VAB

VAB

NASA’S SIGNATURE STRUCTURE KEEPS EVOLVING

Market Spotlight

POLK COUNTY’S CIP AND GROWTH

FLORIDA ENGINEERING STUDENTS SHOW THEIR BEST WORK

Designed by architect Yann Weymouth, the Dalí Museum in St. Petersburg was designed to be a 100-year building, a structure that could resist 20-foot storm surges and withstand 160-mph hurricane winds.

Florida structures must be designed and built to last in a challenging environment that demands resiliency. But some buildings go beyond quality and reliability and stand as works of engineering ingenuity and incredible art. In this issue, we take a closer look at Florida’s engineering marvels.

Welcome to the Summer 2025 issue of Engineering Florida, where we explore the past, present and future of our profession through one powerful lens: Engineering Marvels.

Florida’s landscape is do ed with iconic works of design and ingenuity that continue to awe and inspire. In this issue, we take you on a journey across the state and beyond to rediscover some of the most fascinating engineering feats ever accomplished on our soil.

We begin in St. Augustine, home to the Castillo de San Marcos, the oldest masonry fort in the continental United States. Built from coquina stone in the late 1600s, this enduring structure is not just a marvel of military engineering; it’s a testament to sustainability and the use of local materials, long before these concepts became modern buzzwords.

Follow us down the King's Road, one of Florida’s earliest transportation corridors, which laid the groundwork for future development across the state. Then leap forward in time to the NASA Vehicle Assembly Building at Kennedy Space Center, a true cathedral of technology and one of the largest buildings in the world by volume. It’s where engineering and imagination collide to reach for the stars.

Of course, no issue on Florida’s marvels would be complete without spotlighting the incredible accomplishments in the Florida Keys. The Overseas Highway, with its crown jewel, the 7-Mile Bridge, remains one of the boldest infrastructural

achievements of the 20th century. Even further out, we take a closer look at the challenging construction and maintenance of Dry Tortugas National Park, where history, preservation, and innovation meet at the edge of the Gulf.

We also recognize the role of architecture in our built environment by honoring the work of Frank Lloyd Wright and Yann Weymouth, whose visionary designs, including those found on the Florida Southern College campus and the Dalí Museum in St. Petersburg, blend structure with se ing in a way that continues to influence engineers and architects alike.

In our Education Update, we’re proud to showcase Senior Design Days across several of Florida’s engineering schools. These capstone events are where theory meets real-world application, and tomorrow’s engineering marvels begin to take shape in the minds of emerging professionals.

From ancient forts to space-age structures, from coral rock roads to ocean-spanning bridges, this issue reminds us that engineering is not just about what we build; it’s about what we make possible.

Stacey Butler Director of Marketing & Communications FES | ACEC Florida

Editor-in-Chief Stacey Butler

Managing Editor Joe VanHoose

Creative Direction

Hannah Groseclose

Contributors

Thomas Ehlers

Lindsey Ranayhossaini

Johnathan McGinty Lauren Heighton

Richard G. Acree, PE Terracon Consultants, Inc. | ACEC Florida President

Rick V. Baldocchi, PE AVCON | ACEC Florida

Katie Batill-Bigler, CPSM Patel, Greene & Associates | SMPS

Stacey Butler, Director of Marketing & Communications FES | ACEC Florida

John Constantinide, PE Director and Regional Chair, ASHRAE Region XII

David Cowan, Jr, PE, ENV SP Baxter & Woodman, Inc.

Charles W. Davis, Jr, Ph.D. Associate Professor at Embry-Riddle Aeronautical University | FES President

Allen Douglas, Executive Director FES | ACEC Florida

Charmaine Emanuels Chen Moore & Associates | FES

Sunserea Gates, PE VHB | ASHE

Carmelo Giglio, PE, SI United Professional Engineering | FSEA

Sco Martin, PE, LEED AP, DBIA Walter P. Moore | ACEC Florida

Jennifer Nix McGerald, CPSM RS&H | ACEC Florida

Edie Ousley, President Yellow Finch Strategies

Cherie Pinsky, Chief Operating Officer FES | ACEC Florida

Jignesh Vyas, PE Ardurra | ASCE

Tim Wineberg, PE Michael Baker International | FES

Allen Douglas

EXECUTIVE DIRECTOR, FES AND ACEC FLORIDA

The contentious 2025 Florida Legislative Session continues to be stuck in the mud as Legislative leaders wrangle over the budget. The House and Senate remain far apart in their proposals while Governor Ron DeSantis continues to press for his own plan.

While the session was scheduled to end on May 2, it was extended by both chambers until June 6. The House did convene briefly on May 13 to extend session until June 30, the absolute deadline for the legislature to meet its constitutional requirement to pass a balanced budget, but the Senate has not returned to Tallahassee at the time this article was wri en.

The issue is the leaders' differing tax relief proposals. House Speaker Danny Perez has proposed a reduction in the state sales tax from 6 percent to 5.25 percent and had seemed to agree to 5.75 percent, but the Governor announced he would veto the budget bill if there was any reduction in the state sales tax.

The Governor wants a reduction in property taxes, arguing that would only benefit property owners in Florida, not visitors to the state. Senate President Ben Albri on is not in favor of either, proposing non-recurring tax relief, such as sales tax holidays that would need to be approved by the legislature each year going forward.

The issue for the engineering community, particularly those practicing in the ransportation sector, is the House proposal to take $466.8 billion from the Transportation Trust Fund to help fund the reduction in sales tax.

Additionally, the House proposes to reduce the Florida Department of Transportation workforce by 400 positions or roughly 10%. The Senate has countered with a reduction of 111 employees but does not favor any trust fund sweep.

Of great importance to the entire engineering community, Senate Bill 110, a bill amended in the House to abolish the Florida Engineers Management Corporation and the Florida Board of Professional Engineers, was added to the call for the extended session. However, Senate leaders have rejected the idea, and the House Speaker has announced that the issue is dead for this session.

Stay tuned. The Senate President has stated that he will hold workshops over the summer to discuss the deregulation issue and bring a proposal to the 2026 legislative session.

Weekly legislative reports containing other bills of interest to the engineering community can be found on the FES website at fleng. org/advocacy/legislative-updates/ or the ACEC Florida website at acecfl.org/advocacy/ legislative-updates/.

Jennifer Nix McGerald, CPSM ASSOCIATE DIRECTOR, COMMUNICATIONS, RS&H

Florida is a land of vibrant cities, stunning coastlines and ecosystems unlike anywhere else in the world. Beyond its natural beauty lies an impressive legacy of engineering achievements that have shaped the state’s identity and unlocked its potential.

From awe-inspiring structures to groundbreaking environmental and aerospace initiatives, these feats highlight the vision, creativity and technical expertise of engineers. At the center of many of these extraordinary accomplishments is the American Council of Engineering Companies of Florida (ACEC Florida), an organization dedicated to empowering engineering companies to innovate, lead and achieve groundbreaking results.

Towering over Tampa Bay, the Sunshine Skyway Bridge is a symbol of Florida’s engineering ingenuity. Completed in 1987, the cable-stayed bridge extends nearly four miles and connects Pinellas and Manatee counties. Its striking design, featuring steel cables fanned across two massive pylons, is both functional and aesthetically pleasing.

But this project was more than an artistic endeavor; it was a solution to a tragic loss. The original bridge, built in 1954, suffered a catastrophic collapse in 1980 when a freighter collided with one of its supports, leading to a complete redesign.

Engineers faced unique challenges during the bridge’s construction, from navigating high winds and storm surges to accommodating busy maritime traffic below. The final design incorporated advanced materials, such as high-strength steel and concrete, ensuring durability in Florida’s hurricane-prone environment. The bridge’s foundation was also designed to withstand ship collisions, incorporating fender systems to protect its integrity.

Today, the Sunshine Skyway is not just a critical transportation link but a monument to innovation, safety and resilience.

THE EVERGLADES RESTORATION PROJECT: BALANCING NATURE AND PROGRESS

While a bridge like the Sunshine Skyway represents visible brilliance, projects like the Everglades Restoration Project exemplify engineering’s power to tackle unseen challenges with far-reaching impact.

