improvement

Table of Contents

1. Project Team & Organizational Structure

1.1 Prime Contractor and Subcontractors

1.2 NYSDOT Stakeholders and Project Oversight

1.3 Contractor Sta Roles and Organizational Chart

2. Legal and Regulatory Review

2.1 Governing Laws and Highway Codes

2.2 Stormwater and Environmental Compliance

2.3 Hazardous Waste Monitoring and Disposal

2.4 Tra c Control and Maintenance Requirements

2.5 Utility Relocation and Proximity to Waterways

2.6 Wage Rates and Labor Regulations

3. Project Scheduling and Work Breakdown Structure

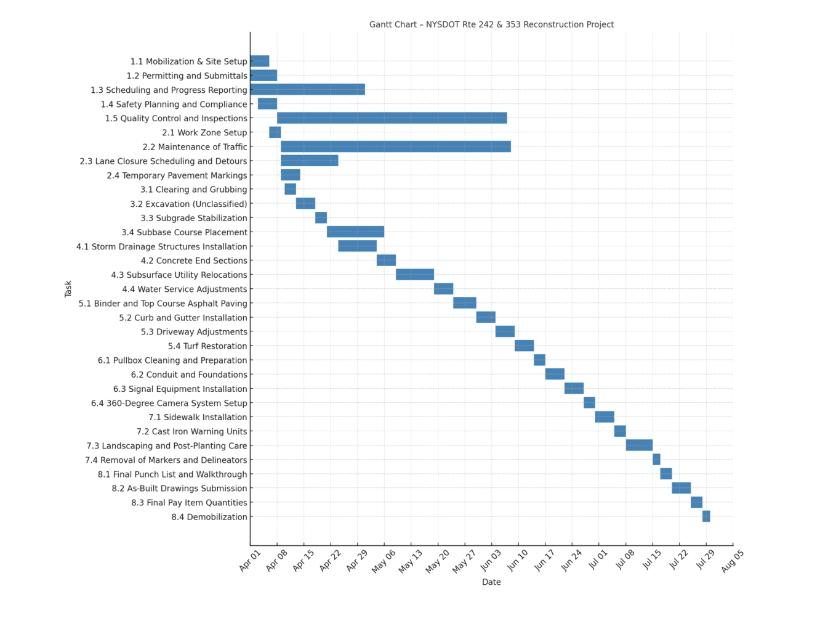

3.1 Task-Level WBS (Two-Tier Structure)

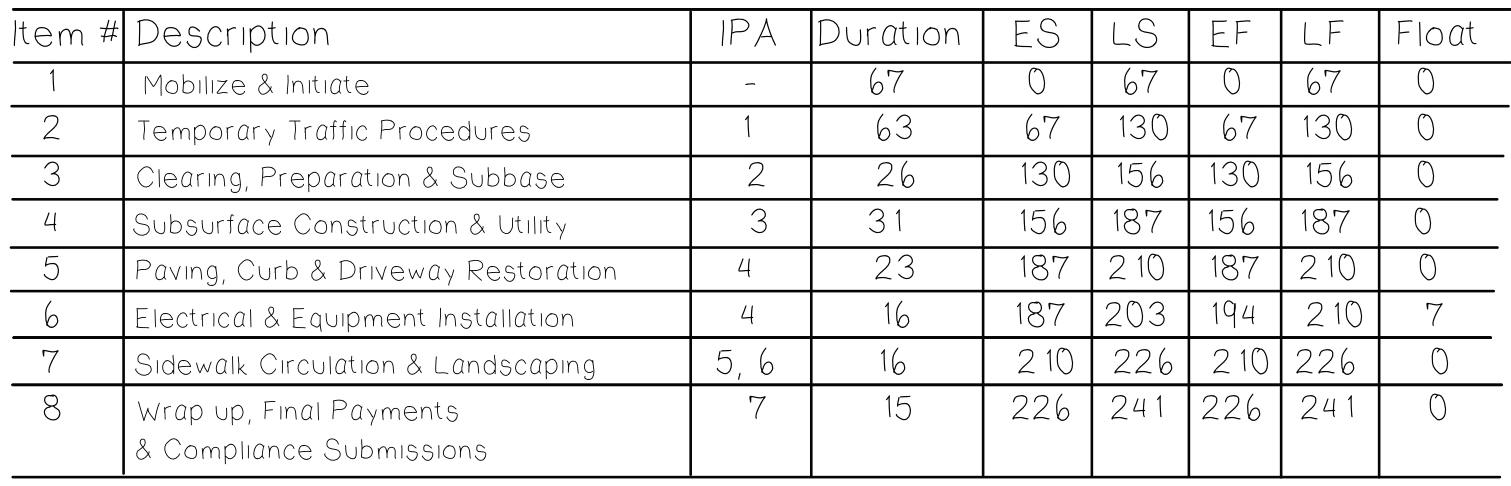

3.2 Critical Path and Precedence Relationships

3.3 Schedule Acceleration Opportunities

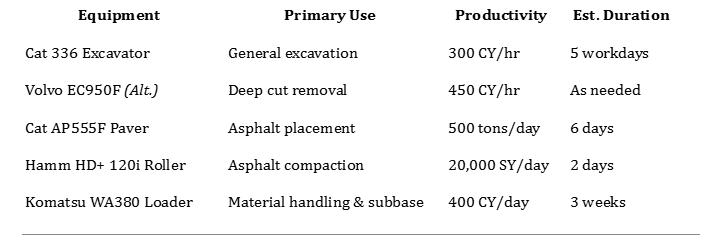

4. Heavy Equipment Selection and Use

4.1 Selected Equipment Overview

4.2 Productivity Rates and Operational Roles

4.3 Estimated Durations and Integration

5. Conceptual Estimate and Cost Basis

5.1 Reference Project Summaries

5.2 Cost Comparison and Unit Rates

5.3 Key Takeaways from Benchmarks

6. Speci cation Review of Major Cost Items

6.1 Top Five Cost/Quantity Line Items

6.2 Cost Impact on Construction Phasing

6.3 Value Engineering Opportunities

7. Project Safety and Risk Management Plan

7.1 Tra c Control and Public Safety

7.2 OSHA Excavation and Trenching Compliance

7.3 Personal Protective Equipment (PPE) Protocols

7.4 Utility Con ict Zones and Mitigation

7.5 Daily Safety Meetings and Incident Response

8. Lean Construction Implementation

8.1 Just-in-Time Deliveries

8.2 Downtime and Labor Optimization

8.3 Material Waste Reduction

8.4 Continuous Improvement and Metrics

9. Appendices

A. Project Plans and Proposal Sheets

B. Equipment Speci cation Sheets

C. Project Organizational Chart

D. Safety Planning Checklist

E. Estimating References and Cost Data

Introduction and Opening Remarks

The New York State Department of Transportation (NYSDOT) has approved the design proposal for the reconstruction of NY Routes 242 and 353 within the Village and Town of Little Valley in Cattaraugus County, New York. This report will detail the construction management strategy, project scheduling, and site layout related to the execution of this roadway reconstruction project, all of which will be performed in compliance with applicable New York State laws, NYSDOT speci cations, and local regulations. The state has awarded this project to a quali ed contractor who will oversee all aspects of construction and project delivery.

We, the contracting team for the NY Routes 242 and 353 Highway Reconstruction Project, are honored to have been selected to carry out, manage, and deliver this infrastructure improvement e ort. The following preconstruction report outlines our planned approach for construction and management throughout the life of the project. This includes descriptions of the work to be completed, key responsibilities of the construction and design teams, compliance with safety and environmental standards, the construction schedule and activity sequencing, selected materials and equipment, conceptual cost estimation, value engineering evaluations, and lean construction principles that will be applied to improve e ciency. This document serves as the foundation for how the project will be executed in the eld.

Key Takeaways

*NYSDOT has approved the reconstruction project for NY Routes 242 and 353 in Little Valley, Cattaraugus County.

*A quali ed contractor has been selected to manage and execute the project per state and local regulations.

*The preconstruction report outlines the construction strategy, scheduling, and site layout.

*It details roles of the construction and design teams, safety and environmental compliance, and activity sequencing.

*Selected materials, equipment, cost estimates, and value engineering assessments are included.

*Lean construction methods will be applied to enhance project e ciency.

*The report serves as a guide for eld execution of the project.

