We strive to act as local guides through the unique and varied terrain of shipping and port logistics, always mapping out the best avenues for our clients and walking them through the tricky areas. Showcasing our expertise inspires the trust that remains the primary ingredient in our relationships and the key to our success.

Expert Advisors in Your Camp:

Editor-in-Chief Carley Fallows editor@littlegatepublishing.com

Advert Space Director Emlyn Freeman emlynfreeman@littlegatepublishing.com

Project Director Andrew Richards andrew@littlegatepublishing.com

Commercial Manager James Hamilton james@littlegatepublishing.com

Lead Designer Adam Knights

Research Kristina Palmer-Holt

Editorial Research David Craig

Corporate Director Anthony Letchumaman anthonyl@littlegatepublishing.com

Founder and CEO Stephen Warman stevewarman@littlegatepublishing.com

For enquiries or subscriptions contact info@littlegatepublishing.com +44 1603 296 100

ENDEAVOUR MAGAZINE is published by Littlegate Publishing LTD which is a Registered Company in the United Kingdom.

Company Registration: 404 2112 62

VAT registration number: 13572767

343 City Road 60 Thorpe Road London 79 Norwich EC1 V1LR NR1 1RY

Littlegate Publishing Ltd does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Copyright© Littlegate Publishing Ltd

This month, we are delighted to share a great insight into the Port of Savannah, the fastest-growing container port in North America. The port delivers vital maritime and cargo services, supporting both local and international shipping lines traversing the State of Georgia’s coastline. We got to see how the port, under the Georgia Ports Authority, has continued to expand the port’s infrastructure to meet the growing cargo demand across the state. We’re thrilled to see O’Neill Logistics providing lead support for this feature.

We also cover two exciting developments from the global Perenco Group. We start with Perenco Brazil, which has been involved in the development of Brazil’s oil industry for many years. We got to see how the company has continued to develop the Pargo Cluster, delivering vital oil resources for the country. For this feature, we’re glad to have DOF Subsea supporting the article, alongside Sulnorte and CPE Technologies. We then turn to Perenco’s operations in Gabon, where Perenco Oil & Gas Gabon has been developing the Cap Lopez LNG Terminal, one of the most ambitious energy developments across Africa. For this, we thank Action Rapide Transit for their support for this article, alongside IGS Logistics.

We also return this month to Maersk, focusing this feature on insights from their North American operations. We got to see how Maersk’s integrated shipping services majorly benefit key traders across the region and allow them to access international markets with ease. Here we’re thrilled to have Alfa Laval supporting our feature on Maersk North America.

by Carley Fallows

A hydropower dam in Tibetan territory has begun to be constructed by Chinese authorities. The dam, once completed, will be the largest dam of its type in the world and is estimated to cost $125 billion. However, the construction has been met with backlash from those living downstream along the Yarlung Tsangpo River in India and Bangladesh due to its potential implications on them, the local environment and local Tibetans. The completed dam will be known as the Motuo Hydropower Station and could generate up to three times the energy of the existing Three Gorges dam, which is currently the world’s largest dam.

Whilst the scheme has said it will prioritise ecological protection and boost local prosperity, many fear that it could have detrimental effects on the environment and pose a threat to livelihoods down the river. India has begun plans to build a hydropower dam on the Suang river, which would buffer against water released from the Motuo Hydropower Station, which could cause flooding in parts of India downstream. .

Australia is known for its Great Barrier Reef, which has been experiencing the effects of climate change on its coral for many years. However, the lesser-known Ningaloo Reef on the other side of the country has been experiencing a marine heatwave, leading to bleaching of its coral too. The marine heatwave has been caused by increasingly high water temperatures, which have stressed the corals, causing them to turn white. This is due to the algal symbionts that live inside the cells of the coral, to break down in their relationship with the coral, resulting in it not functioning as normal. This is what leads to the coral bleaching, and it marks the first time the reefs on both the eastern and western coasts of Australia have been bleached simultaneously.

The elevated sea temperature is being linked to a trend in sea temperature, which has been wreaking havoc across the world. This trend has been likened to ‘a raging underwater bushfire’ by the Australian Marine Conservation Society. The heatwave began causing damage in the Caribbean in 2023 and has now made its way across the Indo-Pacific, leaving coral reefs severely bleached in its path. By the end of last year, and in recent months, temperatures have continued to rise across Western Australia, leading to the Ningaloo Reef now being another victim of the ‘underwater bushfire’.

In recent weeks, many different countries across Asia have seen vast flooding caused by extreme weather. In South Korea, extreme flooding caused by torrential rain has left a wake of destruction, with landslides and water causing widespread destruction to buildings and homes.

The worst-affected areas were in the south of the country, where at least 17 people were killed by the flooding and landslides, whilst many remain missing in Sanchong. 10,000 people were evacuated across the region following the start of the downpour, and 41,000 homes lost power according to local media reports. Footage has shown people wading through thick mud in the resort town of Gapyeong, where a bridge was damaged from the flooding.

Nigeria have taken home the Women’s Africa Cup of Nations trophy after defeating Morocco 3-2 in the final. The game started with Morocco, the host nation, starting strong and scoring two goals against Nigeria by the 24th minute. However, Nigeria came back stronger in the second half, winning a penalty in the 64th minute and a further goal in the 71st. However, 24-year-old Jennier Echegini secured Nigeria the title with a last-minute goal, just 2 minutes before the end of full time.

Nigeria had called their title campaign ‘Mission X’ to reclaim the Women’s African Cup of Nations title after their last win in 2018. It is the 10th time the Nigerian side has got to the finals, and their 10th win. This means that in every final the team has played in, they have come out victorious.

Wild weeds and leafy greens in Kenya are becoming more common as a vegetable of choice for many across the country. Many vegetables, such as cabbage, spinach and spring greens, have been readily available across Kenya since they were first introduced by colonial authorities in the 1960s. However, there has been a significant rise in the number of people utilising locally grown and organically produced varieties of green vegetables such as spring greens. One type is known as ‘sukumawiki’, which means ‘stretch the week’ in Swahili.

Vegetables grown locally have become increasingly popular across the country, with production of these types of greens doubling over the last 10 years. In 2023, More than 700,00 tonnes of sukumawiki were produced across Kenya, making it more than double the volume of all indigenous leafy vegetables combined. For many years, locally grown crops were not as favoured due to attitudes against traditional crops. However, they are now being noticed on a wider scale for their resistance to diseases and pests, which allows them to be grown more organically.

After beating Namibia 30-28 in the Rugby Africa Cup final, winners Zimbabwe have qualified for the Rugby World Cup 2027. The final match saw Zimbabwe face off against Namibia at the Mandela National Stadium in Kampala, Uganda. Whilst both sides seemed pretty even during the first half, Zimbabwe took the lead after a penalty and kept just ahead for most of the game. However, Namibia had a chance to take the lead in the 79th minute, but Namibia sent a penalty attempt just wide of the posts, which sealed the team’s fate.

The win for Zimbabwe means they now qualify for the Rugby World Cup, bringing an end to their absence from the event for the last 36 years. The Rugby World Cup is set to take place in Australia in 2027, and will run from October to mid-November, where it will feature 24 teams for the first time in the tournament’s history.

Lawmakers in Brazil have outlined a new law which has raised concerns about the potential environmental harm it could cause to the Amazon Rainforest and the local area. The plans for the bill outline measures that would simplify environmental licenses for infrastructure. This includes licences for building roads, dams, energy and mines. The changes would mean that developers would have to self-declare the environmental impact of their development via an online form.

However, the proposed bill has been criticised for the potential effects it could have on the environment due to its lighter regulations. If the existing environmental studies are not carried out in the same way as they are now, it could lead to deforestation and land-clearing as a result of excessive mining and agriculture, which are already the leading causes of these issues in the Amazon. Whilst some believe the proposed measures will prevent delays in development projects, including for things such as hydroelectric dams, which drive clean energy, some call for more efficient systems that factor in detailed assessments on environmental impact before they are granted.

Archaeologists working in Peru have announced the discovery of an ancient city located in the Barranca province in the north of the country. The city, named Peñico, is thought to be around 3,500 years old and previously served as a trading hub connecting the Pacific coast with communities in the Andes Mountains and Amazon Basin.

The city, thought to be founded between 1800 and 1500 BC, has shed light on the oldest civilisation in the Americas, the Caral. The archaeologists have released drone footage which shows a circular structure surrounded by the remnants of stone and mud buildings. Over the last 8 years, the researchers have uncovered 18 structures, including ceremonial temples and residential complexes. Within these buildings, researchers have uncovered ceremonial objects, clay sculptures of human and animal figures and necklaces made from beads and seashells

An 8.8 magnitude earthquake has hit off the east coast of Russia in the Kamchatka Peninsula and is one of the most powerful earthquakes ever recorded. According to the US Geological Survey, the tremor had a depth of 18km and sent waves generated by the subsequent tsunami towards American shores. Waves of up to 4 metres were reported by Russian authorities in the town of Severo-Kurilsk, which flooded the port and fish processing facility. The waves reaching Hawaii have reached up to 1.74 metres in Kahului, Maui.

Tsunami warnings have since been downgraded in Japan, Russia and Hawaii. However, evacuation orders remain in place for Colombia and New Zealand, after alerts were also issued for China, the Philippines, Indonesia, Peru and Mexico. Currently, no injuries or fatalities have been reported, and the main damage has been caused to the far eastern coast of Russia, where some buildings have been destroyed, and the port has been submerged.