At over 1.5 million acres, the Everglades is a unique wetland ecosystem that has faced decades of degradation due to urban development and altered water flows. To combat this, the Comprehensive Everglades Restoration Plan (CERP) was launched in 2000, representing one of the largest environmental restoration efforts in history.

Florida’s engineering marvels don’t just shape the state’s physical and economic landscape; they inspire future generations to dream big.

Engineers working on this project confront a dizzying array of challenges, from restoring natural water flows to developing sustainable solutions for South Florida’s growing population. Innovations include the construction of reservoirs and stormwater treatment areas that clean water before it flows into the Everglades. Engineers are also employing advanced modeling tools to predict the effects of their interventions on water quality and wildlife. The project is far from complete, but progress so far has demonstrated the incredible balance that Florida’s engineers can achieve between preserving natural ecosystems and supporting modern urban life. Perhaps most importantly, it serves as a model for sustainable engineering solutions in other fragile environments facing similar threats.

When discussing Florida’s engineering marvels, it’s impossible to ignore the Kennedy Space Center, home to the nation’s most ambitious space exploration endeavors. Located on Merritt Island since 1962, this launch site for NASA’s most iconic missions is a testament to the unbounded potential of engineering and human curiosity. From the Apollo missions that landed astronauts on the moon to the Space Shuttle program that advanced lowearth orbit capabilities, the Kennedy Space Center has been the gateway to some of the most defining moments in history.

The center itself is an engineering marvel. Its Vehicle Assembly Building, one of the largest buildings in the world by volume, was designed to assemble massive rockets under controlled conditions. Equally impressive are the crawler-transporters, which move rockets weighing millions of pounds to the launch pads. Creating structures and vehicles that can withstand the forces of launching into space required Florida’s engineers to push the boundaries of what was possible.

Beyond its storied past, the Kennedy Space Center remains at the forefront of innovation. Recent projects, such as the Artemis program, which aims to return humans to the moon and eventually to Mars, demonstrate that Florida continues to be a hub for groundbreaking engineering advancements.

Another standout example of engineering excellence in Florida is Miami’s flood mitigation efforts. Situated just two feet above sea level, Miami is one of the most vulnerable cities in the United States to the effects of climate change. Rising sea levels and more frequent storms pose existential challenges, making innovative engineering solutions essential for the city’s future.

The Miami Forever Bond, a $400 million initiative approved in 2017, funds infrastructure improvements designed to combat flooding. Projects include the installation of stormwater pumps, raising roads and burying power

lines to minimize hurricane damage. Engineers are also exploring the use of permeable surfaces and other green infrastructure to improve drainage and reduce urban heat. The challenges are immense, but the progress being made demonstrates engineering’s ability to adapt to evolving threats. Miami is rapidly becoming a global leader in urban resilience, and the city’s response is a blueprint for coastal communities worldwide.

Engineering achievements like the Sunshine Skyway Bridge, the Everglades Restoration Project, the Kennedy Space Center, and Miami’s flood mitigation systems are only possible through collaboration, innovation, and support. This is where the ACEC Florida plays an indispensable role. By advocating for policies that foster infrastructure investment and sustainable development, ACEC Florida ensures that Florida’s engineers have the resources they need to continue making a positive impact on the state’s future.

Membership in ACEC Florida offers a range of valuable benefits. Engineering companies gain access to industryleading professional development through workshops, conferences and webinars. These opportunities help members stay abreast of emerging technologies and best practices, enabling them to lead in a rapidly evolving field. Networking events connect engineers with peers, mentors, and industry leaders, fostering a collaborative spirit and facilitating partnerships crucial to large-scale projects.

Perhaps most notably, ACEC Florida provides a unified voice for the engineering community, advocating at the state and federal level for funding, jobs, regulations and policies that drive innovation. Whether it’s securing infrastructure grants or shaping legislation that supports resilience, ACEC Florida ensures its members are heard where it matters most.

Florida’s engineering marvels don’t just shape the state’s physical and economic landscape; they inspire future generations to dream big. Projects like the Sunshine Skyway Bridge and Kennedy Space Center show that daring ideas can become reality with the right expertise and determination. The Everglades Restoration Project and Miami’s flood mitigation systems demonstrate that engineering can solve the pressing challenges of our time while protecting our planet for future generations.

By spotlighting these achievements and the role organizations like ACEC Florida play in driving them, we illuminate the importance of engineering as a profession. Every new project enhances Florida’s infrastructure, strengthens its communities and pushes the boundaries of what’s possible. The future of engineering in Florida is bright, and the engineers of today and tomorrow stand ready to build it.

Veronica Bayó Clifford, Esq. OF COUNSEL FOR GROSSMAN, FURLOW & BAYÓ, LLC IN TALLAHASSEE

igning, dating and sealing your work isn’t just paperwork; it is the moment you tell building officials, clients and the public, I stand behind these plans. Florida gives engineers three recognized ways to convey that message, and once you understand what each path really asks of you, the procedure feels much less complicated.

CLASSIC

Pen, Ink and a Physical Seal (§ 61G15-23.003)

If you prefer the traditional approach, place a handwri en signature, the date and your raised or stamped seal on every sheet that lies within your scope of responsibility. Scanned, copied or “pasted-in” signatures do not count, and the paper originals—not any scanned convenience copy—remain the legal “signed and sealed” set.

Five key take-aways from Rule 61G15-23.004, F.A.C.

A digital seal carries the same legal weight as ink. Subsections (1) and (2) of the Rule confirm that a compliant digital signature is the full equivalent of a handwri en signature and embossed seal.

This method remains explicitly recognized under State rules, and although most Florida building departments will still accept properly sealed paper originals, nearly all now prefer electronic files for storage.

Third-Party Verification with a Single Click (§61G15-23.004)

A certification authority, the online equivalent of a notary, vets your identity and issues a password-protected digital certificate file. Drop that certificate onto the first page of your PDF and the so ware locks the document, so any later tweak breaks the seal. Reviewers appreciate the added certainty, and many Florida jurisdictions now list digitally sealed PDFs as their preferred, though not exclusive, submi al format.

When you use this route, remember two small details that help prevent red tags: place the required disclaimer box (“This item has been digitally signed and sealed by…”) somewhere visible on each sheet, and wait to lock the file until the moment you sign so reviewers can still add comments.

Printed copies of digitally signed plans are not sealed. A printed copy breaks the digital link and therefore is not considered signed and sealed unless the engineer adds a traditional ink signature and seal.

Multi-engineer projects require precise responsibility language. The rule requires each licensee on a shared document to spell out exactly which sheets or calculation sets fall under their seal; blanket language remains insufficient.

FBPE strongly urges hardware or multifactor protection. While not mandated in the text, Board workshops and many permi ing portals recommend storing the private key on a USB token, smart card or equivalent secure device to satisfy the rule’s “sole control” requirement.

Always retain the locked PDF alongside project records. Although the rule does not spell out audit-trail retention, FBPE guidance and Rule 61G15-30.009 on document retention make clear that the digitally signed file itself is part of the record set you must keep for at least three years.

The SHA “Signature Report” (§ 61G15-23.005)

Some clients or agencies still ask for the older electronic method. To comply, convert the project into a single PDF, run a free SHA generator to create a unique code, list that code— and every file name it covers— in a signature report, and then hand-sign, date and seal that report before transmi ing both the PDF and the report together. Again, keep in mind that a paper print-out of an electronically signed document is not considered signed and sealed.

For most projects, the practical flow boils down to three checks. First, is the document final? If so, sign, date and seal it. Second, which format does the submission portal demand—hand, digital or electronic—and are you following the rule that matches that format, and only that rule? Third, can a reviewer recognize at a glance who is responsible for each part of the work?

If the answer to all three is yes, your plans will usually glide through the inbox without delay—no cryptography degree required.

For convenience, see § 61G15-23.001 (documents that must be signed and sealed); § 61G15-23.003 (physical signing procedure); § 61G15-23.004 (digital signing procedure); and § 61G15-23.005 (electronic signing procedure). All citations refer to the Florida Administrative Code as amended through 22 April 2025.

