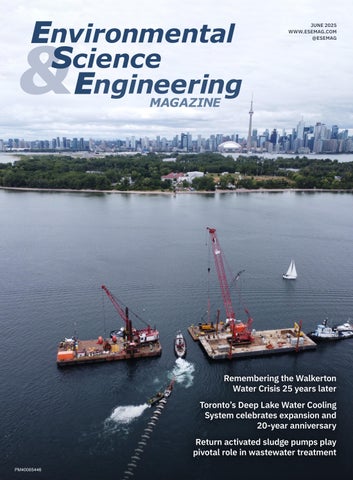

Remembering the Walkerton Water Crisis 25 years later

Toronto’s Deep Lake Water Cooling System celebrates expansion and 20-year anniversary

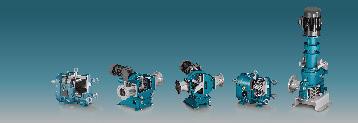

Return activated sludge pumps play pivotal role in wastewater treatment

Remembering the Walkerton Water Crisis 25 years later

Toronto’s Deep Lake Water Cooling System celebrates expansion and 20-year anniversary

Return activated sludge pumps play pivotal role in wastewater treatment

Engineered for Horizontal Directional Drilling (HDD) and other trenchless applications, TerraBrute® CR is a 100% non-metallic, AWWA C900 PVC pressure pipe system. Non-corroding and installation-friendly, TerraBrute® CR lets you standardize on PVC throughout your municipal water infrastructure. Designed for large diameter projects up to 24 inches, it offers unmatched strength and leak-free performance in high-pressure environments, ensuring efficient, cost-effective solutions with minimal disruption.

REDUCED INSTALLATION COSTS

Install low pressure sewer pipes first and delay grinder pump costs until the home is sold

INCREASE SYSTEM FLEXIBILITY

Pressure Sewer Systems can handle long distances and any terrain, overcoming challenges that gravity systems can’t

Closed system eliminates risk of system leaking and contaminating groundwater, streams, lakes, and oceans

cranepumps.com/market/pressure-sewer/

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Contributing Editor DAVID NESSETH david@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

Archis Ambulkar, Toledo Technology Academy of Engineering

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales Second Class Mail

Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812 penny@esemag.com

6 OWWA honours William Fernandes for his mentorship efforts

8 Resilience and reform: Remembering the Walkerton Water Crisis 25 years later

10 Examining the causes of litigious flooding events

14 Retrofitting Acton’s WWTP creates sustainable office space

16 Toronto’s Deep Lake Water Cooling System celebrates an expansion and a 20-year anniversary

19 Preventing VOC leaks in sustainable industrial operations

20 Enhancing groundwater recharge through wetland conservation and restoration

22 Causes and solutions for vapour lock in chemical metering pumps

24 The importance of desiccant cartridges in wastewater sampling flow monitoring

28 Canadian organization helps with capacity building, sustainability and restoring water services

32 Return activated sludge pumps play a pivotal role in wastewater treatment

34 Choosing the best evaporation technique for digestate and sludge

36 Ontario audit finds gaps in inspections, compliance for small non-municipal drinking water systems

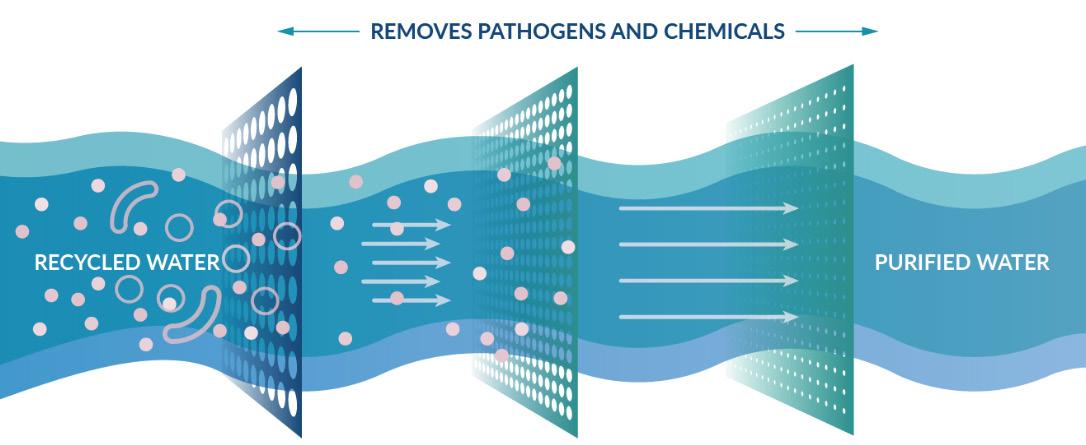

37 Arizona continues to advance potential for wastewater reuse

38 Using wastewater biogas to produce hydrogen and graphene

39 Brantford says reverse osmosis pilot effectively reducing nitrate levels

40 Post-secondary students across Canada propose real solutions for water resilience

42 Carbon dioxide removal and sequestration in Canada: The role of biochar in removing contaminants

45 Innovative approach chosen for a Saskatoon underground stormwater storage project

46 High-capacity PFAS removal system being designed for Vancouver, Washington water system

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6

Tel: (905) 727 4666 www.esemag.com

30 Using the latest equipment and best practices optimizes sewer cleaning time and lowers costs

47 UWaterloo team using imaging tech to track methane hotspots at landfills

52 Rethinking milking centre wash water for on-farm septic systems

Are The Exclusive Suppliers

Pro Aqua, Inc. ca rr ies a co mpl ete range of market leading and innovative products. Let us show you

Providing treatment solutions for more than 30 years.

• Archimedes Screw Pumps

• Screens – Multi-Rake, Perf Plate, Drum, Travelling Band, Step, Climber, Vertical Pump Station Screens, Screenings Washer /Compactors

• Grit Separation, Washing & Dewatering

• Conveyors – Shafted & Shaftless Screw, Belt

• • Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Blowers – Rotary Screw, Rotary Lobe, Single Stage and Multistage Centrifugal, Turbo, Integrally Geared, Advance Control, Rebuilds

• Aeration – Surface, Membrane & Ceramic, Fine & Coarse Bubble, Gas & Liquid Cleaning, DO Control, AlphaMeter

• Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

• Tank Components –

Decanters, Swivel Joints, Telescoping Covers, Watertight Doors

• Primary & Secondary, Circular, Chain & Flight, Inclined Plate Settlers, Weir Washing

• Rotary Lobe Pumps & Grinders

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recovery

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – snoitatS pmuP & retawmrotS ,OSC

Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vortex Valves, Storm Screens

• Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dry Systems

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

Most people I have talked to over the years have at least one favourite teacher who possessed the rare talent of being able to combine the roles of educator, guidance councillor, life coach, motivator and friend. I was fortunate to have two such teachers, who both taught history, my favourite subject. One in Grade 7 and one during my high school years.

Regrettably, I never got a chance to thank my Grade 7 history teacher, as we moved away and our paths never crossed again. By chance, however, I did meet my high school history teacher at a social function a few years ago and took the opportunity to thank him. He was quite amused that, for the online security question: “Name of favourite teacher?”, I have always used his last name as my answer.

As we enter the workplace, it is mentors who take on this important role. I was fortunate enough to have two such individuals in my early career. My first was Gerry Nunn, the publisher of Water & Pollution Control Magazine and my first boss. Despite the 35-year age difference between us, he willingly imparted his knowledge of publishing, the water and wastewater industry, and navigating the corporate world, the latter of which I knew nothing about.

My second one was Tom Davey, my father and cofounder of Environmental Science & Engineering Magazine (ES&E). Tom was an award-winning journalist and successful businessman, long before I approached him with the idea of launching ES&E back in 1987. He did not need to take on the workload and financial risk that such a venture created, but to help me, he agreed to do it. If you are reading this, then you know that my idea worked out.

Mentors are special people indeed, who willingly accept the principle of “paying it forward”. I would like to commend and congratulate long-time ES&E Editorial Advisory Board Member William Fernandes, Deputy General Manager of Toronto Water, on receiving this year’s Marcus P. Firman Mentorship Award from the Ontario Water Works Association (OWWA).

Presented at the OWWA’s recent annual conference, this award recognizes an individual who demonstrates exemplary, sustained commitment to mentoring, and inspiring growth and leadership.

The award presentation citation stated that “William Fernandes’ leadership extends across many other organizations, such as the Water Environment Association of Ontario (WEAO), the Canadian Water and Wastewater Association (CWWA) and the International Water Association (IWA). For many years, he has guided

emerging professionals with wisdom, humility, and a deep commitment to their growth. His impact spans from local initiatives to global platforms like the World Water Congress, where he championed inclusive engagement for youth professionals from 17 countries.”

William has also served on the Board of Directors of WEAO and CWWA and he is a former president of CWWA. Recently, he was elected to the IWA Board of Directors, where he is the only Canadian serving on it, and was “instrumental” in bringing the IWA World Water Congress & Exhibition to Toronto in 2024, according to the award nomination form.

“The heart of every successful and resilient water utility is its people. By investing in the growth and potential of others, you can not only strengthen your team but also ensure communities continue to receive safe, critical services,” said William to ES&E

“Mentorship is a powerful reminder that the future of water utilities depends not just on infrastructure, but on the individuals who make it all work,” he added. “I am honored to receive this award and be recognized for my role in mentoring the next generation of professionals.”

I have had the pleasure of working with William on the WEAO Board of Directors, and have enjoyed our chats at countless industry events over the years. On behalf of all those water and wastewater professionals whose lives you have impacted, thank you, William, and please don’t stop anytime soon!