Widespread destruction has been caused across Syria and Turkey as wildfires have taken hold of forest and mountain areas. In Turkey, blazes have been burning for weeks and have now begun encroaching on the country’s fourth-largest city. The wildfires in the forested mountains of Buras in the northwest of the country have continued to spread rapidly, with the government declaring that the provinces of Izmir and Bilecik are disaster areas.

In Syria, wildfires are ripping through the coastal mountain region of Jabal Turkman. The fires in Syria have already resulted in thousands of hectares of forest being destroyed. With such widespread destruction, emergency services have been vastly overwhelmed, whilst thousands of people have been evacuated. The fires have cut off roads and left some areas without power.

The unseasonably high temperature, dry conditions and strong winds have continued to fuel the wildfires across the countres. With an increase in extreme temperatures caused by climate change, such natural disasters could become more common across the region.

Researchers from the University of Cambridge have discovered a 4,000-year-old handprint on an artefact from Egypt typically found in burials. The handprint was found on a ‘soul house’, which is a type of clay model in the shape of a building, most commonly found in burials in Egypt. It’s thought that the soul houses may act as offering trays or provide a place for the deceased soul to live within the tomb. The handprint is the result of the maker touching the model before it was dry and dates between 2055 and 1650 BC.

The discovery was made by curators when preparing for an upcoming exhibition, and it will now be on display as part of the university’s ‘Made in Ancient Egypt’ exhibition at the Fitzwilliam Museum, set to open later this year. The discovery is a rare find, with no other full handprint being found on an Egyptian artefact before.

The United Nations’ World Meteorological Organisation (WMO) have released data outlining that sand and dust storms are causing premature death, with the increase in such storms often being caused by climate change. The two organisations have outlined their concerns that nearly half of the global population between 2018 and 2022 have been exposed to dust levels that the WHO deem as unsafe.

Some of the most severely impacted areas are the Middle East and North Africa, where more than 80% of the world’s dust is produced from the deserts. Across these two regions, roughly 2.5% of gross domestic product (GDP) is spent annually to tackle dust and sand storms. However, dust from these regions can travel far across the world, with the Sahara Desert dust ending up in the United States, causing widespread issues.

Last year’s Wimbledon Champion, Carlos Alcaraz, faced off against Jannik Sinner in the Wimbledon Men’s Singles final, with Sinner coming out on top. The game was an exciting watch with both players demonstrating their excellence in the sport. Both Sinner and Alcaraz have dominated the Grand Slam Championships, with either one of the men claiming the top titles at the Australian Open, French Open, Wimbledon and the US Open since 2024. To date, Sinner has won 20 titles, with Alcaraz claiming 21.

Sinner is ranked world number one and showed his power on the court, with a four-set victory over the second seed Alcaraz. Whilst this was the pair’s first meeting in the final at Wimbledon, it is very unlikely to be their last. The win for Sinner comes just a few weeks after Alcaraz took the French Open title.

England’s women’s team have taken home the trophy at the UEFA Women’s Euros 2025. England faced off against Spain, who had been playing very well across the tournament. The game opened with Spain going a goal ahead in the first 25 minutes, leaving England with some work to do. However, in the second half, England came back stronger with Alessia Russo scoring the equaliser. With a fierce competition between the two sides, the game was sent into extra time.

After many attempts in extra time, the game was to be decided by penalties. After a retake of the first penalty due to the player slipping, it resulted in a miss for England. However, after scoring their first penalty, Spain wasn’t successful with their next 3 penalties. Therefore, the deciding penalty came down to Chloe Kelly, who has been vital to the success of England’s title campaign through the Euros. Scoring her penalty, Kelly secured the win for England.

Manager Sarina Wiegman has reached the final in all major tournaments in which she has managed, with the England side winning the Euros in the last two tournaments.

Paris Saint-Germain met Chelsea in the final of the Club World Cup, with the Parisian side tipped to win the title after their impressive performance across the tournament. However, Chelsea would bring their winning streak to an end, as it was Chelsea that secured the win with a shocking 3-0 defeat of PSG. One of the stars of the match was Cole Palmer, who scored two goals and assisted with the final goal.

Previously, the FIFA Club World Cup was an annual event; however, following the 2023 games, it was restructured into a quadrennial event for 2025. This means that the event is held much like the FIFA World Cup. This makes Chelsea the first winners of the game in the new format and will mean they will hold the title until the next Club World Cup in 2029.

Shell is present in more than 70 countries worldwide using leading technology and its innovative approach to develop a more sustainable energy future. For Shell, its primary mission is to meet the energy needs of society in a manner that prioritizes the economic, social and environmental impact of energy generation, now and for the future. One of the key focuses for its developments over the last 50 years has been in Nigeria, where Shell has been at the forefront of the country’s oil and gas development. With almost 90% of Nigeria’s export income, and 75% of the country’s overall government revenue coming from the oil and gas sector, Nigeria, with the help of Shell, is primed to deliver significant energy for the country for many years to come.

Shell has been in operation in Nigeria for more than 50 years with its first developments beginning in 1937. Over the years, Shell has been vital in delivering pioneering onshore, shallow and deep-water oil exploration and production projects. These projects are delivered by one of the four subsidiary companies as part of Shell Companies in Nigeria which collectively contribute majorly to the economy thanks to the energy they produce and the revenue this generates for the country. Aside from the development of energy, these companies are also vital in supporting the supply chains, local content and social investment of the country’s energy industry.

The largest Shell company in Nigeria is Shell Petroleum Development Company of Nigeria Limited (SPDC), a joint venture between Shell and the government-owned Nigeria National Petroleum Corporation (NNPC). As part of the SPDC JV, NNPC holds a 55% share, with SPDC holding 30%. The remaining shares are owned by Total E&P Nigeria (10%) and ENI-owned Agip Oil Company Limited (5%). SPDC was responsible for producing the country’s first commercial oil exports in 1958. Today, the joint venture is focused on onshore and shallow water developments to produce oil and gas in the Niger

CSBC-DEME Wind Engineering (CDWE) installed its second offshore substation using ROPES BY BAKAERT, powered by BEXCO’s Ultraline® Slings made with Dyneema® SK78®, a lighter, high-strength alternative to traditional steel

FEWER HANDS GREATER EFFICIENCY

CSBC-DEME Wind Engineering (CDWE) installed its second offshore substation using ROPES BY BAKAERT, powe by BEXCO’s Ultraline® Slings made with Dyneema® SK78®, a lighter, high-strength alternative to traditional steel

This resulted in faster lifts, fewer hands and better efficiency offshore.

This resulted in faster lifts, fewer hands and better efficiency offshore.

For CTRL System Technologies Nigeria Ltd and Nigerian operators, this isn’t just innovation, it’s a shift in how we operate our lifts. Lightweight slings mean easier mobilization, reduced risk, and no compromise on performance. From FPSOs to fabrication yards, CTRL in collaboration with BEXCO is driving smarter, safer, and more costeffective lifting solutions across Nigeria’s energy landscape. Sometimes, the lighter way really is the stronger one.

CSBC-DEME Wind Engineering (CDWE) installed its second of by BEXCO’s Ultraline® Slings made with Dyneema® SK78® steel

For CTRL System Technologies Nigeria Ltd and Nigerian operators, this isn’t just innovation, it’s a shift in how operate our lifts Lightweight slings mean easier mobilization, reduced risk, and no compromise on performan From FPSOs to fabrication yards, CTRL in collaboration with BEXCO is driving smarter, safer, and more costeffective lifting solutions across Nigeria’s energy landscape. Sometimes, the lighter way really is the stronger one

This resulted in faster lifts, fewer hands and better efficien For CTRL System Technologies Nigeria Ltd and Nigerian oper operate our lifts Lightweight slings mean easier mobilizatio

From FPSOs to fabrication yards, CTRL in collaboration with effective lifting solutions across Nigeria’s energy landscape Sometimes, the lighter way really is the stronger one

For over four decades, Python Engineering Company Ltd. has set the standard in West Africa’s marine sector. Operating from its expansive 9-acre marine base in Warri, Nigeria, Python Engineering offers a full suite of marine services—from vessel construction and dry-docking to steel fabrication and offshore support.

Boasting one of Africa’s most diverse and modern fleets, Python’s vessels are built to exacting European & US standards and are tailored for the demanding conditions of both inland and offshore operations.

OUR SERVICES INCLUDE

MARINE SERVICES

From the maintenance of marine vessels, barges and tugboats in her shipyard at 47 Enerhen road, Warri, in the early 90s, PECL has acquired a vast experience in shipyard services and then progressed to the construction of different marine vessels, such as houseboats, ramp barges, flat top barges, fuel barges, water barges, dredgers, pontoons, offshore and onshore Port A Cabins and even tugboats. PECL provides wide range of offshore support services in the oil and gas sector from the logistics and transportations to security patrol services to supporting rigs in their daily drilling operations through provision of various types of offshore vessels

CIVIL & CONSTRUCTION SERVICES

Our Civil design and construction team has executed several projects starting from residential projects, roads & infrastructure, helipads and runways, office complex buildings, to integrated projects ( as Field logistics bases and plant buildings)

Python Engineering Company Ltd has combined its expertise both in marine & civil services and has designed, fabricated, installed and executed several camps both on land and on offshore barges and locations by construction of accommodation units, office units, kitchen and messing units, recreational units, self-contained toilet units and technical units.