Seasoned engineers share a handful of golden rules. They label dra s clearly, so no one mistakes preliminary plans for a final deliverable. They reserve the language of §61G15-23.004 for a genuine digital certificate and use §61G15-23.005 terminology only when the hash-and-report workflow applies, because mixing labels and methods is a quick ticket to rejection. On shared projects they add a concise parenthetical— “Sheets E-1–E-12,” for example—next to each seal so responsibilities are unmistakable.

They archive the locked PDF (or the SHA file plus its report) alongside any paper originals for the full statutory minimum retention period of three years and echoed in FBPE guidance. And, finally, they ask the authority having jurisdiction about its preferred format before hi ing “Submit,” because local quirks still abound. See also Florida Board of Professional Engineers, Signing and Sealing Tips & Tricks (rev. 2024).

Kathleen Ruvarac, PE

PAST PRESIDENT, FLORIDA SECTION, ASCE/HISTORY & HERITAGE CHAIR

On Jan. 20, 2020, the Vehicle Assembly Building (VAB) at NASA Kennedy Space Center (KSC) in Merritt Island was dedicated as a National Historic Civil Engineering Landmark. KSC Director Robert Cabana and Florida Department of Transportation Secretary Kevin Thibault were a part of the dedication ceremony as well as many officers and members of the Florida Section and Region 5.

The application process took over two years, and NASA's Historic Preservation Office (HPO) staff were instrumental in providing the agency's support for the application and planning of the dedication ceremony. This was the first American Society of Civil Engineers’ (ASCE) National Historic Civil Engineering Landmark (NHCEL) dedicated in the state of Florida since the Bicentennial in 1976.

Prior to the VAB, there were only two NHCELs dedicated and installed in Florida. One marker can be found at the Castillo de San Marcos fort in St. Augustine (dated 1975). Located on the western shore of Matanzas Bay in St. Augustine, the Castillo de San Marcos (Spanish for “St. Mark’s Castle”) is the oldest masonry fort in the continental United States. It was designed by the Spanish engineer Ignacio Daza, with construction beginning in 1672. Construction of the core of the current fortress was completed in 1695.

The second ASCE NHCEL marker can be found in Historic King’s Road Park located in Jacksonville (dated 1976). The King's Road was a road built by the British in their colony of East Florida. It stretched from the St. Mary’s River, the border between East Florida and Georgia, to the south of New Smyrna and was mostly completed by 1773.

The third ASCE NHCEL marker can be found at NASA Kennedy Space Center’s Vehicle Assembly Building Entrance.

National Historic Civil Engineering SignificanceApollo Program, Space Shuttle Program. Future use includes the Journey to Mars Program. It has also earned its place on the National Registry of Historic Places.

• Design Civil Engineer: Anton Tedesko; Construction by Army Corps of Engineers

• Uniqueness: When constructed (1966), the VAB was:

- The largest building in the world by volume at 129,428,000 cubic feet

- The largest single-story building at 525 ft tall and 518 ft wide

- The tallest building in Florida (until 1973). It still is the tallest building in the US outside of an urban area.

- Made up of 65,000 cubic yards of concrete and its frame was constructed from 98,590 tons of steel. It stands atop a support base of 4,225 steel pilings driven 164 feet into bedrock.

• Owner: NASA

• Date Construction: Completed in 1966 (59 years old)

• Plaque on site is viewable by the public

In 1963, NASA contracted the Morrison-Knudsen company to design and build the VAB. MorrisonKnudsen designed and constructed major infrastructure throughout the world and was one of the consortiums of firms that built the Hoover Dam, the San Francisco–Oakland Bay Bridge, the VAB, the Trans-Alaska Pipeline, and many other large projects of American infrastructure.

Located on Florida's Atlantic coast, the building was constructed to withstand hurricanes and tropical storms. Construction began with driving the first steel foundation piles on August 2, 1963. The building cost was approximately $100 million to complete. It was part of NASA's massive effort to send astronauts to the moon for the Apollo Program. The building was designed to accommodate a fully assembled Saturn V rocket and housed the Saturn launch vehicles between 1966 and 1975 and in 1980, the Space Shuttle. In 1966, The American Society of Civil Engineers named Launch Complex 39, of which the VAB was an integral part, as the outstanding project of the year.

The VAB is also home to the largest American flag, a 209-foot-tall, 110-footwide star spangled banner painted on the side of the building. A 12,300-squarefoot NASA logo also adorns the side of the massive facility.

The American flag painted on the building was the largest in the world when added in 1976 as part of United States Bicentennial celebrations, along with the star logo of the anniversary, later replaced by the NASA insignia in 1998. The tallest portion of the VAB is called the high bay. It encloses four vertical corridors, each with a door 456 feet high. The doors are the largest in the world and take about 45 minutes to completely open or close. It is the largest vehicle integration facility in the space industry, with connectivity to KSC’s launch control centers and access to vertical launch pads.

The objectives of the NASA Civil Space Research Program were defined in 1958 and reiterated in NASA’s 2014 Strategic Plan and in NASA’s SocioEconomic Impact Report prepared in April 2013. It is impossible to fully quantify or measure how the Space program has impacted the world, but it has been established that the first space vehicles would not have been built without the ingenuity of the engineers and scientists who designed the VAB and Launch Complex 39A.

BY LINDSEY RANAYHOSSAINI, STAFF WRITER

With their unique geology and remote location off the southern coast of Florida, the Florida Keys present distinct challenges for engineers and builders with even the most advanced equipment and technology.

Though modern engineering in the Keys may still seem like a monumental feat, some of the region’s oldest engineering projects remain the most impressive engineering marvels. Designed and built more than a century ago, two legendary structures – Fort Jefferson and the Over-Sea Railroad – demonstrate that modern technology is not always necessary for resilient engineering.

Located on Garden Key within the Dry Tortugas, Fort Jefferson was designed and built by Chief Engineer Joseph Totten and the Army Corps of Engineers to protect the shipping lines between New Orleans and the East Coast markets, as well as to ensure the United States’ claim of the Dry Tortugas. Additionally, a deep basin between Garden Key and Loggerhead Key made the area ideal for military ships to anchor and resupply.

“The idea was to build a fortification to protect the shipping lines, but also to supply these Navy ships so they didn’t have to travel all the way back to the mainland to get supplies,” said Brad Bertelli, author and Florida Keys historian.

Congress appropriated the funds for the construction of Fort Jefferson in 1844, and in 1845, President James Polk declared Garden Key a military reservation. Construction began in December 1846.

The fort was built as an elongated hexagon, with four sides measuring 77 feet and two sides measuring 325 feet, and surrounded by a 70-foot-wide moat. The fort’s 45-foot-tall walls encompass 11 of the 16 acres of land on Garden Key. It was built by slaves who were rented out by their owners for $20 a month.

Approximately 16 million bricks were used in the fort’s construction, making Fort Jefferson the largest brick structure in North America. The structure includes more than 2,000 brick arches and was designed to hold a garrison of 1,500 men.

“The bricks are interesting, because there are two kinds of bricks,” Bertelli said. “First, there were Northern bricks, which were smaller and didn’t work very well. They couldn’t withstand the harsh climate of the Dry Tortugas,

so the bottom two tiers of the fort were built with Southern bricks, which were larger and held up better.”

When the Civil War broke out, however, the U.S. Government no longer had access to the Southern bricks for construction. The top tier of the fort was built with Northern bricks, leaving two distinct sections visible.

Because freshwater access was critical in the Dry Tortugas, Fort Jefferson was built with more than 100 cisterns beneath it capable of holding 1.5 million gallons of water. Additional cisterns were constructed on the parade grounds inside that could hold 92,000 gallons of water.

Though Fort Jefferson is still standing today, the structure itself was never really completed.

“Largely, it was used for Union prisoners and deserters, and for Confederates and their sympathizers,” Bertelli said. “It took too long to finish by the time the Civil War was over.

It was a great idea in the 1840s when it was started, but by the 1860s at the end of the Civil War, there were wartime advances and [the fort] just didn’t work anymore.”

