FASTER LIFTS FEWER HANDS GREATER

CSBC-DEME Wind Engineering (CDWE) installed its second offshore substation using ROPES BY BAKAERT, powered by BEXCO’s Ultraline® Slings made with Dyneema® SK78®, a lighter,

This resulted in faster lifts, fewer hands and better efficiency offshore. For CTRL System Technologies Nigeria Ltd and Nigerian operators, this isn’t just innovation, it’s a shift in how we operate our lifts. Lightweight slings mean easier mobilization, reduced risk, and no compromise on performance. From FPSOs to fabrication yards, CTRL in collaboration with BEXCO is driving smarter, safer, and more costeffective lifting solutions across Nigeria’s energy landscape. Sometimes, the lighter way really is the stronger one.

Heads of Departments

Editor-in-Chief Carley Fallows editor@littlegatepublishing.com

Advert Space Director Emlyn Freeman emlynfreeman@littlegatepublishing.com

Project Director Andrew Richards andrew@littlegatepublishing.com

Commercial Manager James Hamilton james@littlegatepublishing.com

Lead Designer Adam Knights

Research Kristina Palmer-Holt

Editorial Research David Craig

Corporate Director Anthony Letchumaman anthonyl@littlegatepublishing.com

Founder and CEO Stephen Warman stevewarman@littlegatepublishing.com

For enquiries or subscriptions contact info@littlegatepublishing.com +44 1603 296 100

ENDEAVOUR MAGAZINE is published by Littlegate Publishing LTD which is a Registered Company in the United Kingdom.

Company Registration: 404 2112 62

VAT registration number: 13572767

343 City Road 60 Thorpe Road London 79 Norwich

EC1 V1LR NR1 1RY

Littlegate Publishing Ltd does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Copyright© Littlegate Publishing Ltd

Editor’s Note

Welcome back to Endeavour Magazine!

We kick things off this month with an expansive feature from Namibian Ports Authority, otherwise known as Namport, which is developing Namibia into a strategic logistical hub serving customers across the Southern African Development Community. We got to see how the Authority is expanding the Port of Walvis Bay to enhance its handling capacity and remain competitive in global markets. We’re glad to see Nekkov Logsitics Solutions & Marine Agency, Novaship Namibia (Pty) Ltd., Omega Security Services Namibia (Pty) Ltd., and Rental Support Services Pty Ltd. supporting this feature, highlighting their valuable role as key suppliers to Namport.

We then move to the energy sector, where we find Marathon Petroleum Corporation (MPC), who operate the largest refining system in the USA. With operations across the downstream and midstream sectors, MPC has cemented its place as a leading energy company delivering crude oil products supported by the infrastructure and development to serve its customers every day. We’re thrilled to see Flyability supporting the article, along with ESS.

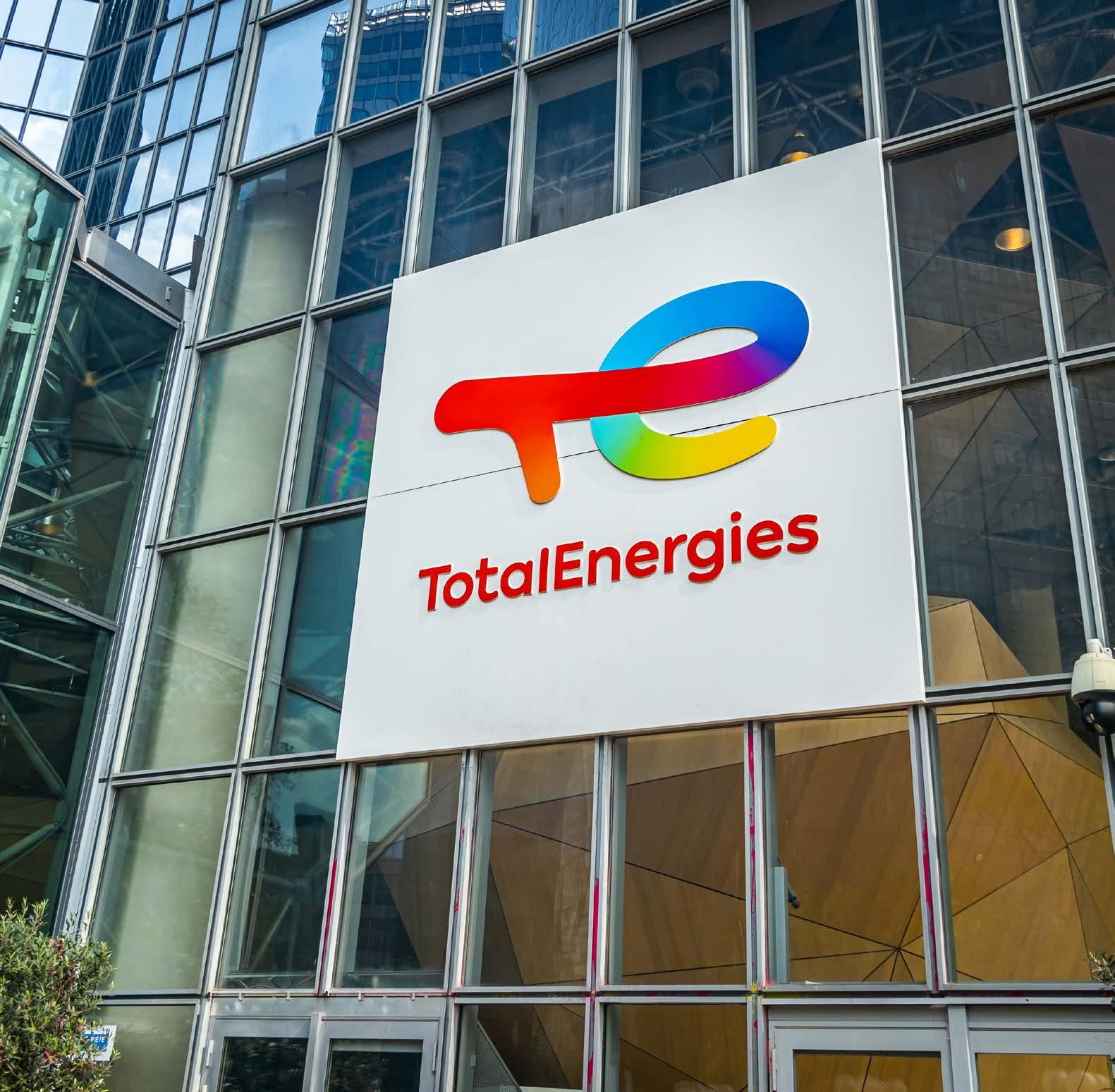

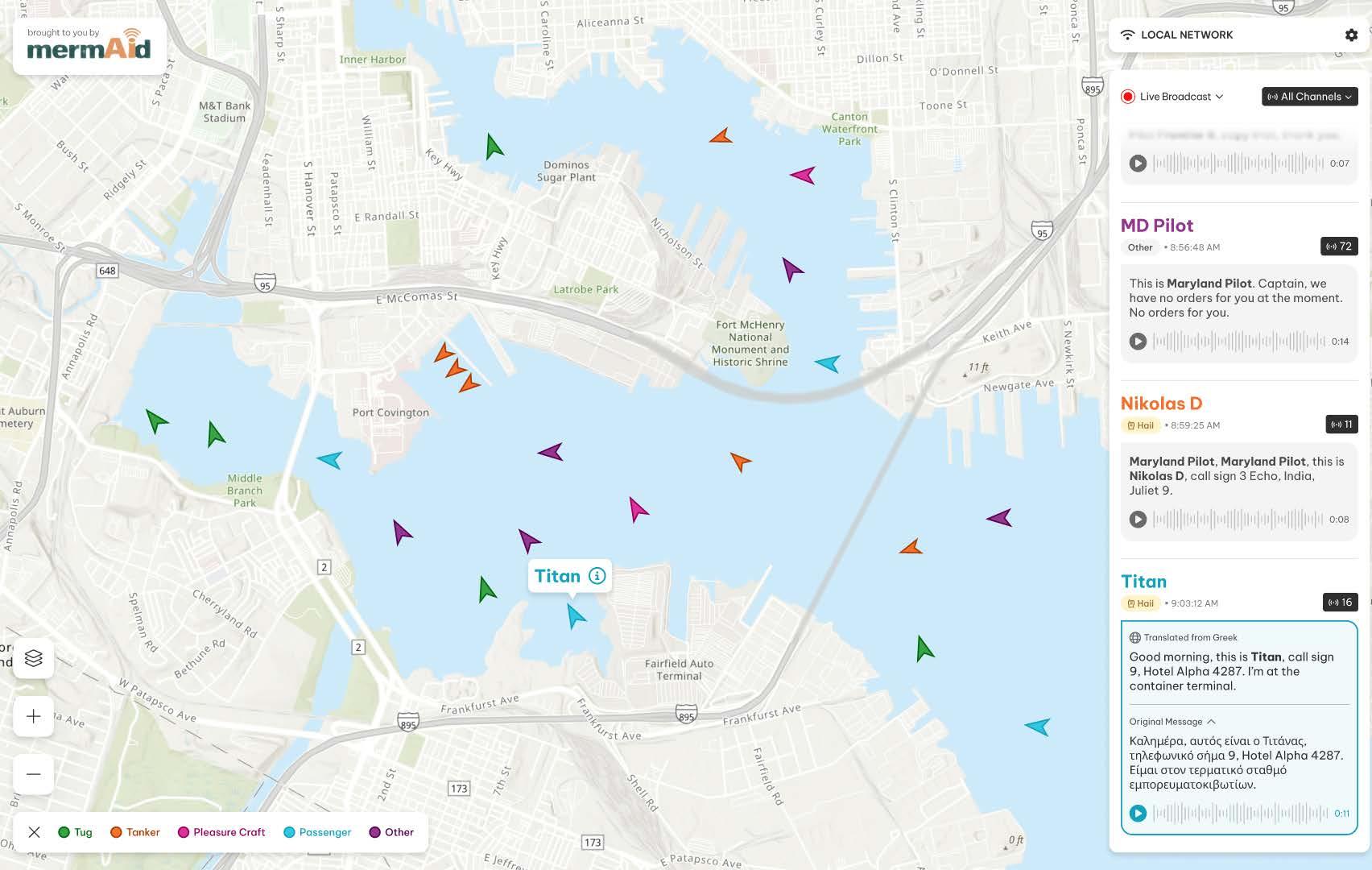

In this edition, we also got to speak with Mermaid AI, Inc., which has developed an AI-focused technology that enables seamless communication across the maritime sector to improve safety. We spoke to CEO and Chairman, Dean Mancini, who outlined how the technology, which was developed for the US Navy, is now being rolled out across harbours and ports to bring greater safety, communication and management of maritime environments. by Carley Fallows

Jebel Ali Port

Shell USA

Asia/Oceania

South Korea Bans Phones in Schools

Many countries across the world have started to crack down on the use of mobile phones during school time, with South Korea being the latest country to restrict the use of phones in the classroom. The law, which will come into effect in 2026, will see smartphones banned during class hours, with teachers being given the power to stop students from using their phones on school premises at all. This move is an effort to reduce the growing concern of smartphone addiction, with many arguing that the use of phones affects academic performance and distracts from learning.