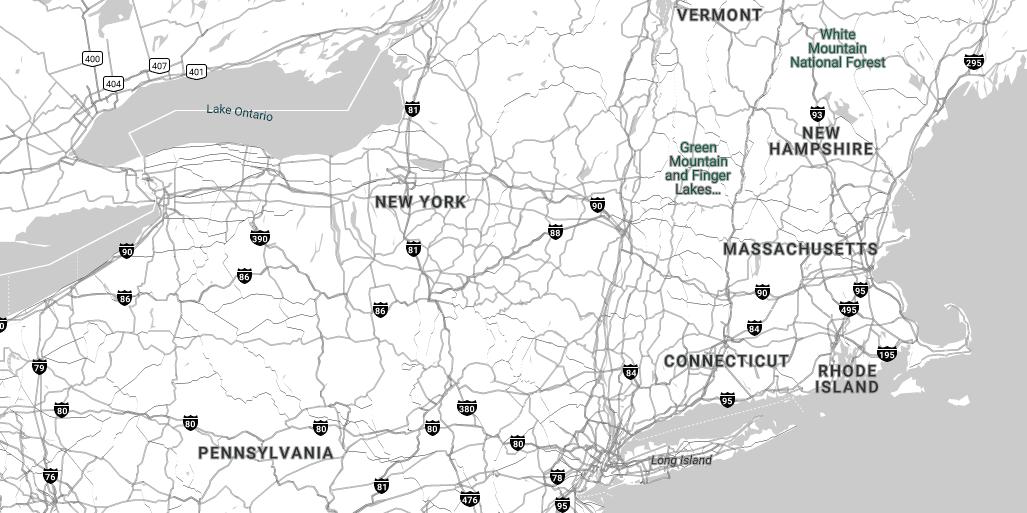

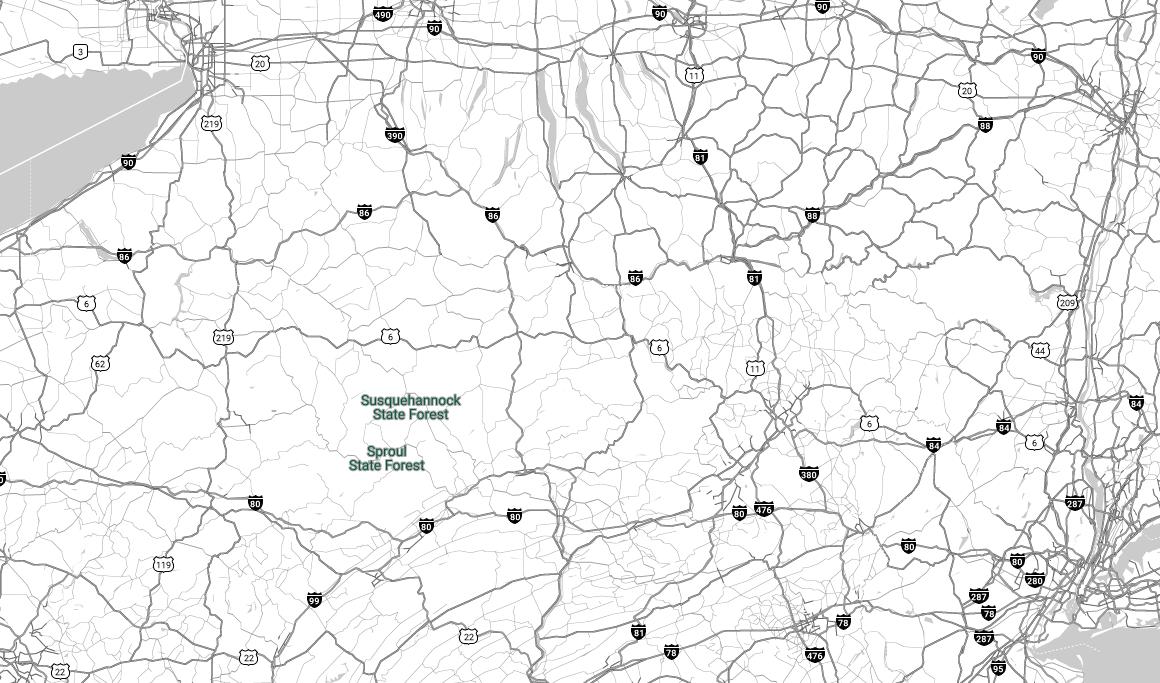

Site Map - NYS Location

1.1

Site Location Description

The NY Routes 242 and 353 Highway Reconstruction Project is a roadway improvement initiative located in Cattaraugus County, New York, within the Town and Village of Little Valley. The project involves reconstruction of deteriorated pavement sections, installation of new subbase materials, resurfacing with hot mix asphalt, and upgrades to the drainage infrastructure to improve stormwater management. Additional scope items include replacement of curbs and sidewalks to meet ADA compliance, turf establishment for erosion control, and implementation of temporary tra c control measures to maintain vehicular and pedestrian safety throughout construction. The project is managed in accordance with NYSDOT standards and is intended to enhance roadway safety, ride quality, and long-term durability for the region’s transportation network.

1.2

Key Takeaways

Location: The project is situated in the Town and Village of Little Valley, Cattaraugus County, NY.

Scope of Work: Includes pavement reconstruction, subbase installation, asphalt resurfacing, and drainage upgrades.

ADA Compliance: Curbs and sidewalks will be replaced to meet current ADA standards.

Erosion Control: Turf establishment is planned to manage erosion and stabilize disturbed areas.

Tra c Management: Temporary tra c control will be implemented to ensure safety during construction.

Standards: All work will be performed in compliance with NYSDOT guidelines.

Project Goals: Improve safety, ride quality, and extend the service life of the transportation infrastructure.

Project Planning

NYSDOT Contract D265434 – Little Valley, NY

Signage Placement

Project Planning

NYSDOT Contract D265434 – Little Valley, NY

Tra c Control and Circulation

2.1

Jurisdiction and Highway Law Compliance

This project is governed under New York State Highway Law Sections 10(25), 12, and 46, which de ne NYSDOT’s authority to construct, maintain, and regulate state highways. Compliance with these laws ensures that all right-of-way operations, construction methods, and design standards align with state policy. In particular, Section 10(25) enables the state to reconstruct and improve highways such as Routes 242 and 353. Highway Law Section 12 authorizes expenditures and contract administration, while Section 46 grants right-of-entry and access permissions. Adhering to these laws is foundational for legal construction operations and avoids con icts with public infrastructure policy and permitting.

