A winning combination

EROWA Robot on Brother

The combination of Brother SPEEDIO machines and the EROWA automation and tooling solutions provides manufacturing companies with a forward-looking setup: minimal footprint, maximum process reliability, full automation, and versatile workholding systems. Especially in small-part production, high-precision or series production with high part variety, this partnership delivers a real productivity boost – efficient, user-friendly, and fully scalable.

Maximum output on minimum space. With just 3.3 × 3.8 m, the combination of BROTHER machining centers and EROWA pallet automation sets the benchmark for the smallest footprint on the market. The result: unmanned production with maximum productivity – perfectly tuned for efficiency around the clock.

Extended runtime, extended success.

With the third magazine, production time stretches far beyond regular shifts, enabling continuous output all weekend long. The perfect setup for higher machine utilization and true lights-out manufacturing.

Double the machines, double the efficiency. For workpieces with long machining times, running two machines in parallel keeps productivity at the highest level – reliable, efficient, and uninterrupted.

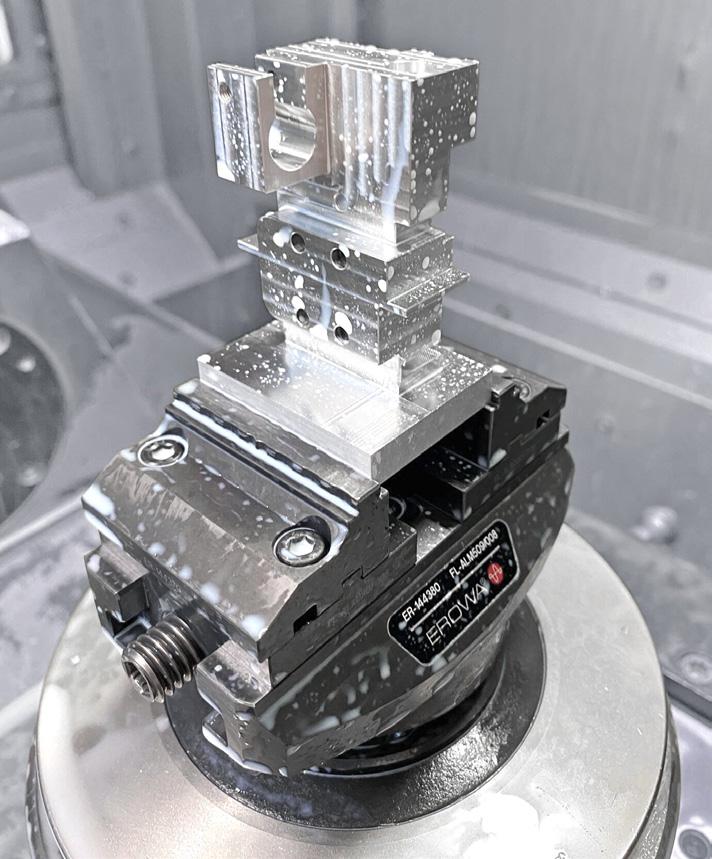

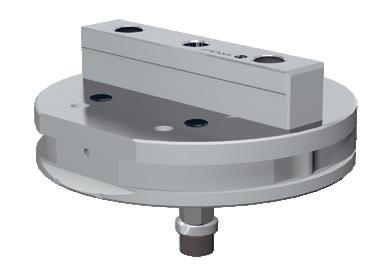

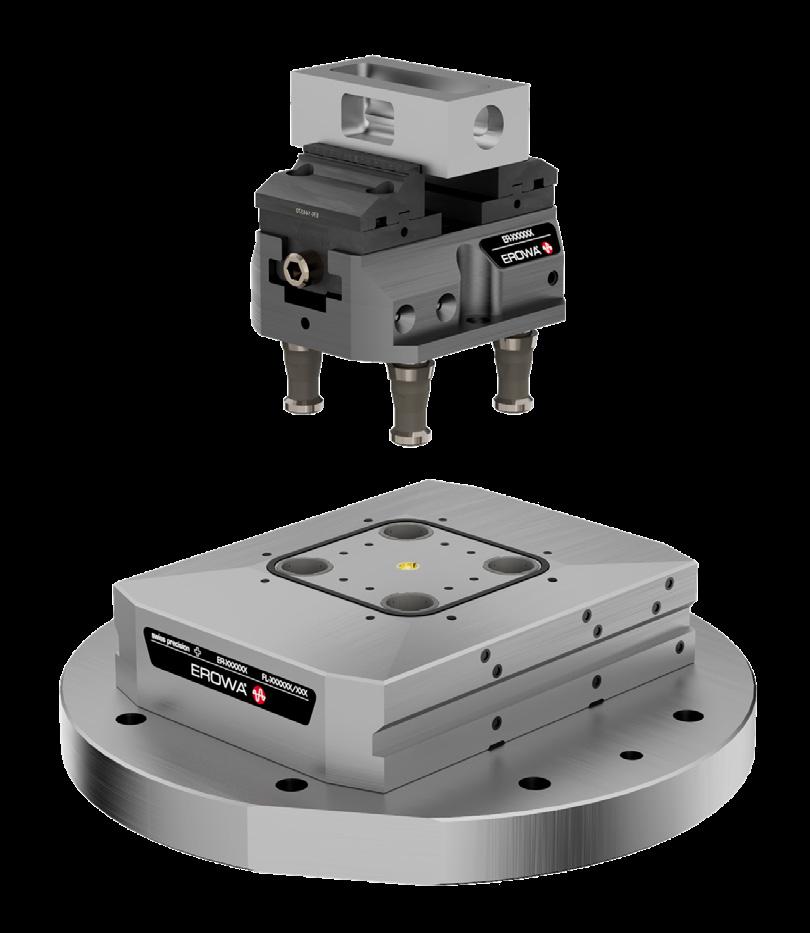

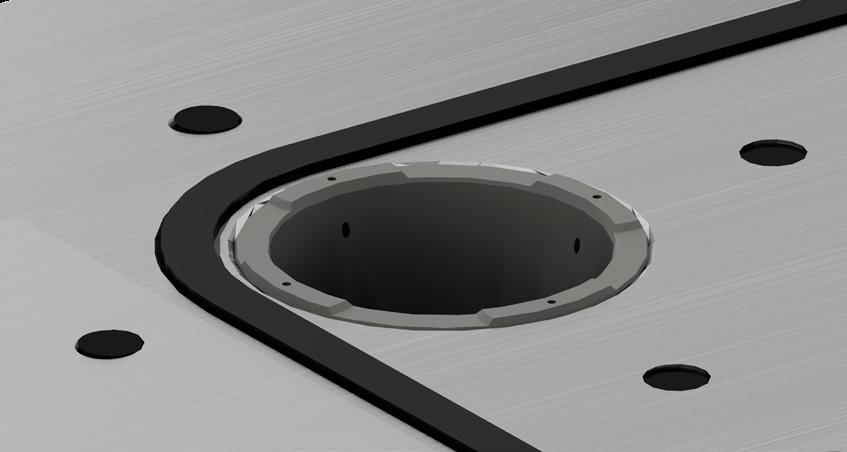

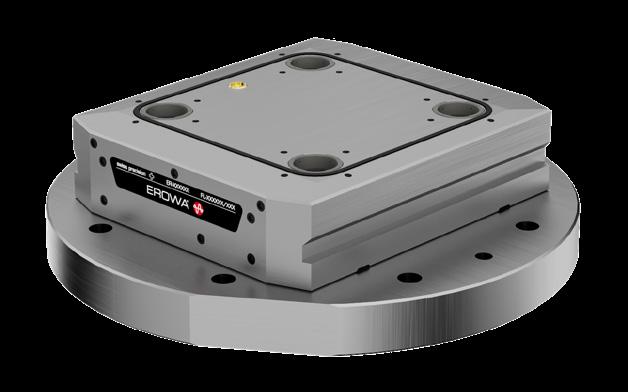

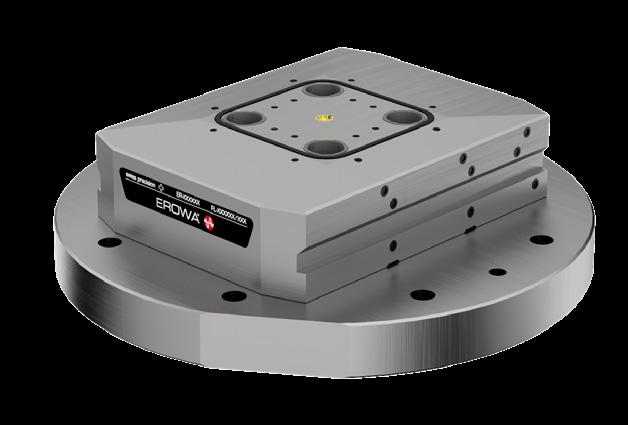

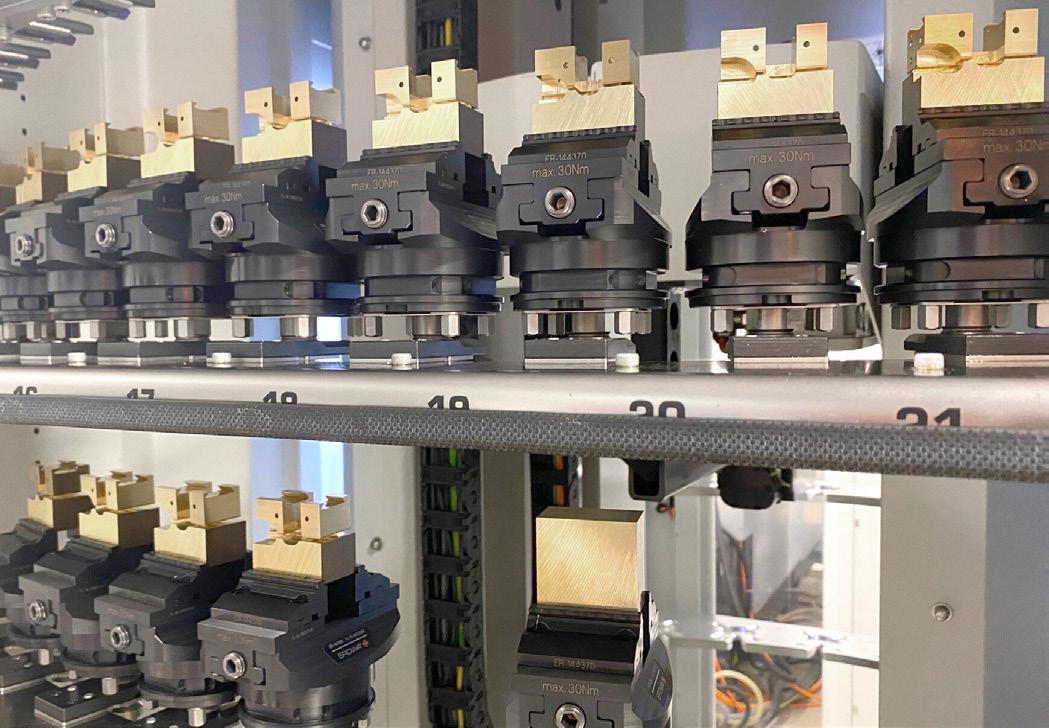

The proven EROWA PowerChuck P workpiece palletizing system clamps a wide variety of workpiece carriers simply, quickly and reliably. In the new design, the PowerChuck P not only looks impressive, it also stands out as a result of its added benefits