Whilst many back the bill, saying it will give teachers better legal backing for banning phones on school premises, some have concerns over how it would stop phone addiction on a wide scale, and whether the ban is addressing the root cause of such addictions among young people. South Korea will now join countries such as Italy and China, where phone use is restricted in all school settings.

Researchers Find Rare Jurassic-Era Fossil in India

The fossil of a rare crocodile-like species dating to the Jurassic era has been uncovered in India. The species is thought to be a phytosaur, which were semi-aquatic animals that are thought to be where the crocodiles we know today have descended from. The fossil measured between 1.5 to 2 metres across, and has been dated by researchers as more than 200 million years old.

The remains were discovered when villagers in the Megha village in Jaisalmer district were digging up a lake in the area. The fossil was discovered alongside what looks to be a fossilised egg, which is thought to have belonged to the reptile. From the size of the fossil, it is thought that the phytosaur was of medium size for the species; however, only a few fossils of phytosaurs have been discovered across the world. Therefore, discoveries of this size are notable and help scientists form a better understanding of the history of these species and how they have evolved into the creatures we know today.

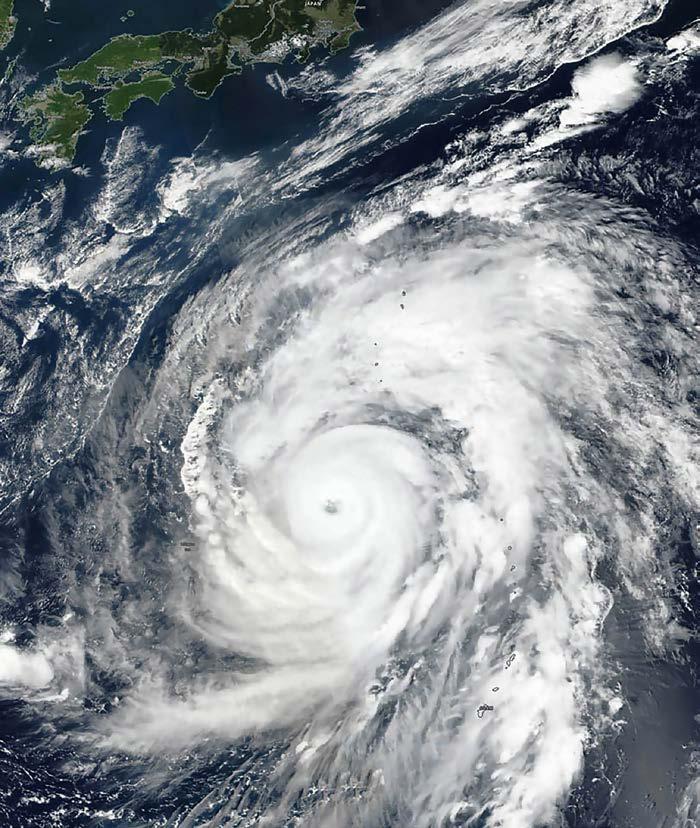

Typhoon hits Vietnam

Vietnam’s north central coast has been hit by Typhoon Kajiki, leading to widespread damage across the region. The typhoon brought with it heavy rains and extreme winds that damaged close to 7,000 homes, brought down 331 electricity poles, felled some 18,000 trees and flooded thousands of hectares of rice plantings. The downing of the electricity poles led to widespread power outages across several provinces. The extensive flooding cut off villages across the region, according to local media, whilst flights from the Thanh Hoa airport were grounded, with other airports in Quang Binh grounding flights too.

Upon making landfall, Typhoon Kajiki weakened and was downgraded into a tropical depression as it moved across the region. However, three people were killed by the effects of the typhoon, with another 13 injured across the province.

Deadly Floods in Cape Verde

A state of emergency was declared in Cape Verde following disastrous flooding, which has devastated infrastructure and left at least 9 people dead. The heavy flooding was caused by heavy rains brought about by Tropical Storm Erin that saw around 7 inches of rain fall on the islands of São Vincent and Santo Antão in just 5 hours. This increase in rainfall, far above the average for São Vincent this time of year, caused flash flooding that devastated infrastructure and left 1500 people displaced from their homes.

The extreme weather is extremely rare for the islands, with the rain levels being way above the average for the climate over the last 30 years. Rescue teams were dispatched to help search for missing people. Money was raised to buy food, water, and emergency supplies for those in need.

Mars Rock Auctioned Off in New York Raises Concerns

A meteorite that was discovered in Niger two years ago has recently been auctioned off in New York. The meteorite, which is from Mars, is the largest one ever found on Earth and was sold for £3.2 million at a Sotheby’s auction. However, concerns have been raised about how the meteorite that was found in West Africa has been auctioned off in New York. These questions came from the government of Niger, which raised concerns about the legality of the export. This is something that Sotheby’s has strongly disputed, outlining that the correct procedures were followed. However, investigations have begun into the circumstances of the sale and discovery of the meteorite.

The Sahara is a hotspot for meteorite discovery, as the climate makes the landscape ideal for the preservation of such rock or metal fragments. Therefore, the desert is a hot spot for those seeking to discover a meteorite that they can sell. The meteorite has previously been examined by scientists to better understand its structure and where it comes from.

Radioactive Rhino Horns to Stop Poachers in South Africa

Poaching in Africa remains a key concern for conservationists, as hundreds of rhinos are poached every year in South Africa. A group from the University of Witwatersrand has developed a venture that would allow customs offices to detect smuggled horns more easily when they’re transported across the world. The initiative is called The Rhisotope Project and has spent the last 6 years researching and testing solutions to limit and prevent rhino horn smuggling. The group have begun a pilot study which would see radioactive material injected into rhinos’ horns. The radioactive material is completely safe for the animals, but it will allow customs officers to detect smuggled horns more easily.

The research project hopes this innovative research could provide a real solution to mitigate, or at least disrupt, the sale of poached rhino horns across the world. The group hope that with better legislation and political support, an end to rhino horn poaching could be possible, and the project is just the first step in that.

Hurricane Erin Causes Disruption Along US East Coast

Earlier this month, locals along the East Coast prepared for the strong winds and rainfall that Hurricane Eric threatened to bring to the coastline. The Hurricane never made landfall but moved along the coast, bringing with it flooding, heavy rains and extreme winds, after it had already caused severe flooding in places such as Puerto Rico.

In Puerto Rico, more than 150,000 people experienced a power outage as electricity lines were damaged in the high winds. Along the US coastline, many beaches, including some in Long Island, New York and in New Jersey, were placed off-limits to swimmers for safety. This followed 60 people needing rescuing from rip currents along Wrightsville Beach in North Carolina. Thankfully, by the time the Hurricane came close to the US shoreline, it had been weakened to a Category 2 storm, but still brought with it wind speeds of up to 105mph.

First Female Umpire in Major League Baseball

History has been made in US Major League Baseball with the appointment of the first female umpire to referee a game during a regular season. Jen Pawol umpired a game between the Miami Marlins and the Atlanta Braves, marking a first for the league. Pawol has been an umpire in the minor leagues for more than 30 years, having overseen more than 1,200 games in the minor leagues alone. She will now make history as the first woman to umpire a Major League Baseball game.

Pawol was well received by fans, with many holding signs throughout the match highlighting this pivotal role in the league’s history. To cement her place in history, Pawol donated the hat she wore umpiring the game to the National Baseball Hall of Fame and Museum.

Taylor Swift Announces 12th Studio Album and Engagement

Taylor Swift took fans by surprise, announcing her 12th Studio Album, ‘The Life of a Showgirl’, on the New Heights podcast, hosted by her boyfriend Travis Kelce and his brother, Jason Kelce. In the podcast, Swift outlined her life since the end of The Eras Tour and revealed the album title and cover art of her new album. The appearance surprised fans as she hasn’t done many interviews in recent years. Over 1.3 million people watched the interview live.

However, this was not the only surprise announcement, as just under 2 weeks later, Swift and Kelce announced their engagement. In a selection of images posted to Instagram by the pair, fans could see Kelce down on one knee proposing to Swift, surrounded by a garden of flowers. The post has seen major attention on social media, with now over 30 million likes on the post alone.

Middle East

Deal Signed in Syria for the Infrastructure

A series of investment deals have been signed between Syria and international companies to deliver redevelopment across the country. The investments span 12 strategic projects focused on infrastructure, transportation and real estate, and total $14 billion. Included in these plans is a $4 billion investment project for Damascus airport, signed with Qatar’s UCC Holding. The plans have been outlined by the Syria’s government to reconstruct the country following the destructive effects the 14-year-long civil war had on infrastructure.

