11 minute read

Education Update: Senior Design Projects - Highlighting Successes of Florida’s Newest Engineers

BY LAUREN HEIGHTON, STAFF WRITER

Talented students throughout the state are closing out a chapter of their lives and entering the workforce ready to make a difference. Utilizing their coursework, creativity and technical skills at their respective colleges, each group of engineering students brings unique ideas to the table with innovative solutions to real world problems.

They represent the talent of students stepping into careers in engineering, equipped with knowledge and experience taking rigorous projects from start to finish.

Here’s a snapshot of students and their senior projects from across the state.

VALENCIA COLLEGE: Mark Figueroa and Pedro Cabrera

At Valencia College, senior engineering students Mark Figueroa and Pedro Cabrera used their senior design project as an opportunity to innovate power where it will be needed in the future. In the next few decades, astronauts will travel to Mars, and options for generating power are in the works.

In the past, ideas for power on Mars have overlooked solar panels because of the dust that can accumulate and render them useless. Instead of accepting this judgement, Figueroa and Cabrera looked for a solution to the issue.

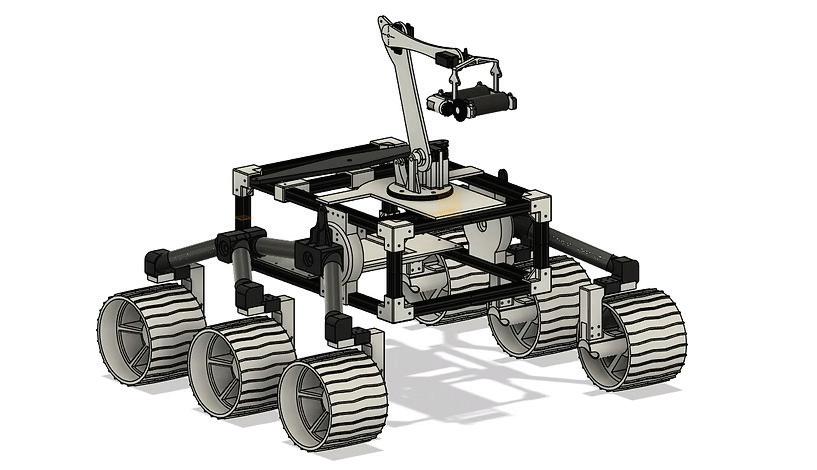

“We thought, ‘OK, there's something here. Let's try to solve this problem without having to put excessive strain on astronauts to have to keep watching solar panels,’” said Figueroa. “So the prototype solar support rover is more of an autonomous cleaning system for them. It has a five axis arm that can then clean the panels and log the data to show that it was cleaned.”

Their project went through several iterations as the individual components were considered.

“We originally intended for an air pressure system that would blow the dust off, but then we started thinking that having an air compressor on Mars is a lot more challenging, because on Earth, we have different density of air pressure,” Cabrera said. “That's why we eventually steered over to an electrostatic brush. As it's brushing, it also creates static electricity between the dust and the solar panel, so it repels a little bit of the dust as well.”

Figueroa and Cabrera devised plans for the solar support Mars rover over two semesters of proposal and design. In that time, the team created models in CAD, 3D printed parts, and incorporated an AI vision system and infrared sensors to make the rover, “Astreus.”

“You can tell [the AI camera] to learn based on the object that you want to find. So we pointed it at the solar panel, and programmed it to pick up on that object, so no matter where it was in the room, it would highlight it with a little box,” said Figueroa. “The infrared sensors also help us with aligning how far away from the solar panels we are because the camera can only do so much. But the infrared sensors can tell us exactly what distance the rover is from the actual solar panels.”

The team will move into the final stage this summer as they build the rover and put their design to the test.