For pallet sizes ITS 50, ITS 72, PM 85, ITS 115, ITS 148

Chuck dimensions ø 250 x 51 mm

System height 91 mm is composed of: 51 mm (chuck) / 40 mm (pallet)

Workpiece sizes l x b x h: 240 x 240 x 250 mm

Repeatability < 0.002 mm

Indexing 4 x 90°

Clamping force 10‘000 N

Clamping with spring tension (clamped without pressure)

Opening pressure min. 6 bar (pneumatic)

Operation with control unit or compressed-air gun

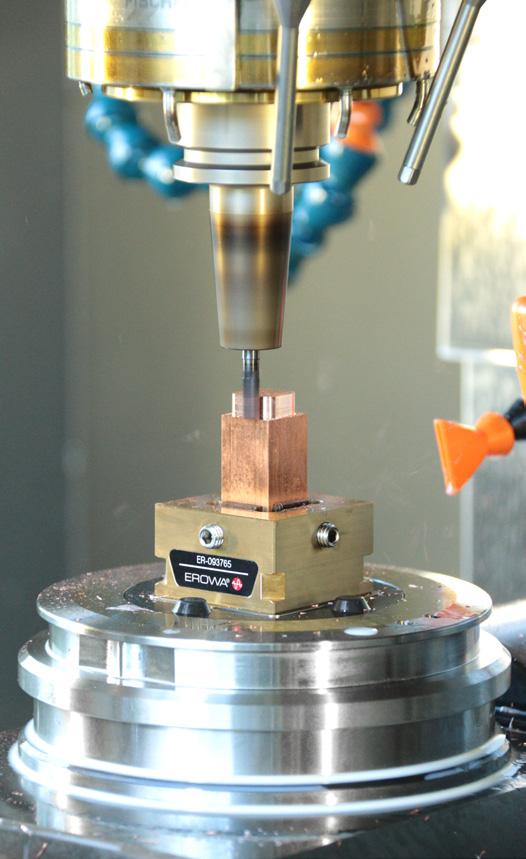

Proven. Versatile. Precise. EROWA workpiece holders stand for a well-established system design, offering maximum versatility –ideal for tool and mold making as well as demanding precision machining.