Other developments include a $2 billion deal with the United Arab Emirates national investment corporation to build a metro service in the country’s capital. Investment will also see the Damascus Towers project developed with Italian-based UBAKO. These investments hope to reshape the country and put in place the essential infrastructure for the future.

6.1 Magnitude Earthquake Hits Turkey

Turkey’s northwestern Balikesir province was hit with a 6.1 magnitude earthquake, destroying some buildings. The initial earthquake was followed by 6 aftershocks, including a 4.6 magnitude aftershock. The earthquake’s epicentre was in the town of Sindirgi, striking at a depth of 11km according to Turkey’s AFAD.

At least 1 person was killed, and more than a dozen buildings collapsed. Rescue efforts swiftly began to pull people from the rubble. 30 people were injured due to the earthquake; however, serious damage or high casualties were not reported. Thankfully, electricity and water services were also not affected by the earthquake. Due to the location of the country along multiple fault lines, Turkey is prone to such extreme events, experiencing frequent earthquakes over the years.

Pope Leo XIV’s First International Trip to Lebanon

It has been announced that Pope Leo XIV is expected to make his first international journey as the new head of the Catholic Church to Lebanon in May next year. Trips conducted by the Pope are intended to connect Catholics worldwide and spread the message and diplomacy of the current Pope. Therefore, there has been speculation about where Pope Leo’s first international destination would be, as this trip often defines the tone of the pontificate.

Lebanon, home to two million Catholics, is expected to be the first place Pope Leo visits, and marks a significant moment, as he repeatedly has urged for peace in the Middle East and for interfaith co-existence. Lebanon is known for its religious diversity and has long carried symbolic weight for the Church.

Changing Ecosystems due to Warming Sea Waters

Climate change has long been an issue that many of us are aware of, as the temperature of the Earth continues to rise. With oceans experiencing this increase in temperature, there has been a shift in the ecosystems of the oceans around the world. In the UK, seas have been at their warmest since records began, which is starting to have some drastic changes on marine life and fishing communities. The temperature of waters off the UK was recorded in July and it more than 0.2 °C higher than in any year since 1980. Due to this warming, scientists have begun to observe changes in the species present in UK waters, with species such as octopus, bluefin tuna, and mauve stinger jellyfish showing up.

With new species showing up in UK waters, this can have a significant impact on the local ecosystem, with natural cycles and fishing cycles at risk of being affected. With rising sea temperatures, fishing communities in the UK are already experiencing challenges. Whelks, a cold-water species, experienced a mass die-off in 2022 due to the marine heatwave in the Thames Estuary. Whilst the snails have started to recover, it is feared that more heatwaves could reduce their numbers and, in the process, affect many businesses across the UK.

Deadly Wildfires in France

More than 17,000 hectares of land, larger than the size of Paris, have been burned through in what is being regarded as France’s largest wildfire for 75 years. The Aude Wildfire sparked on August 5th near the rural village of Ribaute in the Aude region of Southern France, not far from the Spanish border. 2,000 firefighters and 500 firefighting vehicles were deployed to contain the fire, but it is expected to burn for many weeks until it is completely extinguished. Aircrafts were used to drop water on the region in the hopes of extinguishing the flames. Residents were evacuated from their properties, and access to the forests that were devastated by the fire has been banned. The blaze has been linked with climate change, which has seen the country experience dry vegetation, high temperatures, and strong winds, which delivered the perfect conditions for a blaze to spread. Satellite images taken of the fires show the widespread devastation it has caused to the landscape.

Old Swedish Church Moved in Its Entirety Across the Country

Locals from Kiruna saw a rare sight when a 113-yearold church was relocated in its entirety from its home and moved 3 miles away to the new city centre. The church was moved as the original site was at risk of subsidence due to ground fissures caused by the iron ore mining industry in the old city centre. The 672-tonne church was placed on giant steel beams and supported by self-propelled modular transporters. The inside of the church was supported by metal scaffolding.

The wooden church began its journey with a blessing from the church’s vicar. The movement of the church was followed by locals who came out to see the giant structure slowly creep towards its new home, moving just 30 metres in the first hour. To allow the structure to pass through its route more easily, the road was widened to 24 metres, and lamp posts, traffic lights, as well as a bridge (which was already planned for demolition) were removed to allow the church to pass through. The church has now arrived at its new location in the new city centre of Kiruna.

As a pivotal player within the Southern African Development Community (SADC), Namibia is on a mission to be a leading regional logistics hub, capitalising on its strategic port location and transportation routes. With this infrastructure in place, Namibia, supported by the Namibian Ports Authority (Namport), is striving to deliver Namibia’s ports as the bestperforming seaports in Africa through its management and development of port facilities to meet the current and future trade demands.

Namport’s history extends back to 1994, when the Namibian Ports Authority was established and recognised as a public enterprise under the Public Enterprises Government Act. Since its establishment, Namport has been continually developing Namibia’s seaborne trade and maritime industry to deliver it as a regional logistics and shipping hub primed to serve regional and international trade between SADC countries, Europe, Asia and the Americas. With such a broad sphere of operations, Namport is primed to support cargo trade and continually promote the key ports of Namibia, whilst continuing to develop port infrastructure and deliver everyday port services.

One of the key ports under Namport is the Port of Walvis Bay, where the Authority is headquartered. The Port of Walvis Bay, located on the southwestern coast of Africa, is one of the largest commercial ports in Namibia. The port comprises three main sections, including the South Port, the Fishing Harbour, and the North Port. Across these three sections, Namport operates the 13 commercial berths, including a tanker jetty and a dedicated passenger berth for cruise vessels. Annually, the port receives close to 900 vessels a year, handling roughly 8 million tonnes of cargo. With so many vessels arriving at the port each year, bringing with them vital cargo, the port plays a leading role in the country’s import and export market. Therefore, with a leading role in the importing and exporting market, Port of Walvis Bay and Namport are critical entities in supporting the development and bolstering of Namibia’s economy.

One of the major benefits of the Port of Walvis Bay is the mild weather conditions around the port; this means that vessels can easily arrive at the port with very rare delays. This makes the port super competitive along global shipping routes, as vessels are rarely ever delayed when porting at the Port of Walvis Bay. In fact, Namport prides itself on delivering fast turnaround times for vessels, with container vessels being turned around anywhere in 24 to 48 hours. For larger bulk vessels, turnaround times are between 72 and 120 hours, with break-bulk vessels seeing a turnaround time of 35 to 48 hours. With super-fast turnaround times, Namport and Port of Walvis Bay help support more reliable, efficient and speedy supply chains across the world. Thus,

the port is a vital stopping point along many of its customers’ supply chains, as each know that their cargo will be moved with speed and efficiency, whilst being supported by Namport’s excellent customer service.

In recent years, the Port of Walvis Bay has been undergoing vital developments, with the construction of a New Container Terminal (NCT). The new, modern container terminal began construction in 2014 and was commissioned in 2019 to encompass quay walls, paved areas, buildings, roads, railway lines, ship-to-shore quay cranes, and rubber-tired gantry cranes. The construction is on reclaimed land and is part of a much-needed development to expand the port’s footprint and deliver more space for cargo. By expanding the port’s container offerings, the Port can remain competitive in global shipping markets, as the port will now have the facilities to handle a much higher cargo demand for the Port of Walvis Bay. To meet this cargo demand, the NCT will add 600 metres of quay length to the existing 1,800 metres, as well as three new berths at the container terminal.

Harnessing Namibia’s Seaborne Trade

World-Class Security, Tailored

Namibian Ports Authority

In recent months, Namport has embarked on a watershed project for the concessioning of NCT. This concession search aims to find an operator to drive the growth of cargo volume at the Port of Walvis Bay in order to bring significant benefits to Namport and Namibia. In October 2024, Namport announced that following a market bidding exercise, Terminal Investment Limited (TiL) was selected for the concession agreement. The concession agreement outlines that TiL will operate and manage the New Container Terminal for 25 years. This agreement aims to help attract private capital to invest in the port’s infrastructure to help it continue to deliver significant development for Namibia and, in turn, bolster Namibia’s position as a key logistics hub within the SADC. With Namport’s strategic decision to give the concession to TiL, it highlights the Authority’s commitment to improving port operations, addressing the growing demand of the Namibian import and exports, whilst driving the position of Namibia’s ports in local and international shipping markets.

The second key port under Namport is the Port of Lüderitz, located just 254 nautical miles south of the Port of Walvis Bay. Comprising 25 hectares of land, the Port of Lüderitz sits within the Robert Harbour and provides an efficient multi-purpose port serving Southern Namibia. The port handles mostly dry bulk cargo, arriving at the port from the Southern African Northern Cape. In addition to cargo handling, the Port is vital to the fishing industry and provides a thriving base where offshore mining and southern coast oil and gas operations can operate from. The Port of Lüderitz remains a vital hub for Namibia’s import and export markets and today has an annual handling capacity of 3 million tonnes across the port’s 500-metre-long main berth. However, the Port of Lüderitz is playing an increasingly important role in the energy market, and so Namport has set out expansion plans for the future of the port.

As the port is a shallow port which is founded on bedrock, dredging is not considered financially viable. Therefore, Namport is set on optimising the existing land of the Port of Lüderitz to create

Harnessing Namibia’s Seaborne

Nekkov Logistics Solutions & Marine Agency CC

Your trusted Maritime Partner!

We are a professional marine and vessel Agency based in Walvis Bay, Namibia, Dedicated to supporting shipowners, operators And crew with reliable. Efficient and fully compliant Services. With our strong local expertise and global Network, we make maritime operations easier from Port arrival to departure

Our Core Marine & Vessel Support Services:

• Customs & Immigration Handling

• Crew Change & Welfare Services

• Bunkering Coordination

• Port Clearance

• Vessel Husbandry Services

• Cargo Handling & Logistics

• Fresh Water Provisions & Waste Disposal

• Yacht & Offshore Vessel Services

www.nekkov.com

Fast, hassle-free freight handling solutions

Choose Nekkov Logistics Solutions – Namibia’s trusted partner in freight forwarding. We ensure the safe, reliable, and on-time delivery of your cargo by sea, air, or road. With our expert team and global reach, your logistics are always in the best hands.

