Empowering your Production

In flow with the future – production is not a rigid system. It is in motion – dynamic, precise and sustainable. Like a river that seeks its own path: powerful, adaptable, purposeful. This is precisely the basis behind our guiding principle: Empowering your Production.

Our latest EROWA magazine shows how our customers around the world are doing just that. They are making their production more efficient, more intelligent and more sustainable – with solutions that can be networked, supplemented and continuously developed. Whether in medical technology, toolmaking or series production – the creative force is in flux everywhere.

Because a river changes – yet remains true to itself. It forges new paths, adapts to the circumstances without losing its direction. This is also how we at EROWA understand the concept of production. Our automation, clamping and measuring systems, our process control solutions and our engineering are designed to grow with the requirements, while maintaining the proven principles of precision, process reliability and sustain-ability.

We wish you an inspiring read – with exciting customer stories, innovative products and ideas that will sustainably strengthen your production.

Passion in metal form

Passion in metal form

In the world of super sports cars, there are names that give you goose bumps. Pagani is one of them. Vehicles such as the Huayra or the new Utopia are more than just cars - they are moving sculptures. They express a radical demand for form, function and fascination. But to put such masterpieces on the road, you need partners who share

In the world of super sports cars, there are names that give you goose bumps. Pagani is one of them. Vehicles such as the Huayra or the new Utopia are more than just cars – they are moving sculptures. They express a radical demand for form, function and fascination. But to put such masterpieces on the road, you need partners who share this aspiration. Partners like EROWA AG.

Antonio Gerardi, Production Manager Modena Design Luca Bergano, Managing Director EROWA Tecnologie Italia Ivanis Colmanet , Sales Manager EROWA Southern Europe

Here, where passion for every detail lives on, over 700 components are produced per vehicle – many of them from a single block of titanium or aluminum. Take the steering wheel, for example: milled from a solid block, technically perfect, aesthetically a work of art. «When we show it, hardly anyone believes that it was made by machine – the surface is so flawless,» says Production Manager Antonio Gerardi.

But there is more than just high-tech behind this perfection. It is the result of uncompromising thinking that does not leave excellence to chance.

Craftsmanship meets high-tech

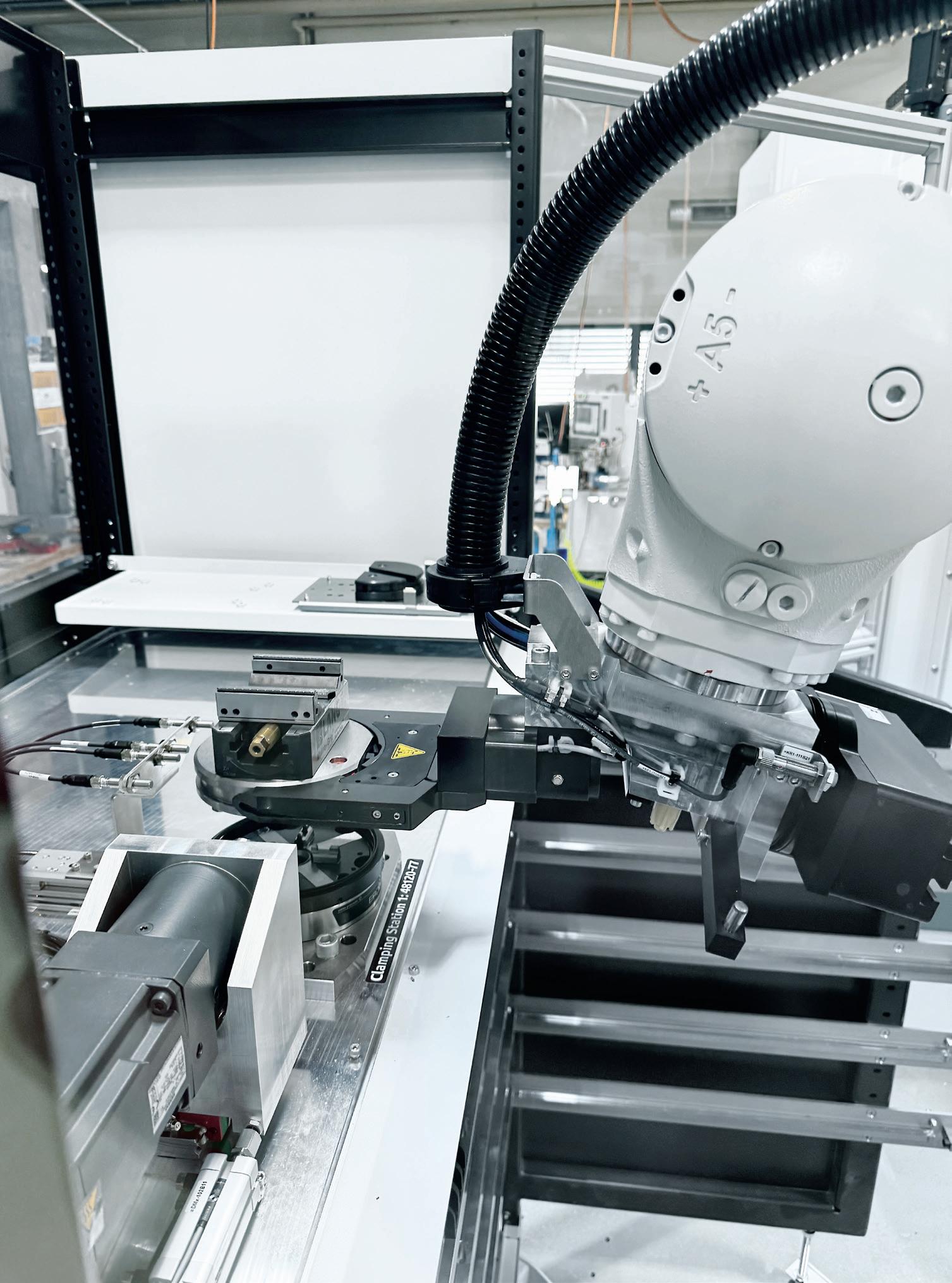

Combining this quality with efficiency and flexibility requires systems that think for themselves. This is why Modena Design opted for the automation solutions from EROWA AG. What looks like rigid technology at first glance is in fact an intelligent partner in the production process.

