One customer, one pen and one thought: «I would like to load blanks automatically.» What began as an idea and a sketch became a sophisticated automation solution at Pavese and EROWA – with raw part and pallet handling in one, automated clamping and fully integrated process control. A story about courage, doers and machines that think for themselves.

How EROWA and Pavese AG are rethinking automation together – The idea

Daniele Pavese, Managing Director of Pavese AG, does not believe in half measures. Anyone who talks to him immediately senses the urge to improve – in every detail. His wish: a more efficient manufacturing future.

The man is serious. And anyone who knows him knows that where others make compromises, Pavese is just starting to warm up: «I want to load pallets AND raw parts automatically – and clamping the raw part on pallets at the same time.» Why?

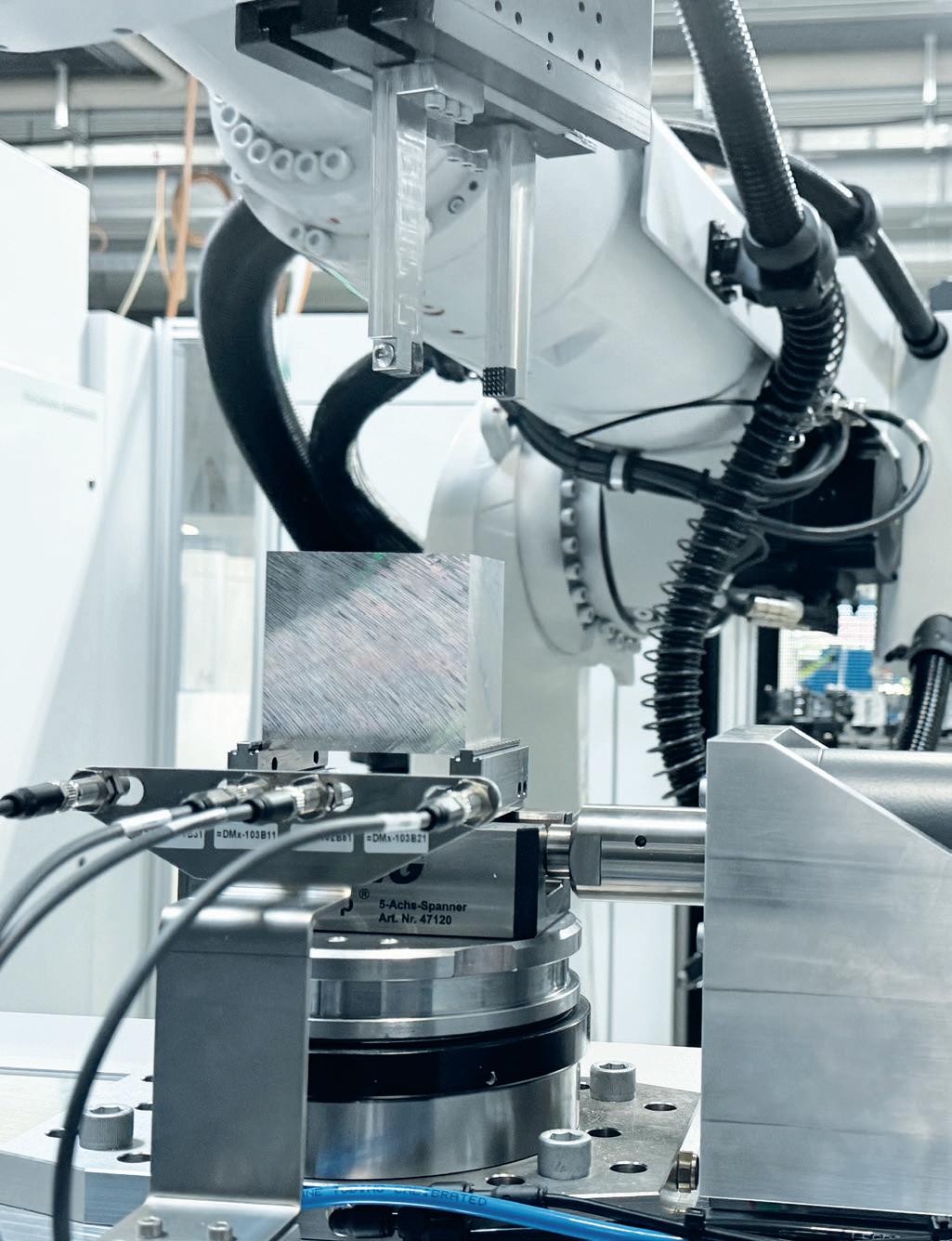

If these processes are automated, several problems can be solved at the same time: Firstly, no one has to manually clamp raw parts anymore. Secondly – and this is the key aspect of this process – a check is carried out before unloading to determine whether any reworking of the finished part is required.

For this purpose, the inspection process is integrated into the higher-level control system and automated: Palletized workpieces are fed to the measuring machine in a flexible and non-linear automated manner – and checked overnight. This relieves our bottleneck – in-process measuring.