Namibian Ports Authority

additional capacity in the short to medium term. However, Namport’s long-term goals outline a plan for a new port planned for Angra Point in Lüderitz. The new port would be located adjacent to Robert Harbour and would have a water depth of 14 to 16 metres to accommodate deeper draught vessels. The development of the Port of Lüderitz, including the expansion of Angra Point, is being fast-tracked to help enhance the capacity for project cargo. Thus, the expansion of the Port of Lüderitz and Robert Harbour hopes to provide the capacity for project cargo imports by 2025/2026. Plus, Namport hopes that the development of an export terminal at Angra Point will be reached by 2028, with the capacity to provide up to 2 Mtpa of ammonia (increasing to 18Mtpa) through the Angra Point Master Plan.

One of the main advantages of the Port of Walvis Bay and the Port of Lüderitz is its vital connectivity with cross-border important exports via 4 main trade corridors. These corridors include the Trans-Kalahari, Walvis Bay-Ndola-Lubumbashi, Trans-Cunene, and Trans-Oranke corridors. Across these, Namport’s port connects the country with vital markets in Zambia, the Democratic Republic

WALVIS BAY

of Congo, Botswana, South Africa, Zimbabwe and Angola. Through these links, Namibia can deliver cargo quickly across the SADC region and, in doing so, support efficient supply chains to make it competitive in both local and global markets. Across these vital links, Namport is supported by the Walvis Bay Corridor Group, a public-private partnership, which promotes the utilisation of Namibia’s transport corridors to help enhance the delivery of operations from the ports and across the country. In addition to this, Namport is supported by its stakeholders and so works with these to deliver a substantial impact on the Authority’s operation and its capacity to generate and sustain value for all stakeholders across the port.

Tourism remains a key and lucrative industry for Namibia, and so Namport’s cruise season between November and March remains a key time for the Authority when the cruise season begins. The arrival of cruise vessels to Namibia’s shores brings a significant influx of foreign currency into the local economy, which in turn creates job opportunities for locals in key tourism sectors, such as tour guides and transportation services. Thus, whilst international tourists descend on Namibia on both

NOVASHI P NAMI BIA (P TY ) LT D

LÜDERITZ

•Ship Husbandry Agency, Port & Liner Agencies Services with Chartering & Brokering,

•WilhelmsenPort Services, Namibia Agents

•ABC Maritime, Namibia Agents

• Noatum Maritime Shipping, Namibia Agents

•Clearing & Forwarding –Seafreight/ Airfreight, Crossborder/ Import & Exports, Corridor Cargoes

•P & I Britannia Insurance, Ship Chandling

NOVACARGO NAMIBIA (PTY) LTD Lüderitz -Stevedoring Services

•Marine Safety & Survival , Sales, Life & rescue boats

•Life-raft & Fire Servicing & Equipment

•NCD Container Depot, Handling & Storage of containers, Reefer containers & repairs

WALVIS BAY

NOVASHIP SAFETY WALVIS BAY

•Complies with ISO 9001:2015

•Class Approvals by:

•US Coastguard

•LLOYDS

•BUREAU VERITAS

•DET NORSKE VERITAS

•RINA

•IRS

•DOT NAMIBIA

•SABS

13, Pescanova House, PO Box 1212

Rikumbi Kandanga Rd, Walvis Bay

Tel: +264 64 203946/7

E-mail: nswvb@novaship.com.na

Web: www.novaship.com.na

•Ship Agency , Husbandry & Port Services with Chartering & Brokering

•Ship Chandling & Novacargo Stevedoring

•Logistics, Clearing & Forwarding & Warehousing, Retail & Wholesale, etc.

•DHL Namibia sub agents

•Sales & Servicing of Marine Safety, Life-rafts and Fire equipment

•Container Depot, Storage & Handling

LÜDERITZ Erf 683, Industry Str, Lüderitz / !Nami#Nus Tel +26463203241

E-mail: agencylud@novaship.com.na

Harnessing Namibia’s Seaborne

short and long cruise journeys, with it, Namibia’s economy and role within the global cruise industry continue to expand. This growth then feeds back into the development of Namport’s ports as key hubs for all kinds of vessels, from cargo to tourism, traversing Namibia’s coastline.

Across Namport’s operations, there is a clear focus on enhancing the port of Namibia so it can meet the cargo import and export demands of the country and surrounding region, whilst working towards ways to extend and enhance its port offerings for the future of the port. With the development of the Port of Walvis Bay and the New Container Facility there, and the enhancement of the Port of Lüderitz whilst developing Angra Point, Namport remain committed to bolstering Namibia’s economic growth. By playing such a pivotal role in managing and developing these port facilities, Namport is positioning itself as a key and competitive hub serving the SADC region.

Marathon Petroleum Corporation

Operating the nation’s largest refining system, Marathon Petroleum Company (MPC) is a leading, integrated downstream and midstream energy company providing energy resources to the United States of America (USA) from its headquarters in Findlay, Ohio. From its branded locations across the country (including its retail outlets), to its role in its midstream company that owns and operates processing and fractional assets, to its crude oil and light product transportation and logistics infrastructure, MPC is a powerhouse in the downstream and midstream energy sector.

MPC’s operations began almost 140 years ago, when several small oil companies across Ohio banded together to form The Ohio Company. From this company, Marathon Petroleum has grown with the development of new gas stations and the introduction of refining processes. By continuing to evolve and innovate, MPC is now proud of the role it plays in helping meet the world’s growing energy needs, while steadfastly adhering to the values of safety, environmental stewardship, integrity, inclusion, collaboration, and excellence that it places at the heart of every operation it undertakes.

The best place to start when examining MPC is its refining operations, which comprise a significant portion of its activities. MPC has 13 refineries spanning 12 states of the USA, which collectively deliver around 3 million barrels per calendar day (bpcd) of crude oil refining capacity. With such a vast network, it’s no surprise that MPC operates the nation’s largest refining system, with each refinery integrated with the others via pipelines, terminals, and barges to maximise the operating efficiency of each one. MPC’s refineries are integrated with its midstream assets to maximise its operating efficiency, and through its Midstream business, which provides the transportation links that connect its refineries and allow the movement of intermediate products between refineries, MPC can optimise its operations and produce higher margins.

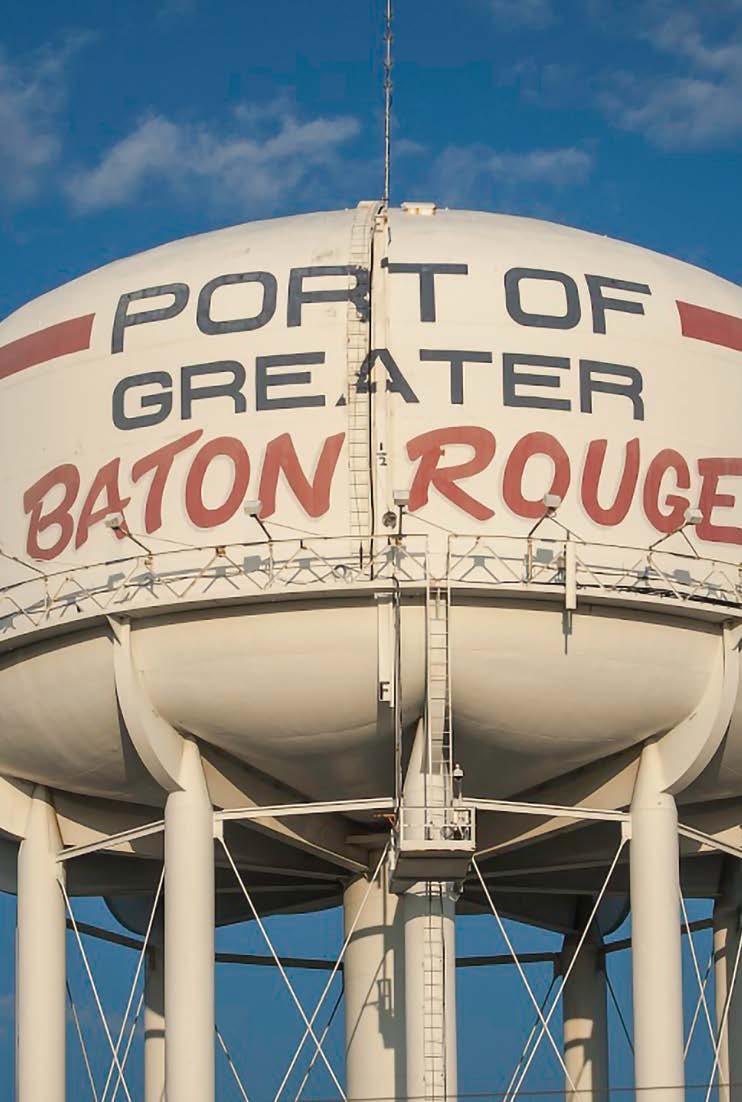

The largest refinery facility operated by MPC is the Garyville Refinery in Louisiana, which is one of the largest refineries in the USA, located along the Mississippi River between New Orleans and Baton Rouge. The facility has a crude oil capacity of 606,000 bpcd and is configured to process a wide variety of crude oils into gasoline, distillates, natural gas liquids and petrochemicals, heavy fuel oil, asphalt and propane. The facility underwent a vital expansion project in 2019, which significantly increased its capacity, which in turn positioned the Garyville Refinery as one of the largest refineries in the USA. Products from the refinery are transported by pipeline, barge, transport truck, rail and ocean tanker. With access to vital export markets and multiple options for selling refined products, the refinery is a vital facility under MPC’s operation.