FACILITIES MANAGEMENT & MAINTENANCE SERVICES

Python Engineering Company Limited is a leading Facilities Management & Maintenance Services Company; since incorporation PECL was & still rendering her services successfully to the Major Oil & Gas Companies with the highest safety standards.

Whether it’s accommodation barges, tugboats, or offshore logistics vessels. Python ensures every asset delivers comfort, safety, and efficiency.

Trusted by leading IOCs, energy and infrastructure firms, Python Engineering is more than a marine services provider—it’s a strategic partner powering progress across the continent.

Partner with Python Engineering for reliable, stateof-the-art marine services tailored to your project’s needs. Explore our capabilities and discover how we can support your operations.

Elshcon Nigeria Limited has since 1990 been the go to ISO 9001:2015 ‑ certified partner for Integrated Maritime Logistics, Steel Fabrication and Construction company servicing both the energy and non‑oil sectors of the economy.

WE DELIVER WITHOUT COMPROMISE

OUR SERVICES INCLUDE:

• Steel Fabrications/Construction & Maintenance Facilities & Pipelines Solutions

• Marine Solutions; Inland Marine Vessels and Machineries/Equipment

• Tugboats, Barges & House Boats Charter. • Machineries & Equipment Supply

• Offshore Marine Vessels: Offshore Barges, AHTS, PSVs, LHT & Security Vessels, Utility Vessels Charter, etc. Marine Logistics & Offshore Support

• Supply Base Solutions • Lifting Solutions – Cranes & Forklifts

• Ship Building, Ship Repairs & Dry docking Solutions, etc.

• Anchors, Chains/Shackles, Deck and Fendering Solutions

CORPORATE OFFICE: Deborah Lawson House Plot F6 Abacha Road, GRA, Phase III, Port Harcourt, Rivers State, Nigeria.

FABRICATION / SUPPLY BASES: 11, Trans Woji Road & #7 Elshcon Road, off #3 Trans Woji Road, Trans Amadi Industrial Layout, Port Harcourt, Rivers State, Nigeria.

LAGOS OFFICE: 33 Kofo Abayomi Street, Victoria Island, Victoria Island, Lagos State, Nigeria.

Delta, with assets spanning 50 oil-producing fields. Across these assets, SPDC JV has a network of 5,000km of oil and gas pipelines and flowlines, 5 gas plants and two major oil export terminals.

For deepwater oil development, Shell holds 100% interest in Shell Nigeria Exploration and Production Company (SNEPCo) which has focused its development primarily on the Bonga Field. Across the Bonga field, Shell is responsible for the production of more than 200,000 barrels of oil per day (bpd) and 10 million standard cubic feet of gas per day (mmscf/d). As the first deepwater development for Nigeria’s oil and gas sector, Shell has played a key role in pioneering this industry for the country, which in 2005 saw Shell increase the country’s offshore capacity in Bonga. Today, almost a third of Nigeria’s deep-water production comes from the Bonga and Erha oil fields, reaching depths of more than 1,000 metres.

In 2014, SNEPCo continued its expansion of the country’s deepwater developments with the establishment of additional deepwater developments in Bonga North West. These offshore deepwater projects have been vital to the social and economic development of Nigeria, with the developments delivering much-needed employment, training and

business opportunities for local people. In fact, the Bonga Field developments have helped establish the first generation of Nigeria’s oil and gas engineers with experience in deep water development.

For gas development, Shell Nigeria Gas (SNG) is the only international oil and gas company established as a gas distributor to industry customers across Nigeria. SNG, incorporated in 1998, has spent more than 25 years focused on the downstream distribution of gas to industries across Nigeria. The company provides manufacturing and industrial customers with access to a clean, reliable and lowcost alternative to liquid fuel. To achieve this, SNG operates a growing world-class gas transmission and distribution network spanning 138km of the country. In recent years, SNG has been focused on a growth phase, and so in recent years has expanded its gas distribution capacity by over 150%. Its network is now able to distribute over 150 mmscf/d of dry processed gas to more than 300 industrial customers nationwide, with more than 100 industrial customers already connected to its gas grids.

To help support SNG’s networks, the company has built strong relationships with virtual pipeline operators, which are focused on developing compressed natural gas and mini-LNG grids

For over 50 years, Survival Systems International (SSI) Africa has been a trusted leader in lifeboat safety, offering comprehensive services including multi-brand lifeboat inspections, maintenance, and repairs. Our patented Triple5LX hook system and ISO-compliant practices ensure your crew’s safety and compliance with international standards.

Services include: Maintenance & Inspections • Repairs & Refurbishments

• Load Testing • Hire Equipment • Life Rafts

Ensure your lifeboats are always operational and compliant. Partner with SSI Africa for unmatched safety and reliability.

T: +234(0)8106687469 richard.omokri@ssiwa.com.ng survivalsystemsinternational.com

across the country. By working closely with these operations, SNG can continue to deliver vital energy infrastructure to meet the needs of the country, and in turn bring more social investments into the local communication through its value chains, revenues and employment opportunities. For this reason, SNG has established itself with a firm identity as a safe and credible gas distributor.

The final company operating under Shell Companies in Nigeria is Nigeria LNG Limited (NLNG). The company is a joint venture with Shell holding 25.6% share, and NNPC, Total E&P Nigeria and ENI holding 49%, 15% and 10.4% respectively. The focus of its operations centres around the NLNG Plant on Bonny Island, where the facility has 5 processing units with a total processing capacity of 22 million tonnes a year of LNG. In addition to this, the facility can produce up to 5 million tonnes of natural gas liquid (liquefied petroleum gas (LPG) and condensate). The facility is responsible for powering more than 200,000 homes and businesses on Bonny Islands, through a rural electrification scheme, Today, NLNG accounts for approximately 7% of the world’s total LNG supply, highlighting the valuable role Nigeria and Shell play in delivering this vital energy to market for a more sustainable future.

BQub Engineering Services Ltd. has provided top notch Automation Solutions to clients in diverse industries for over two decades since it’s inception.

BQub Engineering Services Ltd. delivers top-tier engineering services in Industrial & Process Automation, Instrumentation, Power Electronics, and ICT.

Key Offerings and Commitments:

• Control system design & commissioning

• Skilled support for turbines, compressors & treatment plants

• System upgrades & multi-vendor integration

• Supply of panels, instruments & software

• On-site support & consultancy services

Trusted. Experienced. Reliable. Partner with BQub – Your One-stop Solution in Automation!

Contact us today!

Tel: +234 9023007613, +234 8070809011

Email: Inquiry@bqubservices.com Web. www.BQubservices.com

In recent months Shell completed the sale of SPDC to a consortium called Renaissance for $1.3 billion. The divestment of SPDC is set on helping Shell simplify its presence in Nigeria, through its exiting from the onshore oil production in the Niger Delta. Instead, its focus for the future would remain on investing and developing Nigeria’s deepwater and integrated gas positions. Renaissance, renaming SPDC to Renaissance Africa Energy Company (RAEC), will therefore take over Shell’s previous 30% stake in the joint venture, leaving the company now owned by Renaissance, NNPC, Total E&P Nigeria, and Agip Energy.

Across Shell’s operations in Nigeria, there is a keen focus on making the most of the country’s oil and gas reserves to serve the people and economy of Nigeria. With every aspect of the oil and gas development sector focused on delivering vital resources, Shell continues to invest in people and businesses across Nigeria delivering a better future for the country both now and in the future. With the announcement of the divestment of SPDC to Renaissance, we look forward to seeing how Shell will continue to expand its deepwater and integrated gas positions across Nigeria to deliver vital resources for the future of energy development.

Strategic Business Units (SBU)

ENGINEERING

CONSTRUCTION & MAINTENANCE

Process Design

HAZOP/SIL Review

Mechanical Design/GADs

Structural Design/3D Modelling

Piping Design

Instrumentation Design

Shop fabrication (Steel & Copper Nickel welding)

Blasting, painting, installation, construction, and commissioning for onshore and offshore operations

Facility upgrades, modifications, and operational maintenance

ACCREDITATIONS / CERTIFICATIONS

Our Mangement System Conforms To The Following:

Accredited to ISO/IEC 17025:2017

Certified to ISO 9001:2015

Certified to ISO 14001:2015

Certified to ISO 45001:2018

INSTRUMENTATION & CONTROLS

Instrumentation

Control Safety Systems (DCS and ICSS)

Energy and Transport System (ETS)

Process Systems and Solutions (PSS)

Reliability Solution (RS)

TESTING & CALIBRATION LABORATORY

ASSET INTEGRITY MANAGEMENT

Flow Metering Service

Instrumentation & Laboratory

Calibration Services Process Automation Services

Longevity and reliability of critical assets

State-of-the-art technologies

Sustainable Industry-approved Methodologies

Corrosion control and mitigation Leak detection and repair. Production Operation & Lube oil flushing Flange Management Services Torque & Hot Bolting Services

Corporate Office

3A Sule Onabiyi Street, off Christ Avenue, off Admiralty Road, Lekki Phase 1, Lagos State enquiries@eatlng.com +234 (0) 901-033-6048

Project Office No. 5 Apagodo Street, off Ada George Road, Port Harcourt, Rivers State, Nigeria

enquiries@eatlng.com +234 (0) 901-033-6050

Operational Headquarters

Ikot Udoma - Ataidung Road, Eket, Akwa Ibom State, Nigeria.

enquiries@eatlng com +234 (0) 810-337-5124 USA Office 15915 Katy Freeway Houston, Texas 77094, USA

info-us@eatlng.com +1 (404) 721-7052

Believing that flexibility is essential for meeting the increasing demands of the global shipping industry, the Port of Savannah aims to facilitate flexible and faster-to-market services worldwide from its strategic location along the State of Georgia’s coastline. This prime positioning allows the port to offer weekly container services across global markets, strengthening its role as a major seaport on the East Coast of the United States (US). Managed by the Georgia Port Authority (GPA), the port has continuously expanded its capacity and now hosts the largest and fastestgrowing container terminal in North America.