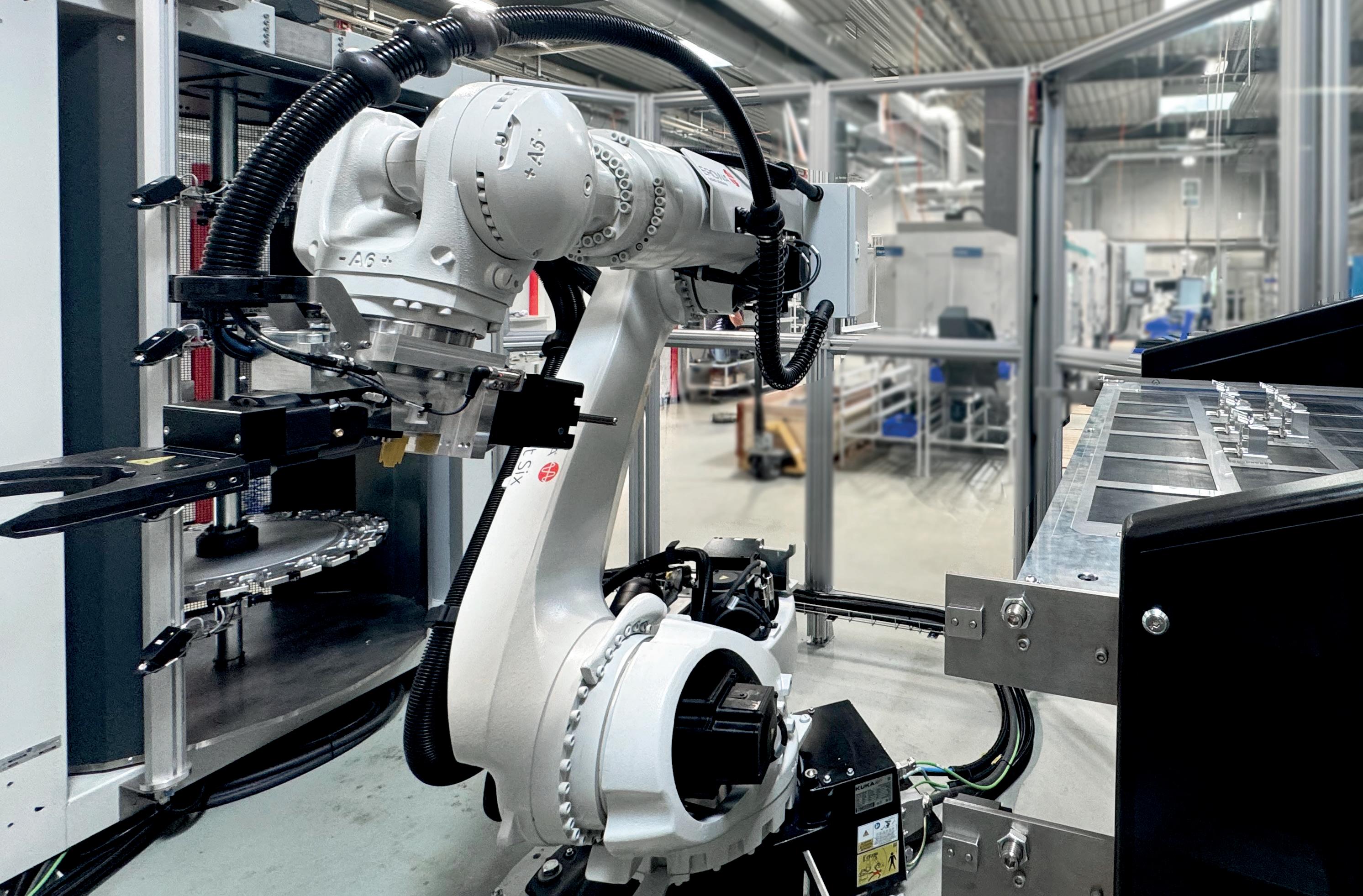

It is precisely these steps that need to be integrated into a joint process. New territory for EROWA: «Our systems were precise, efficient and intelligent – but the handling of raw parts? Uncharted territory.» But if you never question boundaries, you never move forward.

Vision meets development power: a cell that can do everything

In 2022 Pavese explores potential partners. By 2023 it is clear: The project is feasible with EROWA. The interdisciplinary project team at EROWA is the perfect sparring partner: critical, clear, creative. Together, they develop a solution that breaks new ground – but is so robust that it can become the customized EROWA standard for many others.

«I don‘t want a run-of-the-mill solution. I want processes that suit us.»

The managing director of Pavese AG approached EROWA with this clear requirement – and did not simply make a technical request: «It was an invitation to leave our comfort zone and rethink the potential of our automation and software,» says project manager EROWA.

But the solution had to be standardized, reproducible and easy to implement – without compromise. A system that can be retrofitted and updated over decades, even in the event of changes or software updates. Durable, adaptable, future-proof.

Today, Pavese works with a unique cell – modular, scalable and completely sophisticated:

• Blank and pallet handling combined

• Automated clamping of blanks

• In-process measurement

• Open architecture for future expansions

From one hour to ten minutes

The effects? Noticeable – every day. «The user must be able to decide for themselves when the part goes out. Automation works for us – not the other way around.» What used to take an hour to set up and clamp is now done in ten minutes. No more morning traffic jams at the measuring machine. No more random sorting. Instead: continuous correction, smooth processes and relaxed employees.

Automation with a grip