Another significant refinery for MPC is its Los Angeles Refinery in California, which is the largest refinery on the West Coast and a major producer for the clean fuel market. The refinery is located near the Los Angeles Harbour and has a crude oil capacity of 365,000 bpcd. The Los Angeles Refinery is a major producer of clean fuels, producing heavy crudes from California’s San Joaquin Valley and Los Angeles Basin, as well as crudes from the Alaska North Slope, South America, West Africa and other international sources. In terms of clean fuel, the Los Angeles refinery manufacturer produces cleanerburning California Air Resources Board (CARB) gasoline and CARB diesel fuel. CARB is focused on improving air quality and reducing greenhouse gas emissions through regulations on gasoline, and so the Los Angeles Refinery produces gasoline to these standards, highlighting its role in developing clean energy. In addition to this, the refinery also produces conventional gasoline, distillates, natural gas liquids and petrochemicals, heavy fuel oil and propane. These products are shipped via the refineries connected distribution pipelines and terminals, and are connected to the Watson Cogeneration Plant, which produces 400 megawatts and is the largest cogeneration facility in California.

Marathon Petroleum Corporation

The Los Angeles and Garyville refineries add to MPC’s portfolio of 13 refineries across the USA, which are on a mission to deliver vital crude oil products to market, underpinned by a commitment to doing so with sustainability in mind. This focus on sustainable energy delivery is something that remains a priority for MPC throughout its operations, so much so that the company has 5 renewable fuel and feedstock facilities in operation, which collectively produced 600 million gallons of renewable fuels in 2024, with 2.8 billion gallons of traditional fuels delivered in the same period. This section of MPC is committed to meeting the energy demand of the world, whilst lowering the carbon intensity of its operations and the products it manufactures.

Across MPC’s renewable fuels portfolio is the Dickinson Renewable Diesel Facility, located in North Dakota. The facility delivers renewable diesel and naphtha fuel, with a capacity for 184 million gallons per year. The facility became fully operational in 2021 and is now the second-largest facility of its kind in the USA. Other facilities include the Martinez Renewables, Cincinnati Aggregation Facility, Beatrice Pretreatment Facility, Green Bison Soy Processing Facility and LF Bioenergy. These all provide vital renewables for MPC’s portfolio. One of the most exciting ones is LP Bioenergy, which is focused on

developing a portfolio of renewable natural gas (RNG) production facilities on US dairy farms. MPC holds a 49.9% equity interest in LF Bioenergy, and the portfolio’s planned production has the potential to reach over 6,500 MMBtu (million British Thermal Units) per day by the end of 2026. Interest acquisition was announced in 2023, as part of an agreement that included the potential for additional investment.

To fully appreciate the scope of MPC’s midstream business operations, we must look to MPLX LP, which covers the bulk of the company’s operations in this segment. MPLX is MPC’s sponsored master limited partnership, which gathers, transports, stores and distributes the company’s crude oil, refined products (including renewable diesel), and other hydrocarbon-cased production through its regaining logistics assets, pipelines, terminals, towboats, and barges. MPLX gathers, processes and transports the natural gas, whilst also transporting, fractionating, storing and marketing natural gas liquids. Utilising its assets, MPLX includes a network of crude oil and refined product pipelines, an inland marine business, light-product terminals, storage caverns, refinery tanks, docks, loading racks and associated piping, as well as crude and lightproduct marine terminals. With the ownership of many crude oil and natural gas gathering systems and pipelines, as well as natural gas and natural gas liquid processing and fractionation facilities in key US Basins, the subsidiary plays a vital role in supporting the development and delivery of MPC’s crude oil and associated products delivery from its refineries and across to end markets.

Turning to MPC’s downstream operations, the company has two key brands under the MPC name, with Marathon and ARCO-branded locations. These locations include Marathon-branded gas stations, where customers can purchase Marathon-branded gasoline, which is available across retail outlets in the USA. Each station is primarily owned and operated by independent entrepreneurs, and each location offers a range of services, including convenience store products, car washes, and co-branded food products. The other branded locations are the ARCO Gas stations. ARCO has been the leading gasoline provider in the USA for more than 50 years, with its primary locations focused along the West Coast and Upper Midwest, with stations also located in Mexico. The stations offer quality TOP TIER™ gasoline, which exceeds EPA standards to help improve engine performance, efficiency, and cleanliness. Across these service

stations, MPC is providing vital gasoline to the public to help power the daily lives of those across the country. Thus, highlighting MPC’s integrated role across the energy sector.

MPC plays a valuable role across the energy sector of the USA, with both vital refineries and a plethora of retail locations across the country that are delivering a significant amount of crude oil products across the nation. With every aspect of its operations closely intertwined from its refining to its midstream infrastructure and logistics development, and then to its retail outlets and end customer delivery of petrochemical products, MPC maintains an efficient and leading role as an integrated downstream and midstream energy company. However, across these operations, there is always a focus on sustainability and the community. By ensuring that its projects are delivering a better world for all, especially through the development of renewable energy, MPC continues to drive towards a future where energy accessibility continues to evolve and innovate to meet the demands of the population and the planet.

With a portfolio of energy projects spanning across the world, Shell is today recognised for its expertise, knowledge, and proven deep-water technologies, which it utilises to unlock new resources to deliver safe and efficient energy for the globe. It is this deep knowledge of the world’s energy sector that began Shell’s deep-water development era in the Gulf of Mexico (also known as the Gulf of America) more than 40 years ago. Today, Shell is the leading deep-water oil and gas producer in the Gulf of Mexico, playing a critical role in delivering deep-water projects that are powering progress across the region.

Shell’s operations in the Gulf of Mexico began when a team of engineers, scientists and explorers came together to reimagine the future of the region’s offshore oil and gas production. The first platform developed was the Cognac Platform in 1978, which exemplified Shell’s expertise in the deep-water development field as it was the first company to produce resources at water depths of 1000 feet (ft). From the establishment of this platform, it was clear that Shell was to be a leading player in the Gulf of Mexico’s development.

Over the years, Shell has continued to invest in profitable and carbon-competitive oil and gas projects achieved through its exceptional technological milestones across the design, construction, and operation of world-class oil and gas producing assets operating at water depths. It is Shell’s innovative approach to deep-water development, often using standardised designs, which has allowed it to remain so competitive. By standardising its operations, Shell can reduce costs and provide quicker returns, and in turn, Shell’s production across the Gulf of Mexico now ranks among the lowest greenhouse gas (GHG)

THE PROSERV DIFFERENCE

FOCUSED ON ENERGY’S FUTURE

The energy landscape is evolving. Operators need partners who can keep pace, leading the way through transition.

At Proserv, we bridge the gap. With smart technology, service distinction, and empowered people, we help our customers adapt, perform, and thrive.

At Proserv, we deliver client responsiveness and operational distinction through brownfield solution innovation - maximizing uptime with future-proof solutions that never go obsolete.

Proserv – Smart Technology. Service Distinction. Empowered People.

Powering Progress: How Proserv’s Innovative Controls Transform Energy Operations Across North America and the Gulf of Mexico

In a region defined by dynamic offshore and onshore energy activity, Proserv is charting a bold trajectory, driving operational excellence across North America and the Gulf of Mexico with cutting-edge controls technology. Whether safeguarding subsea wells or optimizing ageing infrastructure, Proserv’s solutions are built on decades of heritage, sharpened by a relentless focus on reliability, integrity, efficiency, and productivity.

At the heart of Proserv’s success lies its status as a trusted partner to industry giants like Shell. In the Shell Arran greenfield development, Proserv delivered a high-data-capacity subsea control system that supported real-time well monitoring. This sophisticated, cost-effective alternative to expensive fiber optics not only met Shell’s performance requirements, on time and within budget, reinforcing Proserv’s reputation for ingenuity and cost-efficient excellence.

But Proserv’s impact goes beyond individual projects. Through a powerful blend of hardware control systems, condition-based monitoring,

and advanced analytics, the company offers lifecycle-spanning solutions from initial deployment and performance optimization to legacy asset extension. This full-spectrum approach reflects Proserv’s deep engineering, manufacturing, and field service expertise and underscores its ability to integrate seamlessly into any existing infrastructure, at scale.

Central to this success is Proserv’s people: passionate, forward-thinking technologists with roots in decades of industry leadership. Their commitment to customer success, combined with a heritage of performance and service distinction, defines the Proserv promise: delivering lasting value, wherever energy operates.

For more information on Proserv and our technology solutions, contact Jason Mallory (Director, Americas; jason.mallory@proserv. com; +1 713 550 5397) or Kevin Gentry (Sales & Business Development Manager, Americas; kevin.gentry@proserv.com; +1 281 615 8102).

Visit www.proserv.com

intensity in the world for the production of oil. It is this focus on decarbonisation alongside its project delivery that has set Shell up to deliver vital energy resources across the Gulf region, supported by innovation, research, and development focused on delivering energy now and for the future.

As the largest operator in the Gulf of Mexico, Shell operates world-class oil and gas projects, including one of the world’s deepest offshore drilling and production facilities, the Perdido Platform. The platform operates at water depths up to 2,450 metres, highlighting Shell’s ability to deliver ultra-deep-water exploration at such depths. Perdido began production in 2010, and at its peak and can produce up to 125,000 barrels of oil equivalent per day (boepd). The platform is operated by Shell, who hold a 35% working interest, with joint venture partners of Chevron (37.5%) and BP (27.5%). The platform acts as a hub and enables the development of the Great White, Tobago, and Silvertip fields, extracting oil from 35 subsea wells.