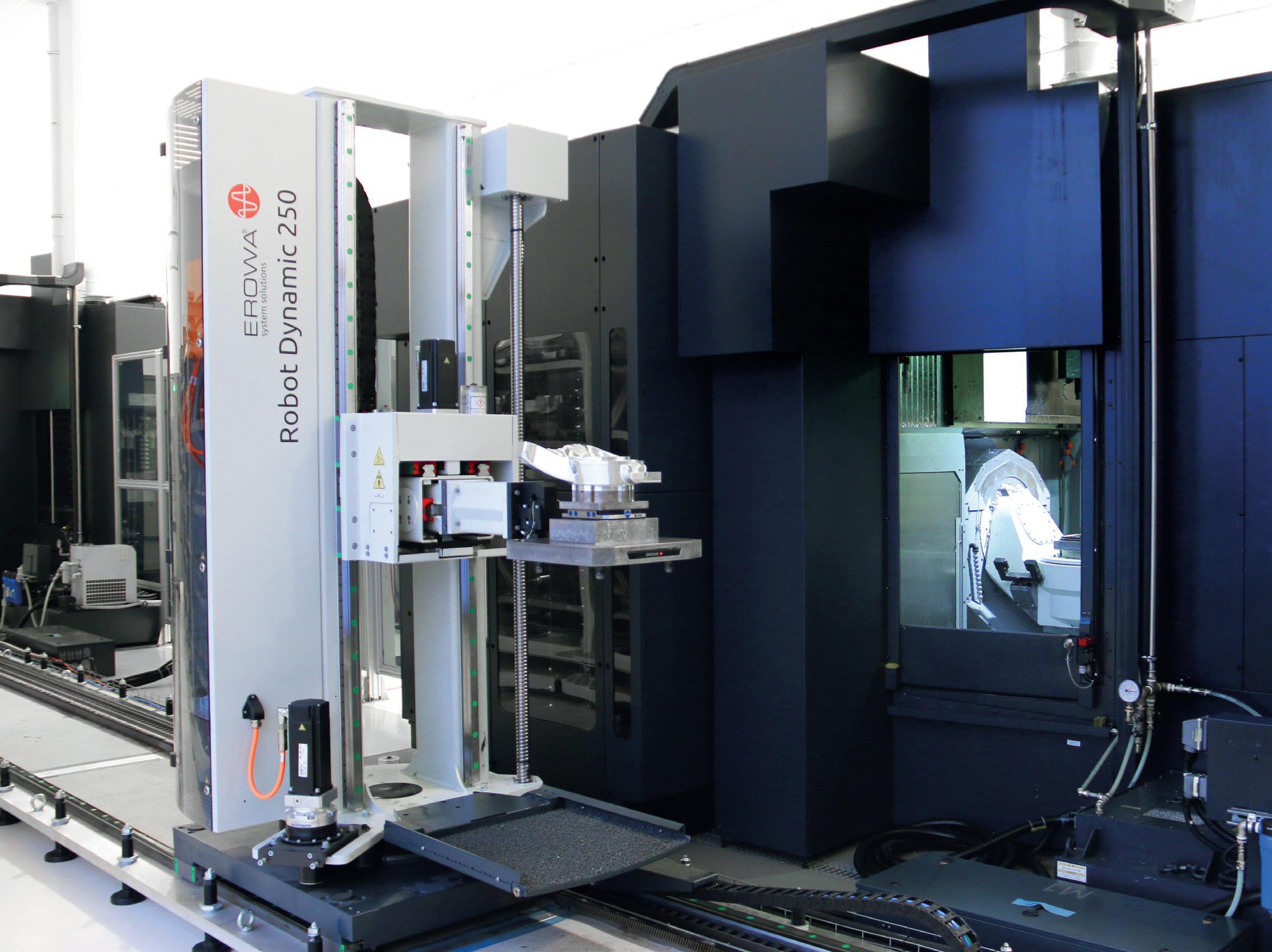

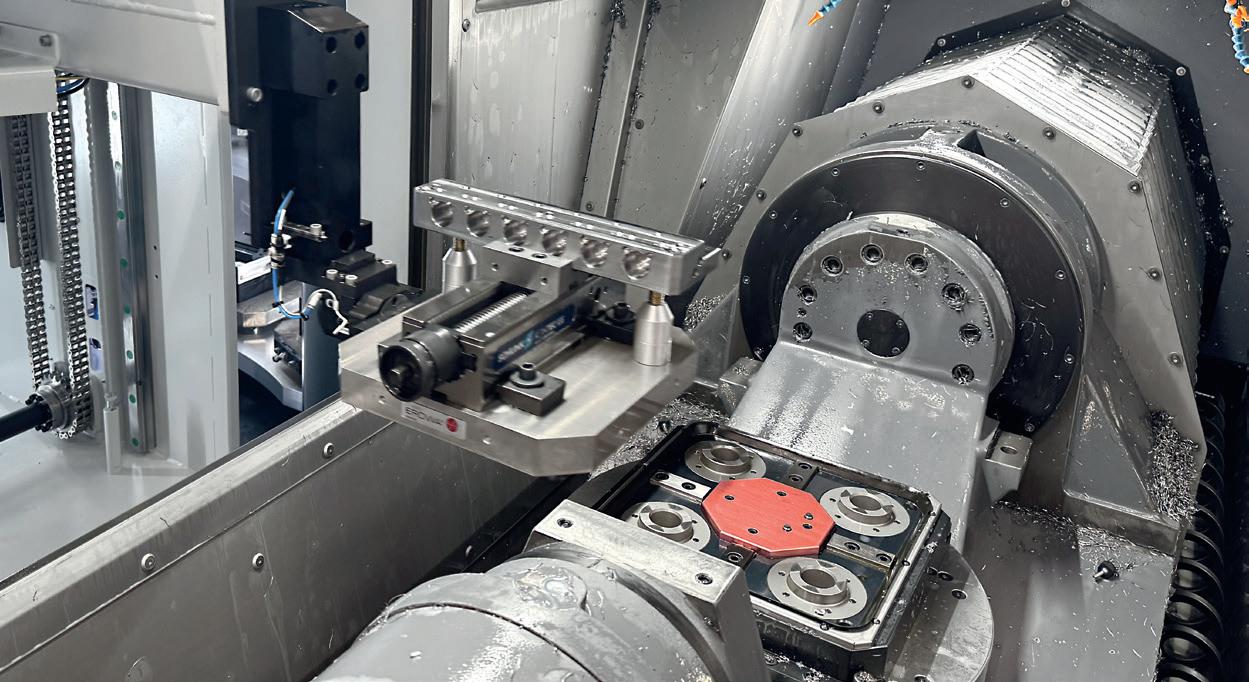

The heart of the system is the EROWA Robot Dynamic 250 Linear, which works in combination with two 5 axis machining centers from MAKINO. The four rack magazines and the central loading station enable fully automatic 24/7 operation – flexible for both individual parts and small batches. Thanks to the MTS and PC210 Combi zero-point clamping systems with pallet sizes MTS 400, PC 210 and ITS 148 mm, workpiece changeover is flexible, fast and reliable – with repeatability less than 3 micrometers.

The result: «over 7,540 machine hours per milling machine in 2024 – with consistently high quality», says Antonio Gerardi.

Automation with soul

But technology alone is not enough. The EROWA JMS 4.0 process control system controls the orders, the EWIS chip system identifies each pallet and the operator always has an overview of capacity utilization and the

order situation. Everything is seamlessly linked. «The introduction of the new machines with the EROWA Robot Dynamic 250 automation system was a decisive step for us,» says Antonio Gerardi. «We didn't want a standard solution, but a system that would maintain our flexibility – because our production relies on precision in small series and individual parts. This is exactly what EROWA delivers.»

Creating great things together

What makes this partnership special is not just the technology – it is the shared understanding. The will to make the best possible, without compromise. The ambition to not only automate processes, but to perfect them.

Modena Design will produce all milled components for 80 Pagani vehicles in 2025 – in-house, automated, but with a passion that you can feel. Because in the end – it's not just metal that's shaped – it's a feeling. A feeling for precision, for speed, for perfection. And for all those who work behind the scenes to put such dreams on wheels.

«When excellence is the goal, you need systems that think along with you. Just like those from EROWA.»

Antonio Gerardi, Production Manager Modena Design

The Robot Compact success story continues

After nearly 1,000 units sold of the Robot Compact 80 – our bestselling model – it was the logical next step to develop a “big brother.” The new “EROWA Robot

Compact 150“ offers nearly twice the transfer weight and expanded magazine capacity, pushing the limits of the ERC 80 in terms of pallet size and capacity.