2.2

Stormwater and Environmental Compliance

In accordance with NYSDEC stormwater regulations and NYSDOT environmental provisions, the project includes a Stormwater Pollution Prevention Plan (SWPPP) to mitigate runo and sediment transport. Controls such as temporary seed and mulch (3,609 SY), check dams, gravel bag inlet protection, and biodegradable lter logs are implemented throughout the site. These Best Management Practices (BMPs) are vital for controlling erosion during earthwork and minimizing pollutant discharge into nearby drains. Regular environmental inspections ensure that all temporary and permanent measures meet GP-0-20-001 permit requirements and do not degrade water quality during construction.

Hazardous Waste Monitoring and Disposal

The site has been tested for environmental hazards, including petroleum products, polychlorinated biphenyls (PCBs), total petroleum hydrocarbons (TPH), and other volatile contaminants. Based on site testing, Item 205.050201 was included to allow for the removal and disposal of approximately 40 tons of contaminated but non-hazardous soil. The waste classi cation process includes Toxicity Characteristic Leaching Procedure (TCLP) testing, which determines if excavated material must be handled as hazardous. The project’s environmental plan ensures proper containment, transport, and disposal of these materials under NYSDEC and federal EPA regulations, reducing risk to workers and surrounding areas.

Federal Wage Rate Regulations (Davis-Bacon Act)

The Davis-Bacon Act mandates that all laborers and mechanics on federally funded public works be paid prevailing wages and bene ts. For this project in Cattaraugus County, NYSDOT enforces compliance through published rates: e.g., Truck Drivers at $46.21/hr and Equipment Operators between $43.39 and $47.89/hr. Additionally, Executive Order 14026 establishes a federal minimum wage oor of $17.20/hr. Contractors must submit weekly certi ed payrolls to demonstrate compliance. Violations can result in withheld payments, legal actions, or disquali cation from future NYSDOT projects.