ER-093758

ER-035210

ER-050195

ER-115699

ER-138950

ER-147223

ER-010742

Self centering vise

ER-067650

ER-094168

ER-115657

ER-075600

ER-115308

ER-115660

PM85 Precise

ER-040701

ER-115379

Magazine configuration ERC 80

20x ITS 148

Magazine configuration ERC 80

30x ITS 148

Magazine configuration ERC 80

70x ITS ø72

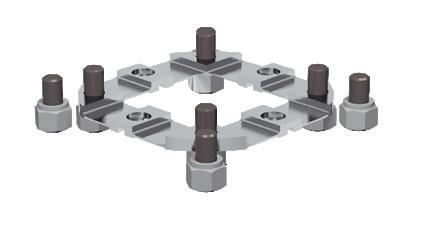

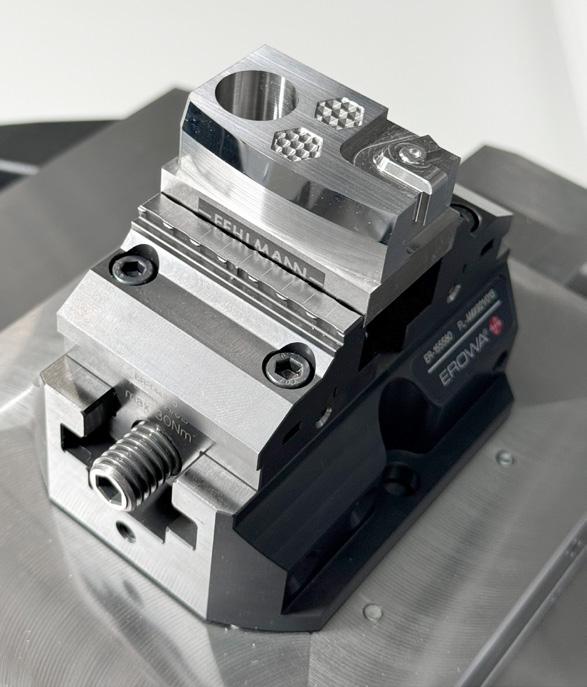

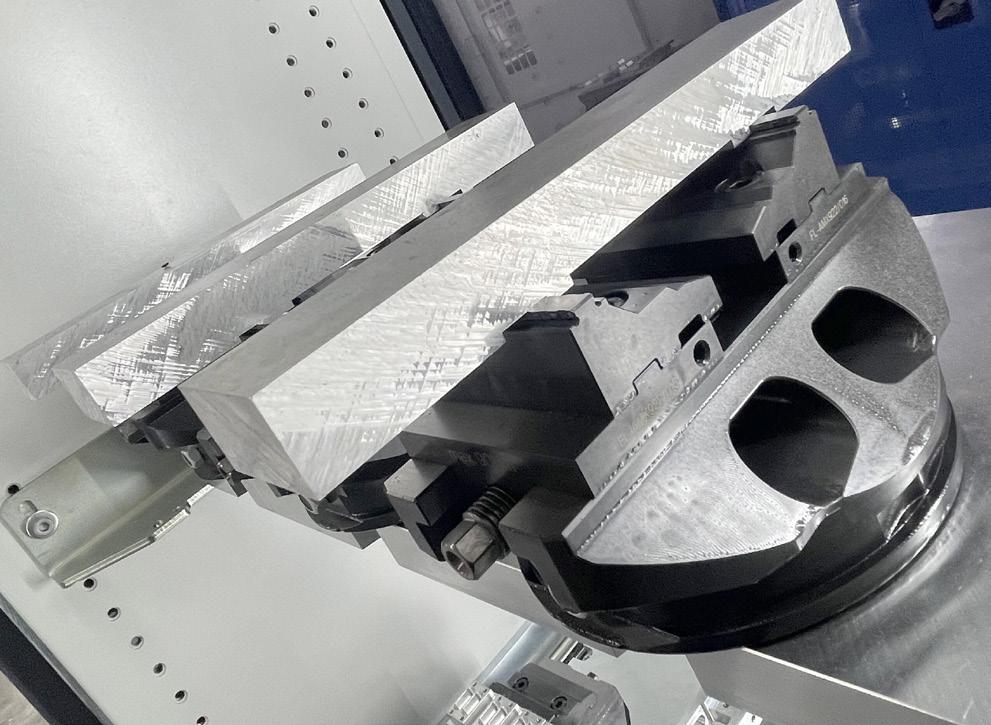

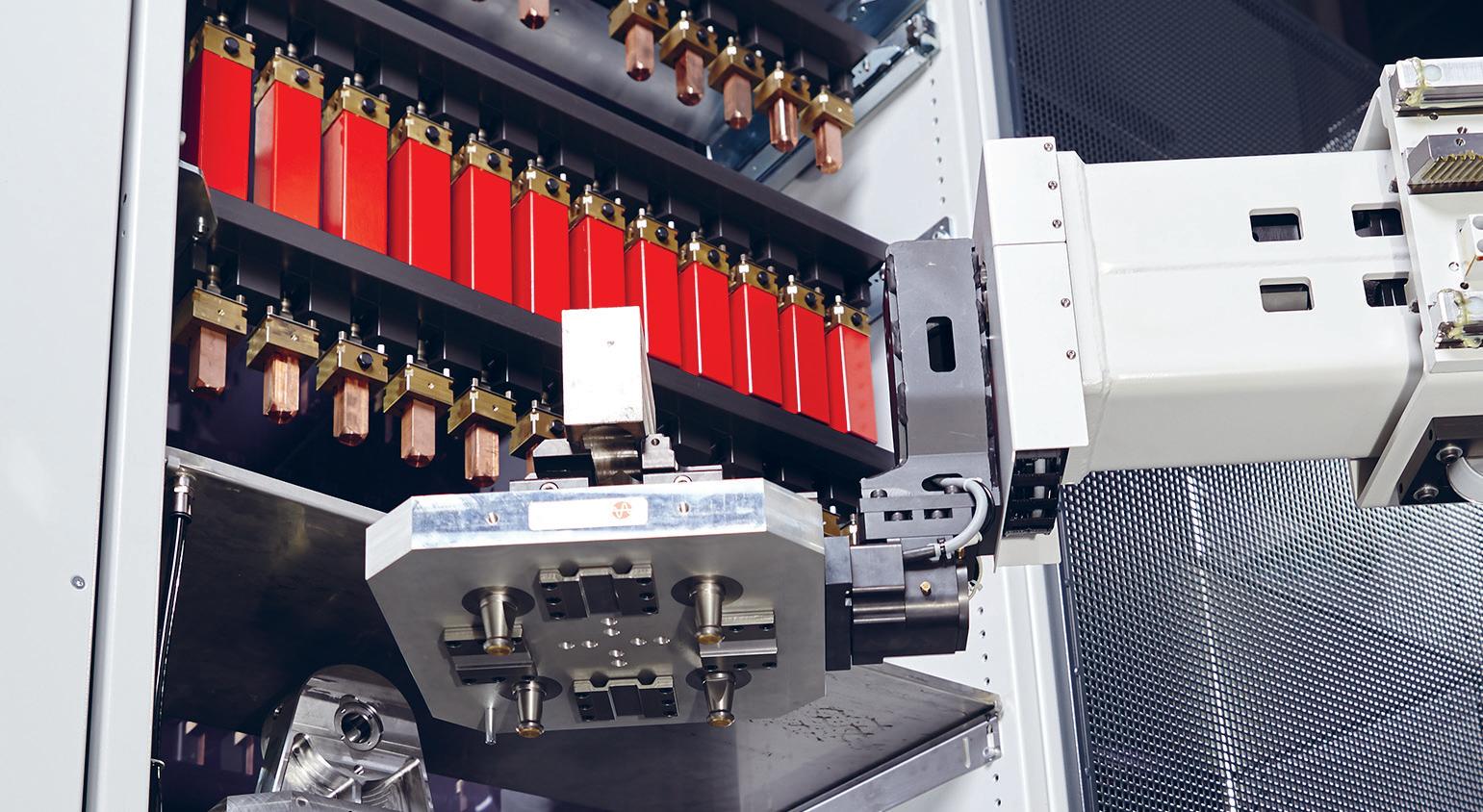

The EROWA Vise Power Clamp VPC Clamping System guarantees powerful, and precise clamping of vises, fixtures and workpieces with pitch dimensions 52 and 96 mm.

Technical details EROWA Vise Power Clamp VPC

Repeatability with chucking spigot < 0.003 mm

Blank Vise 148U

ER-166700

Indexing 4 x 90°

Clamping power (with reclamping) 18‘000 N