As of 1874, Fort Jefferson was no longer used as a prison, and troops were recalled shortly thereafter. In 1888, the fort was turned over to the Marine Hospital Service and used as an isolation ward for patients with yellow fever. President Franklin D. Roosevelt designated Fort Jefferson a national monument in 1935, and it remains a tourist destination as part of Dry Tortugas National Park to this day.

Developed as an extension of the Florida East Coast Railway, the Over-Sea Railroad connected the Florida East Coast Railway to Key West. Henry Flagler, a principal in Rockefeller, Andrews & Flagler and founder of Standard Oil, drove the development of both projects.

Nicknamed “Flagler’s Folly,” the Over-Sea Railroad was designed in response to the U.S. Government’s 1905 announcement of its intent to construct the Panama Canal. Flagler envisioned the railroad as a means of connecting the nation’s closest deep-water port to the new canal.

Engineer William J. Krome led the project and mapped out the ideal route. The resulting structure would span 156 miles and cost an estimated $50 million to build.

“It was a very difficult project, but it really transformed the Florida Keys,” Bertelli said. “Prior to Flagler doing this, the island chain had been unconnected, both from island to island and island to mainland.”

This changed the Florida Keys from a culture reliant on boats to bring people, mail and supplies to the islands and shifted communities from the edges of the island to the right-of-way, Bertelli said. Ultimately, the railroad made life in the Keys easier for residents and provided a more reliable connection to mainland Florida.

However, the process of constructing the Over-Sea Railroad was grueling and arduous. Throughout the construction process, which stretched from 1905 to 1916, the Keys were hit by three hurricanes in 1906, 1909 and 1910. The project required as many as 50,000 laborers in total and 4,000 men at any given time, with approximately 90 worksites operating up and down the island chain.

Laborers were sourced from recruiting offices in Boston, Philadelphia and New York, and the extreme working conditions made for a high attrition rate. Despite blistering heat, the men who built the railroad wore long pants, long-sleeved shirts and jackets to keep the persistent mosquitoes at bay. Dynamite was heavily used in the construction process, leading to countless injuries and even some deaths.

“It was tough to get people to come down and do the work, as you can imagine,” Bertelli said.

Building a railway through the ocean required numerous engineering innovations, as well as materials uniquely suited for the structure. German concrete was used for the foundation of the bridge, as it was more durable and cured faster than other materials.

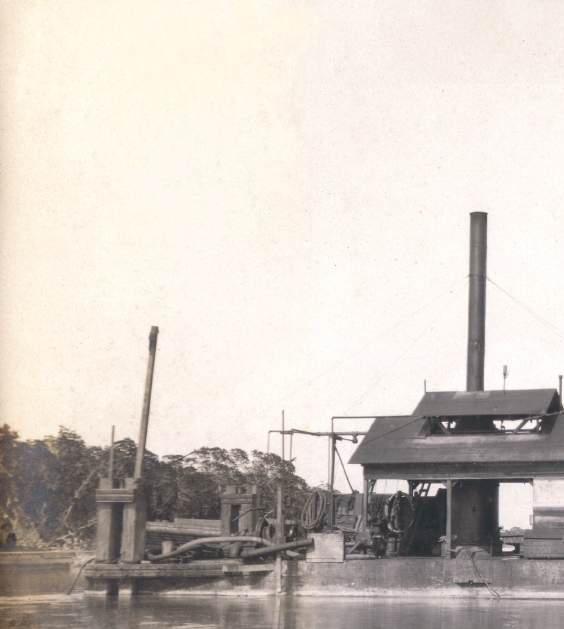

Shallow draft barges were loaded with marl, coral rock and railroad ties for construction, and temporary railroads were built so that small engines and flat railcars – also delivered by barge – could transport materials to the many construction sites.

“It was all boats and barges, and it was difficult because the water here is very shallow,” Bertelli said.

To lay the foundation for the bridge, workers dredged the bottom of the ocean and piled the concrete on top. Two barges worked from one side of each section and met in the middle, dumping marl and coral rock in bigger and bigger piles using slurry pipes.

“A lot of it was kind of making it up as they went along, and the innovation that they had to do was really quite remarkable,” Bertelli said.

One limiting factor in the construction process was the availability of freshwater, as pile drivers and other construction equipment used during the period were steam-powered. Most of the freshwater, Bertelli said, was sourced from Manatee Creek, located along the “18-Mile Stretch.” The project required an estimated 5 million gallons of freshwater every month.

“They built a large freshwater station there, and these large cypress water tanks were placed on flatbed railcars to bring all this freshwater to the work sites,” Bertelli said.

The most difficult bridge to construct was the Bahia Honda Bridge, as the waters in this area are 30 feet deep. Because the rush of water was so dangerous, laborers could only work during slack tide; this limited the workday to just one hour. When the October 1910 hurricane sat over the Keys for nearly 30 hours, part of the foundation the workers had laid was destroyed. An entire shipload of materials was required to rebuild the segment.

Flagler took his first trip across the Over-Sea Railroad in 1912, but Bertelli said construction was not complete until 1916.

Though much of the Over-Sea Railroad was destroyed during the tragic Labor Day Hurricane of 1935, remnants of the structure were sold to the State of Florida and used in the construction of the Overseas Highway. Those components are still intact today.

“What’s crazy is that those railroad bridges are still standing,” Bertelli said. “And the ones that were built in the 70s and 80s are all falling apart.”

John Constantinide DIRECTOR AND REGIONAL CHAIR, ASHRAE REGION XII

As ASHRAE Region XII transitions between two Directors and Regional Chairs (DRCs), the region is in a unique opportunity to update its vision and strategic plan for the coming three years (July 2025 through June 2028).

Coinciding with the new ASHRAE Strategic Plan adopted by the Society Board of Directors, which was revealed in the previous issue of Engineering Florida, my successor Jason Alphonso is cra ing his strategic plan and building on my work from the past three years.

Since the DRC position is very member-oriented, the work of the position revolves around the grassroots activities of the Region’s 16 ASHRAE Chapters, including Florida’s six ASHRAE chapters and their two ASHRAE sections. That is why my theme, “Strong Chapters Make a Strong Region,” focused on building up chapters in three areas: communication, leadership and region-to-chapter resources. These three areas have led to robust growth in the ASHRAE Florida membership, greater growth of Florida-based leaders serving in regional and Society (international) roles, and more reach by the chapters to continue that growth.

What did that translate to in numbers over the past three years?

• Over 30 young professionals from Florida sponsored in training, seminars, leadership weekends and conferences prepared to serve members

• Hosting two Society conferences, providing close access of technical education to Florida-based engineers and leadership opportunities for ASHRAE Florida leaders

• Four government outreach events in Tallahassee

Spotlight Sponsored by:

With the closing of my term as DRC, Jason Alphonso is forming his strategic plan with the theme, “A Region with International Reach, Yet Within Reach.” His work will build on taking those chapter resources strengthened with Society and regional investment and building up three areas for chapters: augmenting member value, enhancing business opportunities and strengthening sponsorship return on investment (ROI).

Evolving from the primary focus on individual members that ASHRAE has relied on for over a century, my successor will empower chapters to pursue engagement more with companies while maintaining the technical integrity of the work of ASHRAE. Elements of his strategy are as follows:

• Rapid grassroots membership growth with a solid technical core

• Artificial intelligence (AI)-powered technical super tools

• Non-profit collaborations and partnerships

• Extending reach into markets in the global south, specifically the Caribbean and Central and South America

When individuals join a technical society, the value of membership is grounded not only in the connections made but the knowledge that is accessible and gained. In today’s world, information is accessible at our fingertips, but expertise behind that information is leaving the workforce in the thousands.

My efforts as DRC to create a recruitment drive that infused our international-level technical commi ees with

Florida and international members maintains the level of expertise to provide current knowledge with today’s technologies and expand the diversity of experiences introduced to create comprehensive solutions. My successor will continue and expand that push.

Along with accessibility of knowledge is the leveraging of technologies, such as AI, to maximize efficiency and productivity. As a technical society, we are investigating and discussing how to bring value to building projects through technology and evolve the built environment to be more resilient, secure, sustainable and healthy.