EROWA ROBOT COMPACT 150

• 4.7m2 footprint for 500+ parts

• Up to 150 kg transfer weight

• Dual-machine operation

• Extra-long reach in the X-axis

• Integrated load station (optional)

• Fully automated mixed operation with different pallet sizes

• Space-saving auxiliary magazine

Extensive Functionality

The Robot Compact 150 is the ideal automation solution for flexible loading of up to two production machines across all processing technologies – from milling, to EDM to Measuring.

High magazine capacity – Minimal footprint

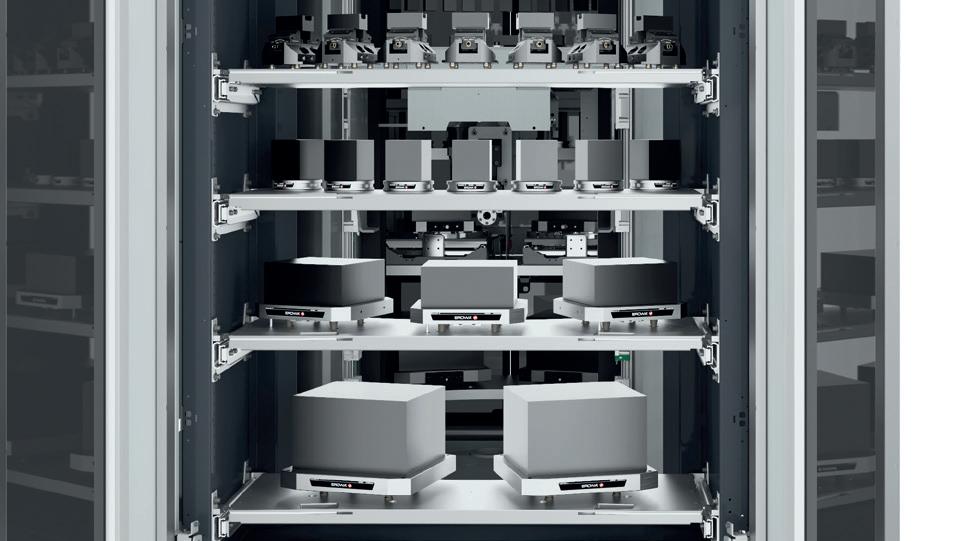

Over 500 EROWA pallets with different system sizes can be stored in the magazines. The magazine levels can be configured according to your needs. Optional pull-out magazine levels make it even easier to load and unload parts. Further options such as a third rack magazine or an additional rotary magazine offer solutions for every production environment.

Space for large workpieces

The system is capable of handling workpieces of various sizes and heights – from small EROWA ITS electrode holders to large MTS 400 pallets and part heights of up to 400 mm.

Extra-long X-axis reach

Thanks to the two independent X-axis drives, the system achieves compact magazine handling and high magazine density. In addition, this design provides extended reach and minimizes interference contours near the machine.

There’s always room for further optimization

Ypsomed is one of Europe’s leading medical technology companies. Headquartered in Burgdorf, Switzerland, and employing over 2,800 people worldwide, the company develops and manufactures high-precision injection and infusion systems for self-medication. As a technology partner to the international pharmaceutical and biotech industries, Ypsomed stands for innovation, quality, and reliability.

In such a dynamic and demanding environment, one thing becomes clear: optimization is not a one-time project, but an ongoing process. Even at the highest level, processes, workflows, and capacities can be continuously improved. Ypsomed’s latest investment in an expanded automation solution demonstrates how the company continues to advance efficiency and production reliability – with a trusted partner at its side.

A conversation with Michael Maurer and Martin Held, Managers Tool Manufacturing, Ypsomed AG.

EROWA: Mr. Maurer, Mr. Held – how did the decision to take your automation to the next level come about?

MICHAEL MAURER: «We had already gained positive experience with automation – in this case, with an EROWA Robot Easy, which was running almost around the clock on one of our milling machines. However, despite our satisfaction, it was clear to us that we needed to expand

capacity and increase productivity. At Ypsomed, we handle a very high volume of parts with varying throughput times. To manage this efficiently both economically and in terms of staffing, the next logical step was an expanded automation solution with more pallet stations and greater flexibility.»

How did you come to choose the EROWA Robot Compact 150?

MARTIN HELD: «The decision wasn’t originally planned. During a visit to EROWA in Büron to explore possible solutions, we came across the ERC 150 – which hadn’t been officially launched yet. That was a stroke of luck for us. The system immediately impressed us: it’s technically wellengineered, neatly constructed, robust, flexible, and perfectly suited to our workpiece sizes and clamping systems. The fact that we were the very first to purchase an ERC 150 speaks volumes about our trust – in both the technology and our long-standing partnership with EROWA.»

How has the new system integrated into your daily production routine?

MICHAEL MAURER: «Seamlessly. It was important for us to continue production during the installation. Apart from a few days when the machine was connected, there was no downtime. Since then, the ERC 150 has been running continuously – and that’s what really matters. We have increased machine operating hours by about 2,500 hours per year, achieving 24/7 operation. For us, this is not just an economic improvement but also a strategic one. The system runs around the clock, which not only boosts output but also provides reliable planning security.»

What do you see as the main benefit?

MARTIN HELD: «Definitely the flexibility. With the ERC 150, we can handle both large pallets like the UPC 320 and smaller ITS 148 pallets. This allows us to take over batches from other machines or fill in gaps as needed.

We use our resources much more efficiently, and our employees stick to regular day shifts. Weekend shifts aren’t necessary; we manage those through on-call duty. The automation takes care of the rest.»

Can you say whether the project has “paid off”?

MICHAEL MAURER: «Yes, without a doubt. The system works flawlessly from a technical standpoint; it’s reliable, low-maintenance, and robust. That’s exactly what we need. For us, it’s not about technological bells and whistles – it’s about the system running smoothly – and it does. Would we choose it again? Absolutely.»

Ypsomed has relied on EROWA for over 30 years. What makes this partnership special?

MARTIN HELD: «It’s the combination of reliability, technical expertise, and experience. EROWA has been supporting us for decades – starting with EDM and now increasingly in milling with modern automation. What’s especially important to us is that their systems are welldesigned, mature, and fit perfectly into our operations. And if we ever need anything, support is always quick to respond. This consistency over decades has become rare and is of great value to us.»

What’s next for Ypsomed?

MICHAEL MAURER: «We are currently preparing a major project. At our new production site in Solothurn, not only is a new manufacturing area being established, but also a fully networked automation line.»

MARTIN HELD: «This marks our next major development milestone, as until now we have automated individual machines. In Solothurn, we are taking a decisive step forward by integrating multiple technologies into one cohesive automation process. By combining milling, measuring, and washing in a continuous production chain, we are achieving an even higher level of efficiency, process control, and reproducibility.»

MICHAEL MAURER: «And here, too, it’s not about replacing personnel at all, but about making the most of our infrastructure. Our skilled employees focus on value-added tasks, while the automation ensures consistent quality and steady utilization around the clock.»

Any final words?

MARTIN HELD: «At Ypsomed, we hold ourselves and our partners to the highest standards. Anyone who thinks that everything in medical technology is already optimized simply doesn’t know us. With the right tools, systems, and mindset, there’s always room to achieve more. And that’s exactly our commitment.»