However, in recent years, Shell has been developing new and innovative platforms, which are focused on decarbonising its deep-water operations. One of the most notable recent developments for this is the Vito Platform, located 150 miles from New Orleans. The Vito Platform has brought a new era for Shell’s offshore production across the Gulf, with the platform designed to be much smaller and more compact than a typical offshore platform. With Vito being roughly 70% of the size of the platforms we typically see for offshore oil and gas production, the platform provides Shell with a more environmentally friendly development for energy production as it requires less steel, cables, space and power to operate. Therefore, Vito greatly reduces the impact of the development and operation of the platform on the environment. To further enhance its sustainability, Vito is expected to see a reduction in its estimated electrical power load consumption across the platform, whilst also delivering more efficient waste heat recovery units. The platform will have optimised turbines to better fit the required load demand needed to operate the smaller Vito. Production began at Vito in February 2023 and now serves as a clear blueprint for Shell to deliver deep-

Innovative Deep-Water Development

water projects across the Gulf of Mexico to help improve its platform delivery and development to be both economically and environmentally enhanced.

Building on the success of Vito, Shell began work on the Whale Platform, the second of three planned oil and gas platforms, which will feature a similar compact size to the Vito Platform. In contrast to many platforms along the Gulf of Mexico, Whale is roughly only a 6th of the size of the tallest offshore platform in the world. The Whale platform has been designed as a close replica of Vito, but the platform is built to withstand 30-metre waves that often occur during hurricane season. The platform was installed in February 2024, located within the Whale oil and gas fields at a depth of 2,600 metres. The platform is operated by Shell Offshore Inc., a subsidiary of Shell Plc, who have a 60% interest in the platform, alongside Chevron (40%).

In January, Shell Offshore Inc. announced that production had commenced from the Whale Platform. The platform is estimated to have a peak production capacity of 100,000 boepd, with an estimated recoverable resource volume of 480 million barrels of oil (boe). Announcing the start of production from Whale was Zoë Yujnovich, Shell’s

Integrated Gas and Upstream Director, outlined that “Whale demonstrates our focus on driving more value with less emissions from our Upstream business as we deliver the energy people need today. Yujnovich continues, “It [Whale] will make a significant contribution to our commitment to bring projects online, with a total peak production of more than 500,00 barrels of oil equivalent per day from 2023 through 2025”. With a significant production capacity expected from Whale over the coming years, this highlights the leading role Shell is playing in developing energy developments across the Gulf of Mexico.

However, with the Whale Platform replicating 99% of the hull design and 80% of the topside from Vito, Whale enhances Shell’s deep-water development, where its oil production has among the lowest GHG intensity in the world. Whale features energyefficient gas turbines and compression systems, which operate with 30% lower GHG intensity over its lifecycle compared to Vito. This development exemplifies Shell’s continual movement towards decarbonising its deep-water operations and ensuring that with every new development, it is building upon this goal.

Across its platforms in the Gulf of Mexico, Shell is proactively managing the greenhouse gas intensity of its deep-water operation through innovative

project design, efficient operations, and strategic handling of late-life assets. In fact, Shell has achieved a 40% reduction in methane emissions in the Gulf of Mexico since 2016, and in 2023, Shell’s Gulf of Mexico emissions were 5% below its planned target, with intensity levels 9% below expectations. This continual movement towards decarbonisation is underpinned by Shell’s constant investment in research and development through collaboration with more than 25 universities and research centres. This research helps Shell to continually develop its project construction, development and delivery to ensure that each platform or energy development is working towards the global company’s long-term investment towards profitable and carbon competitive oil and gas projects across the Gulf of Mexico.

Across the Gulf of Mexico, Shell is playing a leading role in developing vital platforms that are enhancing the region’s vital oil and gas deposits to bring this energy to market. However, their primary focus throughout this is to deliver energy projects that optimise its research, development and expertise to deliver energy resources in a sustainable way. With compact and energy advanced platforms such as Vito and Whale, Shell is delivering vital energy with a low GHG emission intensity that helps deliver the energy needed today, whilst protecting the planet for the future.

FUELLING A GREEN FUTURE

Paria Fuel Trading Company Limited, is transforming the Caribbean’s energy landscape.

As a key supplier of refined petroleum products and a pioneer in sustainable energy, Paria is dedicated to balancing business success with environmental responsibility.

Core Operations:

Trading 40,000 barrels of petroleum products daily, including motor gasoline, kerosene, gas oil, and fuel oil.

Extensive distribution network serving local, regional, and international markets.

Environmental Leadership:

Committed to sustainability with initiatives like distributing 100,000 seedlings to schools and reducing carbon emissions through employee workshops.

Proud recipient of the International Sustainability and Carbon Certification (ISCC), aligning with European environmental standards and exploring low-carbon marine fuels.

Innovative Methanol Bunkering:

Paria recently achieved a historic milestone in Caribbean energy by launching methanol bunkering services, positioning Trinidad and Tobago as a regional low-carbon bunkering hub by 2026.

Looking Forward, Paria is not only powering today but investing in a sustainable future. With a focus on green energy solutions and community impact.

Paria is shaping a cleaner, more sustainable energy future for the Caribbean.

Newmont Corporation Australia

Home to substantial gold reserves, Australia is the third-largest gold producer in the world with a long history in the gold mining sector. For this reason, Newmont Corporation, the world’s leading gold company, has been operating within the Australia’s gold mining sector since 2002. Now with over 20 years of experience within Australia’s mining sector, the bulk of its operations here can be broken down into three distinctive mine operations: Boddington, Cadia, and Tanami. Across these mines, Newmont utilises the company’s over a century of expertise in the global mining sector, to deliver vital gold and metal resources for the Australian metals market.

Some of the most lucrative deposits of gold in Australia are found in the West, where there are a plethora of greenstone belts. Here, Newmont operates the Boddington mine, the largest gold mine in the country based on production, within the Saddleback Greenstone Belt. The mine is a large-scale gold and copper surface mine just 30km from Perth. Commercial production at the mine began in 2009, with the operation reaching 1 million ounces of gold by March 2011. Since it began production, the mine has consistently produced more than 800,000 gold equivalent ounces (GEOs) a year. By 2022, the mine had reached more than 1 million GEOs for the first time in its history, largely thanks to its fully autonomous fleet, which operates within the mine. The fleet, which Newmont invested $150 million in as part of its Autonomous Haulage Project, works across the south pit, which is currently the deepest open pit in the world to deploy such automation technology. However, it is this focus on technological innovation that has long made Newmont a heavyweight in the mining sector.

The development of automation across Newmont’s fleet has significantly reduced the fleet size at Boddington from 46 trucks to just 41 automated vehicles, allowing for a non-segregated haulage network with shorter and more optimised haulage distances. The introduction of automation was part of Newmont’s wider Full Potential program which is designed to encourage new ways of thinking that could push its mines to deliver greater value utilising best practices. The program set out to reduce costs whilst generating productivity improvements, and since 2013, it has generated more than $700 million in value for the mine. Through the program, Newmont has been able to push beyond Boddington’s nameplate capacity of 35 metric tonnes and has processed more than 40 million metric tons whilst adding another 2 years to the mine life. Alongside its significant productivity output, the automated system greatly improves safety and productivity at the mine, making it both an efficient and safety-focused mine delivering significant resources for the future.

The Cadia Mine is another of Australia’s largest gold mining operations and encompasses an underground mine producing both copper and gold. The mine has ore reserves of 15 million ounces (Moz) of gold and 2.6 mega tons (Mt) of copper. The mine site includes the Cadia East Underground Mine, as well as the Cadia Hill Pit Tailing Storage Facility and the Ridgeway Underground Mine, but the latter two are currently on current in care and maintenance. Mining in Cadia East commenced commercial production in 2013, and

PARTS ENGINEERED TO PERFORM IN HARDROCK MINING

SURFACE PARTS SPOTLIGHT

MASPRO is a leading provider of cutting-edge engineering solutions for underground and surface operations in the hard rock mining industry. What sets us apart is our unwavering commitment to optimising the parts we produce to increase safety and reliability. Our team works closely with customers to ensure that their machinery performs at its peak, even in the harshest mining conditions. If you’re looking to drill deeper, move more ore, and push your equipment to the limits while maintaining the highest standards of safety and operational reliability, talk to the MASPRO team today!