Steve Davey is the editor and publisher of ES&E Magazine. Email: steve@esemag.com

By David Nesseth

Ed Houghton’s nine days on the ground in Walkerton are now something of a blur. But the emotion remains vivid as he recalls becoming the de facto spokesperson for a tragedy that would grip the nation — informing the public and media, one death at a time, of the devastating toll of E. coli-contaminated drinking water.

Now Executive Director of the Ontario Municipal Water Association (OMWA), Houghton was called over the Victoria Day long weekend in 2000 by the Walkerton utility’s general manager, who knew of Houghton’s experience dealing with a cryptosporidium outbreak four years earlier in Collingwood, Ontario. The general manager — who would later be imprisoned for risking public safety — told Houghton a boil water advisory had been issued and that he needed help.

Arriving in Walkerton before sunrise the next day with Collingwood’s water superintendent, Terry “Hock” Hockley,

Houghton quickly grasped the seriousness of the situation. Local hospitals were admitting residents with bloody diarrhea, and the town’s chlorinator wasn’t functioning. Before initiating system flushing, Houghton requested the past 60 days of water sampling and lab reports, as well as distribution system drawings.

“It didn’t take me very long after I started reviewing the reports that I saw a trend, and I saw issues,” Houghton said, during a webinar recognizing the 25th anniversary of the crisis, which was hosted by the Walkerton Clean Water Centre (WCWC) on May 21. “The lab results showed many, many signals that should raise significant red flags, but obviously hadn’t.”

As Houghton discussed flushing plans with Hockley that day, he watched Walkerton Utility Manager Stan Koebel — his eyes red, voice shaking — walk out of the office. It would be the last time Houghton would see him until months later at the Walkerton Inquiry.

“I went from trying to restore the health of the water system with Terry Hockley to becoming the spokesperson for the utility,” Houghton recalls. “I attended all the media events. I was informing everyone what we were doing, and informing the media and the public that we now have the first death, the second death, and so on.”

While Houghton says it’s clear that Koebel and his younger brother Frank — the utility’s foreman — were “certainly neglectful,” the systemic problems went far beyond Walkerton.

“Was Walkerton an anomaly, or were they the norm?” Houghton asked during his webinar presentation. Given the state of technology, funding, and training in 2000, he believes it was, “unfortunately,” closer to the norm for many small municipalities.

As information emerged — from unusually heavy rains to a freshly fertilized cattle farm and the shallow, poorly protected Well 5 — the tragedy became a

national wake-up call. The Walkerton Inquiry, led by Ontario Associate Chief Justice Dennis O’Connor, would become a pivotal moment in Canadian environmental and public health policy.

Twenty-five years later, the former judge says he still feels the resilience of the Walkerton community, which lost seven people and saw more than 2,300 sickened by drinking manuretainted water.

“It’s one of my strongest lasting memories,” O’Connor tells the WCWC webinar, recalling how eager the community was to find out exactly what had happened. “It was simply the resilience in the community spirit of the people who went through this devastation.”

Central to what went wrong was Well 5, a GUDI well (groundwater under direct influence of surface water) that, O’Connor noted, should never have been approved by the province in 1978.

“Nobody ever revisited it, but it was a dangerous well and an accident waiting to happen — and eventually did,” he says.

Walkerton operators routinely entered identical data into

their records, and no one noticed. They skipped required residual checks and based chlorination decisions on public complaints. While O’Connor said the Koebel brothers weren’t bad people and truly “loved their community,” the system had failed them — and everyone else.

“People weren’t trained properly,” O’Connor says. “Everybody tends to focus on the two water operators in Walkerton, but the failures are much wider than that. The failures were throughout the system at every step of the way.”

O’Connor’s 121 recommendations reshaped water protection policy in Ontario. He was satisfied by the academic expertise that formed the recommendations and state-of-the-art best practices, but notes that real safety remains an evolving process.

“Human experience tells us in whatever field we look at that as time goes on circumstances change, and in the case of drinking water, new threats emerge,” O’Connor says.

O’Connor notes that he’s pleased Ontarians can have greater confidence in government based on how they responded to the Walkerton water crisis with the creation of Ontario’s Safe Drinking Water Act (2002) and the Clean Water Act (2006). It was a period in time when guidelines began to shift into legislative requirements, with a sharper focus on system operations. Multi-stakeholder source protection committees were formed and gradually O’Connor’s recommendations began to form Ontario’s drinking water protection framework.

“I take my hat off to the drinking water community for actually developing really sound policy that got implemented because it made sense,” says O’Connor.

His recommendations also led to the creation of the WCWC, which has helped to train thousands of water professionals, and hosted the 25th anniversary discussion for the current crop of water professionals, most of whom would not have been working in the sector at the time.

Brian Bates, the Walkerton Clean Water Centre’s CEO, called the event a “solemn but essential anniversary” as the sector moves from a “reactive” position to a “preventative” one.

David Nesseth is with ES&E Magazine. Email: david@esemag.com

By Mike Sklash and Matt Schroeder

Between 2010 and 2020, there was unprecedented precipitation and storm runoff in the central part of North America. This created numerous problems for municipalities, higher levels of government, industry, and homeowners.

Dragun Corporation was asked to provide expert opinions on the cause(s) of reported flooding during 2016 in a swale on an agricultural property located near Lake Erie. The plaintiff, who purchased the property in 2010, alleged that the defendant, a neighboring manufacturing plant, changed the drainage on their property. This caused more storm runoff to flow in the plaintiff’s swale that, in turn, prevented the plaintiff from easily moving between the east and west sides of his property. The plaintiff alleged that the swale had never previously prevented crossing with farm equipment.

Natural conditions: We investigated the nature of the swale as a natural groundwater discharge area. We inspected the site and interviewed relevant parties familiar with the local drainage. We reviewed historical topographic maps and determined that the swale was a natural groundwater discharge area, receiving groundwater from the higher surrounding areas. Although there were no continuous records of groundwater levels in the watershed of the swale, regional data was consistent with natural and significant increases in groundwater levels since at least 2010. We attributed the higher groundwater levels to increased precipitation during the decade.

Nearby groundwater elevation and lake level monitoring data were consistent with the increase in base flow. These data support the concept of wetter conditions in the swale due to natural conditions.

Changes to the watershed: The defendant expanded their plant, located

Between 2010 and 2020, there was unprecedented precipitation and storm runoff in the central part of North America. Credit:photogeek,stock adobe.com

north of the plaintiff’s property in early 2016, including the construction of a storm sewer system and a detention pond. Prior to 2016, the defendant’s property naturally had a topographic divide that caused stormwater to flow in opposite directions. However, the plant expansion redirected some stormwater flow from north to south.

The defendant designed their new drainage system to limit stormwater discharge rates to comply with local requirements. The storm sewer system includes a detention pond and all components of the system complied with reasonable and accepted practices for managing stormwater runoff. In fact, the system limits the maximum flow rate to pre-expansion levels and is designed to drain within three days post-storm.

The plaintiff also made drainage alterations on ground sloping to the swale; these changes were intended to facilitate drainage from the slope into the swale. These improvements on the slope actually contributed to greater wetness in

the swale, particularly following precipi tation events. These changes were made both before and after the 2016 construc tion at the defendant site.

Results: The jury quickly determined that our analysis was reasonable; they recognized that the defendant was not responsible for the flooding in the swale. Our analysis indicated that although the defendant’s drainage modifications and the plaintiff’s flooding problem began at about the same time (and that the plaintiff had not experienced these con ditions previously), the two events were unrelated.

The wet conditions along the swale on the plaintiff’s property were caused mostly by its topographic position, regionally wet conditions between 2010 and 2020, and drainage works conducted by the plaintiff on his property.

Dragun Corporation was also asked

WE HAVE AN EASY

INSTALL A SWM SHIELD TO PRE-TREAT YOUR POND

to provide expert opinions on the cause(s) of reported flooding during 2018 at a cottage. The plaintiffs alleged that the defendant increased runoff onto the plaintiffs’ property by reconstructing the lakeside road adjacent to the cottage.

The plaintiffs purchased the property in 2001 and alleged that the property began to flood in 2012. Flooding became severe in 2018 when the roadway was improved. In 2018, the plaintiff’s driveway and garage filled with sediment during storm events.

Two natural conditions exacerbated storm runoff around the cottage. First, the topography around the plaintiff’s cottage based on topographical maps and our site walk observations indicate the cottage was built in a natural groundwater discharge area. This is similar to the analysis in Case Study #1. In Case Study #2, groundwater from higher surrounding areas in the east discharges into the lake and also causes the water table at the cottage to be close to the ground surface. This condition is conducive to storm runoff generation during precipitation. Secondly, the period from 2017 to 2020 was exceptionally wet in this region, with 2019 being the wettest year on record. This increased precipitation led to higher groundwater levels and more runoff.

One of the most obvious indications that the flooding at the cottage was not the result of road work was the sediment load in the storm runoff.

Screen shots from videos the plaintiffs made during one of the flooding events in 2018 showed the following:

• Ponding at the ground surface adjacent to the cottage.

• Storm runoff flowing in the west side “valley” curb on the lakeside road flowing from right to left towards the cottage

• Sediment-laden storm runoff issuing from the unpaved, private road on east side of the lakeside road flowing towards the cottage.

• Sediment-laden storm runoff crossing the lakeside road toward the sandbags that line the entry to the driveway of the plaintiff’s cottage.

The litigation was ultimately resolved by the parties through a private agreement.