Discussions among professionals at the local level are where the conversations start. That is why strengthening chapters was pivotal in my work as DRC, and my successor will build on that work to create impact in our Florida built environment and economies.

Beyond the built environment, community stakeholders play a variety of roles toward building occupant health and productivity. Infrastructure, logistics, communications and environment come to mind.

Our technical society does not work in a vacuum, so we need to reach out to professionals who work around the built environment to provide the public with holistic solutions. Not only will we have answers to the hardest technical questions, but we will generate resources for industries and business that can further grow and define Florida’s booming economies. Jason Alphonso will focus on that business aspect in his work as DRC.

As the gateway to the Americas, Florida is in a unique position to impact and touch every market in the Western Hemisphere. Although many may be tempted to only look inward in our state for growth, we have opportunities abounding when we look outward and see where our state’s professionals can expand their businesses and build bridges back to our state.

I have set the foundation and made steps towards that expansion to look outwards for our Florida ASHRAE members, and I look forward to the work my successor will accomplish in continuing this work.

I encourage you to keep up-to-date with our ASHRAE Region by going to our social media channels through our website, h ps://region12. ashraeregions.org/.

BY LINDSEY RANAYHOSSAINI, STAFF WRITER

For structural engineers, the goal for any building project is – simply put – to make a building stand up.

Seasoned engineers can easily determine the structural needs for straight-forward building projects like parking garages and office buildings, but high-design architecture projects present more of a challenge. Show-stopping designs, with innovative glazing systems, paneling and layouts, require problem-solving and collaboration between the structural engineering and architecture teams.

In Florida, where severe weather conditions place a high demand on buildings, structural engineers have the added challenge of determining how to push the limits on design while maintaining structural resilience and staying within budget.

“You'll find that architects think they need to push their structural engineers to be less conservative or allow for more architecture,” said Alex Biggs, PE, structural engineer for Walter P Moore. “Personally, I love working with architects and I love working with people who are pushing the limits. I’m usually right alongside them, trying to help push the limits. It’s just a matter of cost and a matter of physics.”

Florida has no shortage of modern architectural marvels that demonstrate the balance between big architectural moments and resilient design. They have added dramatic flair to Florida’s architectural landscape and provided satisfying challenges for the structural engineers who worked on them.

St. Petersburg

Designed by architect Yann Weymouth, the Dalí Museum in St. Petersburg is home to the largest collection of famed artist Salvador Dalí’s work outside of Spain. The goal for the Dalí Museum was to design a 100-year building, a structure that could resist 20-foot storm surges and withstand 160-mph hurricane winds. Throughout the process, the structural engineering team was tasked with turning Weymouth’s vision into a resilient design.

A priority in the design was to protect the museum’s valuable collection of artwork and rare books. Since the glazing system on the first floor could not withstand high winds, the collections are held on higher floors.

“The galleries on the third floor and the rare book collection on the second floor are all encased in heavily reinforced, hurricane-proof concrete block,” said Scott Martin, PE, project director and the design-build market leader for Walter P Moore’s Structures Group, which served as the structural engineer for the project.

Some aspects of Weymouth’s design presented more of an engineering challenge than others. The museum’s bulbous glazing system, intended to mirror elements of Dalí’s artwork, wasn’t manufactured by any U.S. companies at the time of construction. The Walter P Moore team had to find a European company to create the unique, amorphic 3D enclosure called “the enigma.”

“The glass and steel system has different thermal properties and expands and contracts differently than the concrete does,” Martin said. “This one is being held in three dimensions, so that when it wants to expand and contract, it creates a lot of forces we don’t typically design for in a building.”

Throughout an iterative design process, the structural engineering team created a building meant to be part of the St. Petersburg community for generations to come.

“There was a lot of push and pull,” Martin said. “There was a grand vision for what Yann was thinking about and some rough sketches and concepts. Then we would figure out what was realistic and what building materials, curtain walls and glazing system we were going to use for this. And then it's whittling down this grand scheme from a concept sketch into something that’s physically going to stand up to the elements.”

The Judy Genshaft Honors College, housed on the University of South Florida’s main campus, was designed by New York-based architecture firm Morphosis. Additionally, FleischmanGarciaMoslowski was the local architect and Walter P Moore served as the structural engineering firm.

“This building was intended to be a showpiece on campus and to garner national and global attention for the USF Honors College,” said Dylan Richard, PE, project manager for Walter P Moore. “Some of the biggest challenges were not only programmatic in making the building functional but also pushing the envelope on the skin of this building and doing it in a way that would make sense from an environmental standpoint.”

The building’s asymmetric façade was crafted from 127 mega panels infilled with glazing and aluminum with a specialty iridescent dichotic coating that shifts from gold to maroon to green depending on the angle; its metallic properties also reflect the sunlight to help maintain the interior temperature. The sustainability team completed solar studies to determine where the solar heat gains would be on the building and perforated portions of the metal panels to cut down on solar heat gain while maximizing the view from the inside

The highlight of the building’s interior is the five-story atrium that includes a 360-degree walkway at each level. Each level includes learning lofts, spaces where students can meet in groups and study. The lofts are all different sizes and shapes and contain different furniture.

“From a structural standpoint, we had to figure out how to tie multiple levels together,” Richard said. “Each of these learning lofts are on a cantilevered structure. The concrete is the bones, and then there’s a lattice of steel that the wood would clad around to give you that final look and tie it all together.”

The Morphosis, FleischmanGarciaMoslowski, and Walter P Moore teams worked in concert from start to finish to ensure that every element of the design was a showpiece.

“It was a very collaborative effort on this project and, quite frankly, what I think projects of this type really must have,” Richard said. “If you can communicate with the architectural team early and often, you give yourself the best chance to be the most efficient in delivering the project.”

Located on the University of Central Florida’s downtown Orlando campus, the Dr. Phillips Academic Commons serves as the focal point for the university’s presence in Orlando’s Paramore neighborhood. Featuring two concrete wings connected by a glass bridge, the building houses classrooms, laboratories and faculty offices.

The design architect for the building was New York-based firm Robert A.M. Stern Architects, and the production architect was Schenkel Shultz Architects, an Orlandobased firm. Joe Ales, PhD, PE, SE, served as principal-incharge of the project for Walter P Moore, the structural engineer.

“We prefer to do projects that look like this, because you can see geometrically it's very interesting,” Ales said. “There’s a lot going on, and our job is to be able to support it.”

The building features a lot of open spaces, requiring numerous long spans in the structure. Because the

structure is primarily concrete, Ales said, the structure required another posttensioned system.

To accommodate the long spans, the team had to mix both post-tensioned and conventionally reinforced concrete. The large bridge that connects the two pieces of the building, also a long span, was built out of structural steel. Beyond its basic function, the bridge also includes computer labs and tutoring offices, making for a more complex structure

The many different building materials utilized in the design, including glass and precast, required a lot of coordination to manage the various support conditions.

“Precast is very heavy, so we had to design for that as well,” Ales said.

Another structural challenge came with the building’s columns. The design architects did not want to see columns at the corners of the building, so the engineers had to pull the columns back, requiring cantilevered structures.

“There were a lot of challenges with the building, which is good,” Ales said. “We like challenges. We really want the architect’s vision to burst forth from the building. And if we can allow them to do that, that’s really what allows a project like this to come to fruition.”

Gainesville

Located on the University of Florida’s main campus, the Malachowsky Hall for Data Science & Information Technology is the first building prospective students see when exiting the Reitz Union at the start of their campus tour. The nine-story building, which features a unique, origami-inspired facade, has quickly become a centerpiece of campus since its completion in 2024.

The building houses departments from the Colleges of Medicine, Pharmacy and Engineering to encourage interdisciplinary collaboration and the advancement of data analytics. In addition to faculty offices, classrooms and meeting spaces, the ground floor of the building includes a makerspace.

Alex Biggs, PE, senior project manager and principal for Walter P Moore, served as engineer-of-record for the project. Pittsburghbased firm Bohlin Cywinski Jackson was the design architect, and Walker Architects, Inc. was the local architect.