Martin Held, Manager Tool Manufacturing Ypsomed Michael Maurer, Manager Tool Manufacturing Ypsomed

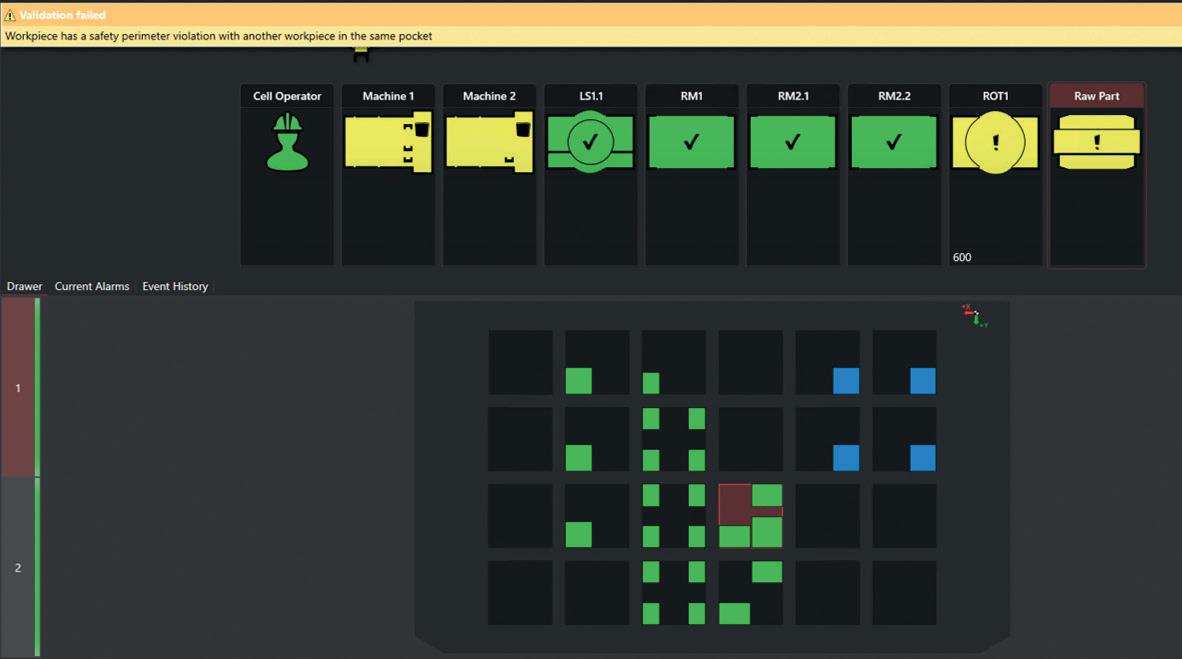

Maximum autonomy for optimum machine utilization

Avoiding downtime becomes increasingly important as greater autonomy is achieved. With JMS 4.0, EROWA offers the solution to optimally plan the utilization of the machines and to monitor and control their operation. Even if the systems are to operate autonomously over a longer period of time – such as overnight or at weekends, JMS 4.0 ensures smooth processes.

With JMS 4.0, plant capacity utilization is planned centrally, whether for a single cell or several cells simultaneously. This enables efficient management and ensures that sufficient orders and materials are always available. In addition, it can be guaranteed that the required processing tools are available in the production cells. This way,

production processes can run smoothly and bottlenecks or downtimes can be avoided. Central planning with JMS 4.0 therefore makes a significant contribution to optimizing production processes and ensures continuous capacity utilization and maximum autonomy of the processing machines.

Part ID's, work steps and NC programs are recorded centrally – for clear structures and fast processes. Orders can be managed efficiently and distributed specifically to production cells. This creates transparency, increases efficiency and optimizes the entire production process.

JMS 4.0 controls the workflow autonomously and consistently follows the target completion date and order priority. The focus is always on maximum productivity –through optimum machine utilization and minimized downtimes.

The process control system takes existing tools and their remaining service life into account. In order to maximize machine utilization and at the same time ensure maximum process reliability, sister tools are also taken into account in the planning.

Production processes can be monitored at any time and from anywhere. Unforeseen events are automatically reported immediately – for a quick response and maximum process reliability.

Push-the-button measuring, that was our vision

At Hörl Kunststofftechnik, high-tech meets efficiency: state-of-the-art, centrally networked injection molding machines form the core of a highly automated production environment. Intelligent systems control and monitor all processes in real time - for maximum quality, reliability, and speed. End-to-end automation handles even complex tasks in the shortest possible time, ensuring consistently high manufacturing standards.

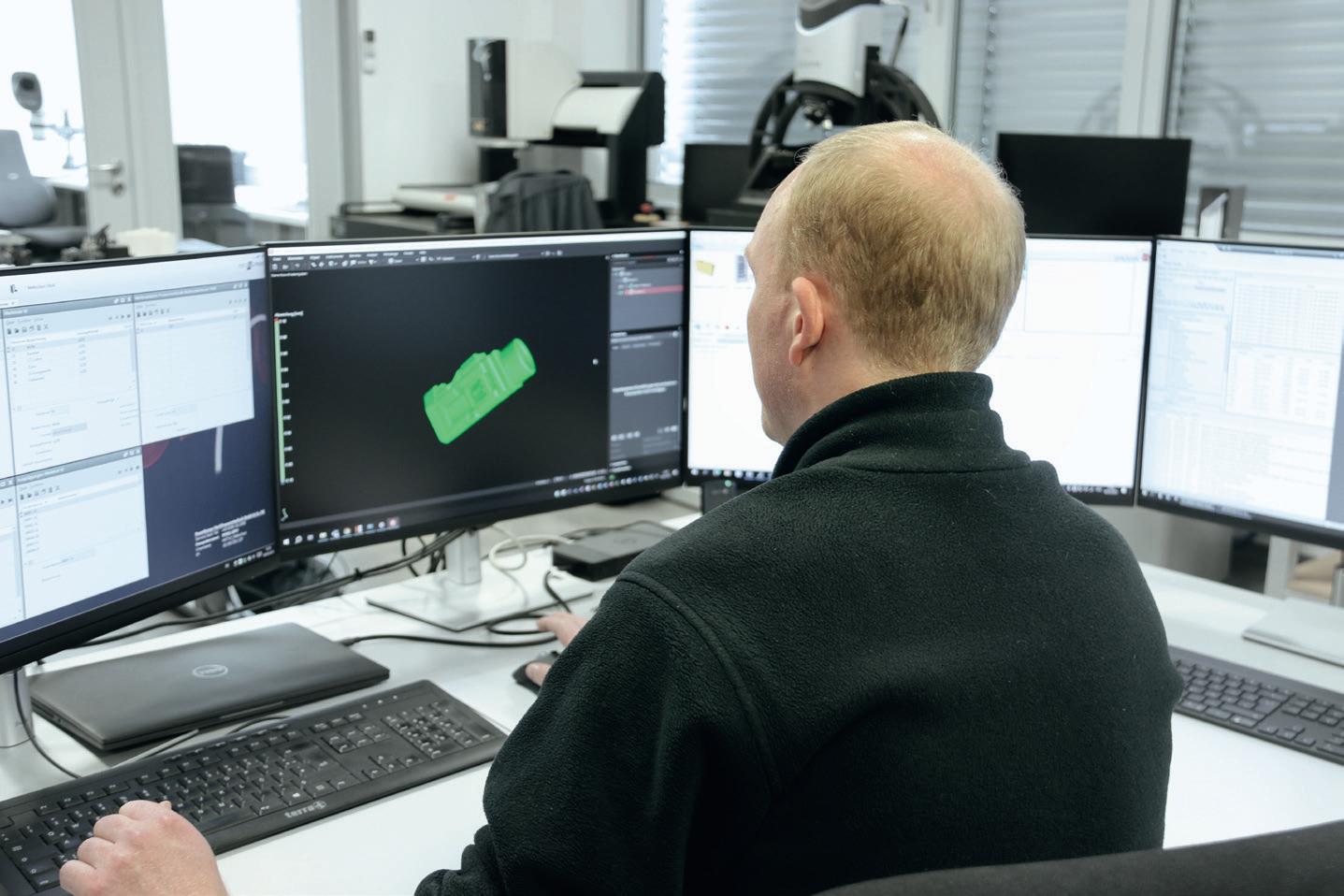

A conversation with Peter Waldhutter, Measurement Technician at Hörl Kunststofftechnik, about in-process automated quality assurance in serial measurement, modular automation – and why EROWA is the right partner.