In this situation, we were asked to provide expert opinions on reported flooding that flowed from a culvert under an unpaved, rural road in front of the plaintiff’s property. The plaintiff alleged that the flooding in June 2017 was due to storm runoff that moved along, and then under, the rural roadway, through a culvert onto their property. The 600-mm diameter culvert was installed many years before the plaintiff purchased the property.

Two natural conditions help to explain the flooding at this location. First, the topography around the plaintiff’s property,

The wet conditions along the swale on the plaintiff’s property were caused mostly by its topographic position, regionally wet conditions between 2010 and 2020, and drainage works conducted by the plaintiff on his property.

based on topographical maps, wetland maps, and our site walk observations, indicated the property sits in the way of natural surface water drainage. This natural surface water drainage was present long before the plaintiff’s property was developed. Secondly, the watershed was unusually wet during the decade and 2017 was one of the wettest years on record in the area. Both of these factors would promote storm and snowmelt runoff.

Again, the litigation was ultimately resolved by the parties through a private agreement.

Between 2010 and 2020, unprecedented precipitation and storm runoff in the central part of North America created numerous property-related problems associated with excess water. The common thread in these case studies was that the plaintiffs experienced an excess water problem they had never seen before. They claimed the problem originated because of something the defendants did on/near their property.

In situations like this, typical site-specific data such as historical groundwater level measurements and runoff measurements are not available. As a result, we used classical hydrogeological evaluations, such as recharge versus discharge area analysis, baseflow analysis, and historical groundwater and surface water records from various sources. We also examined time trends in precipitation to determine whether natural conditions in the watershed could have been responsible for the excess water.

In some other cases we have worked on, the excess water was self-inflicted. If the property’s water supply is from a deep aquifer and the property uses septic tanks for water disposal, there will be excess water on the property. If the property is developed, changing the amount of impermeable surface on a property, such as roof areas and pavement, will create excess water.

Mike Sklash and Matt Schroeder are with Dragun Corporation. Email: msklash@dragun.com, mschroeder@dragun.com

Over 50 years ago, Pentair installed its pumps at the Mill Creek Pumping Station in St. Louis. Today, the city has turned to Pentair to breathe new life into the station.

By Roy Gong and Yang An

Halton Region is a growing municipality of about 600,000 in southern Ontario. It owns and operates seven wastewater treatment plants, as part of its responsibility to provide wastewater management services for the municipality.

Following the construction of a new stand-alone filter building at the Acton Wastewater Treatment Plant, the region wished to retrofit the decommissioned filter building, repurposing the filter wing and combining it with the office wing to create a new administrative building.

This adaptive reuse approach reduces the embodied carbon footprint by minimizing the need for new construction. The region engaged Associated Engineering (AE) to provide engineering services for the filter building retrofit and various plant upgrades. As the prime consultant, AE’s scope of work includes critical elements such as the demolition of the existing process infrastructure, building mechanical services for the retrofitted space, structural retrofit and backfilling of the existing filter tank, and repurposing of the space as offices.

In addition to the retrofit and facility upgrade, the region also wanted to implement energy-saving options to reduce the facility’s environmental impact. Funding is available for green initiatives to support this goal. AE proposed and reviewed several options with the region, and completed a feasibility study to document the viability of potential approaches.

Some of the green initiatives explored to reduce environmental impact included alternative heat sources, such as a

hydronic heating system and geothermal heating. The team also investigated the benefits of upgrading the heating, ventilation, and air conditioning (HVAC) system.

The existing HVAC system for the office area was old and outdated. AE determined the most practical way to serve the retrofitted administrative building was to install roof-top units for conditioning the space. A new HVAC roof-top unit with better energy-efficiency was proposed. Variable air volume boxes are being installed for different rooms to tune the air flow and lower energy consumption when the space is unoccupied.

During preliminary design, the region requested that AE incorporate equity, diversity, and inclusion (EDI) concepts into the design, aligning with their new EDI policy. The EDI design concepts significantly altered the original design, in particular the changing rooms, locker rooms, and showers.

Working closely with the architectural subconsultant, AE developed solutions to minimize the impact on the overall design and re-work efforts. The region acknowledged the scope of these changes and accommodated the additional work required.

During detailed design, the Region asked AE’s team to explore solar thermal wall installation, a technology used to capture and use solar energy to preheat the ventilation air for buildings. Also known as a transpired solar collector, a solar thermal wall is a passive solar heating system designed to reduce the energy required for heating, especially in industrial and commercial buildings. AE’s investigations with a local supplier determined the feasibility of this option.

Roy Gong and Yang An are with Associated Engineering. Email: gongr@ae.ca, any@ae.ca

• No Corrosion or Contamination

• No Chemical Absorption or Wicking

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant.

Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for:

• Chemical Transfer

• Neutralization

• Dosing

• Effluent Control

• Lift Stations

• Odor Control

• Recirculation

• OEM Applications

By Ian Lake-Thompson

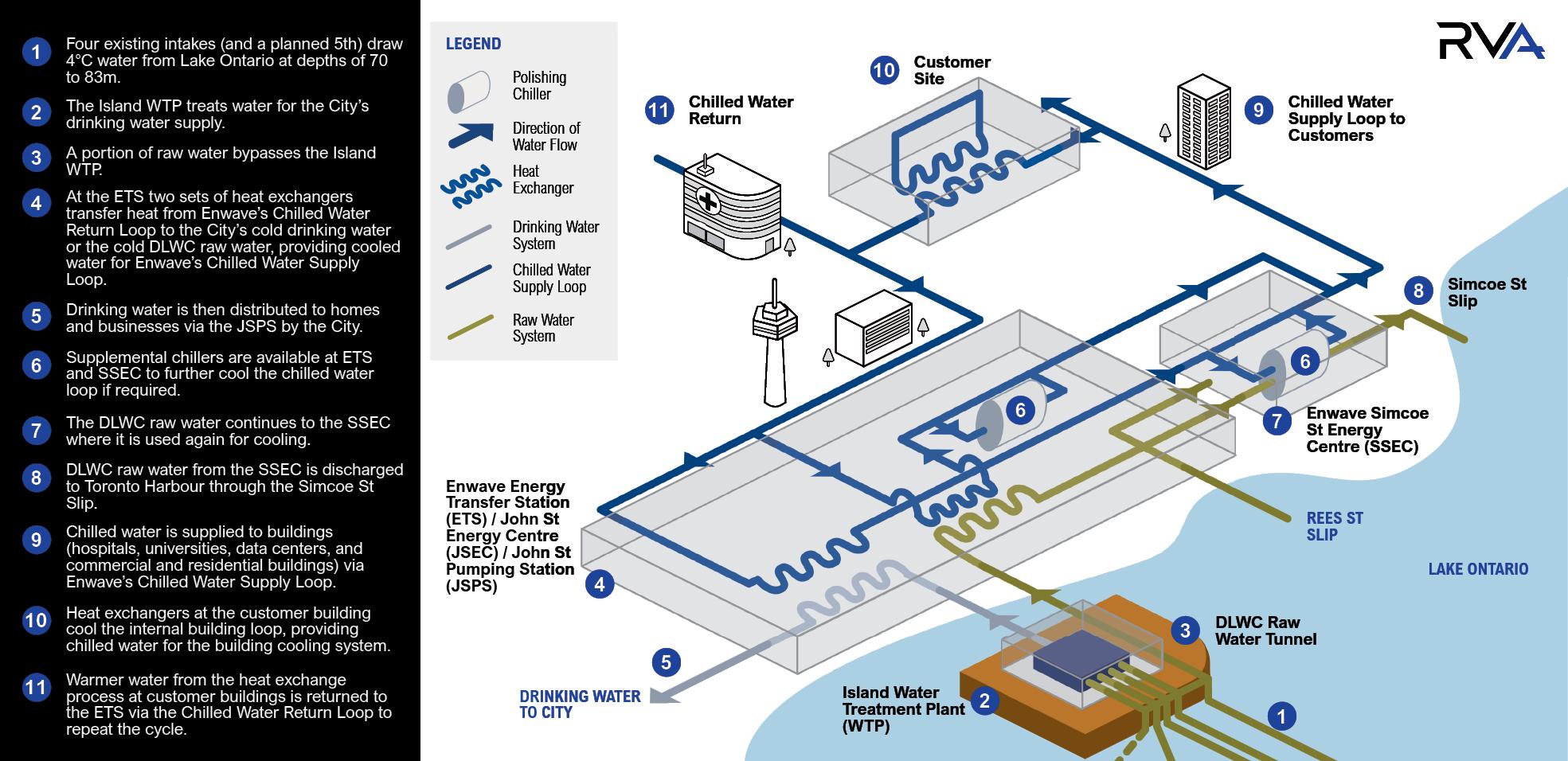

Toronto is home to many engineering marvels, with its tallest being the CN Tower. However, you may want to look near its base for one of its cooler marvels — The Deep Lake Water Cooling System (DLWC).

To the south of the CN Tower is the John Street Pumping Station, which is the epicentre of this system. However, the DLWC stretches over many kilometers

across the City of Toronto, deep underground and far out into Lake Ontario. The concept is simple, using year-round cold water (4°C) from the bottom of Lake Ontario for district energy cooling. However, its implementation is highly complex.

The Deep Lake Water Cooling System is the world’s largest lake-based system used for district energy system cooling. The City of Toronto and Enwave Energy

Corporation operate it under an energy transfer agreement (ETA) that facilitates the transfer of heat energy from Enwave’s District Energy System to the City’s cold drinking water infrastructure through heat exchangers.

This system came to fruition in the late 1990s, with a number of studies and design activities. A key aspect was the formation of the City of Toronto and Enwave partnership to allow its advance-

ment. Following that, the DLWC system, including three new raw water intakes, was constructed, and commissioned by 2004.