2.5

Tra c Control and Maintenance of Tra c (MOT)

Tra c control operations must comply with Section 619 of the NYSDOT Standard Speci cations and the MUTCD. The project utilizes alternating one-way tra c patterns during work hours and restores full two-lane access after hours. Flaggers wearing Class 3 ANSI PPE, temporary signals, and phased lane closures are deployed to maximize both public and worker safety. Maintenance of tra c is coordinated with staging plans that align with paving, drainage, and sidewalk installation schedules. Daily inspections by the Tra c Control Supervisor ensure all signage, devices, and detours remain in compliance and functional.

Legal and Regulatory Review

2.1 Jurisdiction and Codes

Governed under Highway Law Sections 10(25), 12, and 46

NYSDOT Standard Speci cations (E ective: January 1, 2025)

2.2 Stormwater and Erosion Control

Implements SWPPP compliance via:

Temporary seed and mulch (3,609 SY)

Check dams, gravel bag inlet protection

Biodegradable sediment lter logs (per Proposal Book 1)

2.3 Hazardous Waste Considerations

Environmental testing for:

Petroleum contamination, PCBs, TPH, diesel/gasoline range

TCLP testing for hazardous waste determination

Item 205.050201: 40 tons of contaminated (non-hazardous) soil disposal

2.4 Wage Regulations

Davis-Bacon Act: Federal prevailing wage enforcement

Cattaraugus County Rates:

Truck Drivers: $46.21/hr + fringe

Equipment Operators: $43.39–$47.89/hr

Executive Order 14026: $17.20/hr minimum wage oor where applicable

2.5 Maintenance of Tra c (MOT)

Alternating one-way tra c with certi ed aggers during active hours

Full two-lane tra c restored during non-working hours

Staged subbase and paving phasing per MOT plans (see B.P. drawings)

2.6 Utilities and Waterways

Major utility coordination required for gas, water, and electric systems

No protected waterways identi ed; general NYSDOT drainage rules apply

Utility Coordination and Proximity to Waterways

The project involves coordination with utility providers, including National Fuel Gas, for the adjustment and relocation of gas, water, and electrical infrastructure. All utility con ict zones are pre-marked, and excavation is restricted in designated bu er zones, particularly near critical assets. Pre-dig meetings and vacuum excavation are used in high-risk areas to prevent line strikes. Although no protected waterways are present, the drainage system must adhere to NYSDOT design standards for stormwater discharge. Ensuring timely coordination with utility stakeholders is critical to avoid schedule delays and maintain public service continuity. 2.6

Heavy Equipment Selection

https://www.youtube.com/shorts/zpkKwctUwa0

CAT PM822

The CAT PM822 is a high-production, half-lane asphalt milling machine designed for full-depth removal of pavement in a single pass. It features an 88-inch (2235 mm) cutting width and is powered by an 806 hp Cat C18 engine, o ering advanced automation, precise grade and slope control, and e cient material removal systems. A new CAT PM822 typically ranges from approximately $875,000 to over $1 million, depending on optional features and dealer pricing. A 2023 model with under 800 hours was recently listed at $875,000 .

CAT CB64

The CAT CB62 is a mid-sized tandem vibratory asphalt compactor designed for e cient and uniform compaction on urban streets, highways, and large-scale paving projects. It features dual steel drums, advanced vibratory systems, and ergonomic operator controls to ensure optimal performance and operator comfort. While speci c pricing for a new CAT CB62 can vary based on con gurations and dealer options, comparable models like the CAT CB64 have been listed around $120,000 in recent sales.

Heavy Equipment Justi cation

Cat 336 Excavator

*Selected for general excavation due to its high cycle e ciency and reliable output of 300 CY/hr.

*Ideal for bulk earthmoving in roadway widening and subbase prep.

*Projected to complete primary excavation within 5 workdays, minimizing equipment standby time.

Volvo EC950F (Alternate)

*Reserved for deep cut zones where higher breakout force is required.

*O ers increased reach and capacity at 450 CY/hr, deployed as needed for subsurface removal in tight phases.

Cat AP555F Paver

*Chosen for asphalt placement based on its consistent laydown rate of 500 tons/day.

*Well-suited for NYSDOT paving widths and thermal management requirements.

*Enables completion of paving operations within 6 days, assuming two lifts.

Hamm HD+ 120i Roller

*Used for asphalt compaction across both binder and top course.

*Delivers 20,000 SY/day compaction, ensuring density targets are met in two rolling days.

*Smooth-drum vibration matches NYSDOT compaction specs for exible pavements.

Komatsu WA380 Loader

*Utilized for material handling and subbase operations at 400 CY/day.

*Transfers aggregates e ciently from stockpile to paver or subbase zone.

*Supports continuous placement across a 3-week production window without bottlenecks.

Project Sta ng and Organizational Structure

1.1 Prime Contractor & Subcontractors

Prime Contractor: [Insert Firm Name]

Key Subcontractors / Consultants:

Surveying Consultant

Electrical Systems Contractor

Pavement Marking and Signage Subcontractor

1.2 NYSDOT Key Personnel

Engineer-in-Charge:

Agency: NYSDOT Region 5 – Cattaraugus County

Design Job Manager:

Name: Robert Schaller, P.E.