The Port of Savannah delivers vital cargo and maritime services to shipping lines traversing the Gulf Coast, supported by the Port’s integrated interstate and railroad access that extends across the state of Georgia. For many US consumers and manufacturers, Georgia’s integrated interstate and railroad systems are vital to delivering goods and products across the country on time. Therefore, with the Port of Savannah located at the cross-section between these two vital transportation links, it is primed to support the efficient and seamless delivery of such goods to markets across the US and beyond. Therefore, with the continued support of both rail and interstate transportation links, the Port can continue to expand its shipping footprint to position it as a key port ready to deliver diversified cargo solutions to both US and global markets.

One of the central offerings at the Port of Savannah is the Garden City Terminal (GCT), which is the single

Just 15 miles from the Port of Savannah, O’Neill Logistics GA LLC operates a cutting-edge one million sq. ft. warehousing and distribution facility purpose- built for high-performance logistics.

We provide direct service to the ports and rails of NY/NJ, LA/LB, and Savannah, backed by robust in-house assets and technology: With additional facilities in Newark NJ, Monroe, NJ and Rancho Cucamonga, CA, we offer national reach with local expertise— delivering performance you can trust.”

We’re Your Port-to-Door

Whether you’re launching a national brand or scaling an established network, we provide:

• Full-Service Pier Drayage & Port Services

• Direct Service to Ports & Rails in Savannah, NY/NJ, LA/LB

• In-House Fleet, Systems, and Visibility Tools

We specialize in:

Apparel, Footwear, Consumer Goods, and Specialty Food

Ecommerce & Drop-Ship Fulfillment

RFID Technology & Omni-Channel Execution

Pick & Pack Replenishment / Case In – Case Out

Retail Distribution & Value-Added Services

Cross Docking & Transloading

largest and fastest growing container terminal in North America. GCT spans a 1,345-operator terminal set on providing quick and easy connections to global markets whilst facilitating seamless supply chains on both a local and international level. The facility encompasses 36 high-speed container cranes and 158 rubber-tired gantry cranes, which are served by Interstate 16 (I-16) travelling from east to west, and Interstate 95 (I-95) travelling from north to south. The interstate routes allow the port to play a pivotal role in delivering cargo along major transport routes travelling across the country. This is valuable as it means many manufacturing hubs in the Southeast and Midwest can be reached via the port in just a couple of days’ drive, and so the port’s interconnected nature with the country’s transport network makes it a clear choice for moving cargo from international markets and across the country. However, the connected nature of GCT does not end there, and in fact, the terminal is also served by a Class I railway service via CSX Transportation and Norfolk Southern Railroad. These rail network links provide a 2–5-day double-stack rail service that is

available to inland destinations across the country, including Atlanta, Charlotte, Chicago, Dallas, Memphis and beyond to service growing markets across the US. CSX Transportation specifically serves the Chatham Intermodal Container Transfer Facility (ICTF), whilst Norfolk Southern Railroad calls at the James D. Masion ICTF. These facilities are owned and operated by the GPA, which is vital in overseeing the entire operation of the Port of Savannah from cargo arriving at the port to shipping it across the country via these vital road and railway routes.

Alongside GCT is the Garden City Terminal West (GCTW), which adds 100 acres of capacity to the Port of Savannah, providing space to store 20,000 containers at the terminal. The storage solutions are offered to importers who are looking for longterm storage solutions. GCTW is serviced by 15 new electric rubber-tire gantry cranes, which add over 1 million twenty-foot equivalent (TEUs) container units to the port’s existing capacity. The terminal provides a state-of-the-art gate which provides easy access for truck drivers to maximise efficiency

and convenience across the shipping of the port’s facilities.

GCTW is located adjacent to the docks at the Port of Savannah and the Mason Mega Rail Terminal. The Mason Mega Rail Terminal has been a longterm infrastructural investment in GCTW by GPA to help move cargo to key markets much faster. The rail link provides shipping to these markets in less than 3 days and thus supports the Port of Savannah as the largest intermodal facility in North America, servicing 42 trains a week with an annual capacity of 2 million TEUs. In 2024, the Mason Mega Rail Terminal achieved record volumes, moving 540,850 containers via its rail network, a figure that was up 5.7% from the previous year. Thus, through the fluidity and enhanced network provided by the Garden City Terminals and the Mason Mega Rail Terminal, the port’s infrastructure continues to provide the necessary shipping and logistical solutions to deliver the port’s facilities as a vital hub along the east coast of America.

In addition to the Garden City Terminal, there is the Ocean Terminal, which is one of the central developments for the port over the coming years. The current Ocean Terminal spans 5 berths, which are met with full transportation access across both interstate and railroads. The Terminal is located

just 2 miles from Interstate 516 and 10 miles from Interstate 95. Via these roads, cargo trucks can move the cargo from the Ocean Terminal and deliver it across the country efficiently. In addition to road access, the terminal also has integrated rail access via a Class I rail service on the terminal via the Norfolk Southern Railroad. This provides onterminal service and line-haul service thanks to Norfolk Southern Railroad and CSX Transportation, with on-dock rail access served directly to Berths 1, 2, 12 and 13.

However, as the Ocean Terminal looks towards the future, GPA are currently working on an improvement plan for the terminal. The plans outline the renovation of the berths and the container yard, which will allow the terminal to serve two large container ships simultaneously. The start of renovation work will commence in spring 2025, with the construction of a 1,325-foot berth. This berth will be followed by a second, which is planned for completion in June 2026 and will span 2,650 feet. By enhancing its berth capacity, the Terminal will be able to offer an annual capacity of 2 million TEUs.

In January, the Port of Savannah received four new electric ship-to-shore cranes, which were added to the fleet operating across the Ocean Terminal. With the addition of the new crane, the Terminal now

operates 8 Super Post Panamax cranes, designed by Konecranes. These will be vital in helping the port in its development to service two vessels at the Terminals’ berths at once. The Terminal will remain open and operating during the renovation works. In the press release announcing the Ocean Terminal renovation plans, Ed McCarthy, Chief Operating Officer at GPA, outlined that “The completion of this project upgrade in 2028 will enable Ocean Terminal to accommodate the largest vessels serving the U.S. East Coast”. McCarthy continues, ‘Our goal is to ensure customers have the future berth capacity of their larger vessels’ first port of calls with the fastest U.S. inland connectivity to compete in world markets”. McCarthy’s comments highlight the growing role that Ocean Terminal, and in turn the Port of Savannah, will continue to play in delivering the port as a key hub for vessels traversing the East Coast of the US to help facilitate access to the nation’s markets.

Thus, in a further development of Ocean Terminal to enhance its interconnectivity, the GPA board have approved the development of a $29 million exit ramp from the terminal, which will enable direct access to local highway transit to Atlanta. Currently, the ramp is 70% complete and will help support the port’s continued interconnected

nature both within Georgia and across the US. We can see that the developments across the Port of Savannah have been largely successful, as in June, the port announced that it had achieved its third consecutive month handling over half a million TEUs. The announcement came as the port concluded May, having handled 500,900 TEUs of containers, which is a 2.2% capacity increase from the same period last year.

With vital expansion and investment from GPA, the Port of Savannah has continued to enhance its infrastructure and, in turn, see a vast increase in the port’s capacity. As the port continues to grow, supported by the rail and interstate networks across Georgia, and beyond across the nation, customers can choose to utilise the Port of Savannah as a key step in their supply chains, knowing all cargo will be moved reliably, securely and quickly thanks to its faster-to-market service record. Therefore, it is no surprise that the port is now the single largest container terminal in America. With investment and expansion planned over the coming years under the ownership and operation of GPA, we look forward to seeing how the port continues to enhance its offerings to see an increasing cargo capacity with each passing month.

As part of the global Perenco Group, Perenco Brazil brings together the expertise and know-how developed across the global company and utilises this in developing new and exciting offshore developments for Brazil. A key area for oil exploration offshore Brazil is within the Campos Basin, where the first well was drilled as early as 1971. For over 50 years, the field has seen vast exploration, and now, through Perenco Brazil, the company has begun vital production from the Pargo Cluster within the basin, now producing up to 20,000 barrels of oil per day. In delivering such vital oil production for Brazil, Perenco can achieve its central mission to deliver solutions that unlock stranded reserves whilst extending the economic life of the fields it works across. With this mission in mind, Perenco Brazil’s exploration of the Pargo Cluster is vital and looks to deliver valuable oil resources for Brazil.

Perenco Group currently operates across 14 countries worldwide, and across these locations, the company produces a gross total of 500,000 barrels of oil per day (boepd). In recent years, the company’s development in Brazil has been a key focus, especially following its acquisition of key oil fields from Petrobras in October 2019. However, Perenco Brazil, the Brazilian subsidiary of Perenco Group, has been operating in the country for many years, with the company awarded 5 deep water exploration licences in 2008 following a 9th round of licensing. The exploration block awarded to Perenco is held in partnership between the company and OGX and is located within the Espirito Santo Basin.

