3 minute read

Construction Efficiencies

from 2020 US Department of Energy Solar Decathlon, 2nd Place, Mixed-Use Multifamily Division: HILLDING

AFFORDABILITY + FEASIBILITY

Construction in Philadelphia is typically a poorly coordinated process with frequent changes needing to be made in the field, often delaying the construction schedule and inevitably costing more. Our approach seeks to

Advertisement

address this in two ways: 1.The use of prefabricated assemblies 2.Embedded system coordination.

The use of panelized prefabricated elements dramatically cuts back material waste and completely reframes the construction schedule, fully assembling a mid-size house in as little as 5 weeks. Figure 45 - BluePrint Robotics Zip Assemblies

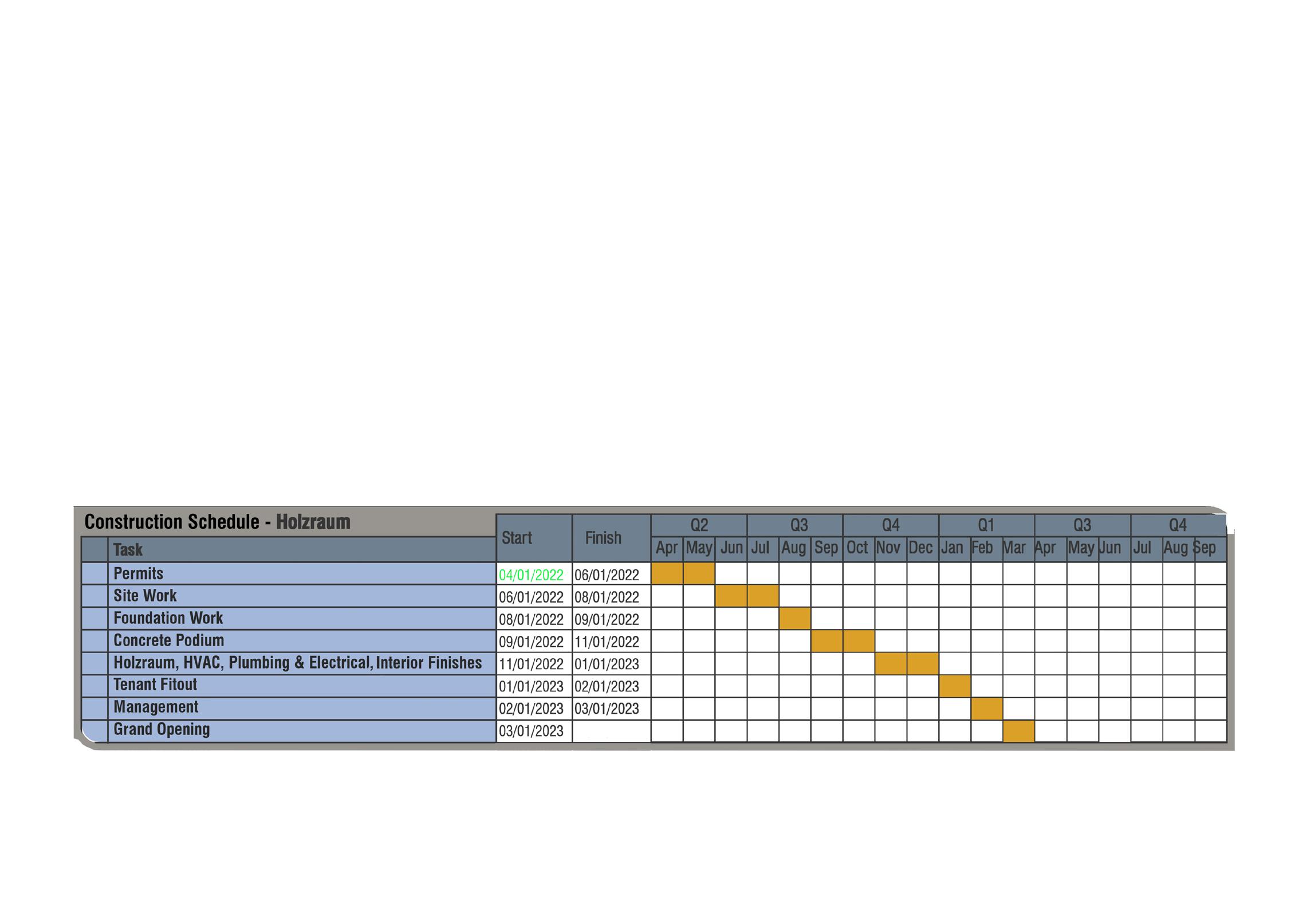

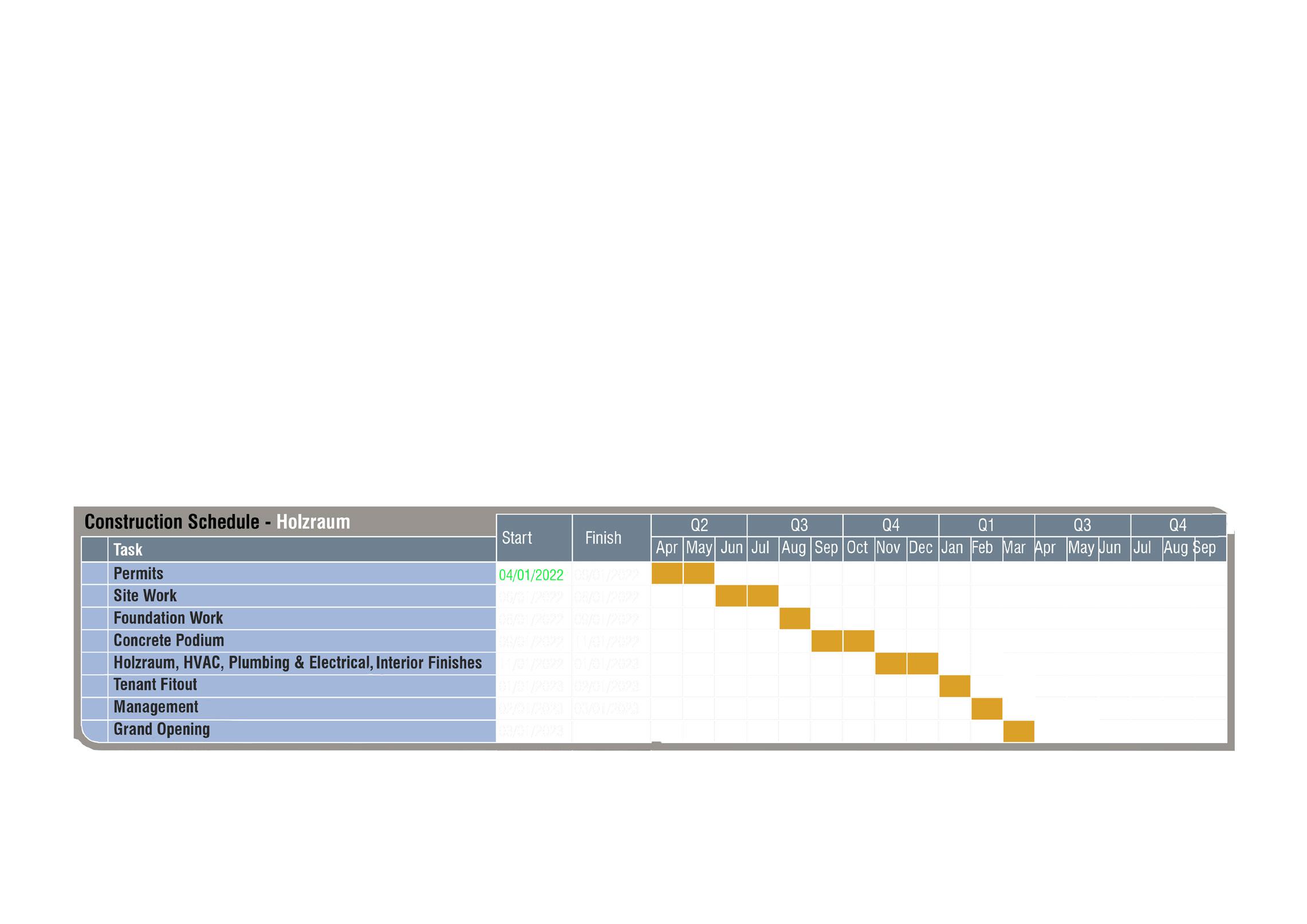

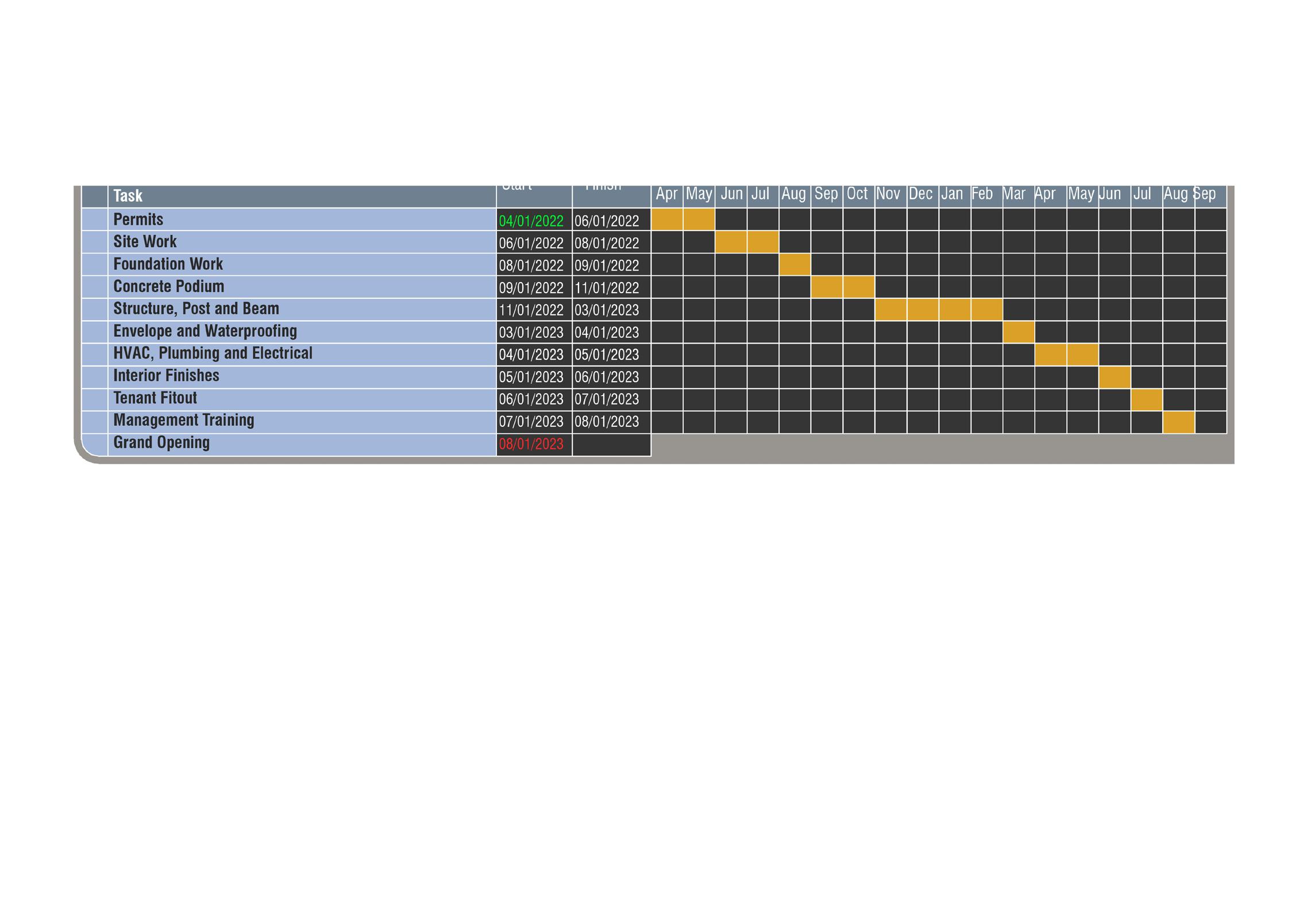

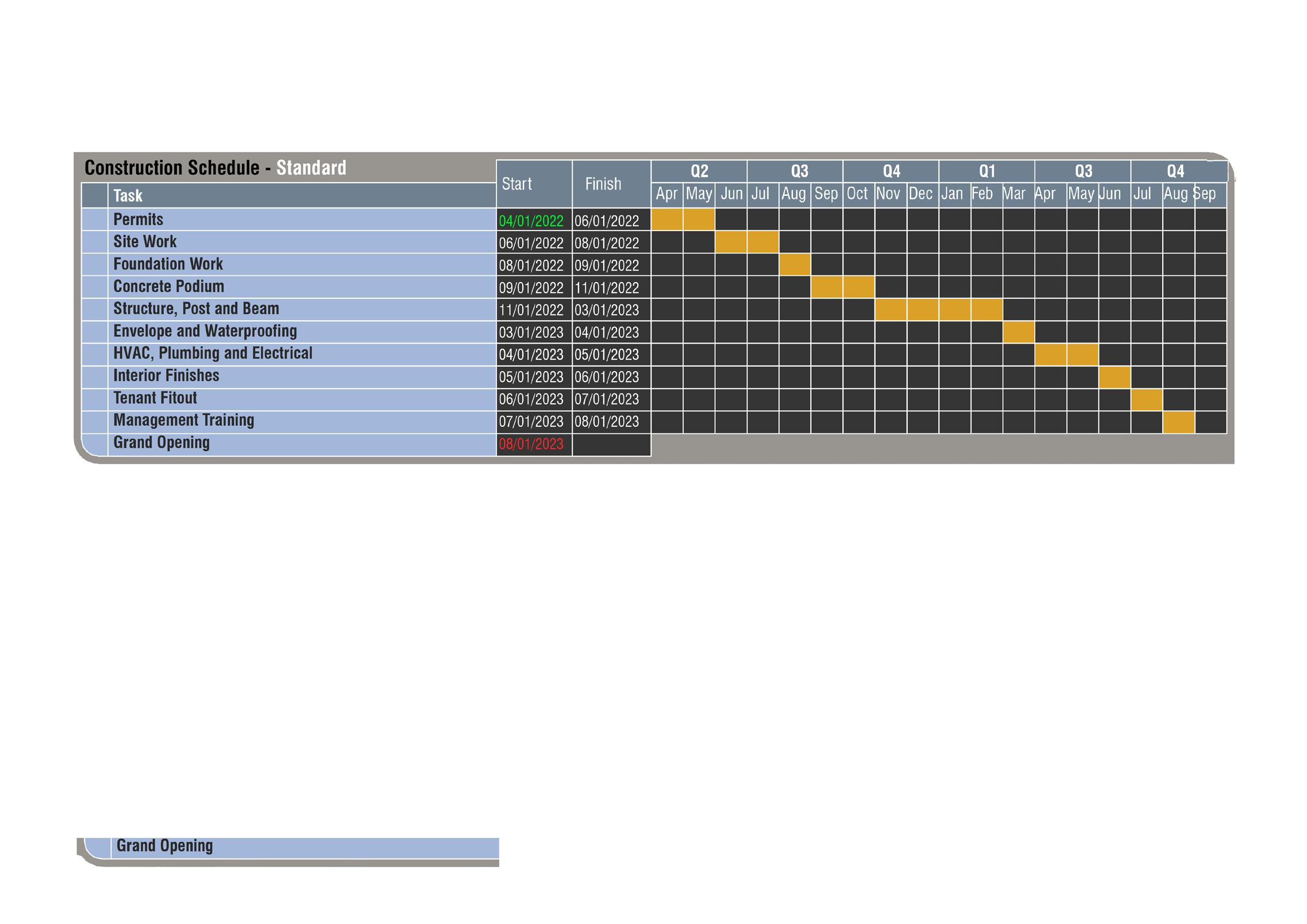

Figure 46 - Typical Construction Schedule vs. HolzRaum Schedule

PANELIZATION

Exterior and interior walls can be manufactured in assemblies as long as 10’ by up to 40’ panels, designed to fit on a flatbed. These panels can contain embedded system ducts, plumbing, and electrical; lining up at the build-site with high accuracy.

BLUEPRINT ROBOTICS

Large savings on labor come through is through the use of prefabricated elements, specifically the HolzRaum System manufactured by Blueprint Robotics in Baltimore, MD.

A standard construction schedule for a development of this scale lasts 17 months.

Since labor costs in large cities like Philadelphia are quite high, a shorter construction schedule translates into significant savings.

By using the prefabricated HolzRaum system, we are able to shorten our construction schedule by five months. These savings are invested in PassivHaus strategies and sophisticated water management, so that we are able to create a higher quality development for code-minimum costs, especially as facilities for prefabricated assemblies begin to open in Pennsylvania.