Role: Oversight of technical design compliance

Project Management Group:

Designation: NYSDOT Group 3

1.3 Contractor’s Project Team (Direct Supervision)

Field Superintendent – Oversees daily site operations and coordination

Scheduler – Maintains and updates project schedule

Estimator – Tracks cost projections and quantity variances

Safety Coordinator – Enforces project safety protocols and conducts audits

(Insert organizational chart here to visually depict reporting structure, note to group)

Chart

As Project Manager for the NY Route 242 and Route 353 Reconstruction Project in Little Valley, I oversee all on-site activities and ensure full compliance with NYSDOT standards. I report directly to the NYSDOT Engineer-in-Charge and maintain close coordination with the Design Job Manager, Mr. Robert Schaller, P.E.

My supervisory responsibilities include direct oversight of the eld superintendent, scheduler, estimator, and safety coordinator. Together, we manage eld operations, cost control, schedule adherence, and site safety. I also serve as the primary liaison with subcontractors—such as National Fuel Gas—to coordinate utility relocations and maintain continuity in the construction schedule.

5.2

Key Roles and Description

Project Manager

Provides overall leadership and direction for the project. Acts as the primary liaison between the contractor, NYSDOT, and key stakeholders. Ensures that the project is delivered on schedule, within budget, and in compliance with all applicable standards and contract documents.

Field Superintendent

Directs all eld operations on-site, including labor, subcontractors, and equipment. Ensures that work is executed e ciently, safely, and according to plans and speci cations.

Scheduler

Develops and maintains the master construction schedule using CPM methodologies. Provides ongoing analysis to ensure timely project delivery and milestone tracking.

Estimator

Responsible for preparing detailed cost estimates for labor, materials, and equipment based on bid items and historical unit prices. Supports budgeting, procurement, and value engineering.

Safety Coordinator

Ensures strict adherence to OSHA, NYSDOT, and internal safety standards. Proactively manages risk and fosters a culture of safety on the job site.

Key Responsibilities

Project Manager

- Oversee all phases of the project from mobilization to nal closeout

- Serve as the principal point of contact for NYSDOT, local agencies, and stakeholders

- Manage budgets, approve change orders, and implement risk mitigation strategies

- Lead coordination meetings and resolve design or construction con icts

- Ensure project compliance with NYSDOT speci cations, environmental regulations, and legal requirements

Field Superintendent

- Assign daily tasks to crews and subcontractors

- Coordinate eld operations to maintain schedule and quality standards

- Monitor site productivity and resource utilization

- Conduct daily site inspections and manage resolution of eld issues

- Enforce safety protocols and coordinate with the Safety Coordinator

Scheduler

- Develop and maintain a baseline CPM project schedule

- Update progress, logic changes, and durations regularly

- Analyze oat, identify delays, and recommend recovery actions

- Coordinate input from eld personnel, subcontractors, and suppliers

- Prepare and submit weekly/monthly progress reports for NYSDOT

Estimator

- Prepare conceptual and detailed cost estimates using historical data and bid tabs

- Perform accurate quantity takeo s and evaluate production rates

- Support the Project Manager in developing budgets and change order pricing

- Participate in procurement strategy and vendor selection

- Contribute to value engineering and cost optimization analyses

Saftey Coordinator

- Conduct safety orientations, brie ngs, and toolbox talks

- Perform site audits and hazard assessments

- Investigate incidents and ensure implementation of corrective actions

- Maintain safety documentation, training logs, and compliance reports

- Collaborate with Field Superintendent and foremen to mitigate jobsite hazards

Safety Management Plan

5.1 Work Zone Tra c Control

Compliance with NYSDOT Section 619 and MUTCD

Daily inspections by Tra c Control Supervisor

Use of temporary signals, signage, and aggers in Class 3 PPE

5.2 PPE Enforcement

Mandatory gear: steel-toe boots, ANSI Class 3 high-vis clothing, hard hats, safety glasses

Enforcement via:

Daily site checks by Superintendent

Written warnings and removal for repeated non-compliance

Daily PPE logs

5.3 Excavation Safety

Adherence to OSHA Subpart P:

Trench boxes or sloping for >5 ft depth

Competent Person on site for inspections

Excavation logs updated per shift

5.4 Utility Protection Zones

Coordination with National Fuel Gas and utility owners

Pre-marking zones and pre-dig meetings required

Vacuum excavation in high-risk areas

“No-machine-dig” bu ers strictly enforced

5.5 Paving Hazards

Crew brie ngs on fume, burn, and equipment hazards

Spotters used near rollers/pavers

Equipment operators must complete safety certi cations

5.6 Documentation & Safety Culture

Daily toolbox talks on task-speci c risks

Weekly audits by Safety Coordinator

Emergency Action Plan: includes nearest medical facilities, spill response, extinguisher stations

Work Breakdown Structure (WBS)

NYSDOT Contract D265434 – Little Valley, NY WBS Code // Category // Subtasks (Level 2)

2.1 Work Zone Setup (Signs, Barriers, Flaggers)

Paving & Roadway Surfacing

5.1 Binder and Top Course Asphalt Paving

5.2 Curb and Gutter Installation

5.3 Driveway Adjustments

5.4 Turf Restoration

6.0

Signal and Electrical Work

6.1 Pull Box Cleaning and Preparation

6.2 Conduit and Foundations

6.3 Signal Equipment Installation

6.4 360-Degree Camera System Setup

7.0

Site Features and Restoration

7.1 Sidewalk Installation

7.2 Cast Iron Warning Units

7.3 Landscaping and Post-Planting Care

7.4 Removal of Markers and Delineators

8.0

Project Closeout

8.1 Final Punch List and Walkthrough

8.2 As-Built Drawings and Utility Survey Submission

8.3 Final Pay Item Quantities

8.4 Demobilization

4.4

Project Management

Oversees the entire project, including coordination with NYSDOT, stakeholder communication, budget oversight, and compliance with contract obligations.

