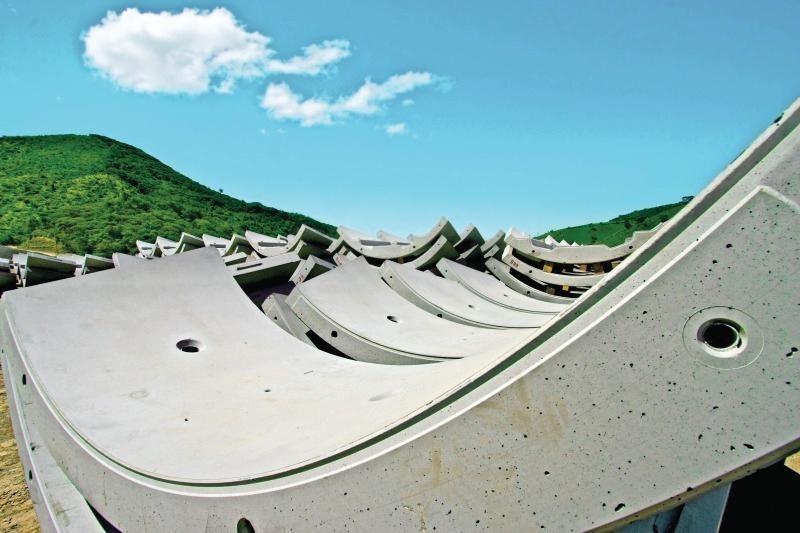

AN EXAMPLE OF A TBM AT THE BORING COMPANY

A MOVE FROM TRADITIONAL TRAPEZODIAL SEGMENTATION LINER TO HEXAGONAL SEGMENTATION DESIGN

NOTICE HERE THAT DIFFERENT SIZED SEGMENTS ARE STACKED TOGETHER. THE ASSUMPTION SUGGESTS THAT EACH STACK REPRESENTS ONE RING.

WHAT IF A SPECIFIC SIZED COMPONENT IS DAMAGED?

WHAT IF A SPECIFIC SIZED COMPONENT IS OVER DELIVERED? UNDERDELIVERED?

ALL PREFABRAICATED PARTS ARE THE SAME SIZE, NO SPECIALIZED MEASURING OR FABRICATION NEEDED, PROCESS IS STREAMLINED.

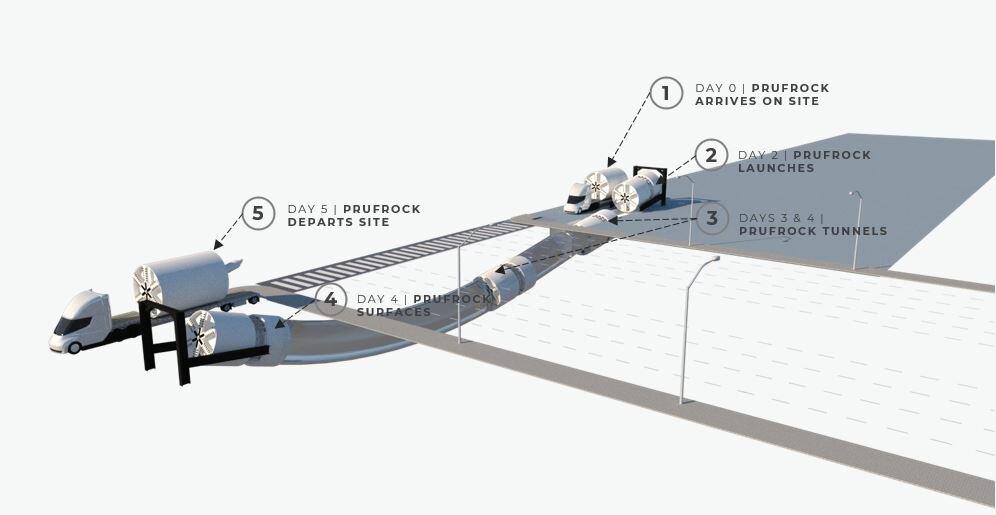

A RING DOES NOT NEED TO BE COMPLETED ENTIRELY IN ORDER FOR THE JACKS TO CONTINUE FORWARD THRUSTING.

TRANSLATION: HEXAGONAL LINER TECHNOLOGY ALLOWS THE TBM TO BORE CONTINUOUS WITHOUT STOPPING.

TUNNEL SITE IN VEGAS SHOWING MATERIAL STAGED IN BOTTOM LEFT OF PHOTO. ALL SEGMENTS ARE THE SAME. STREAMLINED PROCESSING PROMOTES DOWNSTREAM EFFICIENCY IN THE WAY OF FABRICATION, DELIVERY, AND OVERALL WORK PRODUCTION AND ERROR MITIGATION.

JACKING

PLAN VIEW

NOTICE THE REQUISTE OF TRADITIONAL RING ABOVE COMPARED TO HEXAGONAL RING BELOW COMPLETION VS NON COMPLETION

ADDITIONAL THOUGHTS:

CONTINUOUS TUNNELING

MACHINES DO NOT NEED TO STOP

(ACCEL/DECEL OF MACHINERY IS TAXING, DESIGNED FOR CONSTANT USE, CONSISTENT RPM)

ALL SEGMENTS ARE HOMOGENOUS

CONCRETE REQUIRES THICKER BUILD WITH ADDITIONAL REINFORCEMENTS/FIBER IN DESIGN

SLIPPAGE AT JOINTS CAN INDUCE LEAKAGE

THRUST ON TUNNEL FROM THRUST CYLINDERS IS GREATER COMPARED TO TRADITIONAL RING INSTALL

RADIUS LIMITED IN OVERALL DIMENSION

ADDITIONAL THOUGHTS:

SO, ALTHOUGH THE GEOMETRY PERMITS CONTINUOUS TUNNELING. THE ADDED THRUST PRESSURE CAN CAUSE ISSUES IN THE SEGMENTATION, LEADING TO CRACKS AND WATERPROOFING FAILURES.

SO FAR THE BORING COMPANY IS EXPERIMENTING IN ARID GEOLOGY AT MINIMAL DEPTHS TO AVOID WATERTABLE/PENETRATON ISSUES.

ALTHOUGH NOT PUBLIC, THERE IS SPECULATION THAT TBC IS DEVELOPING PROPRIETARY GASKET AND WATERPROOFING TECHNOLOGIES TO EXPAND THE EXPOSURE OF THIS TUNNELING GEOMETRY AND OVERALL INCREASE IN EFFICIENCY.

DEPTH CONDITION IN THIS ILLUSTRATION SEEMS LIMITIED