“This was a departure from other buildings on campus, which had been really traditional before,” Biggs said. “I mean, everyone wants to do nice buildings and nice architecture, but this is a more modern look and more consistent with what Bohlin Cywinski Jackson does in general.”

The structure of Malachowsky Hall, Biggs said, is a balance between a more traditional layout

and visually striking architectural moments.

The architect’s original column layout had long spans, with 50-foot bays on the interior structure. Biggs recommended a more traditional and economical structural system of 26-foot bays, which proved to be an ideal system for the overall design of the building.

Biggs named the building’s first-floor auditorium as one of the most challenging structural engineering components. From a structural perspective, the easiest place to put the auditorium would have been the top floor, but an open lecture space on the bottom floor was important to the owner. The team installed two six-foot-deep concrete beams spanning 72 feet at the base of the building to support the heavy structure above.

“The best part about the design was that it's challenging in specific places,” Biggs said. “That’s what I like to say when I’m working with an architect. Let’s make the most of the moments that you want for the architecture to show.”

The St. Pete Pier has become both an iconic tourist attraction and an integral part of the downtown St. Petersburg community. Designed by New York-based Rogers Partners Architects, the 12-acre pier includes a tilted lawn and a wet classroom, with a wealth of options for dining and recreation.

The local architect on the project was ASD | SKY, and Thornton Tomasetti was the structural engineering firm.

Because the pier is located in a hurricane-prone region, added precautions had to be taken to ensure its structural integrity. Gershon Larsen, who served as a junior staff engineer for Thornton Tomasetti during the pier’s

construction, said the team had to find the right concrete mixtures to make sure the pier would hold up during both normal wave activity and storm surges.

Additionally, the lateral loads from the sheer size of the pier's buildings had to be taken into account.

“It was at a whole different level, because the education and events centers at the end of the pier were picking up all this wind activity and transferring it down the pier,” Larsen said.

The design team, including structural engineering firms Thornton Tomasetti and TLC Engineering, retained a coastal engineer to evaluate the storm surge and wave force potential.

They also consulted with the U.S. Geological Survey to understand the potential effect of sea level rise and how to appropriately elevate the structure to avoid large wave forces in the future.

“As a result of that design foresight, the project performed well under the recent Florida hurricanes, and I think a big reason was that success is the implementation of resilient design considerations,” said David Fusco, PE, senior principal and Florida office co-director for Thornton Tomasetti.

The pier’s unique tilted lawn structure, which provides a gathering space along the water, includes a large, 25-foot cantilever component supporting the soil and grass. The architect wanted a large oculus in the lawn, making the design even more challenging. To meet this challenge, the Thornton Tomasetti team utilized a post-tensioning system that allowed them to span further with less concrete.

Though it presented a fair share of engineering challenges, the St. Pete Pier has become a critical part of the St. Petersburg community.

“Personally, I enjoy all types of engineering projects I work on, whether it's an iconic structure like the pier or if it's a more rudimentary project,” Fusco said. “I think each project has a set of challenges that I enjoy. It's great to contribute to the fabric of a community like the St. Pete Pier does, but every project, large or small, can have a lasting impact.”

As we consider the marvels of engineering in Florida, it’s a perfect time to reflect on the history and people who have shaped this state’s engineering legacy.

As home to one of the oldest European se lements in the United States, Florida’s engineering legacy began early. The Spanish founded St. Augustine in 1565, and construction of the Castillo de San Marcos (completed in 1695) utilized coquina, a locally available material valued for its remarkable ability to absorb cannon fire.

In the 1800s, Henry Flagler built rail lines that opened Florida to tourism, agriculture and commerce. His Overseas Railroad to Key West, completed in 1912, was a monumental engineering achievement that spanned the open ocean and was dubbed the “Eighth Wonder of the World.”

Additionally, Fort Myers and Apalachicola became hubs for legendary engineers and inventors such as Thomas Edison, creator of the phonograph and long-lasting electric light bulb, Henry Ford, who revolutionized the automobile industry with the moving assembly line, and John Gorrie, whose invention of the mechanical refrigeration machine in the 1840s is considered a precursor to modern air conditioning.

As Florida grew, it experienced the growing pains of rapid development. In the early 1900s, cities like Miami, Tampa and Jacksonville surged with urban expansion. At the same time, Marjory Stoneman Douglas's landmark book The Everglades: River of Grass sparked environmental awareness and galvanized efforts to preserve this unique ecosystem.

The U.S. Army Corps of Engineers constructed the Herbert Hoover Dike, a 143-mile earthen structure around Lake

Okeechobee to protect the communities in the area, in tandem with efforts to drain the Everglades for agriculture in the late 1800s. Over time, concerns led to a reversal in policies and through the Comprehensive Everglades Restoration Plan (CERP), one of the largest environmental restoration efforts ever undertaken, the Everglades is recovering even with increasing pressures.

By the 1960s, Florida began a dramatic shi in industry, expanding into the aerospace, defense, tourism, construction and, more recently, biomedical and high-tech sectors. People continue to flock to Florida to live, work and play. According to 2023 data from TheFloridaScorecard.org, if Florida were an independent country, it would rank as the 16th largest economy in the world.

With such a fantastic base of industry, Florida continues to produce exceptional engineers in all disciplines and stands as a beacon of innovation and ingenuity. In the tradition of Florida’s marvelous engineering legacy, modern pioneers like Denver J. Stutler Jr., Carol Weber, Frank Gille e Jr. and Salvatore D. Morgera have carried the torch into the modern era.

Stutler, a proud graduate of the University of Central Florida, made his mark as Secretary of the Florida Department of Transportation and later advanced infrastructure innovation as CEO and co-founder of U.S. Submergent Technologies.

Carol Weber, a University of Florida mechanical engineer, pushed the boundaries of space safety by leading the development of astronaut rescue systems at Kennedy Space Center and now drives innovation at Gates Corporation. Frank Gille e Jr., also a UF alumnus, shaped the future of aerospace as Director of Advanced Military

Programs at Pra & Whitney, guiding breakthrough developments in military propulsion.

Salvatore D. Morgera, emeritus professor at Florida Atlantic University, has led groundbreaking work in both Canadian oceanographic data networks and U.S. military wireless systems. Today, he is advancing research into the brain’s neurological networks to pioneer new therapeutics for neurological diseases. These engineers exemplify Florida’s ongoing impact on the cu ing edge of technology and infrastructure, turning bold ideas into modern marvels.

For lawmakers, municipal leaders, business owners and engineers alike, Florida’s engineering story is more than just a chronicle of achievements; it’s a call to action.

The legacy and momentum are already here. What remains is the commitment to invest in infrastructure, sustainable development, opportunity for industry and the cultivation of world-class talent.

By embracing this legacy and continuing to support engineering excellence, we not only honor Florida’s past, but we shape a smarter, stronger and more resilient future. Let’s keep building marvels and marvelous engineers.

Florida’s engineering story is more than just a chronicle of achievements; it’s a call to action.

As the Element Operations Manager for the Vehicle Assembly Building at NASA's Kennedy Space Center, Elizabeth Kline gets to call the VAB her office.

There aren’t any windows to look out of, but the view doesn’t suffer. The sheer size of the building – over 129 million cubic feet of volume – makes you feel like you’re outside, and the view above could be of the rockets that will ultimately take Americans back to the Moon and farther.

But it’s her coworkers and the scores of people working inside the VAB that make the iconic structure such a special place, Kline said.

“They get excited about what we're launching into space; it's really exciting and the work is a lot of fun, and we enjoy doing the work,” she said. “I know that during

the Apollo program, those people working then were feeling the same excitement just even when they were building the building.”

The first crew of workers on the VAB were so excited that they left behind a message. There is a neatly written note on a beam on the ceiling of the building, out of sight from anyone on the bottom floor and out of reach for anyone except those who would have put the beam there.

On the beam is written a simple objective: “To the Moon.”

“It was the coolest thing I ever found, and you can't reach it so it had to be done while the building was being constructed,” Kline said. “So that was in the Apollo days.

"And I still feel that excitement in this building from everybody. There's an energy to this building in the work that we do.”

BY JOE VANHOOSE, MANAGING EDITOR

Editor’s Note: For more stats about NASA’s Vehicle Assembly Building, be sure to check out ASCE’s writeup on Page 14.

