p e/solids-handling-pumps/

Kam Chan, Global Sector Lead — Infrastructure, with Montrose Environmental Group, shared his insights and predictions for 2026 with Environmental Science & Engineering Magazine in a question-and-answer exchange.

Chan believes that Canada stands at a pivotal moment in a rapidly shifting global landscape. Along with the launch of the new Major Projects Office (MPO), governments across the country are gearing up to deliver once-in-a-generation projects. In September 2025, Prime Minister Mark Carney announced the first series of projects referred to the MPO for consideration, and the federal government has also shared views on several strategies for projects that could be truly transformative for this country, spanning critical minerals, renewable energy, and low-carbon transportation networks.

These nation-building projects share a significant focus on environmental and climate goals, often framing development and environmental protection as inseparable. The government’s Building Canada Act aims to streamline federal approval processes for these and other projects, while maintaining environmental standards and upholding Indigenous rights.

Chan adds that we are entering a period where climate adaptation is just as important as mitigation. Climate change is already altering the world, with more intense and frequent wildfires, storms, and sea-level rises. Across Canada, greater emphasis is being placed on climate resilience planning — whether through flood protection, wildfire risk reduction, or resilient design for transportation and energy systems.

As environmental risks and associated costs rise, adaptation is now a core strategy for clients. This shift is fueling strong demand for environmental consultants, who provide expert guidance on risk assessment, resilient design, and regulatory compliance to help commu-

nities and businesses prepare for more frequent climate impacts.

Q. How do you see climate policy and federal/provincial regulations influencing environmental consulting and infrastructure development in Canada?

A. Canada’s regulatory environment continues to evolve rapidly, especially with strengthened commitments under the Canadian Net-Zero Emissions Accountability Act and various provincial climate action plans. These frameworks are creating new expectations for transparency, emissions monitoring, and community engagement.

For consultants, this means helping clients navigate compliance and strategic alignment — understanding how their operations fit within broader policy shifts and how to future-proof investments. A good example is how Canadian provinces are integrating climate resilience standards into infrastructure funding by requiring climate risk assessments and adaptation measures as part of project eligibility, supported by updated codes, national standards, and technical guidance to ensure that investments are robust to future climate impacts.

Q. What role can engineers play in ensuring critical mineral projects balance global progress with environmental responsibility?

A. Canada’s accelerated push to develop critical minerals projects (backed by programs like the Critical Minerals Infrastructure Fund) demands a careful balance between progress and environmental responsibility. Achieving this balance is a collaborative endeavour that brings together multidisciplinary teams, communities, Indigenous partners, and technical experts to navigate environmental assessments, permitting, and the integration of Traditional Ecological Knowledge into project planning. By fostering collaboration in biodiversity conservation, land reclamation, air and water management, and ongoing monitoring, we can help to ensure that mines and processing facilities operate responsibly while meeting evolving regulatory and community expectations. This holistic approach weaves together diverse perspectives and disciplines, enabling a more comprehensive understanding of the interplay between these natural systems and responsible resource development.

Q. What emerging approaches or technologies are you seeing to address water quality and resource management challenges?

A. Water quality is one of Canada’s defining environmental challenges. Extreme weather, population growth, and industrial demand are all putting pressure on water systems. The good news is that new tools are allowing for smarter, data-driven management.

We are seeing increased use of realtime water quality monitoring, advanced treatment processes, and predictive modelling to safeguard critical resources. For example, in Western Canada, Montrose supported the development of a mine water and selenium management plan that integrates continuous monitoring with adaptive management strategies. This approach not only reduces ecological risk but also provides regulators and communities with greater transparency into water quality performance.

Q. How best to support Canadian industries as they adapt to increasing ESG and sustainability expectations.