EROWA: Mr. Waldhutter, you have been relying on automation at Hörl Kunststofftechnik for years. What was the trigger for the current project?

PETER WALDHUTTER : «The original idea came from our company founder, Thomas Hörl, back in 2017: "Measuring at the push of a button" – fast, simple, reliable. We wanted an automated quality inspection process that would integrate seamlessly into our plastic parts production, without manual steps in between. The challenge was that most systems on the market were simply too complicated for serial measurement.»

And then you remembered EROWA?

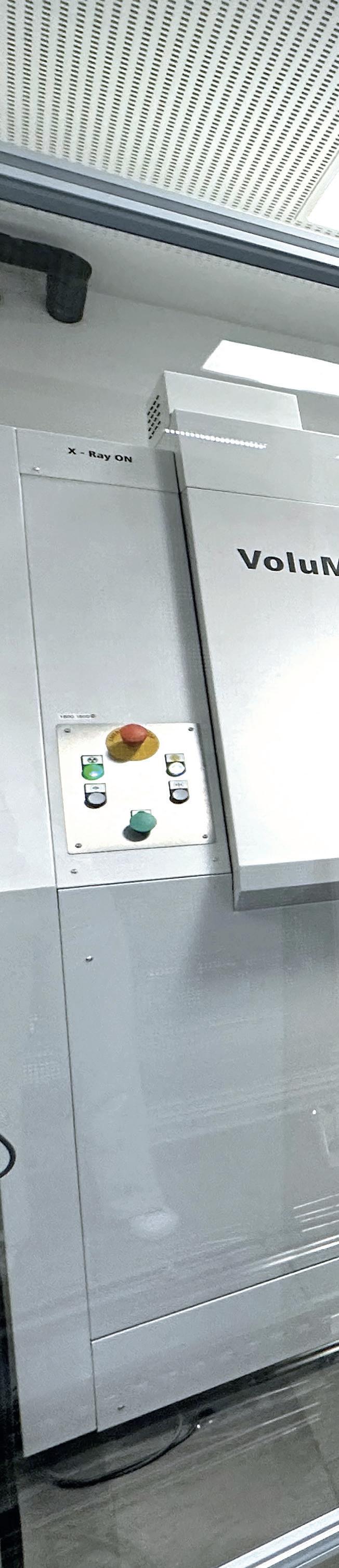

«We already knew EROWA from our toolmaking operations - and that turned out to be a real stroke of luck. The EROWA Robot Dynamic linear robot could be integrated directly without the need for complex special configurations. Combined with the Zeiss VoluMax computed tomography scanner, we created our first fully automated CT measuring cell, featuring both visual inspection and comprehensive dimensional measurement.»

Computed tomography in serial inspection – why take that approach?

«Our plastic parts are often extremely small, with hidden contours. CT offers huge advantages in this regard: it lets us see what would otherwise remain hidden – undercuts, material inclusions, voids. And it does so non-destructively and within just a few minutes.»

How exactly does the process work?

«The workpieces are placed on specially designed carriers developed by us. All information – program, part ID, posi-

tion – is digitally linked via a barcode. The operator scans the code, places the part into the magazine, and the system starts automatically. Measuring, evaluating, documenting –everything runs seamlessly.»

What convinced you most about EROWA?

«Clearly, it’s EROWA’s openness to our individual requirements. We use our own clamping systems and carriers –which was no problem for EROWA. The magazines remain compatible and modularly expandable. This flexibility is invaluable.»

Were there concerns within the team – especially regarding such highly automated processes?

«Of course. Especially among the measurement technicians, there was some skepticism – CT measurement without “holding the part in hand” was unfamiliar. But as experience grew, so did the trust. Today, everyone appreciates the relief – repetitive tasks are eliminated, and expertise is used more effectively.»

How has this affected your productivity?

«Enormously. Previously, we sometimes had to wait up to an hour for a measurement result – today it takes just a few minutes. Without automation, we would need 40 additional quality assurance specialists. And as everyone knows, those are not easy to find.»

What’s next?

«We’re already planning expansions. The system paid for itself within two years. And we know that with EROWA, we can grow – step by step, building block by building block.»

Mr. Waldhutter, thank you very much for the conversation - and continued success with your “push-thebutton measuring” system!

HÖRL KUNSTSTOFFTECHNIK GMBH & CO. KG

Through continuous development, Hörl Kunststofftechnik has evolved from a regional injection molding company into an internationally recognized technology partner for high-precision plastic solutions.

The Milestones

• 1991 - Founded by Thomas Hörl and Alois Hainz as a specialized injection molding company.

• 1999 - Expansion to include an in-house toolmaking department.

• 2004 - Construction of a modern production facility with warehouse and administrative building.

• 2010 - Partnership with Rosenberger Hochfrequenztechnik GmbH & Co. KG; doubling of production capacity and business volume.

• 2013 - Construction and relocation of the injection molding and toolmaking departments to a new, climate-controlled building with visualization of all production equipment.

• 2021 - Climate-neutral manufacturing (Scope 1 and 2).

• 2025 - Full integration as a subsidiary of the Rosenberger Group under the name Hörl Kunststofftechnik GmbH & Co.

Peter Waldhutter in an interview with Felix Meyer Project Manager and Coach at EROWA

«The system runs flawlessly; we are very satisfied, including with the service.»

Peter Waldhutter, Measurement technician, Hörl Kunststofftechnik

New solutions for micro production

Micro and precision mechanics require specialized, precisely coordinated solutions. Particularly in demanding sectors such as the watch and jewelry industry, medical technology and microtechnology, maximum precision, efficiency and sustainability are required.

The industry has been undergoing changes for some time now. The trend is clearly moving towards compact, energy-efficient and high-precision micro-manufacturing systems that are perfectly tailored to the resource-saving requirements of the future. Thanks to the minimal space requirement, the space saved can be used to increase productivity in production. And with significantly lower energy consumption compared to conventional machines, workpieces can be produced more cost-effectively –and more sustainably.