Clamping with spring tension (clamped without pressure)

Opening with dry compressed air min. 6 bar

Number of air ducts: min. 2 (opening and reclamping)

Optional: +1 (for cleaning/ presence control)

Blank Vise 72U

ER-155580

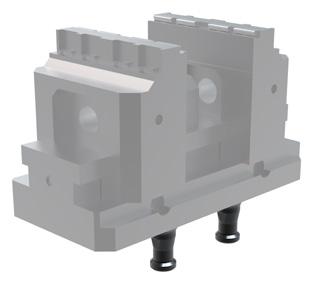

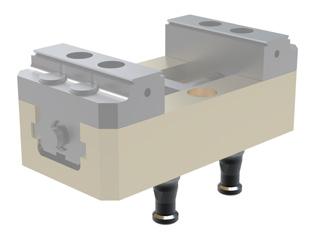

EROWA stands for precision, repeatability, and modularity. With the Blank Vise workholding system, raw parts of different shapes and sizes can be clamped quickly, securely, and with defined forces. This ensures reliable positioning and repeat accuracy from the very first setup, reducing changeover times and minimizing errors. As part of the EROWA system philosophy, all kind Blank Vise integrates seamlessly with zero-point clamping and automation solutions, enabling efficient, flexible, and fully scalable production processes.