Whilst its other licences have been vital for Brazil’s energy development, it is the company’s acquisition of the Pargo Cluster from Petrobras in 2019 that has shaped Perenco’s current developments across Brazil. The Pargo Cluster is held 100% by Perenco and comprises a group of oil fields in the Campos Basin offshore Brazil, including the Pargo, Carapeba and Vermelho fields. The assets upon acquisition were mature developments and would require a revitalisation project to enhance their production. To achieve this, the Pargo Cluster Development Plan was developed and formally approved in 2021. The aim was to revitalise the oil fields across the Pargo Cluster and increase the production from these fields whilst extending their operational life.

DOF Brasil celebrates 25 years of expertise and commitment, delivering integrated offshore services across the energy sector.

Over the years, DOF has expanded its local and global footprint, offering integrated marine and subsea services throughout the offshore lifecycle — all from a single company.

Driven by our core values - Safety, Respect, Integrity, Teamwork and Excellence - we uphold the highest standards by combining a skilled workforce with a high-end fleet to deliver smart, safe and efficient solutions for the most demanding offshore challenges.

DOF supports key segments in the O&G and Renewables markets, including:

• Vessel Management & Operations

• IMR Projects (PIDF – Flexible Lines & Subsea Facilities Inspection Plan)

• ROV, AUV & Survey Services

• Flexible Pipelay Vessels & Service

• SURF & Decommissioning Projects

• SAT & Air Diving Vessel Operations & Service

• Mooring Operations

• Seismic Cables & OBN Installation

• Offshore Wind T&I and Cable Repairs

As we celebrate this milestone anniversary, we look forward to continuing and expanding our successful journey.

One of the central revitalising projects of the Pargo Cluster Development plan was the installation of a Floating Storage and Offloading (FSO) vessel, FSO Pargo. The FSO Pargo project saw the conversion development of a double-hulled vessel, with a 750,000 barrel capacity, that would receive oil from the Pargo platform. The vessel received its first oil from the Pargo Cluster at the end of 2023 and is now anchored by 9 moorings, which connect to a new integrated turret system. The oil is passed through the 2.8km pipeline to connect the FSO with the platform. Currently, the Pargo Cluster produces around 20,000 barrels per day, which is a stark contrast to the production level at 2,800 barrels per day when Perenco took it over in 2019. Today, the development of FSO Pargo forms part of Perenco’s $400 million investment into the Pargo Cluster and provides essential oil production for the country.

Upon the announcement of the first oil delivered to FSO Pargo in December 2023, Yves Postec, General Manager of Perenco Brazil, outlines that “FSO Pargo first oil represents a major landmark for the consolidation of Perenco’s long term strategy for the Pargo Cluster. It will be able Perenco Brazil to structure a new scheme for marketing of Pargo oil, one that reinforces the company’s independent and bold values. This project perfectly illustrated the Group capacity to innovate and execute independently. Perenco is very proud of this important milestone”. As we can see from Postec’s comments, the development of the FSO and the overall development of the Pargo Cluster is a valuable field that is delivering significant results for Brazil. Therefore, with the development of FSO Pargo and the continued revitalisation of the Pargo Cluster, Perenco’s operations in Brazil add to the company’s broader strategy to maximise production and extend the life of the assets within the cluster for many years to come.

However, Perenco has only continued to build on its operation in Brazil, and in April 2024, it acquired the Cherne and Barge oil field concessions. The acquisition deal is between Perenco Brazil and Petroleo Brasileiro S.A. (Petrobras) and will see the Cherne and Barge fields and two fixed platforms taken over. The platforms, PCH-1 and PCH-2, are located about 30km from the Pargo Cluster at water

depths of 120-140 meters and had previously been hibernated by Petrobas in early 2020 and scheduled for decommissioning. Upon the completion of the transaction this year, Perenco is set to implement a vast redevelopment project for these fields and, in turn, restart production. The Cherne and Barge fields are expected to reach a target production rate of 10,000-15,000 barrels of oil per day, whilst Perenco looks to unlock more than 50 million stock tank barrels (mmstb) of reserves. Once in production, these are hoped to be linked with the FSO Pargo to continue enhancing the oil fields of the Campos Basin via a new export pipeline.

Armel Simondin, Chief Executive Officer at Perenco, outlined, “The acquisition is a new milestone for the Perenco Group in Brazil. Since the takeover of the Pargo assets in 2019 at a rate of 2,800 bopd, we have increased production to over 20,000 bopd and successfully installed our own FSO. Perenco is proud to deploy its know-how to extend the life of these mature fields and grow our footprint in Brazil”. What we can see from Simondin’s

comments is that Brazil remains a vital development for the company, and through its constant focus on enhancing existing assets, Perenco can achieve its central mission to unlock and develop existing reserves to extend the economic life of fields by leveraging its solutions and expertise to add value to the industry’s existing mature field challenges.

Across Perenco Brazil’s operations, you can really sense the company’s appetite and capacity to develop the mature assets of the oil industry, in order to maximise production and deliver assets for a much longer life cycle. By investing in mature fields across Brazil, Perenco Brazil has delivered vast oil production for the region and, in turn, delivered the Pargo Cluster as a resource for the future of Brazil’s oil industry. With its vital Pargo Development Plan to the more recent acquisition of further fields across the Campos Basin, Perenco Brazil is aligning itself as a leading energy company on a mission to deliver a fair energy industry that brings together its expertise and innovative global spirit into solutions to enhance Brazil’s energy industry for the future.

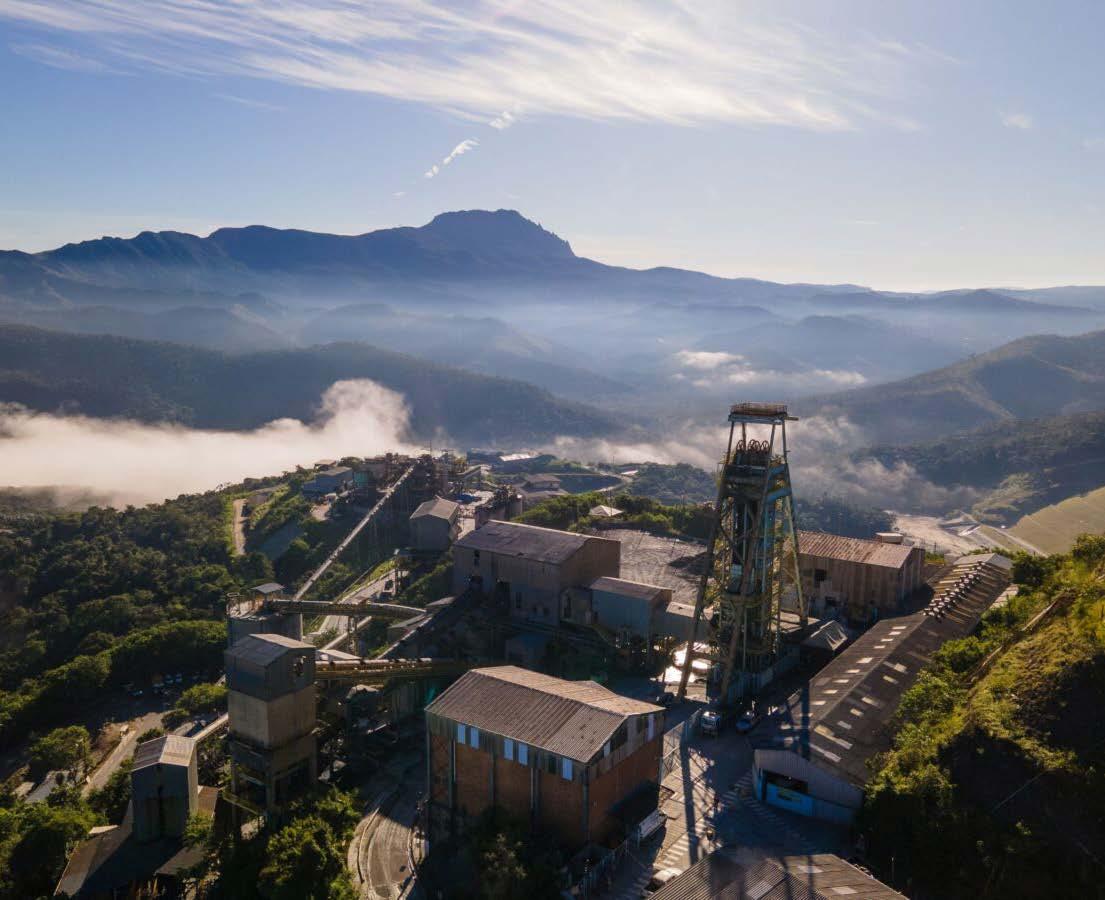

Gold mining is one of the largest industries in Ghana and thus makes up a significant part of the country’s overall economy. With mining operations spread across the country, large-scale mining operations are delivering significant gold resources for the country and solidifying Ghana’s role as the largest gold producer in Africa. Therefore, as one of the largest mining companies in the world, it is no surprise that AngloGold Ashanti has vital mining developments in Ghana set on delivering gold resources to market, and adding to its diverse, high-quality portfolio of mining operations spanning the globe. However, AngloGold Ashanti is committed to delivering valuable resources whilst working to deliver vital community development and social change to support the regions in which its operations are located. For this reason, AngloGold Ashanti today is a leading mining company that delivers resources across Ghana, underpinned by its pursuit to empower people and advance societies.

