improvement

Table of Contents

1. Project Team & Organizational Structure

1.1 Prime Contractor and Subcontractors

1.2 NYSDOT Stakeholders and Project Oversight

1.3 Contractor Sta Roles and Organizational Chart

2. Legal and Regulatory Review

2.1 Governing Laws and Highway Codes

2.2 Stormwater and Environmental Compliance

2.3 Hazardous Waste Monitoring and Disposal

2.4 Tra c Control and Maintenance Requirements

2.5 Utility Relocation and Proximity to Waterways

2.6 Wage Rates and Labor Regulations

3. Project Scheduling and Work Breakdown Structure

3.1 Task-Level WBS (Two-Tier Structure)

3.2 Critical Path and Precedence Relationships

3.3 Schedule Acceleration Opportunities

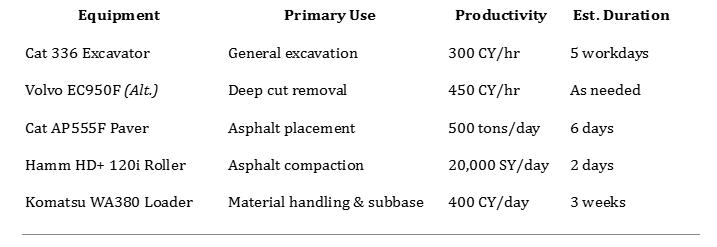

4. Heavy Equipment Selection and Use

4.1 Selected Equipment Overview

4.2 Productivity Rates and Operational Roles

4.3 Estimated Durations and Integration

5. Conceptual Estimate and Cost Basis

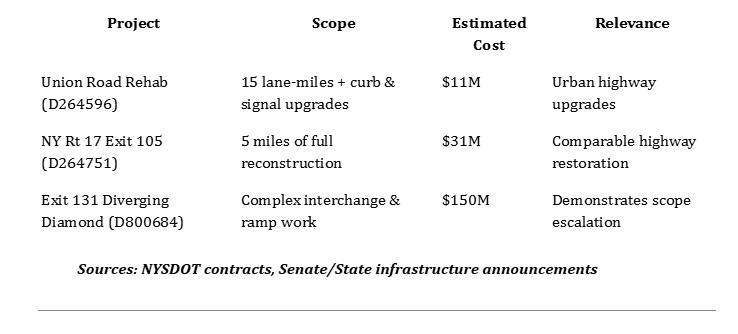

5.1 Reference Project Summaries

5.2 Cost Comparison and Unit Rates

5.3 Key Takeaways from Benchmarks

6. Speci cation Review of Major Cost Items

6.1 Top Five Cost/Quantity Line Items

6.2 Cost Impact on Construction Phasing

6.3 Value Engineering Opportunities

7. Project Safety and Risk Management Plan

7.1 Tra c Control and Public Safety

7.2 OSHA Excavation and Trenching Compliance

7.3 Personal Protective Equipment (PPE) Protocols

7.4 Utility Con ict Zones and Mitigation

7.5 Daily Safety Meetings and Incident Response

8. Lean Construction Implementation

8.1 Just-in-Time Deliveries

8.2 Downtime and Labor Optimization

8.3 Material Waste Reduction

8.4 Continuous Improvement and Metrics

9. Appendices

A. Project Plans and Proposal Sheets

B. Equipment Speci cation Sheets

C. Project Organizational Chart

D. Safety Planning Checklist

E. Estimating References and Cost Data

Project Sta ng and Organizational Structure

1.1 Prime Contractor & Subcontractors

Prime Contractor: [Insert Firm Name]

Key Subcontractors / Consultants:

Surveying Consultant

Electrical Systems Contractor

Pavement Marking and Signage Subcontractor

1.2 NYSDOT Key Personnel

Engineer-in-Charge:

Title: [TBD]

Agency: NYSDOT Region 5 – Cattaraugus County

Design Job Manager:

Name: Robert Schaller, P.E.