The intakes draw cold water from Lake Ontario to feed the Island Water Treatment Plant’s direct filtration processes. Cold potable water is then transferred to the John Street Pumping Station, where it is pressurized for distribution into Toronto Water’s drinking water distribution system. At the John Street Pumping Station heat exchangers are used to transfer energy between the potable water distribution system and the district energy cooling system.

The primary advantage of the DLWC is efficiency both as a district energy system and through the avoidance of conventional chillers for air conditioning. A key metric is 80% less energy requirement compared to conventional cooling systems such as electrical chillers/air conditioners.

able cooling loads in the District Energy System to the more renewable source of cooling through the DLWC supply.

Since 2004, the DLWC system has serviced a lot of the cooling needs of Toronto. continued

However, there is increasing demand for cooling in Toronto’s downtown core. This has come both from development and the desire to shift from non-renew-

The use of renewable energy sources to provide cooling is a key factor in the City of Toronto’s TransformTO Plan implementation strategy. The goal is to reduce greenhouse gas (GHG) emissions and achieve net-zero. As buildings generate over half of Toronto’s GHG emissions, district energy systems such as Enwave’s district heating and cooling systems, are considered critical components of this strategy.

In 2018, Enwave and the City of Toronto continued their ongoing partnership to initiate a program to complete the Deep Lake Water Cooling Expansion — DLWC-E or Fourth Intake. This continued partnership required consideration of both parties’ requirements to allow project advancement. It also required initial background studies and pre-design to finalize agreements and system funding. Design and construction commenced in 2020, with the system commissioned in early 2024. The expansion work was completed utilizing non-conventional implementation methodologies to help expedite the schedule and obtain partner buy-in.

This also included the subdivision of project elements to allow differing styles of design advancement, procurement and construction, allowing certain elements to be completed as a conventional design-bid-build with other elements as

a contractor-led design-build project.

The expansion now provides additional raw water capacity to the Island Water Treatment Plant and to Enwave Energy Transfer Facilities at the John Street Pumping Station and the Simcoe Street Energy Centre.

The completion of the expansion work also nicely coincided with the 20th anniversary of the Deep Lake Water Cooling System. Not only is the system the world’s largest of its kind, it also has many interesting aspects:

• The deepest tunnel in Toronto, extending to 93 m depth below surface. Constructed in downtown Toronto near the John Street Pumping Station and extending 3 km to Toronto Island near the Island Water Treatment Plant. The Island shaft was constructed primarily in sand and utilized ground freezing to facilitate construction to the tunnel connection. The Island shaft includes permanent works above grade for process equipment and surge control.

• Upgrades at the Island Water Treatment Plant for the additional fourth raw water intake.

• Innovative usage of inactive City infrastructure in the form of the rehabilitation of a 600-m long marine pipeline via offshore sliplining. This also helped to avoid nearshore environmental disturbances.

• A new 3.3 km long 1,600-mm HDPE

pipe installed at a water depth of 70 m via controlled sinking (known as the fourth intake).

• Expansion of pumping and heat transfer equipment at the John Street Pumping Station and the Simcoe Street Energy Centre.

• Over 50,000 m2 of heat exchange area via plate and frame heat exchangers. This would be equivalent to approximately 10 football fields.

• Two megawatts of pumping capacity supplied by four new pumps.

• 251 million litres per day capacity expansion, for a total raw water capacity of 704 million litres per day.

• To date the DLWC has saved nearly 130,000 tCO2e over its lifetime, and 1.7B KWh of electricity.

• The expanded DLWC renewable cooling capacity that offsets over 60 megawatts of electricity generation and reduces demand on the downtown Toronto electrical grid.

Congratulations to Enwave Energy Corporation, City of Toronto, and the whole Deep Lake Water Cooling Team.

Learn more about this system by visiting www.enwave.com

Ian Lake-Thompson is with R.V. Anderson Associates Limited. Email: ilake-thompson@rvanderson.com

By Angelica Pajkovic and Tim Goedeker

Gaskets and packing solutions can play a significant role in advancing sustainable industrial operations by focusing on reducing fugitive emissions from valves and flanged pipe connections. By preventing the escape of volatile organic compounds (VOCs), valve packing, such as Teadit’s 2848 or 2236, helps decrease the overall environmental impact of industrial processes. Proper packing selection results in fewer VOCs released into the atmosphere. Low-emission packings are certified to meet stringent requirements of leakage, with some as low as 2 parts per million.

Reduced emissions also mean lower health and safety risks for on-site personnel, as VOCs can be hazardous when inhaled or exposed over time. This reduction is crucial in minimizing the effect of industrial operations on climate change.

In addition to enhancing safety, these solutions help conserve valuable resources. Preventing VOC leaks avoids the wasting of the materials involved in the production and transport of process media, as well as the energy used to move and process it. By containing these elements within the system, sealing technologies like Teadit’s 913M spiral wound gasket maximize process efficiency and resource utilization, ultimately supporting the industry’s shift toward more sustainable practices.

There are several solutions on the market today that arrest fugitive VOC emissions to well under 100 ppm. Facilities and operations should consider the following:

• How much water is used in the production of the solutions?

• What can be done to reduce the freshwater use footprint?

• Can the amount of freshwater be reduced via recycling or can other types of water — rainwater, treated wastewater —– be used instead of freshwater?

• How much waste is generated in the

Gaskets and packing solutions can play a significant role in advancing sustainable industrial operations by focusing on reducing fugitive emissions from valves and flanged pipe connections Credit: engineer — studio,stock.adobe.com.

Preventing VOC leaks avoids the wasting of the materials involved in the production and transport of process media, as well as the energy used to move and process it.

production of the solutions?

• What can be done to reduce the footprint of waste generated?

• Can packaging be reduced to avoid excess waste?

• How is nature (land primarily) impacted by the production of the solutions?

• If fugitive emission solutions use

minerals from the earth, are there other minerals that could be used to produce an equivalent product with less impact on nature, i.e., less invasive mining or mineral capture processes.

Sustainability is not just the use and care of air, but also the use of water, the disposal of wastewater, the creation of waste, and care of nature and biodiversity. As the common goal is sealing for a safer and greener tomorrow, it is important that the world begin to understand and adopt sustainable practices while manufacturing products, such as gaskets and packing, that aim to increase sustainability.

Proactive sealing manufacturers with increasingly efficient, reliable, and responsible processes should be constantly looking for ways to reduce their impact on the environment and the earth.

Angelica Pajkovic and Tim Goedeker are with Teadit. Email angelicap@teadit.com.

By Paula Campbell

As spring runoff begins to flow through Alberta’s valleys, it reminds us of the important role groundwater plays across the landscape. The annual snowmelt influences Ducks Unlimited Canada (DUC) projects in Alberta and impacts our communities through the seasons ahead.

Groundwater is a vital resource for agricultural communities, supplying clean water for crops, livestock, and other farm operations. Many households and municipalities rely on strong groundwater reserves for drinking water and to maintain lake levels and river flows. Groundwater is essential to Indigenous communities, maintaining water levels and flows that sustain the land. It is a sacred element of traditional life and knowledge, connecting people across generations, and foundational to sanctuaries where wildlife and people can thrive harmoniously.

Groundwater resides beneath the Earth’s surface, filling cracks and spaces in soil, sand and rock. It occurs in underground formations called aquifers and is frequently a crucial source of fresh water. Rain and snowmelt percolating through the soil replenish groundwater, which naturally reemerges through springs, rivers and wetlands. This water plays a key role in the global water cycle, contributing to ecosystem health and sustaining life. However, groundwater faces increasingly challenging conditions, putting essential drinking water, ecosystems and the environment at risk.

“Depletion of groundwater has occurred over time largely due to the ongoing development of natural landscapes like grasslands and forests, or the draining of wetlands. Wetland loss disrupts their natural recharge function and can lead to declining groundwater levels, potentially affecting availability and qual -

ity for other uses,” says Pascal Badiou, research scientist with DUC. “Climate change can also deplete groundwater through increased evapotranspiration and decreased recharge, while impacts on precipitation patterns and how those related to groundwater recharge tend to be more variable,” Badiou shares.

These challenges pose a risk to the livelihood of Albertans in so many ways; however, wetlands help mitigate many of these challenges. DUC is dedicated to keeping and restoring wetlands on working landscapes, ensuring they continue to support groundwater security. As nature’s multitaskers, there is no better nature-based solution for the job!

Because wetlands are depressions on the landscape, they collect water and form an essential component of an area’s water regulation. They are connected to water underground, helping to recharge groundwater and aquifers.

As water drains into a wetland, it is filtered, while bacteria in soils and sed-

iments help break down contaminants. Once the water settles into a wetland, it is absorbed in the saturated sediment on the bottom, further filtering the water before slowly releasing it to groundwater aquifers or surface streams, helping to ensure sustainable water resources during periods of drought and unreliable water supply.

“While we generally work with small isolated mineral wetlands like prairie potholes, these can still be hydrologically connected to other wetlands and downstream waterbodies through groundwater,” says Badiou.

Badiou explains, “Ali and Creed’s (2017) modeling work in Alberta showed that prairie pothole wetlands are not hydrologically isolated and that the surface and subsurface hydrologic connections vary significantly in terms of their timing and length. These contributions can be substantial regardless of the wetland’s location in the watershed, and the volume flowing through can be comparable to those associated with surface water connections.”