1.1 Mobilization & Site Setup:

- Deliver equipment

- Install eld o ce

-Establish laydown areas

-Mobilize personnel.

1.2 Permitting and Submittals:

-Prepare and submit required documentation including shop drawings

-SWPPP

-Tra c control plans.

1.3 Scheduling and Progress Reporting:

-Develop and maintain CPM schedule

-Submit progress reports

-Adjust timelines as needed.

1.4 Safety Planning and Compliance:

-Implement site-speci c safety plans and OSHA protocols

-Manage audits and training.

1.5 Quality Control and Inspections:

-Ensure materials and construction methods comply with NYSDOT specs

-Coordinate inspections and testing. 7.1

-Apply striping and markings for work zone visibility and realignment. 7.2

Tra c Control / Maintenance

Ensures safe and e cient vehicle and pedestrian movement throughout all construction phases.

2.1 Work Zone Setup (Signs, Barriers, Flaggers):

-Install temporary signage, barriers, and assign trained aggers.

2.2 Maintenance of Tra c (Phased Access):

-Manage lane shifts and alternating one-lane patterns.

2.3 Lane Closure Scheduling and Detours:

-Coordinate closure times and detour routes with local agencies.

2.4 Temporary Pavement Markings:

7.3

Earthwork and Subbase

Establishes the structural base of the reconstructed roadway.

3.1 Clearing and Grubbing:

-Remove vegetation, debris, and obstacles from work zones.

3.2 Excavation (Unclassi ed):

-Remove existing pavement and unsuitable material.

3.3 Subgrade Stabilization:

-Improve soil stability using geotechnical methods such as compaction or additives.

3.4 Subbase Course Placement:

-Place and compact subbase material to establish a uniform base layer.

Drainage & Utility Coordination

Ensures underground systems are updated, relocated, or protected.

4.1 Storm Drainage Structures Installation:

-Install catch basins, pipes, and manholes to manage runo .

4.2 Concrete End Sections:

-Install headwalls and ared end sections at culverts.

4.3 Subsurface Utility Relocations:

-Shift utility lines in con ict with new construction.

4.4 Water Service Adjustments:

-Modify water services and valves to maintain public access.

Paving & Roadway Surfacing

Re-establishes a smooth and durable road surface for long-term use.

5.1 Binder and Top Course Asphalt Paving: -Lay intermediate and surface asphalt layers.

5.2 Curb and Gutter Installation:

-Install concrete curbs and gutters to de ne edges and manage runo .

5.3 Driveway Adjustments:

-Tie new pavement into existing private driveways to maintain access.

5.4 Turf Restoration:

-Place seed, mulch, and topsoil to stabilize disturbed areas.

Signal and Electrical Work

Involves tra c control devices and related infrastructure upgrades.

6.1 Pull Box Cleaning and Preparation:

-Clean existing boxes or prepare new ones for wiring.

6.2 Conduit and Foundations:

-Install electrical conduit and pole bases.

6.3 Signal Equipment Installation:

-Set poles and connect signal heads and controllers.

6.4 360-Degree Camera System Setup:

-Install surveillance and monitoring systems as speci ed.

Site Features

and Restoration

Restores the project area for public use and visual appeal.

7.1 Sidewalk Installation:

-Construct ADA-compliant concrete walkways.

7.2 Cast Iron Warning Units: -Install tactile warning pads at curb ramps.

7.3 Landscaping and Post-Planting Care: -Plant and maintain grass, trees, or shrubs per contract.

7.4 Removal of Markers and Delineators: -Clear temporary signage and barriers after project completion.

Project Closeout

Final tasks to complete, document, and close the contract.

8.1 Final Punch List and Walkthrough:

-Address outstanding items and nalize work acceptance.

8.2 As-Built Drawings and Utility Survey Submission:

-Submit nal marked-up plans showing installed conditions.

8.3 Final Pay Item Quantities: -Con rm quantities for nal payment.

8.4 Demobilization:

-Remove all equipment, materials, and temporary facilities from the site.