Gold has long been a vital industry for Africa, as the continent is home to multiple large mining operations taking advantage of the rich gold deposits spanning multiple countries. AngloGold Ashanti currently has gold mining operations in Egypt, Guinea, Tanzania, and the Democratic Republic of Congo. Across these, AngloGold Ashanti is focused on pursuing valuecreating opportunities, supported by its global expertise in the minerals and mining industry. However, Ghana is one of AngloGold Ashanti’s central developments in Africa, spanning the Iduapriem and Obuasi mine sites.

A key mining site for AngloGold Ashanti in Ghana is the Iduapriem Mine, located in the west of the country, spanning 137km2, inclusive of the Ajopa south-western region. The history of the Iduapriem Mine dates back to the early 1990s when Golden Shamrock Limited, the original owners of the mine, began construction of the mine with a semi-autogenous mill circuit and carbon-in-pulp (CIP) plant. By 1992, the mine had officially begun construction and poured its first gold. In 2000, AngloGold had purchased the site and began upgrades, which saw the mine’s operation output capacity increased to 4Mtpa following the merger of Ashanti with AngloGold in 2002. Today, AngloGold Ashanti has continued to expand the plant, which now delivers a 5.2 Mtpa capacity.

Across AngloGold Ashanti’s operations, the company is focused on developing methods that safely and responsibly manage mineral waste. When mining activities are conducted, tailings are produced are the waste residue that remains after minerals are extracted from mined ore. This waste residue is typically composed of finely mined ore, water and trace quantities of metals as well as some additives used in processing. Thus, managing this is essential for environmental and human health. Whilst some tailings are utilised as backfill in mines, most are deposited into surface Tailings Storage Facilities (TSF).

At the Iduapriem mine, AngloGold Ashanti has been working on developing a new Beposo TSF, which would take over from the existing Greenfields TSF. The first phase of the Beposo TSF has already been constructed, with the second phase currently underway. The construction of the Beposa TSF is being supported by local leading engineering and construction services, and will significantly help in the company’s goals to manage its tailings and implement the necessary regulations to avoid

After the successful and safe completion of Phase 1, WBHO Quantum LC Company Limited was awarded Phase 2 for the construction of the Tailings Storage Facility for AngloGold Ashanti’s Iduapriem Gold Mine in Tarkwa

We are excited to announce the steady progress on the BTSF Phase 2, which is a 70 million tons TSF over 22-months.

ONE TEAM, ONE GOAL, ZERO HARM, the WBHO QLC way.

overtopping or structural failures to protect the environment and human health and safety.

The other central mine site for AngloGold in Ghana is at the Obuasi Mine, which began operations in 1897, but, in recent years, the mine has run a more limited portion of its total facilities as it has been functioning under limited operational conditions since the end of 2014. However, in 2017, AngloGold Ashanti began developing an underground mine following a feasibility study into the area, which indicated a strong technical and economic case for the mine. Today, Obuasi encompasses an underground mining operation, located within the Ashanti region and consists of a single access decline with interlevel development between 15 and 30 metres, as well as various shafts. With a 20-year life of mine from its initial feasibility study, Obuasi has continued to expand its operations, and now the mine’s infrastructure includes a 2.4 million tonnes per annum (Mtpa) processing plant with flotation and bacterial oxidation, hoisting shafts with associated infrastructure, and power and water reticulation facilities.

Our job is to make any construction project work for you, no matter the size. In fact, think of us as your construction partner from beginning to end.

Following the 2017 feasibility study receiving strong approvals from the AngloGold Ashanti Board, the current stage of the Obuasi mine’s development began with a three-phase approach that commenced in September 2020. The initial phase covered the conceptualisation and planning of the site, whilst the second phase focuses on the construction of the mine and its development, which was completed in 2021. Following the second phase, the mine expanded its capacity to 4,000 tonnes per day (tpd) of gold, with the final stage of the development set to increase this further to 5,000 tpd through establishing the necessary infrastructure to handle the ramping up of gold production in late 2024. However, as mining operations began, AngloGold Ashanti encountered difficult ground conditions, especially in high-grade areas. Thus, a hybrid mining approach was adopted during the 2024 mining development, using sub-level open stopes (SLOS) in the lower grade areas, and UHDF in higher grade areas. These were designed to help deliver a safer, more predictable and ramp-up profile

In May, African Underground Mining Services (AUMS) secured a A$1 billion contract via its Underground Mining Alliance Joint Venture, with AngloGold Ashanti. The contract outlines a 5-year contract where AUMS will deliver underground mining services at the Obuasi Gold Mine for AngloGold Ashanti. AUMS has previously worked with AngloGold Ashanti on the development of the Iduapriem mine, with AUMS working on the mining operations for the Iduapriem and Teberebie pits. Therefore, its role across the Obuasi Mine marks another key contract between the two companies. The new contract for the Obuasi Mine is estimated to be around A$1,020 million, and will be for services including underground development, production and related mining services. Thus, in working alongside AUMS, AngloGold Ashanti can bring greater development to the Obuasi Mine site and achieve even greater gold production for Ghana.

As both mines move towards the future, AngloGold Ashanti is passionate about ensuring that its operations are positively benefiting the local community through economic growth,

empowerment and sustainability. One of the initiatives set up by AngloGold Ashanti is a 10year Socio-Economic Development Plan (SEDP). The initiative launched in 2022 outlines a clear strategy which ensures that those living in the host communities of the Obuasi mine reap sustained benefits from AngloGold Ashanti’s mining business. The 10-year plan aims to improve social development, deliver a diversified and sustained local economy and improve partnerships within the local community.

A key part of the development plan includes the partnership between AngloGold Ashanti and the Otumfuo Osei Tutu II Foundation and the Ghana Education Service, which distributes 34,000 numeracy and literacy books to public schools across Obuasi. This highlights the mine’s close relationship with the local community, and through the continuous implementation of the 10-year plan, aligned with the mine’s business, the SEDP and AngloGold Ashanti can support livelihoods through

things such as education until long after the life of the mine expires.

Across Ghana, AngloGold Ashanti’s operations are delivering vital gold resources for the country through the Obuasi and Idupriem gold mines. Each mine has seen its infrastructure developed to help deliver significant gold resources, for the benefit of Ghana’s economy, as it serves both local and international markets. However, across AngloGold Ashanti’s operations, there is a real focus on the communities in which its projects are operating within. With the development of the SEDP, AngloGold Ashanti continues to give back to the local community to ensure that its operations benefit those in the local community for many years to come. As AngloGold Ashanti looks towards the future, we look forward to seeing how the company continues to expand its mining operations across Africa and, in turn, deliver vital gold resources and community development for Ghana in the process.

As a dynamic leader in offshore energy development, Noble Corporation Plc has long facilitated innovative offshore drilling operations as a contractor for the oil and gas industry. The company’s central mission is to deliver vital drilling activities that can power the world responsibly, aiming to be the leading global driller for offshore energy projects. Therefore, Noble Drilling has positioned itself as the first choice for employees, customers and investors alike to facilitate drilling projects across the world. To achieve this, Noble boasts one of the most modern, versatile, and technically advanced fleets in the offshore drilling industry. This fleet is recognised for high quality and performance, and that is why it is one of the largest offshore drilling contractors in the world today.

Noble has been operating globally for over a century, beginning in 1921 with a single rig. From this initial vessel, Noble has continued to expand its fleet and now delivers vital drilling operations across both established and emerging energy regions worldwide. The company’s international growth has been driven by its central values to deliver the highest quality service and performance across its drilling operations. Most of Noble’s activities are conducted through its subsidiaries and contract drilling services. Across these, the company has a fleet of 25 offshore drilling units, including 12 drillships and semisubmersibles, and 13 jack-ups. These vessels are focused on delivering oil in ultra-deepwater and highspecification jack-up drilling projects worldwide.

A key place of Noble’s current drilling expansion is in Guyana, where its subsidiary Noble Drilling (Guyana) Inc. operates to deliver key drilling vessels to support the country’s oil field development. In Guyana, key oil developments are primarily located in the Stabroek Block, which is home to an expansive offshore oil and gas reservoir. The block is operated by energy giant ExxonMobil, in partnership with Hess and CNNOC. One of the most notable developments in the Stabroek Block is the Liza-1 development. The initial Liza-1 discovery was announced in 2015 by ExxonMobil and was the first significant oil find offshore Guyana. In 2020, Noble announced a drilling services agreement with ExxonMobil. The agreement outlines that Noble would facilitate the drilling services for ExxonMobil across the Liza-1 development within the Stabroek Block of the GuyanaSuriname Basin.

The agreement outlines that Noble will deliver ultra-deepwater drillships, which are already in operation in Guyana for ExxonMobil, and utilise them for delivering new drilling for the project. The vessels include the Noble Bob Douglas, Noble Tom Madden, Noble Sam Croft and Noble Don Taylor, which are Gusto P-1000 design ultra-deepwater drillships that can operate at depths of up to 12,000ft. The rigs, which commenced operation in 2013 and 2014, are equipped with the necessary advanced drilling system and subsea control technology to facilitate the drilling of ExxonMobil’s oil project across Liza-1 for Guyana.