Magazine configuration ERC 80

40x Blank Vise 148

Magazine configuration ERC 80

60x Blank Vise 72

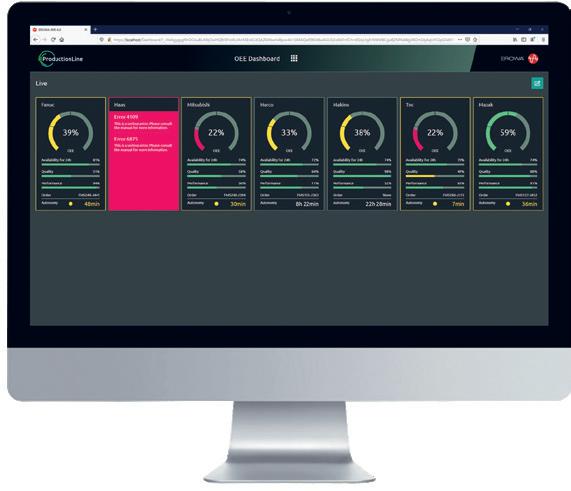

EROWA robots open up previously unused production hours. Autonomous production takes place in the third shift and at weekends. This requires precise, yet flexible planning. JMS® 4.0 provides a clear overview. The order list, the priorities, the CNC programmes, the tool management and the current status messages show at a glance what is going on.

User-friendly and easy to operate

JMS 4.0 ensures a clear overview of current jobs. All the data that is relevant to production are represented in a user-friendly fashion. Current status messages assist the operator.

Controlled data flow

The process control system controls and monitors production cells. The complete universality of the data with all systems allows for genuinely comprehensive monitoring and process security.

FACTS

• Easy-to-view representation of the entire production process

• Import/export interfaces

• 24/7 live machine status via monitoring app

• Transparent analysis of all production data

• Modular software components

• Intuitive user interface

Transparency about productivity

Dashboard and supervision applications show the efficiency parameters in real time, as well as the current status of the production cells in the system.

At EROWA, we have listened to the wishes of our customers from a wide variety of corporate sizes. Thus we provide tailormade solutions that fit your production process and degree of digitalization.

Thus workpieces can be loaded and unloaded in a fully automated process with tailor-made EROWA robots, which, is not an indispensable requirement for an efficient production cell. This starts with the automation of the data, and the automatic loading process can happen in a second step on request.

Job or machine reports can be generated with a few clicks. A user-friendly interface and its availability in the entire network make this application an indispensable tool for process optimization.

We accompany you on the way to the right choice. Our specialists will be glad to advise you and show you what your perfect solutions can look like and be implemented step by step.

EROWA AG, founded in Switzerland in 1971, is now a globally operating organization specializing in the development, production, consulting, and distribution of state-of-the-art manufacturing technology for tool and mold making, as well as for production and precision engineering. With their headquarters located in central Switzerland, EROWA ranks among the world‘s leading companies in clamping technology and automation. Having 13 subsidiaries and 22 representatives, EROWA offers international points of contact and worldwide customer service.

EROWA - Contacts international EROWA Group Business Network: a member of ORENDA Holding Ltd. Subject to technical changes. Registered trademark of EROWA AG, Copyright © EROWA AG, patents are existing or pending for a number of products of EROWA AG.

The next step towards greater efficiency, precision and productivity starts now. With EROWA, you have a partner who will optimize your production holistically - from clamping technology to automation and process control. Our innovative solutions adapt flexibly to your requirements and grow with you - for production that is ready for tomorrow. Get in touch with us - we will be happy to assist you.