EROWA clamping technology as a success factor

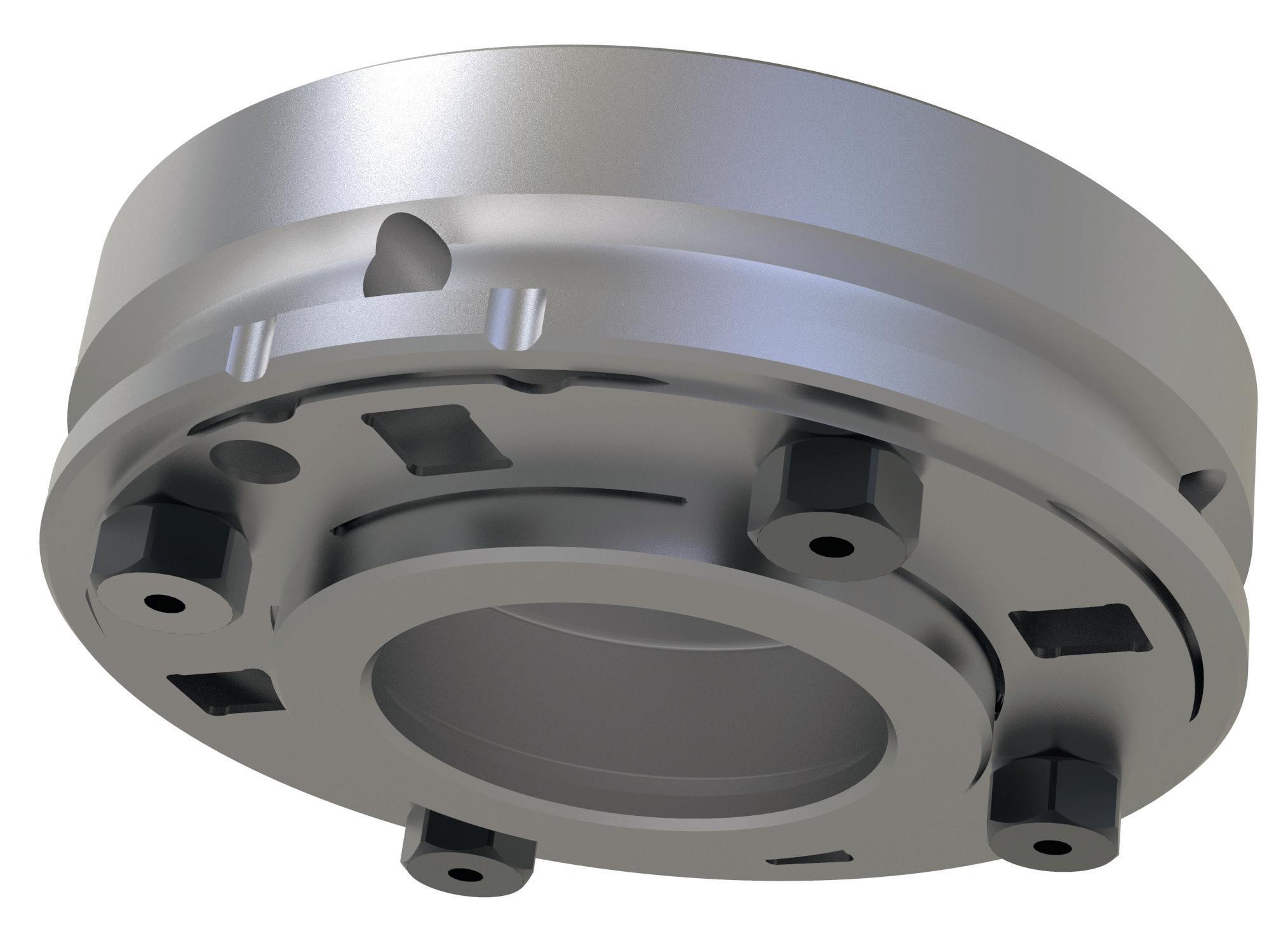

In order to unleash the full potential of micromachines, efficient workpiece handling is also required on the machine. As a pioneer in the field of high-precision clamping systems, we have taken on this task. The newly developed EROWA CMT (Compact Micro Tooling) combines a high degree of quality and precision, as is already known from established EROWA products.

Developed for the next generation of micro machining centers – designed for both manual and automated production. With a diameter of only 45 mm, the clamping system offers maximum efficiency and functionality in the smallest of spaces.

For comparison: The CMT chuck easily fits on a conventional business card – it could hardly be more compact.

Well thought-out clamping technology

The CMT system stands for versatile functionality and precision with the smallest dimensions.

• The clamping system is designed for workpiece sizes up to 50x50x50mm. Ideal for optimum efficiency in the production of small parts and workpieces.

• Clamping is performed using spring force and the chuck can be opened pneumatically. The chuck always remains mechanically locked when depressurized.

• As with other EROWA products, positioning is carried out via a backlash-free centering plate for maximum repeatability and system accuracy.

• A central bushing enables the use of a plunger to activate clamping elements mounted on the pallet, such as collets. For increased requirements, the clamping force can be further increased by means of optional reclamping, which in turn allows greater actuating forces to be applied to the plunger.

• The reference supports with integrated medium feed-throughs also allow direct control of pneumatic clamping elements on the pallet.

We would be happy to advise you personally

With the CMT clamping system, we also offer our proven EROWA values. Highest quality Swiss Made in combination with our worldwide sales and product support.

Trust creates the future

Muottituote Group Oy and EROWA: When automation is not just the future, but the present.

Joensuu, Finland. Late in the evening, the sun hangs low, yet production in Muottituote's manufacturing hall continues undisturbed. No lights, no staff on site-only absolute confidence. Confidence in an automation system that has run reliably for years. For Muottituote Group, this is clear: Only automation that consistently performs allows for genuine productivity.

Over 50 Years of Precision and Partnership Strength

Muottituote Group Oy is a family-owned company founded in 1973, today employing over 100 people across three locations in Rauma, Joensuu, and Korpilahti. As one of Finland's leading mold manufacturers, Muottituote combines toolmaking with plastic injection molding and die-casting under one roof. The result: streamlined processes, rapid response times, and uncompromising quality.

The Future Is Where Trust Prevails

«We operate a single-shift schedule, but our machines run around the clock. That is only possible when we can rely 100 percent on our automation,» says Tero Vanninen, CEO of Muottituote. This level of trust was the decisive factor in building a new automated HSC (high-speed cutting) cell – with EROWA as their automation partner.

The new cell consists of three HSC machines connected via an ERD 150 linear robot. Both UPC and ITS pallets in various sizes are used. This system is not new to Muottituote-EROWA technology has been in service here for over 25 years. However, choosing to create a single cell containing multiple machines capable of unattended operation marks the next step-cementing automation as today's reality.

More Than Technology: Process Reliability at the Core

Customers' high demands-especially in medical and packaging industries-require molds of the utmost precision. As such, repeat accuracy and error-free clamping are crucial. Equally important are uninter-

rupted, secure processes. «Any disruption, any error, any uncertainty jeopardizes our delivery reliability,» explains Tero Vanninen

That is why Muottituote chose EROWA again-not only for compatibility with existing systems but, more importantly, because EROWA has proven itself as a dependable partner for decades: in consulting, implementation, and ongoing support. Even with supply-chain challenges during COVID-19, communication remained constructive, and goals were met which includes many unattended hours, high efficiency, and an intuitive user interface.

People in Transition: Automation Unburdens and Inspires

Internally, implementing the new cell was also a success. The user interfaces are operator-friendly, and the processes are thoughtfully structured. «Our employees appreciate the clarity of the system-and that they can

extract more from the machines,» adds Tero Vanninen Workflow adjustments were minimal, as Muottituote's team was well prepared by earlier experience with EROWA pallet systems.

The Common Thread: Automation as a Growth Driver

«We are growing. And we want that growth to be a win for everyone-our customers and us,» emphasizes Tero Vanninen. Achieving this requires systems you can count on. Systems that run day and night without supervision. Systems like those provided by EROWA.

Hence, the next project is already in planning: automating the sinker EDM cell. Again, the belief is clear: To master the future, you must automate today-and choose the right partner.