In her role, Kline is responsible for preparing the iconic facility to support flight hardware processing for Artemis missions.

“The work here never ends, it never ends,” Kline said. “It's a 1960s building that's close to the beach, and it’s mostly made out of metal, so it rusts a lot.”

Kline started working at Kennedy Space Center in 1993, first as an operations and mechanisms engineer for Lockheed Martin. In 2006, after NASA announced the end of the Space Shuttle program, Kline joined NASA as an orbiter project engineer. In 2012, she started transitioning and retiring components from the Shuttle program.

“So, we went through everything then in the VAB, everything in the OPF (Orbiter Processing Facility), and we also turned over some of the facilities to other programs

that would be able to use them, but we kept the Crawler Transporter Facility because of course we're still going to use crawlers,” Kline said.

Going through everything in the VAB was a particularly huge job because the same process wasn’t undertaken after the Apollo program. Kline and her team even found a lot of mid-century furniture.

“There were offices we found that looked like people from Apollo just sat their stuff down and left, and it was all still there,” she said.

There are other components that are still original to the building, like the 2,000-ton bridge crane on top that needs to be upgraded. Replacement parts are hard to come by.

Other components from Apollo were modified for the Space Shuttle program. The platforms in the high bays that served the Apollo rockets weren’t quite right for the Shuttle, so they were removed, modified and then used in a different order.

“The problem with that is every time you had to retract one of the platforms, you were retracting a bank of two or three platforms,” Kline said. “For the Artemis program, we put in a whole new set of individual platforms, so whenever we needed to retract a platform, it was so much easier because you could just retract one and not have to retract a bank of three.”

For the assembly teams to be able to work on the new Space Launch System (SLS) rockets in High Bay 3, the new platforms had to be able to move in close, retract and re-connect as segments are added, and retract for the Crawler Transporter to move the rocket on the Mobile Launcher out of the VAB to the launch pad.

RS&H designed 10 levels of work platforms engineered to encircle the SLS vehicle at determined mating, testing and integration points along the vehicle. Each half of the giant

steel platforms measures about 38 feet long and close to 62 feet wide, weighing as much as 325,000 pounds.

“To put it in perspective, you can park 20 Ford F-150s on one half of a platform, so they are huge,” said Josh Saltsman, PE, vice president of Aerospace and Equipment for RS&H.

The design incorporated 20 common platform frames to improve fabrication economy, paired with two sets of custom vehicle-specific inserts, enabling the platforms to change out major or minor inserts as needed to support differing elevations along the SLS vehicle or to adapt to another vehicle altogether.

The platform halves are installed in Towers E and F and attached to rail beams that provide structural support and the ability to move vertically in one-foot increments. Each half contains independent drive mechanisms, programmed to retract and extend via a single operator’s input.

Each platform rides on four Hillman roller systems on each side — much like how a kitchen drawer glides in and out. Dual articulating energy chains are used to provide pneumatics, fire protection, electrical and communication cabling throughout translation.

Depending upon where platforms are located, workers are able to access platforms from level elevator landings. In the event of an emergency, however, everyone needs to evacuate to a 2-hour fire-rated enclosure of the building’s stairs. To accomplish this, RS&H designed movable ramps and corridors to connect to the platforms, no matter where they may be positioned.

“Every lighting connection, every electrical connection, every compressed air connection, every fire protection connection had to have flexibility built in,” Saltsman said. “As a result, everything – moveable ramps, corridors, electricity, fire, hydraulics, lighting, pneumatics, water, everything – had to be flexible.”

The work here never ends; it never ends...

—

ELIZABETH KLINE Element Operations Manager for NASA at Kennedy Space Center

A view looking down from one of the higher levels in the Vehicle Assembly Building, or VAB, reveals High Bay 3 at NASA’s Kennedy Space Center in Florida. Banners note the heights of the Saturn V, Space Launch System, or SLS, and shuttle on the steel structure. Photo by NASA/Dimitri Gerondidakis.

Teams with NASA’s Exploration Ground Systems and primary contractor Amentum, use a massive crane to lift the SLS (Space Launch System) Moon rocket for Artemis II on Saturday, March 22, 2025, inside the Vehicle Assembly Building. The move into High Bay 3 allows technicians to integrate the 212-foot-tall core stage with the stacked solid rocket boosters onto mobile launcher 1. Artemis II is the first crewed test flight under NASA’s Artemis campaign and is another step toward missions on the lunar surface and helping the agency prepare for future human missions to Mars. Photo by NASA/Frank Michaux.

To put it in perspective, you can park 20 Ford F-150s on one half of a platform, so they are huge.

— JOSH SALTSMAN, PE Vice President of Aerospace and Equipment, RS&H

The platforms have already processed the Artemis One mission, and more are likely on the way for the VAB, Kline said.

Activity continues to move at a blistering pace inside the VAB. With construction on the building and the rockets inside it happening concurrently, scheduling becomes paramount.

“So we're constructing a rocket to go into space, but we're also modifying the building at the same time,” Kline said. “We have to just look at the schedule and see who takes priority – of course, the rocket always wins there.

“We just work through the conflicts and try to give (construction crews) space where we can, but again, the rocket comes first. So they have to work around us a lot of times. And we keep a close eye on the schedule for everybody.”

A building made out of so much steel changes its shape and dimensions daily in the Florida heat, which must be taken into account on any project within.

“The whole building does sway and it also expands and contracts in the heat of the day; it'll expand, and then at night it will retract up to 6 inches,” Kline said.

Air conditioning is also ineffective in a building with so much volume.

“It gets very hot, but there are roof louvers that we can open that help the hot air escape, and we also open the big doors at the top,” Kline said. “It's 450 feet to the top of that door, so we can open that top door, and it lets the breeze come through, but you know, it is a continuing safety message to tell people to stay hydrated because it does get hot in here.”

The office may be hot and hectic, but Kline wouldn’t have it any other way.

“I very much enjoy my job integrating things here in the VAB and keeping track of everybody and helping everybody get their work done,” she said. “It's a great job!”

BY THOMAS EHLERS, STAFF WRITER

Nestled between two of Florida’s largest cities, Polk County is in the middle of a population boom. In the midst of this rapid growth, the county's distinctive Community Investment Program (CIP) is keeping citizens at the center as it helps facilitate the influx of people and business.

In 2023-24, Polk County represented the fastest-growing county in the U.S. after several years of being on the top-10 list. Growth has been the highest in the northeast segment of the county, the area closest to Orlando and Walt Disney World.

The Polk County Board of Commissioners approves the CIP on a five-year rolling basis, with each project budgeted across several years to reflect the necessary time and spread out the corresponding costs. This year’s CIP programming totals over $700 million, part of the larger near-$1.9 billion CIP for the current cycle.

While some jurisdictions refer to their CIPs as Capital Improvement Plans or Capital Improvement Projects, Polk County refers to their CIP as a Community Investment Program, reflecting the importance of its connection to its citizens.

Polk County Manager Bill Beasley outlined the approach the county uses to reach the public, which allows for more community input and comment on more public-facing projects, while more technical or less headline-driven projects rely on the county’s expertise.

Its Northeast Regional Wastewater Treatment Facility (NERWWTF) project exemplifies the latter. With rapid growth in the service area, the project will increase its permitting capacity from 6.0 to 9.0 million gallons per day (MGD), meeting projected wastewater demands beyond the 2040 planning horizon. The $120-125 million project is being executed in five phases – the first two have already been awarded at a cost around $70 million.

In Polk County, we are doing the rightthings right reasons right manner. for the in the

— BILL BEASLEY County Manager of Polk County

Polk County's Northeast Regional Wastewater Treatment Facility will increase its permitting capacity from 6.0 to 9.0 million gallons per day (MGD), meeting projected wastewater demands beyond the 2040 planning horizon. Photo courtesy of Polk County.

County leaders rely heavily on its seven division directors to know their needs and understand why they exist.

“I’m always challenging the divisions to think outside the box,” Beasley said. “Is there another way, a better way, an additional way to engage the public? We like to hear the good and the bad, but in the end, I think in Polk County, we are doing the right things for the right reasons in the right manner.