UNDERGROUND PARTS SPOTLIGHT

Newmont Corporation Australia

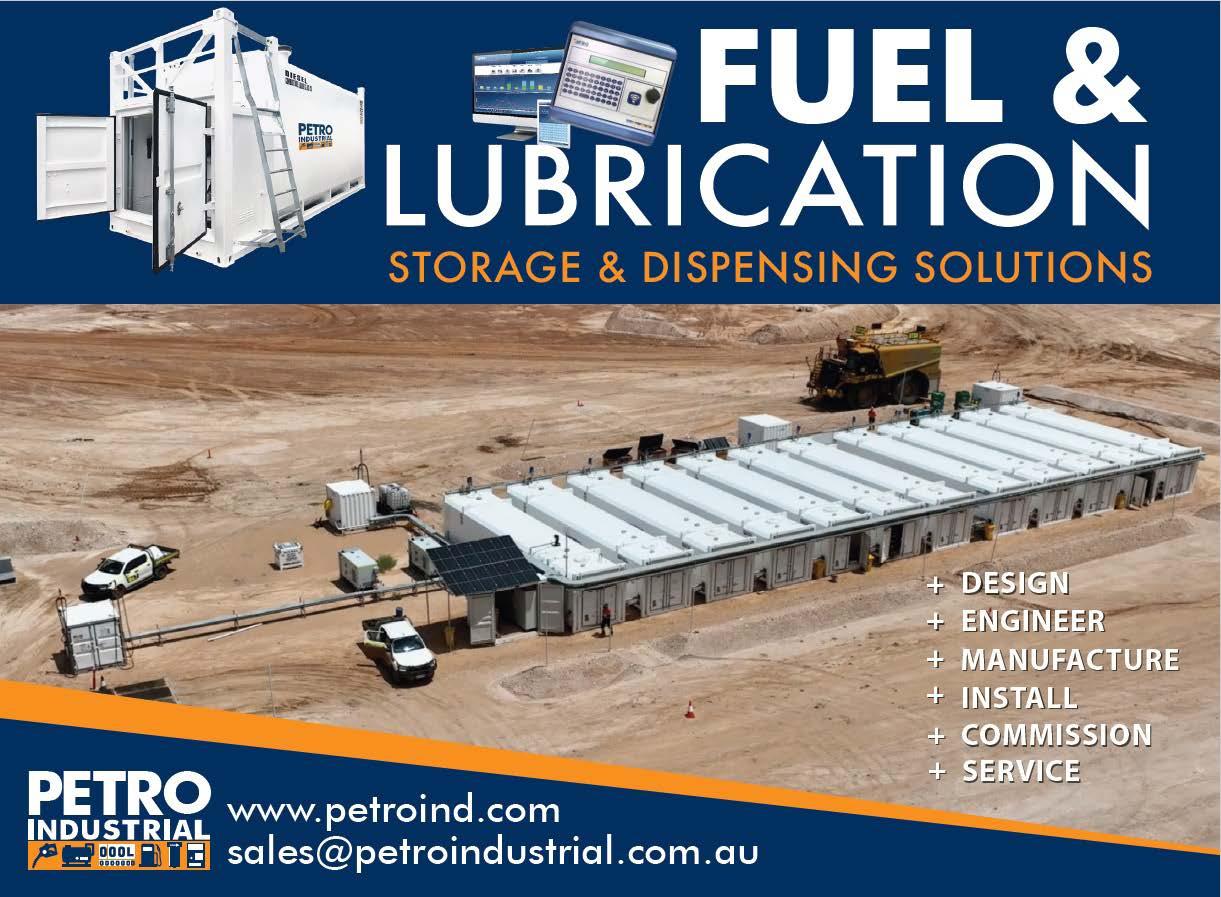

PETRO Industrial – Proven Fuel & Lubrication Expertise

PETRO Industrial delivers world-class fuel farm and lubrication storage & dispensing solutions, engineered for the demands of major mining operations. From design and manufacture to installation, commissioning, and ongoing service, we provide turnkey systems backed by advanced fuel management and secure cloudbased data storage.

Our engineering capability ensures reliability, compliance, and efficiency in every project. Whether buying outright or hiring, PETRO offers flexible options tailored to site requirements. Trusted in the mining industry.

PETRO is your partner in powering productivity.

utilises panel caving mining techniques to access one of the largest gold and copper deposits in the world. Gold is produced in the form of gold doré bars via a gravity circuit and gold-rich copper concentrates from a flotation circuit. In the 2023 fiscal year, Cadia produced 597 thousand ounces (Koz) of gold at an allin sustaining cost of $45 per ounce.

Developing the Cadia mine has been of high importance to Newmont in recent years, with the Panel Cave (PC) 1-2 Feasibility Study approved for execution in November 2022. The project’s PC1 and PC2 are currently being developed to recover a substantial portion of Cadia’s ore reserves, with the first ore from PC 2-3 already delivered. The entire PC1-2 project aims to recover approximately 5.9 million ounces of gold services and 2.9 billion pounds of copper services. This development is expected to continue into the second half of 2026 to deliver significant resources for Newmont from the Cadia mine.

Image credit: PETRO Industrial

Creating Value in Australia’s Mining Industry

One of the central missions of Newmont Corporation is to create value and improve lives through sustainable and responsible mining. This focus can be clearly seen at the Cadia Mine, as it was awarded both The Copper Mark and The Molybdenum Mark in October 2024. These certifications are awarded to companies to recognise responsible production. For Newmont, this is the first mine site for the company that has received the award. The certification is awarded based on an operation meeting more than 30 criteria in critical areas such as environment, community, human rights, and governance.

Cadia is also the only mine in Australia producing molybdenum, and so is the only mine in the country to be awarded The Molybdenum Mark. In the announcement of the awarding to Cadia, Suzy Retallack, Newmont Chief Safety and Sustainability Officer, outlined, “We take great pride in being at the forefront of the copper industry with The Copper mark, which highlights our dedication to responsible production and transparency. Retallack continues, “This means our global customers can now choose to source copper concentrate from an independently evaluated mine that meets the highest standards in environmental, social, and governance practices, responding to the increasing demand for sustainable supply chains”. Retallack’s comments highlight just how vital this mark and The Molybdenum Mark are for the competitiveness of Newmont’s copper and molybdenum resources for global markets. Customers across the world can source these resources from a mine that is known for operating with sustainability and responsibility at the forefront. This makes Cadia’s resources highly valuable for global supply chains and, in turn, develops Australia’s minerals industry.

The final mine operated by Newmont in Australia is the Tanami mine, where the company has been delivering vital gold resources since 2002. The mine is located in the remote Tanami Desert of Australia, within the Aboriginal freehold land that is owned by the Warlpiri people and managed on their behalf by the Central Desert Aboriginal Lands Trust. The mine is in one of the most remote locations in Australia, and so access to Tanami is via a fly-in-flyout basis. The mine began operation more than 20 years ago as an open-pit operation, which over the years has been transformed into one of the largest underground gold mines in Australia, with more than 12 million ounces of gold produced.

Like with the other mines operated by Newmont in Australia, the Tanami mine is undergoing expansion

works to increase the gold production of the mine. Newmont is currently working on the second expansion of Tanami, with investment towards constructing a 1.5-kilometre-deep production shaft. Tanami Expansion 2 aims to increase the average gold production of the mine from roughly 150,000 -200,000 ounces a year to 600,000 ounces per year for the first five years. Whilst expanding the production capacity, the development also hopes to reduce operating costs by around 10%. The main scope of the expansion involves the construction of a headframe and vertical hoisting shaft to a depth of 1,460m to transport people and ore out of the mine.

As part of the expansion, Newmont entered into a strategic alliance with Caterpillar in 2021 to help deliver a fully connected, automated, zerocarbon-emitting, end-to-end mining system. Thus, with this partnership, Newmont can deliver a more technologically advanced mine to optimise production. Newmont’s partnership with Caterpillar aims to develop new battery electric haulage technology for its underground mining, and following the introduction of battery autonomous technology, which will be an industry first for the mine.

Across all three of Newmont’s mine sites in Australia, the company is focused on delivering vital mineral resources in a sustainable and communityfocused way. Newmont is committed to building respectful and mutually beneficial relationships with the communities that surround its operations. By working with local communities, the mines can help deliver long-term economic and social growth. Each mining operation under Newmont has a dedicated community relations team, and through these, Newmont is passionate about maintaining an ongoing dialogue between all stakeholders to ensure positive community growth.

What we can see from Newmont’s operations in Australia is a firm commitment to delivering value through responsible, efficient and communityfocused mining operations. Across Boddington, Cadia and Tanami, there is a keen sense of growth to harness the production of gold and copper for today, whilst delivering the infrastructure and techniques to optimise production for many years to come. With some of the largest mining operations under its portfolio in Australia, Newmont is set to deliver vital resources for the country, supported by its expertise on a global scale, to make its supply chains competitive and mining operations technologically advanced.

Written by Carley Fallows

The S2 Meteorite: Destruction and New Life to Earth

Understanding how life as we know it came to exist, is something that scientists and researchers have long been examining by looking at the geological evidence we have left on Earth. A key place to discover such evidence is at meteorite landing sites, as often these give us big clues on how the earth looked upon impact and what the world looked like following the event. A key focus for this research currently is looking at the S2 Meteorite that impacted Earth more than 3 billion years ago. The meteorite is thought to have brought widespread destruction, whilst also triggering the start of new life in its wake.

The S2 Meteorite impacted the Eastern Barberton Greenbelt region, which is home to some of the oldest exposed rock on Earth. The belt is located on the eastern edge of South Africa, where there has long been rich gold mineralisation and is home to a usual type of ultramafic volcanic rock called komatiites. Since the discovery of the impact site, researchers have been travelling to South Africa to obtain and analyse spherule particles or tiny rocks which were left behind by the impact. By analysing these fragments, the researchers can begin to gather a better picture of what the S2 Meteorite was like, and how the Earth looked at the time.

The S2 Meteorite is an interesting discovery as it is thought to have been 200 times the size of the asteroid that took out the dinosaurs, which shaped the way the earth as we know it now looks. Therefore, studying the fragments from S2 is vital to understanding the earth, which when it hit was in its infancy stage covered with vast amounts of water, with very few continents, and only single-celled microorganisms.

From research conducted at the site, scientists have discovered that the impact would have caused a massive tsunami which would have churned up the ocean floor with debris, causing this to flush through coastal regions. The heat from the impact boiled the top layers of the ocean off and contributed to the heating of the Earth’s atmosphere. Additionally, the plume of dust caused by the impact would have sent a thick layer of dust into the atmosphere blocking out the sun. All of these aspects contributed to many of the single-celled organisms which relied on the sun for photosynthesis to die due to the thick dust layer, effectively killing any of the organisms on earth at the time.

However, the S2 Meteorite didn’t just bring destruction, following the tsunami churning up the ocean, bacteria and archaea would have been pushed into coastal regions. These organisms would have thrived on the influx of iron from the deep-sea floor, as well as on the increased phosphorus levels caused by the meteorite and the coastal erosion of the tsunami. These factors

allowed the bacteria and archaea to thrive, and so began significant population blooms across the land following the impact. Therefore, whilst the S2 Meteorite is thought to have brought destruction, even more significant than the one that killed the dinosaurs, it also led the way to the development of new organisms on Earth.

Overall, researchers continue to investigate the Barberton Greenstone Belt, as the S2 Meteorite discovery is just one of 8 recently found in the region, and so it continues to provide a great landscape for research into the early days of Earth.