And the workforce? Fully involved – the main operator was part of the project right from the start. Automation has not replaced jobs – it has changed them. Work is different today: more structured, more relaxed, more efficient. No employees have been made redundant – on the contrary: the company is growing. Because more is now being achieved with the same team. More output, less pressure – and more space for the essentials.

The dream rides on wheels

What began with a sketch follows a clear vision – conceived in three stages. Following the successful development and implementation of the automated cell, the next stage is now imminent: a driverless transport system (AGV) that independently controls the measuring machine – paving the way for a fully automated process.

What still sounds like a dream of the future today is already taking shape at Pavese. This automates the last manual step and closes the process.

A modular standard was the goal

The biggest challenge? The balance between vision and standardization. The aim of the project was not a one-off solution, but a configurable system with EROWA quality that can also be used modularly in other companies.

Partnership-based, provocative, productive

For Pavese, it was crucial to work with a partner that sees eyeto-eye. EROWA was not just an implementer, but a co-designer. Not just a developer, but a challenger. Daniele Pavese says: «I knew what I wanted - but I needed partners who could make it happen. And that‘s exactly what I found at EROWA.»

Summary

This story is not a product report, but an innovation adventure. With a maker who thinks big – and a development team that not only listens, but executes as well.

What was the result? A cell that delivers maximum productivity. And proof that you often just have to get started – with a simple sketch and a bold first step.

Copyright © 2025 - EROWA AG Pavese AG Zellgut 10 CH-6214 Schenkon www.pavese.ch

EROWA AG

Knutwilerstrasse 3 CH-6233 Büron www.erowa.com