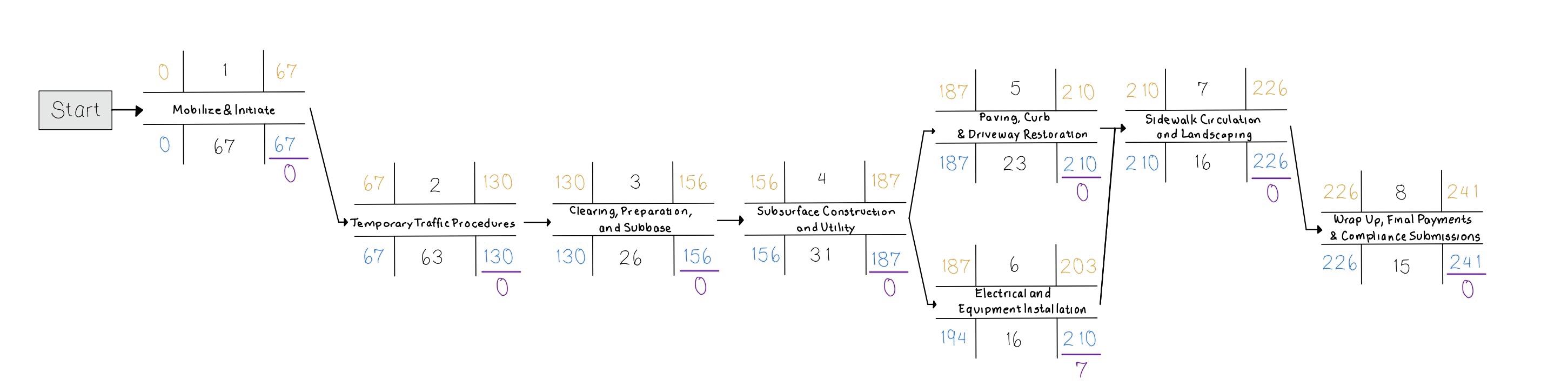

Gantt Chart

NYSDOT Contract D265434 – Little Valley, NY

Gantt Chart - Key Categories

Important Roles and Timing Considerations

1. Mobilize & Initiate (Compliance Submissions & Scheduling)

2. Temporary Tra c Procedures

3. Clearing, Preparation, and Subbase

4. Subsurface Construction and Utility

5. Paving, Curb & Driveway Restoration

6. Electrical and Equipment Installation

7. Sidewalk Circulation and Landscaping

8. Wrap Up, Final Payments & Compliance Submissions

Time O /Holiday Considerations

AON - Key Categories

Important Roles and Timing Considerations

Additional Safety Considerations

All Things Considered

Struck-By Hazards - Risk from moving vehicles, equipment, or falling objects.

Use internal tra c control plans.

Require ANSI-compliant high-visibility apparel.

Assign spotters and de ne exclusion zones.

Caught-In/Between Hazards – Risk of being trapped by equipment, materials, or structures.

Maintain safe distances from equipment.

Use trench protection systems.

Ensure guards are in place and lockout/tagout is followed.

Fall Hazards – Risk of falling from heights or into holes.

Provide guardrails, nets, or fall arrest systems.

Cover oor holes and excavations.

Train workers in fall protection.

Electrical Hazards – Risk of shock or electrocution.

Lockout/tagout before maintenance.

Stay clear of power lines.

Use GFCIs and grounded tools.

Tra c Control Hazards – Risk from inadequate tra c control.

Follow MUTCD-compliant tra c control plans.

Use proper signage, barriers, and aggers.

Inspect tra c control setups regularly.

Heat Stress – Risk of heat-related illness in hot conditions.

Provide water, rest, and shade.

Schedule work during cooler hours.

Train workers to recognize symptoms.

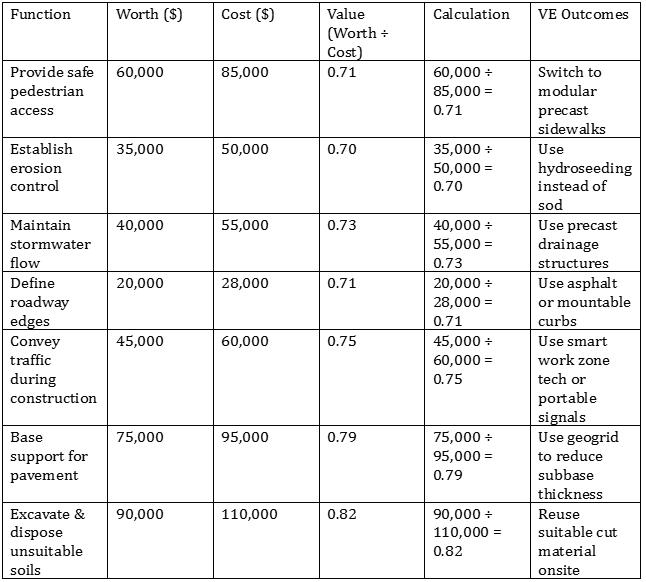

Value Engineering (VE)

Each function is assigned an estimated Worth and actual Cost based on typical NYSDOT item values. Value is calculated using the formula: Value = Worth ÷ Cost. Outcomes represent potential savings or e ciency gains by adopting alternate methods or materials.

Basis for Worth Cost Estimates

The Worth and Cost values used in the Value Engineering matrix were estimated based on historical unit prices from NYSDOT pay item catalogs, recent bid results, and industry-standard cost data for civil infrastructure projects. Worth re ects the lowest reasonable cost to accomplish a function e ciently, while Cost re ects the expected price using standard NYSDOT methods and materials.

Value Engineering (VE) was applied to identify opportunities for functional cost savings without compromising performance, safety, or NYSDOT standards. For each project function, an estimated Worth (the lowest reasonable cost to perform the function e ectively) was compared against the Cost (anticipated expenditure using standard NYSDOT practices). The ratio of Worth to Cost (Value = Worth ÷ Cost) guided whether an alternative method or material could yield a more economical solution.

The table provided identi es six high-cost functions where value improvement was assessed. Below is a summary of outcomes and justi cations for the proposed changes:

Pedestrian Access

Standard Cost: $85,000

VE Alternative: Replace poured-in-place sidewalks with modular precast sidewalk panels, reducing labor and curing time. Result: Faster installation, fewer labor hours, and potential savings of up to $25,000.

Erosion Control

Standard Cost: $50,000

VE Alternative: Substitute sod with hydroseeding, which provides adequate stabilization at signi cantly lower material and installation costs.

Result: Estimated savings of $15,000 and accelerated schedule for vegetative growth. Stormwater Flow Management

Standard Cost: $55,000

VE Alternative: Use precast drainage structures instead of cast-in-place systems.

Result: Reduction in site labor, safety exposure, and potential savings of approximately $15,000.

Curbing and Edge De nition

Standard Cost: $28,000

VE Alternative: Opt for asphalt or mountable curbs, where appropriate, rather than monolithic concrete.

Result: Maintains roadway function while reducing material costs and forming labor.

Construction Tra c Management

Standard Cost: $60,000

VE Alternative: Replace permanent smart workzone setups with portable tra c signal units where phasing allows.