Through partnerships with land stewards and its diverse conservation programs, DUC has indirectly contributed to groundwater storage and filtration while enabling delivery of other ecosystem services that support many different people, places and wildlife in Alberta. Key impacts include managing 1,690 basins that store 1.6 billion m³ of water. This is the equivalent to 90 Glenmore Reservoirs or 640,000 Olympic-sized swimming pools.

Millions of dollars have been invested in initiatives like wetland restoration, forage programs, and conservation easements to restore and enhance water filtration, groundwater recharge, and wildlife habitat.

Since 1938, DUC has conserved 2.3 million acres across Canada, focusing on restoring wetlands and grasslands to sustain biodiversity and counter habitat loss. By working with partners and land

stewards, DUC ensures wetlands remain on the working landscape, supporting clean water, climate resilience and sustainable livelihoods.

Paula Campbell is with Ducks Unlimited Canada. To learn more about DUC projects, visit: www.ducks.ca

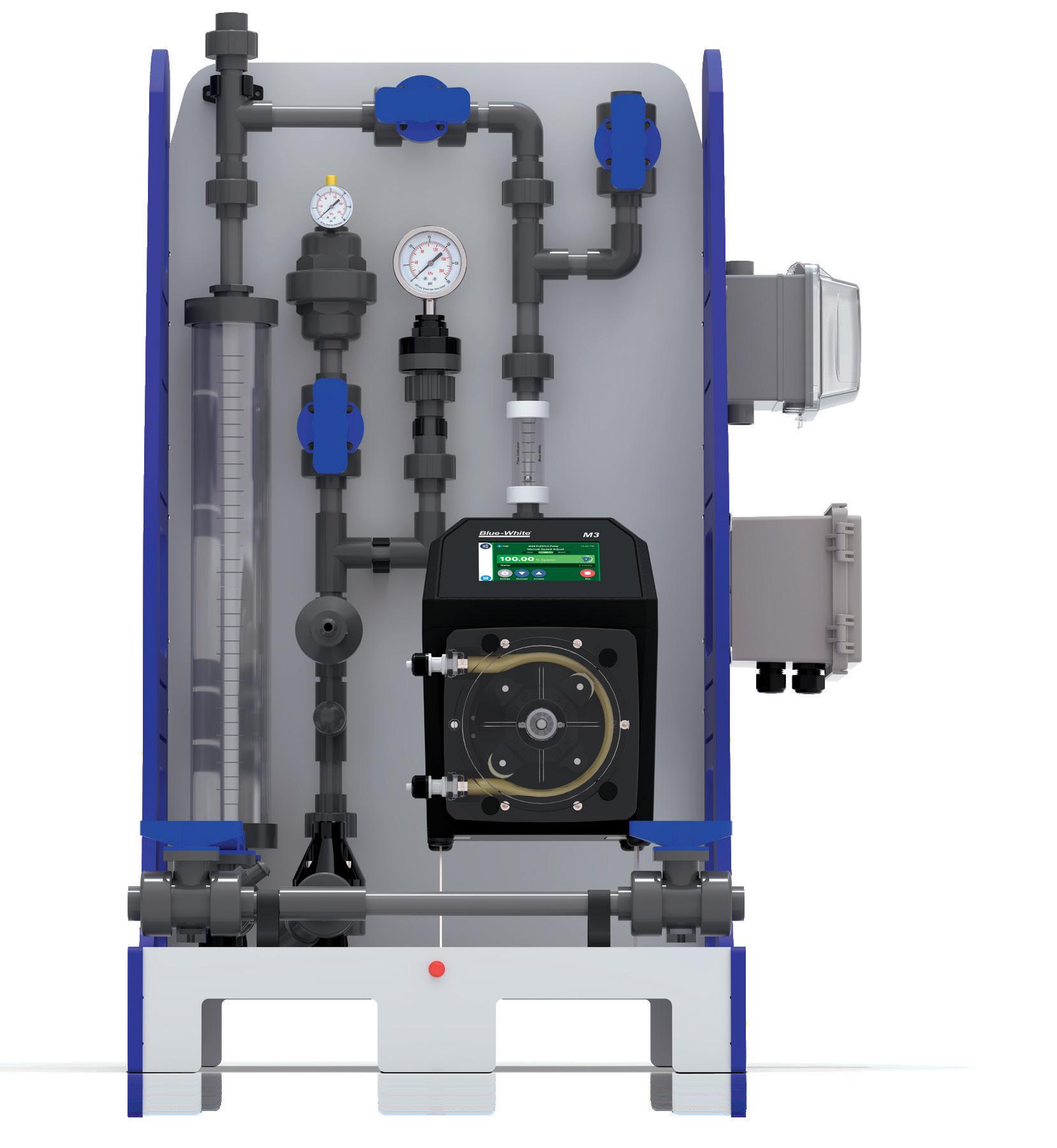

By Jeanne Hendrickson

Chemical metering pumps are used in water treatment plants to deliver precise volumes of sodium hypochlorite, peracetic acid and other disinfectants into the systems. Depending on the type of pump, the chemical being dosed, and other circumstances, operators can experience vapour locking.

This phenomenon occurs when gases, typically formed due to the volatility of certain chemicals, accumulate within the pump head. Because gas is compressible, it doesn’t allow for the proper movement of liquid. This creates a blockage, which can result in an improper dose or no dose at all. It may even stop the pump. Several factors contribute to vapour locking in chemical metering pumps. Chemicals that off-gas or vapourize can create air pockets that can cause vapour locking. Sodium hypochlorite, for example, is known to release chlorine gas when it breaks down.

Some liquids that remain stable at room temperature can vapourize when temperatures increase too much. This is particularly problematic in warmer climates or with pumps that have motors which generate too much heat during operation.

A high suction lift, or insufficient inlet pressure, can also promote vapour locking. When the pressure at the pump’s inlet drops below the vapour pressure of the fluid, the liquid turns into gas, creating a blockage before the fluid even enters the pump.

Choosing an oversized pump can also contribute to vapour lock. If a pump is too large for the system’s needs or if it’s running too slowly, gas can accumulate in the pump head without being pushed through.

The short-term effects of vapour locking are often immediately noticeable. When it occurs, the pump either

Depending on the application, operators could use peristaltic metering pumps, such as these ones from Blue-White Industries, rather than a diaphragm pump.

stops injecting fluid entirely, or it fails to deliver the required dose of chemicals. This can lead to significant disruptions in the disinfection process, potentially compromising water quality and safety.

In the long term, prolonged exposure to gas buildup can cause wear and tear on pump components, including seals and diaphragms. In extreme cases, it may also lead to pump failure, requiring costly repairs or replacements. In addition, vapour lock can damage the integrity of the entire chemical dosing system, which can result in downtime and increase maintenance costs.

While vapour locking is a serious concern, there are several strategies and technologies available to mitigate its impact and ensure continued system performance.

Some pump manufacturers offer auto degassing valves to combat vapour locking. These are designed to allow trapped air to escape from the pump head without letting the liquid leak out. The valve automatically opens as air accumulates, releasing the gas and allowing the pump to continue pumping.

Auto priming is an advanced software feature, which is available on some diaphragm pumps. It will detect when no fluid is being injected and automatically adjust the pumping operation to prime the pump. By running the pump at a higher speed for a short burst, the auto

prime function helps expel air from the system and restore proper fluid flow.

As mentioned earlier, using an oversized pump that is running too slow can create vapour locking as fluid spends too much time inside the pump’s chambers. Using a smaller pump running at a higher speed could help to minimize gas accumulation.

Depending on the application, operators could use a peristaltic metering pump rather than a diaphragm pump. Peristaltic pumps are very effective when dosing fluids that contain trapped gases because they are not affected by air bubbles. They simply pass through the pump tube. There is no vapour lock and no loss of prime. However, peristaltic pumps are not always a good choice in high pressure applications.

Older pumps prone to issues of vapour locking can often be upgraded with aftermarket degassing valves. In other cases, operators can switch to a more suitable pump design. Another option involves regular maintenance, such as checking for leaks and ensuring that seals are intact. These simple procedures can extend the lifespan of the pump, improve overall performance, and reduce instances of vapour locking.

Vapour locking can be a challenge with chemical metering pumps, but it is not insurmountable. By understanding the causes and consequences of vapour lock, operators can take proactive measures to prevent it, including utilizing advanced valve technologies, optimizing pump operation, and maintaining proper system design.

By addressing vapour locking effectively, water treatment plants can ensure the continued reliability and efficiency of their chemical dosing systems, ultimately helping to maintain the safety and quality of treated water.

Jeanne Hendrickson is with Blue-White Industries. Email: jeanne@bwadvertising.com

1.8 billion people lack access to clean water

2.5 billion people—more than a third of the world’s population —lack access to a toilet

Women and children spend 200 million hours a day collecting water

Hygienic practices such as washing hands with soap can reduce the risk of diarrhea by at least 35%

More than 3.4 million people each year die from water related diseases—that’s nearly the population of LA

Nearly 90% of global cases of diarrhea are estimated to be attributable to unsafe drinking water, inadequate sanitation and poor hygiene

is

We’re taking big steps to solve the world’s water crisis—permanently. We want complete water coverage for every family, every school, and every clinic. And we’re teaming up with Everyone to make this difference last Forever.

Water For People brings together local entrepreneurs, civil society, governments, and communities to establish creative, collaborative solutions that allow people to build and maintain their own reliable and safe water systems. We’re not just addressing the symptoms of the problem, but preventing it from happening again in the future.

The road to permanent water coverage for Everyone Forever is challenging. If we invest more now to create sustainable and replicable water and sanitation infrastructure, we can achieve incredible outcomes—more children are in school, more individuals are employed, more families are healthy and thriving, and more communities are collaborating and growing. From there, the impact continues to ripple out on a national and global scale.