“People generally accept what it costs to do business in Polk County – (they ask if) the cost of government is acceptable to the people in Polk County who pay those taxes and fees. It sounds like certainly most do – that’s why they keep coming.”

Beasley indicated three primary drivers of growth in Polk County: quality education, affordability and, most importantly, a sense of public safety. The third is well represented in the CIP.

The Board of Commissioners identified $15 million to build a new fire training and rescue center. The new facility will include a burn tower structure and administrative office center for in-house training, while future plans include a burning vehicle and aircraft crash training protocols to simulate real-life calls. County officials traveled to states across the Southeast to investigate facilities and integrate their systems, such as carcinogen-limiting zones.

“(Polk County first responders) have been getting quality training, but I would argue it’s been in a less-than stellar facility,” Beasley said. “The idea that we will have in the next year a state-of-the-art training facility says a lot about how we’ve moved the needle and how we believe when you dial 911 in Polk County, we’re going to send the best trained people, the best equipped people with the best apparatus to answer that 911 call. And it takes training to do that.”

The training facility parallels similar investment into first responder facilities, as the county has completed eight new fire stations with another four or five scheduled in the coming years. In addition to replacing aged-out apparatuses, the county has invested into lake and river rescue units and tactical teams that coordinate with other first responders, like the Polk County Sheriff ’s Office (PCSO).

Additional safety projects include the construction of the PCSO K-9 Training Facility – a $1.4 million project – as well as the PCSO Burnham-McCall Training Center. The new training facility, which recently opened and cost just north of $7 million, features state-of-the-art classrooms, training simulators and physical training courses. The county is currently searching for a site to build a storage center for the PCSO for storing records, equipment and gear, and evidence property.

There’s a bit of a balancing act when it comes to improving roadway conditions associated with growth, but Beasley and the county’s CIP initiatives strive to ease more highpriority problems.

Beasley gave the example of Ernie Caldwell Blvd – a roadway built some 15 years ago that travels over U.S. 27 to S.R. 72 – that caused initial consternation with citizens when it was initially pitched and completed. The stretch is now a critical passageway in the county.

“I feel really bad when we inconvenience and have to inconvenience the motoring public by way of lane closures, road closures, detours, all of those things,” Beasley said.

In total, $1.03 billion of the CIP’s five-year plan is pledged to road and drainage improvements, including Lake Wilson Road. The widening of a 1.1-mile stretch spanning from C.R. 532 to C.R. 54 came with a near $42 million cost, and while it might be a more extreme example, the project showcases the price tag that governments must work with to enhance roadways.

“When you add all of the costs associated with having to buy right-of-way, relocate utilities, potential wetland mitigation issues, the design and have to build it… it’s not uncommon to see a mile of road that has to be widened in an urban corridor to cost $20 million a mile,” Beasley said. “It is hugely expensive to be in the public roadway business.”

The C.R. 557 project will expand a near-six mile stretch two-lane road used as a reliever to U.S. 27 into a four-lane divided highway at a projected cost of $140-150 million. With design complete and bids to take place in the summer, the 2-3 years of construction through the wetlands is planned to begin shortly thereafter. The West Pipkin Road project – another two-lane to four-lane expansion – is planned to completely reopen in the next 60-90 days.

The Thompson Nursery Road project, an important East-West corridor that connects S.R. 17 with U.S. 27, is fully-funded and about to begin construction. A five-phase project, the internal phase three has already been completed due to a developer agreement, and bids are currently underway on the remaining portions of the estimated $150-170 million project.

Polk County is larger than the entire state of Rhode Island and Delaware, and despite its size, it has to weigh which projects are more important and how to tackle the biggest needs.

“The county has probably 25-28 roadway projects independent of these that are needed but unfunded that are pushing a $2 billion deficit,” Beasley said. “I don’t have a sustainable funding source where I can do all of these projects. I only have incremental funding, and that’s when we prioritize roadways for that incremental funding.”

Despite the growing population, some citizen sentiments have helped absorb Polk’s expansion. In 2022, the citizens of Polk County voted to pass a land conservation property tax, which was first passed 18 years earlier and allows for the preservation of properties and purchase conservation easements. This mirrors a ballot initiative by voters to introduce a half-cent sales surtax for indigent healthcare, helping those who can’t afford healthcare plans.

During the 2023-24 fiscal year, additional projects included the completion of nearly 22,684 linear feet of sidewalks across the county and the preservation, reconstruction and rehabilitation of additional roadways across Polk County’s more than-2,500 mile inventory.

That attitude towards helping others carries over to Beasley and those in the county office, as they seek solutions to the growing populace in Central Florida.

“That says a world about what the citizens of Polk County try to do to help others,” Beasley said. “It speaks volumes to the culture and the heart that exists in Polk County.”

STRUCTURAL ENGINEERS ASSOCIATION

David Fusco, P.E., FRSE, LEED AP

SENIOR PRINCIPAL AT THORNTON TOMASETTI, FSEA PAST PRESIDENT

The world’s great engineering marvels – those iconic structures that appear to defy gravity, logic and the natural environment – share more in common than concrete, steel and other innovative materials. Whether it's the Hoover Dam, built by 21,000 workers, or the Panama Canal, which took 56,000 to construct, the force of manpower is only part of the story.

Behind every engineering marvel is a structural engineer who doesn't just calculate loads but imagines the impossible and finds a way to make it reality.

Florida has its own share of these projects: the Seven Mile Bridge in Marathon Keys, Breakers Hotel in Palm Beach, St. Pete Pier in St. Petersburg and the IST Building at Florida Polytechnic, to name a few. Each of these structures responds effectively to its location, its purpose and the vision of its designers.

To meet the challenges of designing a structural marvel, an engineer needs more than just technical know-how. A solid foundation in mathematics, physics and modern design so ware is essential, but that’s just the beginning. Creating something extraordinary requires the ability to innovate, think critically and to clearly communicate ideas to a wide range of collaborators. Some teammates may be fluent in engineering language, while others may not. Either way, it's the engineer’s job to translate complex problems into clear, actionable solutions.

A structural engineer must think like a scientist, dream like an architect and calculate like a mathematician, all while keeping the public’s safety at the forefront. Strong interpersonal skills, clear communication and collaborative thinking are just as important as equations and models.

to set egos aside for the be erment of the project,” said retired structural engineer and FSEA member Tom Grogan. “Structural engineers need to collaborate with architects to ensure the ‘form’ is elegantly and efficiently achieved. The contractor's input is paramount to ensure the ‘dream’ can be built in an economical manner.”

Creativity helps solve unprecedented challenges; adaptability keeps a project on track when conditions change. A ention to detail ensures the final product is not just visionary but safe, efficient and resilient.

“Knowledge of relevant engineering and scientific principles provides a solid foundation and must be the starting point,” Thornton Tomase i Principal Len Joseph shares. “They support 'back of the envelope' calculations for a sense of what may or may not work, and rough values for comparison to more detailed analysis results.”

“I believe the best outcomes for engineering marvels occur when the entire team is completely integrated and willing

Len knows; he has played a central role in designing and reviewing scores of tall and supertall towers — including Wilshire Grand Center in Los Angeles, Shanghai Tower, Petronas Twin Towers in Kuala Lumpur and Taipei 101 — as well as many other well-known structures around the world. Beyond calculations, Len emphasizes the importance of understanding the broader context and drawing on historical precedents and project-specific needs to inform design decisions.

“How did project-specific loads, forms, dimensions, materials and performance requirements affect and direct the designs used?” he asks. “This understanding puts current and historical designs in context.”

Innovation must be tempered with careful scrutiny. “New ideas and methods warrant a skeptical, ‘show me’ a itude for ve ing before use,” Len said. “Only adopt them if you can understand the proposer’s explanations

and supporting data. You, not the proposer, know the new project best.”

Len emphasizes the importance of diligence and humility. “Confidence is built on a 'worrywart' mentality that considers what could go wrong and ways to avoid it,” he said. “Ask lots of questions—of yourself and others—and then develop satisfactory answers for them.”