EMBRY–RIDDLE AERONAUTICAL UNIVERSITY: Spencer Armstrong, Kendall Jarre , Jace Martin, Bastien Melin, Cassandra Paerson, Je Valle and Andrew Zubyk

A group of students from Embry-Riddle Aeronautical University was challenged to design an aircraft for their senior project, spanning a year of work. Spencer Armstrong, Kendall Jarrett, Jace Martin, Bastien Melin, Cassandra Patterson, Jett Valle and Andrew Zubyk settled on a design project from The American Institute of Aeronautics and Astronautics (AIAA) requesting a proposal for a homeland defense interceptor.

Their designs went through a preliminary stage for one semester before a second semester of detailed design.

“Everything that we've been learning, from structures to stability to flight dynamics, aerodynamics, everything together, when you get to prelim, they sort of just let you freelance,” Valle said. “It was pretty cool to have it be structured by everything that we have learned over the years. And we've carried it now into detailed design, where we went a little bit more specific into the structural components of the wings, ring frames, bulkheads, and more internal structure there.”

In the design phases, they calculated variables including the stress that materials could endure in order to validate their choices for the aircraft.

“The stresses relate to when a material will fail,” Armstrong said. “So you have to design not only the shape, but also pick the material and make sure that the max stress acting on the component doesn't exceed a certain stress that the material can withstand called the strength.”

Beyond designing the fighter with engineering specifications, the team was encouraged to develop a product that could be sold to the Department of Defense. With this, they did market research for pricing and utilized their resources to make it as competitive as possible.

In addition to submitting the designs to the AIAA design competition, the team presented the final product, UI-24 Accipiter, as their senior design project, receiving helpful feedback from engineers at top companies in the industry.

“We were very fortunate to have a really good team here,” said Martin. “Everyone was thinking ahead, doing their work on time, looking at what they can do in the future, and anticipating every other step. And that was paramount to us being able to perform how we did.”

UNIVERSTIY OF CENTRAL FLORIDA: Gabriel Gadala-Maria, Viviane Dornelas and Juan Gomez

Industrial engineering students Gabriel Gadala-Maria, Viviane Dornelas and Juan Gomez were tasked with a senior project with a clear goal and little guidance.

The team was instructed to create a system that would streamline scheduling at spaceports, given the growth in demand for launches in both the private and public sector.

“A lot of the spaceports are running into capacity issues because they're doing a lot of their scheduling manually, since there hasn't been a need before to come up with a rigorous system for an optimal scheduling system,” Gadala said. “The provider wanted us to come up with something more rigorous that can be easily implemented to spaceports across the United States.”

The provider for the request, the U.S. Space Force, had restrictions on the amount of data and information that they could specify. Still, the team utilized what information they could to create a mathematical model.

“It's definitely a growing need, globally, since from what they told us no one's really done this before. This is really pioneering for spaceports,” said Gadala-Maria. “Similar problems have been tackled before for airports, but it's a different level of complexity.

“The margin for failure is much higher with a spaceport and you have to respect a lot of the internal intricacies of the system.”

For the project itself, Gadala-Maria’s team set out to create a mathematical conception for the system, which takes into account restrictions for the launch window, pad capacity and availability, and additional safety requirements.

“Once we found a way to conceptualize [everything] in mathematics, we then went over and made an alpha version of a program that could do all of that almost instantly,” she said. “Manually, it's impossible to do all of the math in one go to find the schedule, but the computer can do it very quickly."

The team utilized Python and IBM’s education resources to program it and checked their work with a case study using approximate values in place of the actual data.

“We conducted [the case study] to determine the upper and lower limits of the number of launches that they can handle at that spaceport, given the approximations,” said Gadala-Maria. “Right now, they're really looking to see what the limit is, so that they can inform the rest of their organizations and public and private interests.”

The team presented their findings at UCF and provided them to stakeholders at the Space Force. In its next phases, the project could change the scheduling of spaceports forever.

VALENCIA COLLEGE: James Covey and Francisco Cuesta

Vintage audio formats are growing in popularity with new generations of music listeners, inspiring artists to release their music on vinyl and cassette. However, listening to these formats on old equipment creates challenges when that equipment doesn’t hold up.