MUOTTITUOTE GROUP OY

• Founded: 1973, family-owned

• Locations: Rauma, Joensuu, Korpilahti (Finland)

• 100+ employees

• Over 200 molds produced annually

• 60+ injection molding machines (20-450 t clamping force)

• Industries served: Medical technology, packaging, general industry

• Philosophy: Quality – Efficiency – Precision

EROWA Systems in Use

• HSC cell with ERD 150L

• 3 HSC machines, 1 linear robot

• Pallet systems: UPC, ITS 148

• Also deployed in die-sinking and wire EDM operations

The perfect combination

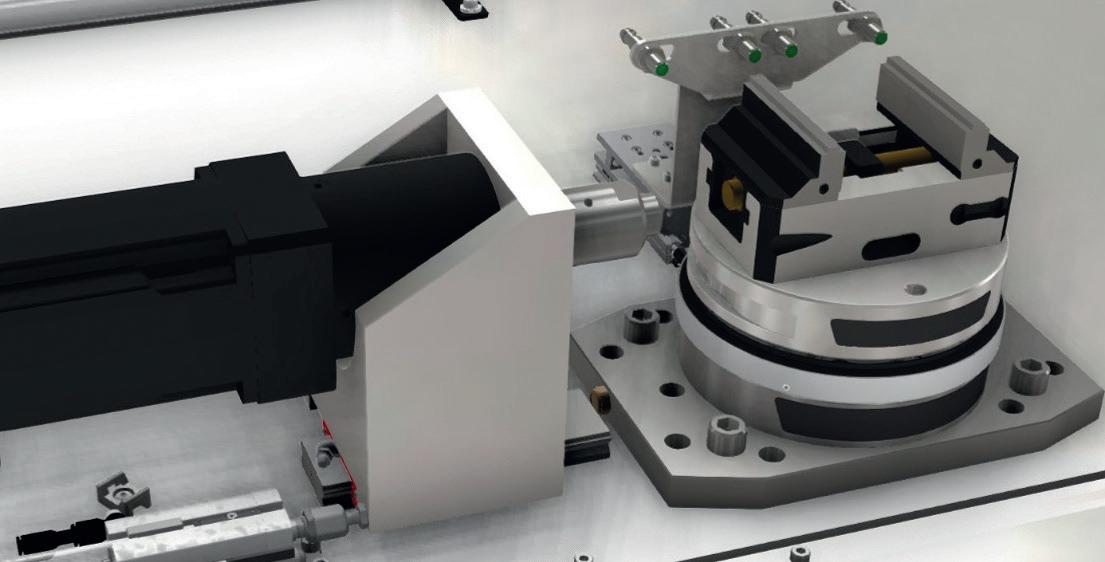

In modern manufacturing environments, efficiency and flexibility are essential to remain competitive. An automation system that enables the combined operation of production machines with workpiece carrier pallets and automated part handling offers a powerful solution to increase productivity and quality. By strategically expanding the EROWA Robot Six modular system with a drawer magazine and an automatic screwing station for both part and pallet handling, this becomes seamlessly possible. Our Robot Six takes over precise handling and ensures a smooth, fully automated production process.

• Mixed part and pallet handling

• Customizable gripper adaptation

• Flexibly configurable drawer magazine

• Automated loading of the screwing station

• Clamping station with torque up to 100 Nm

• Seamless integration into the JMS 4.0 PL control system

• Easy operation

• Standardized and scalable automation solution

ROBOT SIX PART- & PALLET HANDLING

Everything Under Control

The dual gripper is equipped with an EROWA standard coupling for interchangeable grippers used in pallet handling, a gripper for raw and semi-finished parts, as well as a drawer opener. Optionally, a nozzle for blowing off chips and coolant can also be integrated.

Securely Clamped

Depending on the size and geometry of the workpiece, the gripper automatically adapts accordingly. After removing the workpiece from the drawer magazine, it is precisely placed into the centering vise located on the clamping station and secured with the desired torque. In the next step, the centering vise with the secured workpiece is placed in a free robot magazine slot until a suitable machine in the robot cell becomes available for processing.

Everything at a Glance

Seamless integration into the EROWA JMS 4.0 ProductionLine control system – intuitive operation via the touch monitor located directly on the drawer magazine. Always in view: current drawer loading status and automatic validation of space conflicts.

Configure the Drawer Magazine as Needed

The customizable drawer grid layout allows for the integration of customer-specific grid plates for raw parts or form nests for semi-finished parts, depending on individual requirements. Additionally, different grid configurations can be implemented across various drawers to ensure maximum capacity for a wide range of workpieces.

Securely Clamped

The clamping station can be individually configured based on the model of the centering vise used. Automatic docking, exact positioning of the clamping jaws and monitored clamping included.

He had an idea –We had the solution

One customer, one pen and one thought: «I would like to load blanks automatically.» What began as an idea and a sketch became a sophisticated automation solution at Pavese and EROWA – with raw part and pallet handling in one, automated clamping and fully integrated process control. A story about courage, doers and machines that think for themselves.

How EROWA and Pavese AG are rethinking automation together – The idea Daniele Pavese, Managing Director of Pavese AG, does not believe in half measures. Anyone who talks to him immediately senses the urge to improve – in every detail. His wish: a more efficient manufacturing future.

The man is serious. And anyone who knows him knows that where others make compromises, Pavese is just starting to warm up: «I want to load pallets AND raw parts automatically – and clamping the raw part on pallets at the same time.» Why? If these processes are

Andreas Tassone, Sales Manager Switzerland EROWA AG Daniele Pavese, Managing Director Pavese AG

automated, several problems can be solved at the same time: Firstly, no one has to manually clamp raw parts anymore. Secondly – and this is the key aspect of this process – a check is carried out before unloading to determine whether any reworking of the finished part is required.

For this purpose, the inspection process is integrated into the higher-level control system and automated: Palletized workpieces are fed to the measuring machine in a flexible and non-linear automated manner – and checked overnight. This relieves our bottleneck – in-process measuring.

It is precisely these steps that need to be integrated into a joint process. New territory for EROWA: «Our systems were precise, efficient and intelligent – but the handling of raw parts? Uncharted territory.» But if you never question boundaries, you never move forward.

Vision meets development power: a cell that can do everything

In 2022 Pavese explores potential partners. By 2023 it is clear: The project is feasible with EROWA. The interdisciplinary project team at EROWA is the perfect sparring partner: critical, clear, creative. Together, they develop a

«If the AGV soon drives through the hall, then we will have achieved what others consider to be science fiction.»

Daniele Pavese, Managing Director Pavese AG

solution that breaks new ground – but is so robust that it can become the customized EROWA standard for many others.

«I don't want a run-of-the-mill solution. I want processes that suit us.»

The managing director of Pavese AG approached EROWA with this clear requirement – and did not simply make a technical request: «It was an invitation to leave our comfort zone and rethink the potential of our automation and software,» says project manager EROWA.

But the solution had to be standardized, reproducible and easy to implement – without compromise. A system that can be retrofitted and updated over decades, even in the event of changes or software updates. Durable, adaptable, future-proof.

Today, Pavese works with a unique cell – modular, scalable and completely sophisticated:

• Blank and pallet handling combined

• Automated clamping of blanks

• In-process measurement

• Open architecture for future expansions

From one hour to ten minutes

The effects? Noticeable – every day. «The user must be able to decide for themselves when the part goes out. Automation works for us – not the other way around.»

What used to take an hour to set up and clamp is now done in ten minutes. No more morning traffic jams at the measuring machine. No more random sorting. Instead: continuous correction, smooth processes and relaxed employees.

Automation with a grip

And the workforce? Fully involved – the main operator was part of the project right from the start. Automation has not replaced jobs – it has changed them. Work is different today: more structured, more relaxed, more efficient. No employees have been made redundant – on the contrary: the company is growing. Because more is now being achieved with the same team. More output, less pressure – and more space for the essentials.

The dream rides on wheels

What began with a sketch follows a clear vision – conceived in three stages. Following the successful development and implementation of the automated cell, the next stage is now imminent: a driverless transport system (AGV) that

independently controls the measuring machine – paving the way for a fully automated process.