Role: Oversight of technical design compliance

Project Management Group:

Designation: NYSDOT Group 3

1.3 Contractor’s Project Team (Direct Supervision)

Field Superintendent – Oversees daily site operations and coordination

Scheduler – Maintains and updates project schedule

Estimator – Tracks cost projections and quantity variances

Safety Coordinator – Enforces project safety protocols and conducts audits

(Insert organizational chart here to visually depict reporting structure, note to group)

Legal and Regulatory Review

2.1 Jurisdiction and Codes

Governed under Highway Law Sections 10(25), 12, and 46

NYSDOT Standard Speci cations (E ective: January 1, 2025)

2.2 Stormwater and Erosion Control

Implements SWPPP compliance via:

Temporary seed and mulch (3,609 SY)

Check dams, gravel bag inlet protection

Biodegradable sediment lter logs (per Proposal Book 1)

2.3 Hazardous Waste Considerations

Environmental testing for:

Petroleum contamination, PCBs, TPH, diesel/gasoline range

TCLP testing for hazardous waste determination

Item 205.050201: 40 tons of contaminated (non-hazardous) soil disposal

2.4 Wage Regulations

Davis-Bacon Act: Federal prevailing wage enforcement

Cattaraugus County Rates:

Truck Drivers: $46.21/hr + fringe

Equipment Operators: $43.39–$47.89/hr

Executive Order 14026: $17.20/hr minimum wage oor where applicable

2.5 Maintenance of Tra c (MOT)

Alternating one-way tra c with certi ed aggers during active hours

Full two-lane tra c restored during non-working hours

Staged subbase and paving phasing per MOT plans (see B.P. drawings)

2.6 Utilities and Waterways

Major utility coordination required for gas, water, and electric systems

No protected waterways identi ed; general NYSDOT drainage rules apply

Conceptual Estimate (Benchmark Projects)

Site Maps Coming, Inserted Here

Heavy Equipment Selection

Safety Management Plan

5.1 Work Zone Tra c Control

Compliance with NYSDOT Section 619 and MUTCD

Daily inspections by Tra c Control Supervisor

Use of temporary signals, signage, and aggers in Class 3 PPE

5.2 PPE Enforcement

Mandatory gear: steel-toe boots, ANSI Class 3 high-vis clothing, hard hats, safety glasses

Enforcement via:

Daily site checks by Superintendent

Written warnings and removal for repeated non-compliance

Daily PPE logs

5.3 Excavation Safety

Adherence to OSHA Subpart P:

Trench boxes or sloping for >5 ft depth

Competent Person on site for inspections

Excavation logs updated per shift

5.4 Utility Protection Zones

Coordination with National Fuel Gas and utility owners

Pre-marking zones and pre-dig meetings required

Vacuum excavation in high-risk areas

“No-machine-dig” bu ers strictly enforced

5.5 Paving Hazards

Crew brie ngs on fume, burn, and equipment hazards

Spotters used near rollers/pavers

Equipment operators must complete safety certi cations

5.6 Documentation & Safety Culture

Daily toolbox talks on task-speci c risks

Weekly audits by Safety Coordinator

Emergency Action Plan: includes nearest medical facilities, spill response, extinguisher stations

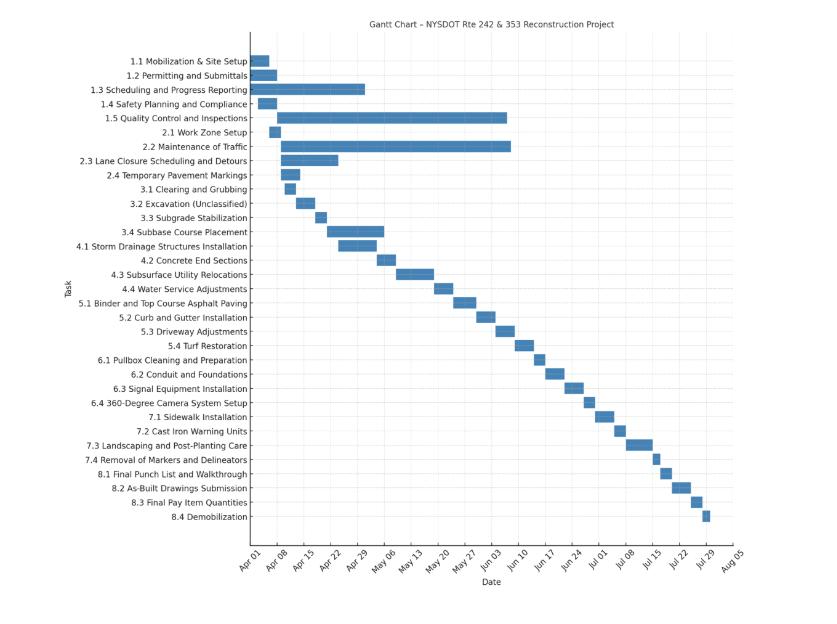

Work Breakdown Structure (WBS)