Thus, the agreement signed between Noble and ExxonMobil is vital in helping to deliver valuable resources to Guyana’s energy sector. For this, Noble plays an important role as a leading drilling contractor, helping global energy giants such as ExxonMobil deliver vital drilling solutions for the future. The president, CEO and chairman of Noble in 2020 outlined that “The Guyana-Suriname basin stands as one of the world’s premier offshore exploration and development opportunities. Since establishing an operational presence offshore Guyana in March 2018 with the Noble Bob Douglas, we have continued to expand our footprint in the region”. The CEO’s comments highlight the pivotal and expansive role that Noble has continued to play across Guyana’s energy sector, as its drillships have long been used to deliver vital energy development projects for the benefit of the country’s energy delivery and economic growth.

Furthermore, Noble’s role across Guyana has only continued to expand, and in the months following its agreement with ExxonMobil, Noble announced it had extended its contract with

Europe Caribbean Line (ECL) is your trusted partner for dependable, Fortnightly breakbulk and project cargo services between North & West Europe, the Caribbean, and the North Coast of South America. Our versatile fleet of multi-purpose vessels, equipped with heavy-lift capabilities (up to 150 metric tons), ensures your cargo moves safely and efficiently—no matter the size, shape, or complexity.

Our Vertraco Reefer Service offers weekly sailings from Northern Europe to Suriname & Guyana—delivering palletized, refrigerated, and break-bulk cargo in just 12 days.

Europe Caribbean Line – Dependable. Flexible. Proven.

Independent Estimating Quantity Surveying

Contract Management Project Cost Control

Procurement

Commercial Management

Risk Analysis (QRA) Cost Management

Expediting Mine Closure Cost

Estimate Validation, Review & Audit

Investment Assurance Reviews (Project Management and Project Controls)

Administration

Scheduling

Benchmarking

ExxonMobil just 6 months after the announcement of the previous agreement. In October of 2020, Noble announced that its ultra-deepwater drillship, Noble Tom Madden, was awarded roughly 6.5 years of additional contract terms under the Commercial Enabling Agreement with ExxonMobil for work offshore Guyana. This agreement extends the existing agreement that was set to end in 2024 until 2030.

Upon the announcement of the contract extension, the CEO of Noble outlined that “We are extremely pleased to further our relationship with ExxonMobil and their partners offshore Guyana. This award demonstrates the capability of the Commercial Enabling Agreement to align the interests of Noble and ExxonMobil while continuing our participation in one of the world’s premier offshore exploration and development opportunities and supports additional investment by Noble in local content”. The CEO’s comments here exemplify how pivotal Noble remains in bringing such valuable resources to market, thanks to its modern fleet of drillships.

However, Noble’s role alongside ExxonMobil doesn’t end there, as ExxonMobil is continuing its pursuit of more oil and gas resources with the support of Noble Drilling. Since it began operations in Guyana, ExxonMobil has made over 30 new discoveries, which equate to more than 11 billion barrels of oil equivalent (boe). Therefore, as ExxonMobil continues to expand its reach across Guyana’s Stabroek Block region, it looks set to hand more work out to the four drill ships currently in operation by Noble in Guyana. The Noble Tom Madden, Noble Sam Croft, Noble Don Taylor, and Noble Bob Douglas have secured an additional 4.8 rig years of backlog in Guyana, which has extended

To learn more visit weatherford.com/victus SAFE, RELIABLE, AND EXPEDITED OFFSHORE INSTALLATION EVERY TIME

The heart of the Victus™ Intelligent MPD System is the automated MPD riser system for offshore and deepwater applications. Its integrated, compact, and smart design reduces installation time from 2 days to 20 minutes, resulting in more than 80% faster rig up and rig down time.

each rig’s contract. In particular, the Noble Bob Douglas rig is conducting vital activities with assistance from multi-purpose subsea vessels that are designed for well intervention, subsea construction and equipment installation, as well as inspection, repair and maintenance (IRM) and remotely operated vehicle (ROV) services.

One of the central focuses of Noble in Guyana is delivering its drilling operations with sustainability in mind. For the global company, Noble is focused on reducing its carbon intensity by 20% by 2030. To achieve this target, the company is committed to trying and testing energy consumption methods, including monitoring, energy management, behaviour programs, and natural energy efficiency upgrades that help its vessels and operations remain as sustainable as possible. In fact, with

more than 100 years of experience behind it, responsible drilling is a core value of the business. Today, the company has developed such initiatives as the Energy Efficiency Insights (EEI) program, which monitors the energy consumption across its rigs. Through EEI, and with the support of the sustainable behaviour programme, Noble could deliver a 6-10% reduction in fuel consumption and derived emissions. This aims to help the company move towards global net-zero targets and ensures that when customers choose Noble for its drilling operations, they know that they are supported by a company pushing towards sustainable targets.

As part of Noble’s sustainable development, the company has developed the world’s first green methanol drilling rig design. The conceptual design for the jack-up rig would be powered by

green methanol in place of traditional diesel. By making this switch, the rig could result in up to a 95% reduction of carbon dioxide emissions. This development could pave the way for an exciting next step in the company’s development to bring energy efficiency, safety and sustainability to the forefront of its drilling operations across the world.

Across Noble’s operations on both a global and local scale, there is a real focus on delivering drilling operations that help companies achieve their energy operations to bring vital oil and gas resources to market. Through Noble’s fleet of modern, versatile and technically advanced vessels, the company is the leading offshore drilling provider. With energy operations across the world utilising Noble’s drilling

solutions, the company plays a valuable role in supporting the energy sector and in turn helps bring economic development to countries across the world as they make the most of the energy resources offshore their countries. One of the most vital parts of Noble’s operations is its commitment to sustainability. By fostering sustainable practices from its design to its delivery, Noble can deliver vital energy development whilst working to protect the planet for future generations. We look forward to seeing how Noble’s fleet continues to service ExxonMobil’s developments in the Stabroek Block off Guyana’s coastline for many years to come.