By Jim Caruso

Often overlooked, the small, nondescript desiccant cartridge is an important component in maintaining the performance and operation of electronics associated with flow measurement instrumentation, much of which is submerged within water or wastewater flow (or close to it).

But can that tiny dehumidifying packet truly have such a profound impact on the condition and performance of flow meter electronics and sensors? When utility managers and technicians rely on real-time, accurate flow data to maintain compliance, make informed decisions about daily operations, and potentially bill for water usage, fouled electronics have significant consequences.

Flow instrumentation often contains a desiccant cartridge, or drying agent, within the electronics to remove any moisture that may have entered the unit during the manufacturing process. Additionally, this safeguard is in place to protect the unit when the customer replaces the batteries or opens the unit for maintenance purposes.

For open channel flow instrumentation such as level sensors, bubblers, or flow loggers, the desiccant cartridge is in-line with the vent tube. The vent tube allows the pressure transducer to isolate the pressure imparted by the water and negates the pressure contributed by atmosphere.

Without a free-flowing tube, the pressure transducer would see the pressure from the water depth and the weight of atmosphere. Atmospheric pressure changes with the weather; note that your local weatherperson says the pressure is rising or falling, and this is what is being referred to. In the case of a submerged area velocity sensor, a pressure transducer in the sensor converts the pressure the water places on the transduce of the water to a level measurement.

A desiccant cartridge attached to the cable and in-line with the vent is located near the flow logger and is positioned vertically with the end cap pointed down, so the atmospheric pressure reference is protected from moisture entrapment.

Put simply, a desiccant or drying agent ensures proper operation of the flow instrumentation. If the desiccant isn’t included, or is not properly maintained, moisture will alter the integrity of the flow and level readings.

In open channel applications such as wastewater or stormwater channels, high humidity and surcharge are inevitable, threatening flow and level measurement equipment. Should condensing moisture intrude and block the reference air tube,

A diagram identifying the desiccant cartridge on the FLO-DAR® Area Velocity sensor. Courtesy of McCrometer

the level transducer will produce readings that drift from the device’s usual accuracy.

In addition to fouling, a depleted desiccant is the most common cause of level drift. Inaccurate, untrustworthy flow and sensor data will prevent wastewater professionals from making informed decisions about their collection system.

DESICCANT CARTRIDGE BEST PRACTICES

Each desiccant cartridge will need to be refilled at some point during the lifespan of the flow instrument, but the frequency will depend upon the flow application, location, seasonality, and surcharges.

If the installation is in a humid, contained location such as a manhole measuring wastewater flows, technicians may find that the desiccant requires replacing more frequently.

Certain environments are more humid or arid than others. Flow applications in dry locations may require less frequent cartridge replacement than applications in humid subtropical environments, especially if exposed to the elements rather than contained within a manhole.

Technicians and operators may find that desiccant cartridges need more frequent replacing during the rainy season or during months with higher humidity levels. After wet weather events, a site visit is suggested to ensure proper functionality and performance of the flow devices is maintained, which may include desiccant replacement. This is especially important when surcharges have occurred at the installation site.

Wastewater professionals who have numerous installation sites to maintain may find it difficult to visit each device frequently enough to sufficiently inspect the desiccant cartridge for necessary replacement. Flow and level devices don’t contain alarms to notify users when the desiccant needs replac-

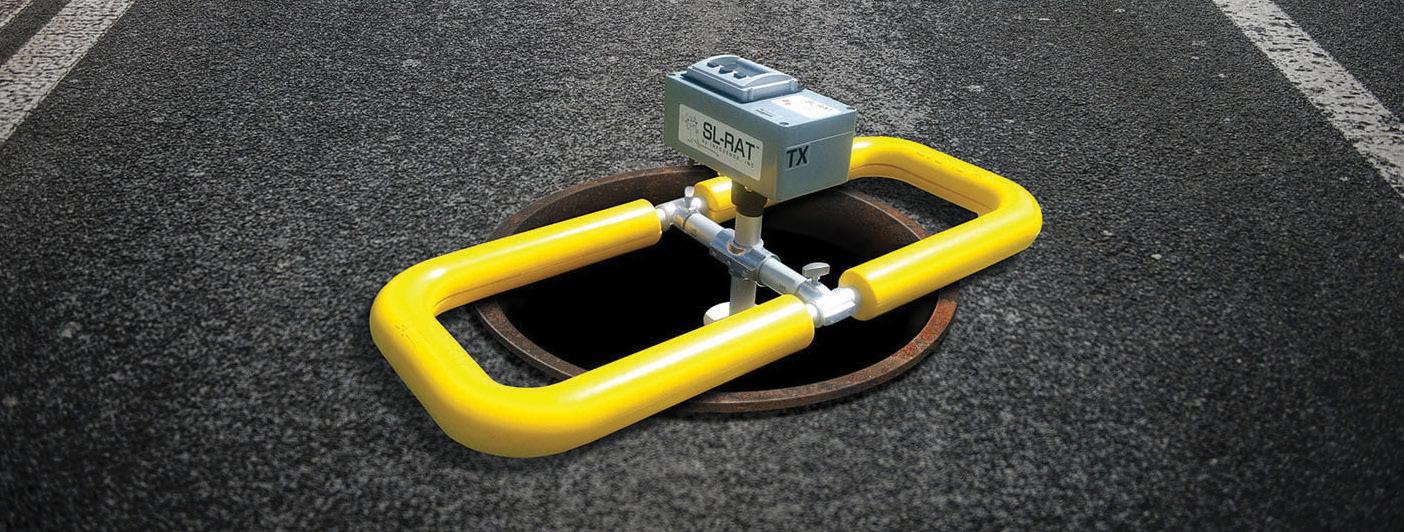

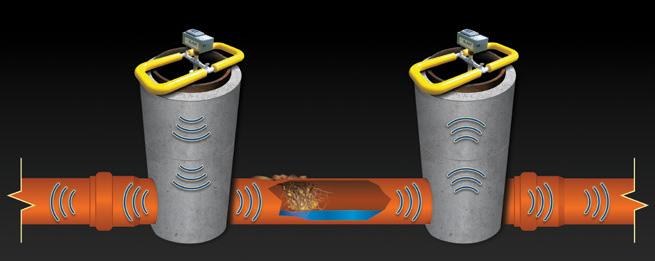

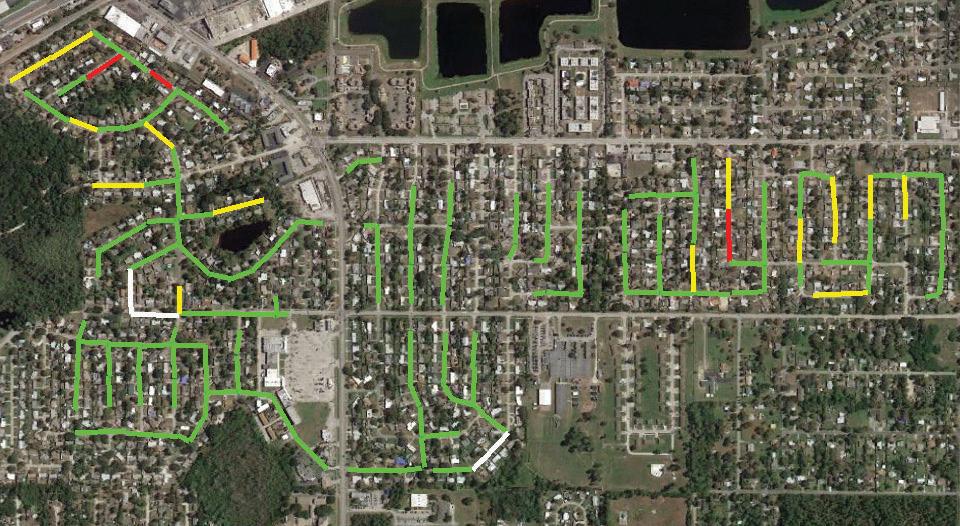

Whole-network CCTV sewer line assessment is very costly and is a slow process Rapid Assessment Technology Services (RATS Inc.) has redefined the assessment process by providing municipalities with comprehensive acoustic network condition data in a fraction of the time and cost required by the old, costly CCTV methods

Our patented acoustic technology provides real-time blockage assessments and records the condition of approximately 3,000 Meters of 150-450 mm gravity sewer lines per day Using the most commonly used mapping and database platforms, Municipalities receive a whole-network map and condition report pinpointing the areas which require the more expensive and resource intensive CCTV and repair crews only where needed – usually less than 25% of the entire network!

Ontario municipalities now can focus their high-cost resources only on the small percentage of the network that represents a potential service disruption or hazard to the community.

To find out how using RATS will result in lower overall project costs and annual required maintenance completed in less time, contact RATS today.

ing and rely wholly on visual inspection to determine if maintenance is required. Technicians can double up on desiccant cartridges and daisy chain them together to safeguard their device for longer periods of time before scheduling routine maintenance.

However, best practices state that users should visually inspect the desiccant cartridge during each site visit and develop a unique maintenance schedule based on the needs of that installation site and the instrumentation installed.

While installing multiple desiccant cartridges is an added level of protection, it doesn’t eliminate the need for manual inspection and a dedicated maintenance schedule. Should technicians and operators fail to maintain their flow devices’ desiccant cartridges and withhold site visits, their indication for needed maintenance would be in the form of level readings beginning to drift.

With enough time, irreversible damage to the sensor would occur, causing a

complete loss of real-time, accurate data, plus the cost to replace and install new flow instrumentation.