Sources:

www.bbc.co.uk/news/articles/c4g4g455p8lo

https://en.wikipedia.org/wiki/Barberton_ Greenstone_Belt#:~:text=%5B2%5D-,Impact%20 event,-%5Bedit%5D

www.space.com/meteorite-s2-dinosaur-killing-life

Turks and Caicos Airports Authority

The Turks and Caicos Islands are an idyllic destination, seeing a great number of tourists descend onto its shores to experience the luxury resorts, impressive landscapes and local cuisine that the islands have on offer. Therefore, tourism remains one of the key drivers of economic development for the country. Thus, to help transport many of the tourists to the island, the aviation industry is vital to supporting the tourism sector and, in the process, the local economy. For this reason, the Turks and Caicos Airports Authority (TCIAA) was established to oversee the airports of the Islands and help them deliver them as world-class airports ready to deliver leading airport operations and development.

Established in 2006, TCIAA is the statutory body that controls and manages the 6 public airports within the Turks and Caicos Islands. Operating with a forward-looking and proactive approach, TCIAA oversees the planning, development, redevelopment, construction, administration, control and management of the port. Some of the key roles for the Authority are to maintain runways, taxiways and terminal buildings, provide Border Control Services, deliver air navigation and air traffic control services, whilst overseeing the safety and regulation of the airports in line with government legislation.

The hub for TCIAA’s operation is in Providenciales, where the Howard Hamilton International Airport, previously the Providenciales International Airport, operates. The airport is vital to TCIAA as it is where the bulk of the Islands’ regularly scheduled international flights arrive, and so is often seen as the ‘gateway’ to the Turks and Caicos Islands. Providenciales is the most well-known island in Turks and Caicos, with tourists arriving on the island to experience the hotels, restaurants and attractions, or, to then move to other Islands which do not cater to international flights. Regular flights to Providenciales include those from London, New York, Washington D.C., Miami, Toronto, Boston, Chicago, Dallas, Philadelphia and Atlanta.

One of the other central airports operated and managed by TCIAA is the JAGS McCartney International Airport in Grand Turk. The airport focuses on domestic flights, allowing locals and tourists alike to hop between the islands easily. These services are supported by airlines including interCaribbean and Caicos Express, which facilitate flights between Providenciales, South Caicos and Salt Cay. The other airports under TCIAA include the Norman B. Saunders Sr. International Airport in South Caicos for domestic flights, Clifford Gardiner International Airport in North Caicos, Eric Arthur Airport in Middle Caicos, and Henry Leon Wilson Airport in Salt Cay. Across these 6 airports, TCIAA supports and develops the region’s economy, the largest through tourism, with more than 200,000 tourists arriving at the islands annually.

Dwayne Gardiner, Executive Chairman, outlined in his chairman’s message on the Authority’s website that ‘We at the TCIAA understand the importance of the Authority and the six airports under its control as a catalyst for national development, particularly in the areas of tourism growth and international trade relations. Like many of our regional counterparts, air travel is directly connected to and predominantly

drives our community’s main sources of revenue. Therefore, in our management practices, we continue to strive to promote a culture of honesty, integrity, transparency, creativity, and excellence”. Gardiner’s message exemplifies how vital TCIAA is for national development across Turks and Caicos, and under its authority, the airports can deliver vital tourism and international trade relations that bring significant economic benefits to the region.

One of the most valuable parts of TCIAA’s operations is the development and redevelopment of the Islands’ airports to constantly meet the demand of passengers travelling through them. In May 2022, TCIAA outlined the Howard Hamilton International Airport Redevelopment Project to expand the infrastructure of the airport, to increase the terminal capacity and add new taxiways and a new passenger terminal building. The project was awarded to ALG Transport & Infrastructure Advisors PLC upon the culmination of an open tender exercise.

The development could see over 1.2-2 years the implementation of a new turn pad airside, an increase in the apron size to 282,000 square feet (sq. ft) and the expansion of the existing passenger terminals by 26,7000 sq. ft. This expansion hopes to increase the terminal capacity from 0.9 million passengers to 1.11.6 million passengers, as well as expand the surface area of the port to include a new car parking capacity and improve the overall access of the port. This vital development project at the largest airport in Turks

and Caicos provides the Authority with the ability to enhance the place of the airport as a key tourist destination with the necessary infrastructure and development to meet the needs of its passengers today and in the future.

In addition to the development of the Howard Hamilton International Airport Redevelopment, TCIAA is also working towards the construction of a new terminal at both the South and North Caicos airports, whilst revitalising the JAGS McCartney International and Salt Cay airports. Plus, TCIAA has been investing in the construction of a modern administration building, a new fire hall, an Air Traffic Control Tower and a Meteorological Facility on the Island of Providenciales. Collectively, these developments highlight TCIAA’s continued commitment to enhancing the airports of Turks and Caicos.

Across TCIAA’s operations, that is a keen awareness of just how vital the airports are to the development of Turks and Caicos. With many hundreds of thousands of tourists visiting the islands annually, it creates significant employment benefits for locals and, in turn, a vast influx of cash into the local economy. By ensuring that the airports are up to scratch, TCIAA encourages more international airlines to fly directly to the Islands, bringing vast tourism revenue. With vital development plans in the works, we look forward to seeing how TCIAA will continue to enhance the international and domestic interconnectivity of the airports across Turks and Caicos.

TotalEnergies is a leader in the global energy sector, as a multi-energy company set on delivering affordable, accessible, and sustainable energy across its 130 countries of operation. With the global demand for energy continuing to rise, TotalEnergies is delivering energy projects that can deliver the vital resources needed for today, whilst doing so in a way that protects the energy resources of the future. TotalEnergies achieves this through close work with the local communities in which it operates to ensure that every development across its energy portfolio is towards one cohesive goal. In recent years, we’ve seen TotalEnergies’ operations expand rapidly across Africa, utilising the rich deposits across the coast of the continent to deliver energy resources to its respective countries. One project that has been of particular interest is TotalEnergies Tilenga Project within Uganda, which is delivering significant oil for the country and neighbouring markets.

TotalEnergies has been operating in Uganda for 70 years, with its operations today spanning from downstream petrol and retail locations to upstream activities in offshore development. Its initial role in Uganda was via TotalEnergies Marketing Uganda Ltd, the marketing and services subsidiary of the global operation in the country. Across this division, TotalEnergies operates more than 200 stations countrywide, positioning the company as the leading downstream retailer for the country. However, as TotalEnergies’ role in Uganda has continued to expand, it began operations within the upstream development, with its operations falling under TotalEnergies E&P Uganda. It was this upstream affiliate which began work offshore and is now home to two of Uganda’s most vital oil projects: Tilenga and EACOP.

TotalEnergies E&P Uganda is part of a joint venture partnership with CNNOC Uganda and the Uganda National Oil Company (UNOC). TotalEnergies holds 56.67% interest in the subsidiary, with CNNOC and UNOC holding 28.33% and 15% respectively. The central purpose of the joint venture is to oversee and develop the upstream sector of Uganda, making the most of the deposits in Lake Albert. The most notable development across this region is the Tilenga project, which spans 6 fields of operations, including the districts of Bulisa and Nwoya. Across these fields, TotalEnergies E&P Uganda are drilling 400 wells across 31 well pads. At peak production, the project is expected to deliver 190,000 barrels of oil per day (bopd), delivering significant oil development for Uganda.

TotalEnergies E&P Uganda

The Tilenga project is being developed with TotalEnergies’ commitment to limit social, environmental and biodiversity impacts in mind. In fact, Phillippe Groueix, Country Chair of TotalEnergies Uganda and the General Manager of TotalEnergies EP Uganda, outlined on the company’s website that as a company, “we are proud to be part of Uganda’s energy journey by supporting the development of not only oil and gas resources but also renewables in line with our multi-energy ambition. Our ambition is anchored on our desire to achieve together with society net zero emissions by 2050 and to foster sustainable development in the countries where we operate”. Grouiex’s comments highlight how TotalEnergies E&P Uganda’s projects are founded on a commitment to deliver vital energy resources but in the most sustainable way possible, whilst supporting the local communities in which they operate at every step.

Oil produced from the Tilega project will then be transported via the East African Crude Oil Pipeline (EACOP), the second of TotalEnergies E&P Uganda’s key developments in the upstream energy market. EACOP is operated by EACOP Ltd., and shareholder TotalEnergies East African Midstream with a 63% share, whilst UNOC (15%), CNOOC (8%) and the Tanzania Petroleum Development Corporation

UGANDA

PETROLEUM INSTITUTE KIGUMBA

A Centre of Excellence for Oil & Gas Training

(TPDC) (15%) hold the remaining shares. EACOP is vital for Tanzania, as it will connect the oil developed from Tilenga to the country via the pipeline and to the Port of Tanga in Tanzania, where the oil reserves will be stored in a terminal, and then loaded onto a jetty and distributed to end markets. The pipeline connects directly with the central processing facility, flow lines, lake water abstraction facility, and feeder lines, as well as to construction camps and support bases.

Both the Tilenga Project and EACOP are vital to the local community surrounding the developments as they provide close to 80,000 jobs, with at least 11,000 of these being direct jobs given to the local community. Therefore, through the development of both projects under TotalEnergies, the company remains committed to ensuring that its operations support the local community on both a social and economic level. This approach, which centres its employees, is further reflected in TotalEnergies E&P Uganda’s commitment to safety, where the company continues to foster a culture of safety and responsibility across its operations. In fact, in 2023, the Tilenga project announced it had reached a new milestone of 20 million man-hours achieved without lost time accidents. With the announcement of this milestone, it is clear that throughout all operations

Sustainable Energy Development

TRAINING PROGRAMMES

The Institute offers both National Diploma Programmes and International Vocational Qualifications (IVQ). The National Diploma Programmes are accredited by the National Council for Higher Education while the IVQs lead to Certifications awarded by various International Assessment bodies including:

Offshore Petroleum Training Organisation (OPITO), City & Guilds, Engineering Construction Industry Training Board and American Welding Society

We currently offer the following programmes:

Diploma in Downstream Petroleum Operations Diploma in Upstream Petroleum Operations And International Vocational Qualification (IVQ) in:

Petroleum Operations

Instrumentation

Mechanical Maintenance

Electrical Maintenance

Health Safety and Environment