Written by Carley Fallows

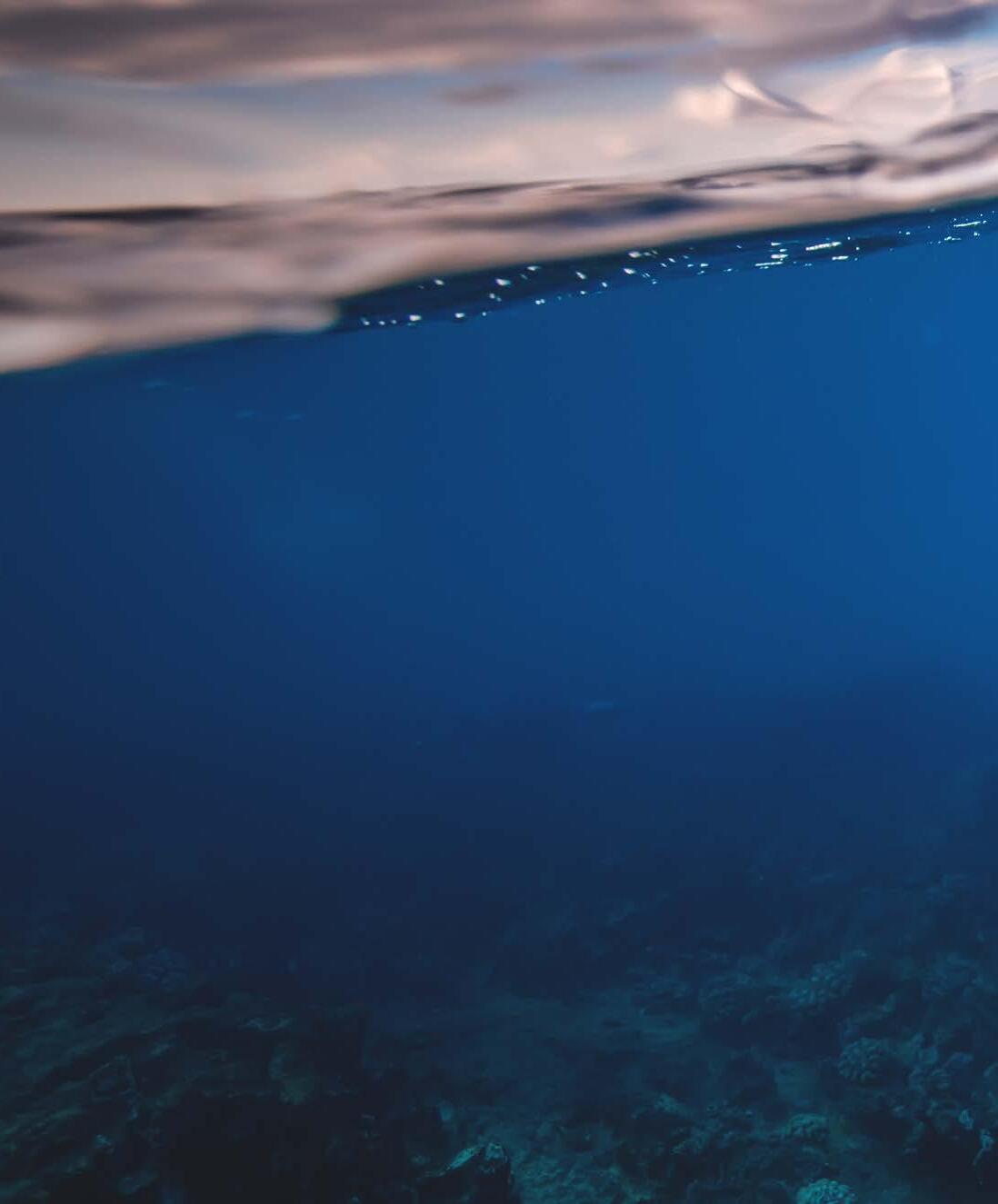

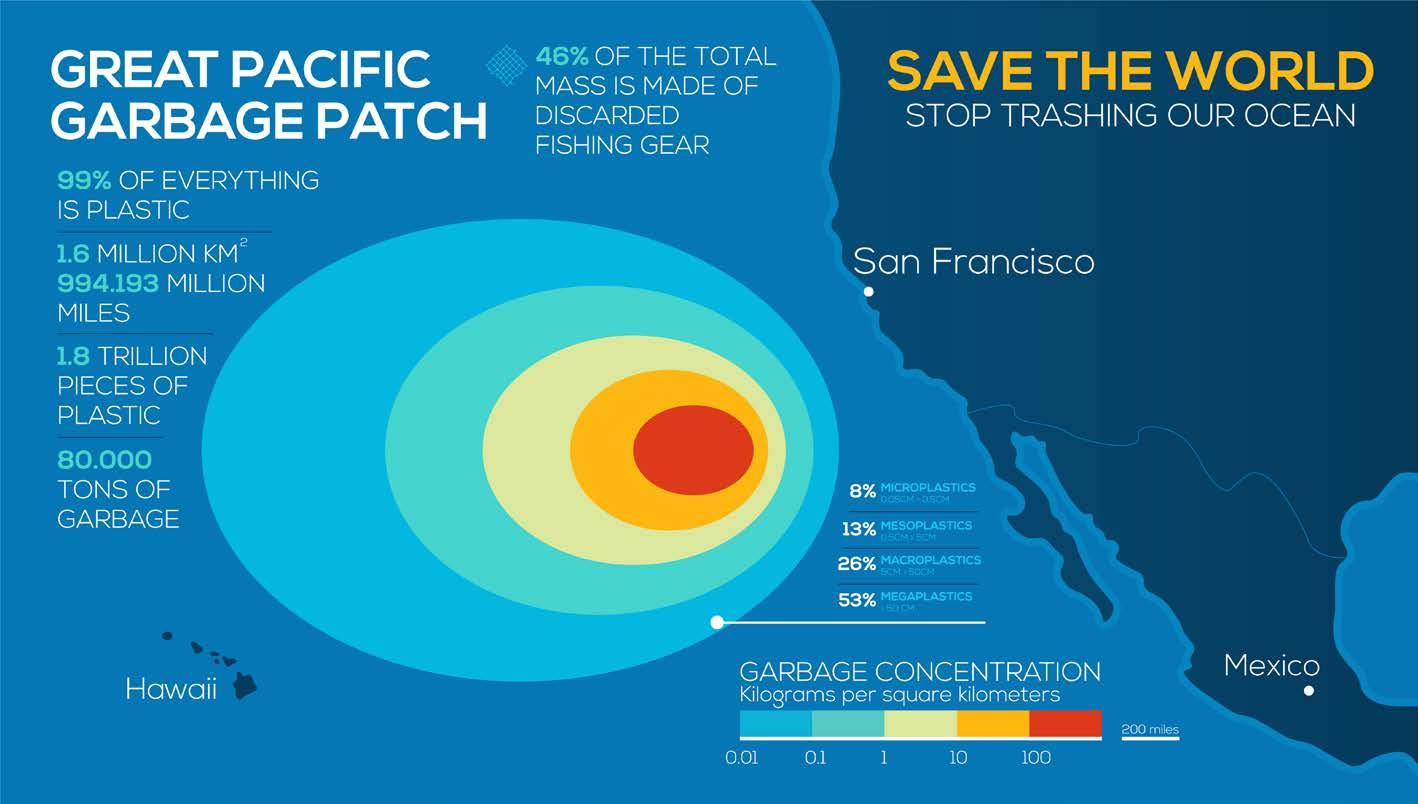

We’ve all heard about the effects of plastic pollution on the planet, whether from ending up in landfills or littering natural habitats. However, with more and more plastic being produced, and the plastic already created not going anywhere as it doesn’t biodegrade, plastic is turning up in all aspects of life, from the food we eat, the water we drink and the landscapes we live in. One of the most prominent examples of plastic polluting the planet can be seen in the form of the Great Pacific Garbage Patch in the North Pacific.

The Great Pacific Garbage Patch is the largest accumulation of marine debris in the world, formed through naturally occurring currents that push waste into two distinct collections of debris, making up what is coined the ‘Pacific Trash Vortex’. The reason that rubbish ends up in this area is due to the subtropical gyre, which sees the California, North Equatorial, Kuroshio and the North Pacific current meeting and rotating clockwise across 20 million square kilometres. These currents push marine debris, which leads to it getting trapped in the centre of these currents in a more stable and calmer zone. In these calmer waters, surrounded by the currents, the Great Pacific Garbage Patch has been formed.

However, whilst you might be thinking that the Great Pacific Garbage Patch is like a floating island of rubbish, you’d be wrong. Instead, it’s actually two distinct collections of debris, many of which are made up of tiny pieces of plastic. These tiny bits of plastic are called microplastics and are formed

from plastic waste being broken down by the sun through a photodegradation process. These microplastics are then joined by larger debris such as ghost fishing nets, which turn the Great Pacific Garbage Patch into an area of murky water littered with waste rubbish of all sizes.

Whilst the exact amount of debris that makes us the Great Pacific Garbage Patch is unknown, it has been estimated to be around 100,000 tonnes, which puts it much larger than it was previously calculated to be. With this much waste, the Great Pacific Garbage Patch can be compared in weight to that of 740 Boeing 777s, according to Ocean Cleanup, which begins to capture the vast nature of this debris accumulation. With plastics making up a large majority of this material, it only continues to grow as the plastic will not biodegrade, and so it remains stuck there.

A central concern when it comes to the Great Pacific Garbage Patch and the wider pollution of the ocean is the impact that such plastics and

waste material can have on the environment and subsequent ecosystems. Within the subtropical gyre, species such as sea turtles and seals are at risk, mistaking plastic bags for food or getting caught in disposed of or abandoned fishing nets, causing them to drown. Furthermore, as the Great Pacific Garbage Patch continues to grow, it will block out more and more sunlight, resulting in algae and plankton not being able to grow. This will mean food chains will be disrupted, which could have wider implications on feeding grounds and the subsequent ecosystems.

Therefore, it’s clear that ocean cleaning solutions are needed to help stop the Great Pacific Garbage Patch from growing and clean up what has already accumulated. However, cleaning up such plastics that are present in the Great Pacific Garbage Patch is a difficult task, as many are suspended at varying depths, and many are the same size as many sea animals, which could result in them being captured if a standard net technique were utilised. However, Ocean Cleanup, a non-profit environmental engineering organisation, has been working on developing solutions to help clean up the Great Pacific Garbage Patch.

Since its operations began, Ocean Cleanup have been carrying out research in both the laboratory and in the field, to optimise its positive impact on the environment. Through innovative solutions, it has been working to help reduce ocean pollution by capturing waste in the ocean, whilst also working to prevent such materials from ending up in the ocean

in the first place. For the Great Pacific Garbage Patch, Ocean Cleanup has developed System 03, which is its current ocean cleaning technology innovation, that is designed to capture plastic ranging from small pieces as little as just a few millimetres in size to large debris.

One of the ways that System 03 is so effective is due to computational modelling, which helps to predict where the hotspots are whilst the Great Pacific Garbage Patch moves around with the currents. By tracking where these hotspots occur, it can direct its vessel to these areas and collect more plastic, whilst also cutting costs and reducing emissions. Plus, System 03 has been constructed with deterrents, cameras, escape aids and other features to help minimise the risk posed to marine wildlife. Therefore, with the help of System 03, Ocean Cleanup believes it can clean the entirety of the Great Pacific Garbage Patch in just 5 years.

Across the Great Pacific Garbage Patch, one thing is for certain: the amount of plastic we produce

across the world is a growing problem, especially when it is not biodegradable and not enough of it is being recycled. Instead, we are leading to our entire ecosystem being littered with microplastics, which is having a detrimental effect on the world’s oceans. Whilst Ocean Cleanup’s work is vital across the world, and particularly at the Great Pacific Garbage Patch, a move towards more biodegradable options is needed to help limit plastic pollution on a global scale and protect the planet’s oceans.

Sources: https://education.nationalgeographic.org/resource/ great-pacific-garbage-patch/

https://theoceancleanup.com/great-pacific-garbagepatch/

https://theoceancleanup.com/oceans/

Africa remains a vital player in global energy markets, with valuable oil and gas deposits across both onshore and offshore fields that supply essential energy resources to power daily life. With such an expansive energy industry across the continent, Perenco, a leading independent global hydrocarbon producer, has been present in Africa for many years, investing in African energy projects in the hope of generating substantial capital expenditure across its operational countries. One of the most prominent countries for Perenco’s current development in Africa is in Gabon, where Perenco Oil and Gas Gabon (POGG) has spent over three decades delivering the country’s energy needs. Its operations across the country remain crucial to energy delivery, with POGG now producing approximately 110,000 barrels of oil equivalent per day in Gabon.