A dehumidifying cartridge or drying agent, as insignificant as it seems compared to the essential role of a level sensor or flow meter, contributes substantially to accurate, repeatable flow data. Even one droplet of water can interfere with the performance of flow and sensor equipment, producing erroneous readings. The difference between 100 mm and 112 mm of water doesn’t seem significant, but when moving at a high velocity, it’s a sizeable amount of water not being properly accounted for by flow devices.

Water and wastewater professionals often have an overwhelming pipeline network and a bevy of instrumentation to maintain. Visiting each installation site can take time away from other import-

ant, higher priority tasks, especially for a smaller municipality or one with limited “boots-on-the-ground” personnel.

One program exists to help water and wastewater professionals with ongoing maintenance of their flow instrumentation, specifically for McCrometer’s FLODAR area velocity sensor. This comprehensive service repair program is designed to keep flow monitoring equipment operating at peak performance, whether a unit requires routine maintenance or a complete repair.

In addition to sensor diagnostics, verification of measurement readings, and instrument cleaning, this service includes replacement of the unit’s desiccant cartridges to protect against moisture damage and ultimately extend the lifespan of the device.

Jim Caruso is with Hach’s Flow Solutions by McCrometer, who have representatives across Canada. Email: james.caruso@mccrometer.com

Thank you to everyone who participated in this year’s CANECT Environmental Compliance and Due Diligence Training Event. We look forward to seeing you at CANECT 2026!

SPONSORS & PARTNERS

COURSE CHAIR COMPANIES

EXHIBITORS

Bureau Veritas

CADUCEON Environmental Laboratories

CM3 Environmental Inc.

Dragun Corporation

eCycle Solutions Inc.

LimeGREEN Equipment Inc.

OACETT

Resource Productivity and Recovery Authority

Testmark Laboratories

Trinity Consultants

Tri-Phase Group

Vector Process Equipment Inc.

By Mike Hewitt

Operators Without Borders (OWB), a Vancouverbased charity, has emerged as a key player in global water and wastewater management, offering technical support, training, and disaster recovery services to regions affected by both conflict and environmental disasters. Founded in 2017 by Valerie Jenkinson in response to critical needs in the Caribbean following Hurricanes Irma and Maria, OWB’s mission centres on capacity building, sustainability, and the restoration of water services. Since its inception, the organization has trained over 500 professionals and delivered services valued at nearly $2 million globally.

The roots of OWB were planted in the aftermath of the catastrophic hurricanes that devastated the Caribbean in 2017. Bernard Ettinoffe, the general manager of the Dominica Water and Sewerage Company (DOWASCO), reached out for skilled assistance to restore water and wastewater services. In response, Jenkinson rallied a group of certified water operators from Canada and the United States to assist in recovery efforts. This collaboration laid the foundation for what would grow into a global organization, addressing broader water management challenges, particularly in disaster preparedness and recovery.

OWB’s impact in Ukraine has been profound, as the ongoing conflict has targeted essential water infrastructure, leaving utilities in a state of crisis. Despite the dire conditions, OWB has been providing virtual and remote assistance, including in-person training at Gdansk, Poland.

One of the organization’s key interventions has been the delivery of Incident Command System (ICS) training to more than 500 Ukrainian and Polish water professionals. These workshops have helped operators manage and respond to the continuous threats posed by the conflict, particularly in the aftermath of the Kakhovka Dam destruction.

In addition to ICS training, OWB has focused on chemical, biological, radiological, and nuclear (CBRN) contamination of water supplies, a pressing concern given the heightened risk of environmental contamination. OWB also provided trenching safety and water quality safety programs, including a “train the trainer” initiative, which ensures that local trainers can cascade essential knowledge to their colleagues in the field.

Moving forward, OWB plans to expand its training programs, including specialized workshops on water quality safety and lagoon revitalization, to further bolster Ukraine’s ability to recover and rebuild its critical water infrastructure.

OWB’s reach extends far beyond Ukraine, with a significant

focus on Africa. In Kenya, OWB has worked closely with the Nakuru Water and Sanitation Services Company (NAWASSCO) to deliver certified training for water distribution and wastewater collection operators. This initiative, which is part of a UN Habitat and Global Wastewater Initiative (GWI) pilot project, has already led to the certification of the first six Kenyan operators, a critical step in strengthening local water management capabilities.

In collaboration with the Kenya Water Institute (KEWI) and the Water and Sanitation Providers Association (WASPA), OWB is promoting the use of decentralized wastewater treatment systems and innovative technologies, such as biogas recovery and digital water monitoring. These efforts aim to reduce the reliance on centralized systems, which are often less efficient in rural and remote areas.

Additionally, OWB has worked across other parts of Africa, including Nigeria and South Africa, addressing aging infrastructure, non-revenue water losses, and limited regulatory enforcement. OWB’s technical expertise, combined with its strong local partnerships, has laid the groundwork for sustainable water management solutions that are both innovative and scalable.

OWB has also been instrumental in providing support across the Caribbean and Latin America. Following the destruction wrought by Hurricane Dorian in the Bahamas, OWB deployed teams to assist with water quality management and safety repairs to wastewater treatment plants.

Similarly, in Haiti, OWB’s HANWASH initiative successfully reduced non-revenue water levels in Pignon from 80% to 35%, a remarkable achievement that highlights the potential of targeted capacity-building programs.

In Latin America, OWB has worked with AySA in Argentina to address wastewater effluent issues and has partnered with Caribbean utilities to provide ICS and safety training. These programs not only bolster emergency response efforts but also contribute to long-term resilience by enhancing the technical skills of local water professionals.

Despite its successes, OWB faces numerous challenges, including logistical complexities, cultural differences, and varying local conditions. However, the organization has overcome these hurdles by building strong local partnerships, tailoring its interventions to meet the unique needs of each region, and emphasizing mentorship and long-term capacity building.

Looking ahead, OWB is focused on expanding its global presence, particularly through the launch of OWB Australia, which will serve as a hub for water and wastewater projects across Asia and the Pacific. Additionally, OWB is preparing for future disaster response initiatives, particularly in the Caribbean, and aims to become a full UNICEF Standby Partner, which would further enhance its ability to respond to global emergencies.

OWB’s work relies on the dedication of its volunteers and

OWB’s impact in Ukraine has been profound, as the ongoing conflict has targeted essential water infrastructure, leaving utilities in a state of crisis.

the support of individuals and organizations who share its commitment to sustainable water and wastewater solutions. Volunteers with relevant expertise are crucial to the success of OWB’s programs, and donations help fund operational expenses, including travel and accommodation costs for volunteers. Individuals can also become members of OWB, with membership fees contributing directly to the organization’s initiatives. To learn more about how you can get involved or support OWB, visit www.operatorswithoutborders.org, or email: info@operatorswithoutborders.org.

Mike Hewitt is with Almaquin Enterprises Limited and volunteers with Operators Without Borders. Email: mike@almaquin.com

For years, sewer maintenance crews have been taught to shoot a nozzle up a line in a hurry and clean as they come back. But this is not a race. If you are not slowing down to cover all the ground, it simply is not going to work very well, according to Dan Story, a trainer and operations manager at KEG Technologies. Instead, he trains sewer crews to clean as you go in and rinse as you come out.

“With this approach, 95% of the time you will clean a line in one pass instead of making many passes,” says Story, who travels across Canada conducting training on sewer cleaning techniques.

He says you can learn a lot by paying attention to what is happening in the line going in and coming back. “Crews need to be trained to understand what they are ‘reading’ coming out of the pipe. The information can tell you whether you are going too fast or too slow, how much debris is in the line, and whether the line is clean after the first pass, or not,” he says

When going up the line, for example,

it is beneficial to observe the amount of debris present. If there is minimal debris returning, it indicates that the

pipe is in relatively good condition, with a low accumulation of debris. So, operators can accelerate their cleaning speed.

An employee-owned company, Associated Engineering fosters collaboration and teamwork, and promotes professional and personal growth. We have immediate openings for the following positions:

• Project Managers - All Offices

• Civil Engineers & Technologists - All Offices

• Agricultural Ecologist - Vernon

• Environmental Scientists - Regina, Yellowknife

• Water Resources Engineers - Vancouver, Victoria, Kelowna, Calgary

• Wildlife Biologists - Calgary, Saskatoon

To apply and for information on these and other opportunities in our offices across Canada, visit ae.ca/careers

However, an excessive amount of recovered material suggests the need to slow down. In such cases, the flow of water acts as a conveyor belt, effectively carrying the debris out.

When the water flow confirms the pipe has been cleaned at the right speed, the maintenance crew can then lower the pressure in the hose to between 900 – 1,000 PSI and come back through the pipe at the same speed. This final single “rinsing” pass can leave the line totally clean.

A common sewer cleaning misconception is that you don’t need to open the upstream manhole when cleaning sewer pipes. This can actually increase pressure in the system and lead to blown toilets, where sewer gases flow up the laterals and cause sewage water to overflow from residential toilets. According to Story, approximately 95% of blown toilets can be attributed to how the operator cleans the lines.

Slowing down and observing the results allows for cleaning to be performed in a single pass, which helps safeguard the hose from potential damage. “If you are going into each pipe once, rather than three times, to clean it, you are basically tripling the life of a three to four thousand dollar hose,” says Story. Beyond the wear and tear on the equipment there are also operational costs to consider, such as water, fuel, as well as the productivity of the operators. “Cleaning more efficiently and effectively means lowering the operating costs per pipe and increasing what a city’s public works department can do,” explains Story.