James Covey and Francisco Cuesta approached their yearlong senior project with this issue in mind. Both Valencia College students spent the first semester designing a tape deck calibration unit, which cuts out the guessing of determining what is wrong with a cassette player, saving time and money for the user looking to correct it.

The current solution for fixing distorted cassette players is using outdated technology that is no longer in production and can cost hundreds or thousands of dollars. Cuesta has taken to fixing these broken units as a business, and he has seen firsthand the high demand.

“When they're not in production, you have to get an older unit and get it working again, and those are the best ones to be honest,” Cuesta said. “Ones that are already fixed are incredibly expensive. You can find one that's broken down, but then you've either got to fix it yourself or get somebody to fix it for you.”

Covey and Cuesta’s system, the RetroSpec, measures test values from audio inputs in real time. The user is then able to compare these measurements to the optimal ones in the manufacturer's repair manual. In total, it performs nine essential functions for tape deck calibration.

“It'll measure the speed of the two different channels and compare them. It compares the output levels of the two channels of a cassette deck, the phase of the waves coming out of them,” said Covey.

“It performs all of the measurements to diagnose the problems so that you can calibrate it.”

In their presentation, the team had to be creative in presenting the issue; picking out the issues in audio quality can be difficult, so they utilized a song by their classmate, Dylon Webb.

“We made it start sounding bad halfway through the presentation; made it sound really bad. So people can get an idea of, ‘OK, this is what a cassette deck should not sound like,’” said Cuesta.

The next step for Covey and Cuesta’s project was to build the device. In their presentation, they showed designed circuits as a proof of concept.

“[Through the presentation] we got a couple of great contacts, people in the industry that are nearby that were judges and have actually offered to help us out with testing the unit once it's completed,” said Covey.

The project itself is a big lift for the two students, but they are driven by the call to solve an issue for both audio technicians and enthusiasts in the resurgence of cassette popularity.

UNIVERSITY OF FLORIDA: Ethan Lantzy, Nicholas Manco, Sarah Laboda and Quinn White

University of Florida biological engineering students Ethan Lantzy, Nicholas Manco, Sarah Laboda and Quinn White created a farming irrigation app to address fertilizing issues in their area. Verifying that fertilizer is distributed evenly throughout the field is an essential part of farming, and small discrepancies can result in entire sections of land not receiving adequate nutrition.

The team first settled on the project in their Irrigation and Drainage Engineering course, choosing to extend it for their senior design project. They worked with an extension agent who brought the specific issue of fertilization distribution nearby farms were experiencing.

“He came to us because he was noticing a problem with fertilizer distribution in fields and he had done some electro-conductivity testing,” said Laboda. “[He said] ‘I'm seeing this problem. I don't really know how to explain what's happening to farmers or how they should fix it. And so I need you guys to help me figure out some way to do that.’”

Their project dealt with fertigation, combining fertilization and irrigation and distributing it through a pipe system. While it is often assumed that equal parts of the fertilizer are distributed, they found that often the plants closer to the pump receive more fertilizer.

“As water travels through the network, there’s friction loss that causes a decrease in pressure,” Lantzy said. “The pressure gradient is responsible for pushing the water and pushing the chemicals. And that causes some areas to receive more or less water.”

They first built a mathematical model in Excel to mimic the spatial components of the irrigation system, and after adjustments they created the modular app. It allows farmers to input their farms’ specifications, like type of pipe, fertilizer injection points and additional components.

The output is a color coded map that highlights which areas of the farm are receiving adequate fertilizer and which aren’t. This, accompanied by recommendations for improvements, gives farmers the opportunity to see what problems they currently face and address them.

“We decided we wanted to strike a balance between something that is technical enough to provide good information, but also simple enough that farmers and extension agents could use it,” said Lantzy.

The group presented their project ahead of the growing season and looks forward to continued field testing and fine tuning.