NYSDOT Contract D265434 – Little Valley, NY

WBS Code // Category // Subtasks (Level 2)

1.0

Project Management

1.1 Mobilization & Site Setup

1.2 Permitting and Submittals

1.3 Scheduling and Progress Reporting

1.4 Safety Planning and Compliance

1.5 Quality Control and Inspections

2.0

Tra c Control & Maintenance

2.1 Work Zone Setup (Signs, Barriers, Flaggers)

2.2 Maintenance of Tra c (Phased Access)

2.3 Lane Closure Scheduling and Detours

2.4 Temporary Pavement Markings

3.0

Earthwork and Subbase

3.1 Clearing and Grubbing

3.2 Excavation (Unclassi ed)

3.3 Subgrade Stabilization

3.4 Subbase Course Placement

4.0

Drainage & Utility Coordination

4.1 Storm Drainage Structures Installation

4.2 Concrete End Sections

4.3 Subsurface Utility Relocations

4.4 Water Service Adjustments

5.0

Paving & Roadway Surfacing

5.1 Binder and Top Course Asphalt Paving

5.2 Curb and Gutter Installation

5.3 Driveway Adjustments

5.4 Turf Restoration

6.0

Signal and Electrical Work

6.1 Pull Box Cleaning and Preparation

6.2 Conduit and Foundations

6.3 Signal Equipment Installation

6.4 360-Degree Camera System Setup

7.0

Site Features and Restoration

7.1 Sidewalk Installation

7.2 Cast Iron Warning Units

7.3 Landscaping and Post-Planting Care

7.4 Removal of Markers and Delineators

8.0

Project Closeout

8.1 Final Punch List and Walkthrough

8.2 As-Built Drawings and Utility Survey Submission

8.3 Final Pay Item Quantities

8.4 Demobilization

Gantt Chart

NYSDOT Contract D265434 – Little Valley, NY

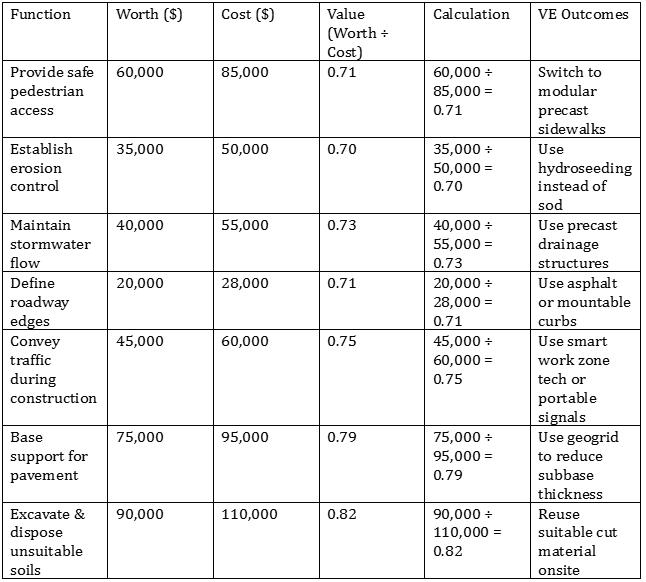

Value Engineering (VE)

Each function is assigned an estimated Worth and actual Cost based on typical NYSDOT item values. Value is calculated using the formula: Value = Worth ÷ Cost. Outcomes represent potential savings or e ciency gains by adopting alternate methods or materials.

Basis for Worth Cost Estimates

The Worth and Cost values used in the Value Engineering matrix were estimated based on historical unit prices from NYSDOT pay item catalogs, recent bid results, and industry-standard cost data for civil infrastructure projects. Worth re ects the lowest reasonable cost to accomplish a function e ciently, while Cost re ects the expected price using standard NYSDOT methods and materials.