Story cautions departments not to overlook the importance of nozzles, even when expensive trucks are purchased for providing a water supply. While a department may have invested a half-million dollars for a truck to clean sewer lines, its impact is only as good as the nozzle at the end of the hose. There are tiers of nozzles which are rated for water efficiency from Tier 1 (about 30% efficient), Tier 2 (50-60% efficient), to Tier 3 (75-98% efficient).

Approximately 95% of blown toilets can be attributed to how the operator cleans the lines.

According to Story, a Tier-1, 30-degree drilled nozzle, running 275 litres per minute at 2,200 PSI, will only exert 13 pounds of force to move debris three metres away from it. In contrast, a very high-efficiency Tier-3 nozzle, running 230 litres per minute at 2,000 PSI, will exert 98 pounds of force to move debris three metres away from it.

Effective cleaning involves more than

just using a powerful nozzle. It also entails understanding the proper positioning and placement of the nozzle within the pipe. “We teach about the difference between laying a nozzle on the bottom of the pipe and centering it into the pipe,” says Story. “We teach about the flows and angles based on the size of the pipe, and the condition of the pipe based on the last camera footage.”

“If there is an issue with roots or heavy grease, you want to use a controlled rotation nozzle which will cut and chop it up enough to avoid debris going through the manhole and creating blockages downstream,” says Story.

He recommends using a nozzle capable of breaking up blockages to a particulate size small enough to go all the way to the treatment plant without creating a problem downstream.

For more information, visit: www.kegtechnologies.net

By Logan Peak

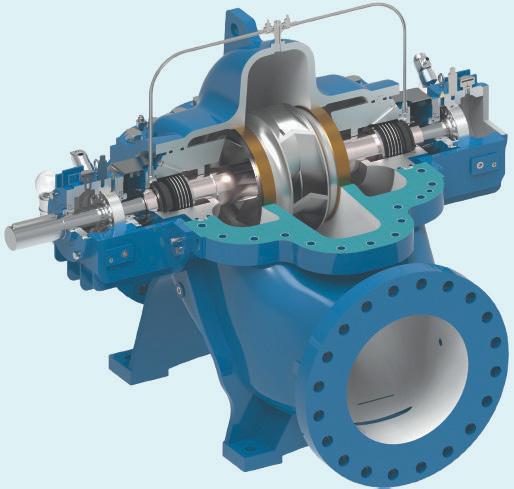

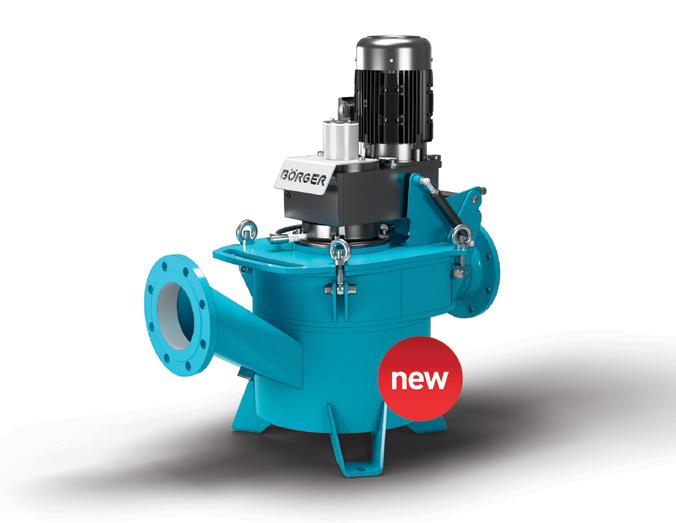

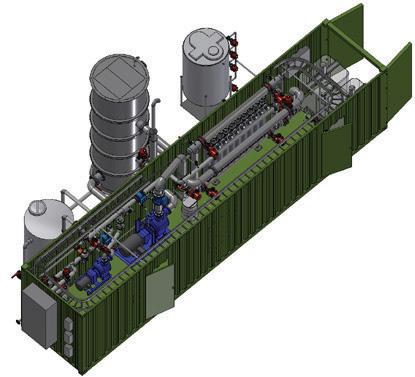

One critical component of effective wastewater treatment is the return activated sludge (RAS) pump. These pumps play a pivotal role in maintaining the fragile balance of biological activities within the treatment process.

In primary treatment, wastewater enters a primary clarifier or sedimentation tank. Here, the water is held so that larger, heavier solids can settle at the bottom, while oil, grease, and lighter solids rise to the surface. The settled material, known as primary sludge, is then removed from the tank using mechanical scrapers and pumps.

Sometimes, this primary sludge is transported out of the facility for further treatment and reuse in various applications. Primary treatment removes only about 60% of the suspended solids from wastewater. Consequently, secondary treatment is necessary to eliminate biological matter and soluble materials that need oxygen to decompose, along with any remaining suspended solids.

There are various methods for secondary treatment, with the activated sludge process being one of the most common.

Activated sludge is a mixture of microorganisms and suspended solids that metabolize and break down organic contaminants in wastewater. The process begins with wastewater and primary sludge in an aeration basin, where air is injected to help break down organic matter. Once this biological treatment occurs, the sludge is settled out in a secondary clarifier. A portion of this settled biomass, designated as return activated sludge, is then pumped back into the aeration basin to maintain a healthy and active microbial population.

Without this step, levels of settled sludge will continue to rise, eventually leading to overflow of the clarifier and a disruption in the treatment process.

Continuous flow is required to keep the microorganisms alive and maximize the efficiency of the process.

RAS pumps play a vital role in sustaining the microbial balance necessary for effective treatment. They are unique in that they must move large volumes of sludge with high solids content while minimizing shear forces that could damage the biological floc. This requirement places specific demands on their mechanical design.

Key features typically found in effective RAS pumps include large-passage impellers, often in a two-vane or recessed configuration. This allows the passage of fibrous and stringy materials without clogging.

The impellers are usually precision-cast and designed to reduce turbulence and maintain smooth flow, preserving floc integrity. Pumps with thick-walled volutes and smooth internal passages help reduce wear from abrasive materials, extending the service life of components. Pump reliability is further enhanced by the use of heavy-duty bearings and sealing systems designed for long service life under demanding conditions.

High-strength, corrosion-resistant shafts, often with renewable stainless-steel sleeves, are used to handle the mechanical stress of continuous operation while simplifying maintenance. Close-coupled vertical configurations are particularly advantageous in space-constrained treatment facilities, offering compact design and easier alignment.

Additionally, features like accessible packing boxes, clean-out ports, and externally adjustable impellers facilitate regular maintenance and minimize downtime.

Modern control strategies such as variable frequency drives (VFDs) are frequently employed to modulate flow rates, ensuring optimal return sludge flow while minimizing energy consumption. Remote monitoring promotes preventive maintenance and allows operators to fine-tune performance in real time and respond swiftly to changing influent characteristics.

These technical considerations are essential for maintaining stable biomass concentrations, avoiding upsets in biological treatment, and complying with

effluent quality standards.

Due to the requirement for continuous operation and often demanding conditions, redundancy and backup systems for RAS pumps are a necessity. Wastewater treatment plants cannot afford prolonged downtime, especially in the activated sludge process, where microbial stability is key. Designing systems with adequate redundancy ensures that maintenance or mechanical failure does not compromise effluent quality.

This is especially important in northern climates, where extreme weather can exacerbate equipment stress and complicate repair logistics. Proactive asset management and life-cycle planning are increasingly being adopted by municipalities to address these vulnerabilities and extend the operational lifespan of critical infrastructure.

Compounding the existing challenges are new and emerging contaminants that conventional secondary treatment methods may not adequately address.

Pharmaceuticals, microplastics, endocrine disruptors, and other trace pollutants are becoming increasingly prevalent in municipal waste streams.

While RAS pumps do not directly remove these substances, their role in maintaining stable and efficient biological treatment supports the broader functionality of advanced treatment processes, including tertiary filtration and disinfection. As regulatory standards evolve to address these emerging threats, the importance of foundational systems like RAS pumps will only grow.

Return activated sludge pumps may not be the most visible component of a wastewater treatment facility, but they are undoubtedly among the most critical. They play a crucial role in maintaining the delicate balance of biological processes.

Logan Peak is with Pentair, whose Canadian office is located in Cambridge, ON. For more information, email: orders.cacam@pentair.com

By Arnold Kleijn

Over the last couple of years, we have seen increased client interest in using mechanical vapour recompression (MVR) for evaporation. Given the turbulent rise and fall of energy markets since 2020 this is understandable, as the electrical energy employed in MVR is normally considerably cheaper than the thermal energy needed for traditional evaporation.

However, there are a number of limiting factors and key considerations when using MVR, particularly for very thick and viscous products like digestate and sludges. This can add to the capital cost (and complexity) of an MVR-based evaporation solution. It is therefore very important that all these elements are considered from the outset, so that an accurate investment decision based on both capital (Capex) and operational (Opex) costs can be made.

Traditional evaporation techniques use a high temperature service fluid

(such as pressurized steam) to raise the temperature of the product above its boiling point so that water (and other volatile compounds) is driven off, leaving a more concentrated solution. The principal source of energy for this process is therefore the fuel used to heat the water (steam) in the boiler, such as gas or oil.

In MVR, the steam which comes off the product in the evaporator is channeled into a compressor which increases the pressure (and therefore the temperature). This steam, which is now above the boiling point of the product, is then used as the service fluid for the evaporator. As the compressor uses an electric motor, the process is driven by electricity rather than thermal energy. Because the compressor reuses/recycles evaporated steam, a lot of latent heat is recovered. This makes MVR one of the cheapest methods of evaporating water in terms of operational costs.

However, because of the way MVR works, there are some inherent limita-