What still sounds like a dream of the future today is already taking shape at Pavese. This automates the last manual step and closes the process.

A modular standard was the goal

The biggest challenge? The balance between vision and standardization. The aim of the project was not a one-off solution, but a configurable system with EROWA quality that can also be used modularly in other companies.

For Pavese, it was crucial to work with a partner that sees eye-to-eye. EROWA was not just an implementer, but a co-designer. Not just a developer, but a challenger. Daniele Pavese says: «I knew what I wanted - but I needed partners who could make it happen. And that's exactly what I found at EROWA.»

Summary

This story is not a product report, but an innovation adventure. With a maker who thinks big – and a development team that not only listens, but executes as well.

What was the result? A cell that delivers maximum productivity. And proof that you often just have to get started – with a simple sketch and a bold first step.

«What we have built here can also help others. You just have to dare to think in new ways.»

Andreas Tassone, Sales Manager Switzerland EROWA AG

EMPOWERING YOUR PRODUCTIONEMPOWERING OUR PEOPLE

EROWA stands for efficiency, precision and sophisticated solutions in production technology. But behind every system, behind every automation solution and behind every further development are people. People who think, shape and develop together with the company. Because just as we strengthen our customers' production, we also promote the potential of our employees.

Development begins with trust

At EROWA, you take on responsibility right from the start. Even the apprenticeship training is characterized by practical relevance, team spirit and real tasks. Our apprentices grow up in an environment that takes them seriously – and gives them the space to develop. Many stay because they see it: Anyone who wants to make a difference will find the right conditions here. Many return after gaining experience elsewhere, which makes us proud.

Agility that is lived

Innovative products are not created in a quiet room, but through exchange. Our teams work on an interdisciplinary basis, processes are lean and decisions are shared.

This agility characterizes not only our technology – but also the way we work together. Those who contribute ideas are listened to. Those who want to take on responsibility are given the opportunity to do so. It's not always easy or convenient, but it helps us to constantly improve.

Learning never ends

In an industry that is developing rapidly, standing still is not an option. That is why we invest specifically in the further training of our employees – professionally,

methodically and personally. Internal training courses, external programs or individual development paths: at EROWA, we promote what makes people strong. Because this is the only way we can remain strong as a company.

Family culture, international perspective

Despite our global orientation, there is a palpable sense of cohesion at EROWA. Distances are short, doors are open and we treat each other with respect. Shared experiences – from team events to spontaneous exchanges at the coffee machine – strengthen the sense of togetherness. Here, people meet at eye level, across all areas.

Work with impact

What we do has meaning – for our customers, but also for everyone on the team. We develop solutions that make production around the world more efficient. And we create an environment in which people can unfold and develop their skills.

Because empowerment doesn't start with the customer – it starts with us.

Full Throttle Toward Lights-Out

When the lights go out in a workshop, it doesn't always mean the end of the shift; quite the opposite. At GM Diecron, located in Griffin, Georgia, the future of manufacturing shines bright precisely because the machines keep working even when no one is in the room. With the help of EROWA, this aerospace supplier has made the leap from a classic CNC operation to a cutting-edge, lights-out pioneer.

Today, the company operates an EROWA Robot Compact 80 robot with PC210 pallets and JMS process management. Integrated with an Okuma MU4000V, the system now runs around the clock – something that used to be unimaginable: «Machines used to run 8–9 hours a day with an operator; now they run 24/7 – no breaks.»

Lights Off – Performance On

The numbers speak for themselves: up to 100 additional machine hours each week thanks to the lights-out setup. And all while maintaining tolerances of ±0.002 inches – a level of precision made possible by EROWA’s reliable workholding technology.

From Manual Shop to High-Tech Manufacturer

Founded in 1977 as a manual machine shop, GM Diecron has grown over the decades into a modern CNC hub for structural aircraft components, industrial parts, and high-complexity precision pieces. With just 30 employees, the company may be small – but it’s incredibly efficient, especially since it embraced EROWA automation.

«One employee per machine? That’s simply no longer viable», the management puts it plainly. The solution: an automated production system that multiplies productivity – without compromising on quality.

The Challenge: More Output Despite Labor Shortages

Like many manufacturers, GM Diecron struggled with limited manpower in a tight labor market. New projects were waiting, but new hires were hard to find. The answer was clear: automation. Thanks to the team at Morris South, GM Diecron discovered EROWA. A visit to a reference site sealed the deal.

«It’s comforting to know we can fully trust the system», says the production lead. Product quality remains high, and output is increased. Meanwhile, operators can oversee multiple projects simultaneously – a clear boost in flexibility.

More Than Just Technology – A Cultural Shift

The move to automation was more than an investment in hardware. It was a strategic shift toward the future. And it also transformed daily work life for employees. Resistance? Not here.

«We’re a company that thrives on change. If you don’t change, you stagnate. Our team was on board from day one», they say. Increased efficiency and the new roles for employees – moving from machine operators to process overseers – have improved motivation and workplace morale.

Challenges? Solved Together

Of course, there were bumps in the road. Specifically the first steps after training took some getting used to. But GM Diecron reacted quickly by bringing the EROWA team back on site, and soon the system was running smoothly.

Ty Stallings, Cell operator GM Diecron Mitch Dappen, Regional Sales Manager EROWA

«Automation helps on many levels. But the best part is seeing how excited our employees are about it.»

Codi Chapman, General Manager GM Diercon

Looking Ahead

The journey doesn’t end here. GM Diecron plans to expand automation year after year. New spindles, new cells – all with the goal of scaling output without adding staff.

«Our goal remains the same: more output with the same team. With EROWA, we’ve found a partner that makes that possible.»

The experience has proven: automation doesn’t just increase productivity, it also empowers people. When machines assume responsibility of the night shift, space opens up – for innovation, development, and for the next success story.

Conclusion: Trust in Technology Pays Off

GM Diecron is living proof that lights-out manufacturing isn’t just a vision for the future – it’s a present-day reality.

With smart automation strategies, EROWA’s cuttingedge technology, and a team that embraces change, a new kind of manufacturing is emerging: efficient, flexible, and sustainable. Or as the team at GM Diecron puts it: «Automation helps on many levels. But the best part is seeing how excited our employees are about it.»

EROWA - Manufacturing automation at its best

EROWA AG, founded in Switzerland in 1971, is now a globally operating organization specializing in the development, production, consulting, and distribution of state-of-the-art manufacturing technology for tool and mold making, as well as for production and precision engineering. With their headquarters located in central Switzerland, EROWA ranks among the world‘s leading companies in clamping technology and automation. Having 13 subsidiaries and 22 representatives, EROWA offers international points of contact and worldwide customer service.

EROWA Group Business Network: a member of ORENDA Holding Ltd. Subject to technical changes. Registered trademark of EROWA AG, Copyright © EROWA AG, patents are existing or pending for a number of products of EROWA AG.

Empowering Your Production

The next step towards greater efficiency, precision and productivity starts now. With EROWA, you have a partner who will optimize your production holistically - from clamping technology to automation and process control. Our innovative solutions adapt flexibly to your requirements and grow with you - for production that is ready for tomorrow. Get in touch with us - we will be happy to assist you.

Imprint: © EROWA AG, 2025 - Story: Shutterstock, OpenAI, S.Wetzel, Pagani S.P.A., Modena Design, Ypsomed AG, Hörl Kunststofftechnik GmbH & Co. KG, Muottituote Group, Pavese AG, GM Diecron LLC.