Result: Savings of $15,000 and easier deployment across stages.

Excavation Support

Standard Cost: $110,000

VE Alternative: Shift from sheet pile or trench boxes to graded side slopes or reusable modular wall systems where OSHA compliance permits.

Result: Up to $20,000 in cost avoidance, with simpli ed back ll procedures.

12.3

Value Engineering Recommendations That Justify Higher Initial Cost But Could Lessen or Delay Future Maintenance Costs

Use of Polymer-Modi ed Asphalt (PMA)

Justi cation: PMA o ers superior rutting resistance, crack prevention, and temperature durability.

VE Trade-O : Adds ~10–20% to paving cost but extends service life by 5–8 years.

Lifecycle Impact: Reduces frequency of resurfacing, lane closures, and patching.

Geotextile Reinforcement Under Subbase

Justi cation: Stabilizes weak subgrade soils, reduces pumping and settlement.

VE Trade-O : Upfront material and labor costs increase, but improves load distribution.

Lifecycle Impact: Prevents premature pavement deformation, reduces patch repairs.

Full-Depth Reclamation (FDR) with Cement or Asphalt Stabilization

Justi cation: Recycles in-place materials for base strengthening and improved performance.

VE Trade-O : Costlier than mill-and- ll, but eliminates deep base failures.

Lifecycle Impact: Creates a more homogenous, resilient substructure.

Concrete Curb and Gutter with Deep Frost Footing

Justi cation: Improves edge retention and drainage channeling in northern climates.

VE Trade-O : More excavation and material than asphalt curbing.

Lifecycle Impact: Prevents curb heave and cracking, lowers rework frequency.

LED-Based Smart Lighting and Power-Saving Tra c Signals

Justi cation: Reduces energy and bulb replacement costs dramatically.

VE Trade-O : Higher capital cost for LED systems.

Lifecycle Impact: 10+ year lifespan, reduces operational cost and service interruptions.

Ductile Iron or Composite Drainage Grates and Frames

Justi cation: Resistant to corrosion and freeze-thaw damage.

VE Trade-O : Higher material cost than traditional cast iron.

Lifecycle Impact: Less prone to cracking, rust, or failure in high salt/brine environments.

Main Lean Wastes:

UPFRONT OR BACK END

Lean Principles

Project Management

Disorganization Motion and Waiting

Lean Delivery: 5S

2 - Tra c Control & Maintenance

Disorganization Motion and Waiting

Lean Delivery: Kanban

3 - Earthwork and Subbase

Disorganization Motion and Waiting

Lean Delivery: 5S

4 - Drainage & Utility Coordination

Waiting, Defects and Inventory

Lean Delivery:

Just-In-Time Delivery (JIT)

5 - Paving & Roadway Surfacing

Waiting, Defects and Inventory

Lean Delivery:

Just-In-Time Delivery (JIT)

6 - Signal and Electric Work

Waiting, Defects and Inventory

Lean Delivery:

Just-In-Time Delivery (JIT)

7 - Site Features and Restoration

Waiting, Defects and Inventory

Lean Delivery:

Just-In-Time Delivery (JIT)

8 - Project Closeout

Waiting

Lean Delivery: 5S

Lean Principles

Bene ts of Each Delivery: JIT

Reduces space congestion and costs for storage Reduces theft risk

Helps maintain a safe work environment

Increased productivity

5S Organization Consistency

Increased productivity Kanban

Visuals make it easier to to understand

Better communication

Increased productivity

Conclusion and Wrap Up NYSDOT Contract D265434 – Little Valley, NY

*THE NYSDOT-APPROVED PROJECT IN LITTLE VALLEY AIMS TO MODERNIZE AND REHABILITATE KEY REGIONAL ROADWAYS FOR IMPROVED SAFETY, ACCESSIBILITY, AND DURABILITY.

*A COMPREHENSIVE CONSTRUCTION MANAGEMENT STRATEGY WAS ESTABLISHED, COVERING SCHEDULING, STAFFING, TRAFFIC CONTROL, AND SAFETY COMPLIANCE.

*HIGH-PRODUCTIVITY EQUIPMENT WAS STRATEGICALLY SELECTED TO MAXIMIZE EFFICIENCY, MINIMIZE DOWNTIME, AND ALIGN WITH NYSDOT PERFORMANCE STANDARDS.

*COST ESTIMATION WAS BENCHMARKED AGAINST SIMILAR PROJECTS, AND A VALUE ENGINEERING (VE) MATRIX WAS USED TO IDENTIFY AREAS FOR FUNCTIONAL COST SAVINGS.

*LEAN CONSTRUCTION METHODS—SUCH AS JUST-IN-TIME DELIVERIES AND WASTE REDUCTION PRACTICES—WILL SUPPORT OPERATIONAL EFFICIENCY THROUGHOUT THE PROJECT.

*RISK MANAGEMENT PROTOCOLS AND A STRONG SAFETY CULTURE ARE EMBEDDED IN DAILY OPERATIONS, ENSURING COMPLIANCE WITH OSHA AND DOT STANDARDS.

*LONG-TERM DURABILITY IS PROMOTED THROUGH VALUE-BASED UPGRADES LIKE POLYMER-MODIFIED ASPHALT AND GEOTEXTILE REINFORCEMENT, OFFERING LIFECYCLE COST BENEFITS.

*THE PROJECT SHOWSAN INTEGRATED AND FORWARD-LOOKING APPROACH TO RURAL INFRASTRUCTURE RENEWAL, WITH COORDINATION ACROSS ENGINEERING, CONSTRUCTION, AND REGULATORY SECTORS.